Patents

Literature

210results about How to "Improve curling effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

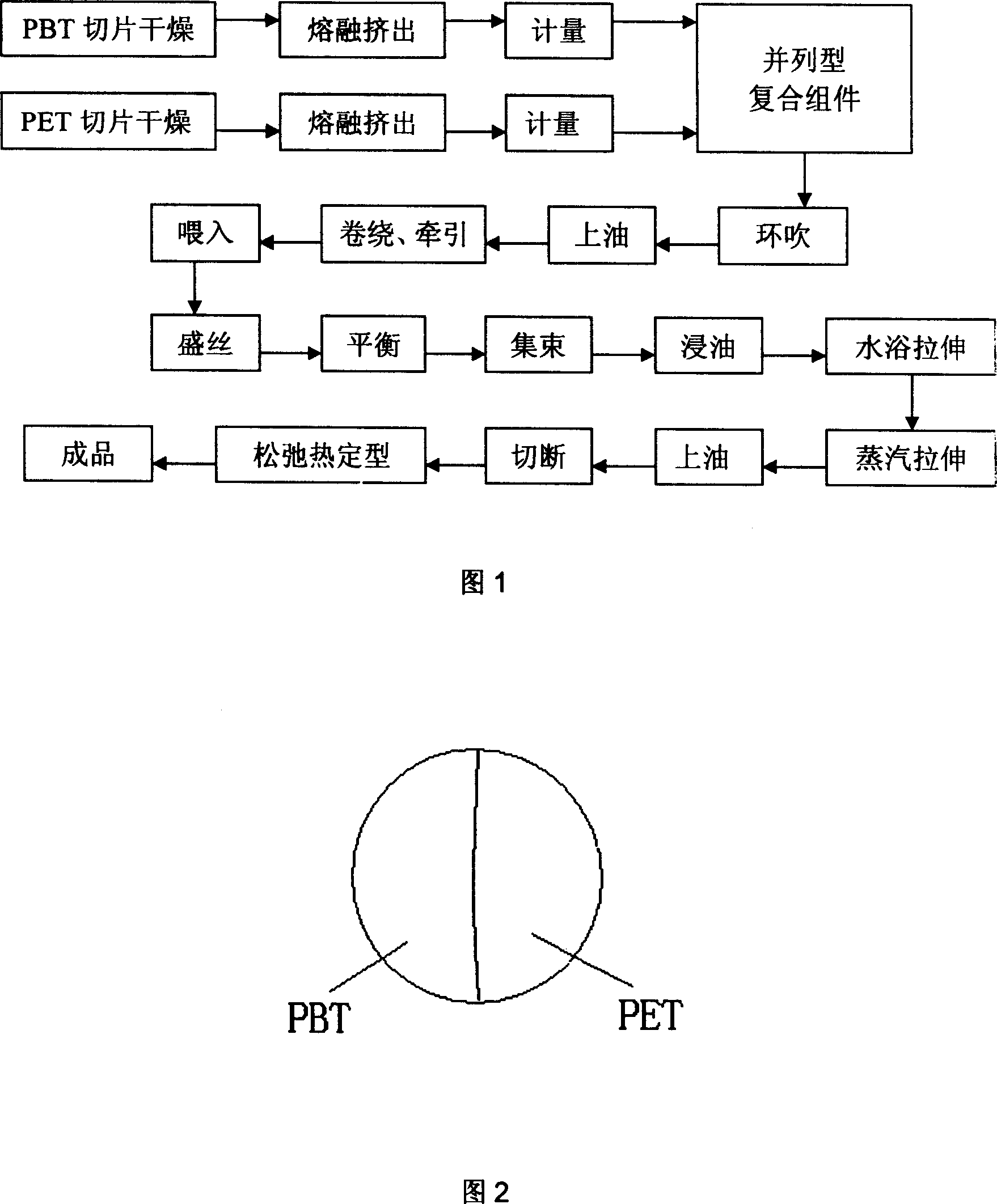

Method for preparing PBT/PET 3-D crimped fiber and use thereof

InactiveCN1962968AIncrease elasticityHigh modulusFilament/thread formingConjugated synthetic polymer artificial filamentsFiberHeat resistance

The invention involves a product method of PBT / PET 3D crimp fiber fabrication which includes steps: (1) PBT biopsies are composed with the PET on the after drying; (2) PET slices are after drying, through high-temperature melting e composite; (3) After blowing Central, greasing winding drive, feed, Sheng be parallel wire composite fiber winding wire; After balancing, cluster, the Baptist tensile oil bath, steam tensile, greasing cut off heat and relaxation to be stereotyped PBT / PET 3D curly fibers. The fibers produced through the method are system of the fiber's flexibility, dyeability and heat resistance and used in flexible woven and knitted fabrics such as high-end sportswear, stretch jeans and strait jacket, Nonwovens and filler widely.

