Patents

Literature

53results about How to "Improve the effect of surface treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

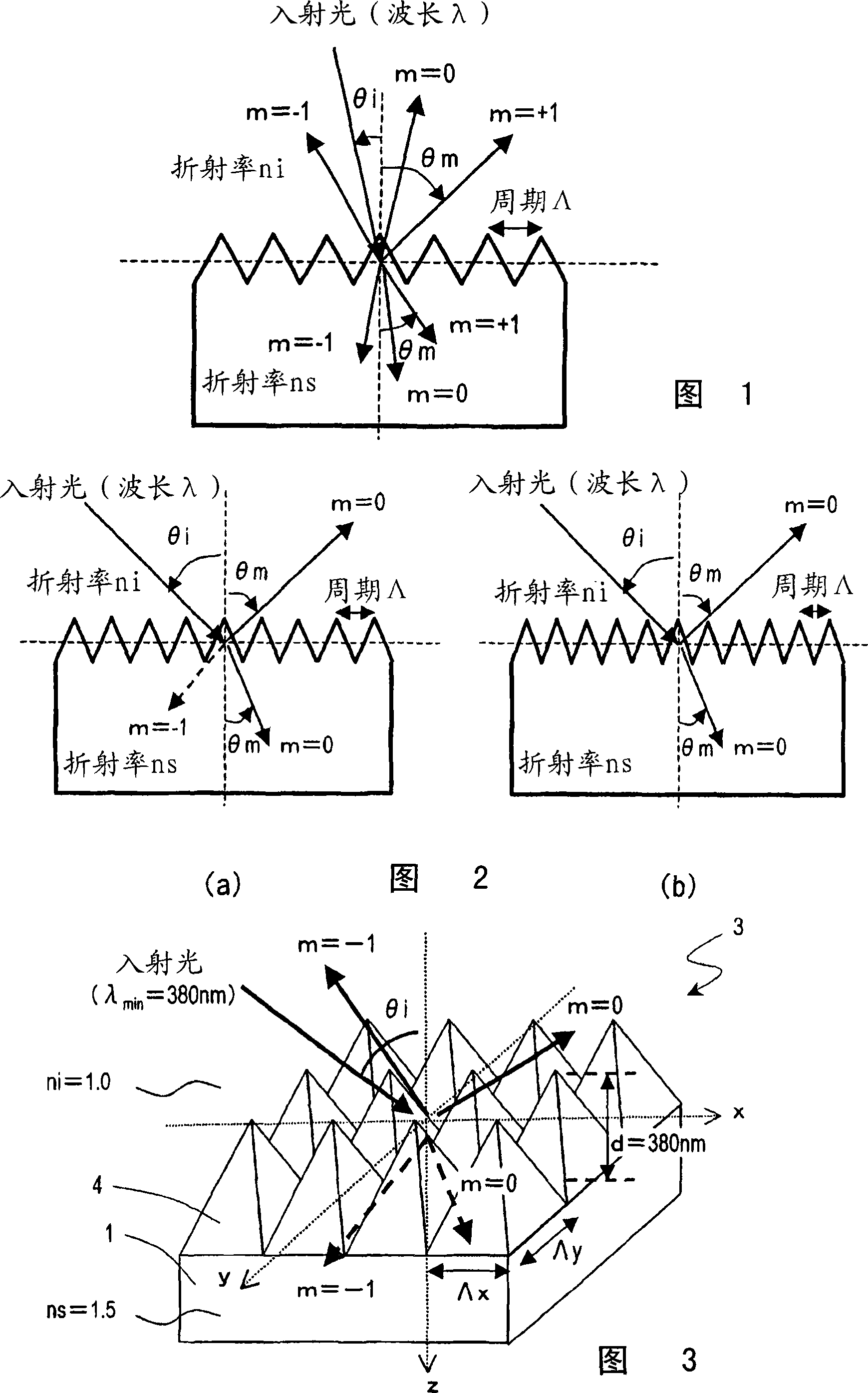

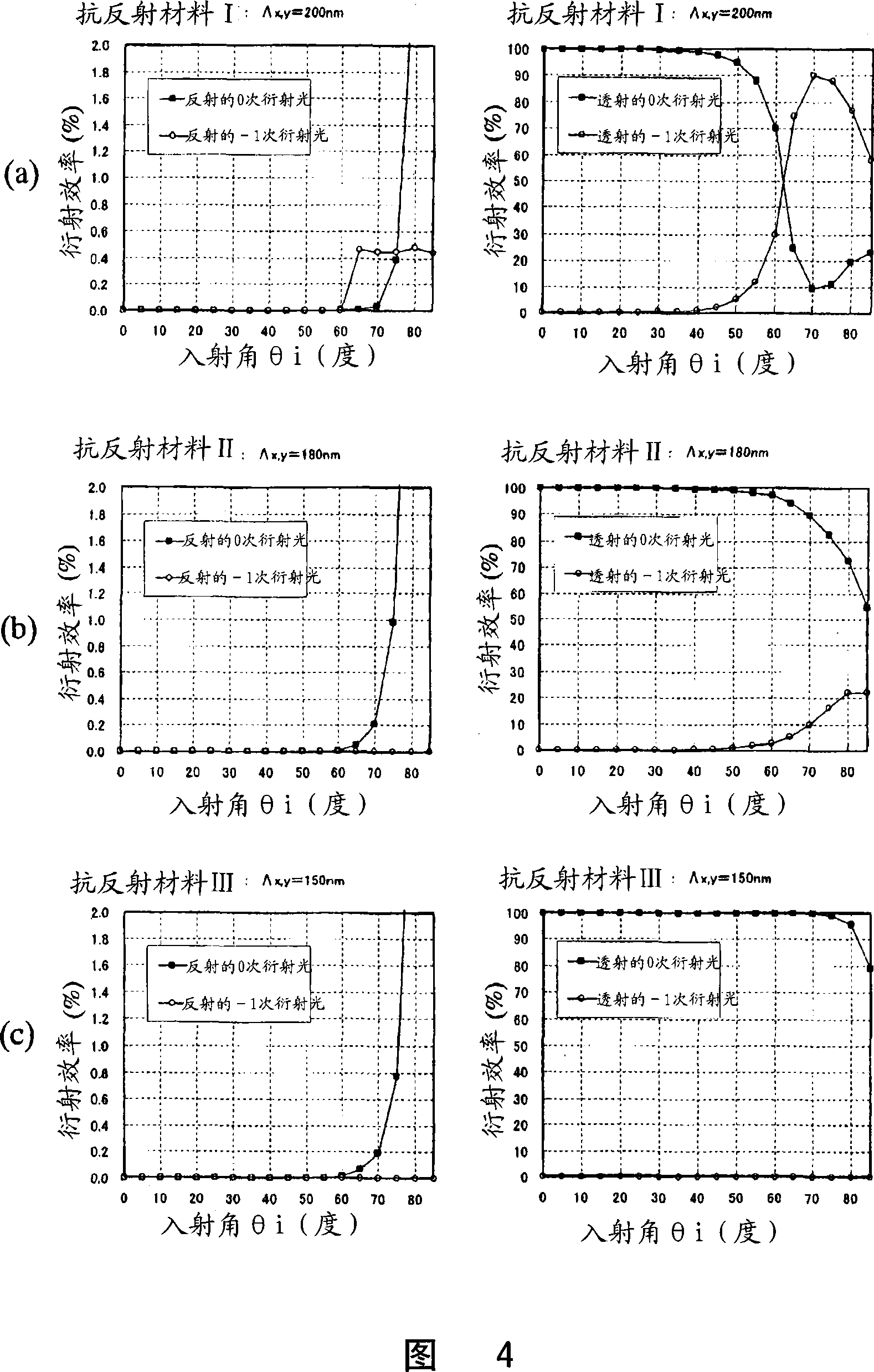

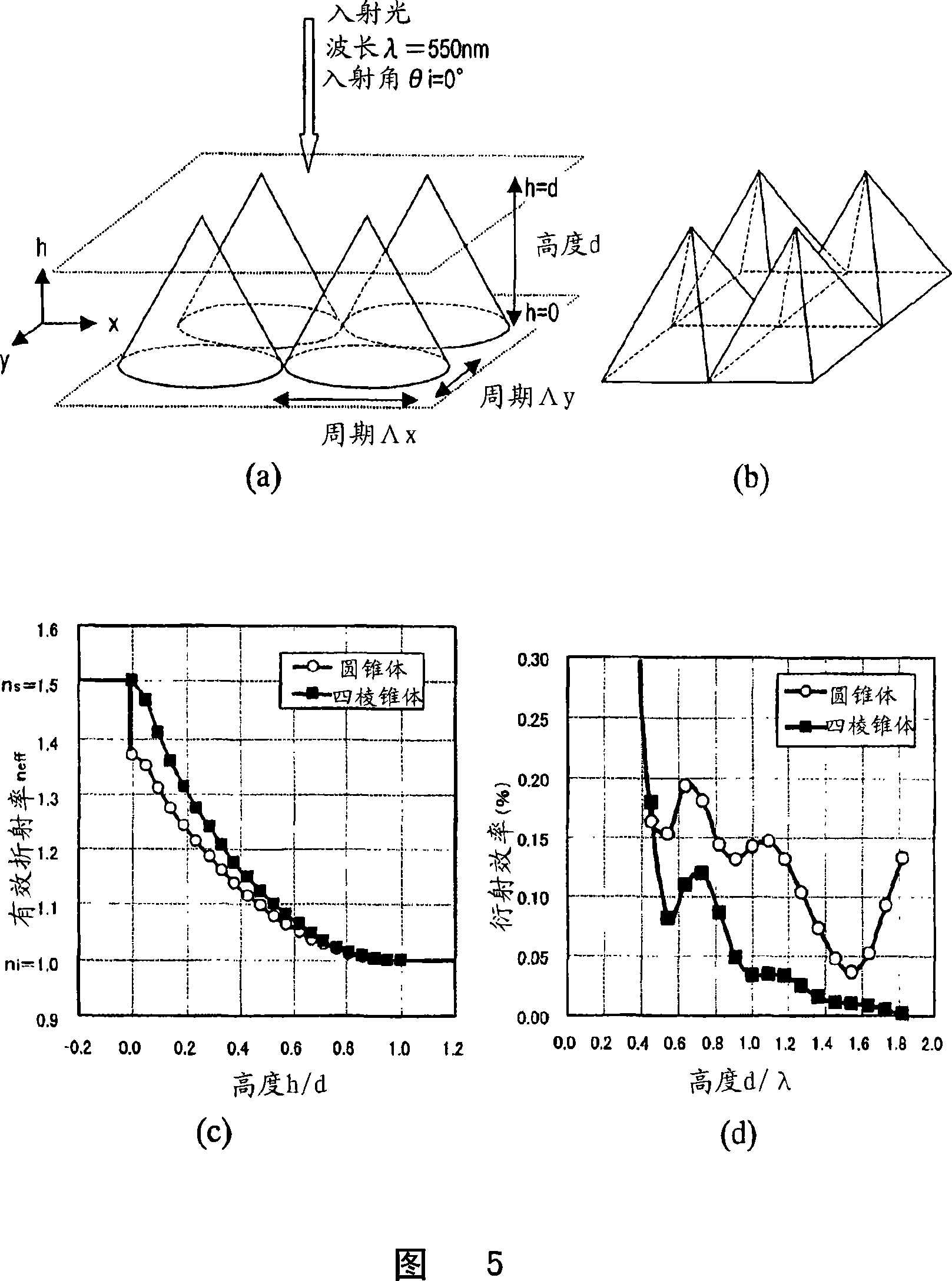

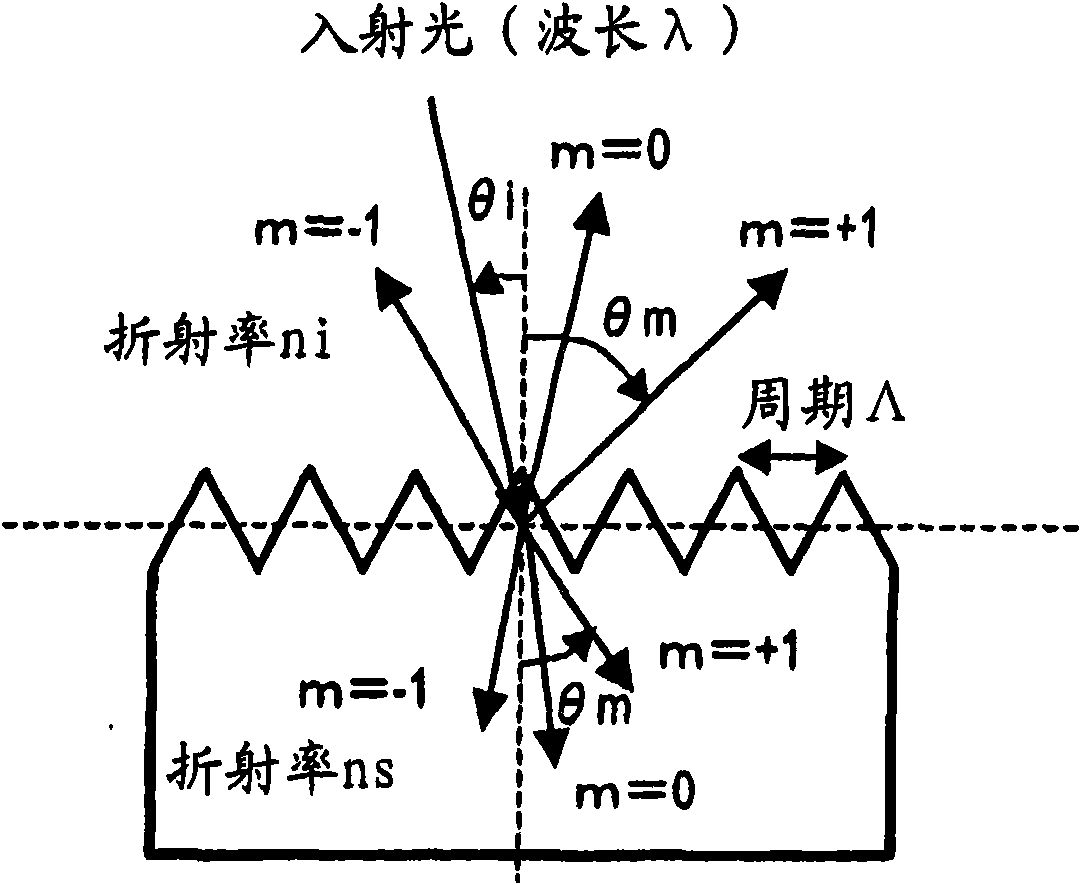

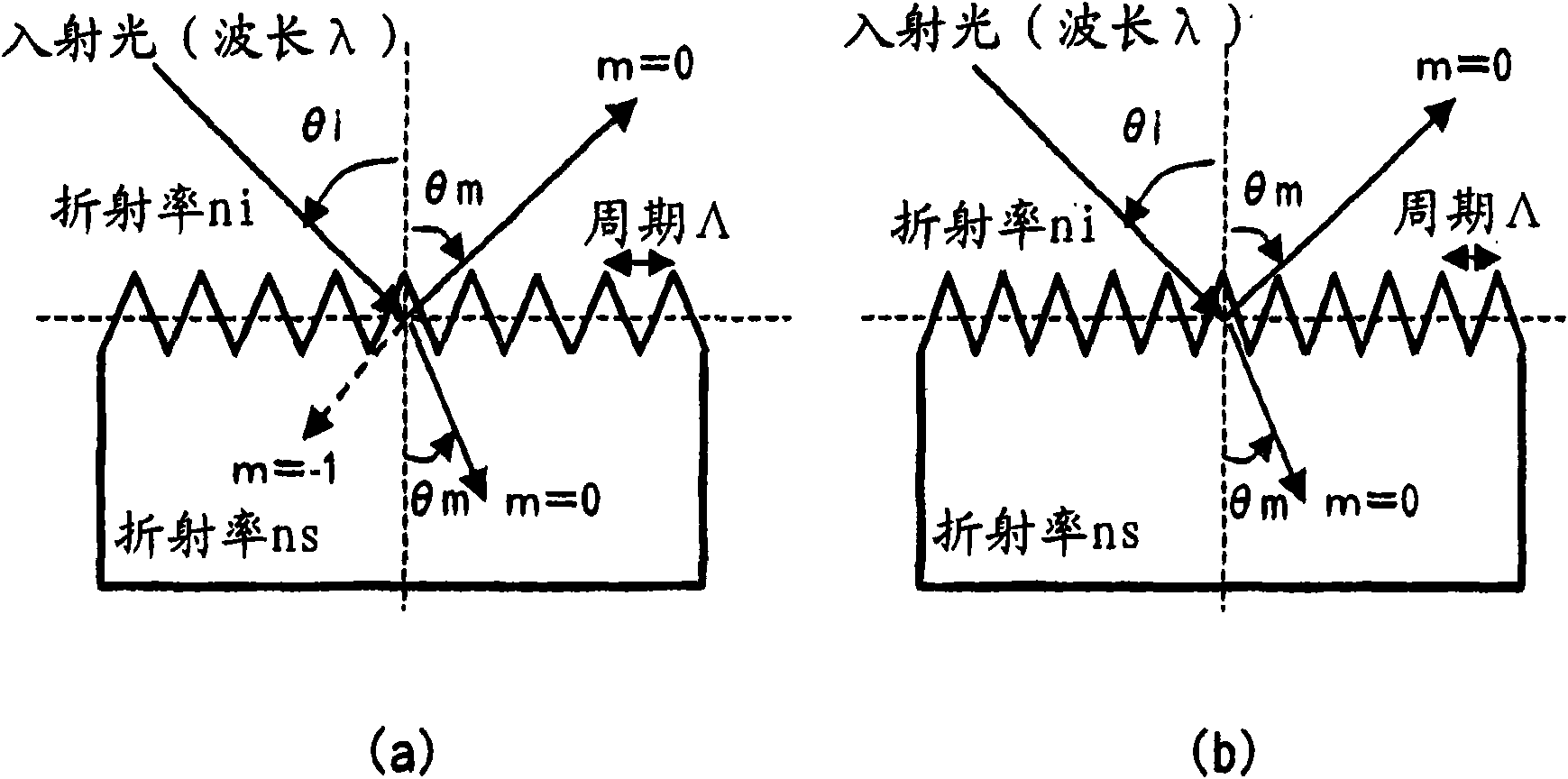

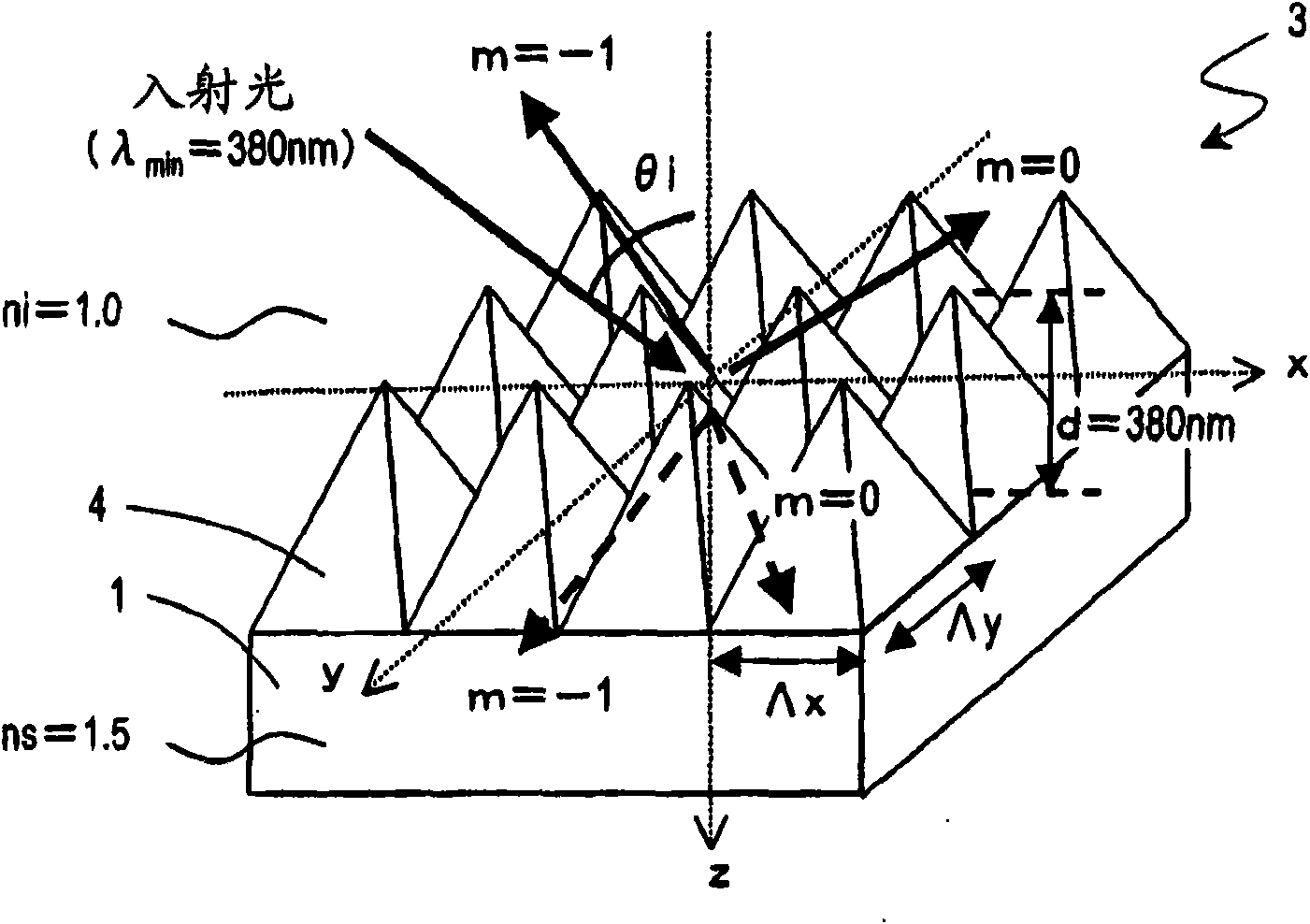

Antireflective member, optical element, display device, method of making stamper and method of making antireflective member using the stamper

