Patents

Literature

103results about How to "Increase inertial force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

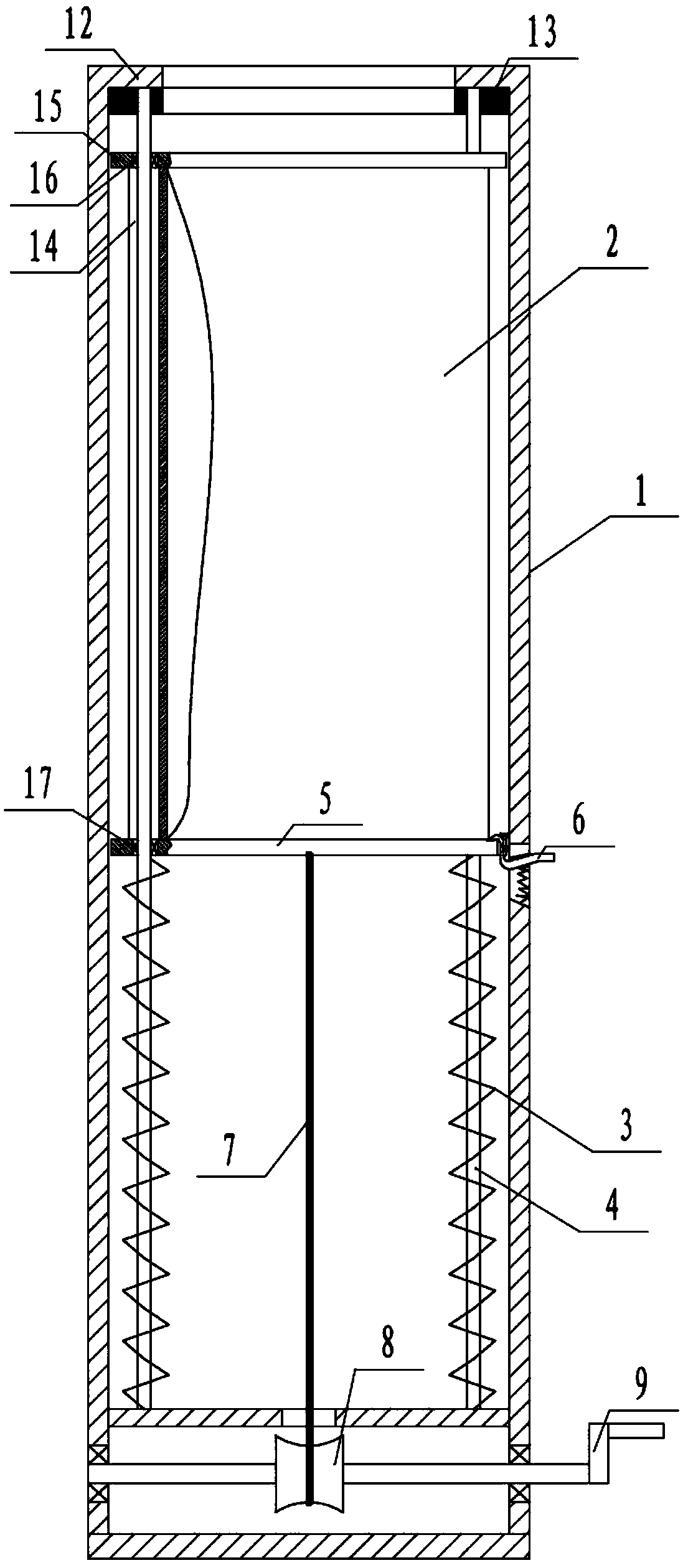

Automatic packaging and discharging device

ActiveCN106976598AWeight increaseIncrease inertial forceSolid materialPackaging poultryImpellerEngineering

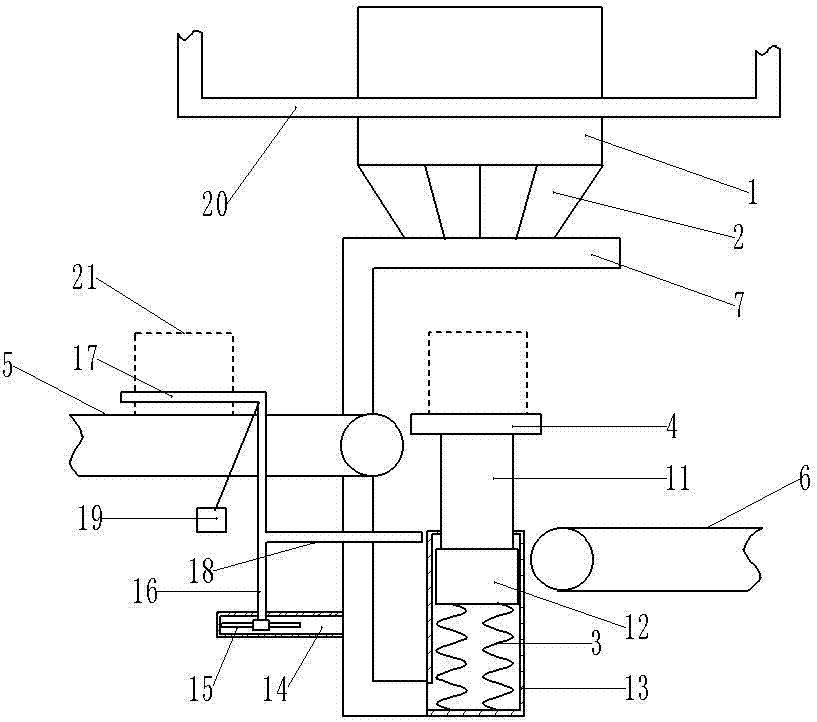

The invention relates to the technical field of packaging and discloses an automatic packaging and discharging device. The automatic packaging and discharging device comprises a feed hopper. A plurality of discharge plates are hinged to the feed hopper and define a discharge outlet. A pressing table is arranged below the discharge outlet. The outer side of the pressing table is provided with a first conveying mechanism. The outer side of the discharge outlet is provided with an annular pipe provided with an elastic layer. The discharge plates are all connected to the elastic layer. The pressing table is connected with a compressing column. The other end of the compressing column is provided with a piston. The outer side of the piston is provided with a pipeline in clearance fit with the piston. The pipeline communicates with the annular pipe. The outer side of the first conveying mechanism is provided with a bellows internally provided with an impeller. A rotary rod connected with the impeller is arranged outside the bellows. The upper end of the rotary rod is provided with a support rod provided with a hanging block. The support rod comprises an upper support rod body and a lower support rod body. A second conveying mechanism is further arranged on the outer side of the pressing table and comprises a second conveying belt. The upper end face of the second conveying belt and the lower support rod body are in the same horizontal plane. Through the automatic packaging and discharging device, the problem that a packaged product is liable to damage during automatic discharge stopping of an existing subpackaging device can be solved.

Owner:CHONGQING HAOJIE FOOD

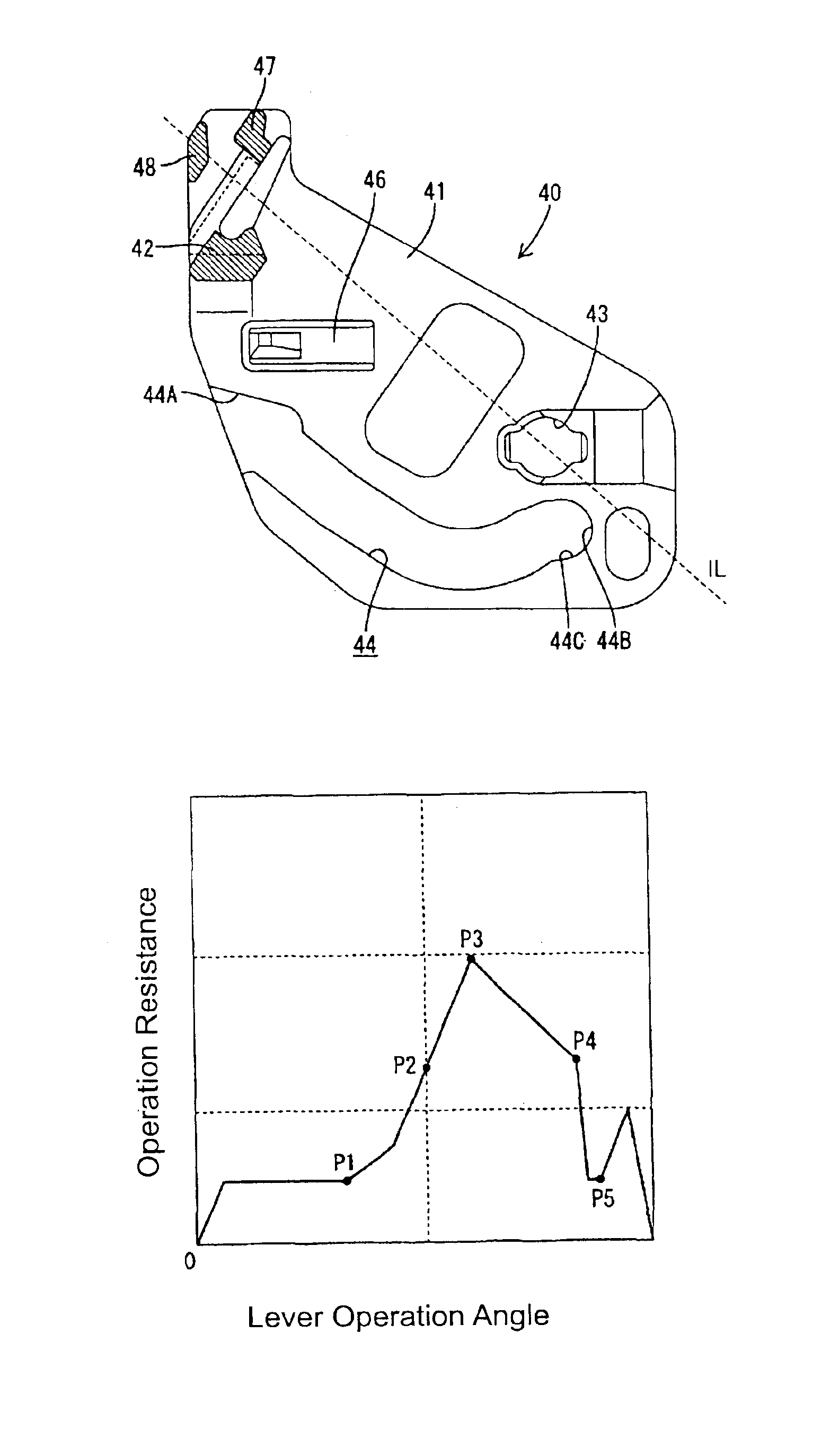

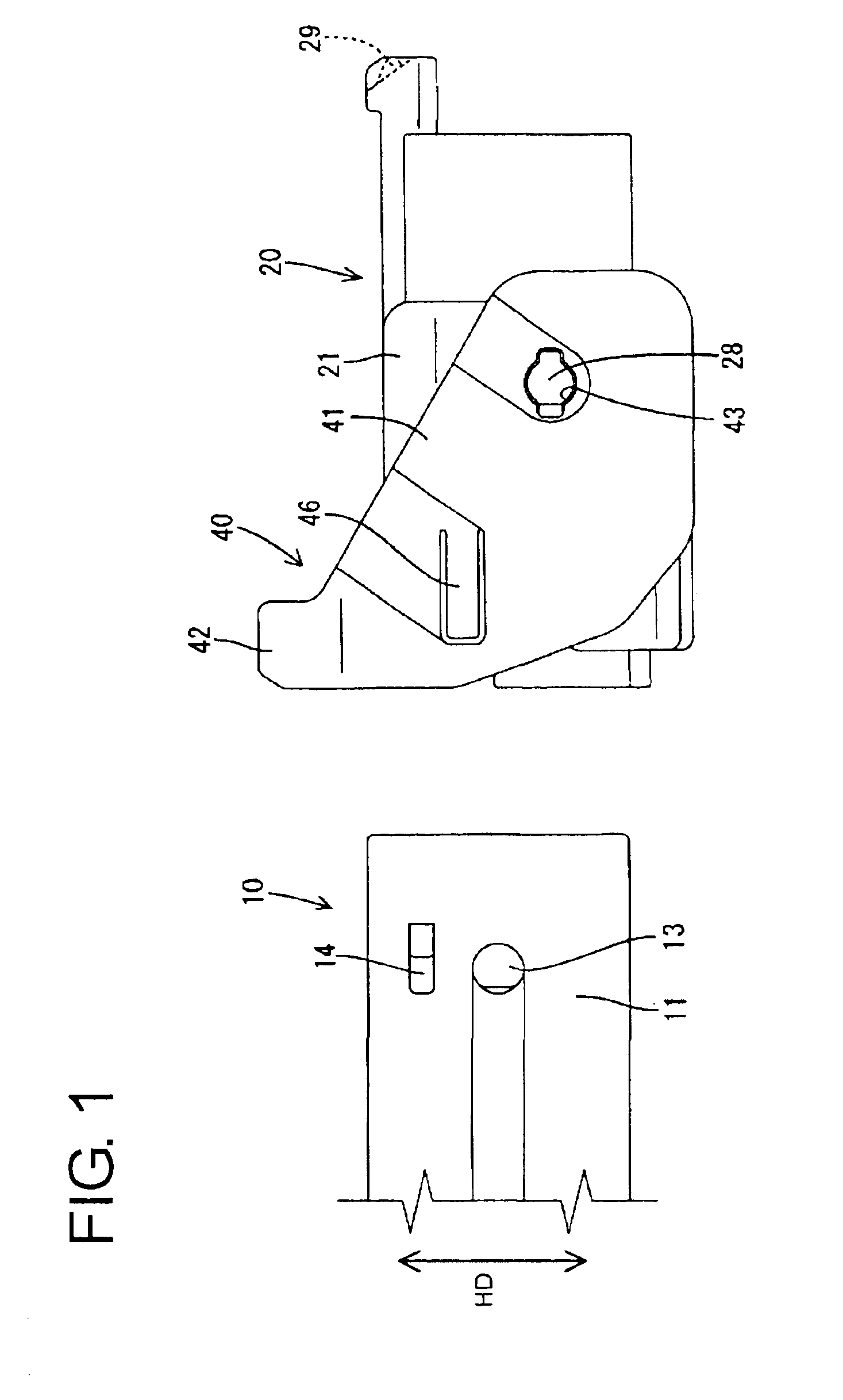

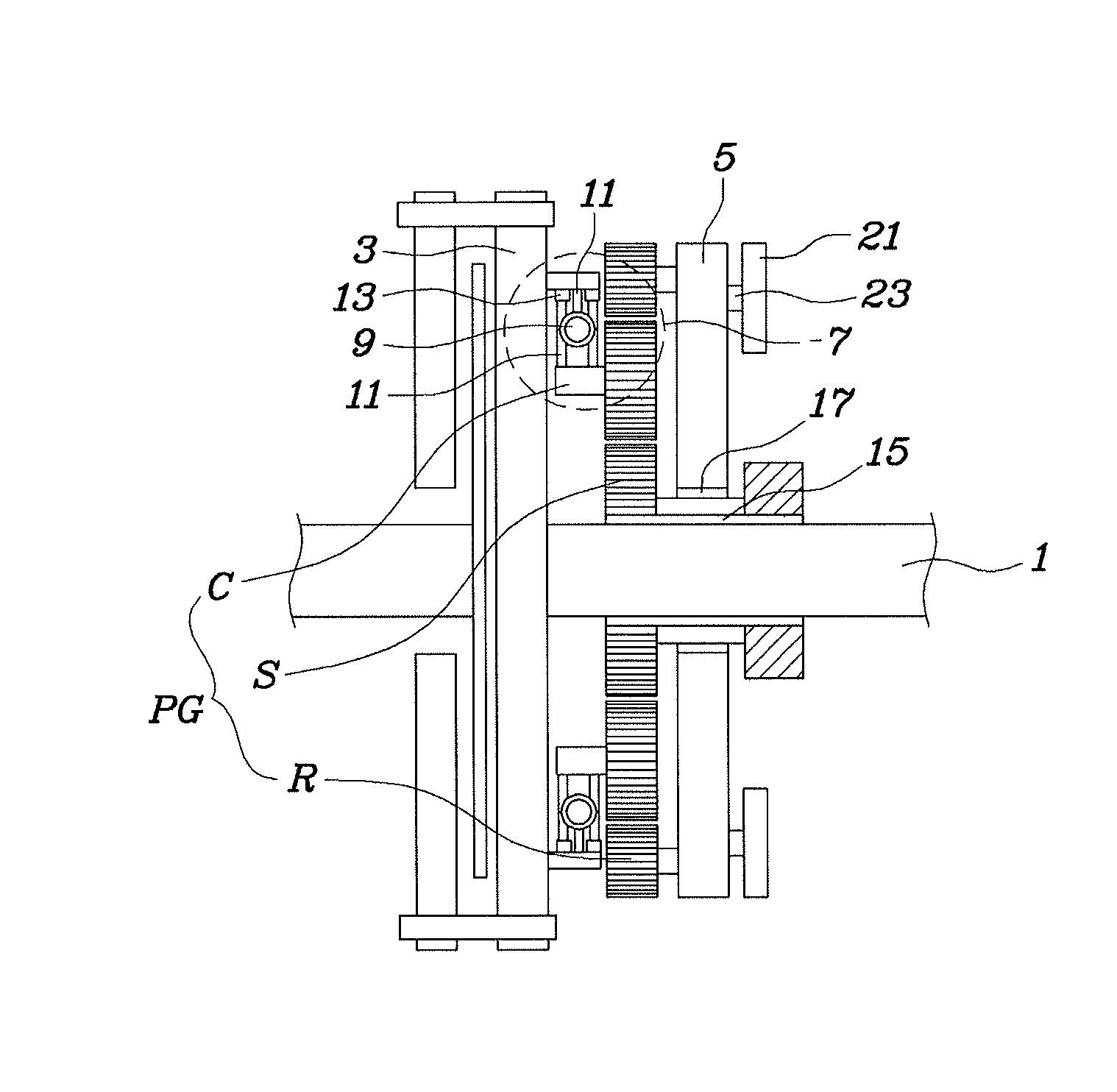

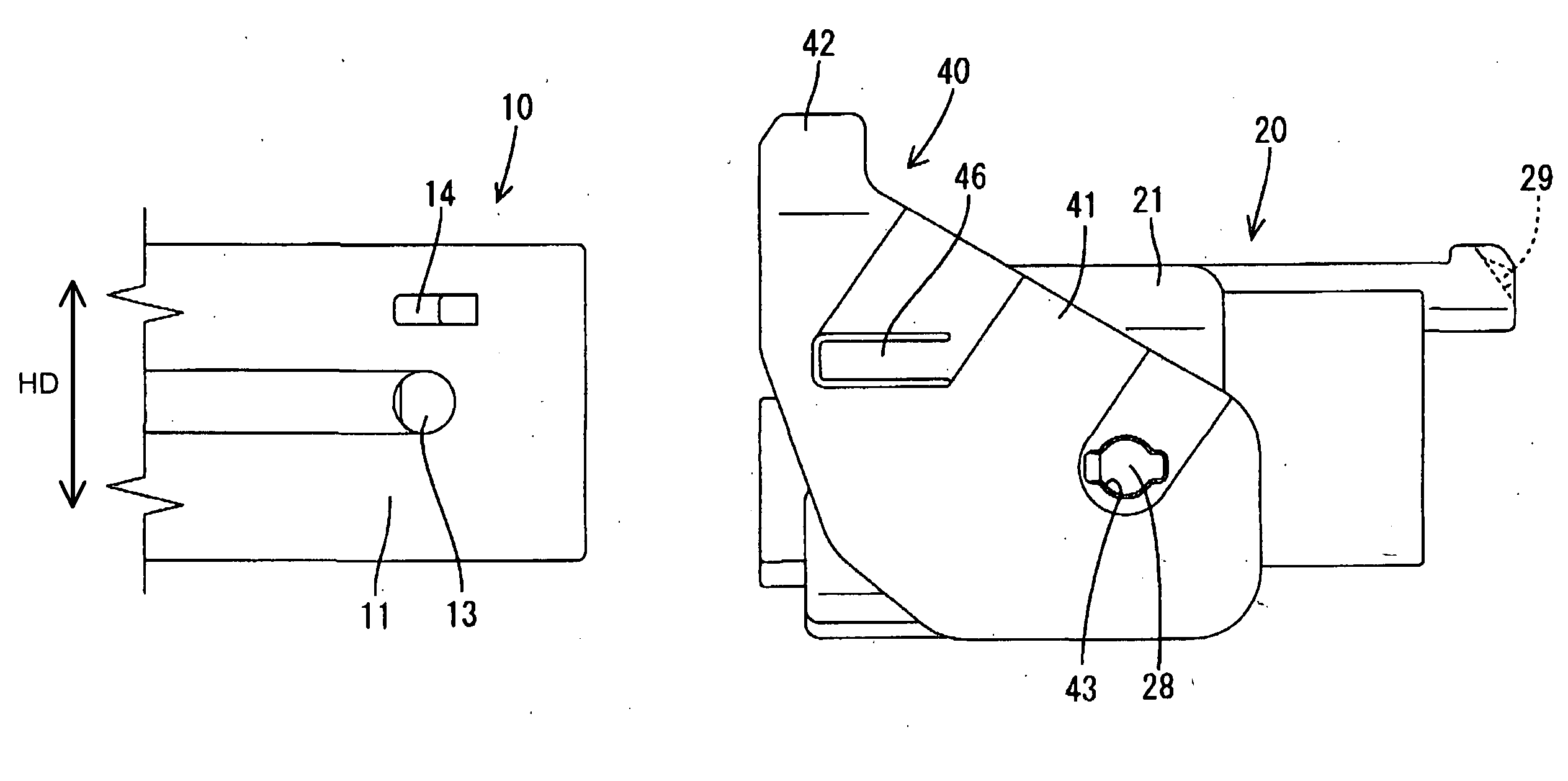

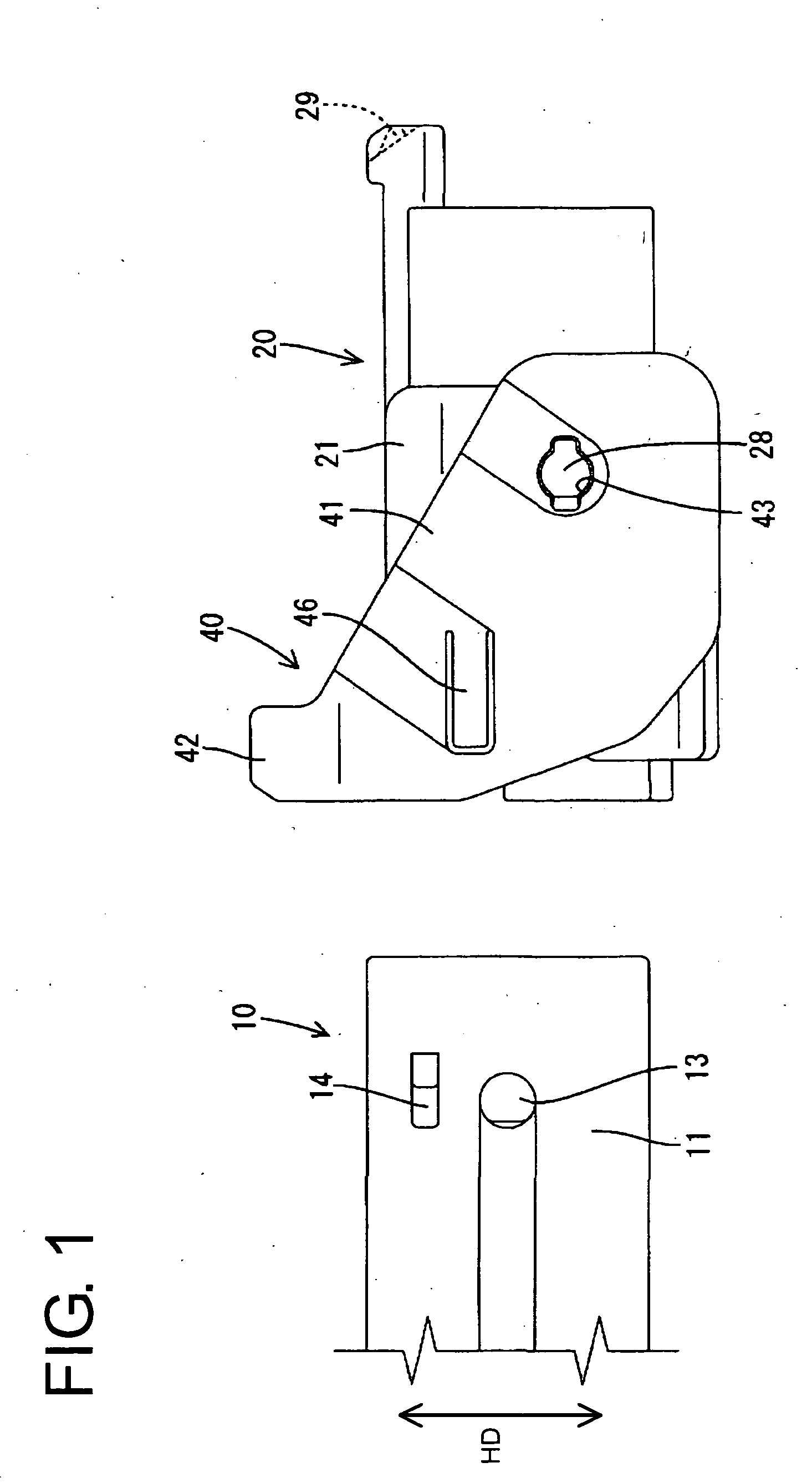

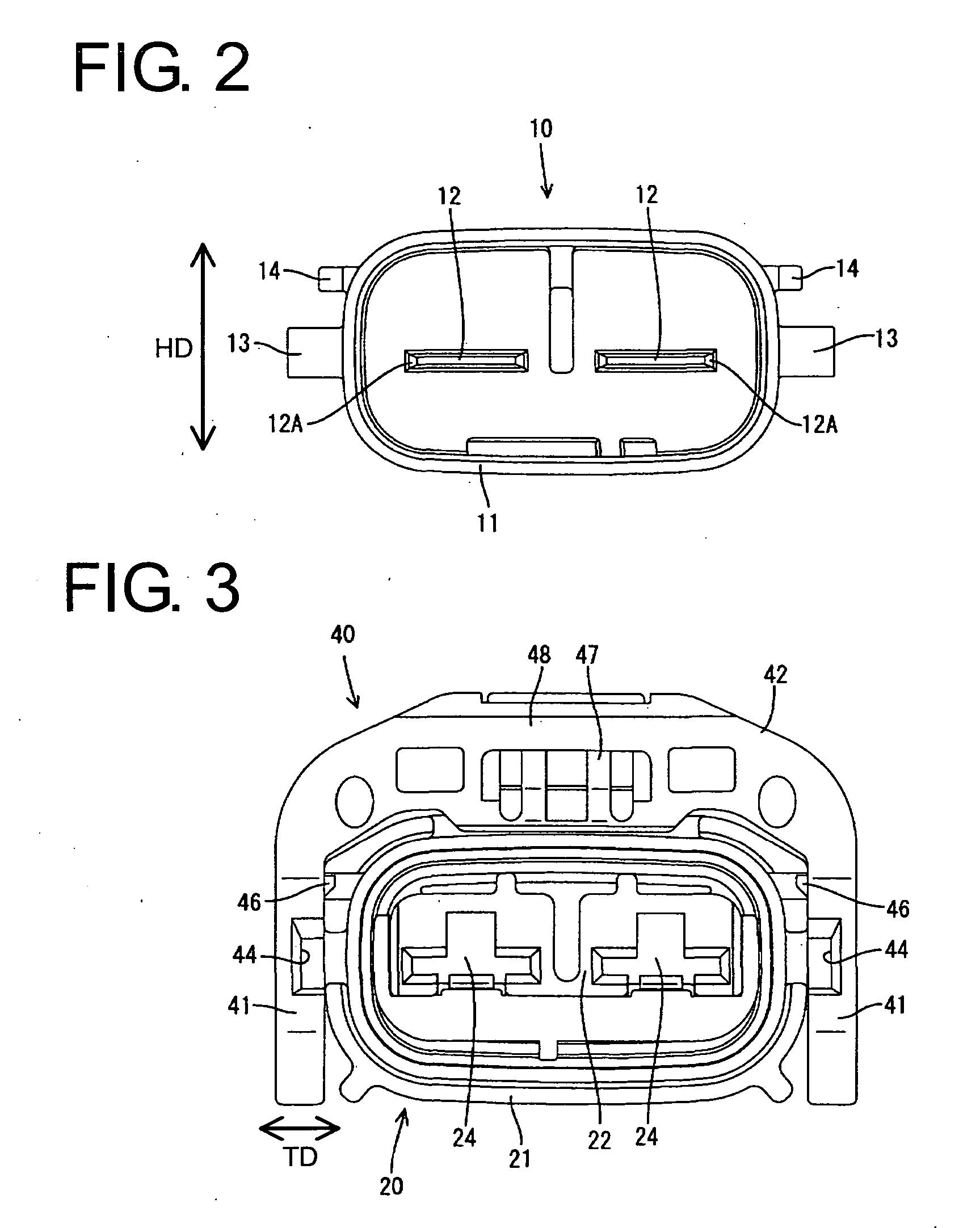

Lever-type connector and connector housing therefor

InactiveUS6905355B2Reduce stepsAccurate connectionEngagement/disengagement of coupling partsIncorrect coupling preventionEngineeringCam

A lever-type connector has two housings (10, 20) and a lever (40) with a cam for facilitating the connection of the housings (10, 20). The connector is configured so that a connection resistance between the housings (10, 20) and an operation resistance on the lever (40) reach their maximums at substantially the same time. Thus, a separate resistance generator is unnecessary, and an operator is less likely to erroneously stop the connecting operation upon an increase in the operation resistance caused by a separate resistance generator. Accordingly, the two housings (10, 20) can be connected properly with high reliability.

