Machining method for improving micro-area surface quality of alloy component

A processing method and technology of surface quality, applied in the field of electrolytic machining of laser additive manufacturing, which can solve the problems of inability to achieve surface micro-region leveling, lack of surface microstructure research, and poor surface treatment quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

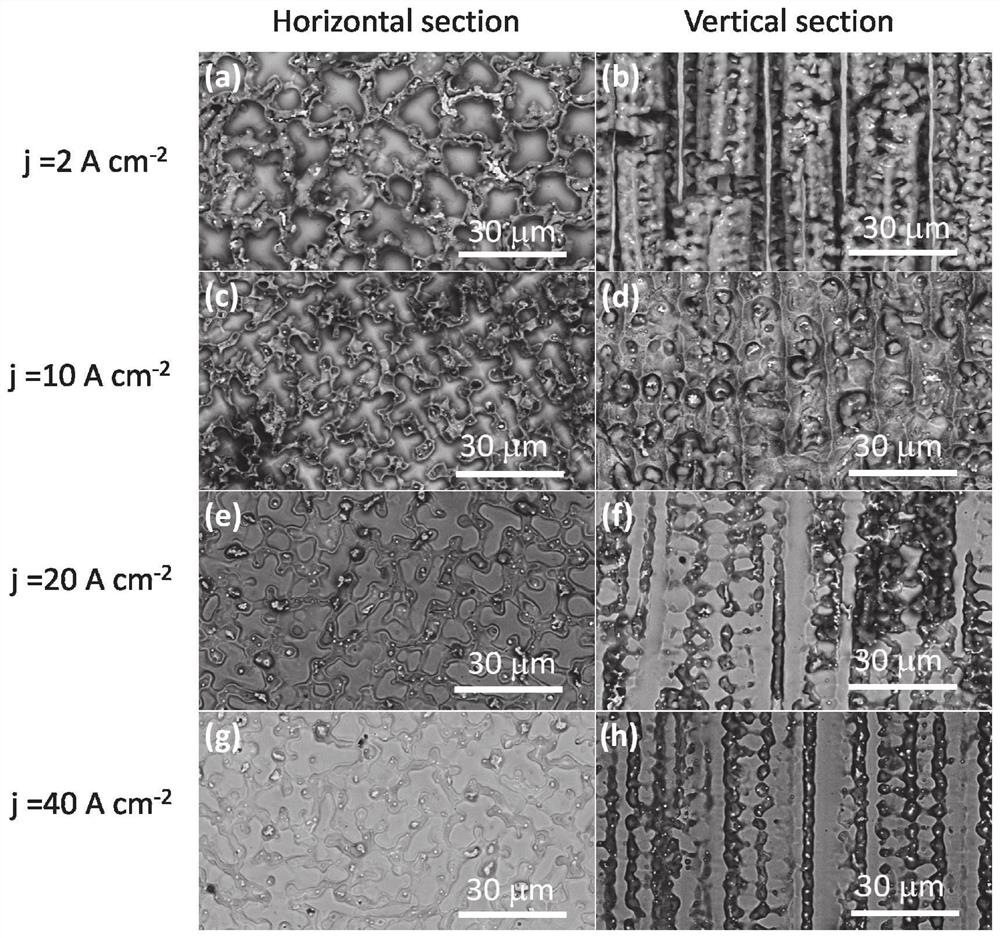

Image

Examples

preparation example Construction

[0037] There is no specific limitation on the preparation method of the alloy component, and those skilled in the art can select the preparation method of the original alloy component based on actual needs. Among them, the alloy component can be prepared by laser three-dimensional forming technology that feeds materials synchronously. The laser three-dimensional forming process parameters are: laser power 2-6KW, scanning speed 800-2000mm / min, spot diameter 4-6mm, single layer thickness 0.3-1.1mm, the overlap ratio is 40-60%; preferably, the laser power is 4kW, the scan rate is 900mm / min, the spot diameter is 5.3mm, the single layer thickness is 0.9mm, and the overlap ratio is 50%. Based on the alloy component obtained under this condition, the deposition rate can reach 1.2kg / h, and the surface quality is good. However, it is more difficult to further improve the surface quality of the alloy component.

[0038] In one embodiment of the present disclosure, the alloy member obtai...

Embodiment 1

[0045] A processing method for improving the micro-area surface quality of an alloy component, using nanosecond pulse electrolytic machining directly on the surface of the alloy component, specifically:

[0046] After the laser three-dimensional forming Inconel 718 alloy component is completed, it is directly subjected to nanosecond pulse electrolytic machining. Due to the uneven surface of the component, when using a stainless steel tube electrode (1.2mm in outer diameter and 0.8mm in inner diameter) for processing, the highest point of the sample should be used as the reference for processing. The distance between the end face of the tube electrode and the highest point of the sample is 1 μm, the feed rate in the horizontal plane is 2 mm / s, the flow rate of the electrolyte is 5 ml / s, the electrolyte is sodium nitrate solution (mass fraction is 10%), and the applied potential is 10V , the pulse frequency is 10ns, and the duty cycle is 50%. After processing this layer, the tu...

Embodiment 2

[0049] A processing method for improving the surface quality of micro-regions of alloy components, firstly performing DC electrolytic machining, and then performing nanosecond pulse electrolytic machining, specifically:

[0050] Firstly, direct current electrolytic machining is performed on the Inconel 718 alloy component formed by laser stereoforming. The process parameters of direct current electrolytic machining are: the tool electrode is a stainless steel tube electrode (1.2mm outer diameter, 0.8mm inner diameter), the applied voltage is 24V, and the machining gap is 0.5mm , the feed rate is 1.5mm / s, the electrolyte flow rate is 10m / s, and the electrolyte is selected from sodium nitrate solution (mass fraction is 10%). After processing one layer, adjust the height of the tube electrode so that the processing gap is 0.5mm, and Start the processing of a new layer until the remaining finishing allowance is 0.5mm. Then, nanosecond pulse electrolytic machining is carried out. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com