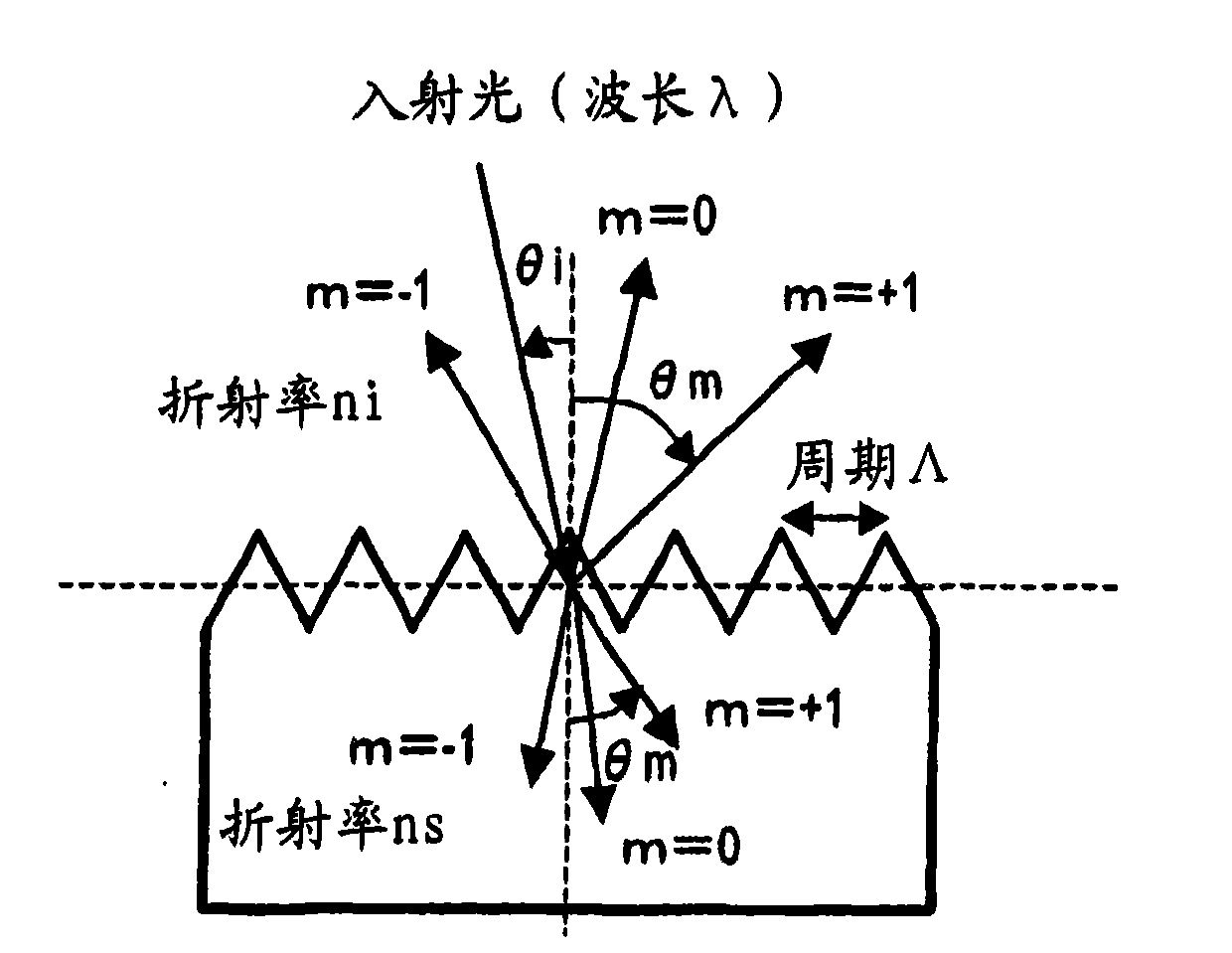

ActiveCN101088030ASuppression of regular reflectionImprove anti-reflection effectLayered productsCoatingsSurface patternAngle of incidence

An antireflective member according to the present invention has an uneven surface pattern, in which unit structures are arranged in x and y directions at respective periods that are both shorter than the shortest wavelength of an incoming light ray, on the surface of a substrate and satisfies the following inequality (1): lambda, / lambda ) . . ., where lambda is the shortest wavelength of the incoming light ray, theta i is the largest angle of incidence of the incoming light ray, ni is the refractive index of an incidence medium, lambda is the period of the uneven surface pattern in the x direction, and lambda is the period of the pattern in the y direction. As a result, diffraction of short-wave light components can be reduced in a broad wavelength range.

Owner:SHARP KK

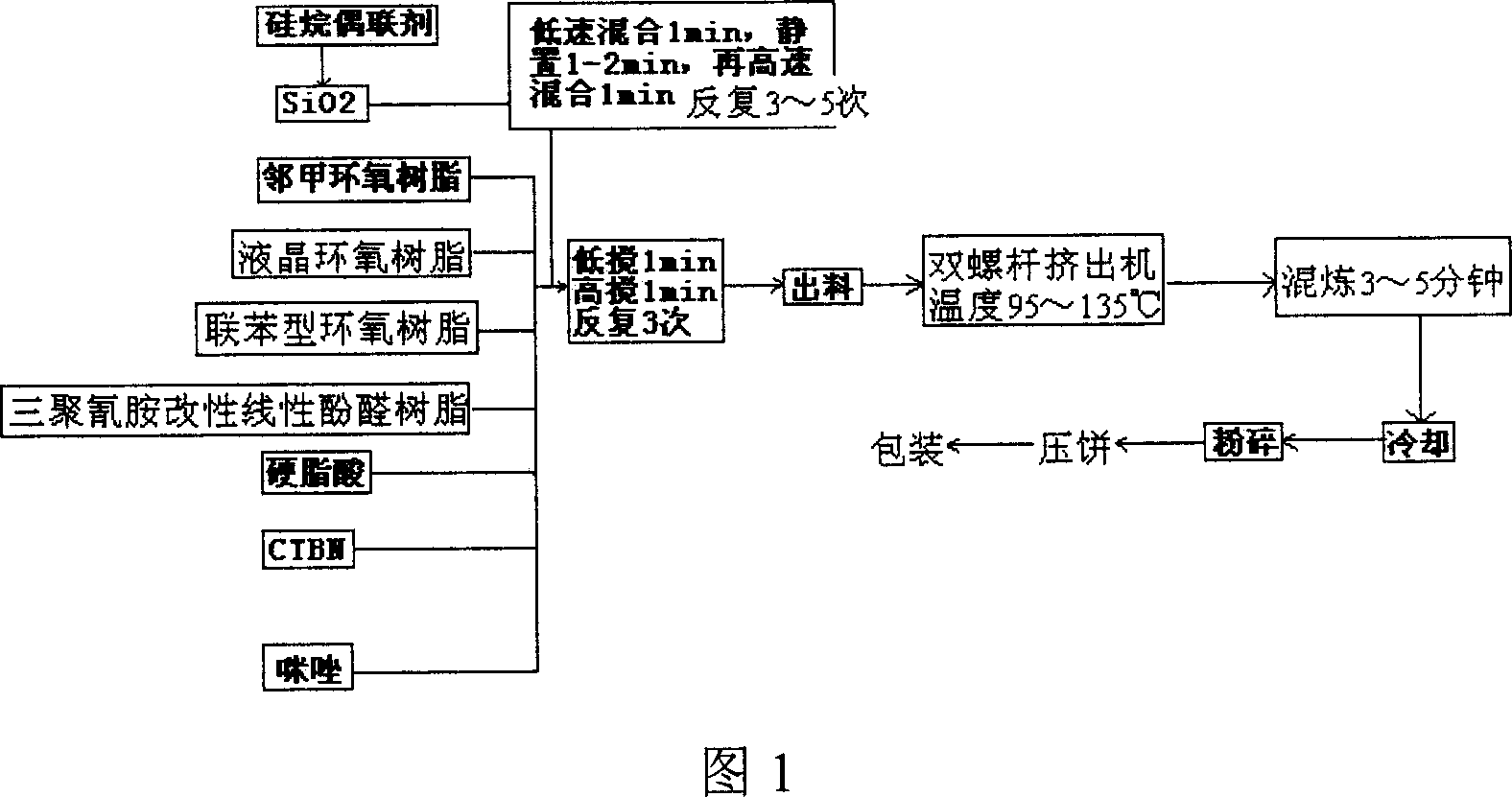

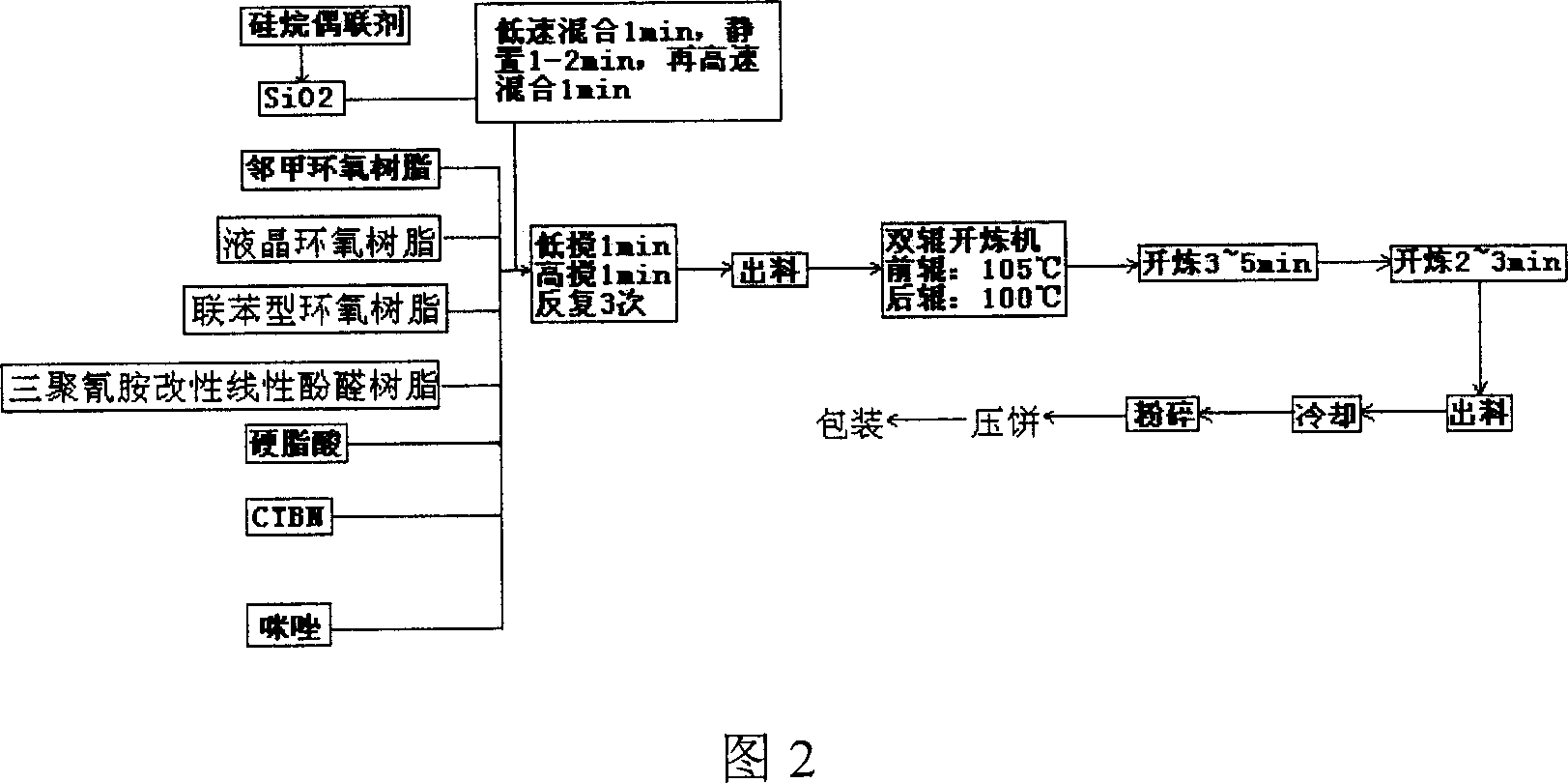

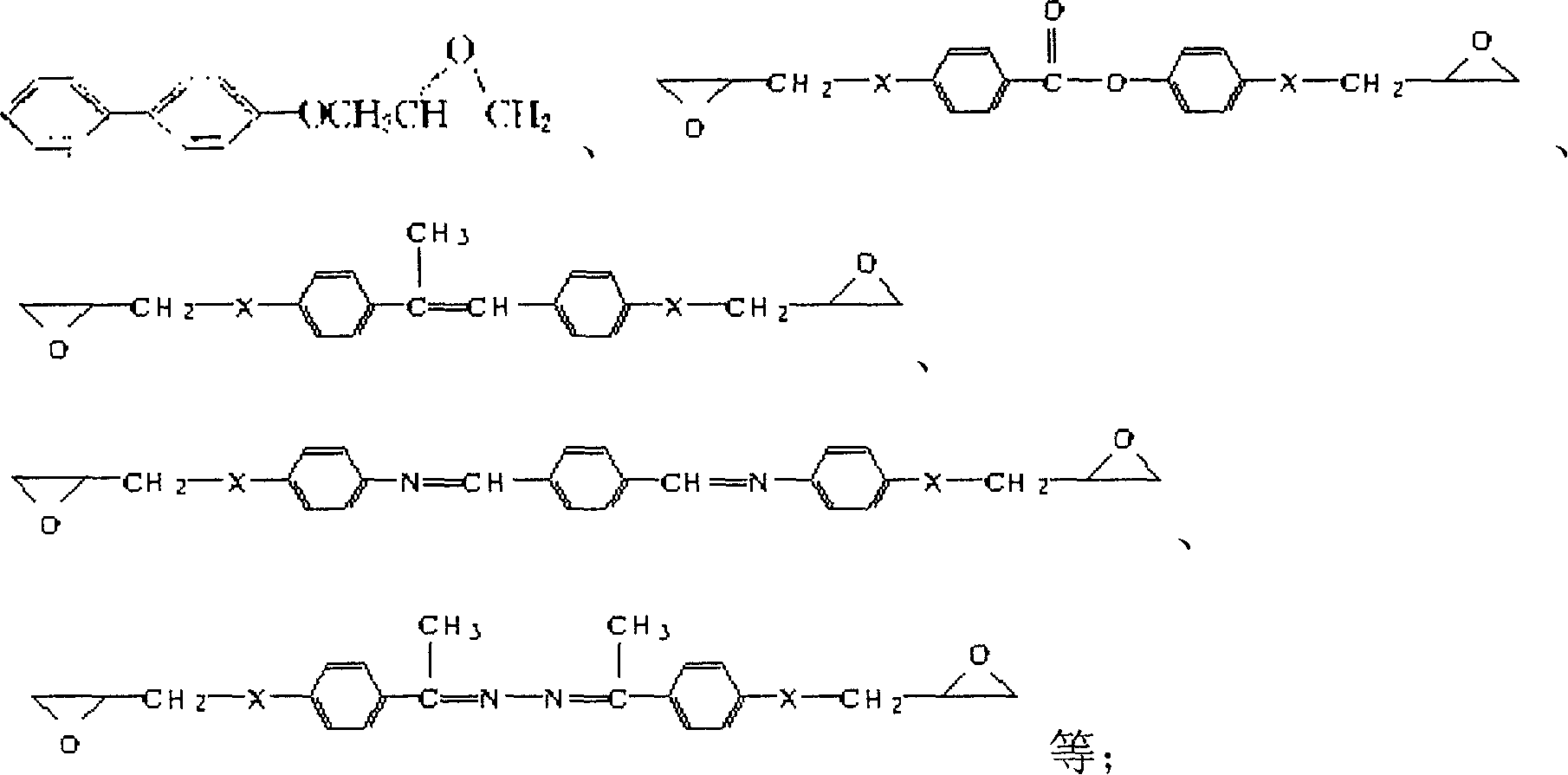

Epoxy-resin mould plastic for packing IC circuit and its production

InactiveCN101029165AHigh glass transition temperatureReduce melt viscositySemiconductor/solid-state device detailsSolid-state devicesEpoxyThermal expansion

An epoxy resin mold plastic and its production are disclosed. The mold plastic consists of liquid-crystal epoxy resin, methyl-phenolic epoxy resin, epoxy resin containing biphenyl unit structure, melamine modified linear phenolic resin, silicone micro-powder, imidazo curing improver, toughening agent and silane coupling agent. The process is carried out by treating silicone micro-powder in mixer by coupling agent for 2-5mins, adding into other components, mixing for 3-5mins, melt milling at 95-135 degree for 3-5mins, cooling, crushing, mesh screening, pressing into material cake and storing below 6degree. Its advantages include low thermal expansion coefficient, excellent heat and fire resistances, better toughness and fluidity, no phosphor, no antimony and environmental pollution. It can be used to pack large-scale circuit and electronic devices.