Owner:SUMITOMO WIRING SYST LTD

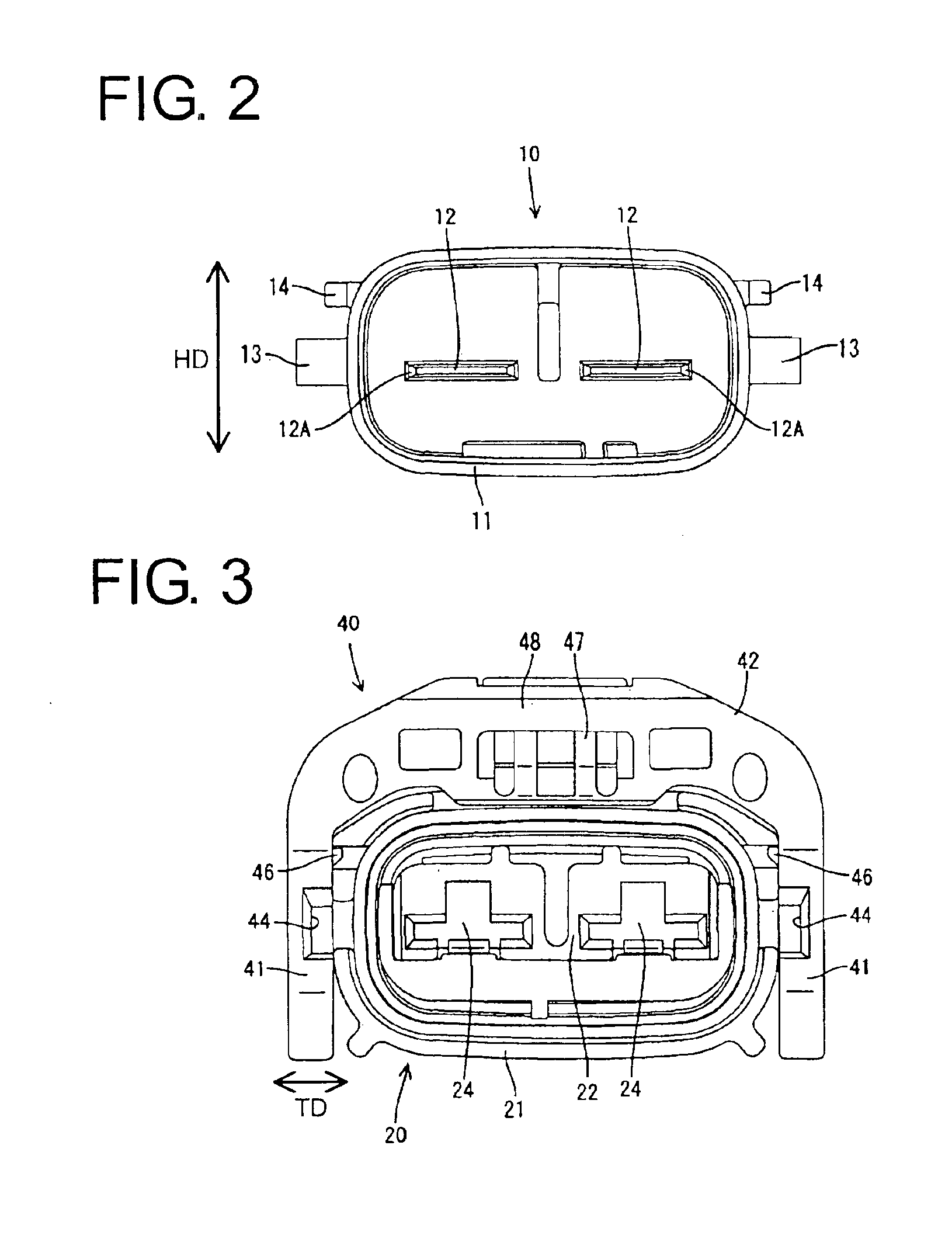

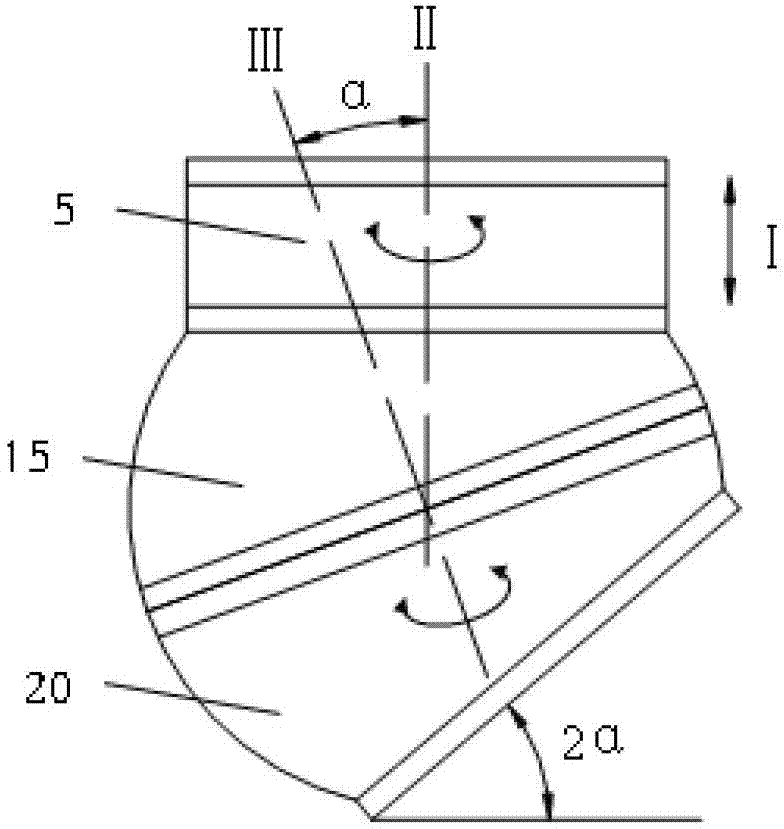

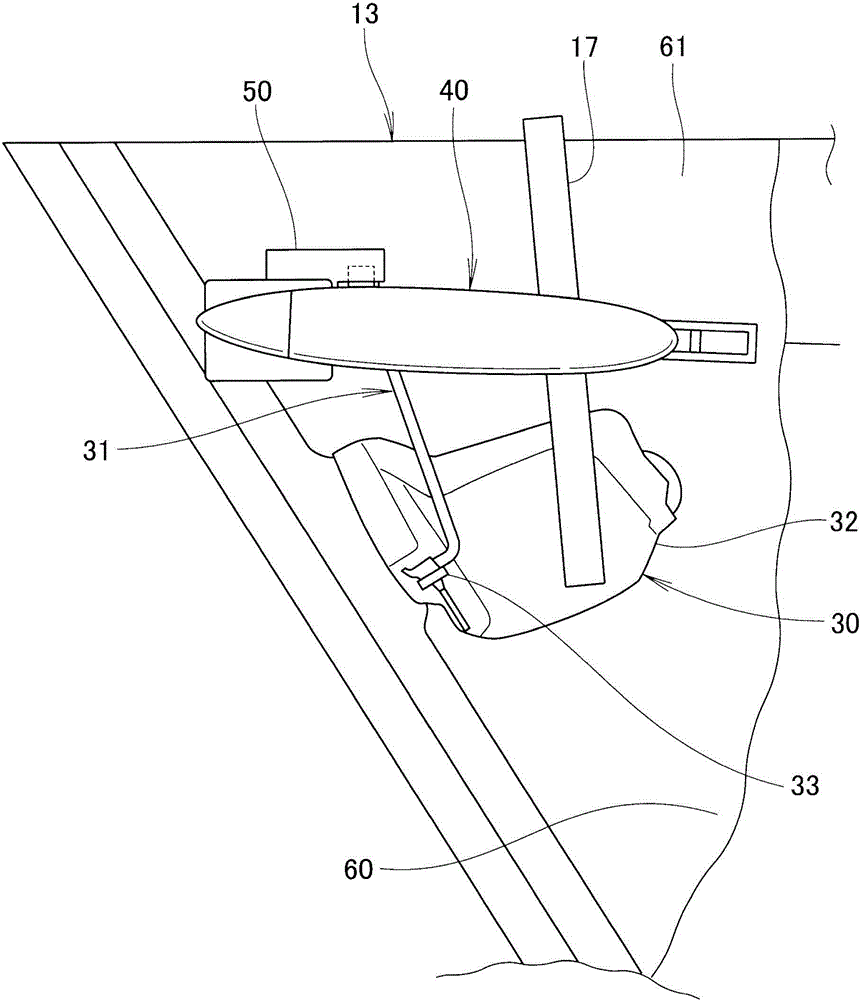

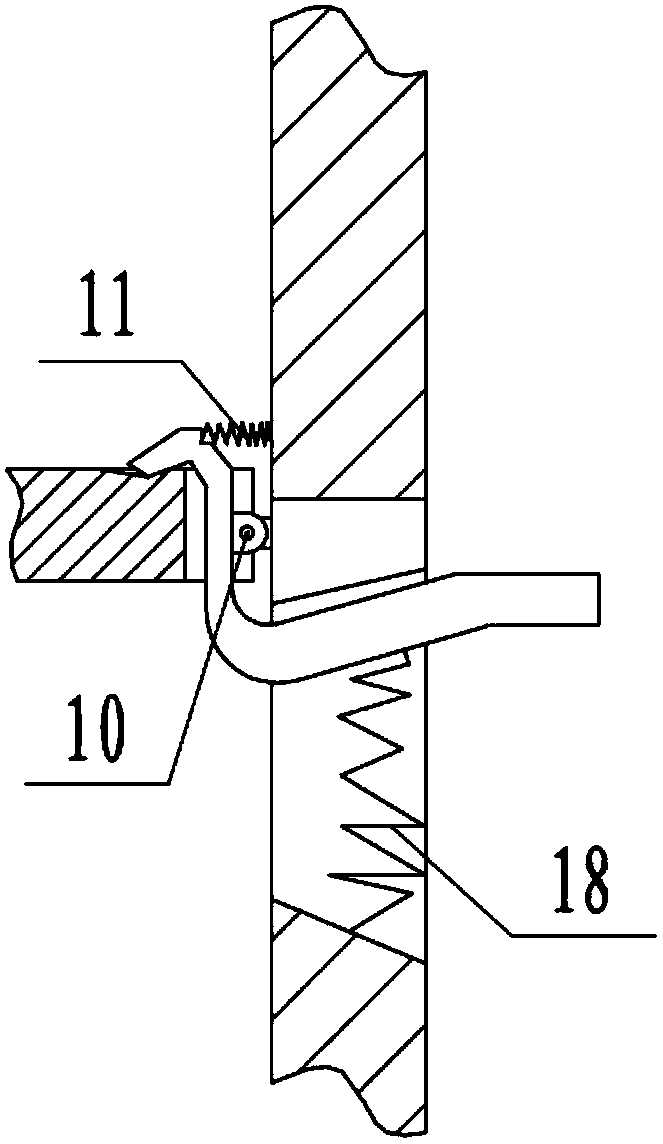

Submersible vehicle embedded type butting device

InactiveCN103085953AImprove mobilityPrecise positioningUnderwater vesselsUnderwater equipmentHydraulic cylinderDrive motor

The invention provides a submersible vehicle embedded type butting device. A butting device body is embedded in a groove in a submersible vehicle body. A moving sliding way is arranged in the groove in the submersible vehicle body. A moving skit is arranged in the moving sliding way and driven by a hydraulic cylinder to move vertically. A cylinder rod of the hydraulic cylinder is hinged with the moving skirt. A cylinder body of the hydraulic cylinder is hinged with the submersible vehicle body. A direction skirt drive motor is fixedly arranged in the moving skirt. An angle skirt drive motor is fixedly arranged in a direction skirt. A first inner gear ring and a second inner gear ring are respectively fixed at the upper ends of the direction skirt and an angle skirt. Output shafts of the direction skirt drive motor and the angle skirt drive motor are respectively provided with a transmission gear. The transmission gears are respectively engaged with the first inner gear ring and the second inner gear ring. The submersible vehicle embedded type butting device enables a submersible vehicle to adapt to change of sea conditions of a platform tilt angle and ocean current influence, fast and accurate butting of the submersible vehicle is achieved, and therefore continuity of personnel and article transportation work is guaranteed and overall butting is safe and reliable.

Owner:HARBIN ENG UNIV

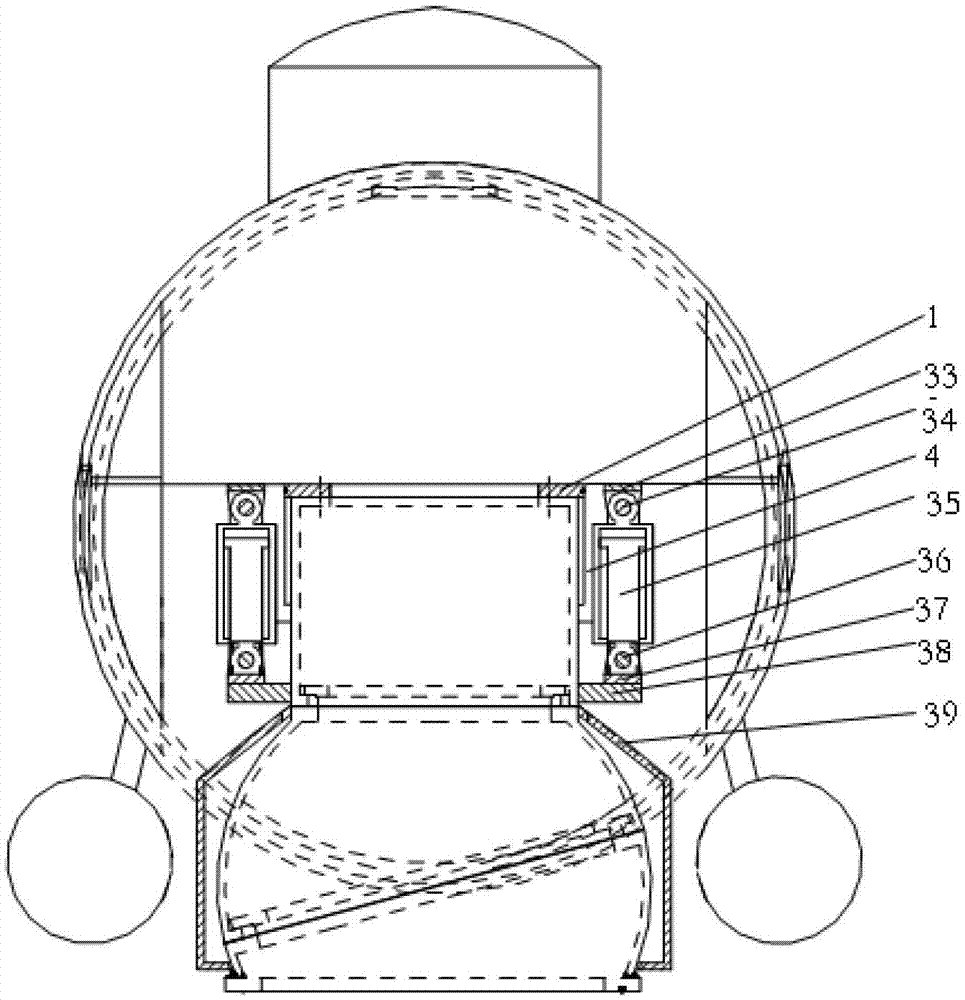

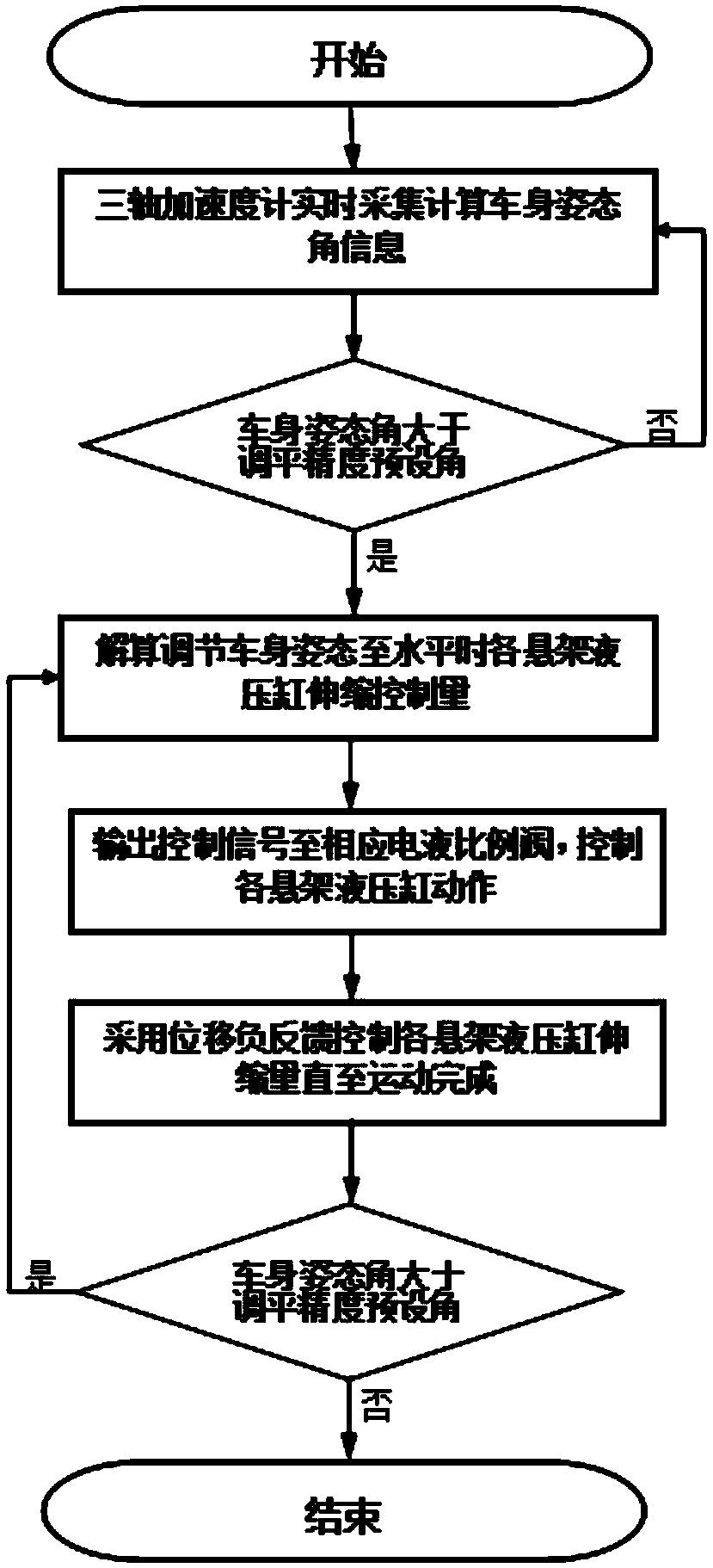

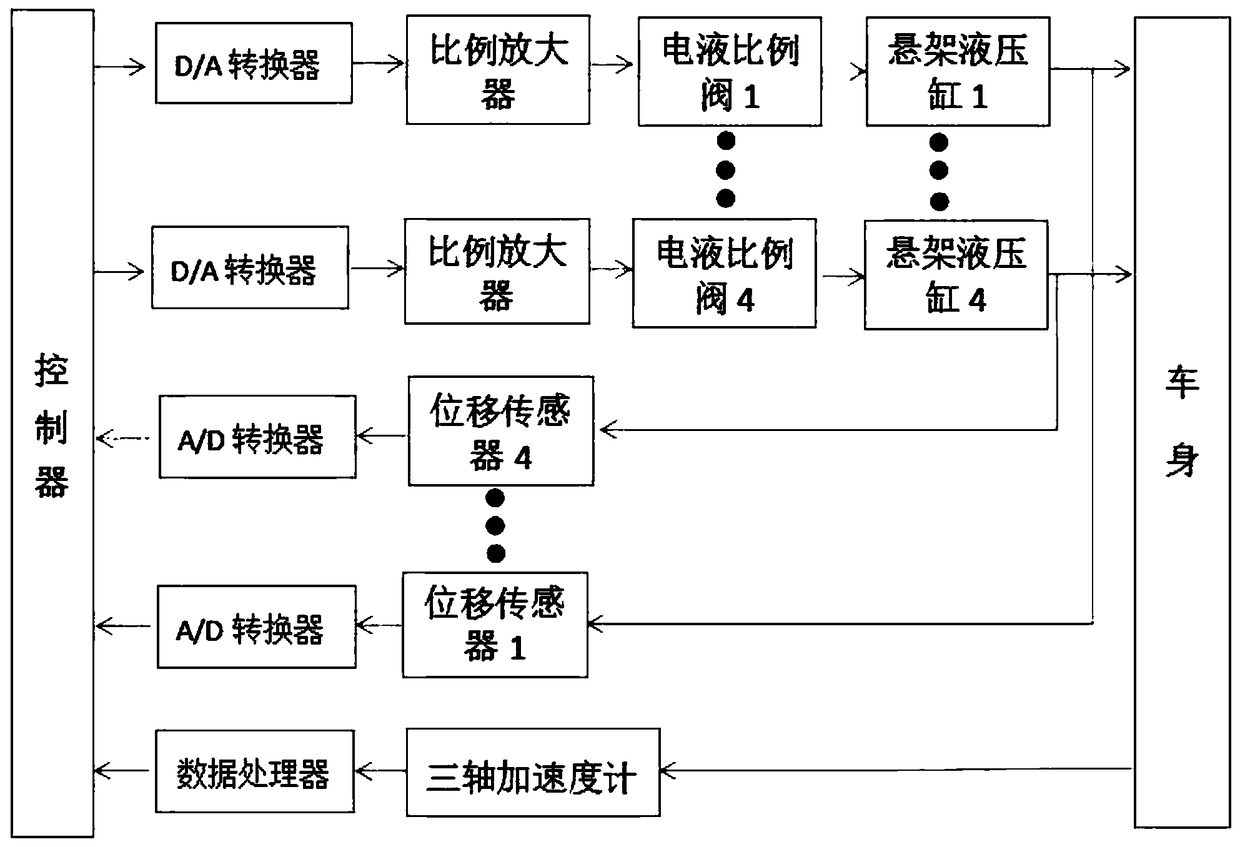

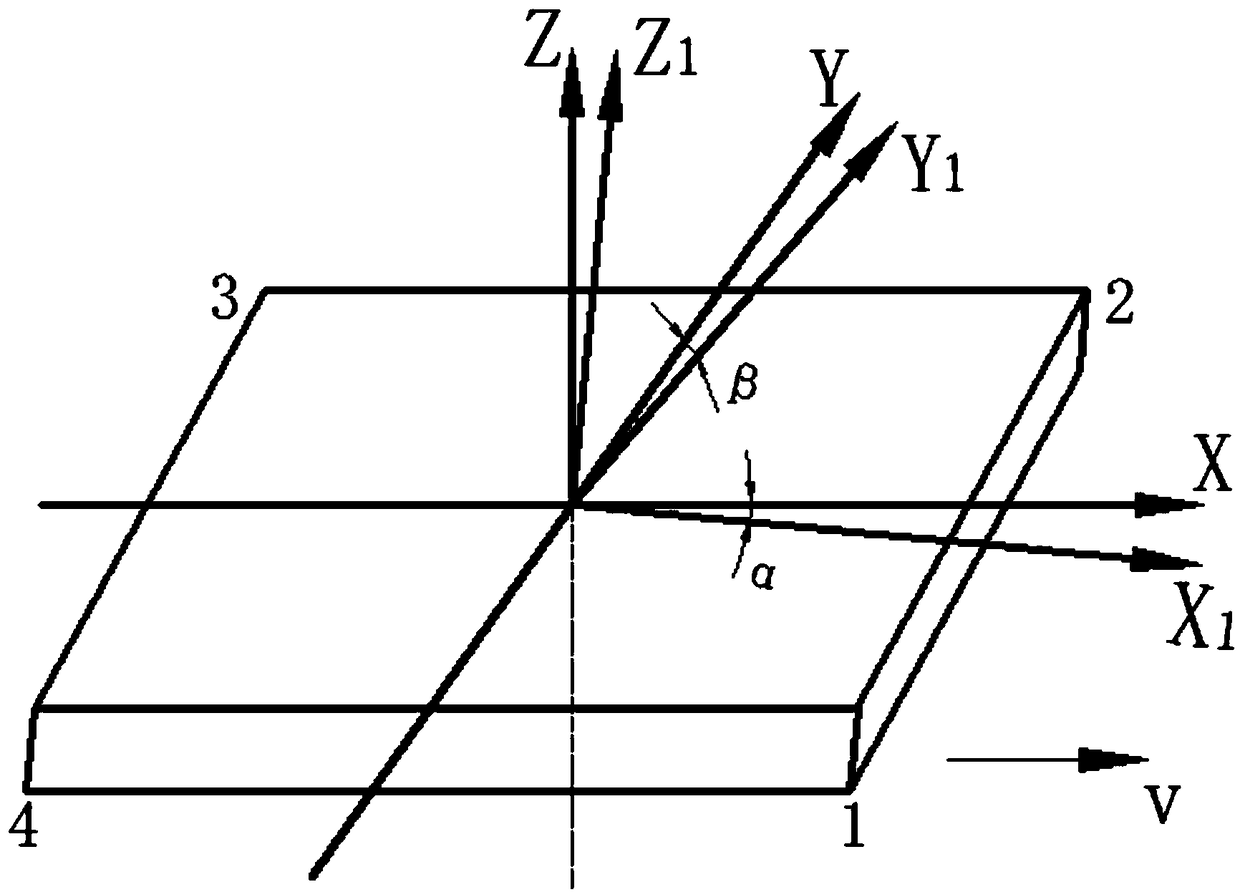

Body attitude leveling control system and method for emergency rescue vehicles

ActiveCN108819651AImprove stabilityReduce actuation displacementResilient suspensionsThree axis accelerometerPosition error

The body attitude leveling control system for emergency rescue vehicles disclosed in the invention comprises a three-axis accelerometer for measuring the acceleration of a low-speed vehicle in real time; a processor which calculates the vehicle body attitude angle based on the acceleration measured by the three-axis accelerometer; a controller which reads the information of the attitude angle of the vehicle body, and compares the attitude angle of the vehicle body with a leveling accurate preset angle of the vehicle in real time to determine whether the vehicle body needs to be leveled and controlled. The vehicle body leveling system of the present invention can adopt a centroid position error leveling method, and combines the active suspension system of the vehicle to control the movementof each suspension hydraulic cylinder of the suspension system to achieve smooth leveling of the vehicle body. The vehicle body leveling system of the present invention can also adopt a coplanar bodyleveling method to keep the suspension hydraulic cylinders of the suspension system and the vehicle body connection point in the same plane movement, thereby improving the speed of the body levelingcontrol.

Owner:YANSHAN UNIV

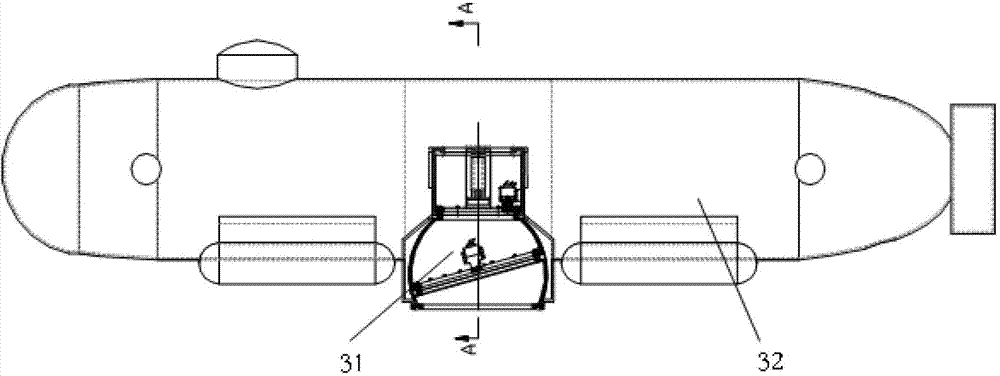

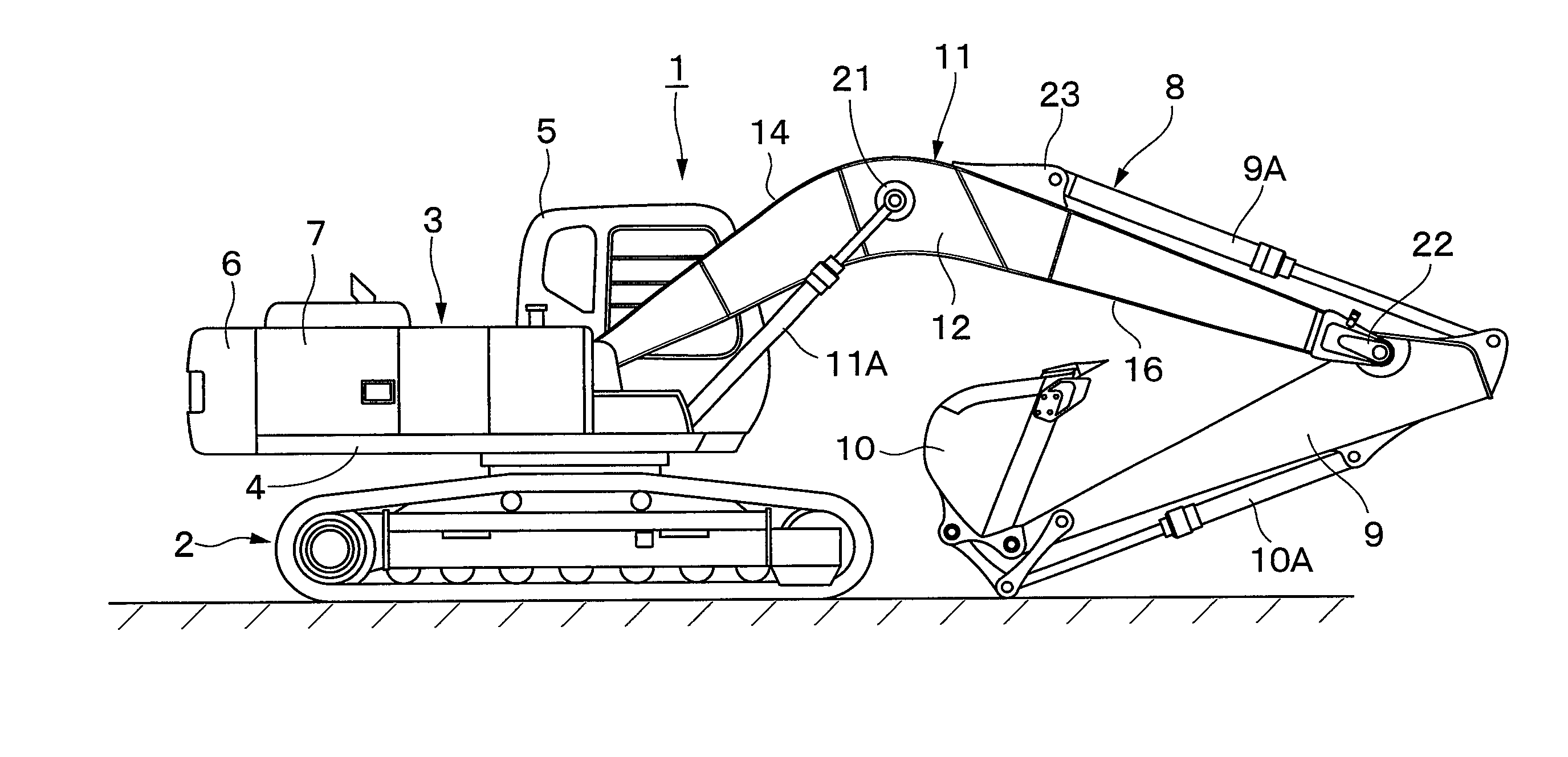

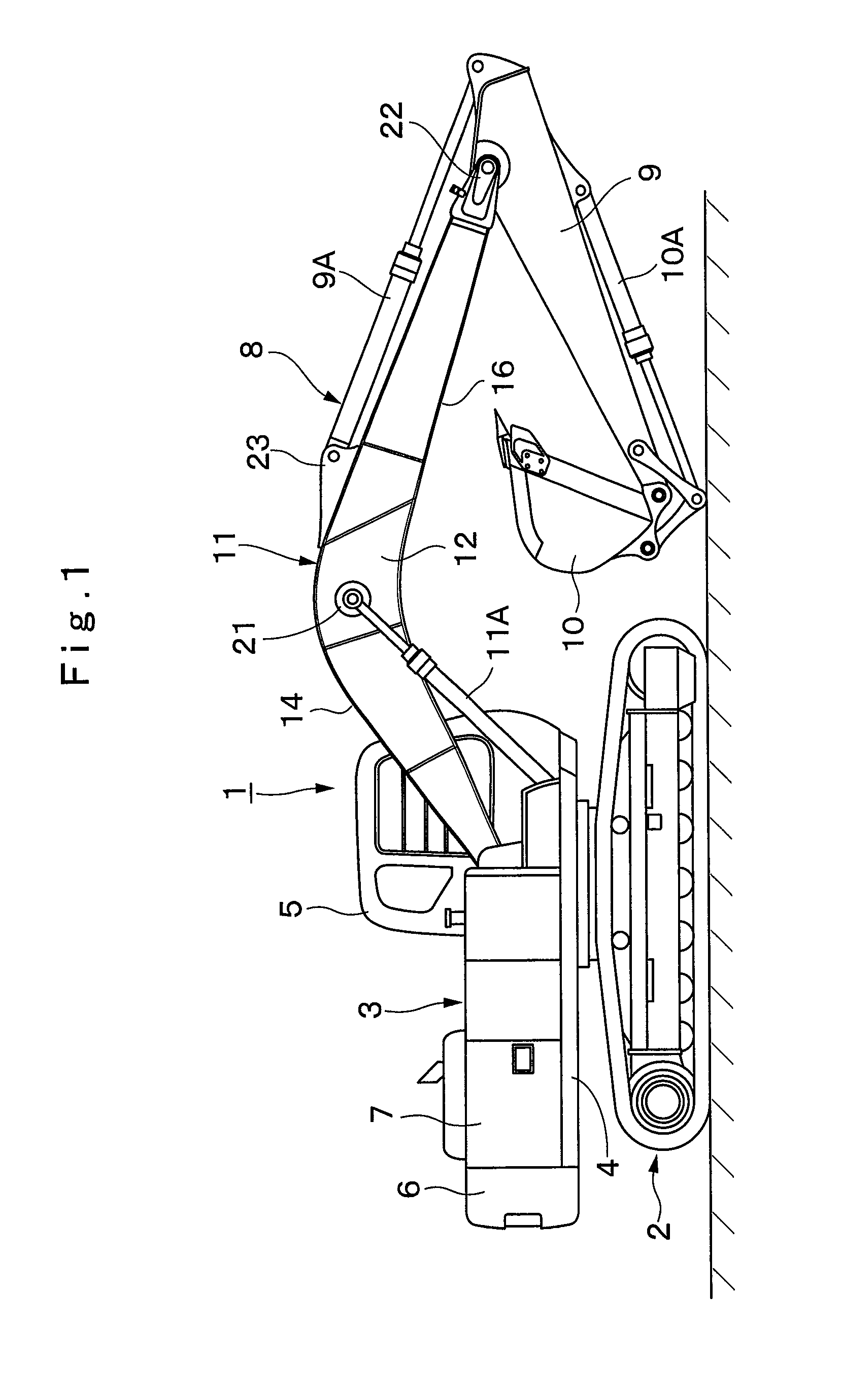

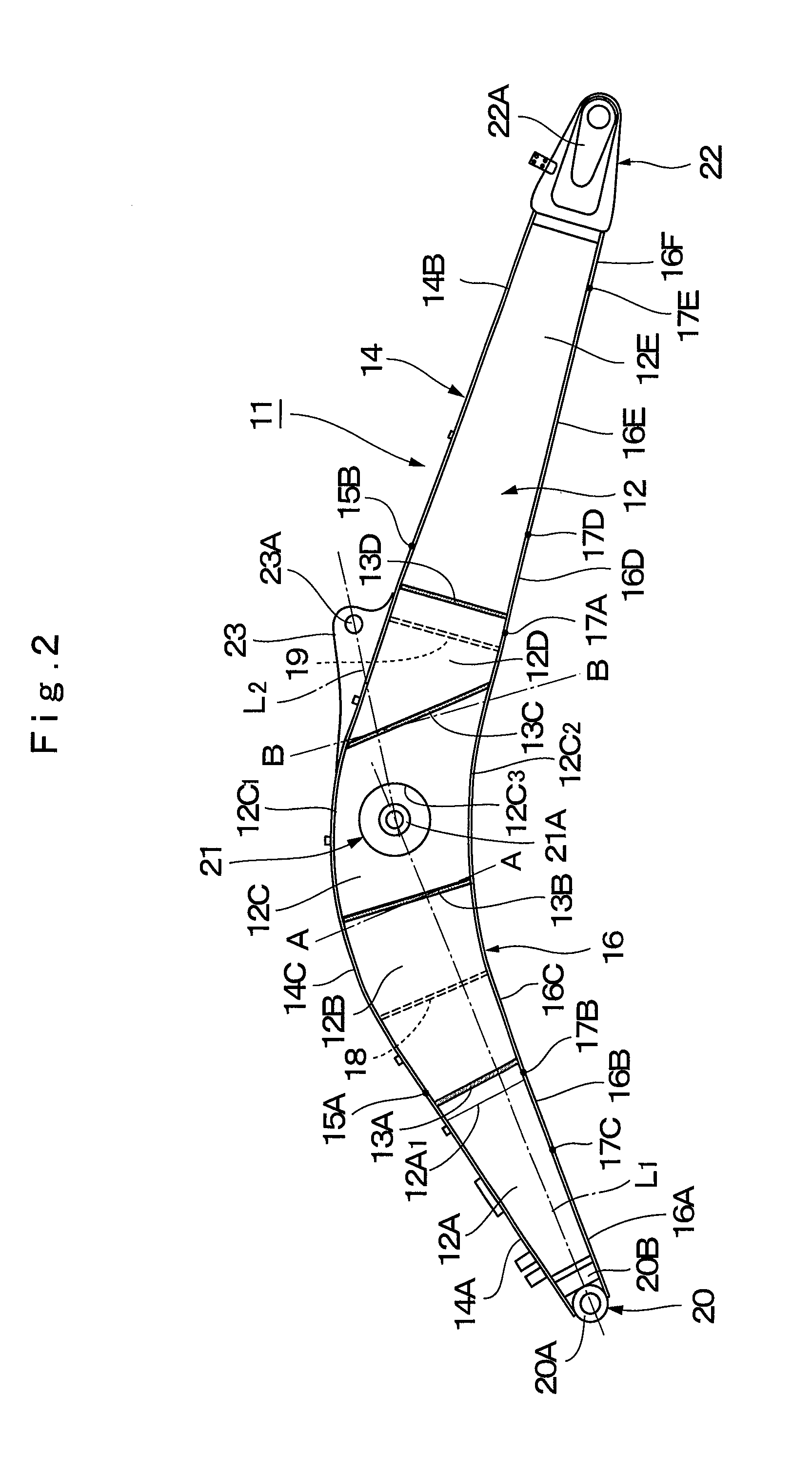

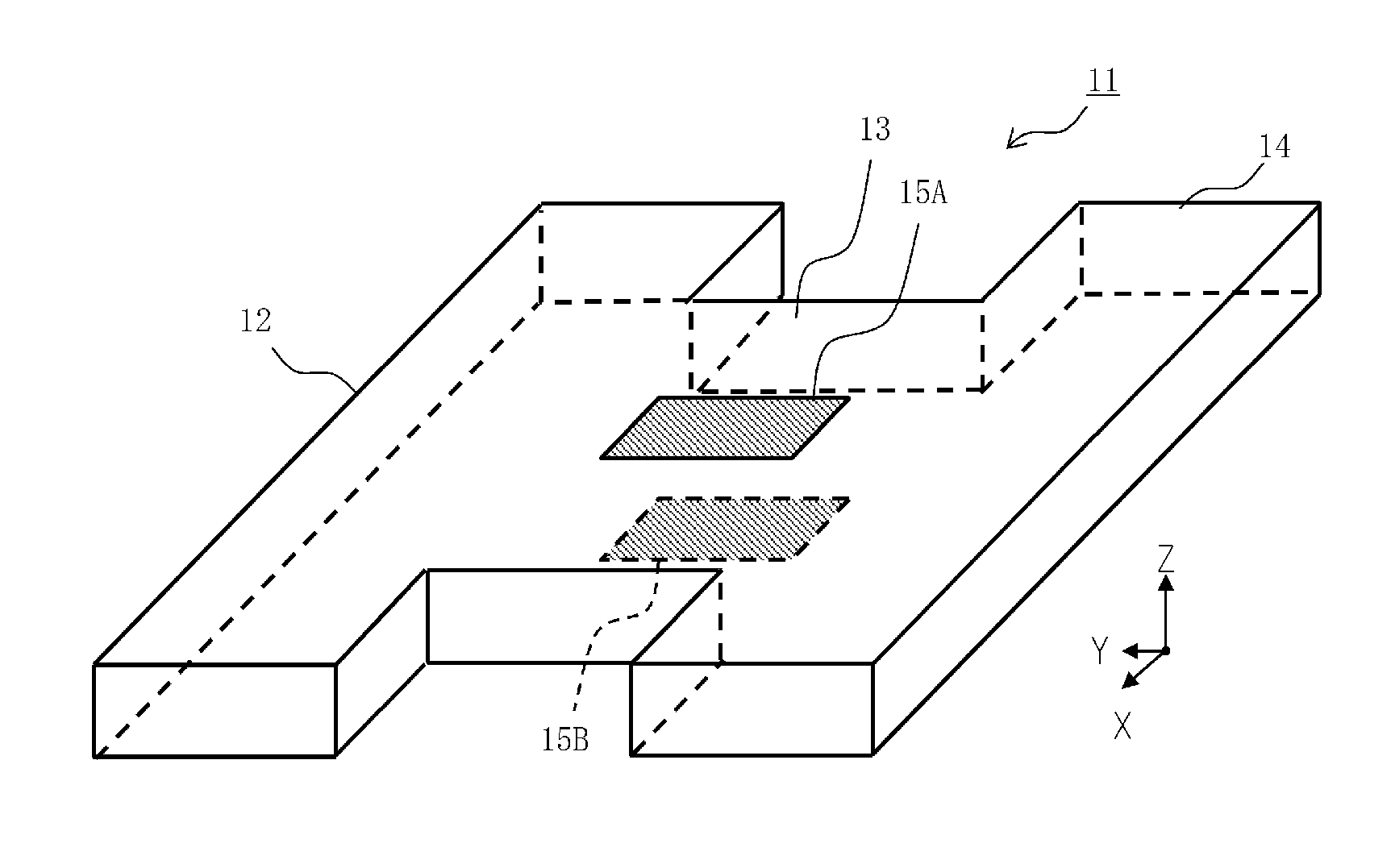

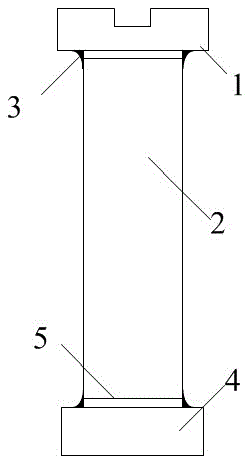

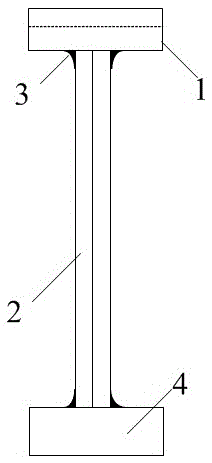

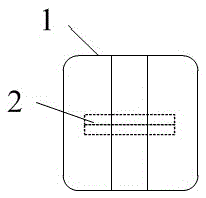

Boom for construction machine

InactiveUS20140056677A1Improve joint strengthBending strengthMechanical machines/dredgersLifting devicesClassical mechanicsFlexural strength