Owner:DONGHUA UNIV

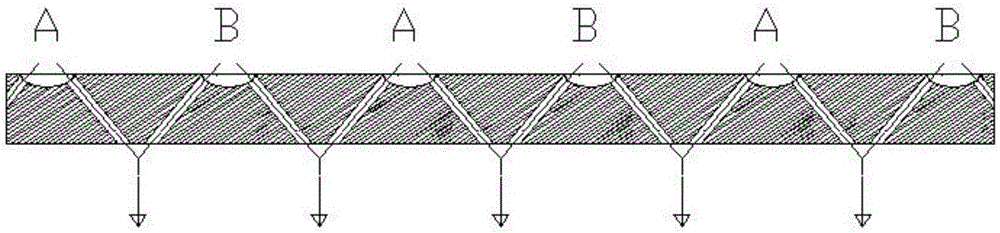

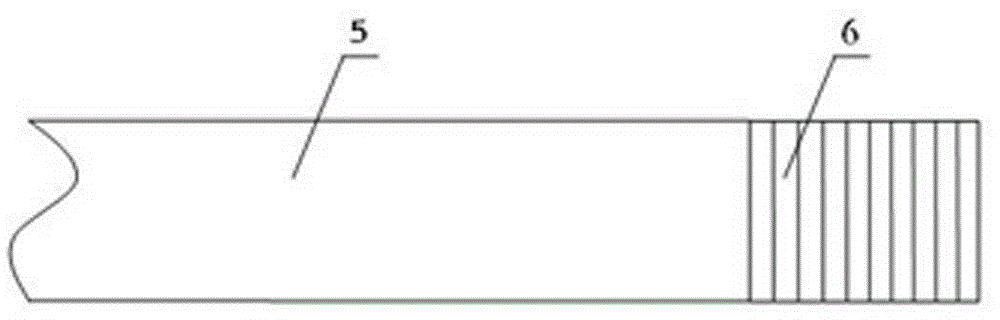

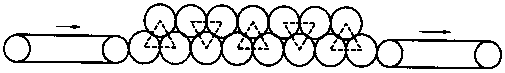

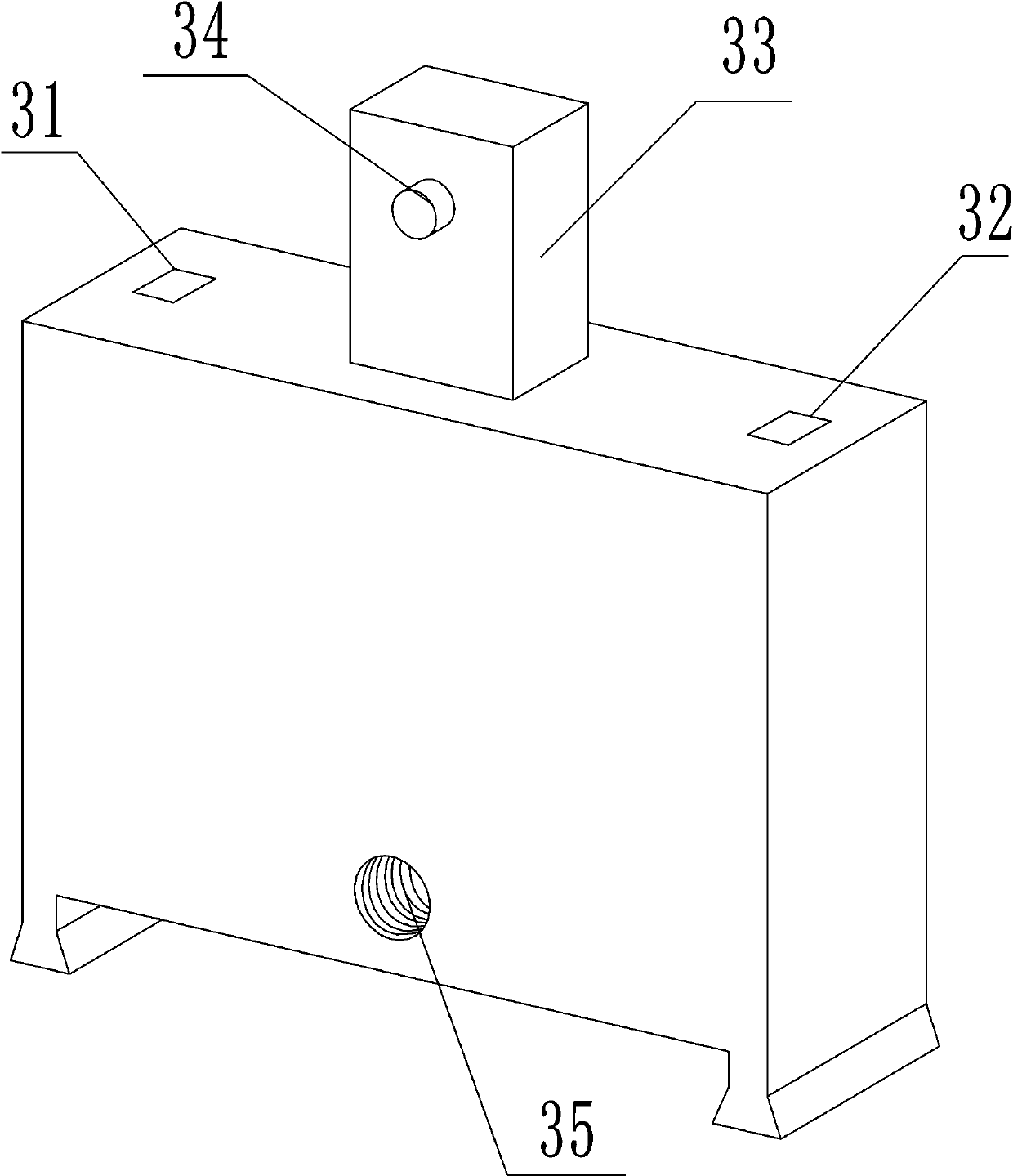

Production method of double-component spinneret outside composite parallel self-crimping elastic short fiber

ActiveCN106149071AIncrease elasticityImprove curling effectArtificial filament heat treatmentConjugated synthetic polymer artificial filamentsFiberElastic fiber

The invention relates to a production method of double-component spinneret outside composite parallel self-crimping elastic short fiber. The production method includes: adopting high molecular polymer components A and B different in shrinkage characteristics as raw materials; subjecting AB melt to outside compositing through a double-passage spinneret to obtain an AB parallel composite filament bundle; subjecting the AB parallel composite filament bundle sequentially to air-blowing cooling, oiling, winding traction and filament carrying to obtain AB parallel composite fiber protofilament; subjecting the AB parallel composite fiber protofilament sequentially to inter-cluster balance, drafting, thermal setting, oiling, crimping, loosening and drying and cutting to obtain the double-component spinneret outside composite parallel self-crimping elastic fiber. The fiber has excellent and lasting crimping performance, is high in elasticity, elastic recovery rate and spinnability, wide in application range and suitable for nonwoven filling.