Owner:GUANGDONG RONGTAI IND

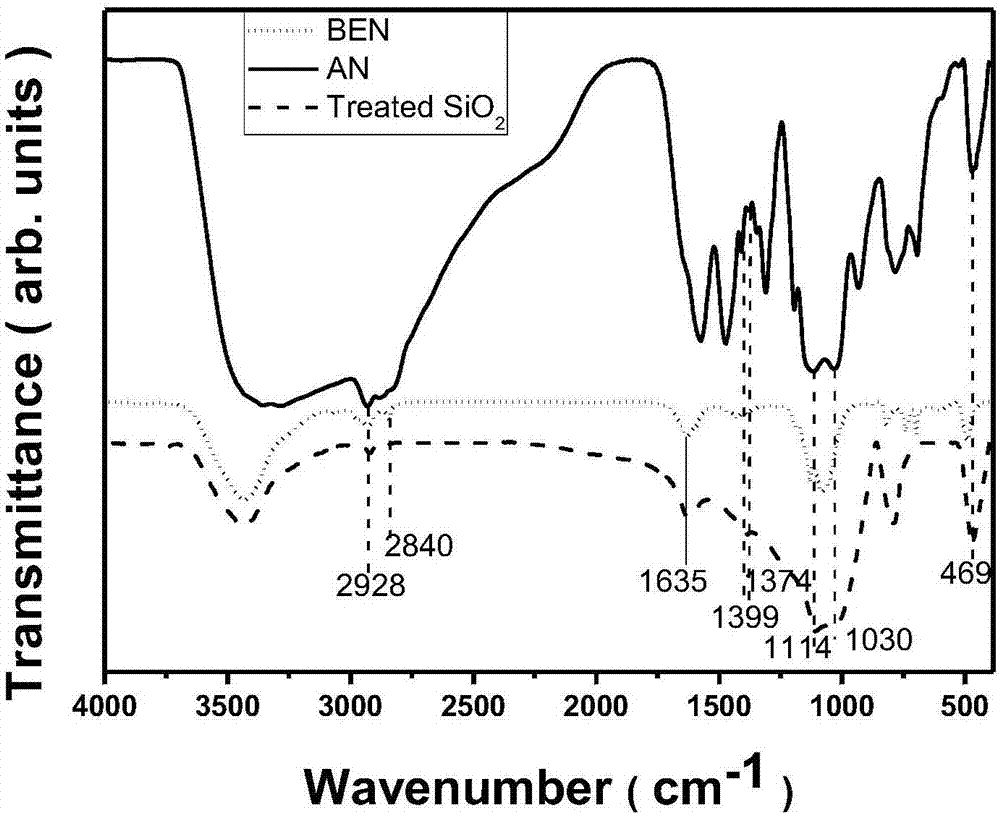

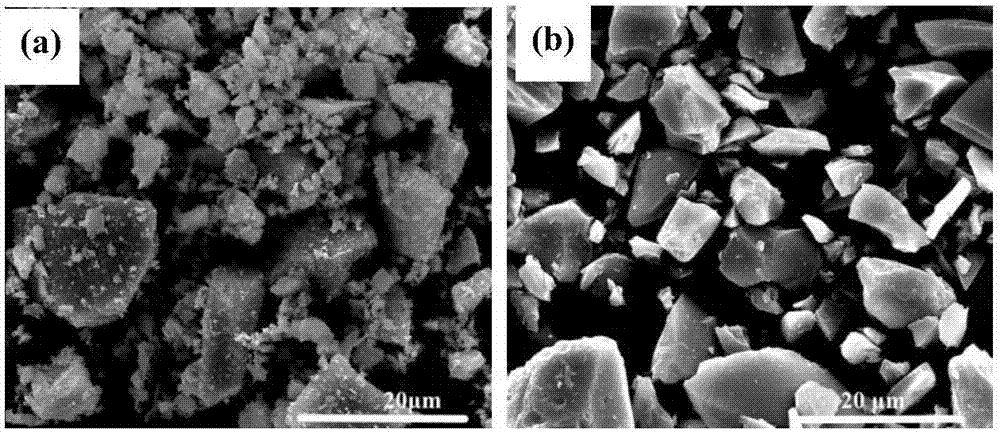

A preparing method of a ceramic-filled polytetrafluoroethylene microwave composite-medium substrate

A preparing method of a ceramic-filled polytetrafluoroethylene microwave composite-medium substrate is disclosed. The method includes 1) adding silicon dioxide ceramic powder into a liquid mixture of hydrogen peroxide and concentrated hydrochloric acid after the silicon dioxide ceramic powder is dried, and heating the mixture to 50-70 DEG C to obtain a suspension; 2) subjecting the suspension to suction filtration and drying a product in a vacuum environment; 3) adding the silicon dioxide ceramic powder obtained in the step 2) into a solution mixture of deionized water and absolute alcohol, adjusting the pH value to be 3-5, weighing a coupling agent the weight of which is 1.0-2.5% of the weight of the silicon dioxide ceramic powder, performing ball milling, and fully mixing the mixture to obtain a material mixture; 4) filtering and drying the material mixture to obtain modified silicon dioxide ceramic powder; 5) ball-milling and mixing the modified silicon dioxide powder, chopped glass fibers and polytetrafluoroethylene, and then performing demulsification to obtain dough; and 6) subjecting the dough to molding and hot-pressed sintering. The ceramic-filled material prepared by the method has a low dielectric constant (with epsilon being equal to 2.94), ultralow dielectric loss (with tg[delta] being less than 0.0008, 10 GHz), low water absorption (less than 0.02%) and a small thermal expansion coefficient (less than 20 ppm / DEG C).

Owner:汕头超声覆铜板科技有限公司

Modified material and treatment method of low-quality aggregate

The invention belongs to the technical field of building materials, and specifically relates to a modified material and treatment method of a low-quality aggregate. The modified material of the low-quality aggregate provided by the invention comprises the following components in percentage by mass: 46-50% of cement, 10-15% of a mineral admixture, 2-5% of an active powder, 0.2-0.6% of a water reducing agent, 0.001-0.004% of a viscosity adjusting agent, 0-3.2% of an expanding agent, 0-0.12% of an air entraining agent, and 0-0.0007% of a defoaming agent. The modified material provided by the invention can realize effective filling and coating modification of the low-quality aggregate through the cooperation between the components, and the adjustment of the use amount, and especially through the cooperation of the specific use amount of the cement, active powder and viscosity adjusting agent, the surface tension and viscosity of the modified material can be effectively adjusted, and a porepenetration amount and a shell coating thickness are coordinately optimized. The combined use of the inorganic and organic components promotes the secondary hydration / chemical bonding of a slurry layer, and improves the strength of an interface between the aggregate and the slurry layer. The cylindrical compress strength of the aggregate after modification treatment is increased by 40% or more, acrushing value is reduced by 30% or more, and a water absorption rate in 24 h is reduced by 15% or more.

Owner:CHINA BUILDING MATERIALS ACAD

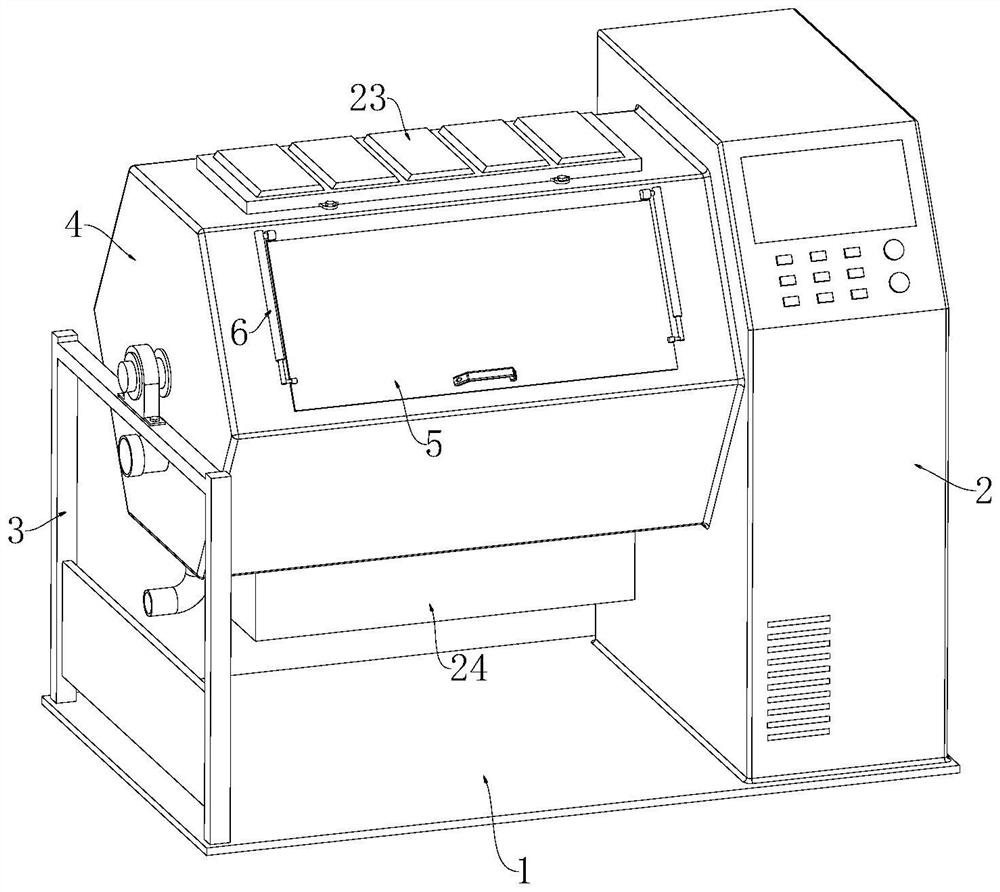

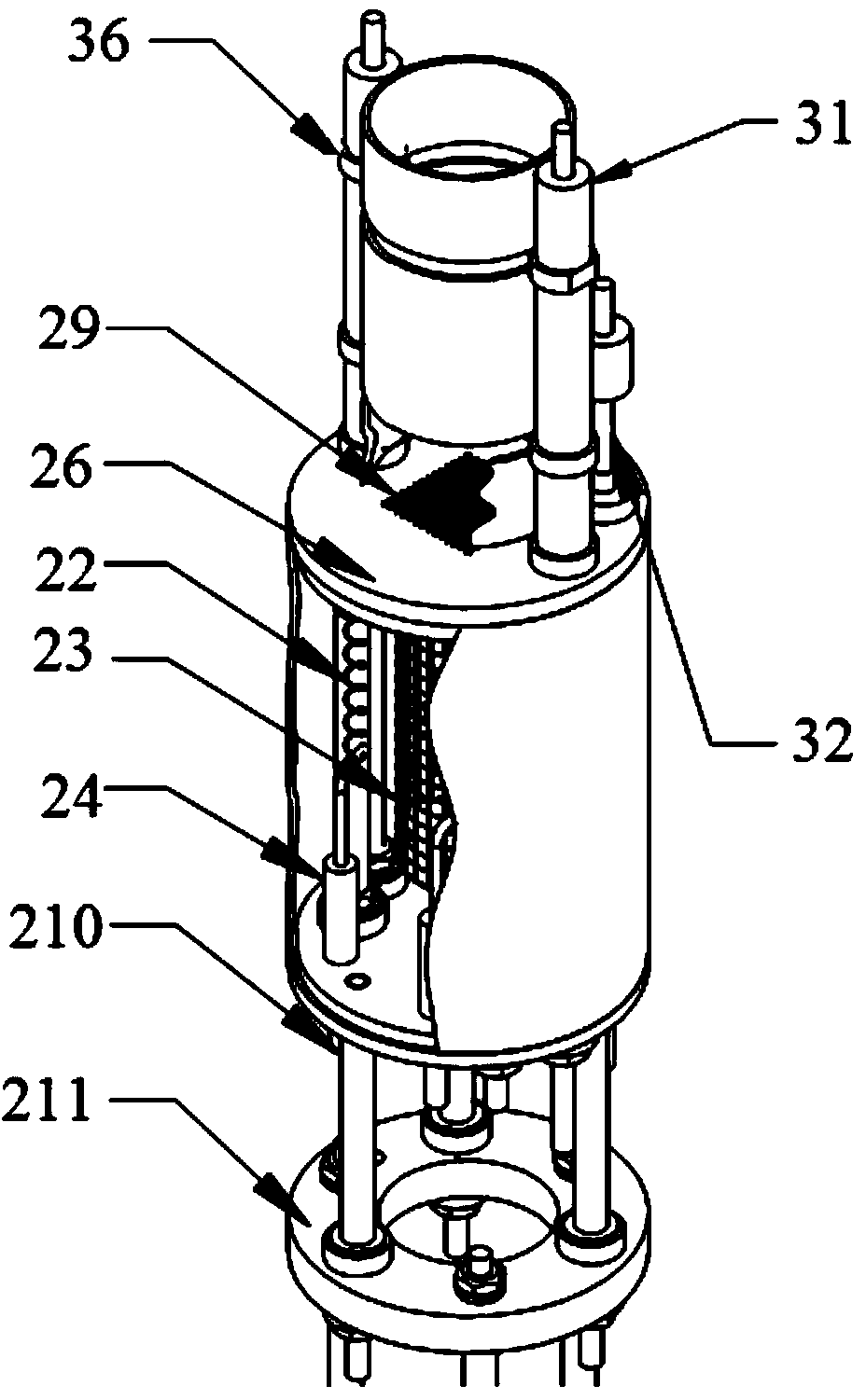

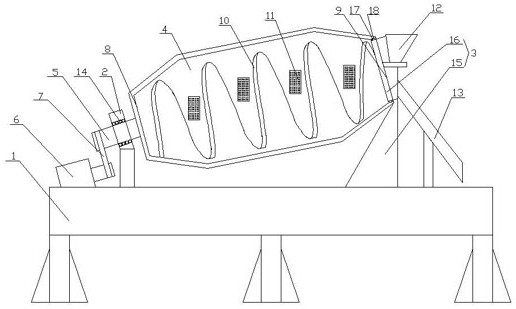

Precision treatment system for surface of split blade of aircraft engine and treatment process of precise treatment system

ActiveCN114131499AImprove uniformityCompact structureEdge grinding machinesPolishing machinesGrindingAirplane

The invention discloses an aircraft engine folio blade surface precision treatment system and a treatment process thereof.The aircraft engine folio blade surface precision treatment system comprises a base, a control box and a support are arranged on the two sides of the top of the base correspondingly, a through driving shaft is arranged in a barrel, and a plurality of connecting bases which are annularly and evenly distributed are arranged on the outer wall of the center of the driving shaft; driving parts are arranged on the two sides of the connecting base, each driving part is composed of a clamping mechanism and a guiding mechanism, and an upper magnetic pole mechanism and a lower magnetic pole mechanism are arranged on the upper side and the lower side of the barrel correspondingly. According to the invention, the driving part is arranged in the barrel body to drive the blade to move, the relative movement modes between the blade and the grinding material are diversified through the mutual cooperation of the fixed magnetic pole and the movable magnetic pole, and the module in the grinding material can always rub the surface of the blade with larger pressure by increasing the disorder of the movement; and the surface of the blade is completely treated, and meanwhile, the surface treatment efficiency is improved.

