A Construction Technology of Composite Road Maintenance Overlay

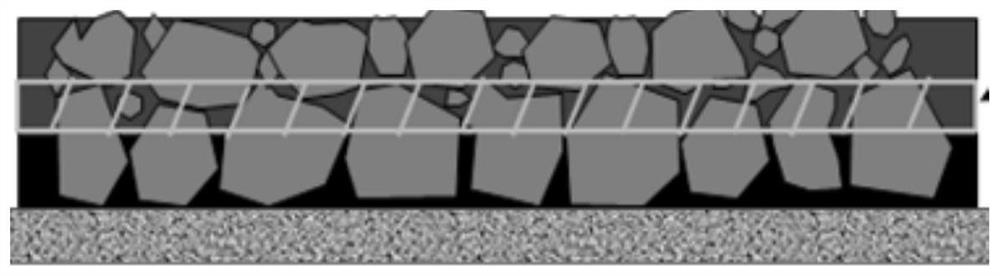

A technology of road maintenance and construction technology, which is applied in the direction of roads, roads, road repairs, etc., can solve problems such as the inability to prevent and delay the reflective cracks on the original road surface, the inability to achieve rapid maintenance, serious pollution and safety, and achieve the goal of not easy to delaminate and fall off, Stable structure and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

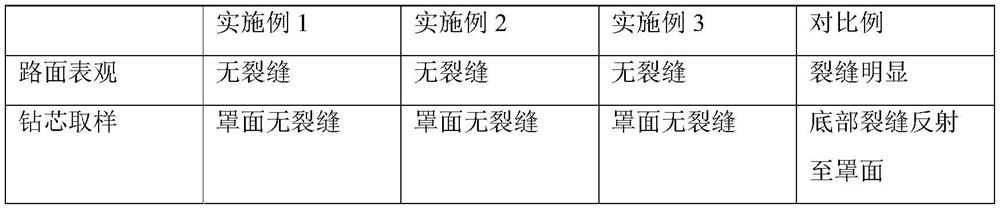

Embodiment 1

[0047] Close the construction road to traffic, pre-treat the original road surface disease, and plan and roughen the original road surface. Sprinkle a layer of modified asphalt gravel seal (the gravel has been pre-treated), and after the gravel seal is spread, roll it three times with a 6-ton rubber-tyred road roller, so that at least 1 / 2 of the gravel is embedded in the modified asphalt. Use a gravel sweeper to clean the pumice 3 times; spread a layer of emulsified asphalt mixture with a slurry sealer, and after the emulsified asphalt mixture breaks, that is, 1 hour after the emulsified asphalt mixture is paved, Use a 6-ton steel wheel roller to roll the road twice and then open it to traffic.

[0048] The pretreatment of the disease on the original pavement is specifically: digging and repairing the pits, and filling the cracks exceeding 2cm.

[0049] The modified asphalt is SBS rubber powder composite modified high viscosity and high elastic asphalt, the spraying amount of...

Embodiment 2

[0053] Close the construction road to traffic, pre-treat the original road surface disease, and plan and roughen the original road surface. Spread 1 layer of modified asphalt gravel seal (the gravel has been pre-treated). After the gravel seal is sprayed, roll it 5 times with a 6-ton rubber roller, so that at least 1 / 2 of the stone is embedded in the rubber powder modified asphalt . Use a gravel sweeper to clean the pumice 3 times; spread a layer of emulsified asphalt mixture with a slurry sealer, and after the emulsified asphalt mixture breaks, that is, 1 hour after the emulsified asphalt mixture is paved, Use a 6-ton steel wheel roller to roll the road surface three times and then open it to traffic.

[0054] The pretreatment of the original pavement disease is as follows: the pits are excavated and repaired, and the cracks exceeding 2cm are filled with cracks.

[0055] The modified asphalt is SBS modified high-viscosity and high-elasticity asphalt, and the spraying amount...

Embodiment 3

[0059] Close the construction road to traffic, pre-treat the original road surface disease, and plan and roughen the original road surface. Sprinkle a layer of modified asphalt gravel seal (the gravel has been pre-treated), and after the gravel seal is spread, roll it three times with a 6-ton rubber-tyred road roller, so that at least 1 / 2 of the gravel is embedded in the modified asphalt. Use a gravel sweeper to clean the pumice 4 times; spread a layer of emulsified asphalt mixture with a slurry sealer, and wait for the emulsified asphalt mixture to break, that is, 1 hour after the emulsified asphalt mixture is paved. Use a 6-ton steel wheel roller to roll the road twice and then open it to traffic.

[0060] The pretreatment of the disease on the original road surface is specifically: the pits are excavated and repaired, and the cracks exceeding 2cm are treated with joint filling.

[0061] The modified asphalt is SBS rubber powder compound modified high viscosity and high ela...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com