Surface Processing Device

A surface treatment device and surface treatment technology, applied in the direction of cells, electrolytic processes, circuits, etc., can solve problems such as difficulty in removing bubbles, and achieve the effect of improving surface treatment capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Hereinafter, preferred embodiments of the present invention will be described in detail. In addition, the present embodiment described below does not unduly limit the content of the present invention described in the claims, and does not limit that all the configurations described in the present embodiment must be the solution of the present invention.

[0044] 1. Overview of surface treatment equipment

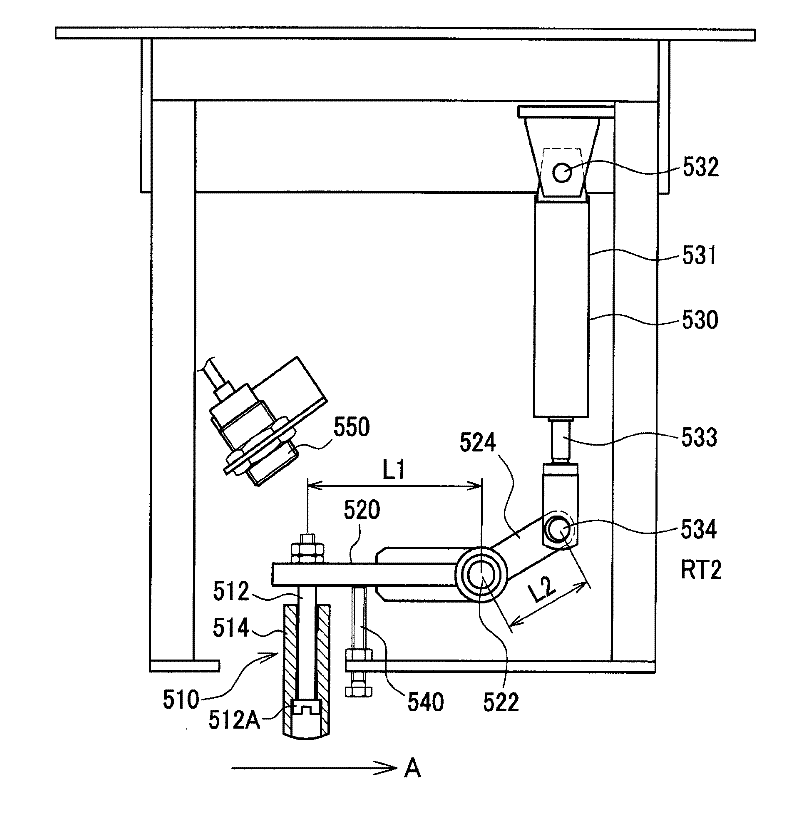

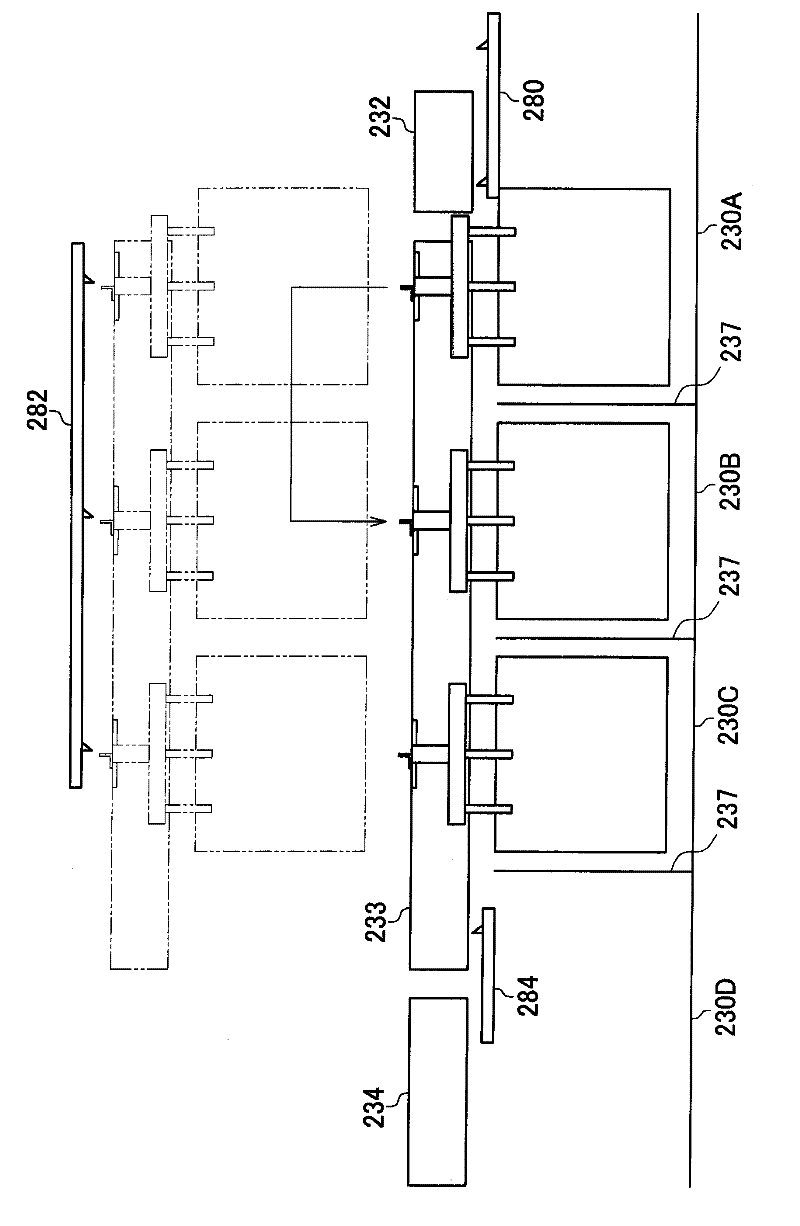

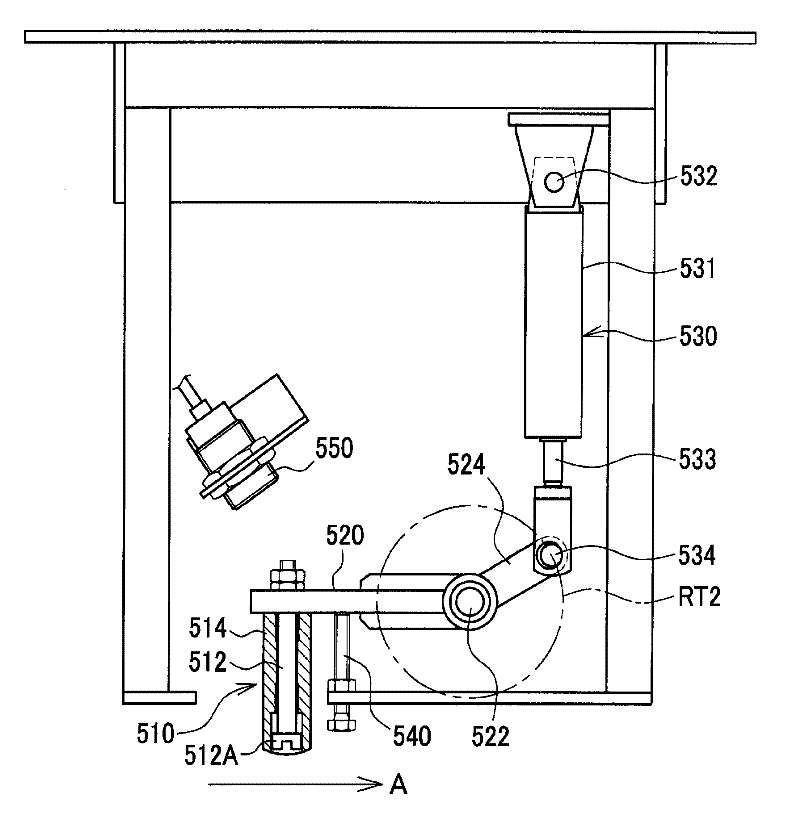

[0045] figure 1 is a plan view of a surface treatment device, for example, a continuous plating treatment device. The continuous electroplating processing apparatus 10 has a plurality of transport jigs 30 that respectively hold workpieces 20 such as circuit boards along the figure 1 For example, the circular conveying path 100 is circularly conveyed in the right-handed circular conveying direction A. In addition, in figure 1 The illustration of a part of the workpiece 20 and a part of the transport jig 30 is omitted.

[0046] In the circulation transport path 100...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com