Owner:CHENGDU HONGXIA TECH CO LTD

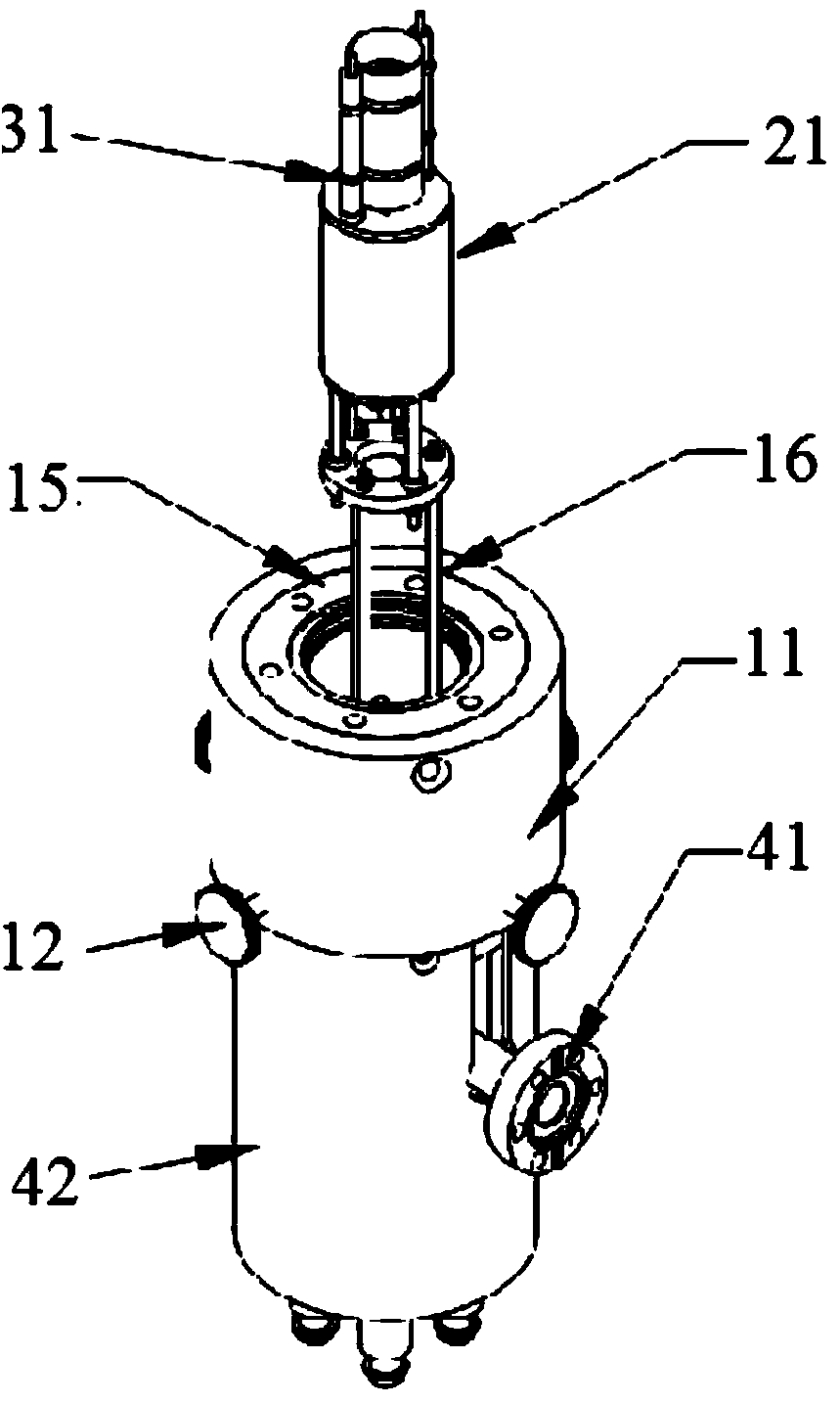

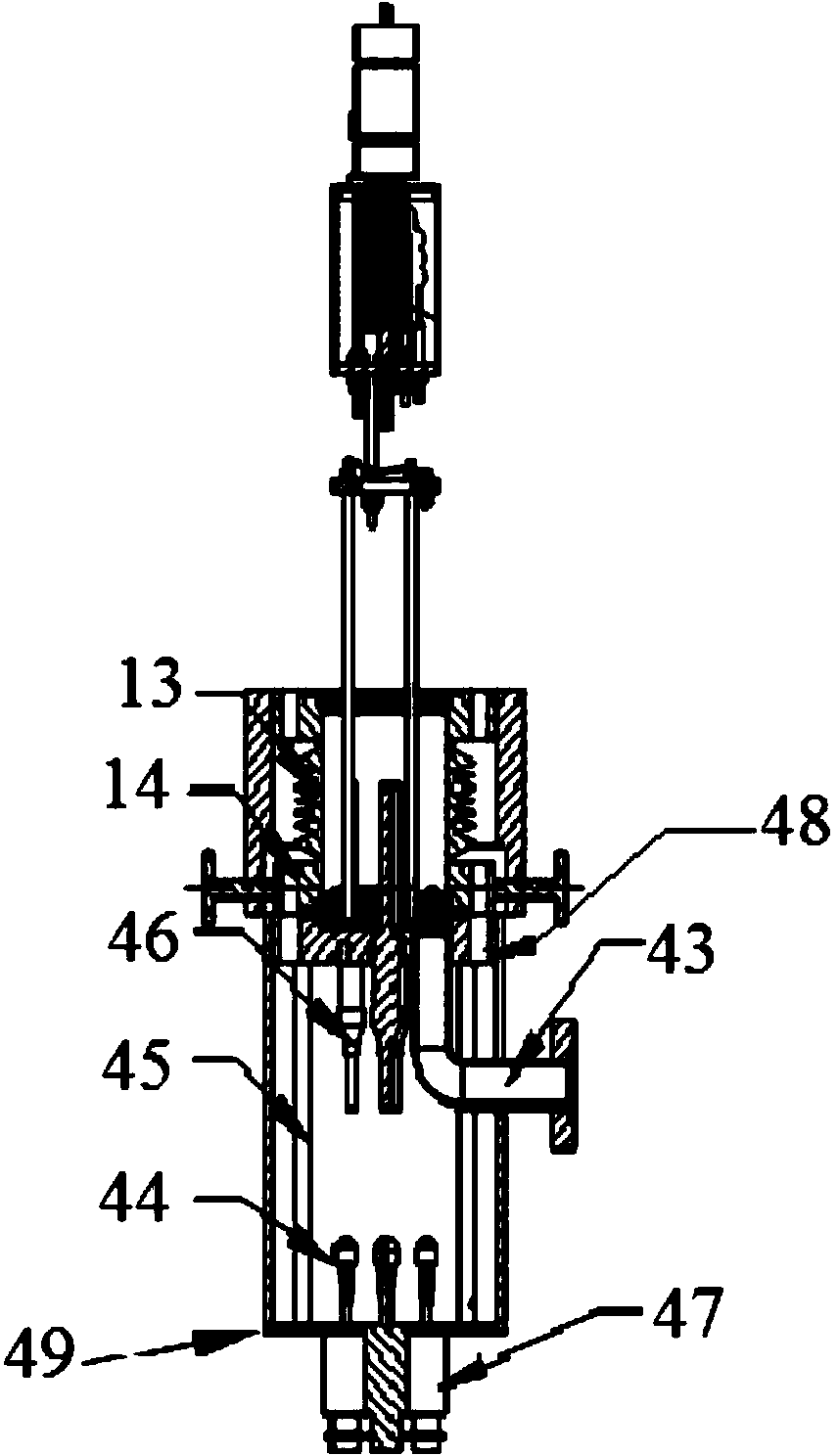

Sputtering ion gun

InactiveCN103474318ASimple structureEasy to useElectric discharge tubesSurface cleaningTherapeutic effect

The invention discloses a sputtering ion gun which is provided with an airflow direction regulating device, an argon ion generating device and a focusing lens, wherein the argon ion generating device is internally provided with an on-load voltage adjustable electronic accelerating grid mesh and a lamp filament correlated with a reference point position of the electronic accelerating grid mesh; one side wall of the electronic accelerating grid mesh is provided with a circular tube of a metal mesh; the electronic accelerating grid mesh is provided with a grid mesh anode at the front end and a grid mesh cathode at the rear end; the motion speeds of argon ions along the axial direction of the grid mesh are controlled through regulating a voltage loaded on the electronic accelerating grid mesh, thus the ion generating efficiency is regulated. The sputtering ion gun can be used alone during surface etching or deep analysis, and can be used for obtaining an improved surface treatment effect and ensuring that a surface treatment process is controllable. The ion sputtering and vacuum annealing can be adopted for performing repeated circular treatment during sample surface cleaning treatment or surface reconstruction. The material of the whole set of ion gun completely meets the requirement for use in an ultrahigh-vacuum environment, and can resist to baking at high temperature of over 200 DEG C.

Owner:DALIAN JIAOTONG UNIVERSITY

Antireflective member, optical element, display device, method of making stamper and method of making antireflective member using the stamper

ActiveCN101566699ASuppression of regular reflectionImprove anti-reflection effectAnodisationOptical elementsSurface patternAngle of incidence

An antireflective member according to the present invention has an uneven surface pattern, in which unit structures are arranged in x and y directions at respective periods that are both shorter than the shortest wavelength of an incoming light ray, on the surface of a substrate and satisfies the following inequality (1): lambda, / lambda ) . . ., where lambda is the shortest wavelength of the incoming light ray, theta i is the largest angle of incidence of the incoming light ray, ni is the refractive index of an incidence medium, lambda is the period of the uneven surface pattern in the x direction, and lambda is the period of the pattern in the y direction. As a result, diffraction of short-wave light components can be reduced in a broad wavelength range.

Owner:SHARP KK

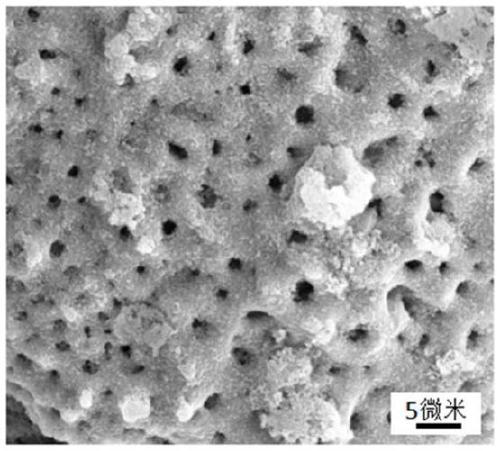

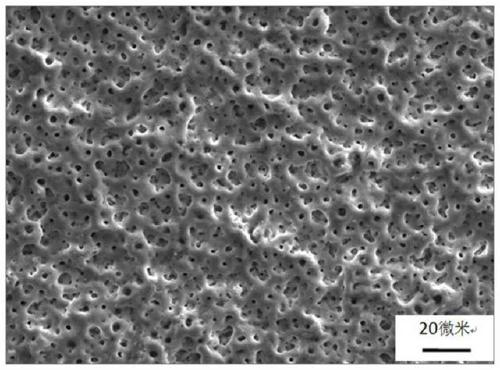

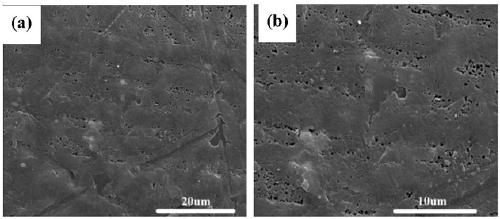

Preparation method of bioactive porous tantalum implant

ActiveCN111481738AImprove dissociation abilityImprove distribution uniformitySurface reaction electrolytic coatingTissue regenerationElectrolytic agentMicro arc oxidation

The invention discloses a preparation method of a bioactive porous tantalum implant, which comprises the following steps: carrying out acid pickling treatment on a three-dimensional porous tantalum implant material to obtain a pretreated material; performing micro-arc oxidation treatment on the pretreated material, an in-situ growth film layer with bioactive substances is formed on the surface ofthe pretreated material, and an electrolyte adopted in the micro-arc oxidation treatment comprises bioactive functional substances; and carrying out hydrothermal treatment on the in-situ growth film layer to obtain the bioactive porous tantalum implant. Tests prove that the in-situ growth film layer can effectively endow the three-dimensional porous tantalum implant material with a biological activity function. The prepared porous tantalum implant with the living activity is simple in technological process, easy to realize industrial production, simple in electrolyte and hydrothermal treatmentsolution components, free of pollutants, easy to control and low in cost, can be used for preparing various orthopaedic implant materials, and has a wide application prospect.

Owner:天衍医疗器材有限公司

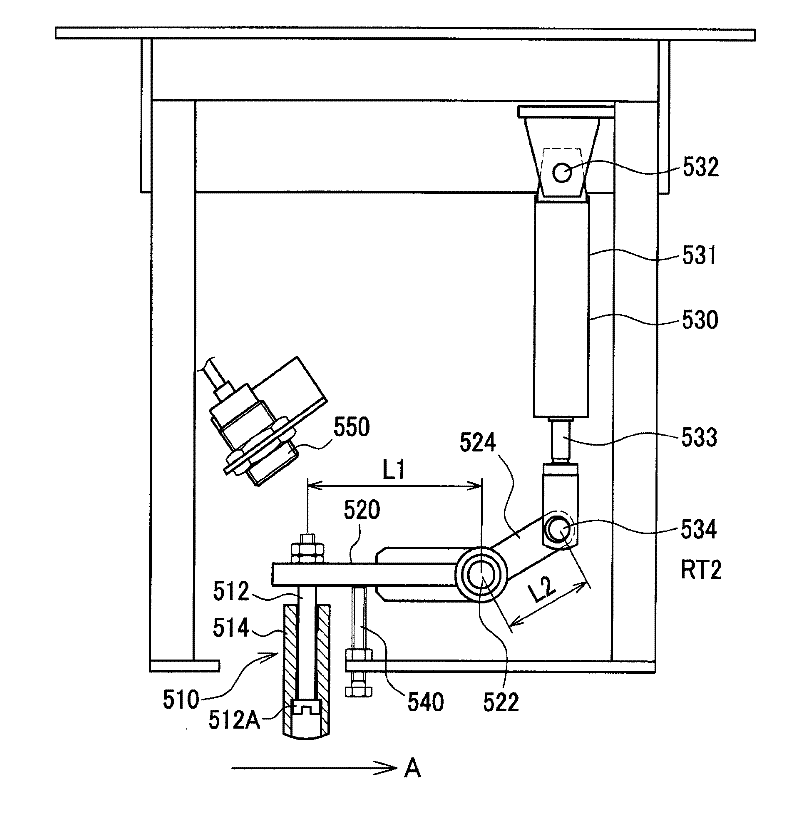

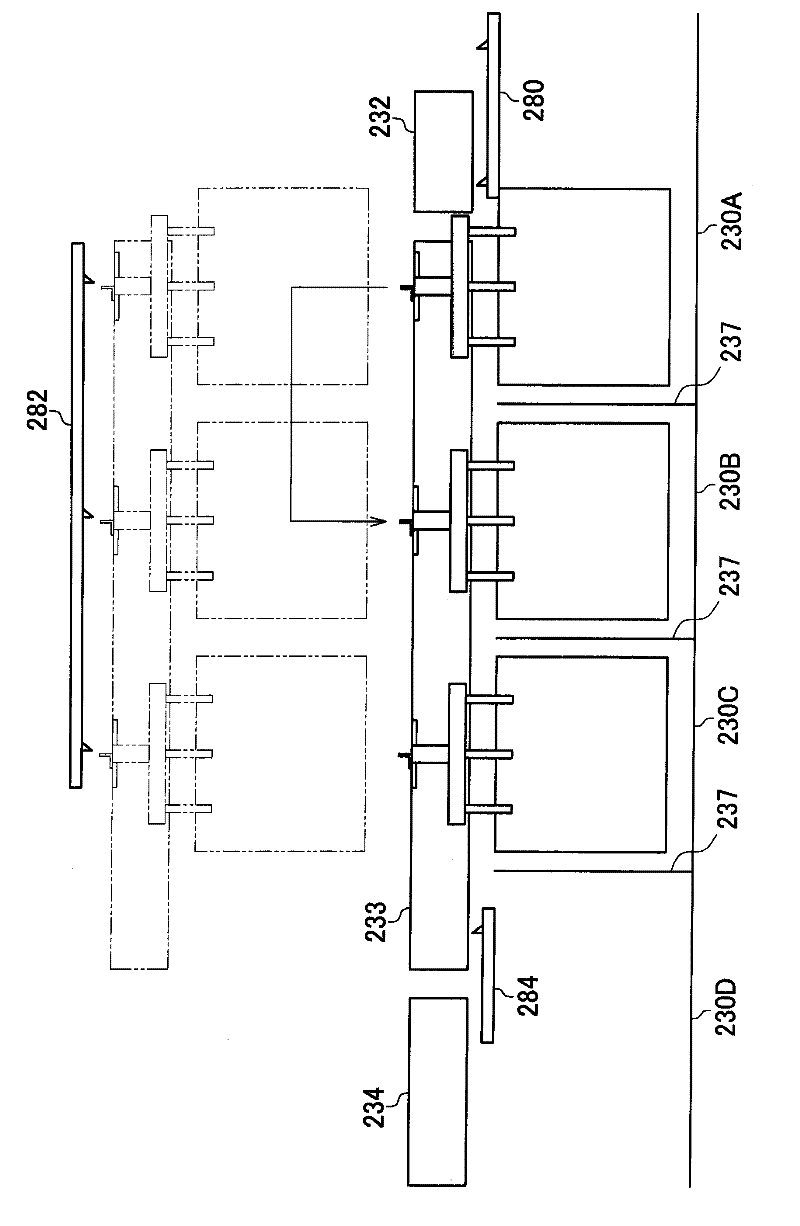

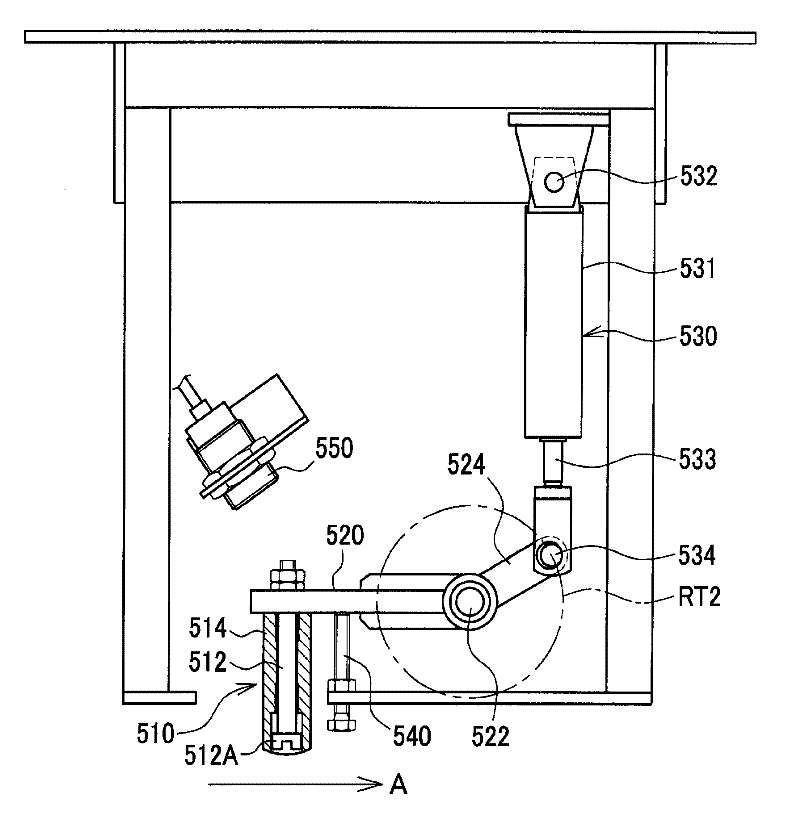

Surface Processing Device

InactiveCN102409387AImprove the effect of surface treatmentMovement speed increaseCellsSemiconductor devicesMechanical engineeringSurface processing

The invention provides a surface processing device. The surface processing device can remove bubbles adhering to the surface and in holes of a work piece physically, and improve the surface processing ability. The surface processing device used for processing the surface of the work piece (20) is provided with a guide rail (201, 231-235); a transporting fixture (30) guided by the guide rail and transporting and retaining the work piece in a transporting direction (A) along the guide rail; a surface processing groove (200) used for surface processing of the work piece retained by the transporting fixture; a front processing groove (230A) arranged on a side of the upper stream of the transporting direction (A) of the surface processing groove and dipping the work piece retained by the transporting fixture into processing liquid (290) for processing; and a vibration giving part (500) giving vibration to the transporting fixture retaining the work piece dipped in the processing liquid in the preprocessing groove, thereby letting the work piece vibrate in the processing liquid.

Owner:ALMEX PE INC

Environment-friendly chromium-free rust-proof passivation solution and preparation method thereof

InactiveCN107699883AImprove the effect of surface treatmentImprove adhesionMetallic material coating processesCerium nitrateCerium nitrate hexahydrate

The invention discloses an environment-friendly chromium-free rust-proof passivation solution. The rust-proof passivation solution is prepared from the raw materials of, by weight, 100 parts of deionized water, 2-10 parts of salicylic acid, 4-10 parts of benzotriazole, 3-10 parts of sodium citrate, 2-10 parts of 2-chlorine-4,5-dihydro-1H-imidazole sulfonate, 1-10 parts of hexafluorotitanic acid, 1-5 parts of sodium gluconate, 1-5 parts of zinc oxide, 4-10 parts of cerium nitrate, 3-10 parts of silane-modified polyphosphazene-polyethersulfone block copolymers, 5-10 parts of silver nitrate, 1-10parts of n-butanol, 1-5 parts of sodium silicate, 1-5 parts of 2-mercapto benzimidazole-5-sodium sulfonate dehydrate, 1-10 parts of oxalic acid, 1-5 parts of ethyl alcohol and 1-5 parts of 3-[(methylol)methylamine] ethanesulfonic acid. The obtained environment-friendly chromium-free rust-proof passivation solution can be used for low-temperature surface treatment, is high in surface treatment efficiency, environmentally friendly and good in rust-proof performance and has good market prospects.