In left and right web plates (12) of a boom (11), first to fifth web materials (12A to 12E) are joined at edge portions in a front-rear direction along welding lines (13A to 13D). In an upper flange plate (14), a rear upper flange material (14A), a front upper flange material (14B), and a middle upper flange material (14C) are joined at edge portions in a front-rear direction along welding lines (15A, 15B). Ina lower flange plate (16), first to sixth lower flange materials (16A to 16F) are joined at edge portions in a front-rear direction along welding lines (17A to 17E). The welding lines (13A to 13D) of the left and right web plates (12) are disposed in positions that are different from those of the welding lines (15A, 15B) of the upper flange plate (14) and the welding lines (17A to 17E) of the lower flange plate (16) in a front-rear direction. This makes it possible to reduce the entire weight and thereby achieve reduction in weight while ensuring bending strength, torsional strength, and the like of the boom (11).

Owner:NIHON KENKI CO LTD

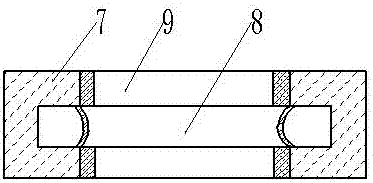

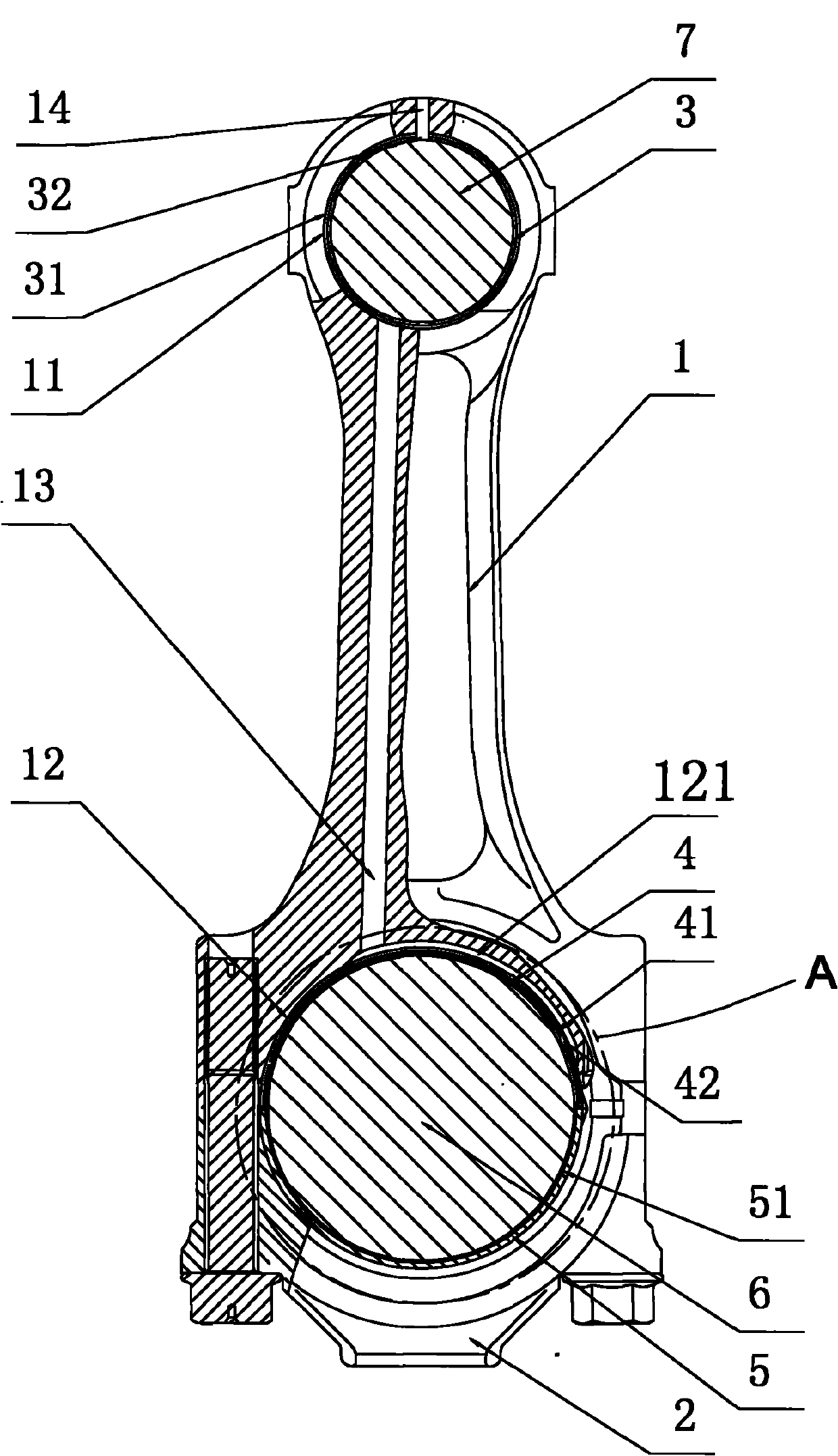

Structural improvement of engine connecting rod

The invention discloses structural improvement of an engine connecting rod. A big end of a connecting rod body is detachably and fixedly connected with a connecting rod cover to form a crank shaft hole; a bushing is fixedly inserted into a piston pin hole at a small end of the connecting rod body; an upper bearing bush and a lower bearing bush are inserted into the crank shaft hole; the inner walls of the upper bearing bush and the lower bearing bush are provided with a second minor arc-shaped concave oil groove and a first semicircular concave oil groove which are communicated with each other respectively; the second oil groove of the upper bearing bush is provided with a first oil hole in the radial direction; the inner wall of the crank shaft hole of the connecting rod body is provided with a third arc-shaped concave oil groove which is communicated with the first oil hole; the outer wall of a bushing is provided with a fourth concave annular oil groove; the inner wall of a fourth oil groove is provided with at least one radial through hole; and the connecting rod body is provided with at least one oil way which is communicated with the third oil groove and the fourth oil groove respectively. In the structural improvement, lubricating oil in a crank shaft can be led into the bushing, so that the junction of the connecting rod and a piston pin and the junction of the connecting rod and the crank shaft are fully lubricated, the connecting rod produces small impact force to the crank shaft during reciprocating motion, and the upper bearing bush, the lower bearing bush, the connecting rod and the bushing have long service life.

Owner:苏州麦格特发动机有限公司

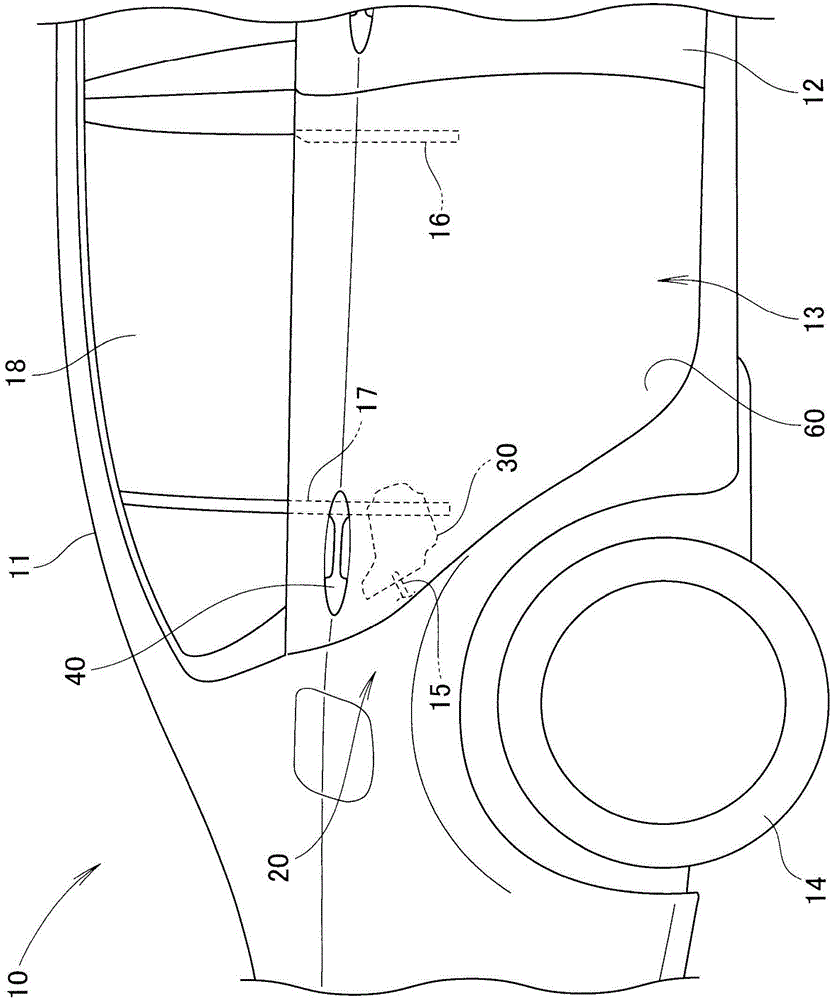

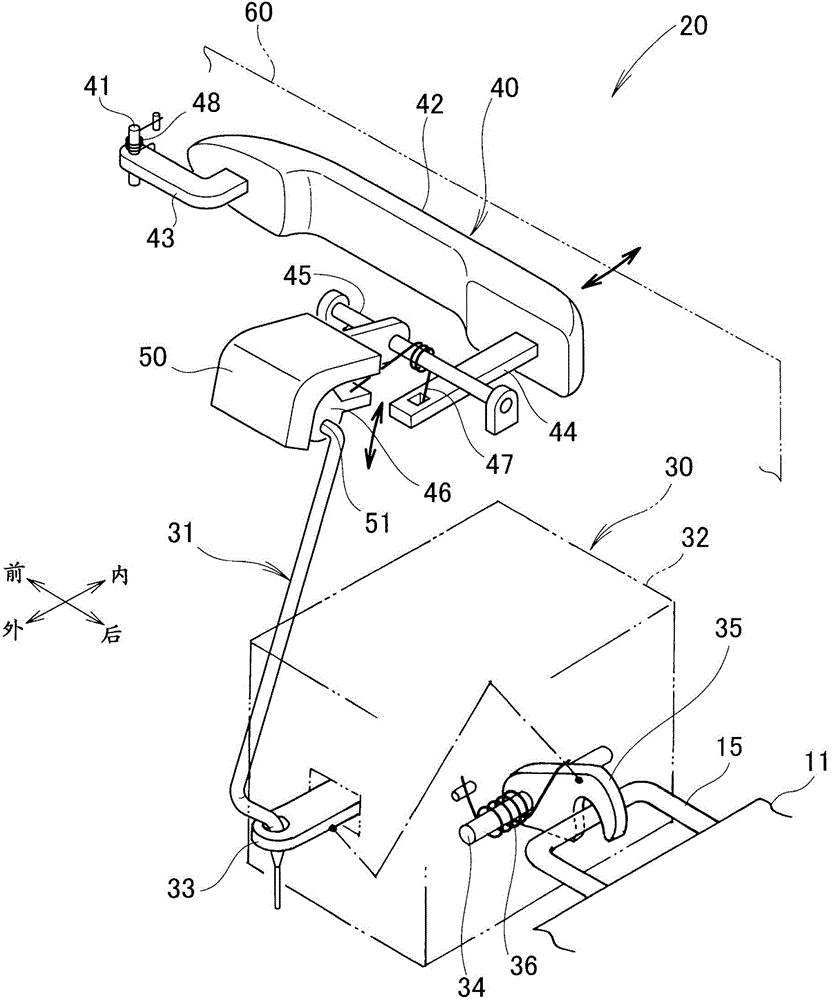

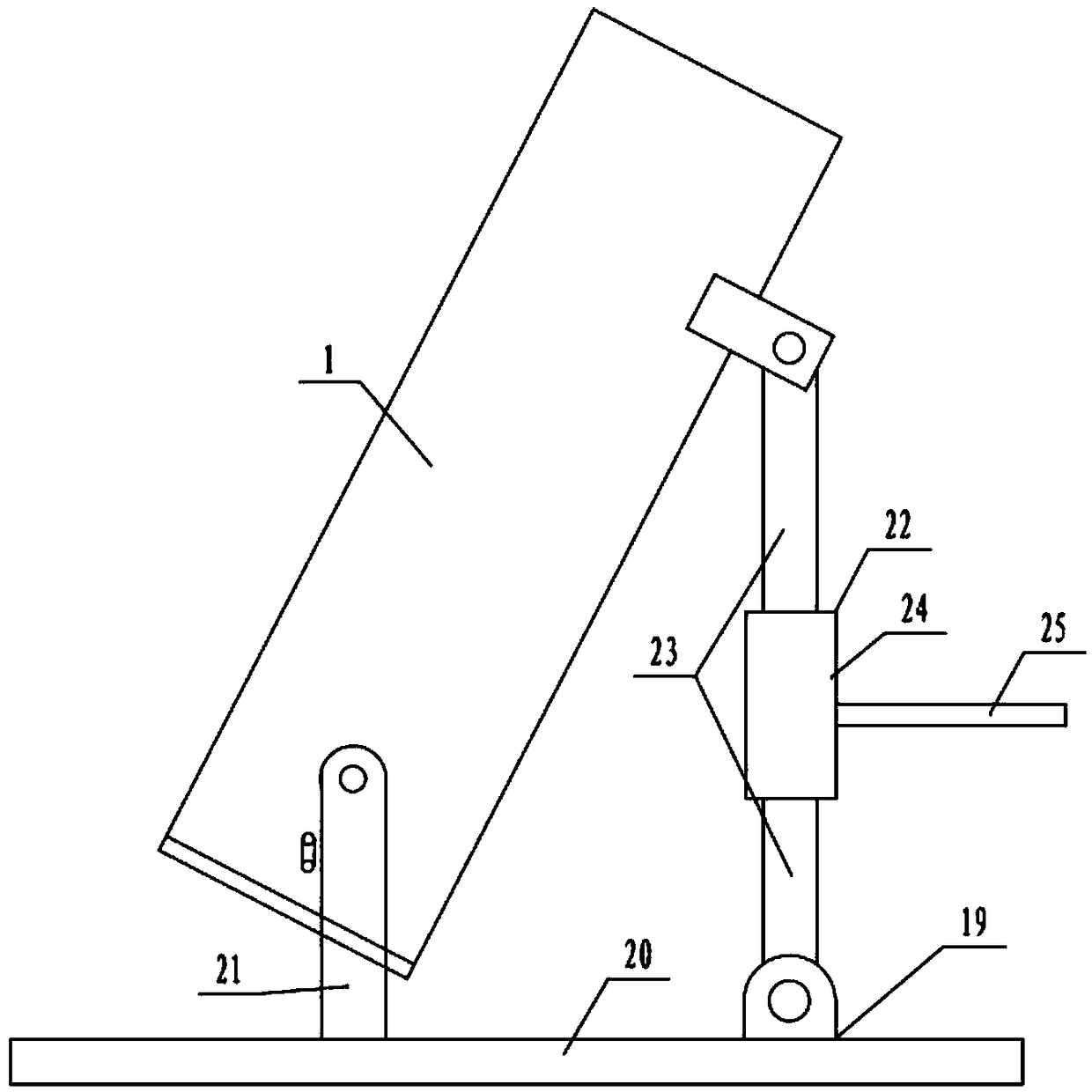

Door outer handle

ActiveCN104417327AIncrease in sizeReduce sizeAccident situation locksPassenger lock actuationEngineeringCar door

A door outer handle which can be easily attached to an outer panel from the outside and in which the size of a counter weight is sufficiently ensured is provided. A door outer handle has an elongated shape. A hinge portion provided at one end of the door outer handle is inserted into a first attachment hole, and a counter weight provided at the other end of the door outer handle is inserted into a second attachment hole. An outer circumferential surface of the counter weight, which is located farthest from a contact point, is formed in an arc shape with a first radius, centered at the contact point. Furthermore, an inner circumferential surface of the counter weight, which is located closer to the contact point than the outer circumferential surface, is also formed in an arc shape with a second radius, centered at the contact point.

Owner:HONDA MOTOR CO LTD

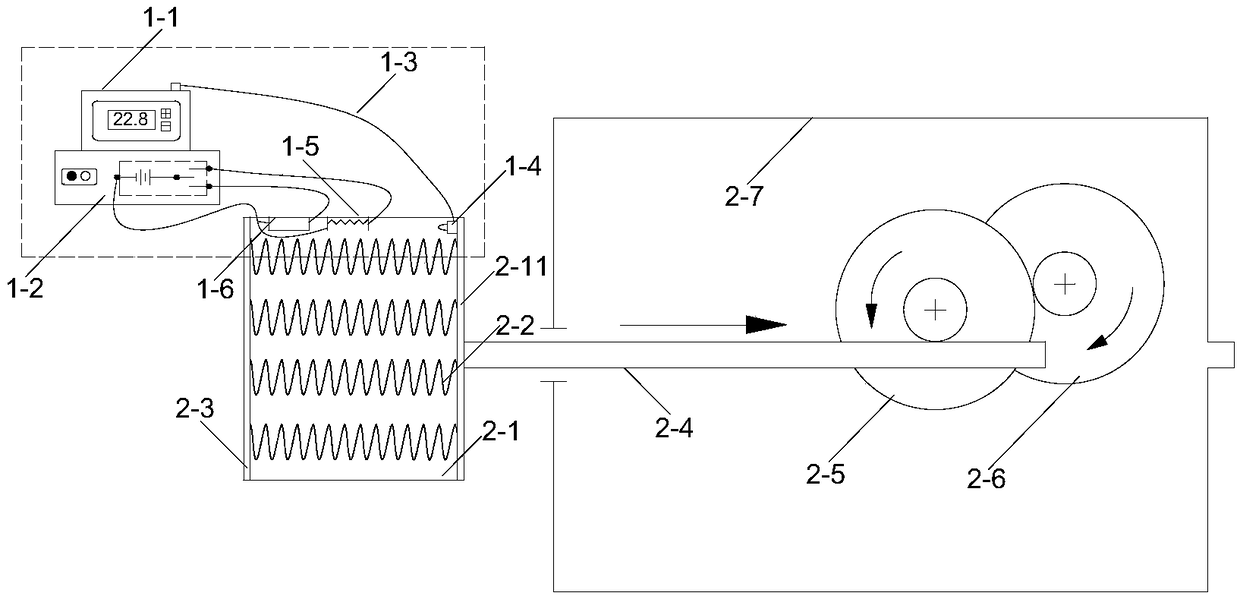

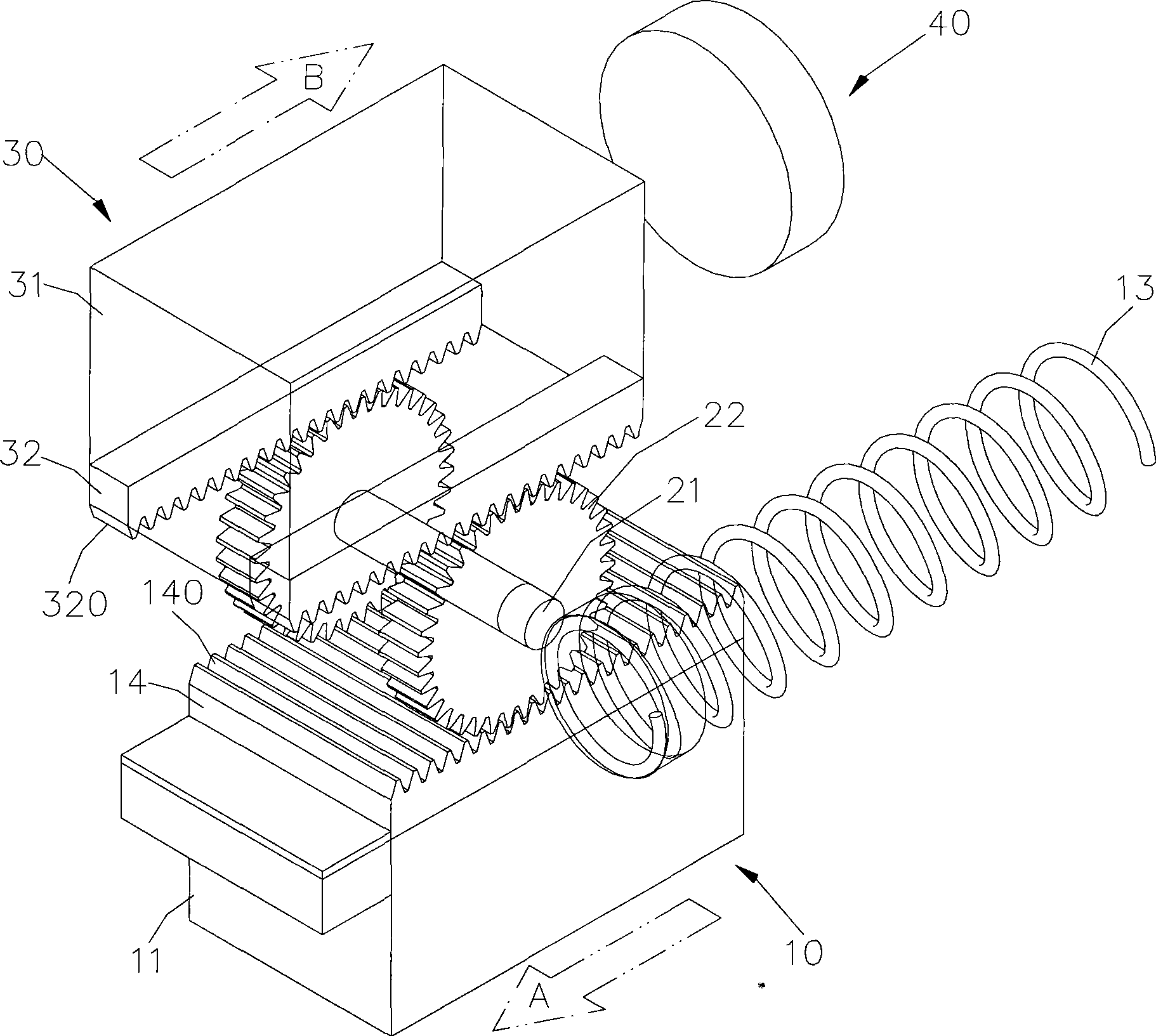

Temperature-controlled intelligent tuned inertial mass damper

ActiveCN109025450AIntelligent control frequencyLight in massProtective buildings/sheltersShock proofingTemperature controlViscous liquid

The invention discloses a temperature-controlled intelligent tuned inertial mass damper. The damper is composed of two parts, namely a working cavity temperature control part and a main damper body part. The working cavity temperature control part comprises a temperature monitoring part and a temperature adjusting part. The main damper body part comprises an SMA spring and an inertial mass damperbody connected with the SMA spring through a rack, the rack is connected with a driving gear, the driving gear is in contact with a follow-up flywheel, the follow-up flywheel is connected with a cylinder, and the cylinder is located in a box body filled with viscous liquid. According to the temperature-controlled intelligent tuned inertial mass damper, the inertia force of the damper body can be increased by converting axial motion into rotary motion, and on the premise of ensuring the damping effect, the mass of the damper body is reduced. The damping and stiffness of the SMA spring can alsobe adjusted in real time by changing the temperature, so that the damper body has the stable working performance in a wide frequency domain, and therefore the good damping effect is achieved.

Owner:SHANDONG UNIV

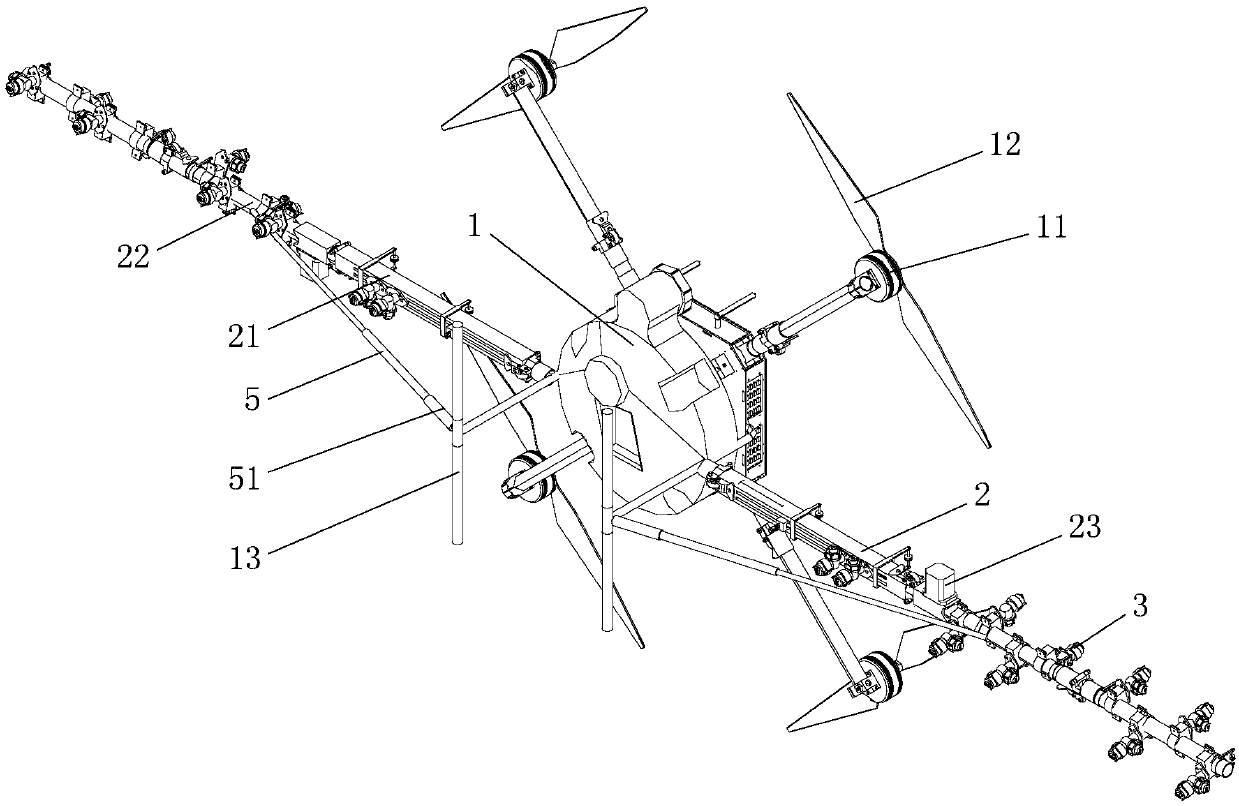

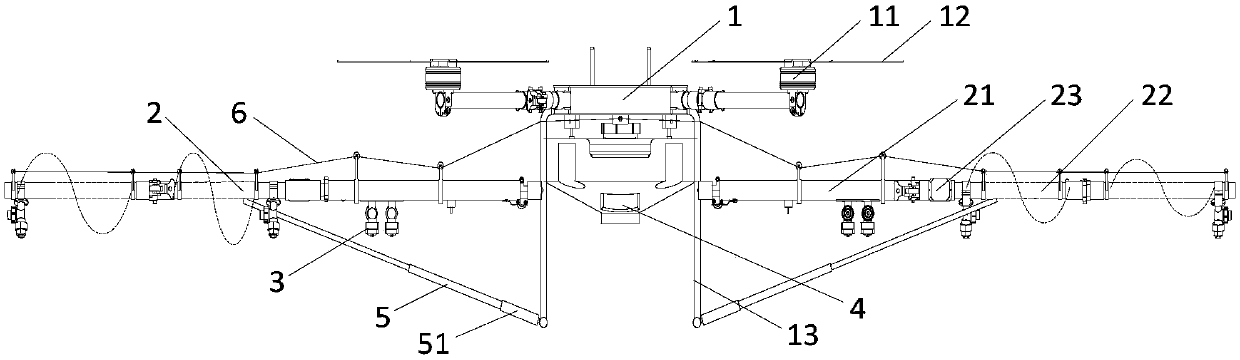

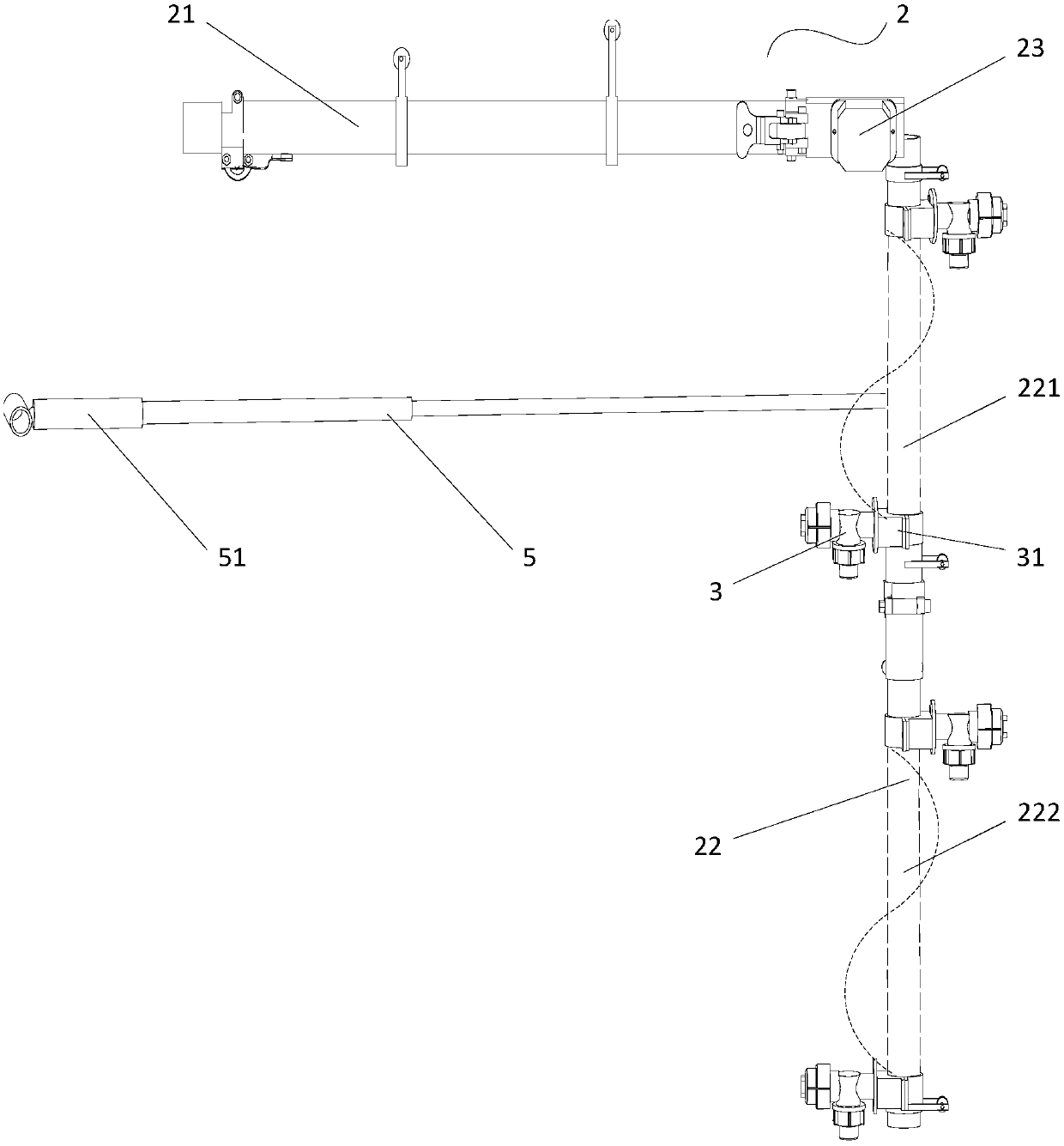

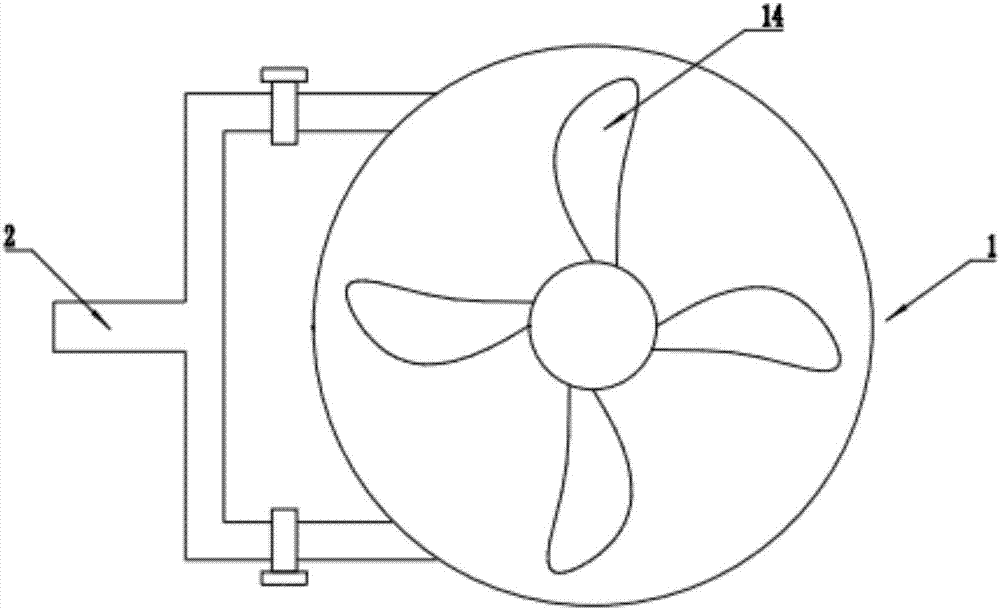

Plant protection drone

PendingCN109677614ARealize horizontal sprayingAchieve vertical sprayingAircraft componentsLaunching weaponsVertical planeAgricultural engineering

The invention discloses a plant protection drone. The plant protection drone comprises a drone body, a spray bar and a plurality of spray heads, wherein the spray bar comprises an inner spray bar andan outer spray bar; one end of the inner spray bar is connected with the drone body; the other end of the inner spray bar is connected with the outer spray bar; during working, the outer spray bar canbe rotated in a vertical plane relative to the inner spray bar to move to a vertically downward position or a horizontal position; and the spray heads are arranged on the inner spray bar and the outer spray bar along the length direction of the spray bar at intervals. The plant protection drone disclosed by the invention has the beneficial effects that when the plant protection drone works, the outer spray bar can be rotated in a vertical plane relative to the inner spray bar to move to a vertically downward position or a horizontal position, so that the horizontal spraying and the longitudinal spraying of a medicine can be realized and the plant protection drone can adapt to various sprayed objects, is suitable for spraying needs of different crops and different environments, meets practical application needs and has strong practicability and a broad application prospect.

