Calcium carbonate powder surface modification equipment

A calcium carbonate powder, surface modification technology, applied in inorganic pigment processing, chemical instruments and methods, fibrous fillers, etc., can solve the problems of lack of good production methods, affecting production efficiency, time-consuming and laborious, and achieving increased inertia power, energy saving, and the effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

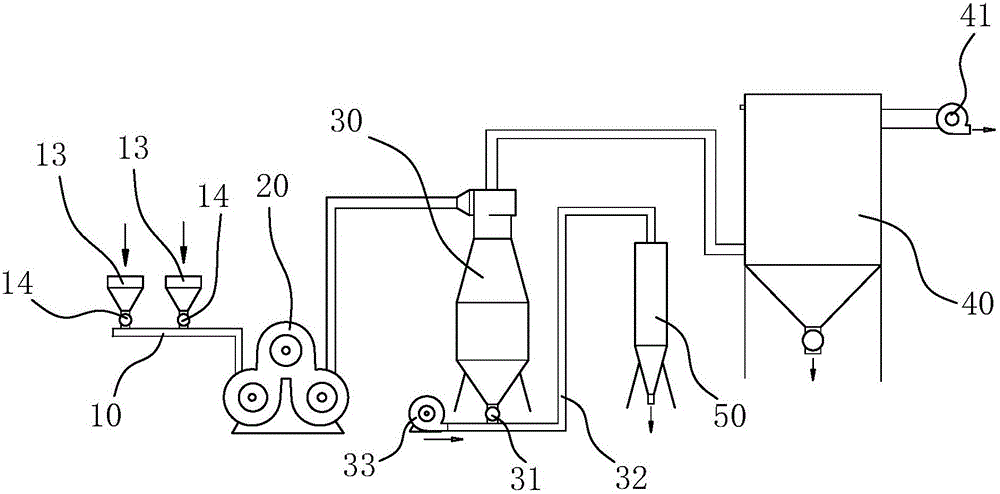

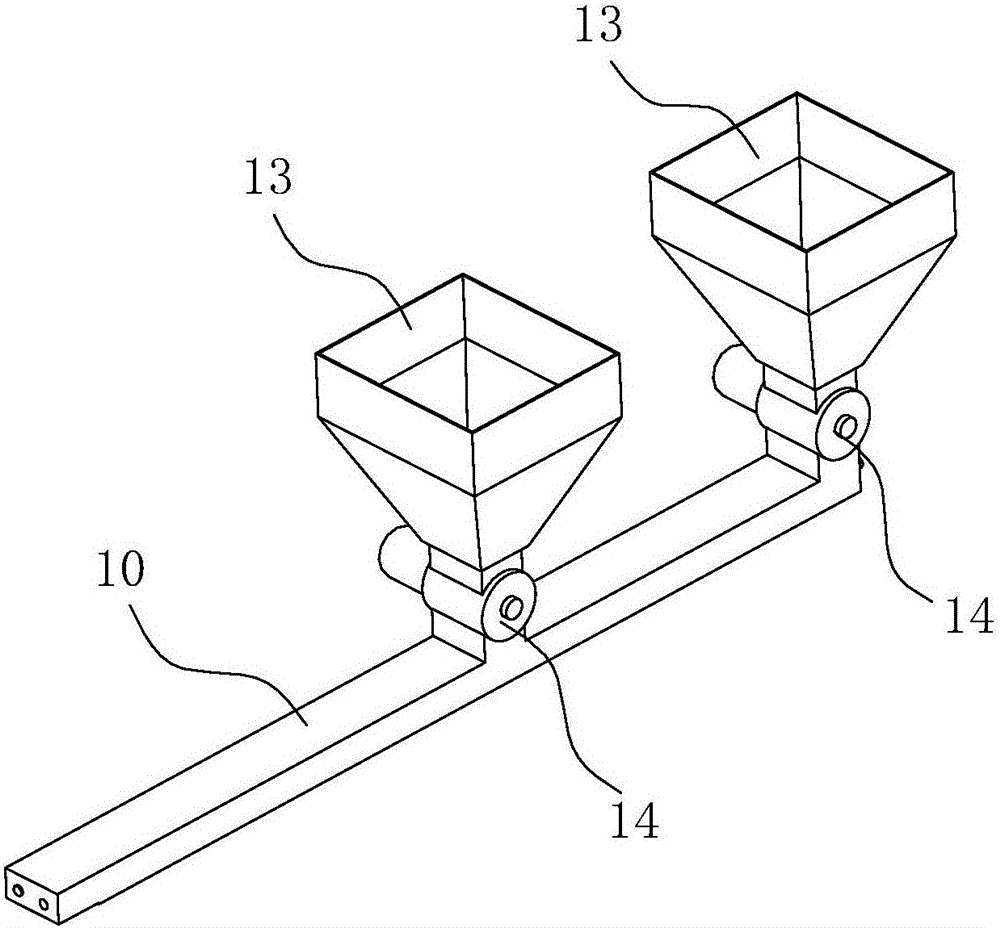

[0016] Such as figure 1 Shown, a kind of calcium carbonate powder surface modification equipment, comprises the calcium carbonate powder mixing and stirring and conveying device connected in succession, calcium carbonate powder surface film coating device, wind energy filter collection device;