Owner:JINGMEN TUODA TECH CO LTD

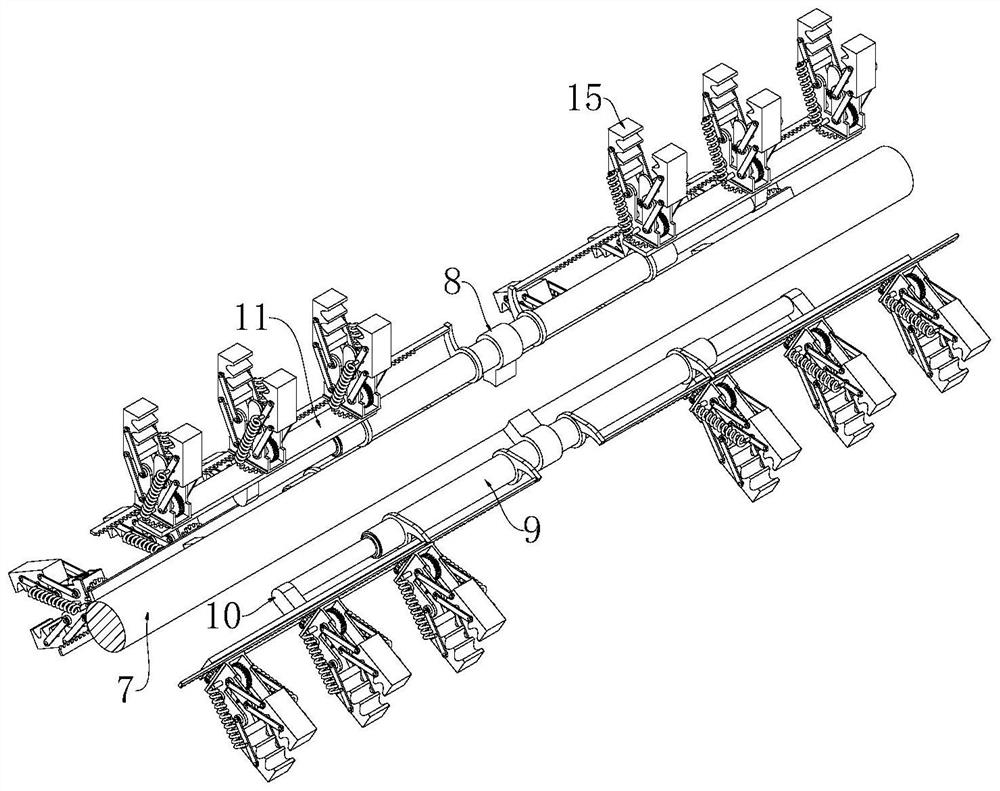

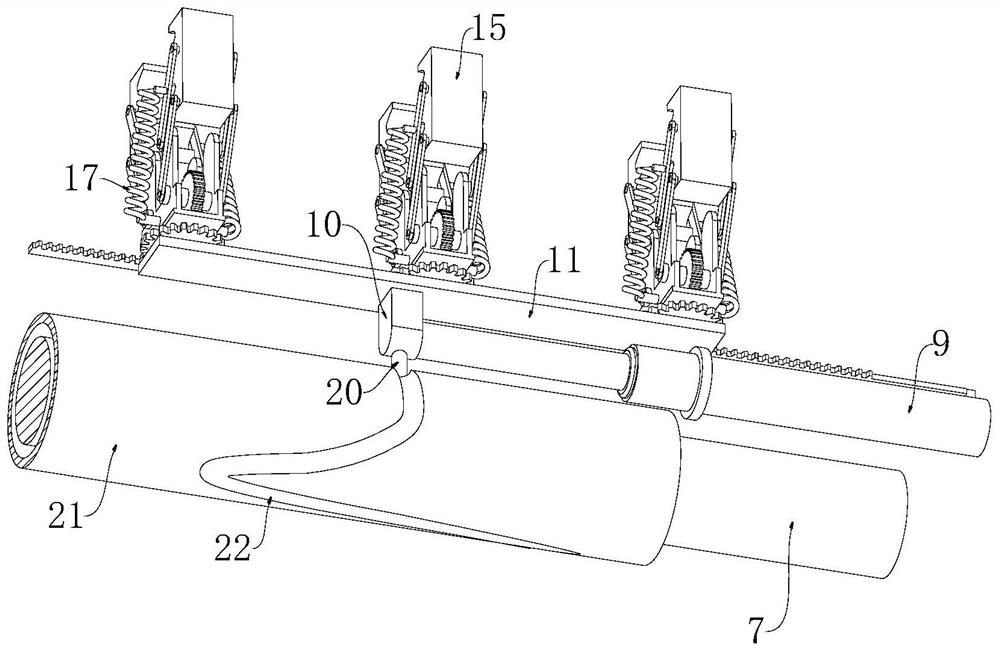

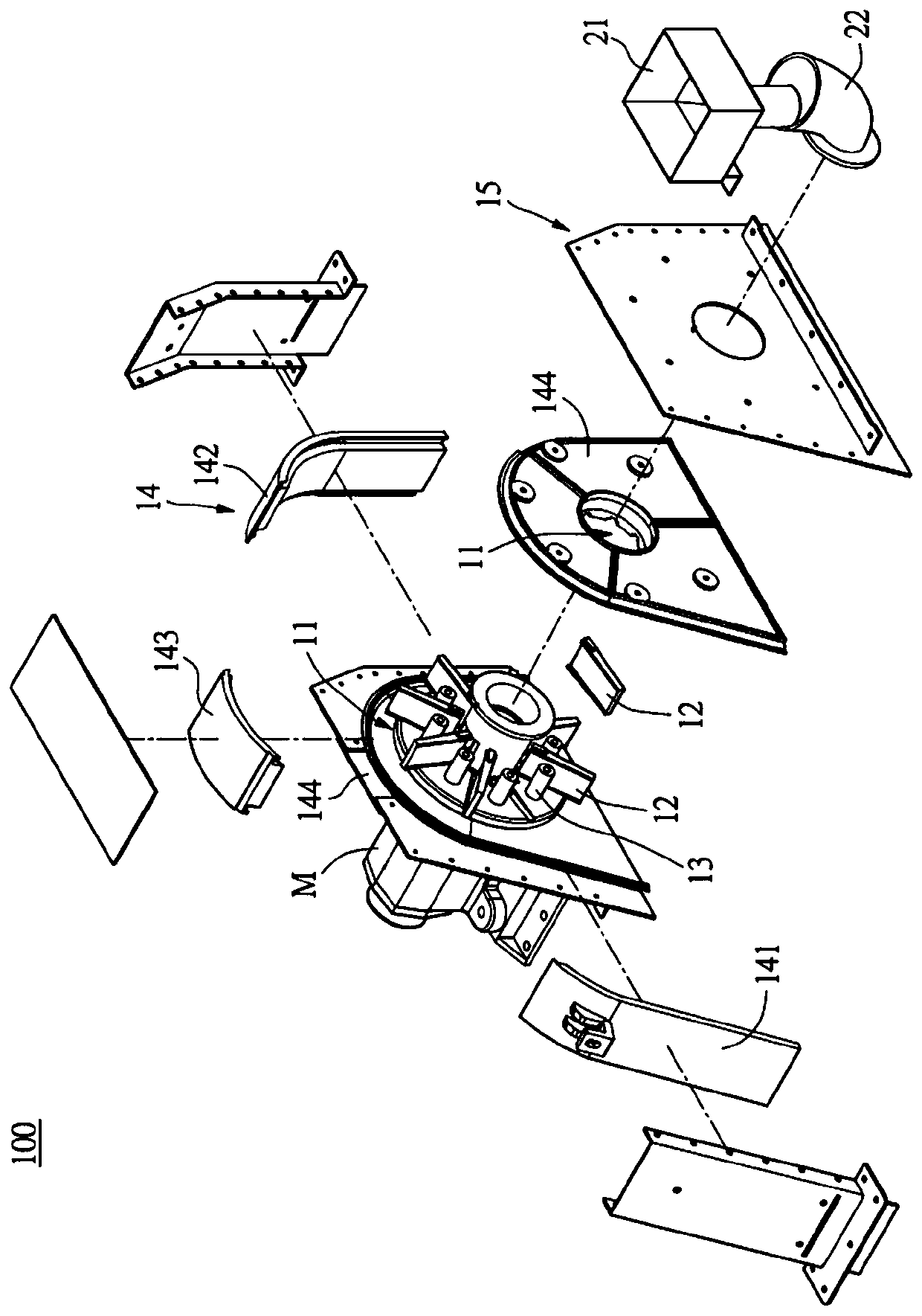

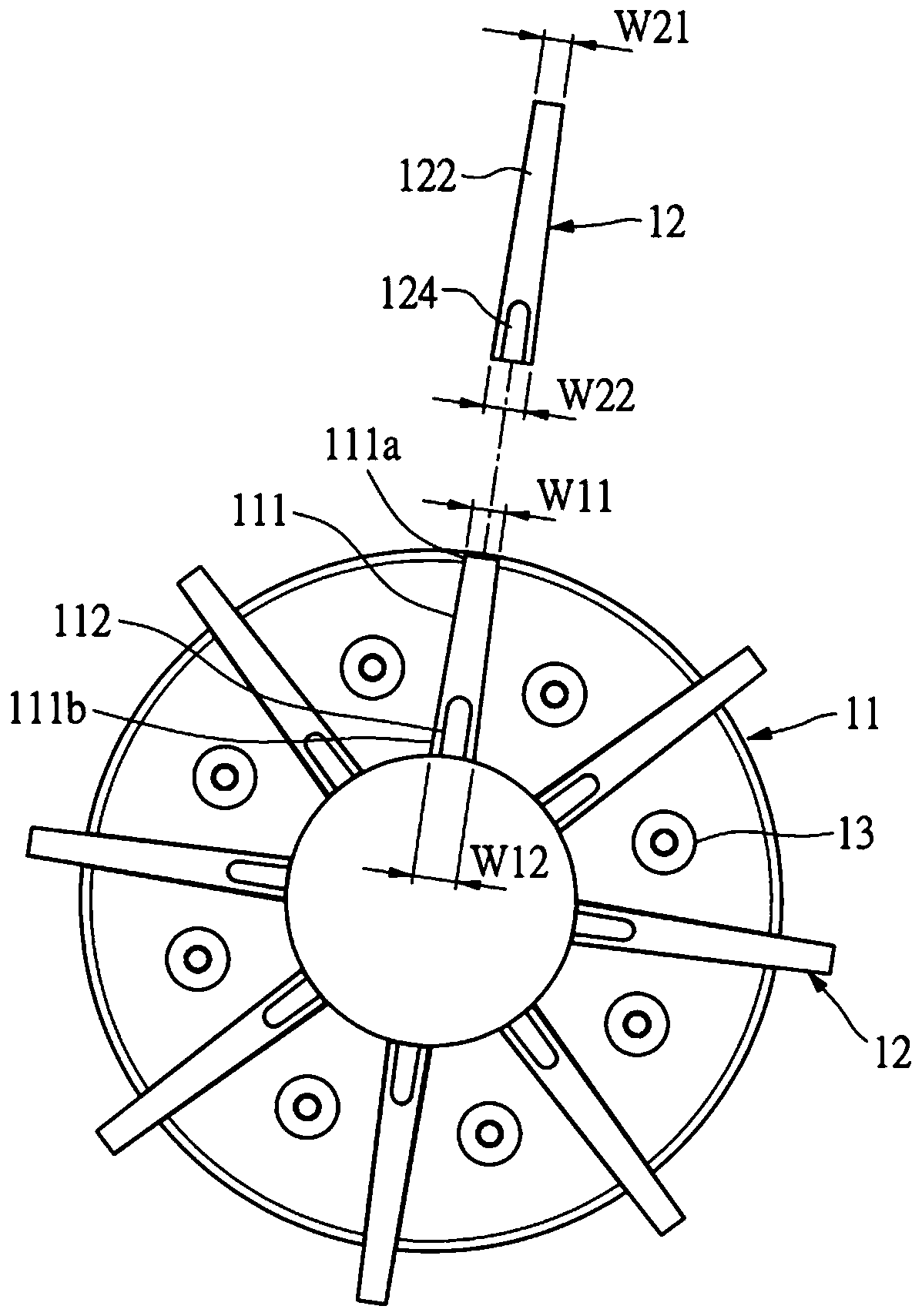

Impeller equipment for sand blasting-shot peening machine table, and sand blasting-shot peening machine table

PendingCN110625537AImprove fatigue strengthHigh hardnessImpeller wheelsRotor bladesImpellerGroove width

The invention provides impeller equipment for a sand blasting-shot peening machine table, and the sand blasting-shot peening machine table. The sand blasting-shot peening machine table comprises particle treatment equipment, at least one piece of impeller equipment, one piece of collection equipment, and one piece of lift equipment. The impeller equipment comprises two oppositely-arranged rotary discs, a plurality of blades, a plurality of connection rods, and a protection box body, and each rotary disc is provided with a central hole, a plurality of blade grooves and a plurality of limit grooves. Each blade groove is provided with a groove bottom adjacent to the central hole and a groove top adjacent to the circumference. The inner-groove width of the groove bottom is greater than the inner-groove width of the groove top. Each blade is provided with a blade plate part and two oppositely-arranged side plate parts, and each side plate part is provided with a limit lug. The side plate parts are accommodated into the blade grooves, the limit lugs are accommodated into the limit grooves, and the root width of each side plate part is greater than the top width; the plurality of connection rods are connected with the two oppositely-arranged rotary discs; and the protection box body is provided with a front inclined baffle and a rear baffle, and the front inclined baffle is inclined towards a sand blasting-shot peening outlet surface.

Owner:KUNSHAN AIRBAG PACKING CORP

Production technology for elevator balance chain

PendingCN111618532AIncrease the carrying loadAvoid distortionManufacturing engineeringSurface smoothness

The invention relates to a production technology for an elevator balance chain. The production technology comprises the following steps of: S1: pointing; S2: drawing wires: carrying out drawing processing on a steel material by an inverted wire drawing machine, in a wire drawing process, adding wire drawing powders to lubricate the steel material, recycling the wire drawing powders, and supplementing taken-away loss in fixed time so as to prevent from generating waste wire drawing powders; S3: knitting: enabling the steel material to be formed into a spiral shape by a chain automatic knittingmachine, shearing the spiral steel material to enable the spiral steel material to be formed into an annular shape, clamping two ends of the annular steel material, enabling one end to rotate for 45 degrees, twisting a chain link into a three-dimensional annular shape to finish the shaping of one chain link, feeding the spiral material to enable the spiral material to penetrate through the shapedchain link, and circulating to form the chain; S4: carrying out butt welding; S5: correcting; and S6: carrying out shot blasting: utilizing friction between leather and the chain to carry out lubricating and polishing processing on the balance chain. The production technology has the following advantages that the bearing load of the elevator balance chain is improved, the elevator balance chain isprevented from twisting and deforming, and a surface degree of finish and surface smoothness can be improved.

Owner:南通市博创新材料有限公司

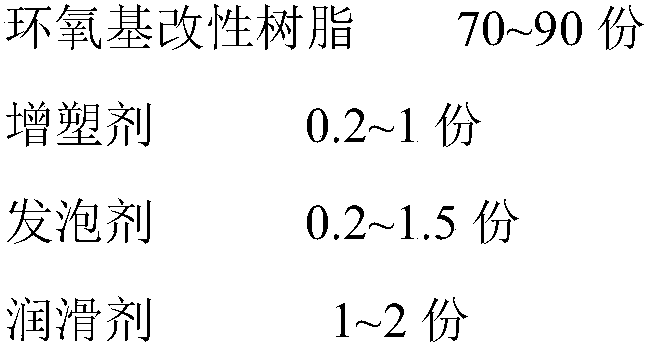

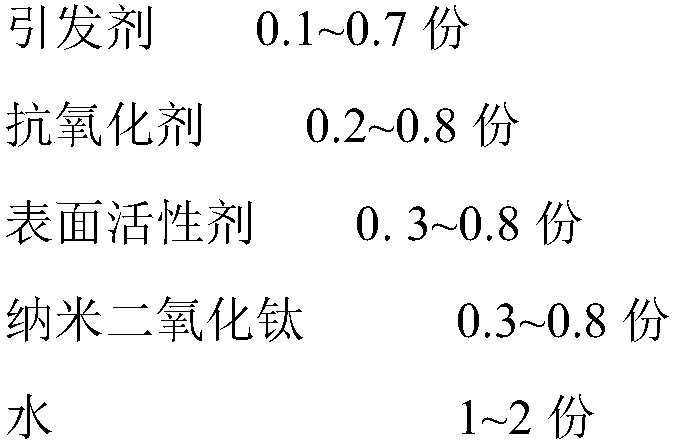

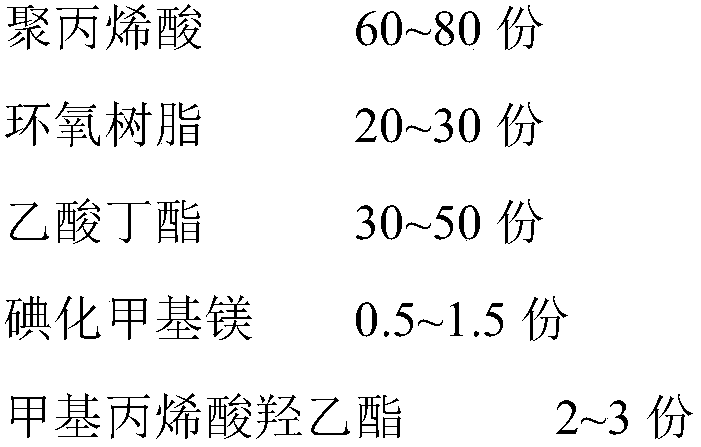

Nanometer titania antibacterial plastic and production process thereof

The invention relates to the technical field of antibacterial plastics and in particular relates to a nanometer titania antibacterial plastic and a production process thereof. The nanometer titania antibacterial plastic is prepared from 70-90 parts of epoxy modified resin, 0.2-1 part of a plasticizer, 0.2-1.5 parts of a foaming agent, 0.5-1 part of ethylene bis-stearamide, 0.5-1 part of zinc stearate, 0.1-0.7 part of an initiator, 0.2-0.8 part of an antioxidant, 0.3-0.8 part of a surfactant, 0.3-0.8 part of nanometer titania and 1-2 parts of water. The nanometer titania antibacterial plastic has uniform and lasting antibacterial effects. The production process of the nanometer titania antibacterial plastic comprises the following steps: 1, preparing epoxy modified resin; 2, performing surface treatment on nanometer titania; 3, performing melt mixing on the epoxy modified resin and the nanometer titania subjected to surface treatment; and 4, performing extruded granulation. The nanometer titania antibacterial plastic has the advantage of being easy to operate.