Owner:LINYI UNIVERSITY

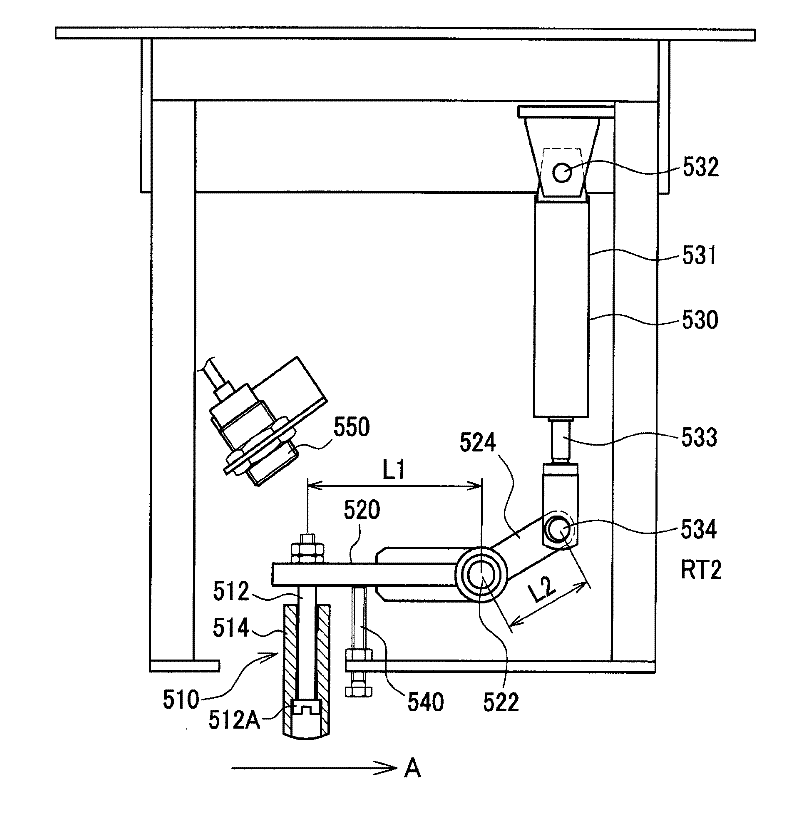

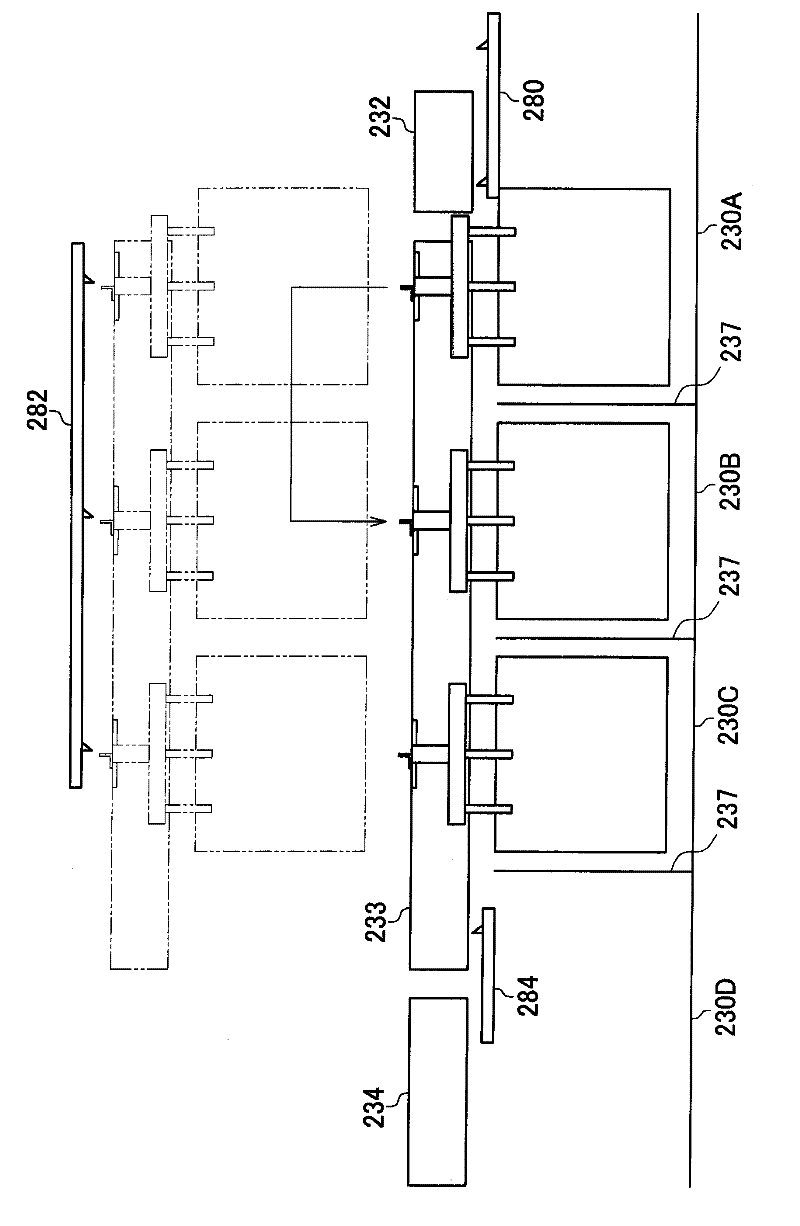

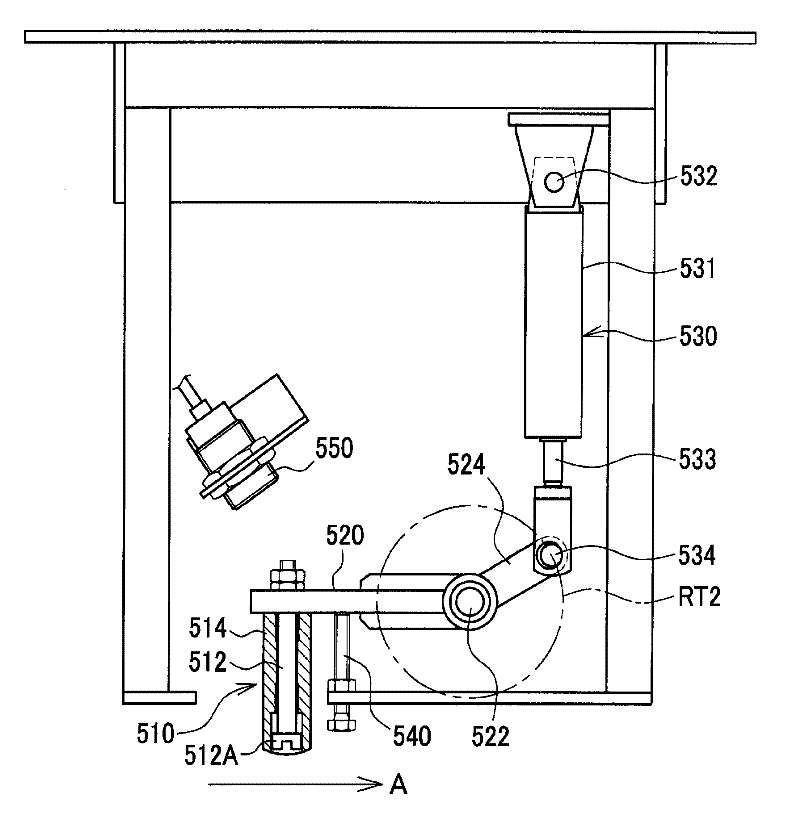

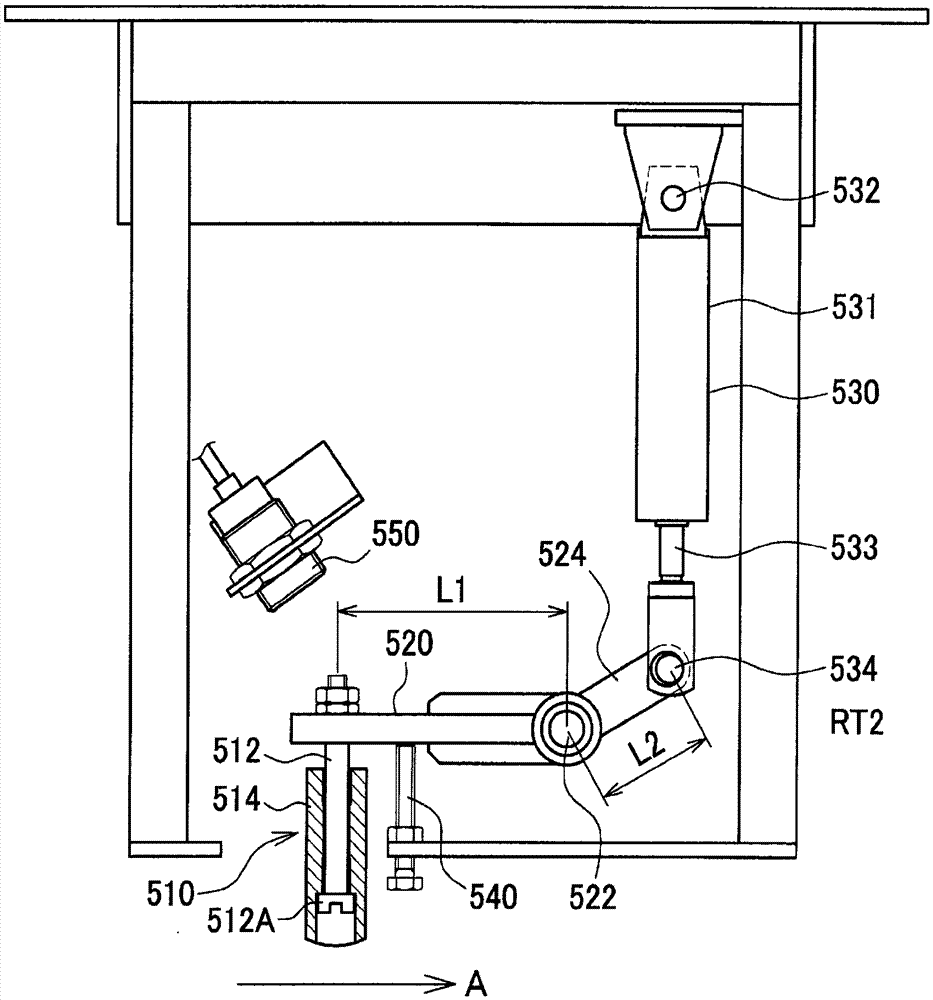

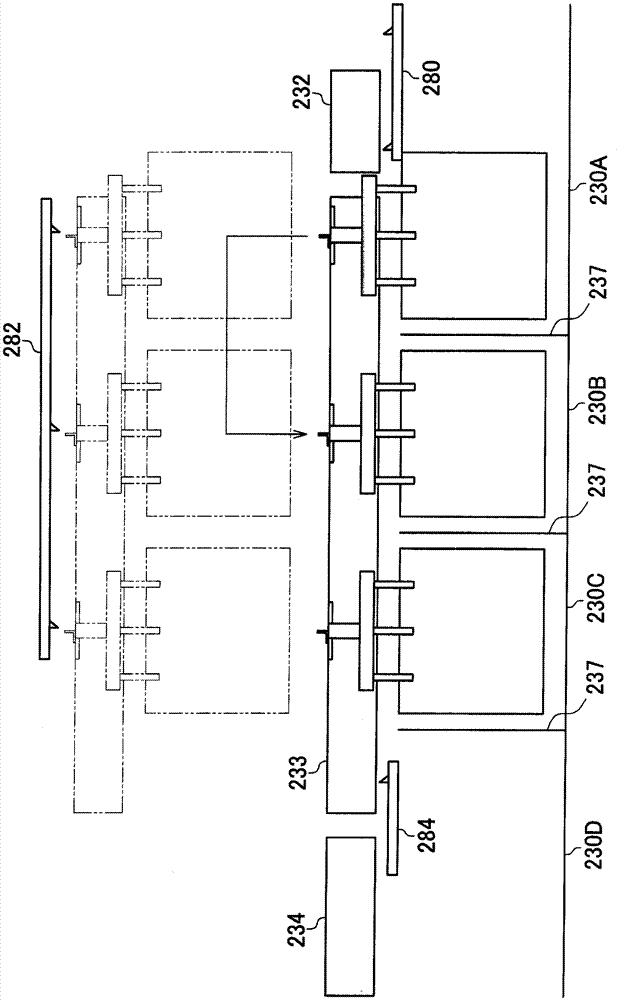

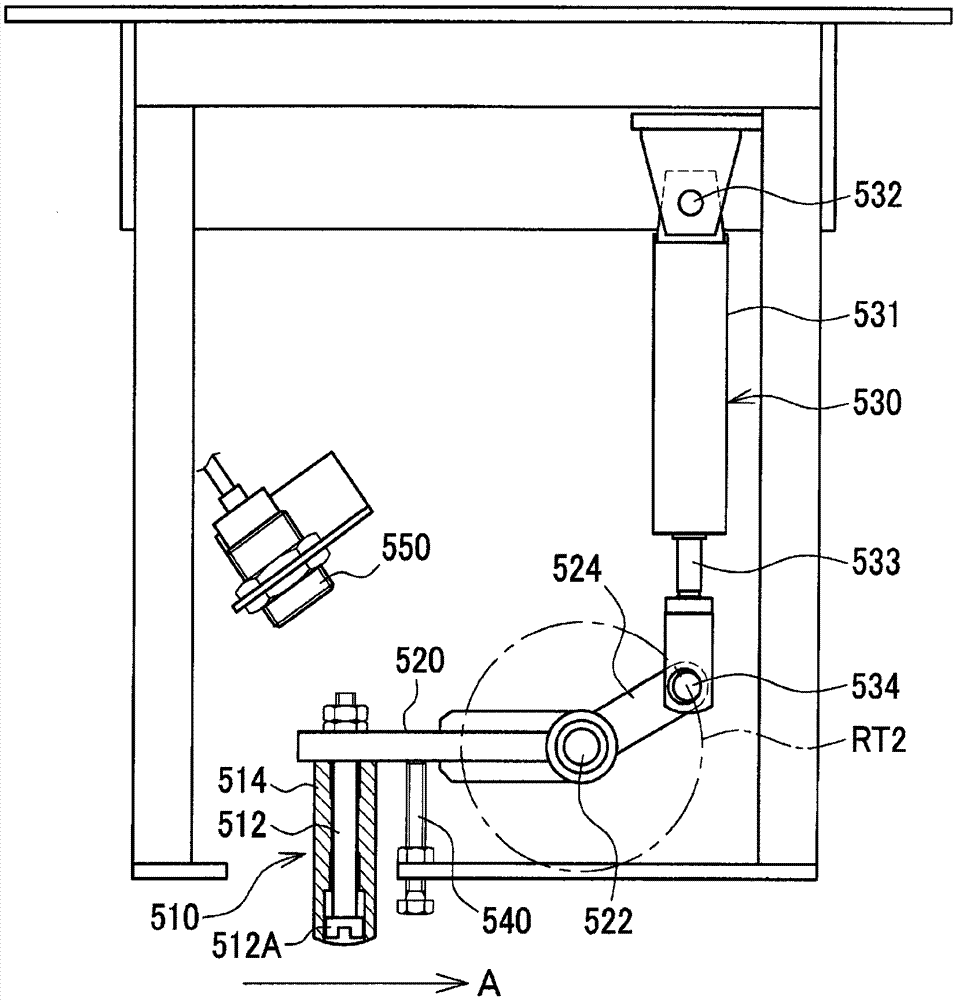

Surface Processing Device

InactiveCN102409387AImprove the effect of surface treatmentMovement speed increaseCellsSemiconductor devicesMechanical engineeringSurface processing

The invention provides a surface processing device. The surface processing device can remove bubbles adhering to the surface and in holes of a work piece physically, and improve the surface processing ability. The surface processing device used for processing the surface of the work piece (20) is provided with a guide rail (201, 231-235); a transporting fixture (30) guided by the guide rail and transporting and retaining the work piece in a transporting direction (A) along the guide rail; a surface processing groove (200) used for surface processing of the work piece retained by the transporting fixture; a front processing groove (230A) arranged on a side of the upper stream of the transporting direction (A) of the surface processing groove and dipping the work piece retained by the transporting fixture into processing liquid (290) for processing; and a vibration giving part (500) giving vibration to the transporting fixture retaining the work piece dipped in the processing liquid in the preprocessing groove, thereby letting the work piece vibrate in the processing liquid.

Owner:ALMEX PE INC

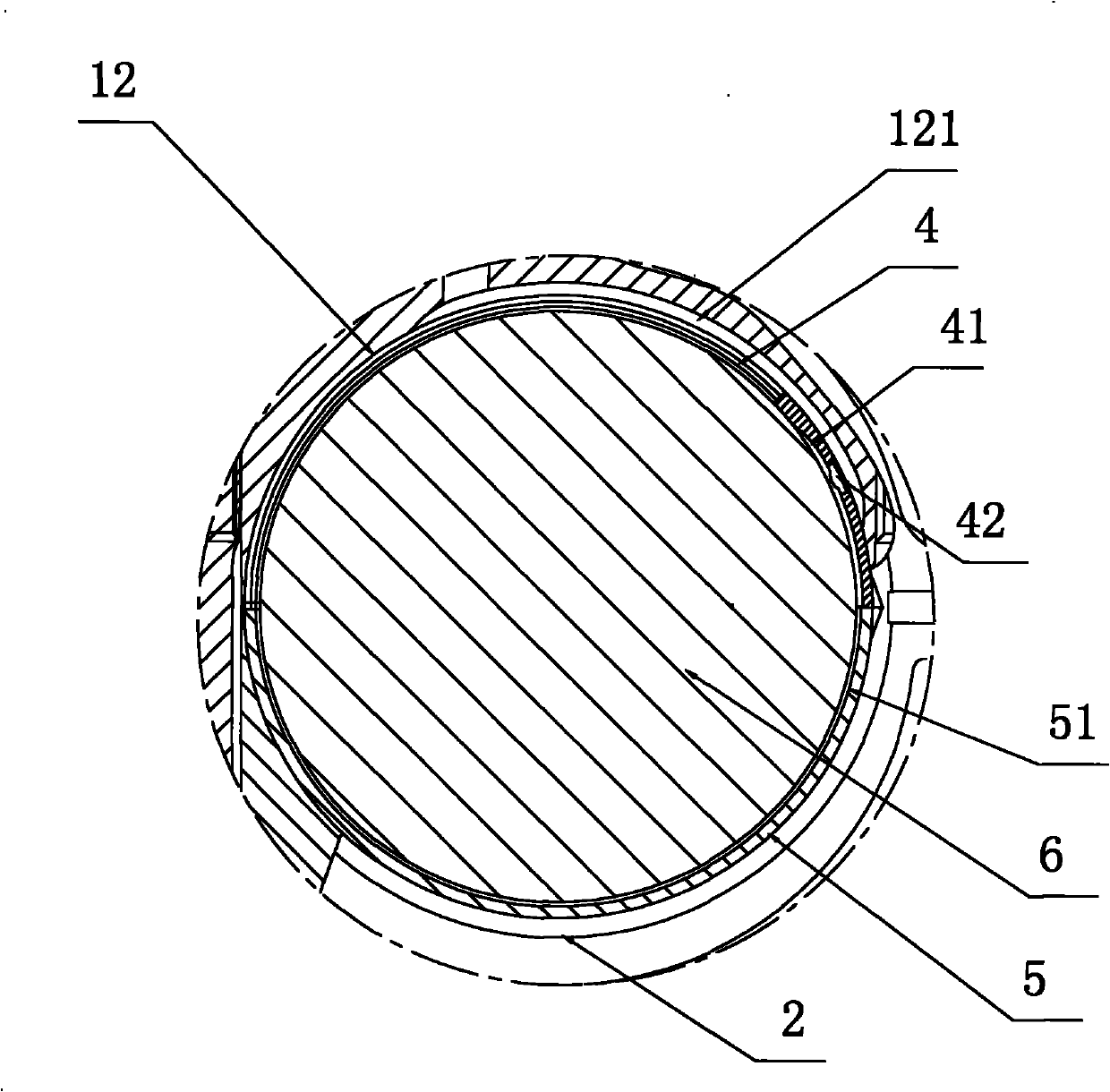

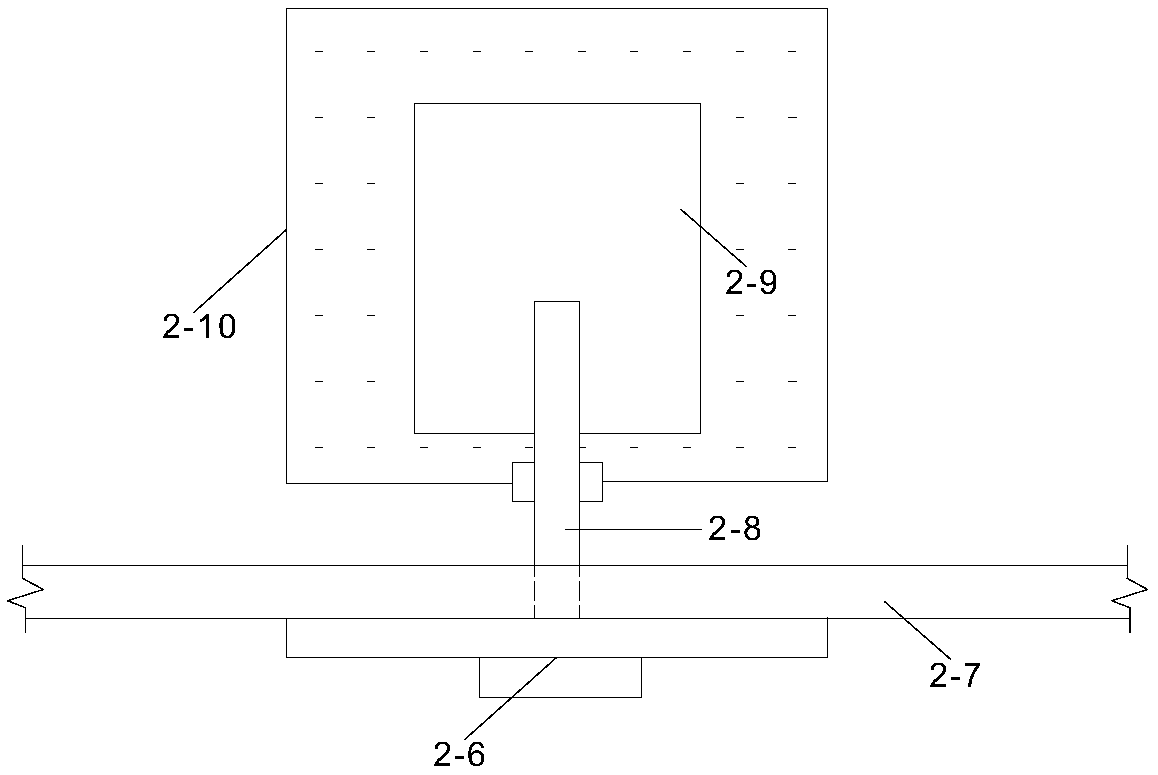

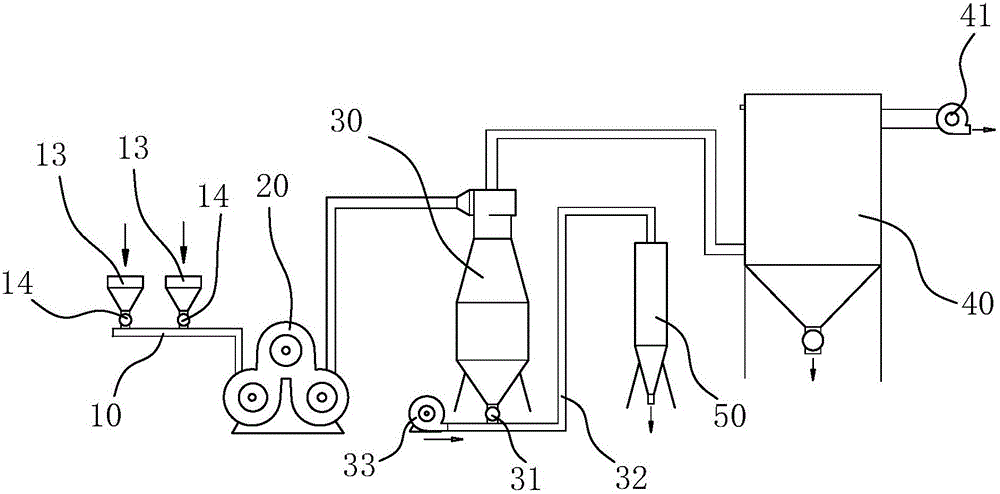

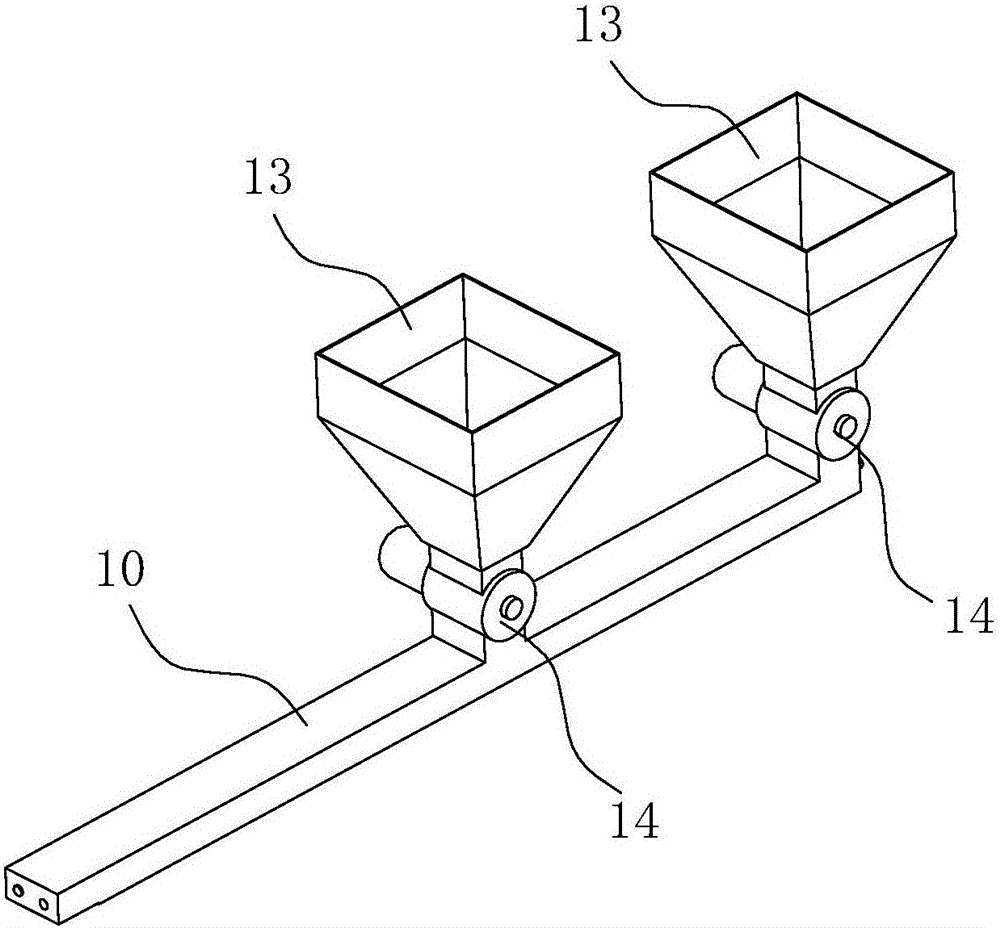

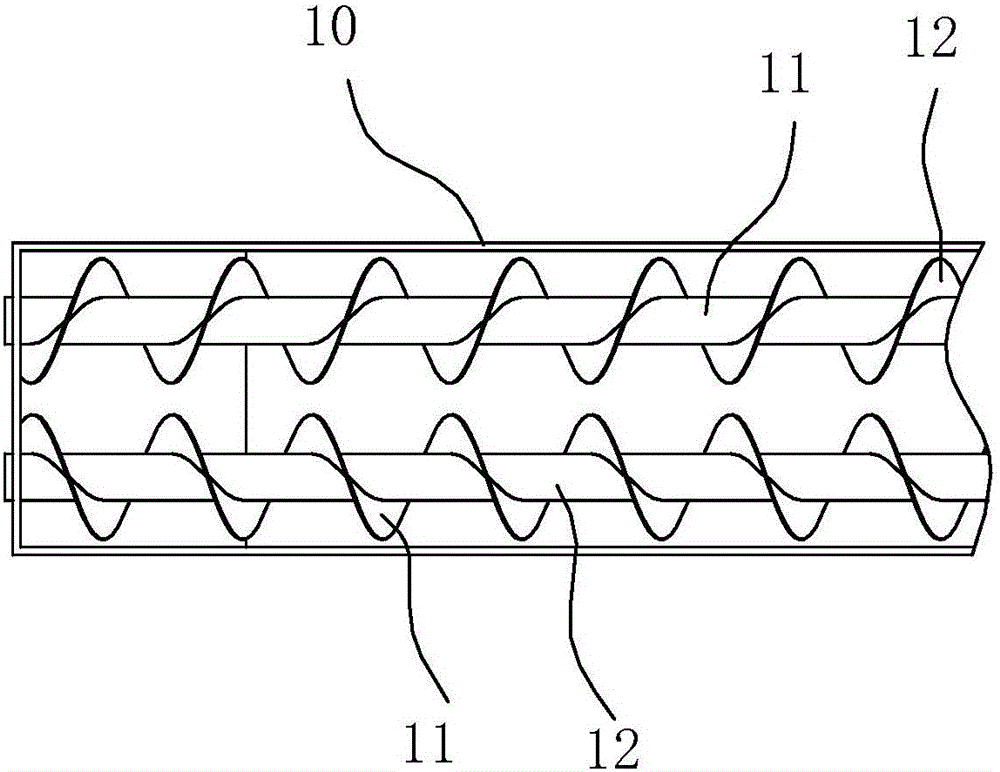

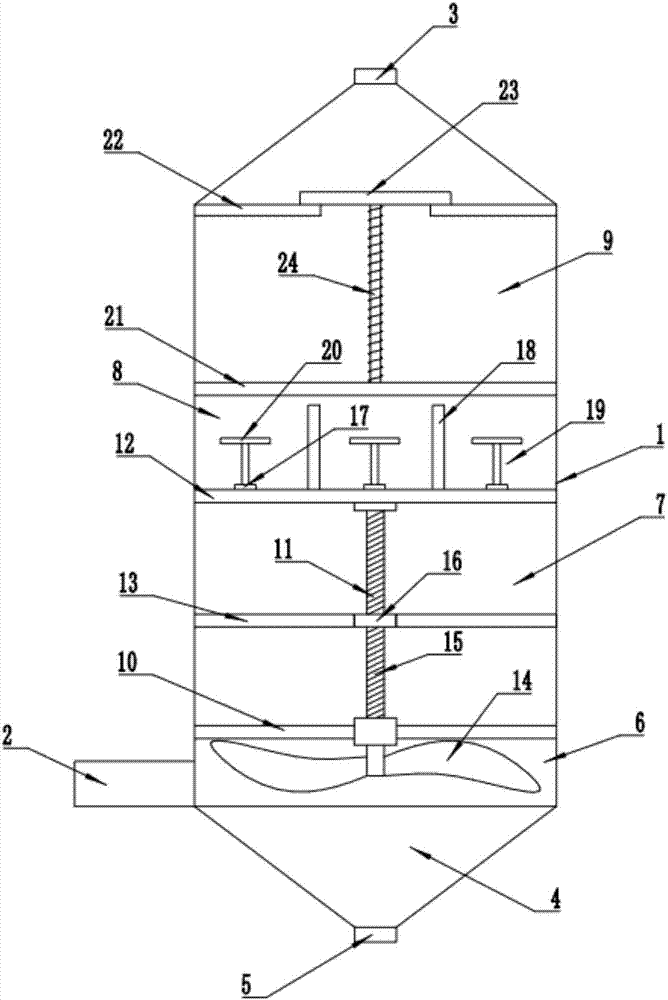

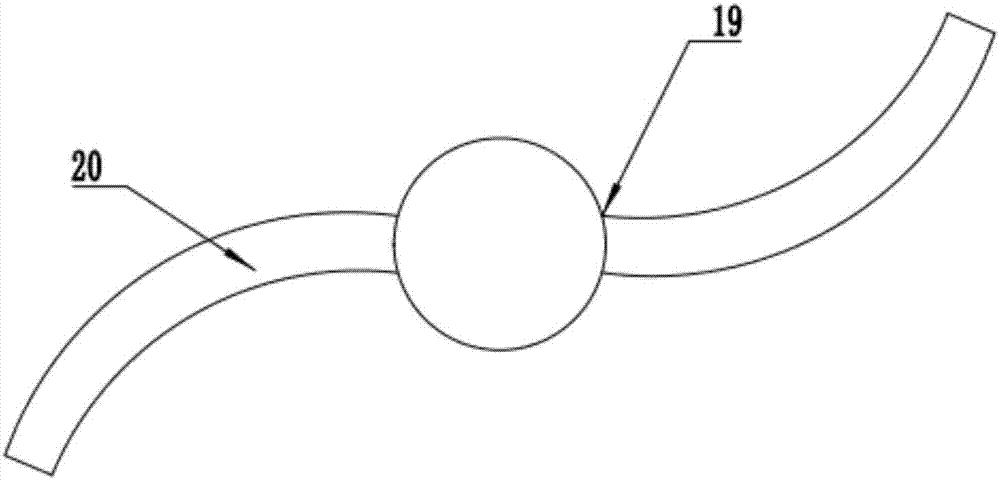

Calcium carbonate powder surface modification equipment

ActiveCN105860587AIncrease productivityIncrease inertial forceInorganic pigment treatmentLiquid stateMetallurgy