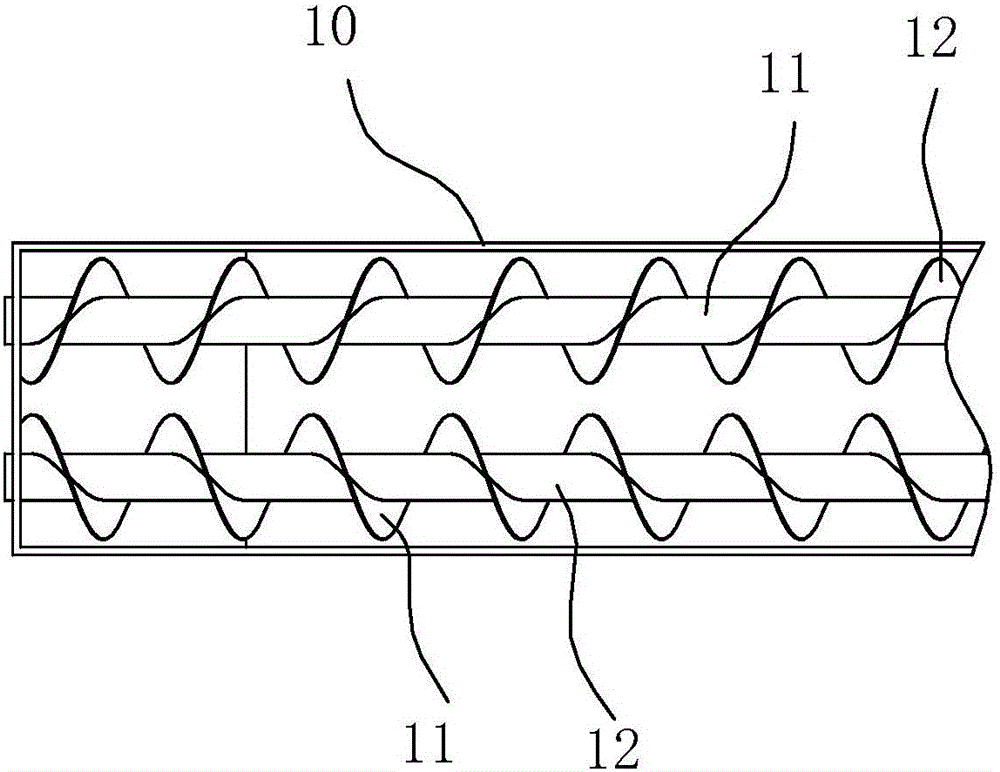

[0017] The calcium carbonate powder mixing and conveying device mixes calcium carbonate powders of different particle sizes and conveys them to the calcium carbonate powder surface coating device;

[0018] The calcium carbonate powder surface coating device sprays the liquid organic matter on the calcium carbonate powder and stirs it with a high-speed mixer, so that the organic matter is fully coated on the calcium carbonate surface;

[0019] The wind energy filter collection device uses the fan 41 to extract the material in the high-speed mixer, and uses a dust collector to filter out the calcium carbonate powder in the airflow and collect the calcium carbonate powder.

[0020] prefe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com