Owner:GUANGDONG GUOLI SCI & TECH CO LTD

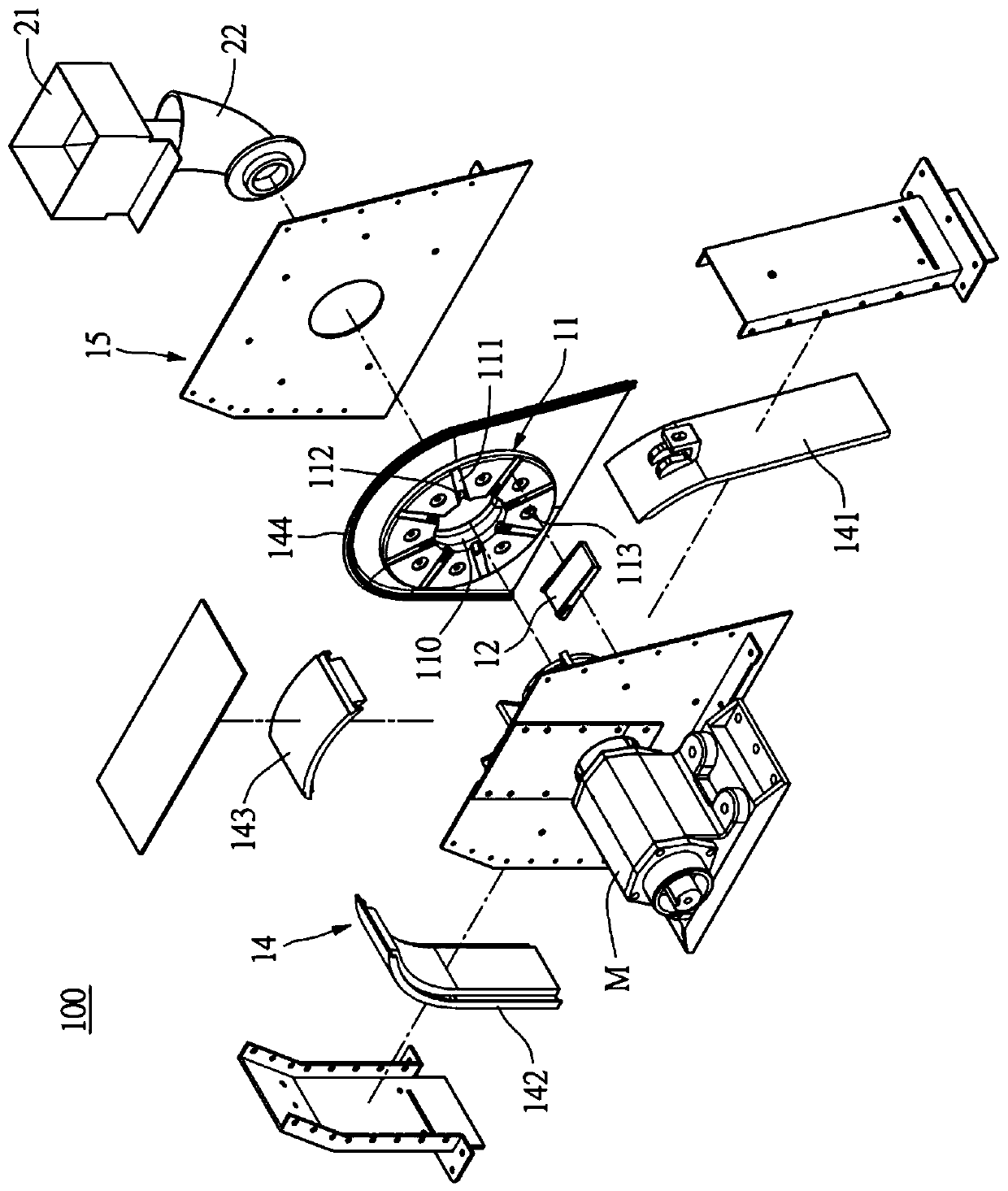

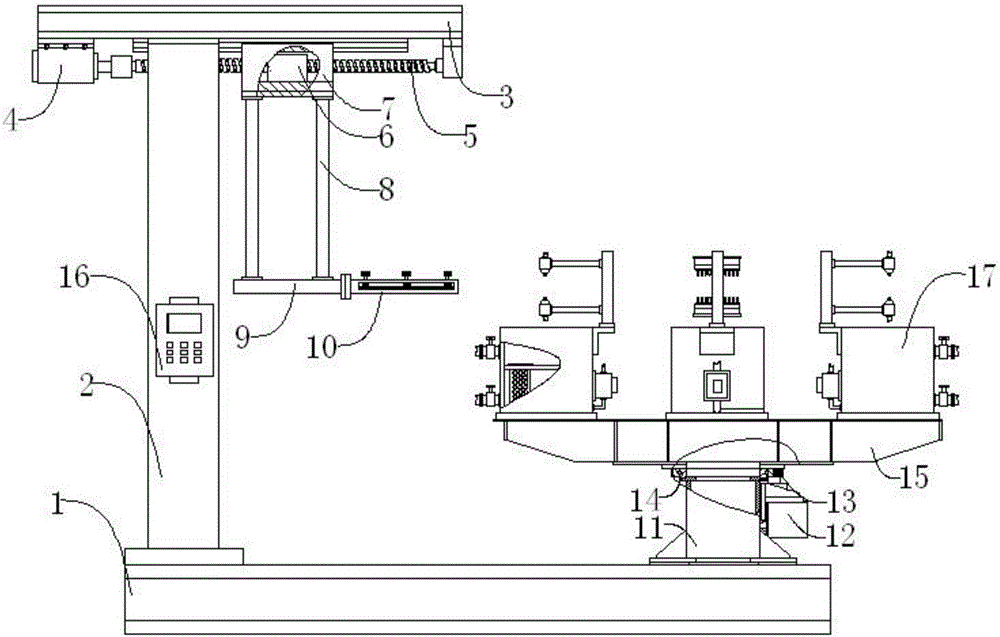

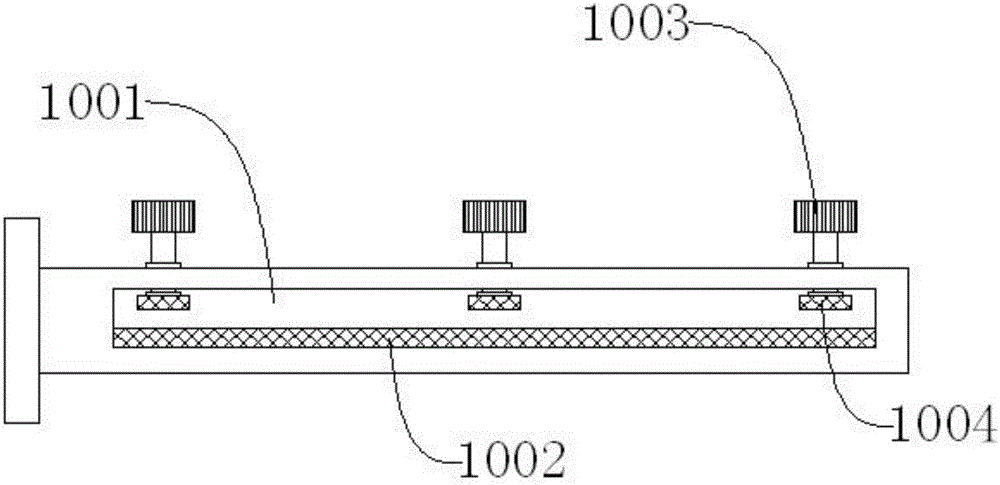

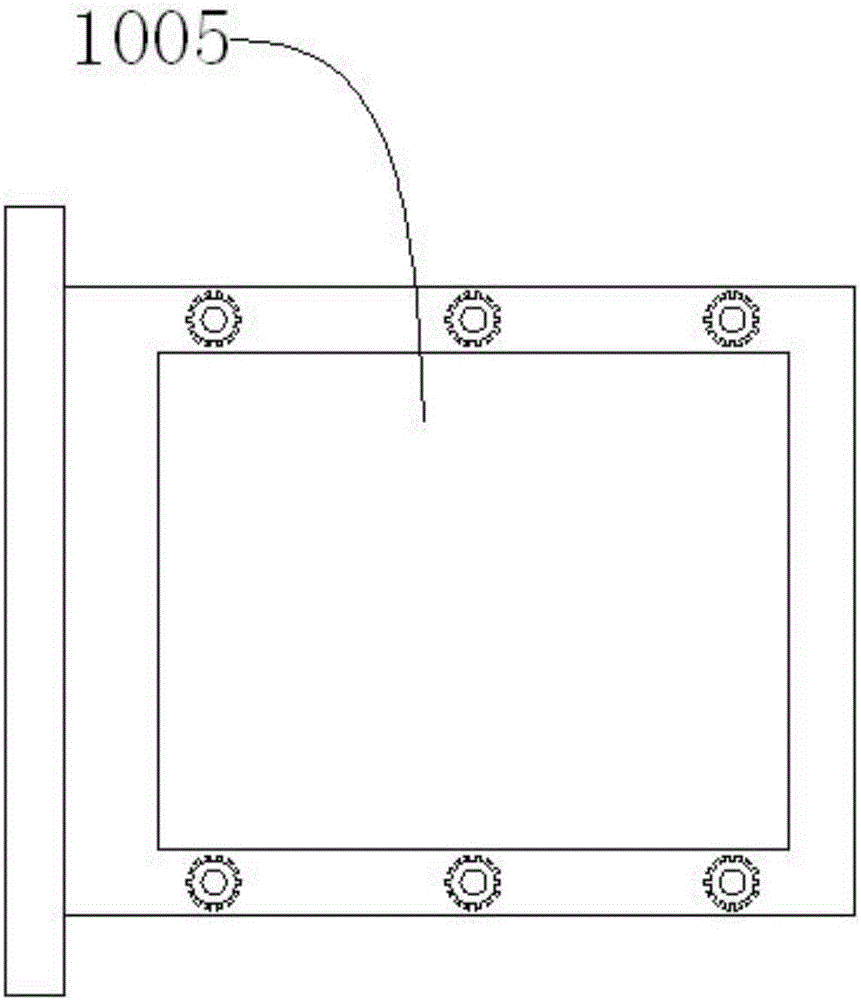

Rotary printed circuit board (PCB) surface automatic processing apparatus

ActiveCN106211602AImprove the effect of surface treatmentHigh degree of automationConductive material chemical/electrolytical removalCircuit liquid treatmentsElectric machinerySmall footprint

The present invention discloses a rotary printed circuit board (PCB) surface automatic processing apparatus. The apparatus comprises a base, two uprights disposed parallelly along the base, a top frame, a first servo motor, a screw, a feed nut, a slide base, two support rods disposed symmetrically along the slide base, a support plate, a clamping frame, a support base, a second servo motor, a gear, a rotary support, a workbench, a controller, and at least two sets of surface treatment mechanism. A PCB is put in a clamp slot, hand screws are tightened by hands so as to fix the PCB, and the controller controls the second servo motor to rotate by a set angle, so that the workbench is driven to rotate by a set angle; then the first servo motor rotates by a set angle, so that the clamping frame moves by a set distance; next, a corrosion-resistant pump pumps a liquid medicine to a water knife, so that the surface of the PCB is treated; and the treated liquid medicine flows into a through so as to be collected, and a filter filters waste bits in the liquid medicine so that the liquid medicine is recycled. The apparatus has a simple structure, is simple and convenient to operate, occupies a small area, and has high automation degree.

Owner:苏州市相城区姑苏线路板厂

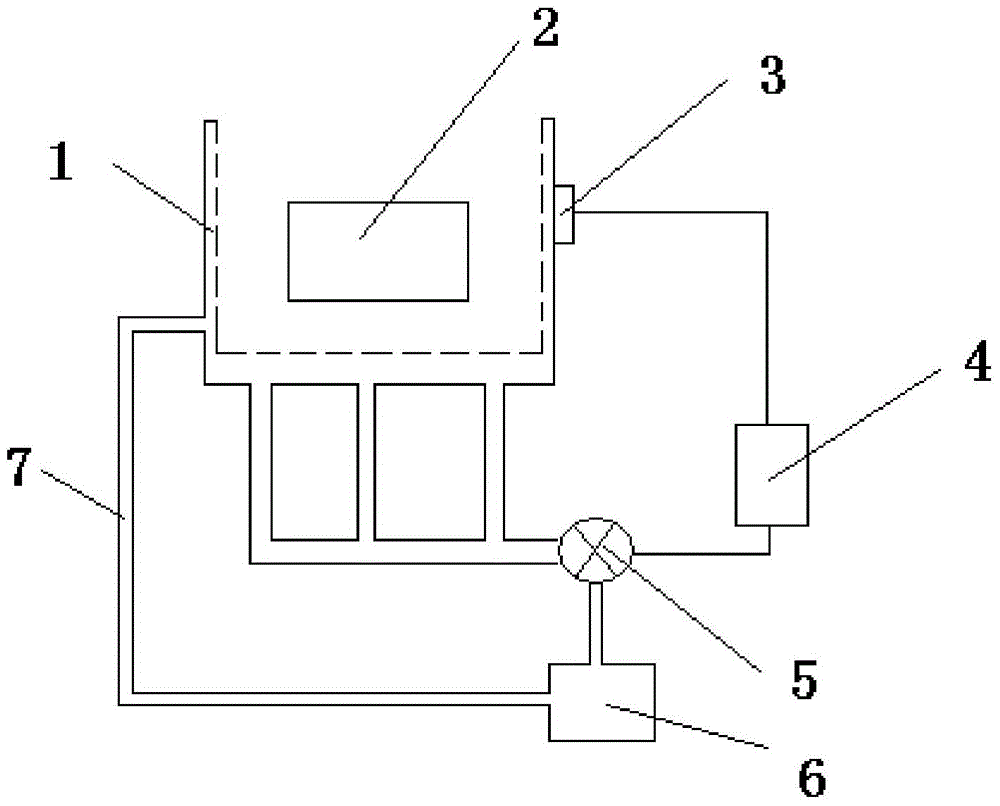

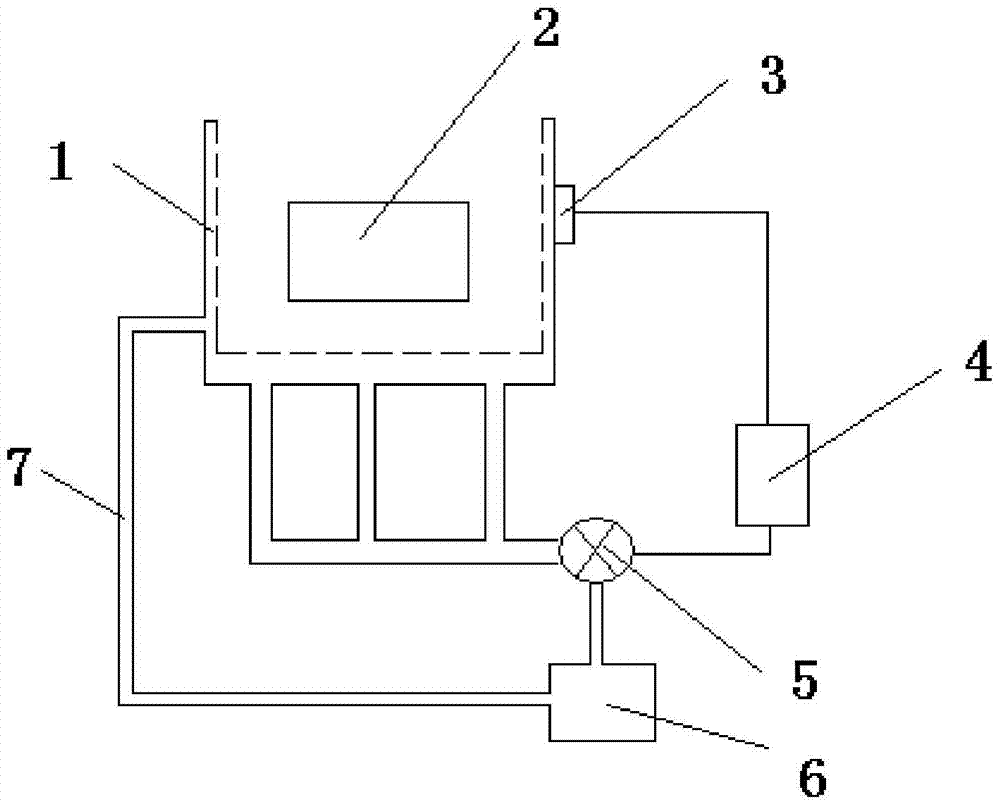

Magnesium-lithium alloy surface treatment device

ActiveCN104862685AEfficiency for uniform surface preparationImprove Surface Treatment EfficiencyMetallic material coating processesLithiumSalt spray test

The invention discloses a magnesium-lithium alloy surface treatment device, and aims to enable a magnesium-lithium alloy to be uniform in a conversion film layer in the chemical conversion process and to generate no corrosion spots in inspection by a salt spray test. The magnesium-lithium alloy surface treatment device is characterized by comprising a treatment tank for placing treatment liquid, wherein multiple liquid spray holes are formed in the bottom of the treatment tank; the liquid spray holes are connected with a variable frequency pump through a liquid channel formed in the bottom of the treatment tank; the variable frequency pump is connected to a treatment liquid source; a control end of the variable frequency pump is connected to a controller; a position sensor is arranged on the side wall of the treatment tank, and is connected to the controller; when a magnesium-lithium alloy workpiece is treated, the treatment liquid is sprayed through the liquid spray holes to suspend the magnesium-lithium alloy workpiece in the treatment liquid; the position sensor detects position change information of the magnesium-lithium alloy workpiece to return to the controller; and the controller adjusts the liquid outlet pressure of the variable frequency pump according to the position change information so as to stably suspend the magnesium-lithium alloy workpiece in the treatment liquid.

Owner:西安四方超轻材料有限公司

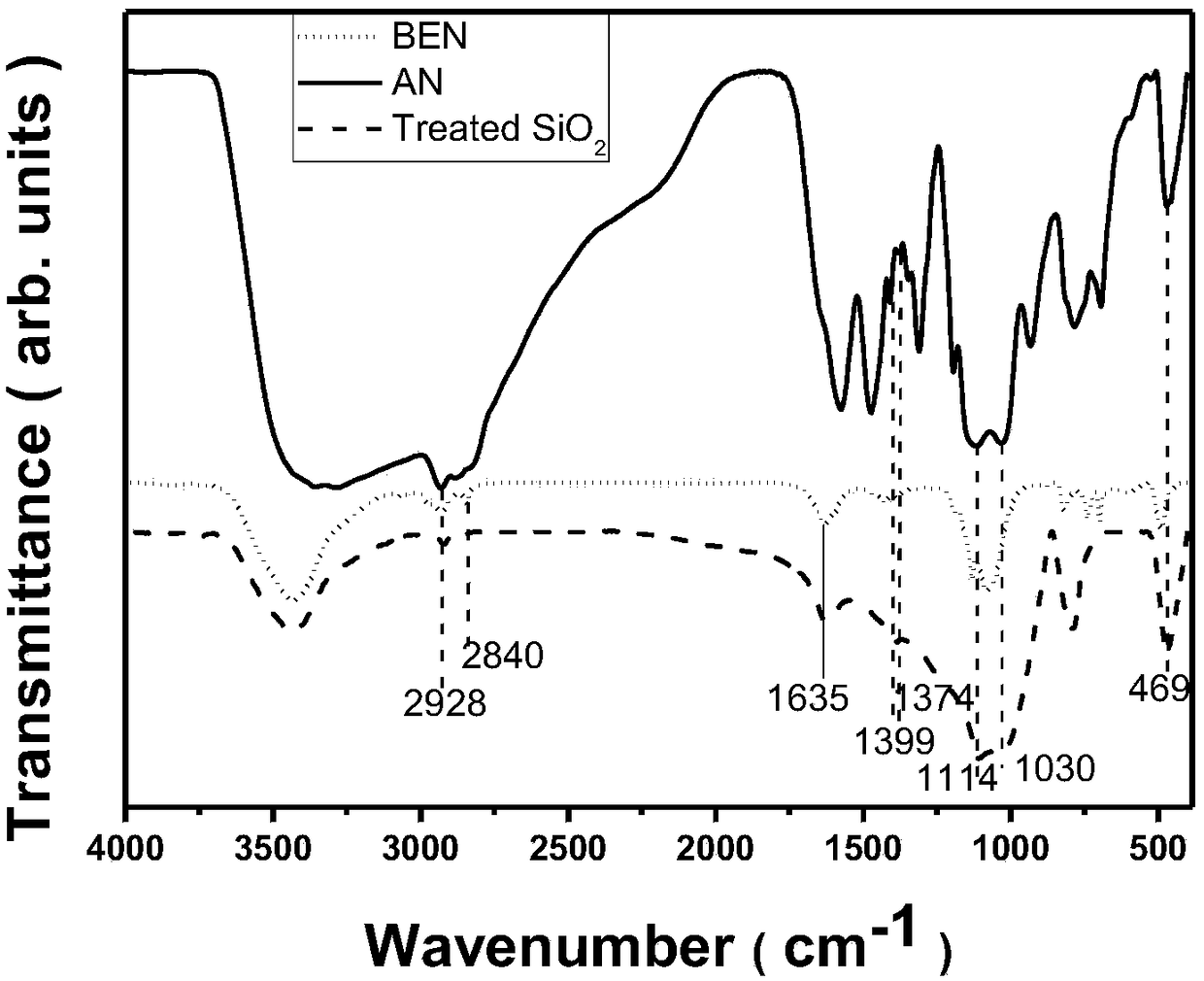

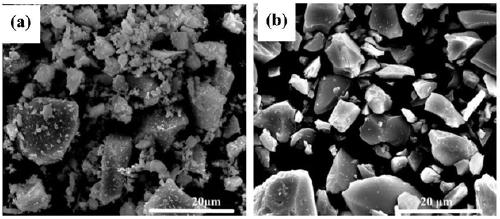

Preparation method of ceramic filled polytetrafluoroethylene microwave composite dielectric substrate

ActiveCN107474312BImprove the effect of surface treatmentBall milling process is simpleFiltrationDielectric substrate

A preparing method of a ceramic-filled polytetrafluoroethylene microwave composite-medium substrate is disclosed. The method includes 1) adding silicon dioxide ceramic powder into a liquid mixture of hydrogen peroxide and concentrated hydrochloric acid after the silicon dioxide ceramic powder is dried, and heating the mixture to 50-70 DEG C to obtain a suspension; 2) subjecting the suspension to suction filtration and drying a product in a vacuum environment; 3) adding the silicon dioxide ceramic powder obtained in the step 2) into a solution mixture of deionized water and absolute alcohol, adjusting the pH value to be 3-5, weighing a coupling agent the weight of which is 1.0-2.5% of the weight of the silicon dioxide ceramic powder, performing ball milling, and fully mixing the mixture to obtain a material mixture; 4) filtering and drying the material mixture to obtain modified silicon dioxide ceramic powder; 5) ball-milling and mixing the modified silicon dioxide powder, chopped glass fibers and polytetrafluoroethylene, and then performing demulsification to obtain dough; and 6) subjecting the dough to molding and hot-pressed sintering. The ceramic-filled material prepared by the method has a low dielectric constant (with epsilon being equal to 2.94), ultralow dielectric loss (with tg[delta] being less than 0.0008, 10 GHz), low water absorption (less than 0.02%) and a small thermal expansion coefficient (less than 20 ppm / DEG C).