The invention belongs to the field of production and processing of powder materials and in particular relates to calcium carbonate powder surface modification equipment. The calcium carbonate powder surface modification equipment comprises a calcium carbonate powder mixing, stirring and conveying device, a calcium carbonate powder surface coating device and a wind energy filtering and material collecting device which are sequentially connected; the calcium carbonate powder mixing, stirring and conveying device is used for uniformly mixing calcium carbonate powder with different particle sizes and conveying to the calcium carbonate powder surface coating device, the calcium carbonate powder surface coating device is used for spraying liquid-state organic matter onto calcium carbonate powder and stirring by adopting a high speed mixer, so that the organic matter is fully coated on the surface of calcium carbonate; the wind energy filtering and material collecting device is used for pumping out materials in the high speed mixer by utilizing a fan, filtering out the calcium carbonate powder in air flow by adopting a dust remover and collecting the calcium carbonate powder. The calcium carbonate powder surface modification equipment has the advantages that multiple feeding holes are formed, a feed pump used for regulating feeding rate is arranged at the feeding holes, and different materials can be mixed in specific ratio in a conveying process; and a ball head is arranged at the top end of a stirring rod, inertia force of a stirring device can be effectively increased, energy sources can be greatly saved, and the ball head also can increase contact area between the stirring rod and the calcium carbonate powder, so that stirring is more sufficient.

Owner:XUANCHENG XINTAO CALCIUM CARBONATE

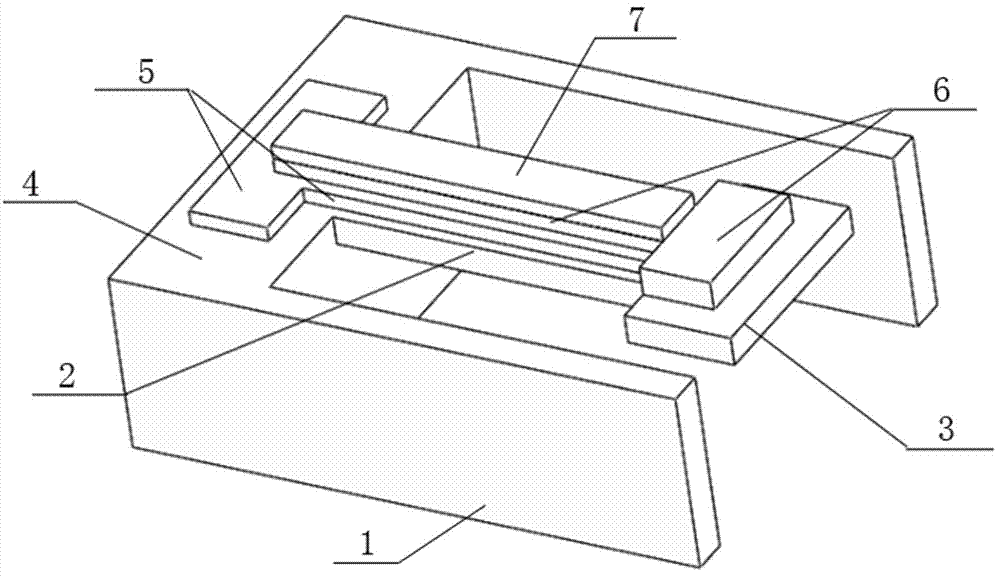

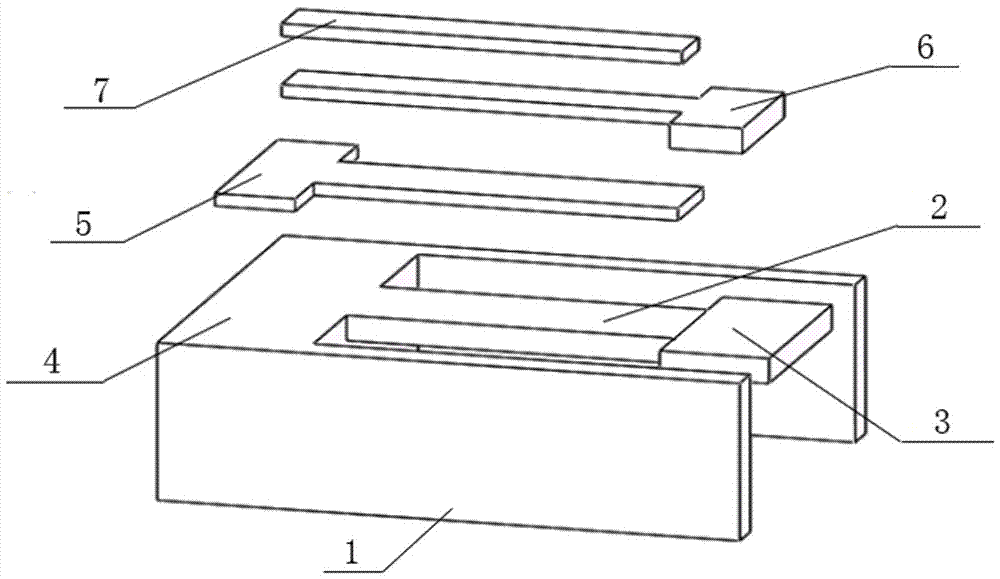

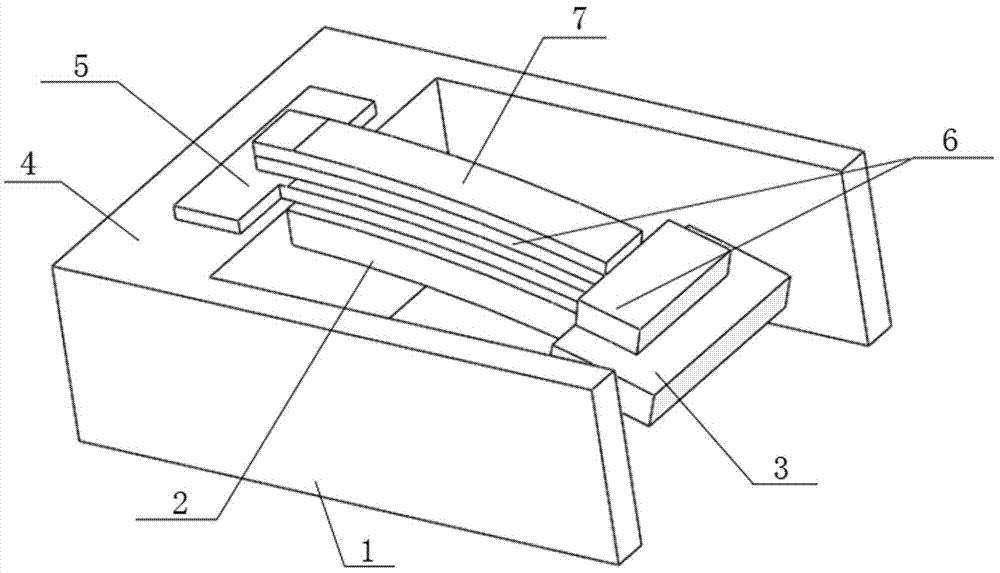

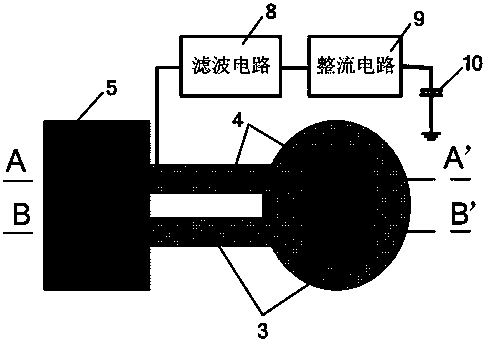

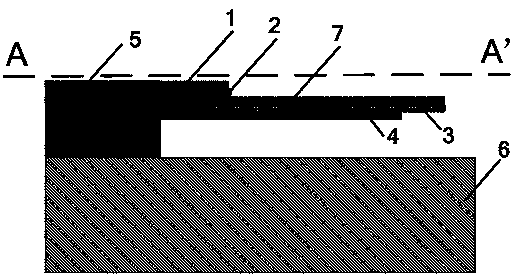

Cantilever beam type membrane stress power generation structure

InactiveCN106966356ALower natural frequencyLarge deformationDecorative surface effectsChemical vapor deposition coatingInsulation layerMembrane stress

The invention belongs to the field of Micro-Electro-Mechanical System (MEMS), more specifically, the invention relates to a cantilever beam type membrane stress power generation structure, which comprises a frame type substrate, wherein a silicon cantilever beam suspended in the frame type substrate is positioned on a beam facing an opening of the frame type substrate, the free end of the silicon cantilever beam is fixedly provided with a mass block, a silicon dioxide insulation layer is also positioned above the beam facing the opening of the frame type substrate, a bottom electrode layer is positioned on the silicon dioxide insulation layer, a strip bottom electrode layer positioned above the silicon cantilever beam extends on the bottom electrode layer in the direction towards the opening of the frame type substrate, a PZT piezoelectric layer is positioned on the mass block, a strip PZT piezoelectric layer positioned above the strip bottom electrode layer extends on the PZT piezoelectric layer in the direction towards the silicon dioxide insulation layer, and a top electrode layer is positioned above the strip PZT piezoelectric layer. When the system is in a vibration environment, the vibration in the external environment can be transferred to the system, vibration and bending deformation of the silicon cantilever beam are caused, mechanical energy is stored in the silicon cantilever beam, thereby, the piezoelectric layer is stretched and contracted and an electrical signal is generated, and the conversion of mechanical energy to electrical energy is realized.

Owner:ZHONGBEI UNIV

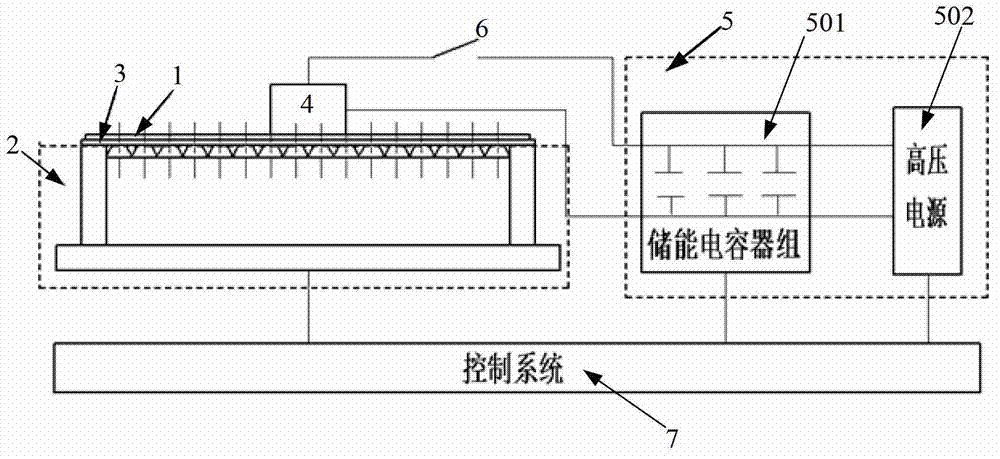

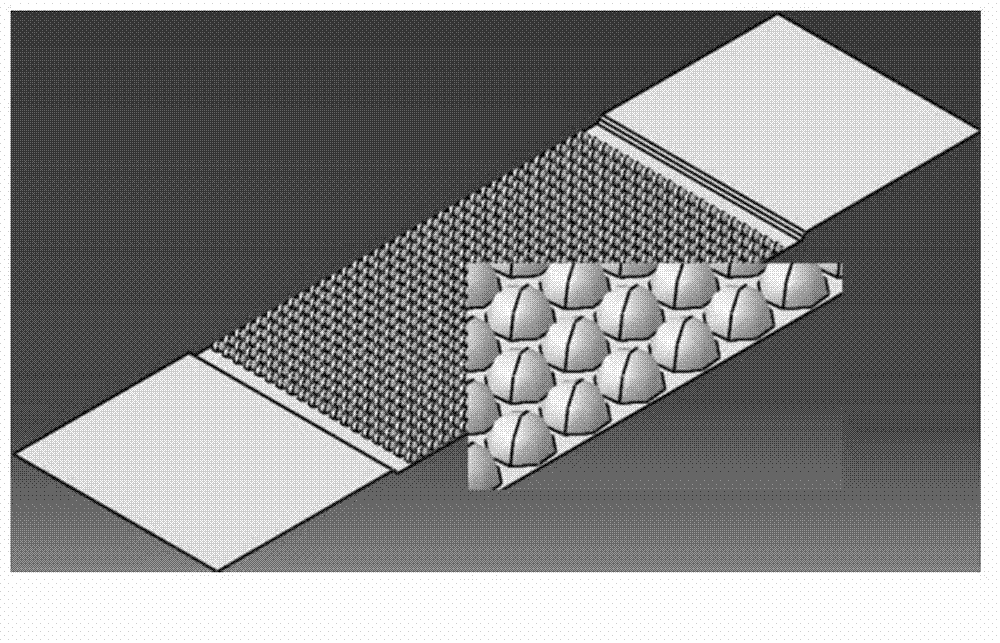

Electromagnetic pulse strengthening and forming device adopting small ball cushion die

The invention discloses an electromagnetic pulse strengthening and forming device adopting a small ball cushion die. The device mainly comprises the small ball cushion die, a flexible cushion layer, an electromagnetic coil, an electromagnetic pulse power source and a control system, wherein the flexible cushion layer is laid on the small ball cushion die; a skin wallboard blank is laid on the flexible cushion layer; the electromagnetic coil is connected with the electromagnetic pulse power source through a wire; and the control system is connected with the electromagnetic pulse power source and a driving device of the small ball cushion die and the electromagnetic coil. Under the dual action of pulse magnetic field force generated by the electromagnetic coil and the supporting force of the small ball cushion die, the upper and lower surfaces of the skin wallboard blank are respectively provided with a pressure stress layer with certain depth, and effects of strengthening a skin wallboard and prolonging fatigue life are achieved. When skin wallboard parts are processed by using the device, a heat treatment state of the skin wallboard blank can directly adopt a using state, so the steps of pretreatment, intermediate heat treatment or final heat treatment in the conventional process are simplified or eliminated.

Owner:BEIHANG UNIV

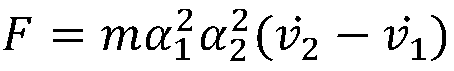

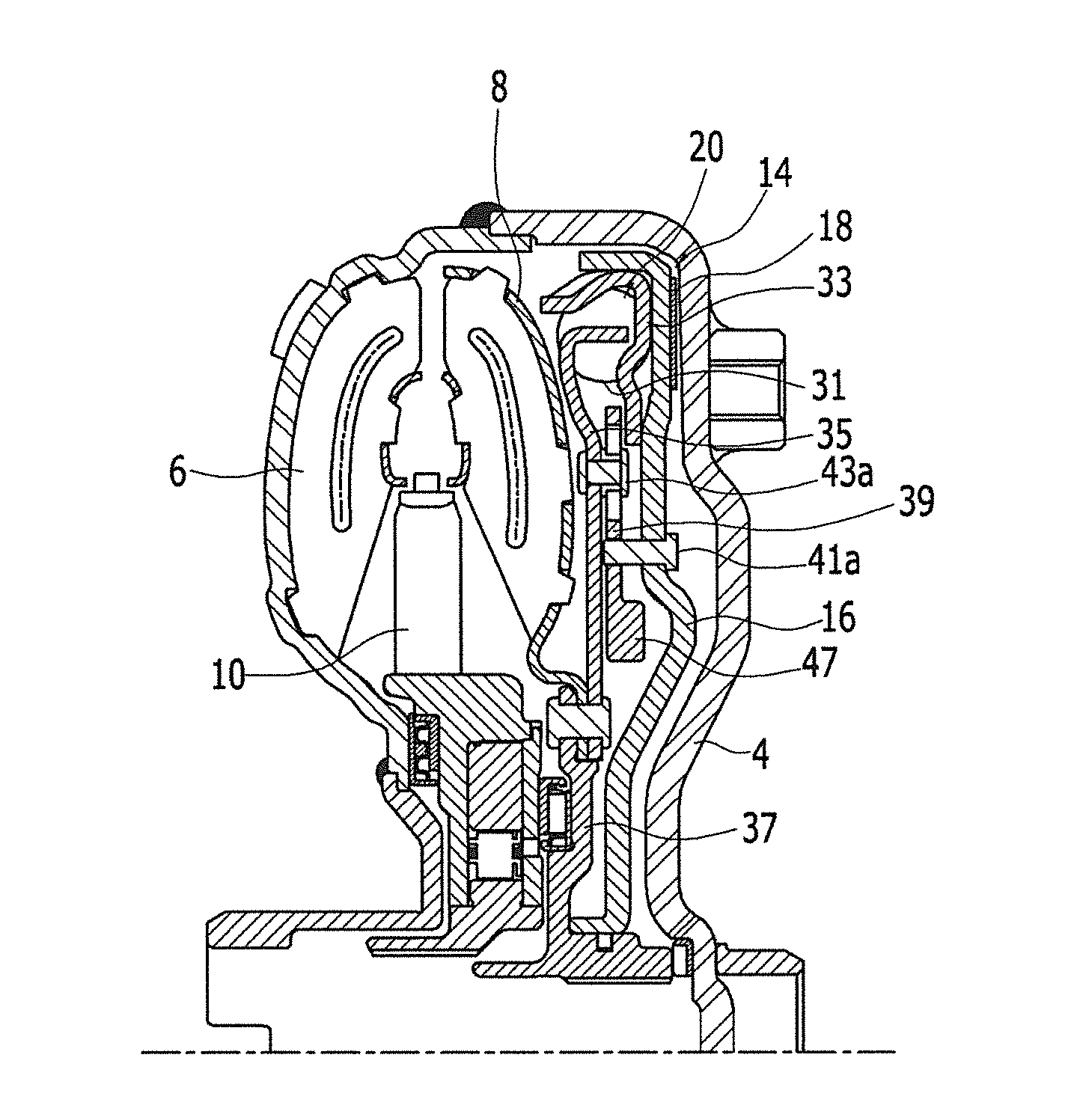

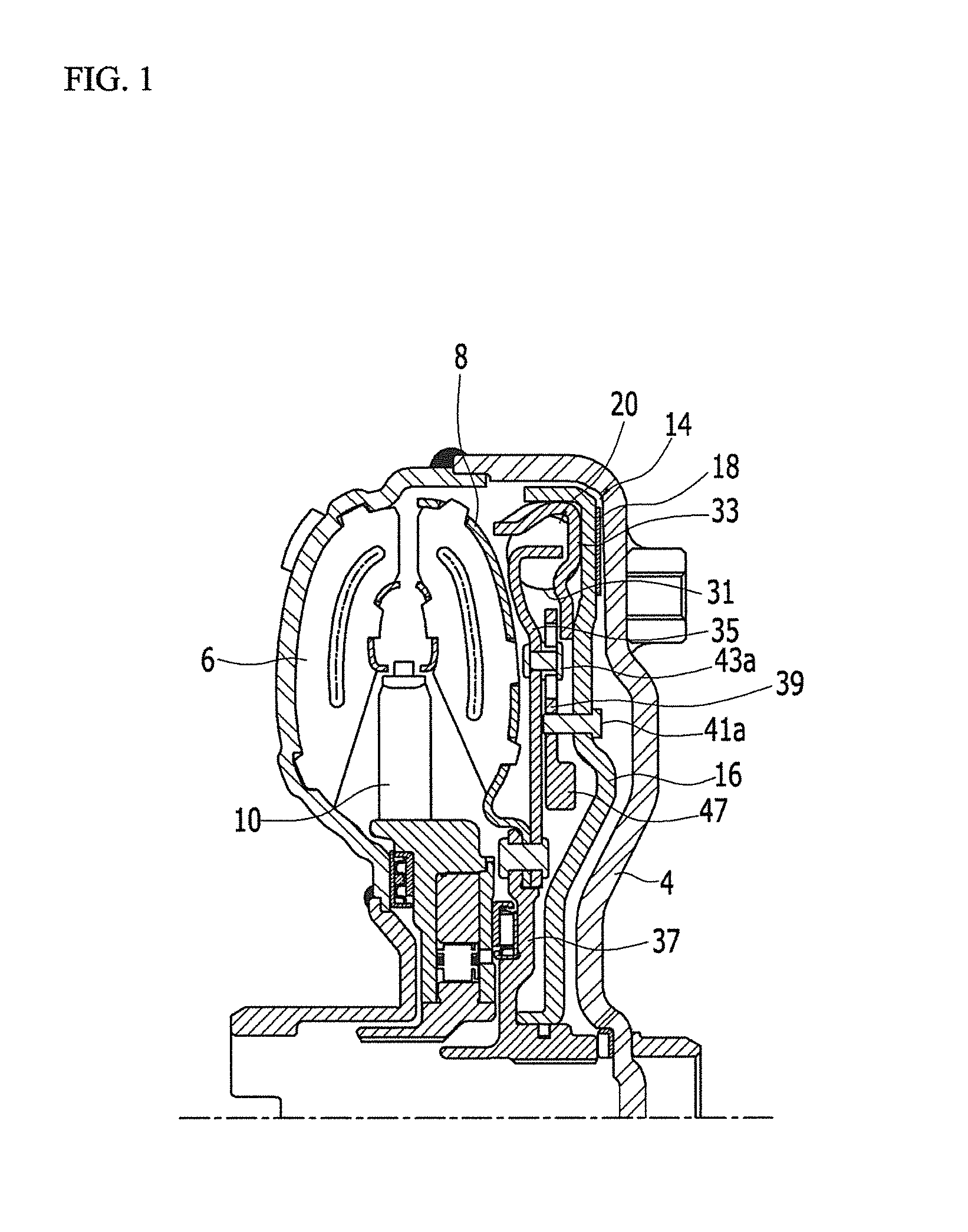

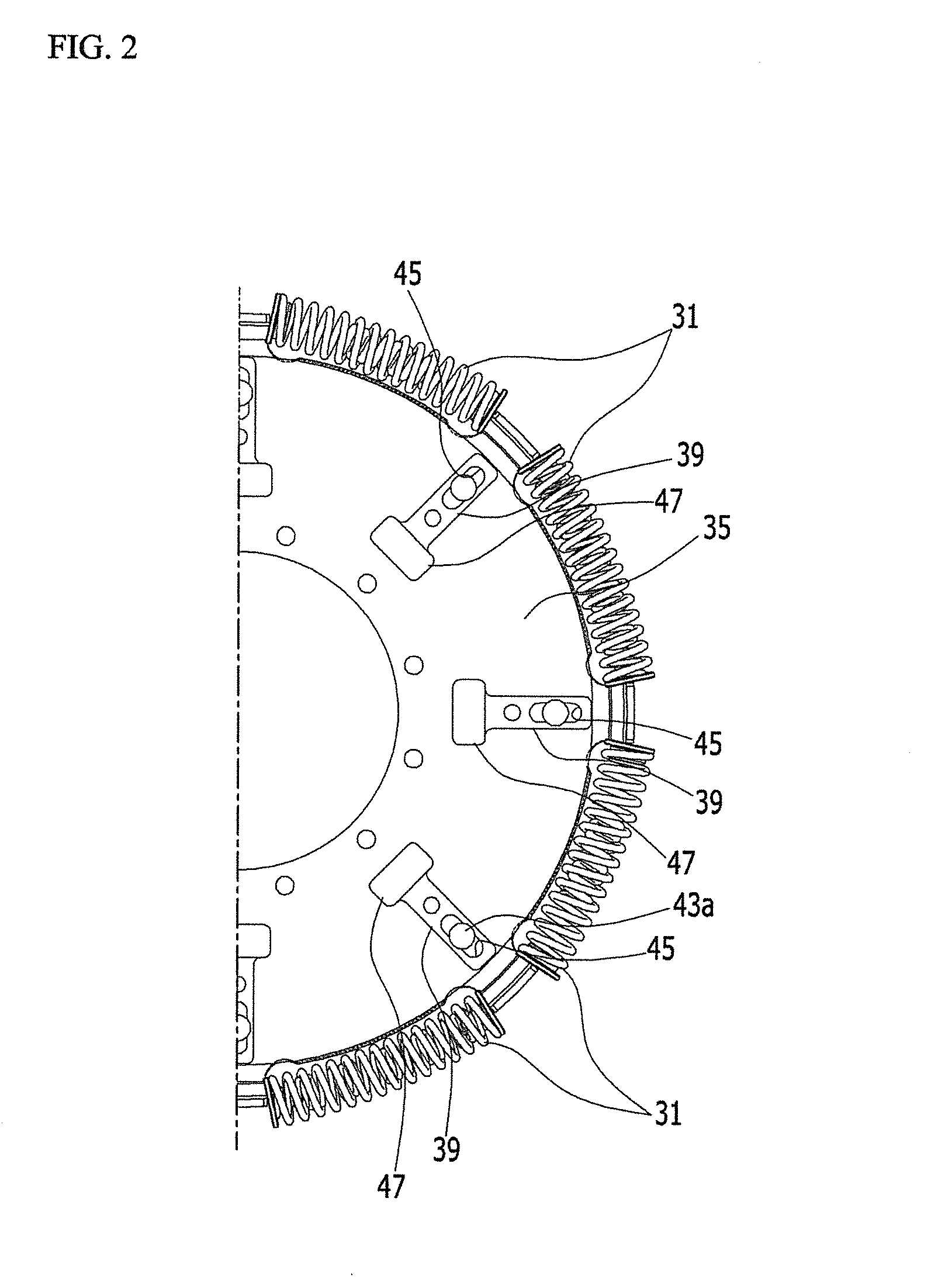

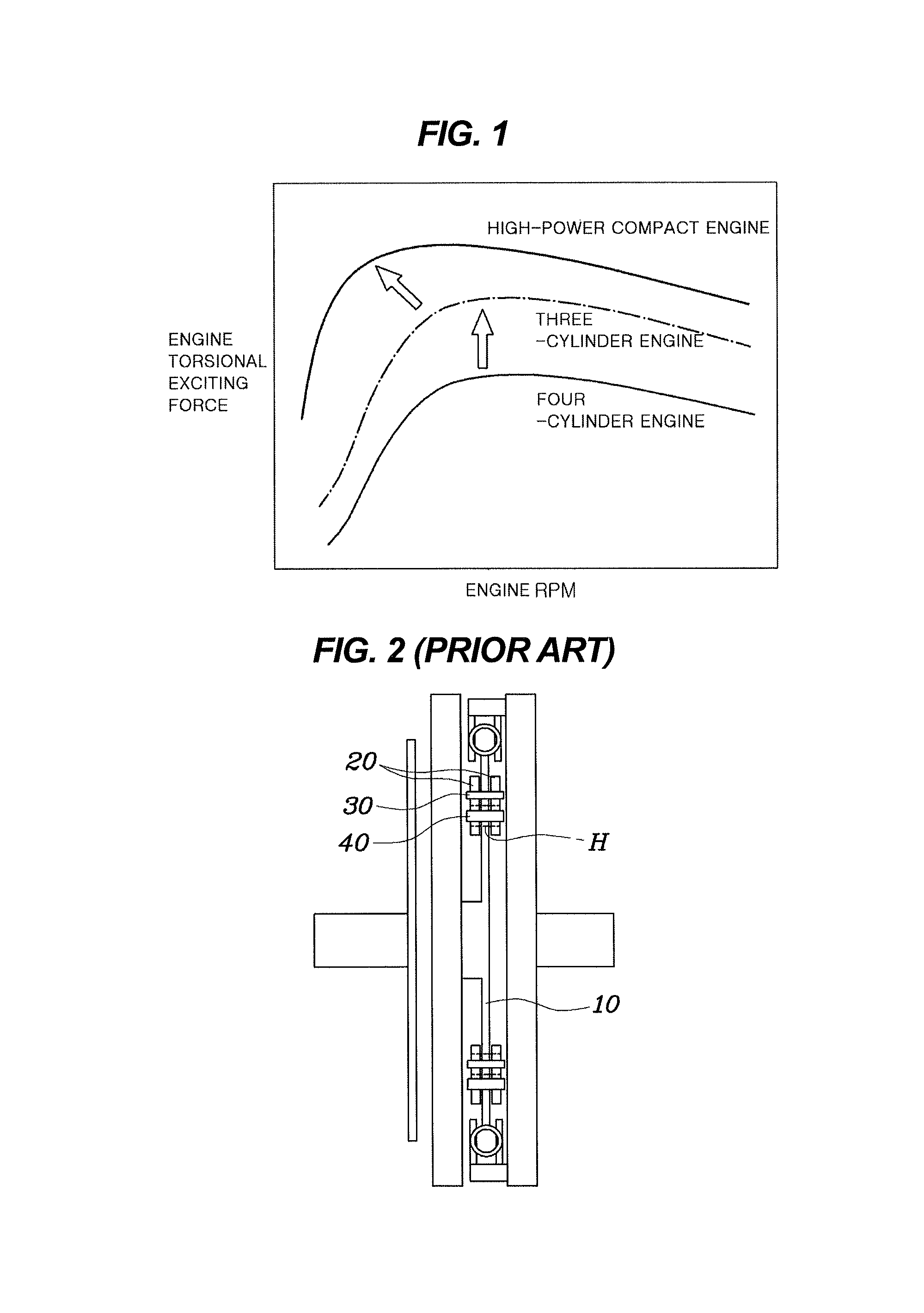

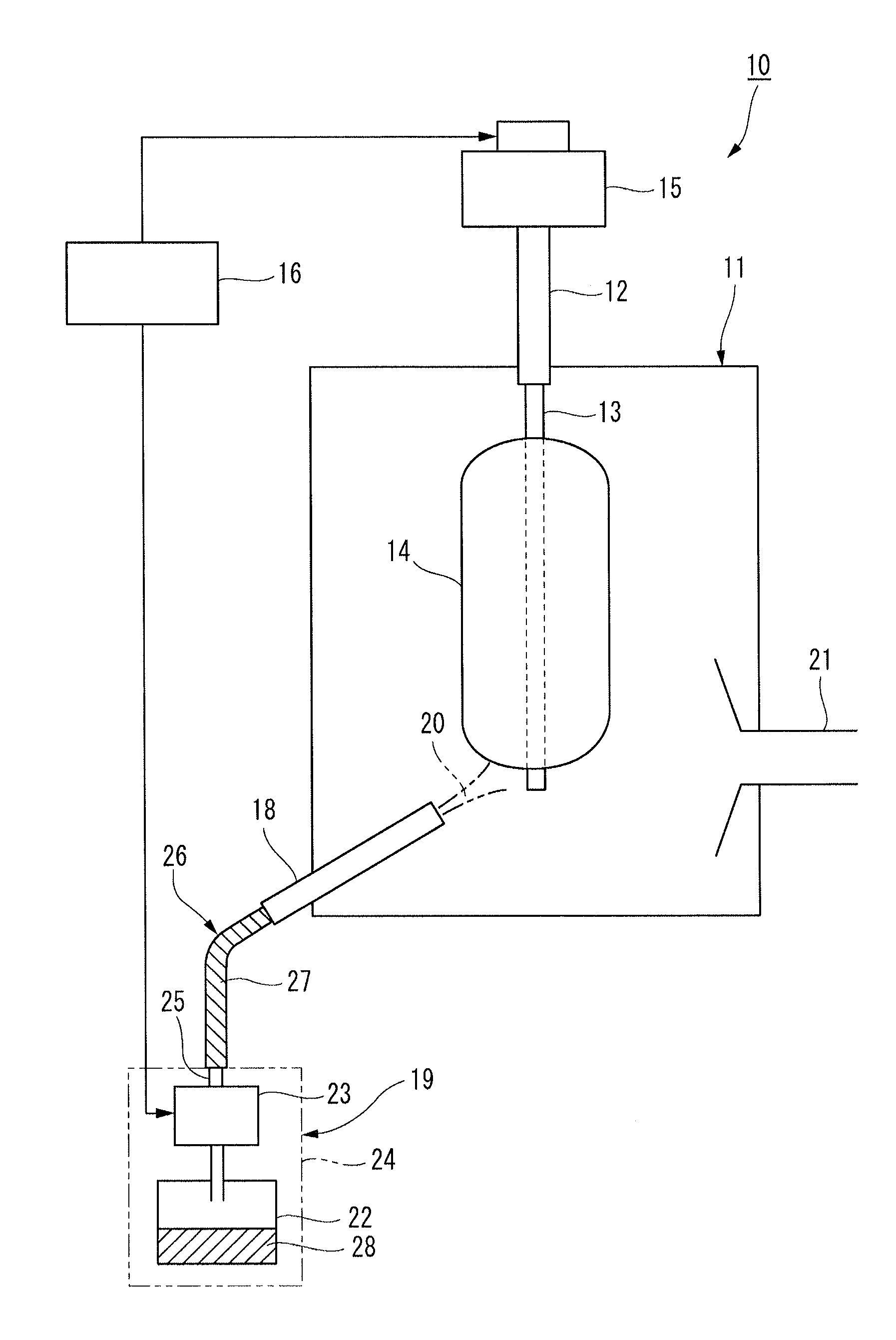

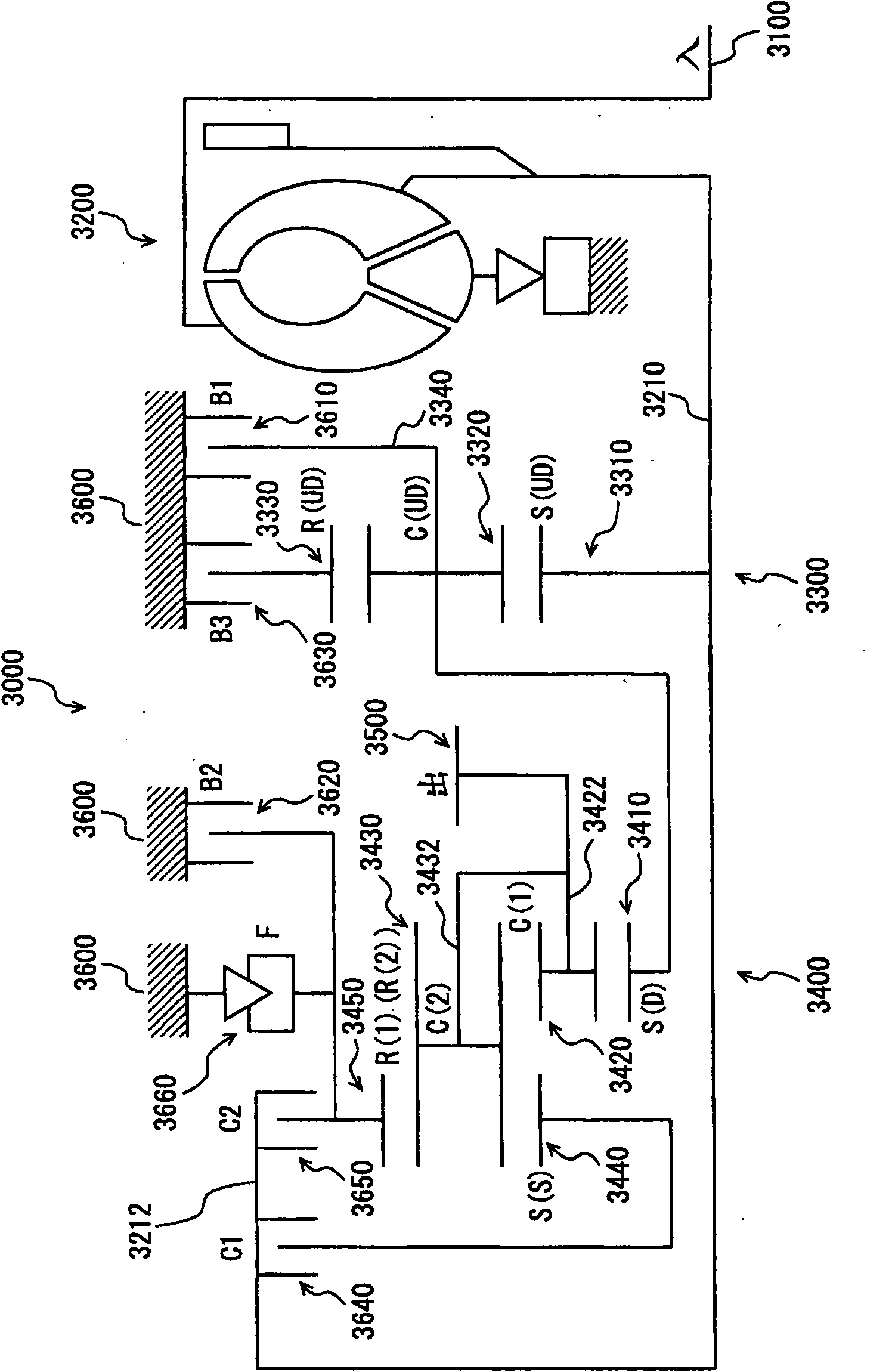

Torque converter in vehicle

ActiveUS20150260270A1Quality improvementIncrease inertial forceRotating vibration suppressionRotary clutchesCouplingResonance

Disclosed is a torque converter in a vehicle, in which a torsional damper reduces a natural frequency and absorbs vibration energy in an anti-resonance state for enhancing a vibration isolation function. The torque converter in a vehicle includes a torsional damper including a retaining plate coupled to the piston, a plurality of springs arranged at the retaining plate for imparting elastic force in a circumferential direction, a driven plate coupled to a spline hub which acts as a reaction force on the springs and forwards driving power to a transmission, and an inertial lever arranged between the piston and the driven plate, the inertial lever including a fixed pivot coupling portion coupled to the piston with a fixed pivot and a movable pivot coupling portion coupled to the driven plate with a movable pivot.

Owner:KOREA POWERTRAIN

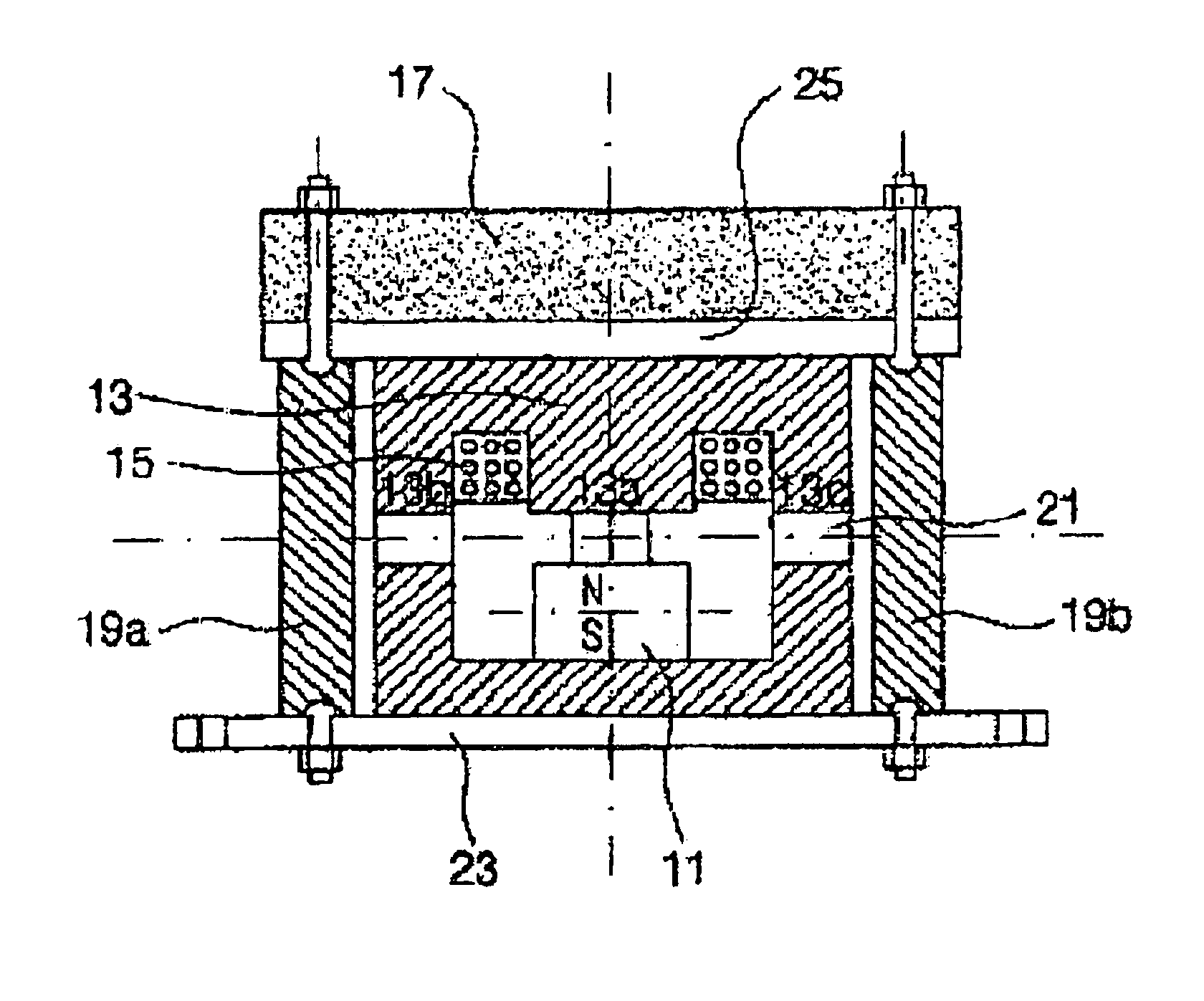

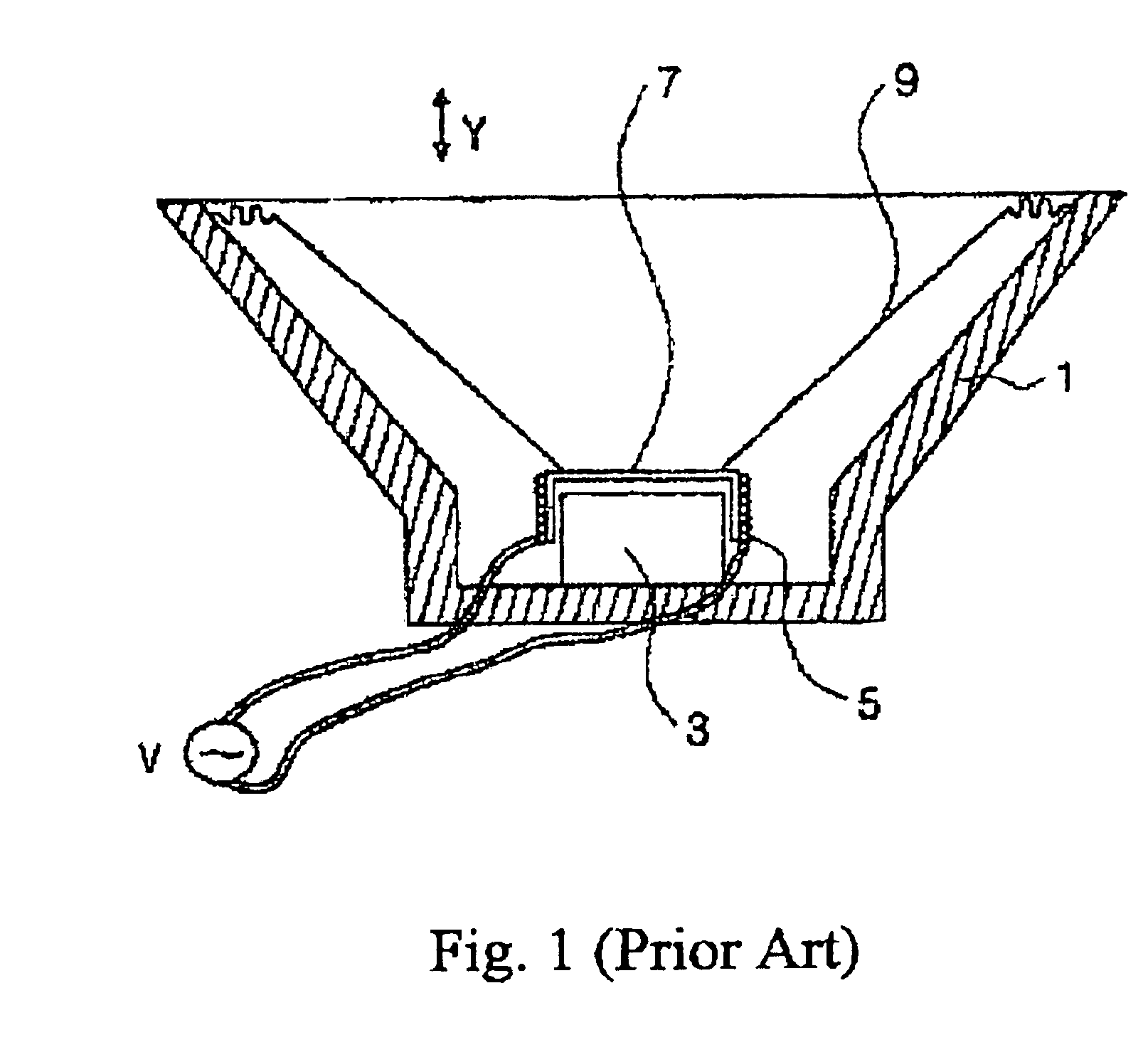

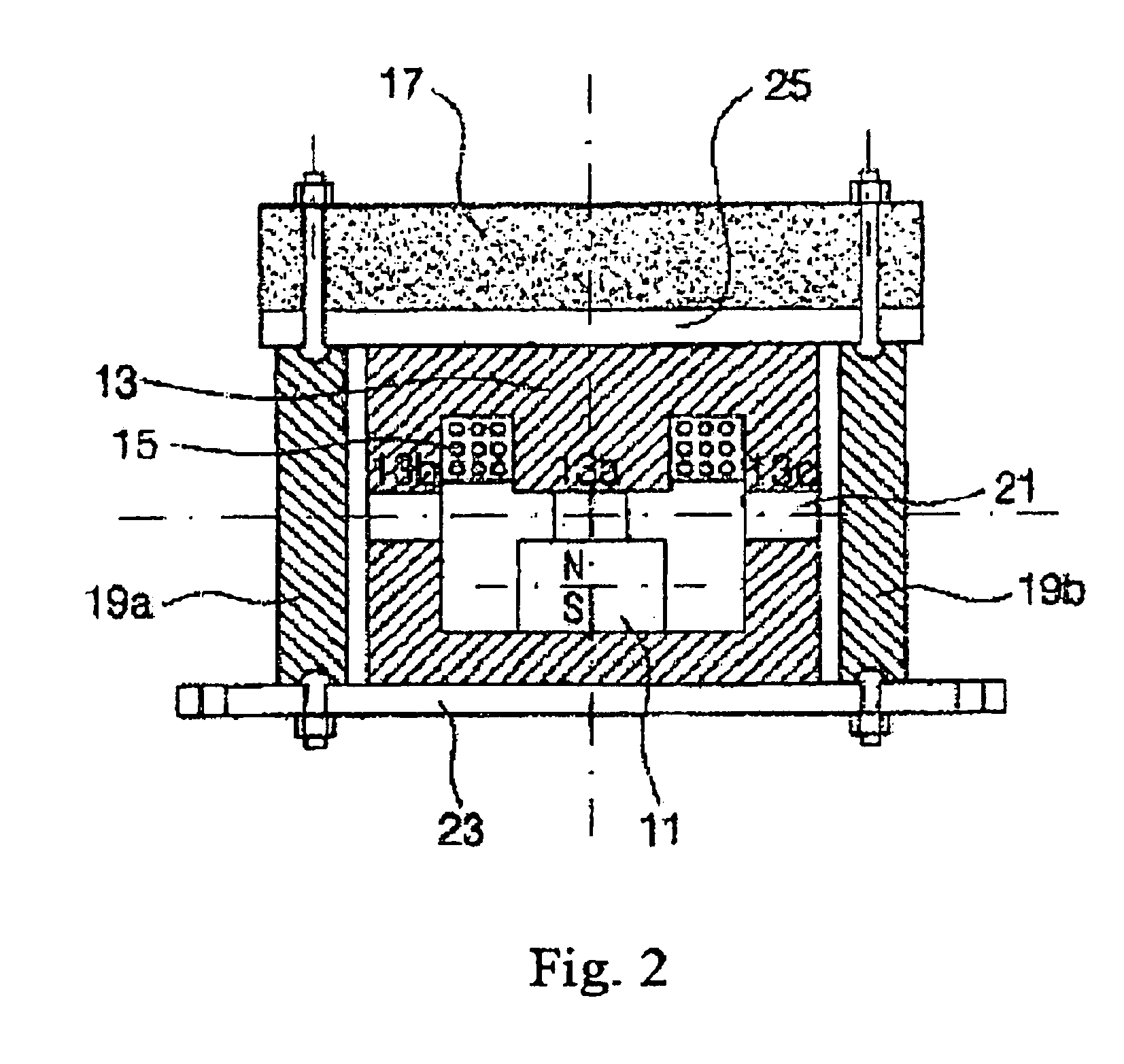

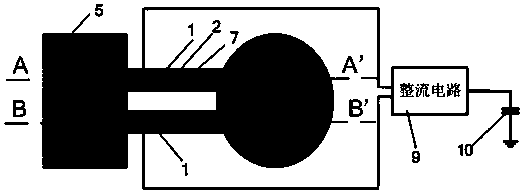

Electro-mechanical transducer

InactiveUS6903474B2Increase in inertial forceIncrease vibrational energyElectrical transducersBone conduction transducer hearing devicesEngineeringTransducer

An apparatus adopting an iron core and an inertial mass is disclosed for exerting high power output by converting a sound signal to vibration so as to stimulate the human hearing organs through the bones. A sound-to-vibration conversion apparatus comprises a housing, a permanent magnet having an N-pole and an S-pole, only one pole of which is fixed to the housing, an electromagnet movably installed into the housing faced either the S-pole or N-pole of the permanent magnet, whichever one is not fixed to the housing, and an inertial mass for amplifying the inertial force of reciprocating movement of the electromagnet, so that the housing with the permanent magnet can be vibrated by the electromagnet, whereby the electromagnet vibrates in a reciprocating fashion towards or away from the permanent magnet in accordance with the incubation between the polarity formed at the electromagnet by acoustic signal applied to the electromagnet and either the N-pole or the S-pole of the permanent magnet.

Owner:TWIN SAVER

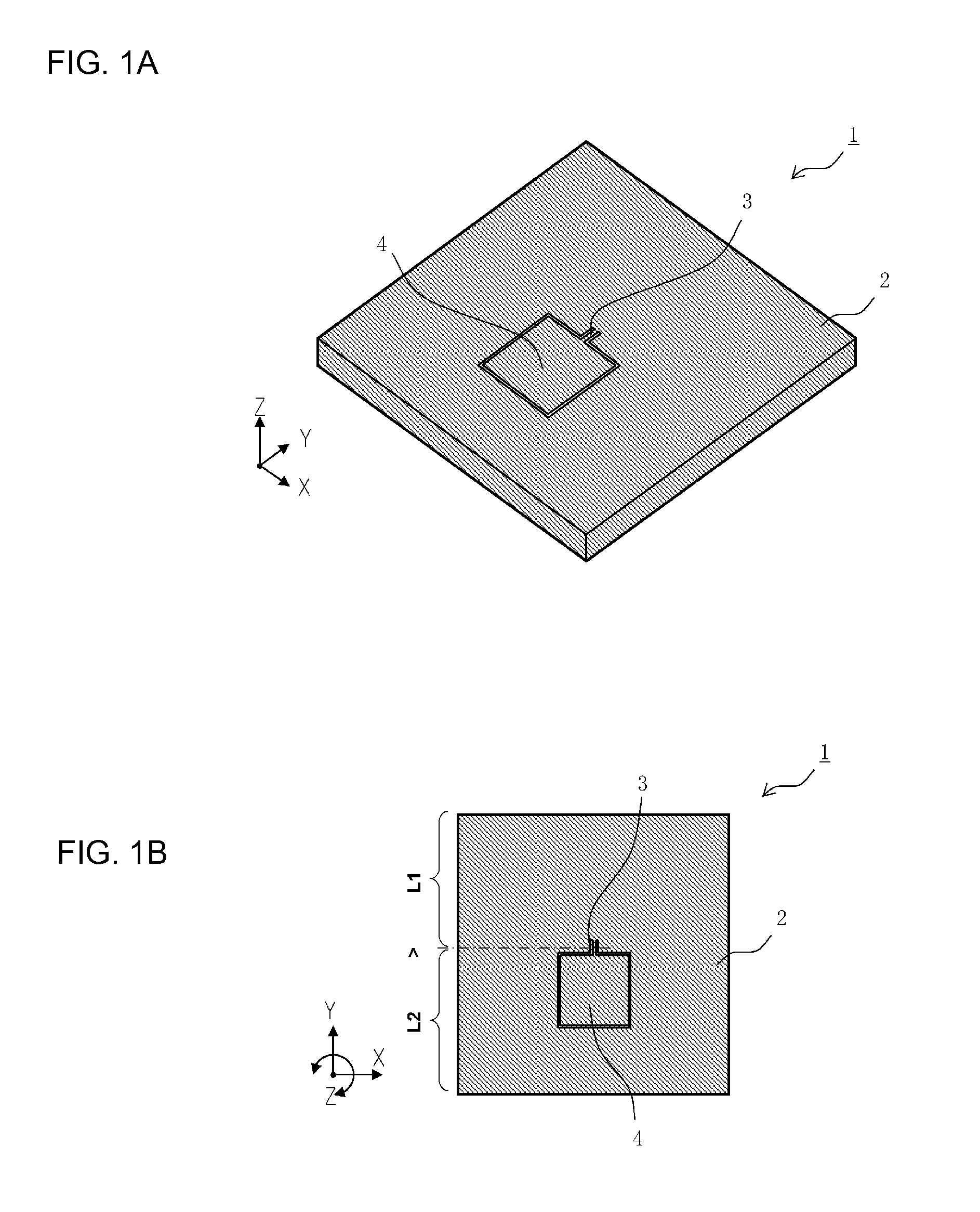

Angular acceleration detection device

ActiveUS20140047919A1Impact performanceAvoid stress concentrationAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsGravity centerAngular acceleration

An angular acceleration detection device includes a rotating weight, a fixed portion, a support beam, and a detection portion. The rotating weight is rotatable about a Z-axis with respect to the fixed portion by action of an inertial force generated by an angular acceleration about the Z-axis. The fixed portion is disposed at a position spaced from the rotating weight. The support beam is disposed in an X-Y plane between the fixed portion and the rotating weight, the support beam elastically supporting the rotating weight with respect to the fixed portion. The detection portion outputs a detection signal corresponding to stress generated in the support beam. A gravity center position of the rotating weight is aligned with the support beam when viewed in a Z-axis direction.

Owner:MURATA MFG CO LTD

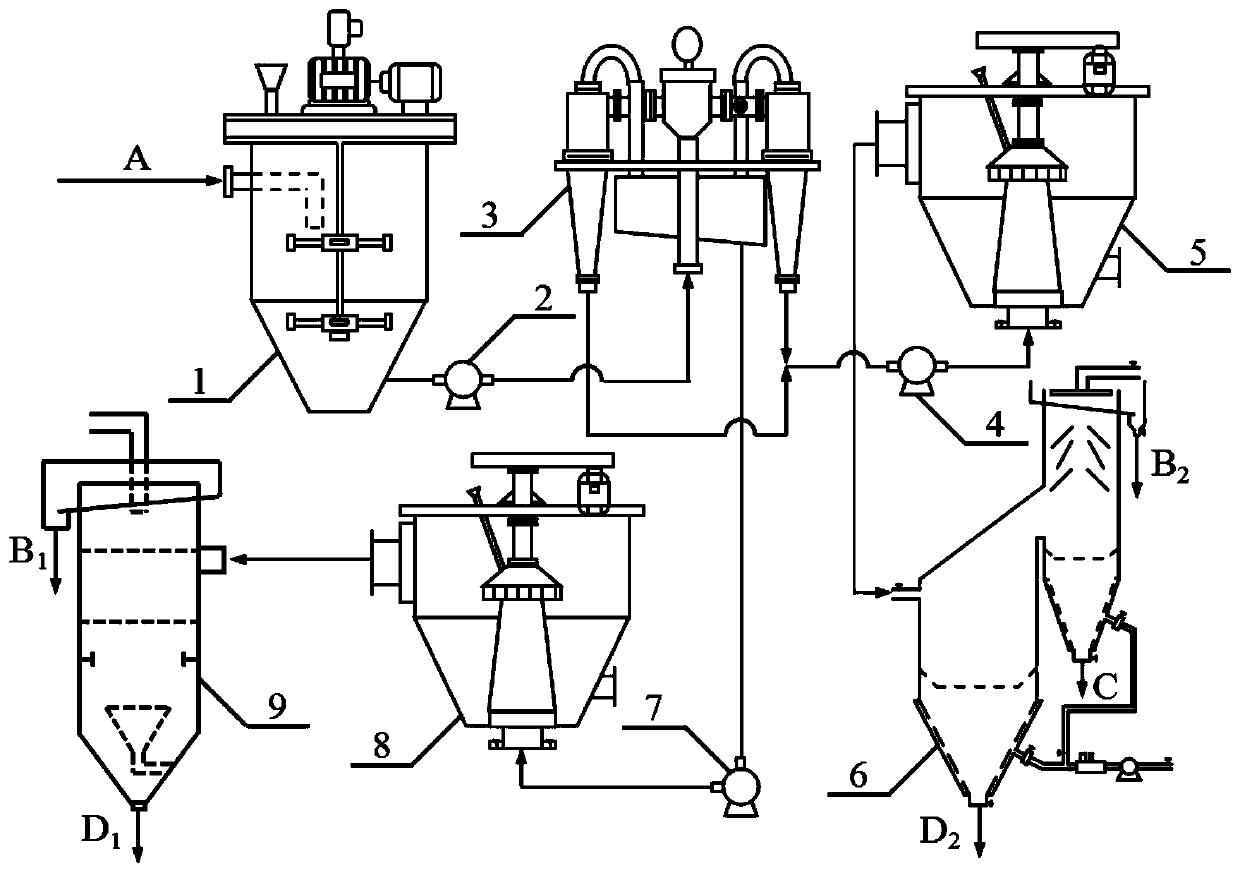

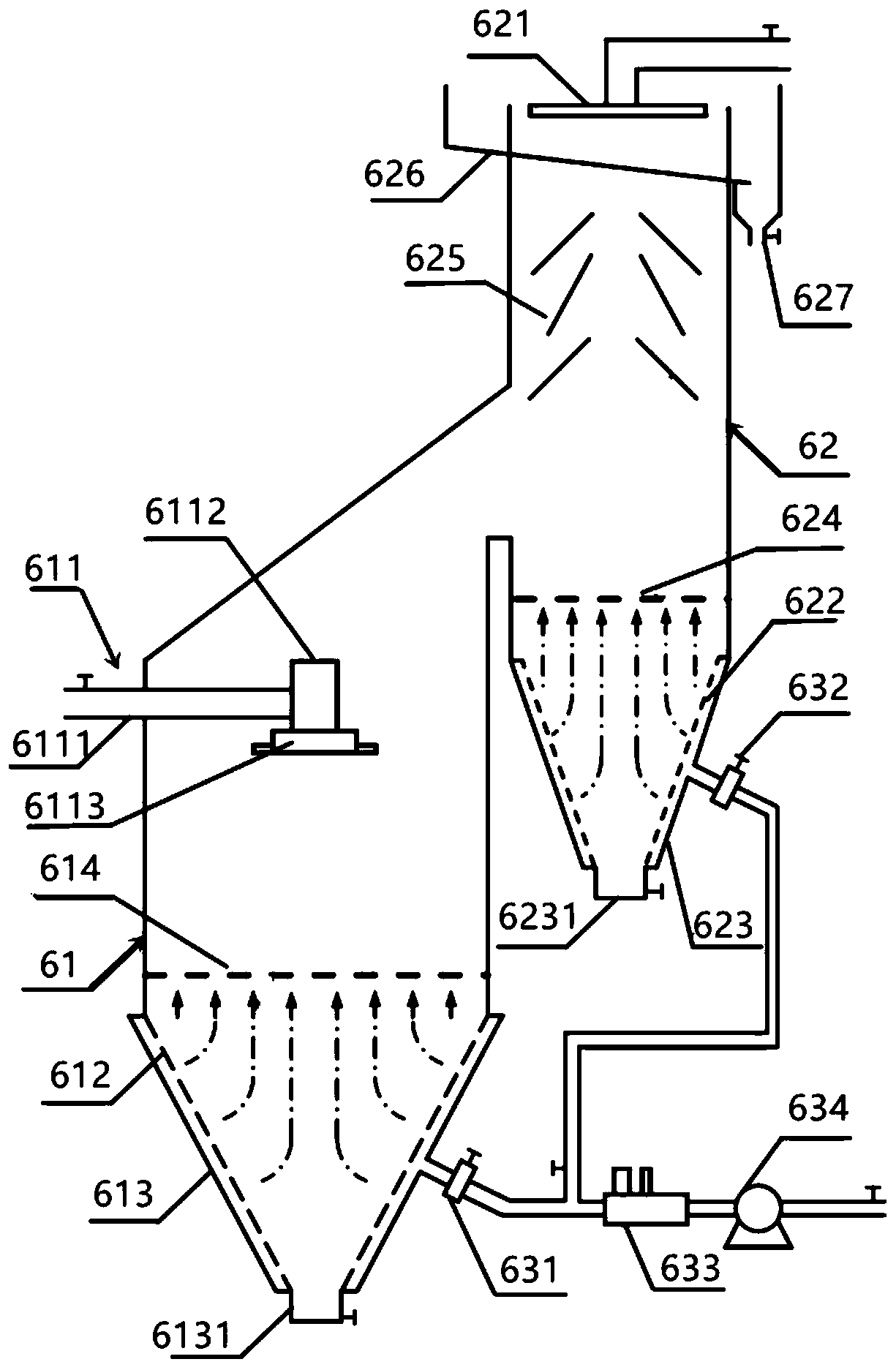

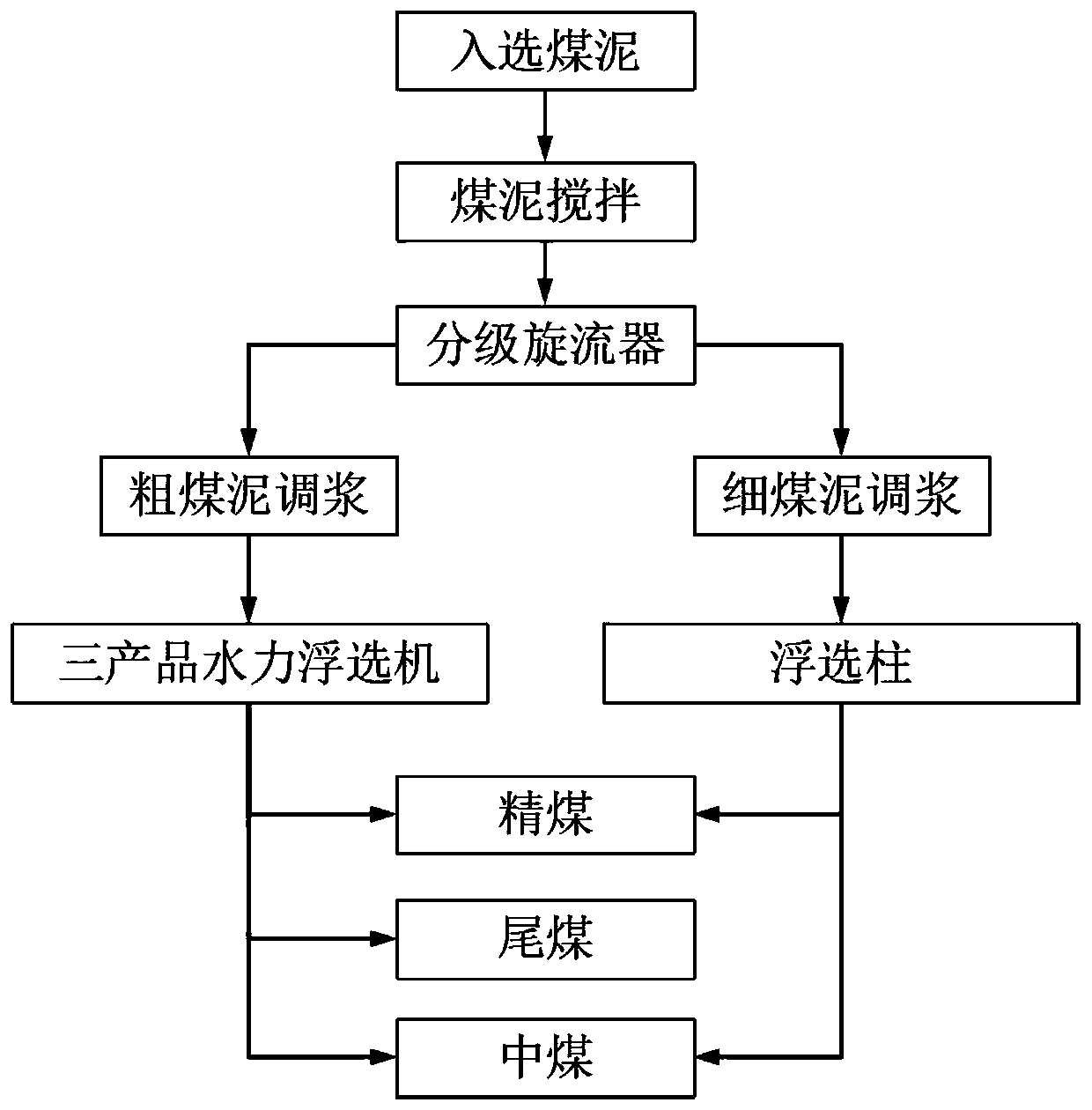

Sorting system and technology used for coal slime recycling

ActiveCN111375483AIncrease inertial forceWiden the density differenceVortex flow apparatusFlotationThermodynamicsProcess engineering

The invention relates to a sorting system and technology used for coal slime recycling and belongs to the technical field of coal slime sorting and recycling. The problems that an existing coal slimesorting technology is complex in process, low in treating capability and high in product misplaced material content and cannot achieve continuous sorting and recycling of coal slime. The sorting system comprises a coal slime stirring barrel, a classifying cyclone, a first ore pulp preprocessor and a three-product hydraulic flotation machine. The coal slime stirring barrel is connected with the classifying cyclone through a first slurry pump. The classifying cyclone is connected with the first ore pulp processor through a second slurry pump. The first preprocessor is connected with the three-product hydraulic flotation machine. By means of the sorting system and technology used for coal slime recycling, fluidization and sorting are conducted on 2-0.25 mm coarse-particle coal slime in the three-product hydraulic flotation machine, cleaned coal, middling coal and tailings are obtained, reverse flow sorting is conducted on 0.25 mm-0 mm fine-particle coal slime in a flotation column, cleancoal and middling coal are obtained, refining recycling on the coarse and fine coal slime is achieved, gradient utilization on coal resources is also achieved, and economic resource benefits can be maximum.