Owner:汕头超声覆铜板科技有限公司

Iron oxide color paste and preparation method thereof

The invention discloses an iron oxide color paste, which comprises the following raw materials by weight: 55 parts of iron oxide pigment, 10 parts of an impregnating compound, 3 parts of a nano slurry, 5 parts of an organic silicon defoamer, 10 parts of lithium magnesium silicate and 40 parts of deionized water. The impregnating compound added into the iron oxide pigment is formed by combining lauryl sodium sulfate, a silane coupling agent KH560 and other surfactants, a coupling agent and the like, and aims to enable dual amphoteric surface treatment on the iron oxide pigment so as to enhancethe surface treatment effect, and the added modified silicon dioxide can enhance the contact effect of the impregnating compound and the iron oxide pigment, thereby enhancing the treatment capacity.

Owner:铜陵同达兴实业有限责任公司

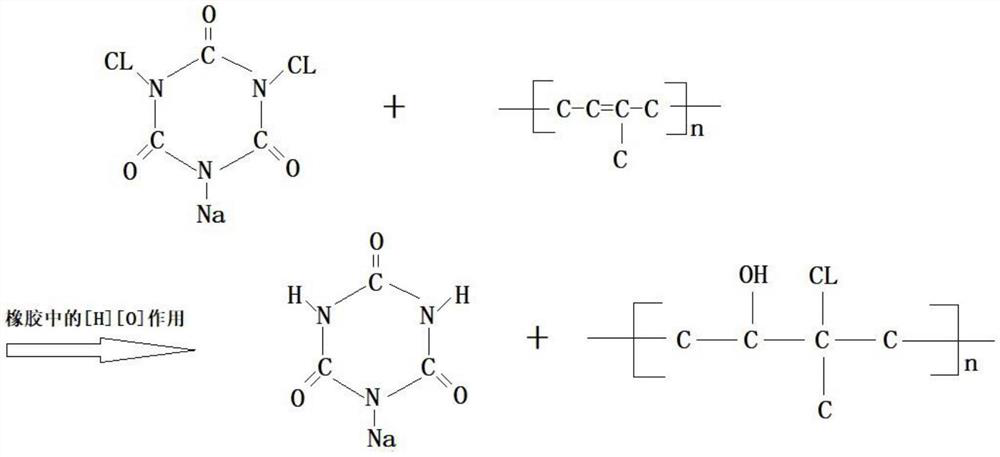

Water-based rubber treating agent

InactiveCN110183708AModified dispersion propertiesImprove the effect of surface treatmentAdhesive processes with surface pretreatmentBenzimidazoleMethyl methacrylate

The invention discloses a water-based rubber treating agent. The water-based rubber treating agent is prepared from raw materials in parts by weight as follows: 3-5 parts of nano-silica, 80-100 partsof methyl methacrylate, 10-15 parts of rosin, 3-5 parts of polyethylenimine, 4-7 parts of oleic acid, 0.3-1 part of 2-mercapto-benzimidazole, 20-30 parts of a rubber matrix, 2-4 parts of ammonium persulfate and 0.7-1 part of a dispersant. The treating agent improves a traditional organic solvent treatment method and is high in safety and environmental protection property and good in effect.

Owner:南宝树脂(佛山)有限公司

Automobile interior trim surface treatment technology

InactiveCN106884160AImprove the effect of surface treatmentImprove efficiencyLiquid/solution decomposition chemical coatingElectrolysisEngineering

The invention discloses a surface treatment process for automotive interior parts, which comprises the following steps: 1) ultrasonic degreasing; 2) roughening; 3) palladium activation; 4) debonding; 5) chemical nickel; 6) pre-nickel plating; 7) 8) semi-gloss nickel; 9) full-gloss nickel; 10) nickel seal; 11) decorative chrome; Improve the effect of surface treatment of automotive interior parts, increase the yield, good aesthetics, long service life, save costs and resources, and rationalize the boric acid in the electroplating process, so that the efficiency and effect of nickel plating are significantly improved improve.

Owner:宣城托新精密科技有限公司

Antireflective member, optical element, display device, method of making stamper and method of making antireflective member using the stamper

ActiveCN101566698ASuppression of regular reflectionImprove anti-reflection effectPrismsCoatingsSurface patternAngle of incidence

An antireflective member according to the present invention has an uneven surface pattern, in which unit structures are arranged in x and y directions at respective periods that are both shorter than the shortest wavelength of an incoming light ray, on the surface of a substrate and satisfies the following inequality (1): lambda, / lambda ) . . ., where lambda is the shortest wavelength of the incoming light ray, theta i is the largest angle of incidence of the incoming light ray, ni is the refractive index of an incidence medium, lambda is the period of the uneven surface pattern in the x direction, and lambda is the period of the pattern in the y direction. As a result, diffraction of short-wave light components can be reduced in a broad wavelength range.

Owner:SHARP KK

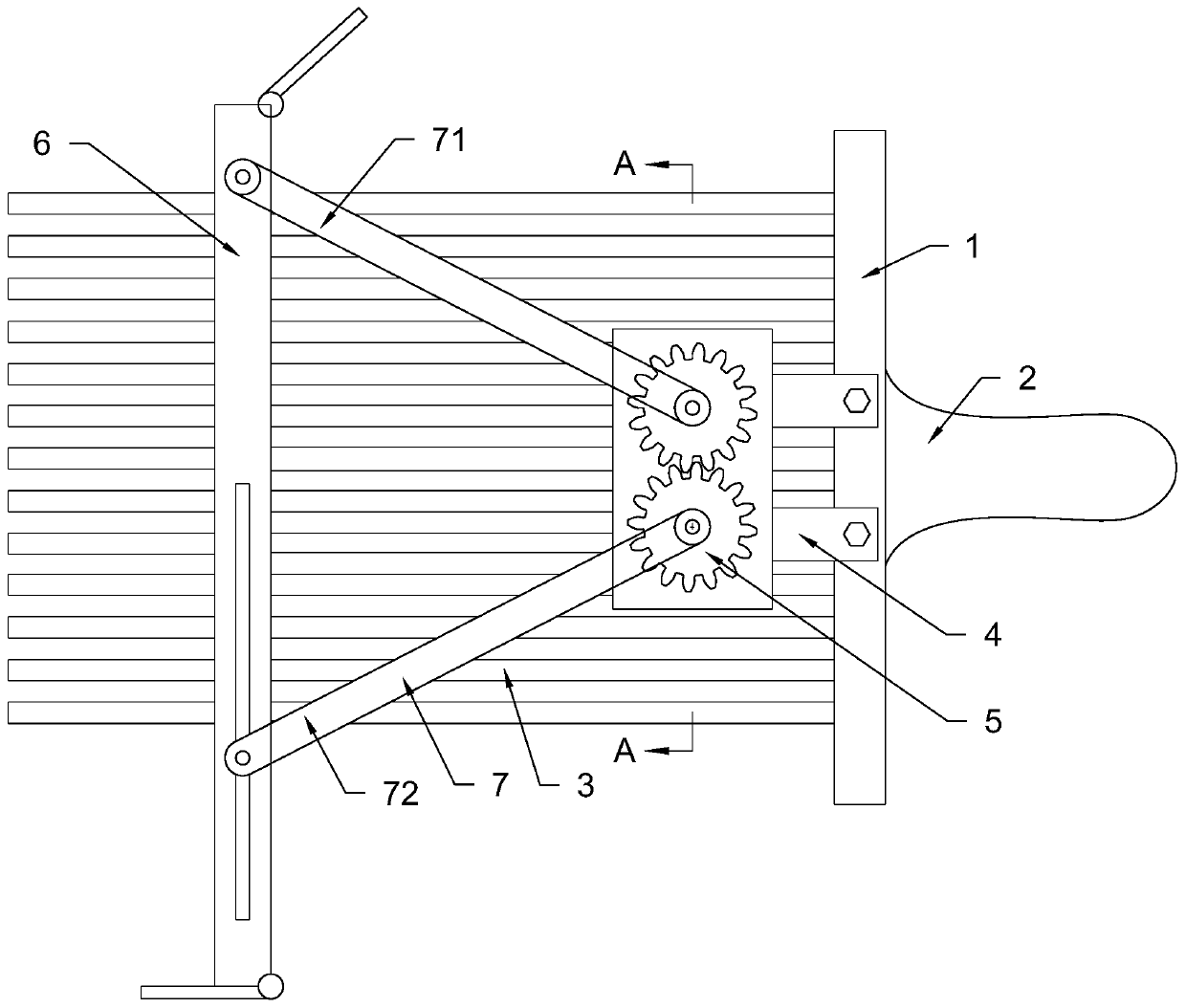

Tool for surface treatment

InactiveCN111571401AChange densityImprove the effect of surface treatmentGrinding drivesPortable grinding machinesBristleGear wheel

The invention relates to a product surface machining device, in particular to a tool for surface treatment. The tool for the surface treatment comprises a substrate, a handle, bristles, supporting frames, a gear set, a silk feeding adjusting plate, a connecting rod and round rods; the handle is arranged at the top of the substrate; the bristles are arranged at the bottom of the substrate; the supporting frames are arranged on the two side surfaces of the substrate; the gear set is arranged on the supporting frames and rotatably connected with the supporting frames; the two ends of the connecting rod are correspondingly arranged on the silk feeding adjusting plate and the gear set; the number of the round rods is several; the round rods are evenly arranged between the connecting rods; and the bristles pass through gaps between the round rods. According to the invention, by adjusting the position of the silk feeding adjusting plate, the silk feeding adjusting plate is driven to open outwards or approach inwards, the bristles between the round rods are scattered outwards or gathered inwards to change the density of the bristles and the length of silk feeding, so that the treatment ofdifferent degrees of pollution on the surface of a complex material is completed.

Owner:于鑫

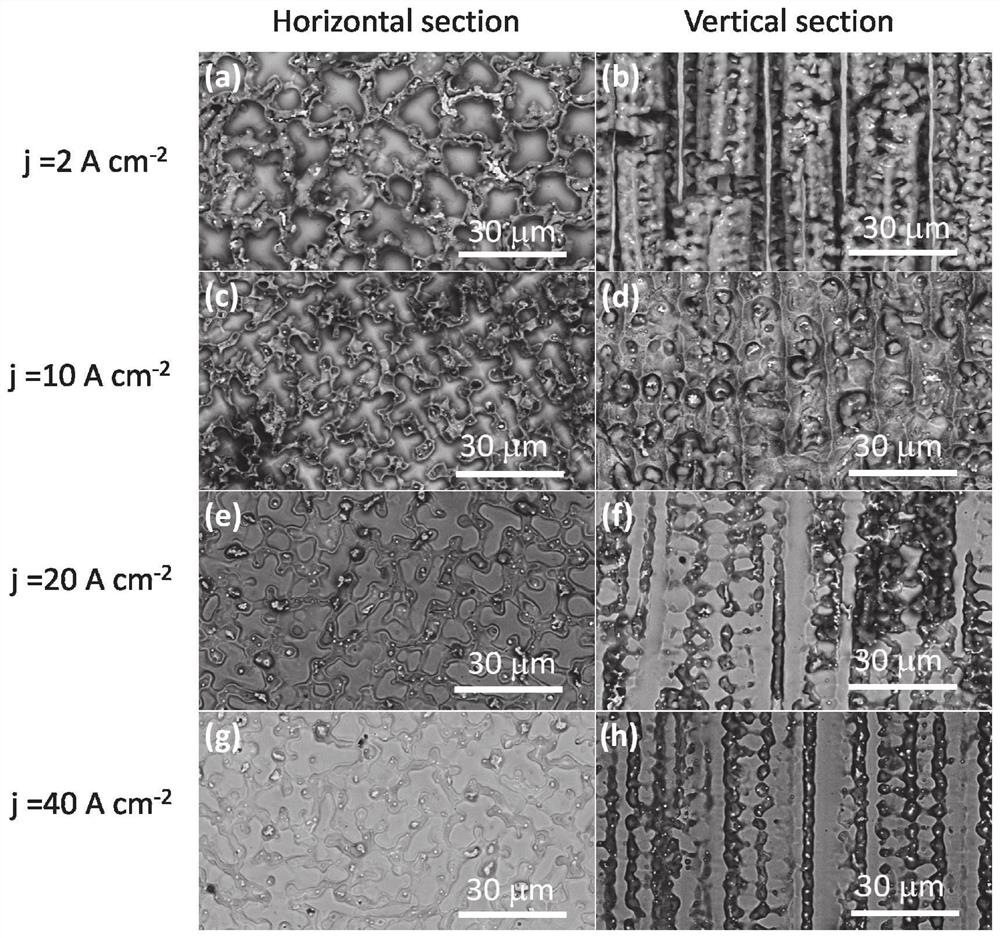

Machining method for improving micro-area surface quality of alloy component

ActiveCN113319386AImprove micro-flatnessImprove surface qualityMachining working mediaIncreasing energy efficiencyElectrolysisNanosecond pulse

The invention relates to the technical field of electrolytic machining of laser additive manufacturing, in particular to a machining method for improving the micro-area surface quality of an alloy component. By adopting a nanosecond pulse electrolytic machining process, the surface treatment effect of the alloy component can be further improved, and a high-quality surface workpiece can quickly and well obtained.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY +1

All-water-based rubber treating agent for shoe making industry

InactiveCN112920292AEasy to handleImprove the effect of surface treatmentRubber materialShoe industry

The invention discloses a full-water-based rubber treating agent for the shoe making industry. The treating agent the following raw materials in percentage by weight: 95%-99% of deionized water, 0.01%-0.04% of hydrophilic chlorinated rubber resin, 0.01%-0.04% of hydrophilic vinyl chloride-vinyl acetate resin, 0.01%-0.04% of modified organic acid, 0.01%-0.04% of inorganic acid, 0.5%-2% of an organic silicon surfactant, 0.5%-2% of a polysiloxane wetting agent and 0.01%-0.04% of an indicator. Modified aids with high adherence are introduced, the materials are dissolved for 1-2 hours under constant-speed stirring, so that the dispersing performance of the raw materials in polymer emulsion is modified, the surface treatment effect on rubber is improved, a full-water-based system is adopted, the problem of environmental pollution caused by the product is solved, the production cost is reduced, potential production safety hazards are eliminated, the treatment effect on rubber materials is good, and the later tension is greater than 4.5 kg / cm.

Owner:南宝树脂(佛山)有限公司

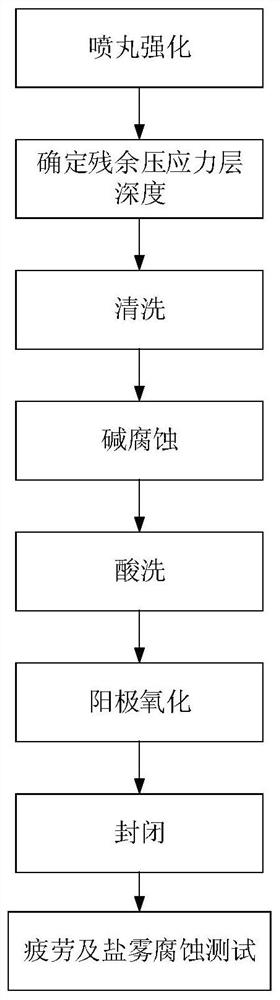

A method for improving corrosion resistance and fatigue resistance of aluminum alloys

ActiveCN113215634BImprove fatigue lifeAccelerated corrosionAnodisationProcess efficiency improvementAnodizingSocial benefits