Owner:CHINA UNIV OF MINING & TECH

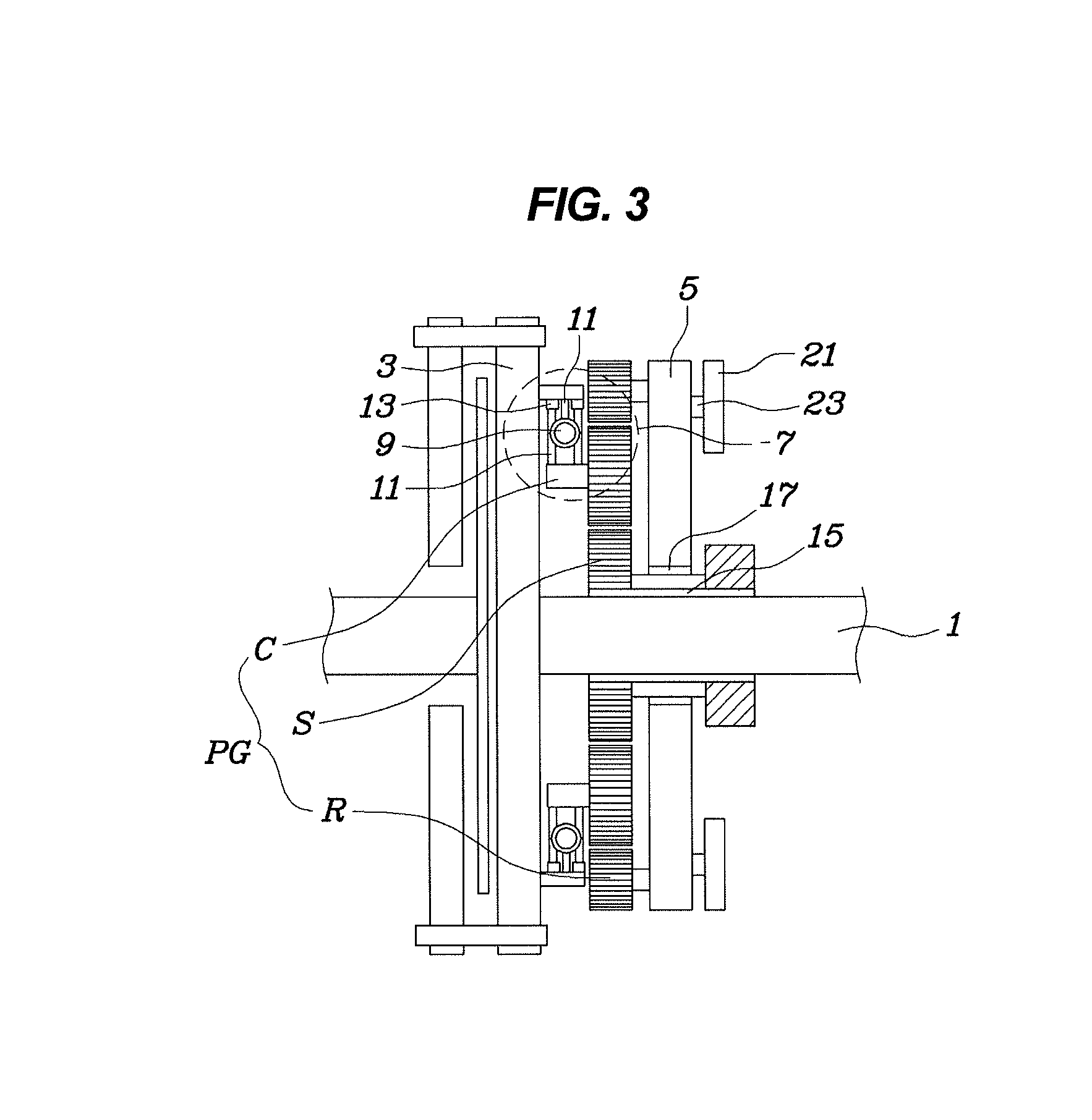

Apparatus for damping flywheel

InactiveUS9074655B2Small volume and weightImprove NVH performanceToothed gearingsFlywheelsEngineeringFlywheel

An apparatus for damping a flywheel includes a drive plate integrally connected to a crankshaft. A flywheel is connected to receive a rotating force from the drive plate through planetary gearing, and is mounted to rotate relative to the crankshaft. A rigidity imparting means is disposed on a path along which a rotating force is transferred between the drive plate and the flywheel. A mass body is provided on the flywheel, and is configured to perform relative rotation in a direction that offsets a torsional vibration of an engine transmitted to the flywheel.

Owner:HYUNDAI MOTOR CO LTD

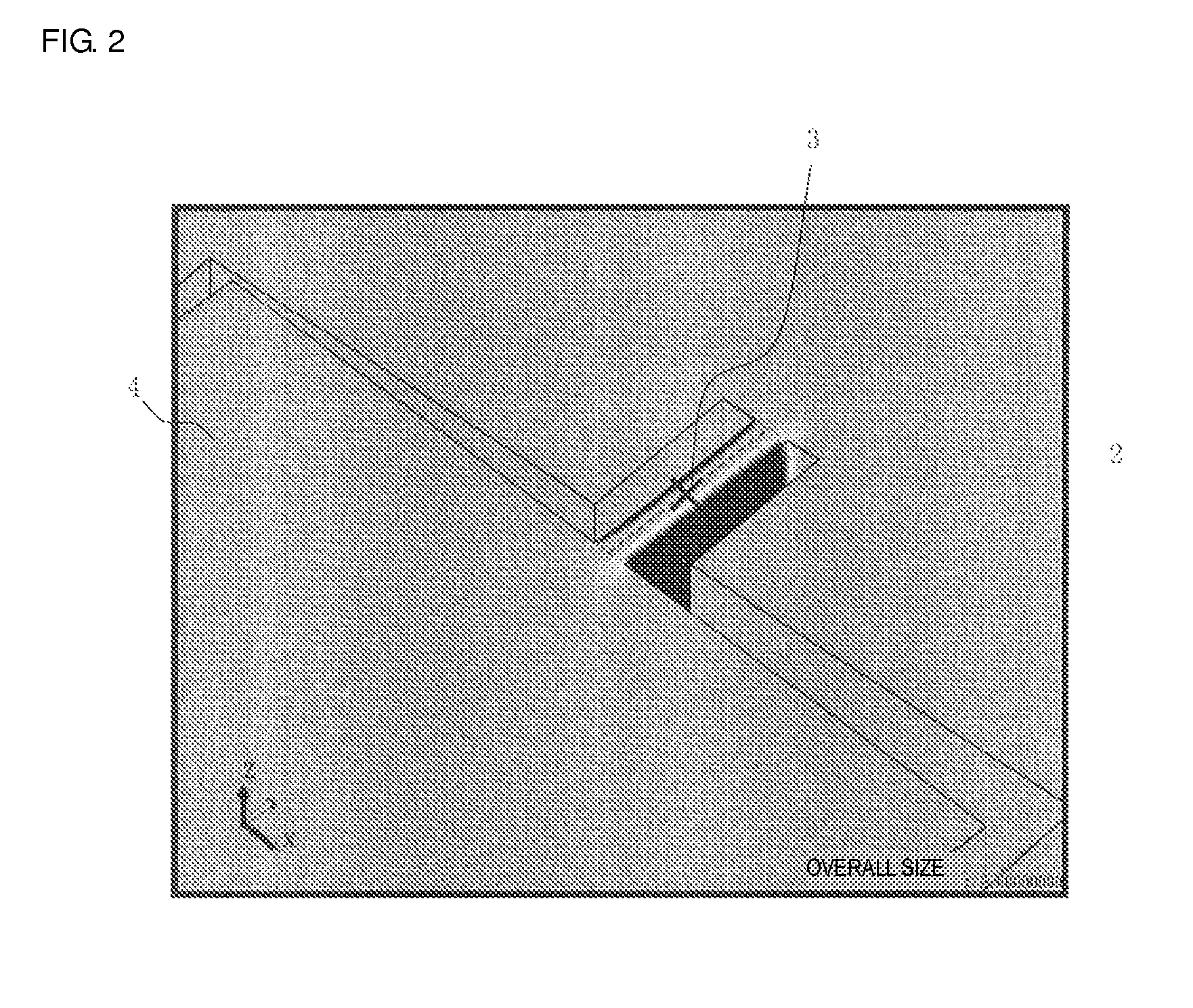

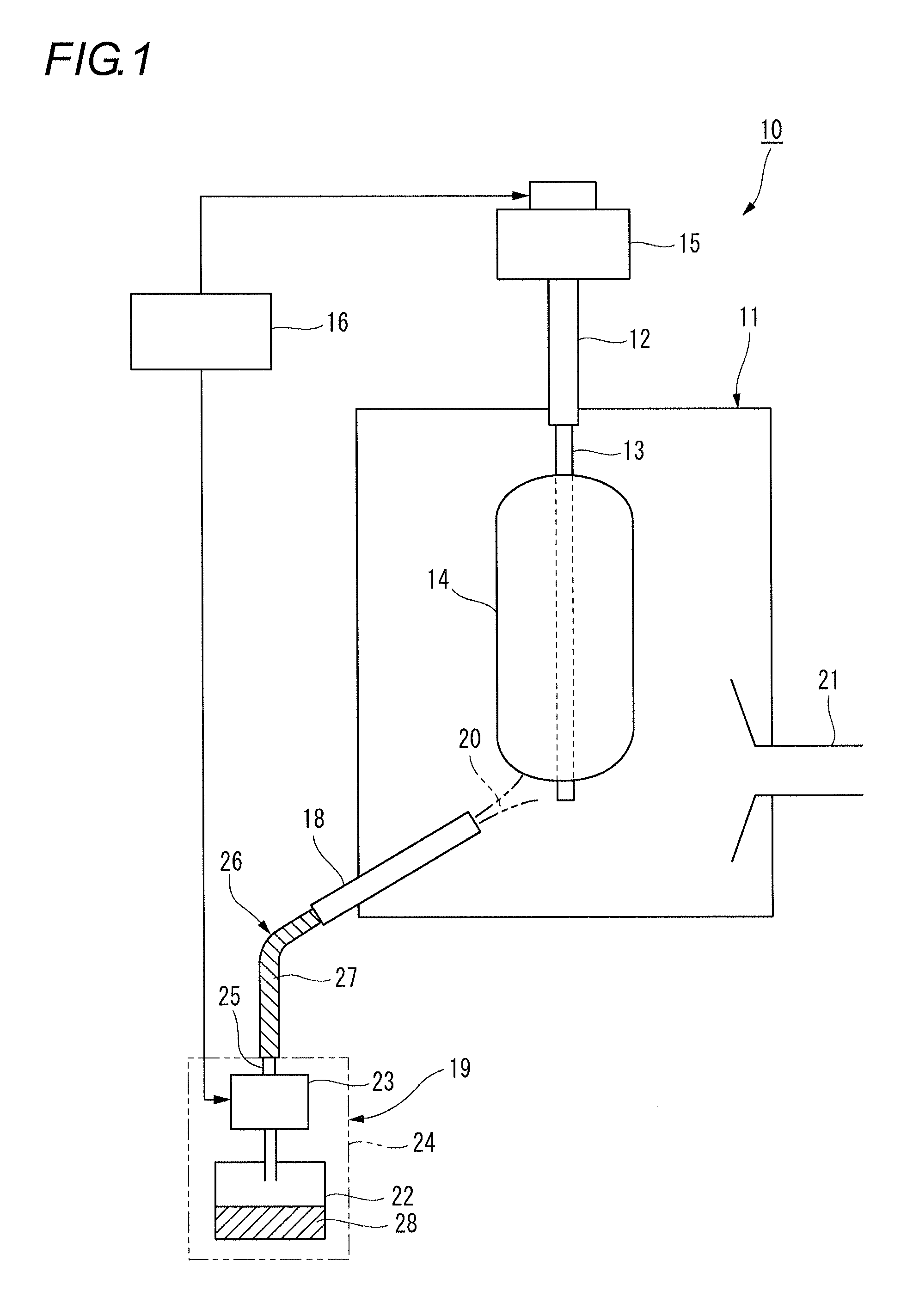

Method for manufacturing glass-fine-particle-deposited body and method for manufacturing glass base material

ActiveUS20140305168A1Improve efficiencyImprove material yieldGlass deposition burnersGlass productionTemperature controlEngineering

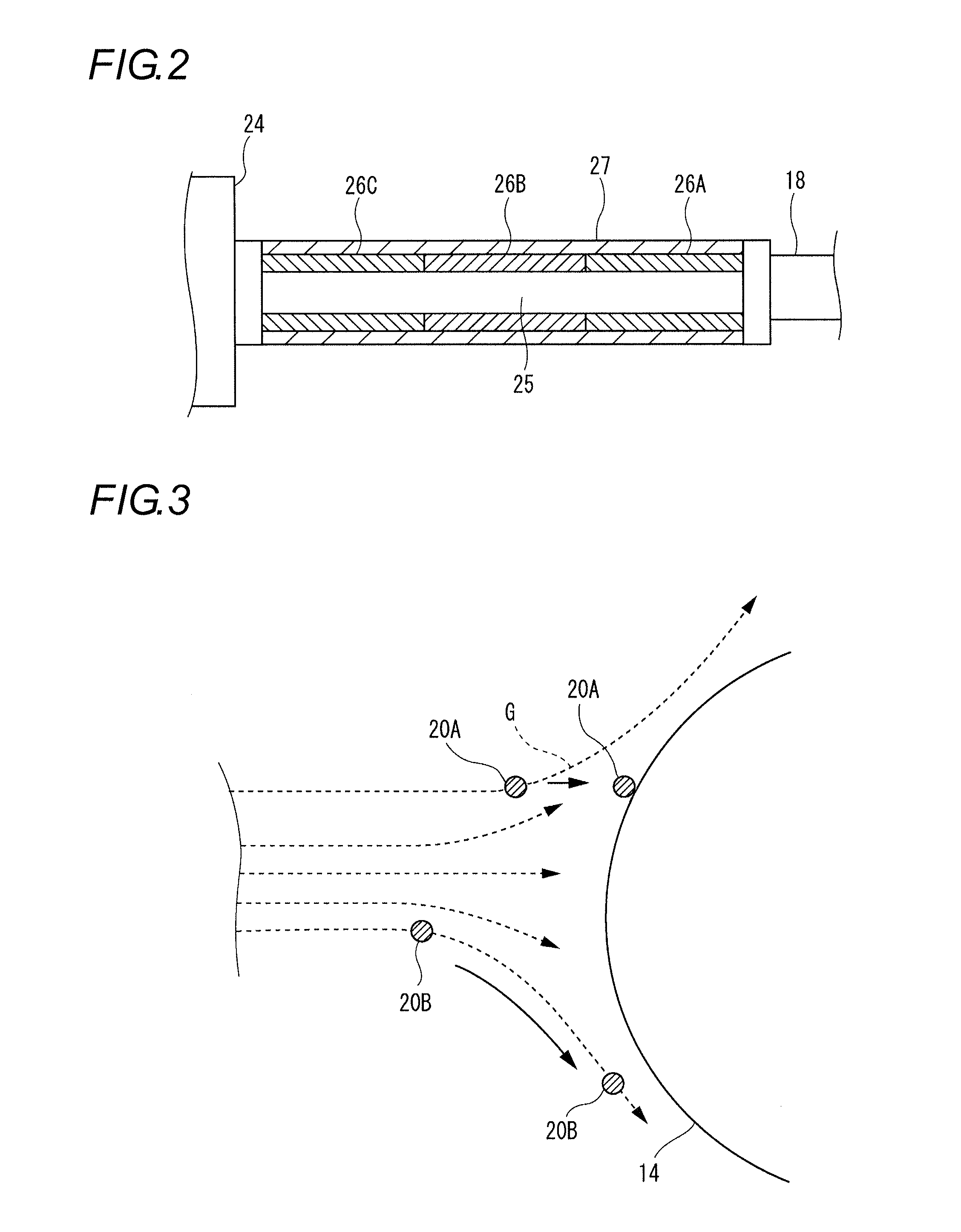

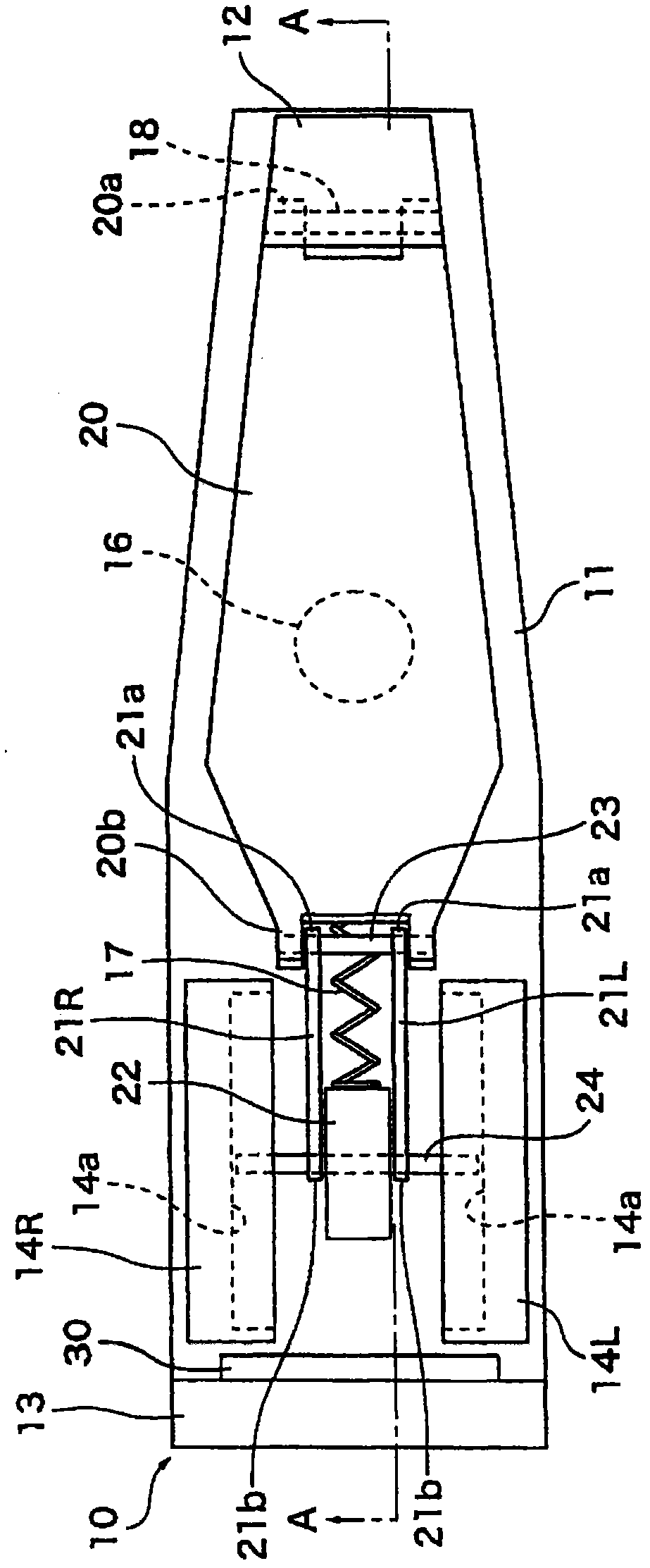

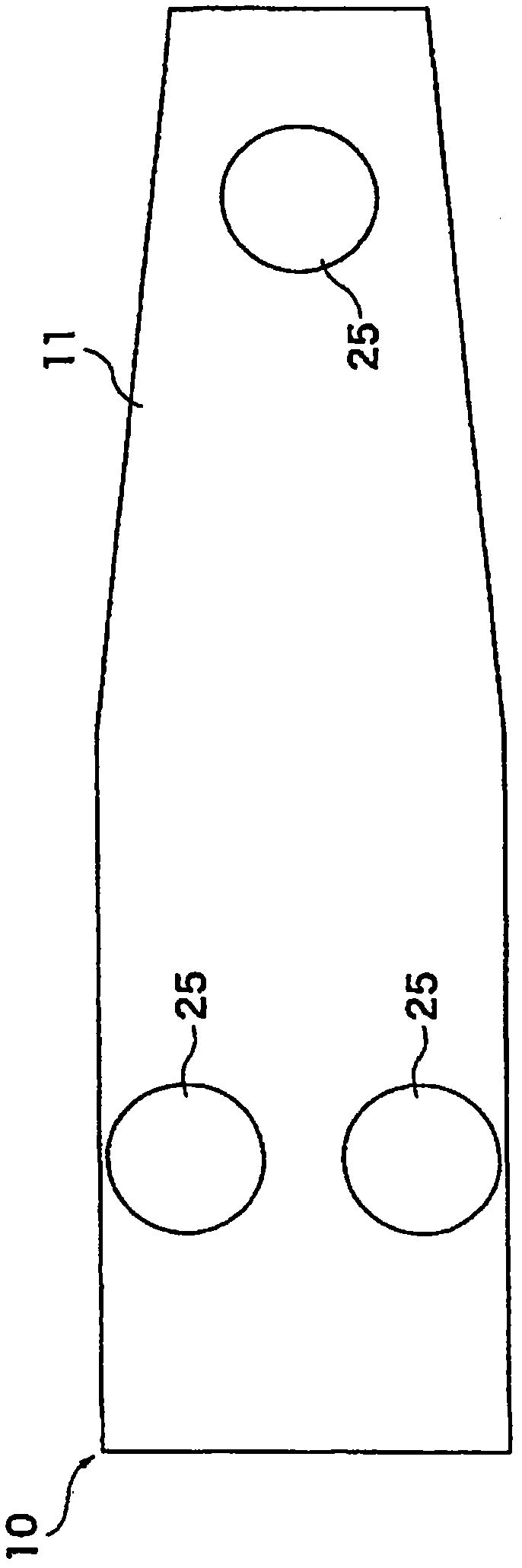

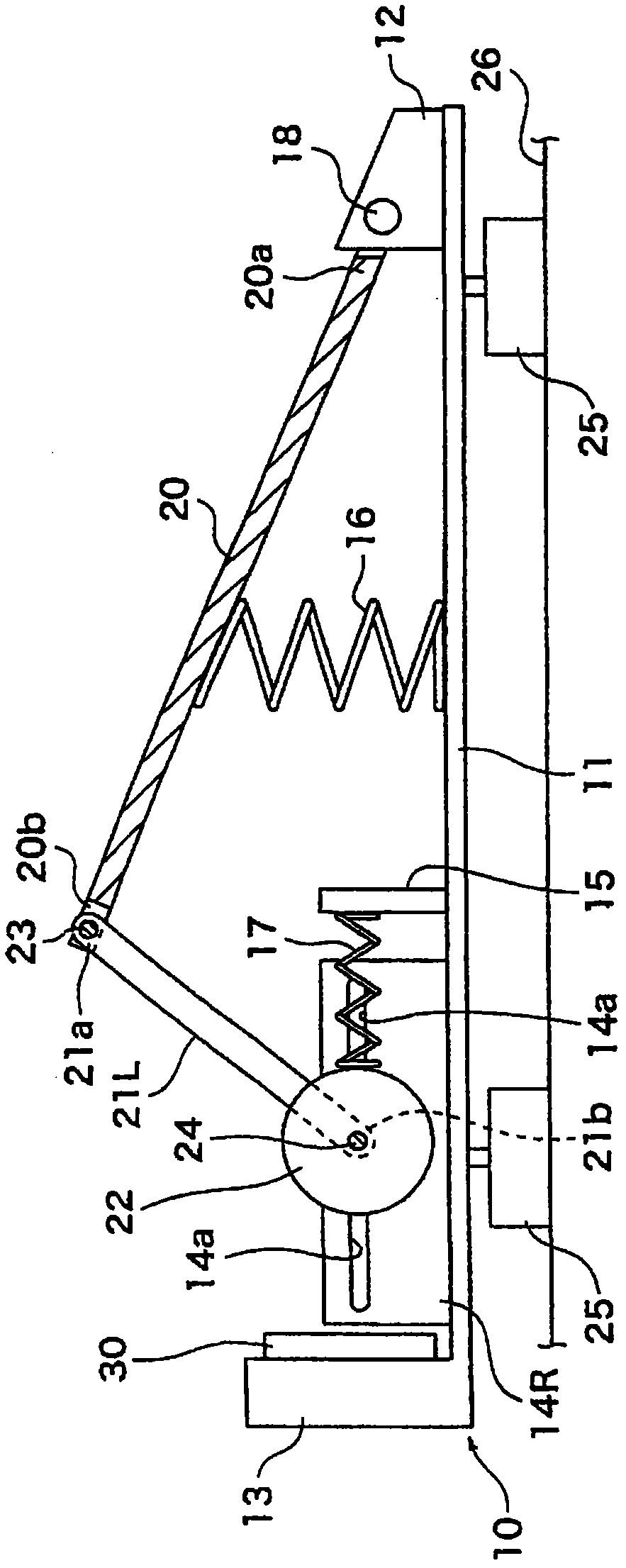

In the method for manufacturing a glass-fine-particle-deposited body according to the present invention, at least a part of a gas supplying pipe 25 from a temperature controlled booth 24 to a burner 18 for cladding is temperature-controlled so that the temperature at the burner side becomes high and temperature gradient becomes 5° C. / m or more. The temperature control is performed so that the temperature gradient becomes preferably 15° C. / m or more, more preferably 25° C. / m or more. Specifically, the part is controlled to the predetermined temperature gradient by winding a tape heater 26 that is a heating element on the outer circumference of the gas supplying pipe 25 from the temperature controlled booth 24 to the burner 18 for cladding and temperature-controlling the tape heater 26.

Owner:SUMITOMO ELECTRIC IND LTD

Pedal device for electronic percussion instrument

InactiveCN102436803AIncrease inertial forceImprove down pressureElectrophonic musical instrumentsMechanical apparatusEngineeringRisk stroke

A pedal device for an electronic percussion instrument, including: a base; a foot board supported at its first end portion to the base and configured to pivot by depression; an arm rotatably supported at its first end at a pivot point located near to a second end portion of the foot board, the arm being pivotable about the pivot point; a mass portion provided near to a second end of the arm; a regulating portion for regulating a locus of displacement of the mass portion when the foot board is moved from a depression start position to a depression end position; and a stopper portion provided on the base for defining the depression end position by contacting the mass portion in a forward stroke of depression, the regulating portion regulating the locus of the displacement of the mass portion so as not to contain a downward component in the forward stroke.

Owner:YAMAHA CORP

Surface treatment device

InactiveCN105442027AMovement speed increaseIncrease inertial forceCellsSemiconductor devicesPre treatmentMechanical engineering

Owner:ALMEX PE INC

Bidirectional air feeding type pressurization and dust filtration electrostatic dust collector

PendingCN107042045AImprove removal efficiencyAdjustable direction of rotationCombination devicesFiltrationDust collector

The invention discloses a bidirectional air feeding type pressurization and dust filtration electrostatic dust collector which comprises a device main body, wherein the device main body is mainly composed of an air inlet pipe, an air exhaust port, an ash hopper, an ash outlet, a rotating chamber, a pressurizing and filtering chamber, an electrostatic adsorption chamber and a settling chamber; the air inlet pipe is connected with the bottom of a side wall on the left side of the device main body; a rotating shaft is vertically arranged in the pressurizing and filtering chamber; a top plate is arranged at the top of the pressurizing and filtering chamber; a base plate is arranged at the bottom of the pressurizing and filtering chamber; a rotating component is arranged on the rotating shaft; an internal thread is arranged on the rotating component; a rubber plate is connected with the side wall of the rotating shaft; the electrostatic adsorption chamber is arranged at the top of the pressurizing and filtering chamber; a plurality of static plates are fixedly jointed in the electrostatic adsorption chamber; a plurality of jetting pipes are arranged in the electrostatic adsorption chamber; an annular plate is arranged at the top of the settling chamber; and a resisting pressing plate is arranged on a center position of the top of the annular plate. The electrostatic dust collector is high in dust collection efficiency, the inertia force of the smoke is increased under mechanical effects, and the removal efficiency is increased.

Owner:合肥九州龙腾科技成果转化有限公司

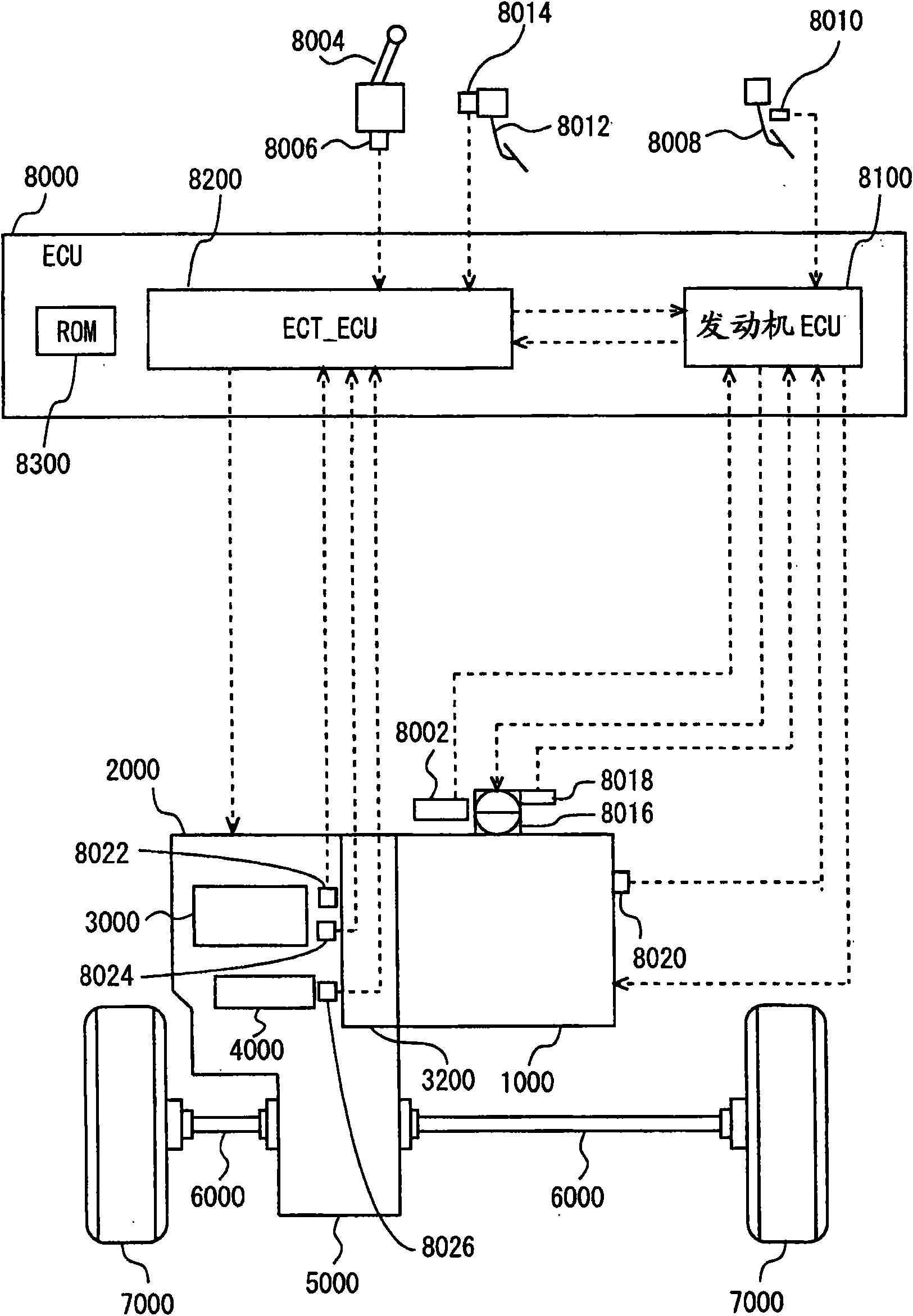

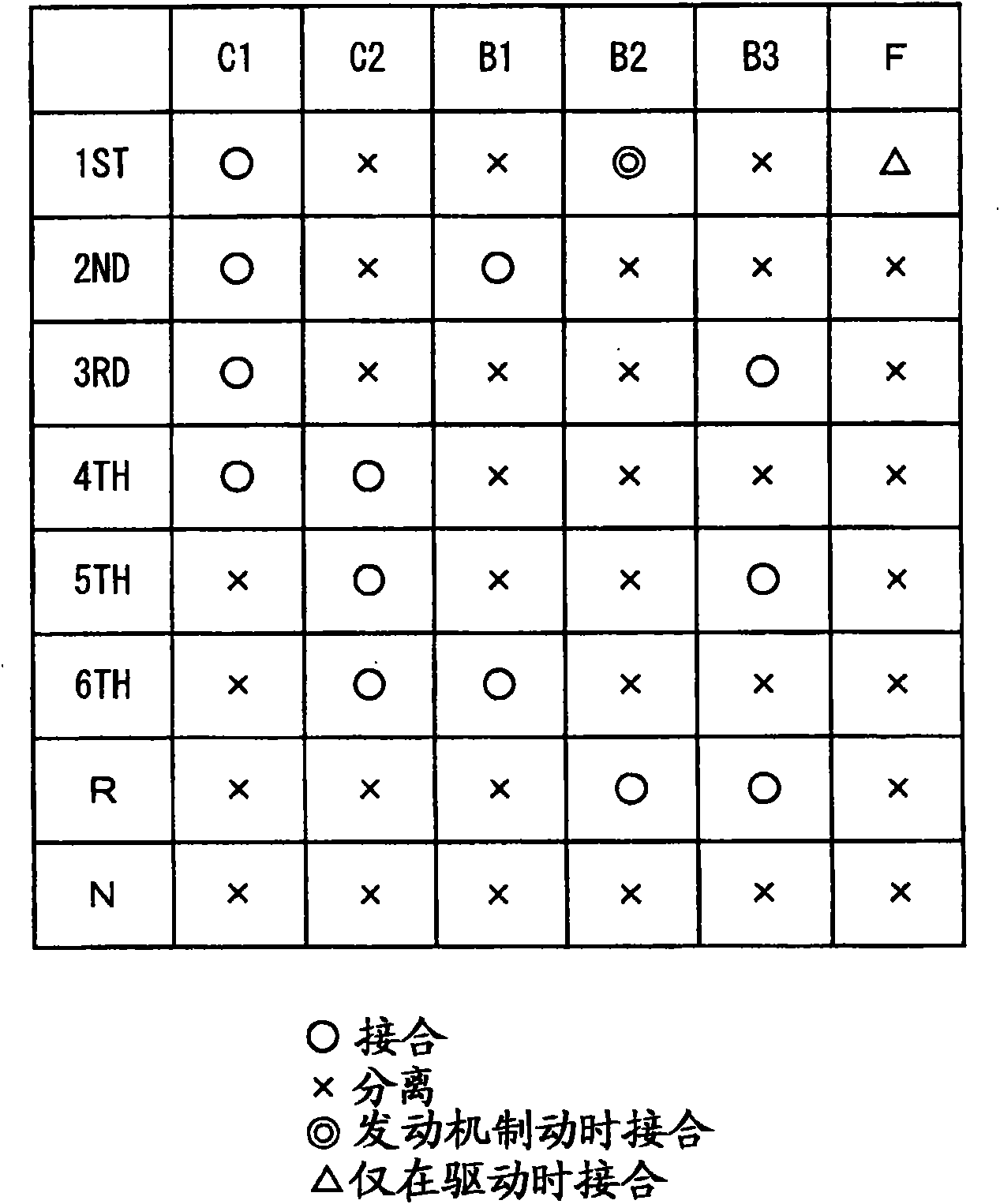

Vehicle, and control method and control apparatus for an automatic transmission

InactiveCN101652586AIncrease inertial forceImprove joint forceGearing controlTarget engagementAutomatic transmission

Owner:TOYOTA JIDOSHA KK

Piezoelectric bimorph type inertial piezoelectric motor

InactiveCN105634326AObvious bending deformationReduce manufacturing costPiezoelectric/electrostriction/magnetostriction machinesElectricityMicro nano

The invention discloses a piezoelectric bimorph type inertial piezoelectric motor, and belongs to the technical field of the piezoelectric motor. According to the key points of the technical scheme, the piezoelectric bimorph type inertial piezoelectric motor comprises a base, two piezoelectric patches and a guide rail, wherein the two piezoelectric patches are arranged between the base and the guide rail in parallel; one ends of the piezoelectric patches are perpendicularly fixed to the base through adhesive while the guide rail is fixed to the other ends of the piezoelectric patches through adhesive; the piezoelectric patches are polarized along a thickness direction or a radial direction; and the direction of the groove of the guide rail is consistent with the polarized direction of the piezoelectric patches. The piezoelectric bimorph type inertial piezoelectric motor is relatively low in manufacturing cost, simple in process, easy to operate, and stable and diversified in structure; and in addition, the manufactured piezoelectric motor can be driven by a low voltage, so that the piezoelectric motor is safer and more excellent in performance, and can be widely applied in the applications of micro-nano manipulation and control fields.

Owner:HENAN NORMAL UNIV

Electric power sand throwing fire extinguishing device

PendingCN108543249ARealize long-distance fire extinguishingImprove the safety of useFire rescueElectric power systemEngineering

The invention discloses an electric power sand throwing fire extinguishing device. The electric power sand throwing fire extinguishing device includes a launch cylinder and a sand loading cylinder, the upper end of the sand loading cylinder is open, the sand loading cylinder is placed in the launch cylinder with an open upper end and can movably axially move along the launch cylinder, and the bottom of the sand loading cylinder is connected to the launch cylinder through an ejection mechanism. The ejection mechanism comprises springs, guide rods and a push plate, the push plate is fixedly connected to the bottom of the launch cylinder and is connected to the multiple guide rods through through holes in a sleeving mode, and both ends of the multiple guide rods are fixedly connected into thelaunch cylinder and are arranged circumferentially and uniformly in the length direction of the launch cylinder. The guide rods are sleeved with the springs, one ends of the springs are fixedly connected to the push plate, and the other ends of the springs abut against the launch cylinder. A mechanical switch is arranged at the bottom of the launch cylinder, the mechanical switch can be clamped onto the push plate after the push plate retracts. According to the electric power sand throwing fire extinguishing device, long distance fire extinguishing is achieved, the service safety is improved,and the electric shock hazard is avoided.

Owner:GUIZHOU POWER GRID CO LTD

Lever-type connector and connector housing therefor

InactiveUS20050003690A1Reduce stepsAccurate connectionEngagement/disengagement of coupling partsIncorrect coupling preventionCamElectrical and Electronics engineering

A lever-type connector has two housings (10, 20) and a lever (40) with a cam for facilitating the connection of the housings (10, 20). The connector is configured so that a connection resistance between the housings (10, 20) and an operation resistance on the lever (40) reach their maximums at substantially the same time. Thus, a separate resistance generator is unnecessary, and an operator is less likely to erroneously stop the connecting operation upon an increase in the operation resistance caused by a separate resistance generator. Accordingly, the two housings (10, 20) can be connected properly with high reliability.

Owner:SUMITOMO WIRING SYST LTD

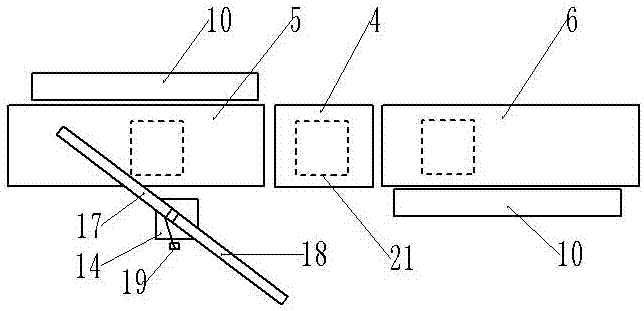

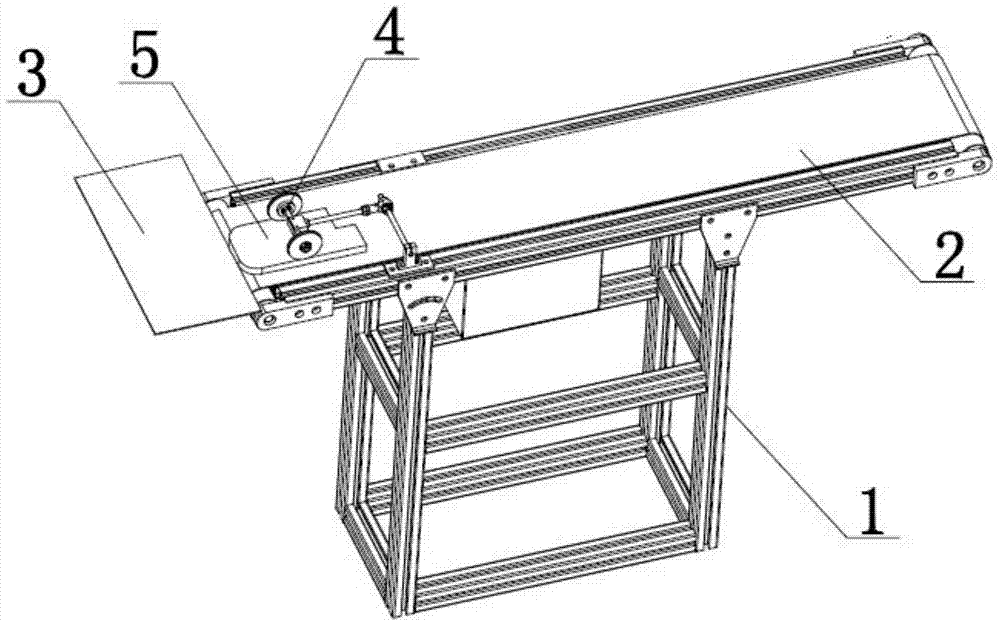

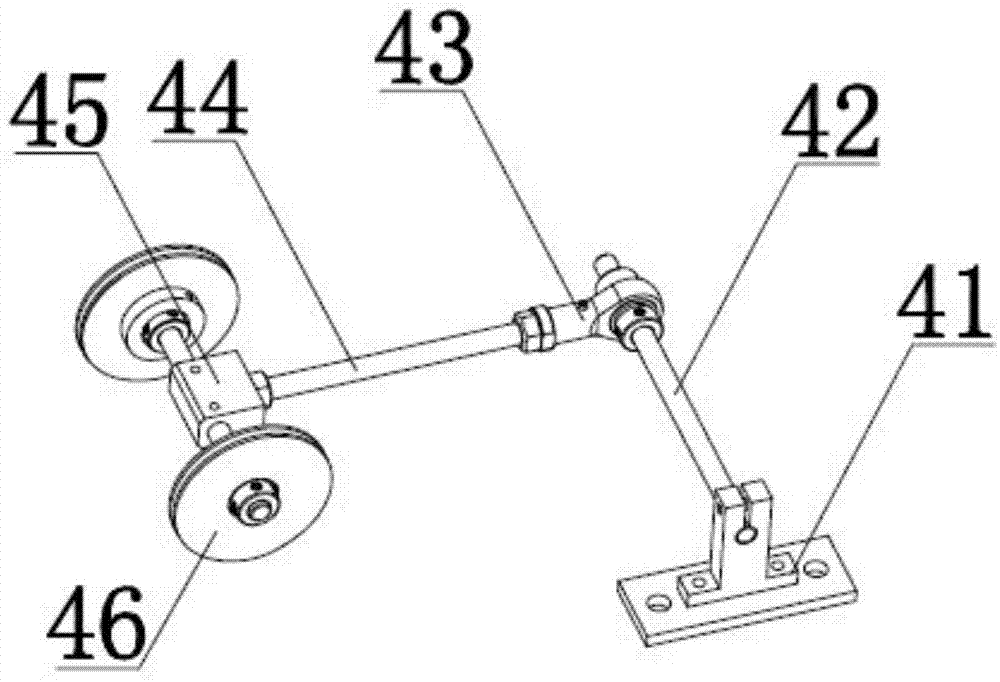

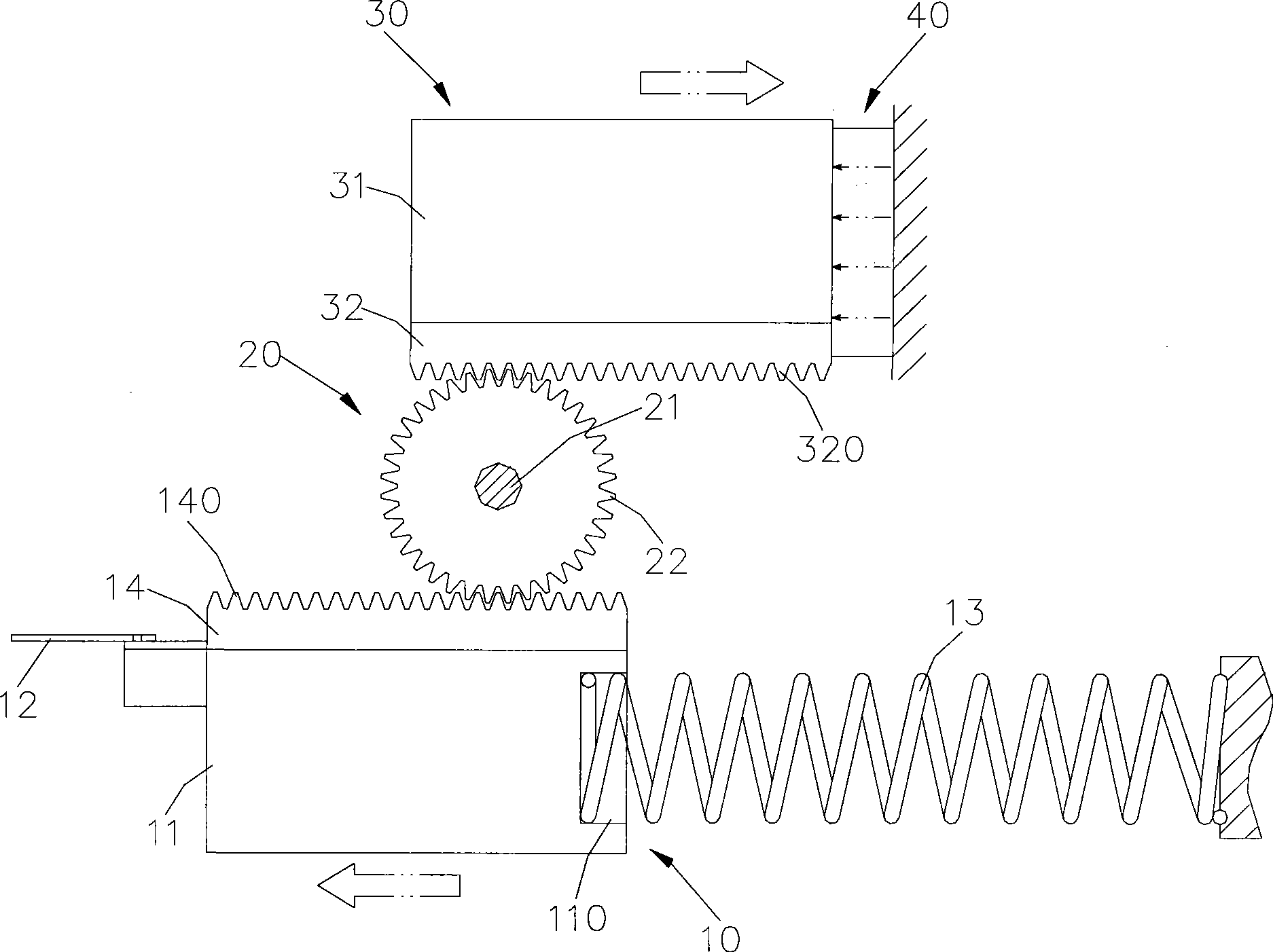

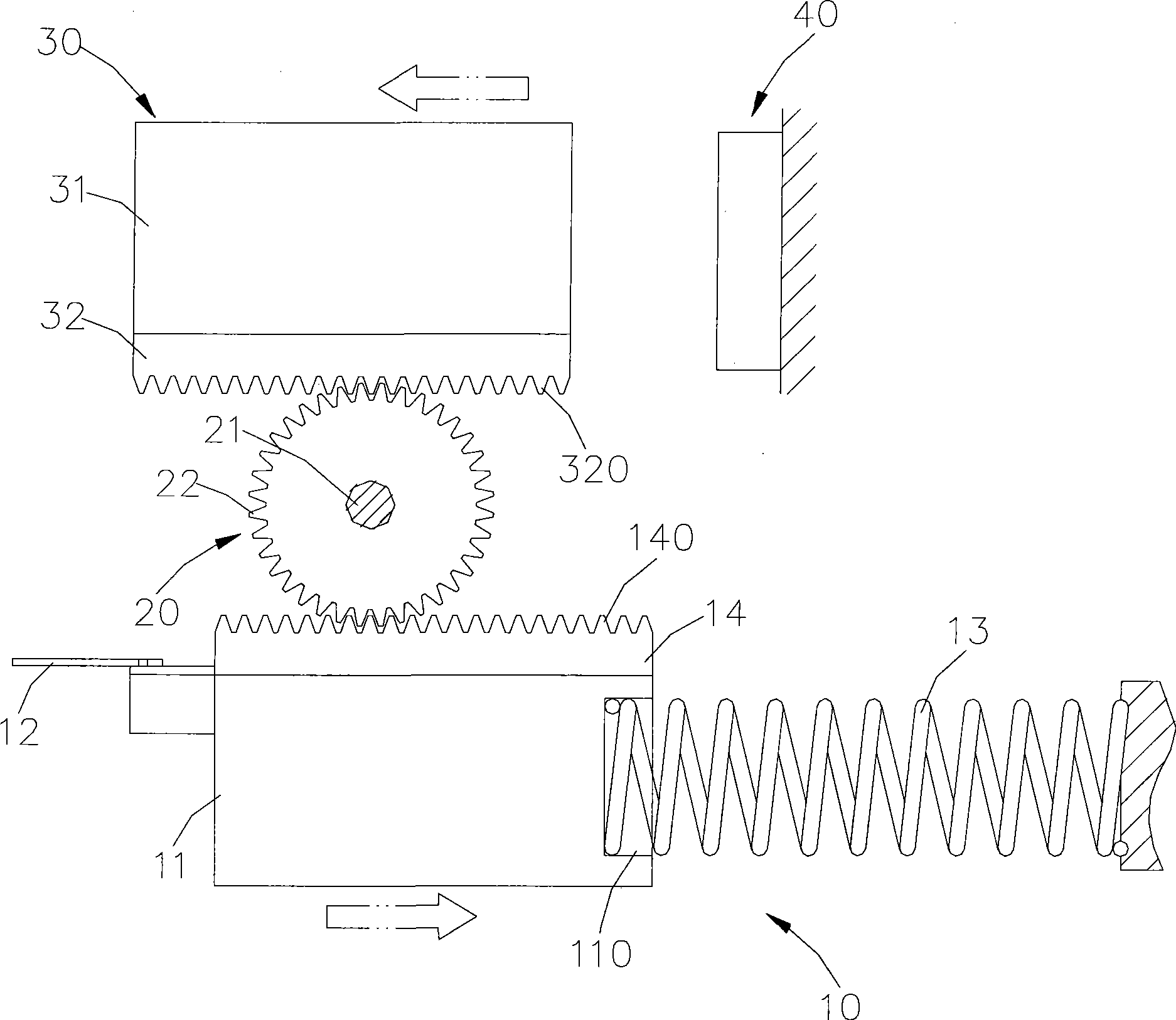

Auxiliary stocking propelling device and propelling method thereof

ActiveCN104326112AGuaranteed inertia forceIncrease inertial forcePackagingTransmission beltEngineering

The invention discloses an auxiliary stocking propelling device and a propelling method thereof. Stockings are conveyed from a starting end to a tail end on a transmission belt, and are about to stride on a static working panel. The stockings gain forward inertia force under the transmission of the transmission belt. Friction force exists between the stockings and the working panel, so that the own inertia force of the stockings is reduced gradually along with striding of the stockings on the working surface, and most stockings are clamped at the critical point. After the propelling device disclosed by the invention is arranged, thrust force for assisting the stockings in moving forwards is provided through a contact point between a roller and the transmission belt by using the inertial force gained by a roller on the transmission belt, so that certain acceleration is provided for the stockings, and the stockings can stride on the working surface smoothly.

Owner:ZHEJIANG MENGNA SOCKS & HOSIERY +2

Counterforce counteraction device of neil catcher

InactiveCN101386183AEliminate reaction forceSimple structureStapling toolsNailing toolsEngineeringCounterforce

The invention provides a counterforce bucking device for a box nailing machine. The box nailing machine is provided with a drive device, a rotating piece and a balance weight device, wherein, the drive device is linked with the rotating piece and the balance weight device, when the drive device of the box nailing device is actuated for action, the balance weight device is driven by the rotating piece to generate counterforce, thereby bucking acting force after the box nailing machine is actuated, and achieving the aim of safe application, simple assembly and other high practicalities for a user.

Owner:SHENZHEN MORGAN FUWANG TECH CO LTD

Cantilever beam vibration and electromagnetism self-powered microsensor of Internet-of-things radio frequency transceiving assembly

InactiveCN103840707AIncrease inertial forceImprove deformationElectromagnetic wave systemPiezoelectric/electrostriction/magnetostriction machinesMicrostrip patch antennaCapacitance

The invention discloses a cantilever beam vibration and electromagnetism self-powered microsensor of an Internet-of-things radio frequency transceiving assembly. According to the cantilever beam vibration and electromagnetism self-powered microsensor, two energy collection self-powered modules including a piezoelectric transducer and a rectification antenna system are integrated, and can play a role in energy collection, energy conversion and energy storage of mechanical vibration energy and stray electromagnetic energy respectively. The cantilever beam vibration and electromagnetism self-powered microsensor is arranged on a gallium arsenide substrate, and comprises an MEMS cantilever beam, a filter circuit, a rectifying circuit and an energy storage capacitor, wherein the MEMS cantilever beam is composed of an upper electrode, piezoelectric film, a lower electrode, a silicon nitride dielectric layer and rectangular microstrip patch antennas from top to bottom, and an oval structure at the tail end is supported by two abreast narrow beams connected with anchoring areas. According to the cantilever beam vibration and electromagnetism self-powered microsensor, the two energy collection self-powered modules can complement with each other through integration of the two energy collection self-powered modules, rectangular microstrip patch antenna structures serve as mass blocks to improve inertia force and deformation of a cantilever beam in the vibration process, and vibration extension antennas of the cantilever beam are used for collecting the directivity range of energy. According to the cantilever beam vibration and electromagnetism self-powered microsensor of the Internet-of-things radio frequency transceiving assembly, energy collection efficiency and the power supply capacity are improved, and influence of a stray magnetic field and mechanical vibration on the Internet-of-things radio frequency transceiving assembly is reduced.

Owner:SOUTHEAST UNIV

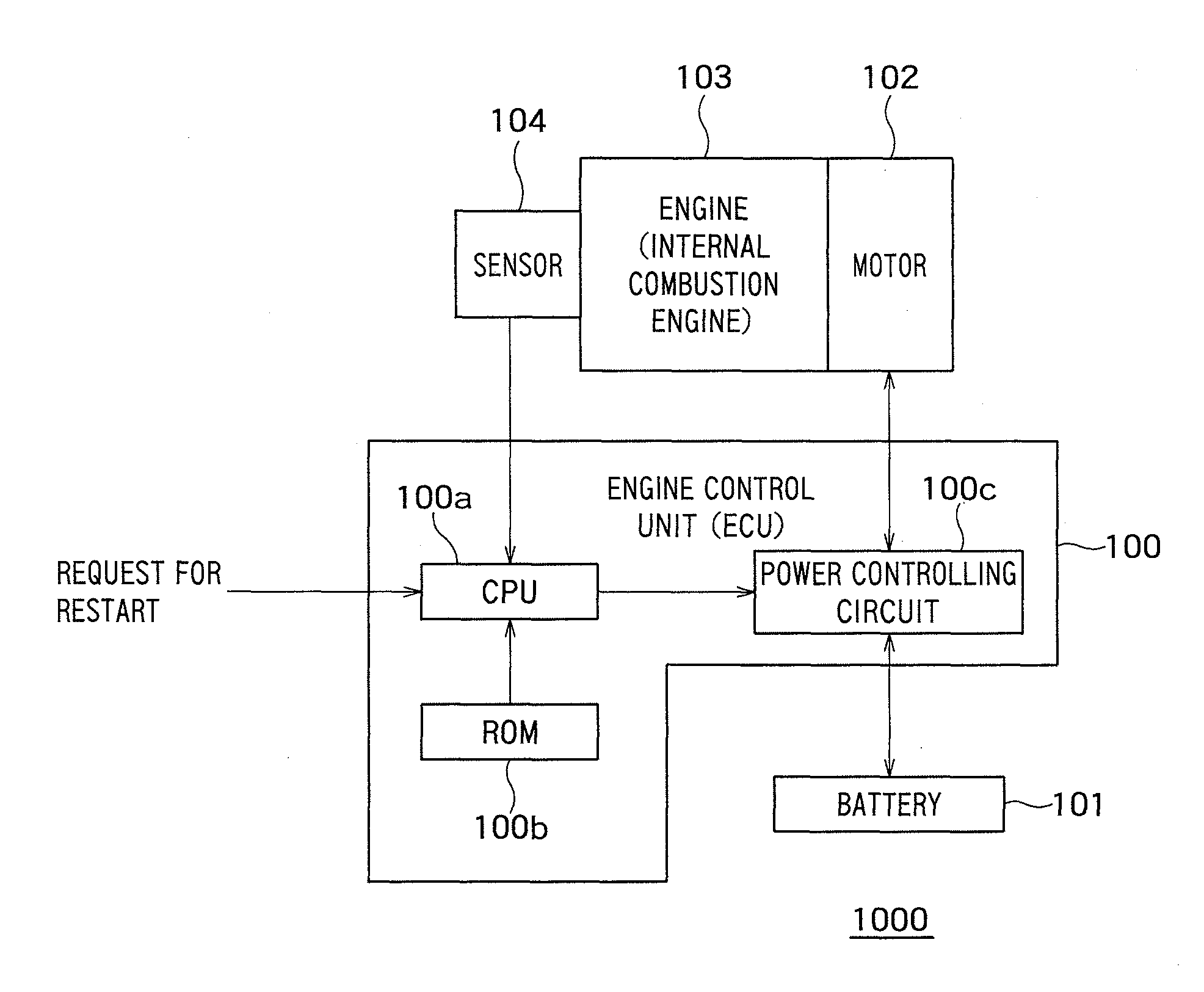

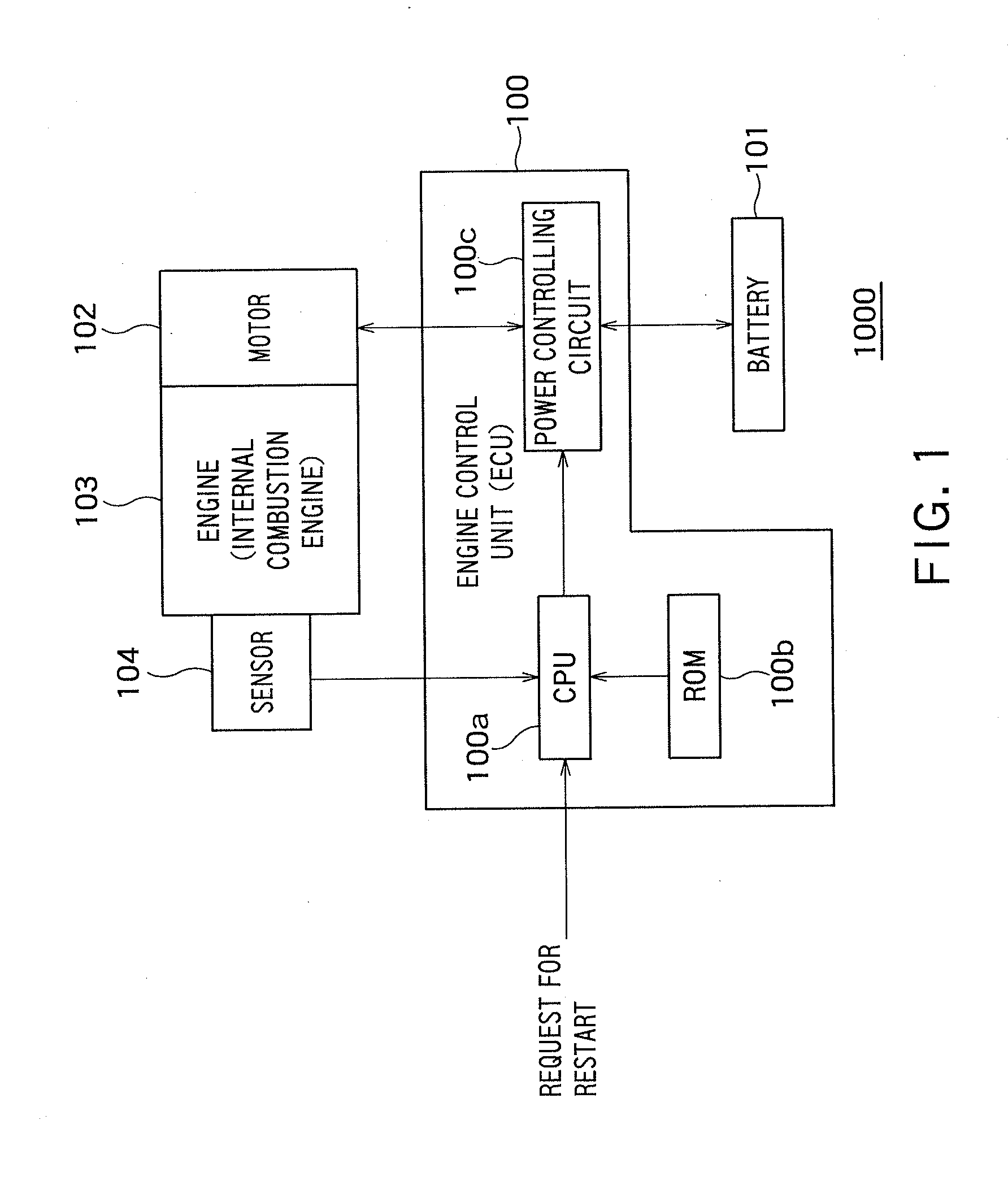

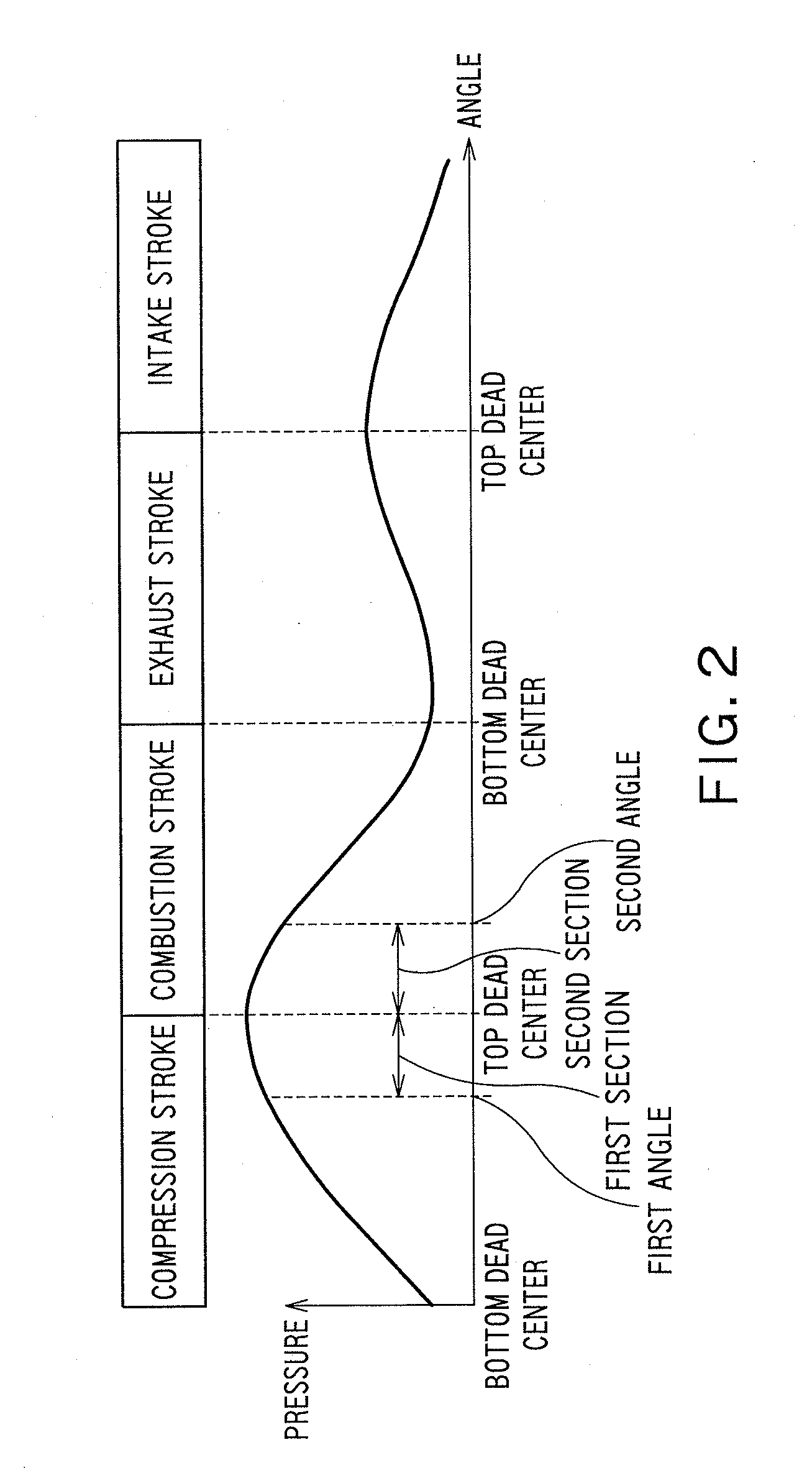

Engine control unit, engine control system and engine control method

ActiveUS20130180501A1Increase inertial forceImprove reliabilityElectrical controlProgramme-controlControl systemElectric motor

An engine control method includes: a step of running the engine in a forward direction by driving a motor that applies a torque to a crank of the engine in the forward direction in a case where the crank angle of the engine does not lie in the first section; a step of removing any load from the motor in a case where the crank angle of the engine lies in the first section; a step of braking the motor in a case where it is determined in the sixth step that the crank angle of the engine lies in the second section; and a step of running the engine in the forward direction by driving the motor in the forward direction in a case where it is determined that there is the request for restart of the engine.

Owner:SHINDENGEN ELECTRIC MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com