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

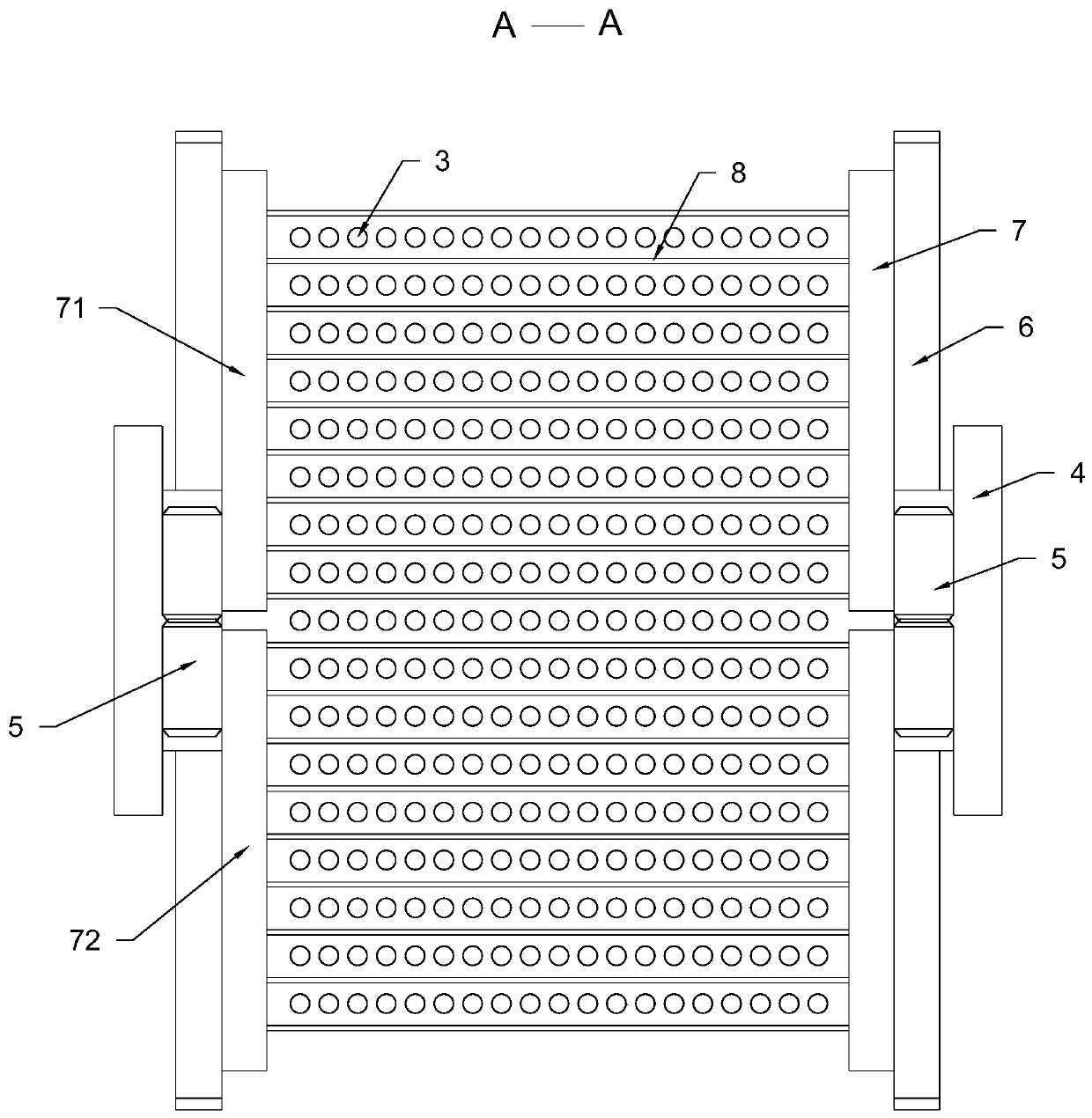

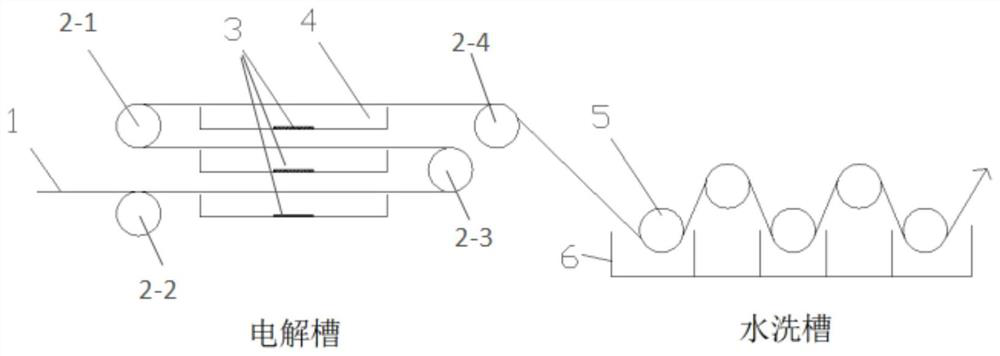

Surface treatment method of dry-jet wet-spinning high-modulus carbon fibers

ActiveCN114086386ASmall footprintReduce distanceAnodisationCarbon fibresPolymer chemistryElectrolytic cell

The invention discloses a surface treatment method for dry-jet wet-spinning high-modulus carbon fibers. The method comprises the following steps: electrolyzing the dry-jet wet-spinning high-modulus carbon fibers in a manner of connecting multiple stages of electrolytic cells in parallel, then washing the dry-jet wet-spinning high-modulus carbon fibers in a washing tank, and finally drying the dry-jet wet-spinning high-modulus carbon fibers in a contact drying manner. Based on the anodic oxidation surface treatment principle, the total resistance of a surface treatment section is reduced in a manner of connecting multiple stages of electrolytic cells in parallel, and the surface treatment electric quantity is increased to a greater extent within a safe voltage range; in the aspect of equipment layout, an up-and-down superposition mode is adopted, the occupied area is reduced, meanwhile, the distance of connecting wires is shortened, and the surface treatment electric quantity can be increased; and through matching of the electrolyte concentration, the temperature and the total electrolysis electric quantity, regulation and control of different surface treatment degrees of the high-modulus carbon fibers are achieved, and the method is suitable for preparing the dry-jet wet-spinning high-modulus carbon fibers needing higher surface treatment degrees.

Owner:ZHONGFU SHENYING CARBON FIBER

Automobile component surface treatment spraying system

InactiveCN106607288AImprove the use effectImprove the effect of surface treatmentLiquid surface applicatorsCoatingsMotor vehicle partSurface finishing

The invention relates to an automobile component surface treatment spraying system. The automobile component surface treatment spraying system comprises a bottom supporting system. A spraying chamber is arranged at the upper portion of the bottom supporting system. A left bearing mechanism and a right bearing mechanism are arranged on the left side and the right side of the spraying chamber correspondingly. A top supporting connecting mechanism system is arranged at the upper portion of the left bearing mechanism and the upper portion of the right bearing mechanism. A stirring system is arranged at the upper portion of the top supporting connecting mechanism system. A liquid loading system pipeline is arranged on the right side of the upper portion of the stirring system. A left liquid loading pipe and a right liquid loading pipe are arranged on the left side and the right side of the stirring system correspondingly. A liquid loading system is arranged at the lower portion of the left liquid loading pipe and the lower portion of the right liquid loading pipe. A lower power system is arranged at the middle position of the bottom supporting system. By means of the system, surface treatment can be effectively conducted on automobile components, and the surface treatment and using effect is improved.

Owner:巴南区鑫锐齿轮制造厂

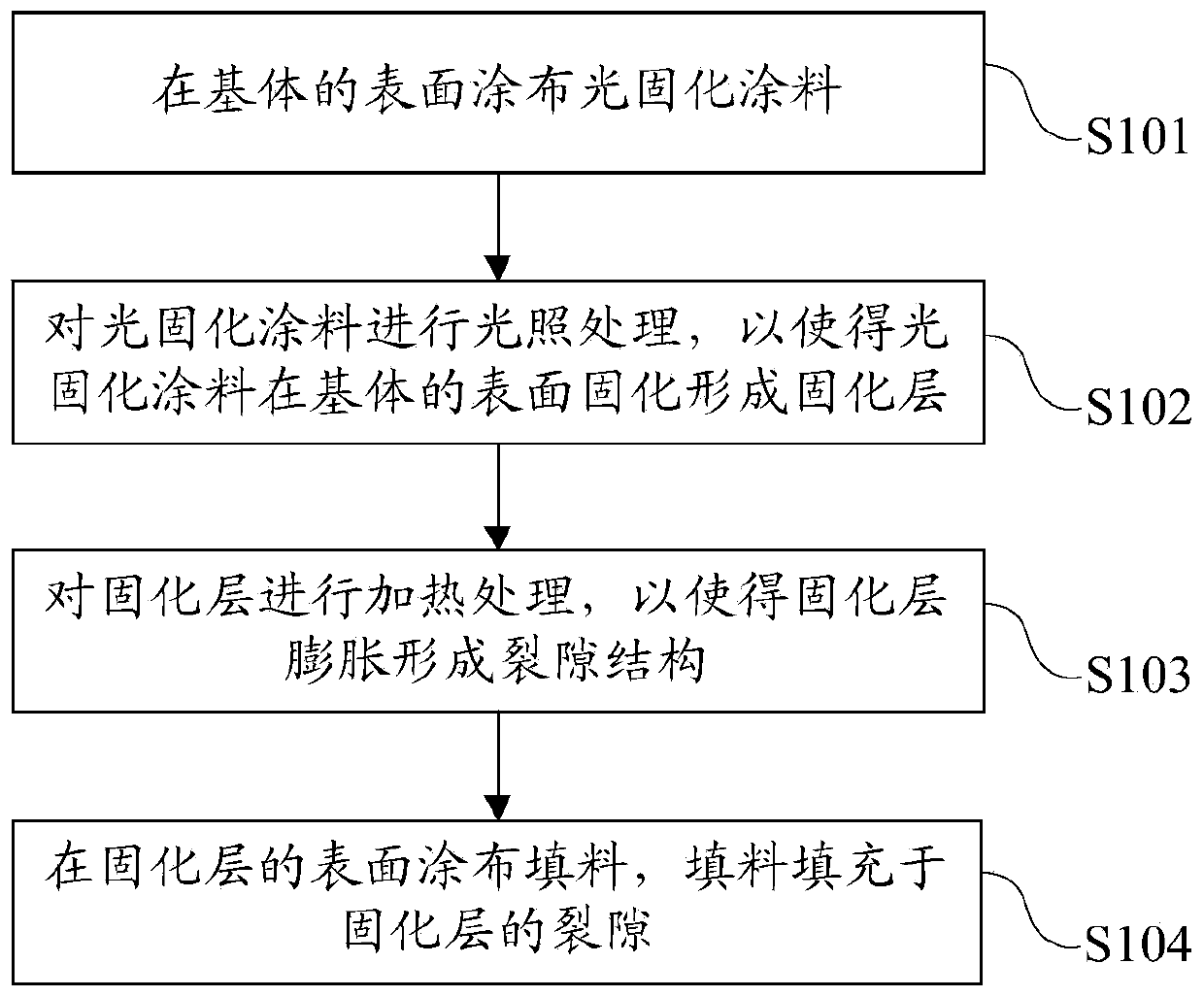

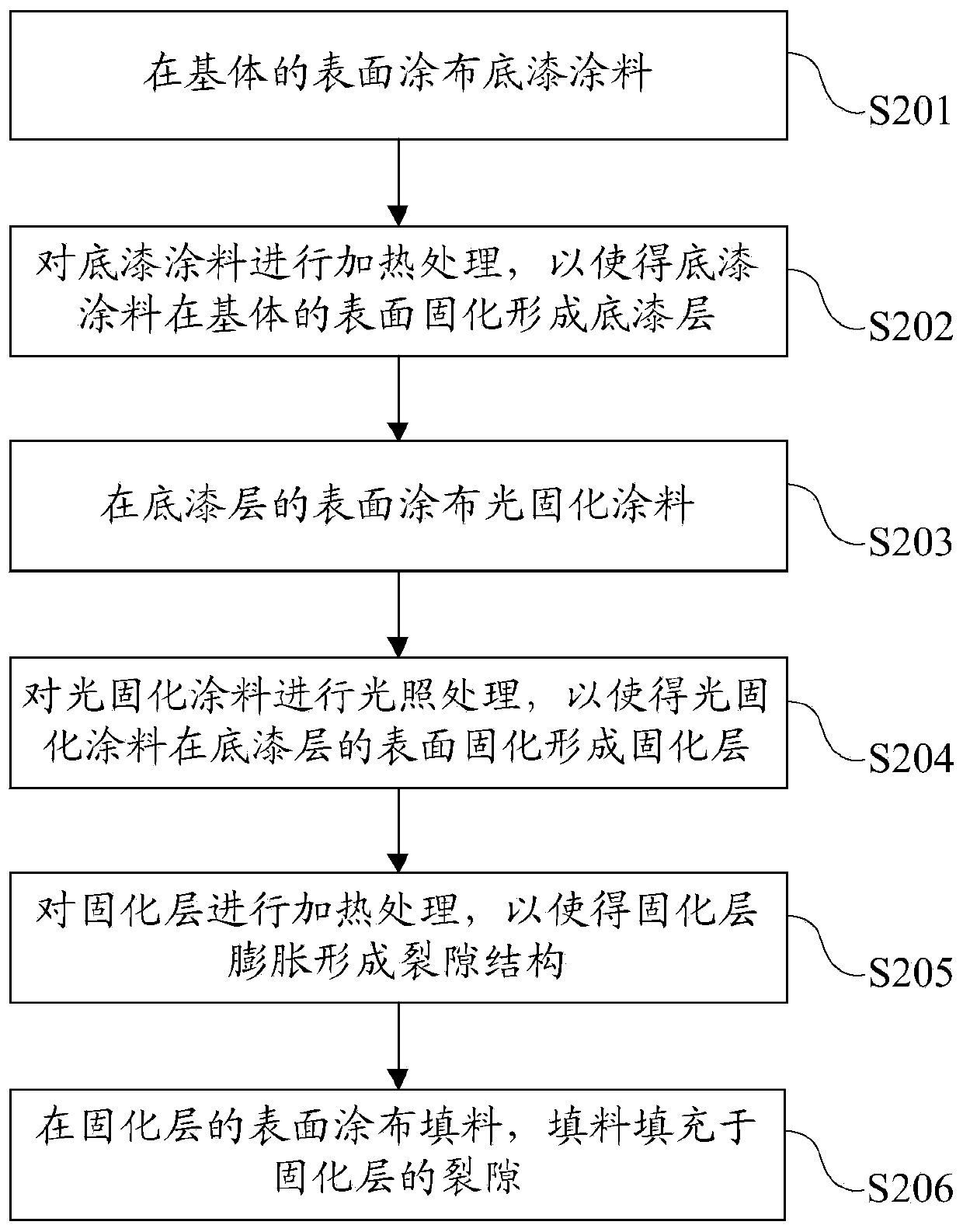

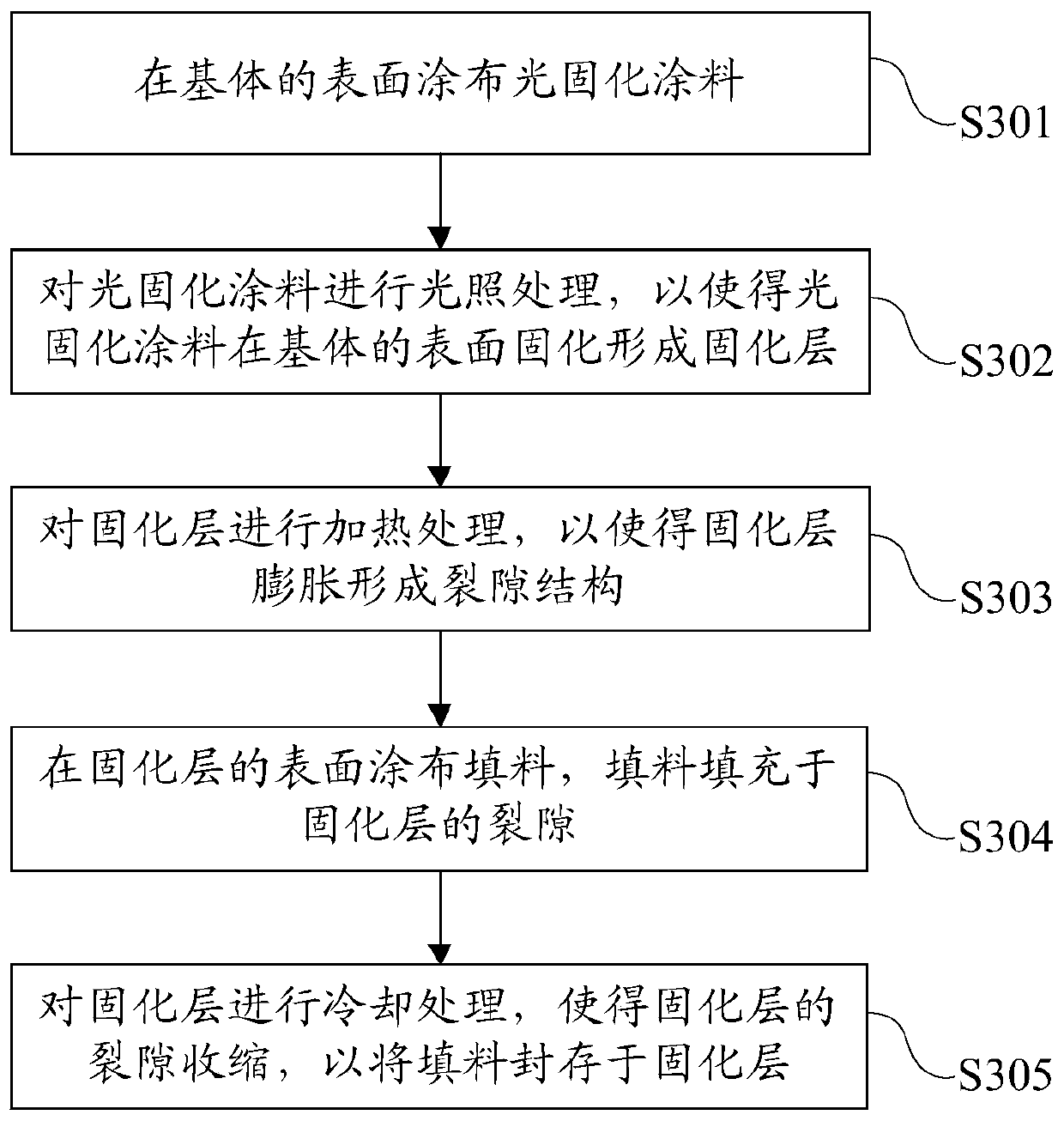

Appearance part and surface treatment method thereof and electronic equipment

ActiveCN110650602AImprove the effect of surface treatmentGuaranteed curing effectOrnamental structuresCasings/cabinets/drawers detailsPolymer sciencePolymer chemistry

The invention mainly relates to an appearance part and a surface treatment method thereof, and electronic equipment. The method comprises steps that the surface of a substrate is coated with a photocureable coating; illumination treatment on the photocureable coating is performed so that the photocureable coating is cured on the surface of the substrate to form a cured layer; the curing layer is heated to enable the curing layer to expand to form a crack structure; the surface of the curing layer is coated with filler, and fissures of the curing layer are filled with the filler. The method isadvantaged in that the curing process of the photocureable coating is separated from the adding process of the filler in another way, that is, the photocureable coating is firstly cured and then added, so the curing process of the photocureable coating is not influenced by the filler, the curing effect of the photocureable coating can be ensured, selectivity of the filler in the aspects of variety, concentration, particle size and the like can be improved, so the surface treatment effect of the appearance part and the application range of the photocureable coating are improved.

Owner:OPPO CHONGQING INTELLIGENT TECH CO LTD

Automobile lamp surface treatment process

InactiveCN111001621AAvoid damageImprove the effect of surface treatmentPackagingCoatingsMetallurgyPhysical chemistry

The invention relates to an automobile lamp surface treatment process. The treatment process comprises of 1, placing a prepared automobile lamp in a cleaning solution for ultrasonic cleaning, fillingwith a pressure of 15-20 KPa, carrying out ultrasonic oscillation for 20 min under a frequency of 59 Hz, washing with clear water, and placing the cleaned automobile lamp into a drying machine for drying treatment; 2, carrying out automobile lamp dipping treatment, and specifically the dried automobile lamp is placed in dipping liquid to be dipped, wherein the dipping liquid comprises 2% of metavanadate, 5% of manganous nitrate, 20% of weak acid and the balance deionized water, and then the automobile lamp enters the drying machine to be dried; 3, carrying out waxing and polishing treatment, and specifically waxing and polishing is carried out the whole automobile lamp; and 4, carrying out protective film plating, and specifically the whole automobile lamp is covered with a tpu protectivefilm, and thus a finished product is obtained. According to the treatment process, the automobile lamp cannot be damaged, and good surface treatment effects are achieved.

Owner:常州市固歌光电有限公司

A kind of cylindrical plastic container surface treatment process

ActiveCN103660326BIncreasing the thicknessImprove the effect of surface treatmentTherapeutic effectEngineering

Owner:霍山诚宇新材料科技有限公司

A kind of magnesium-lithium alloy surface treatment device

ActiveCN104862685BEfficiency for uniform surface preparationImprove Surface Treatment EfficiencyMetallic material coating processesLithiumSalt spray test

Owner:西安四方超轻材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com