Owner:王家铭

Liquid ammonia modified method of cotton fibriia and yarn

InactiveCN101413213AGood flexibilityImprove curling effectLiquid/gas/vapor removal by centrifugal forceTextile treatment by pouringYarnVegetable fibers

The invention provides a method for modifying cotton and long vegetable fiber or yarn by ammonia liquid, which comprises the following steps: firstly, drying pre-treatment of raw materials; secondly, ammonia leaching of the raw materials in a hermetical treatment tank; thirdly, spin-drying of the raw materials subjected to ammonia leaching when a creel is twirled; fourthly, drying of the raw materials subjected to spin-drying by ammonia flow when the creel rotates slowly; fifthly, flushing of the raw materials which are dried by the ammonia flow by airflow when the creel rotates slowly; and so on. The method keeps the inherent advantages of the cotton, the long vegetable fiber and the yarn, overcomes the defects of the cotton, the long vegetable fiber and the yarn, increases softness, crimp tendency and fluffiness of the cotton, the long vegetable fiber and the yarn, improves the dye-uptake rate, the leveling property and the showy dye level, and further solves the problems of energy conservation, efficiency improvement and environmental protection.

Owner:上海业安纺织科技有限责任公司

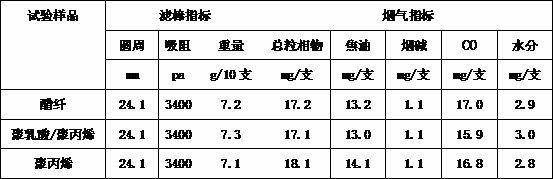

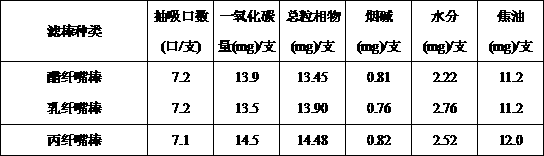

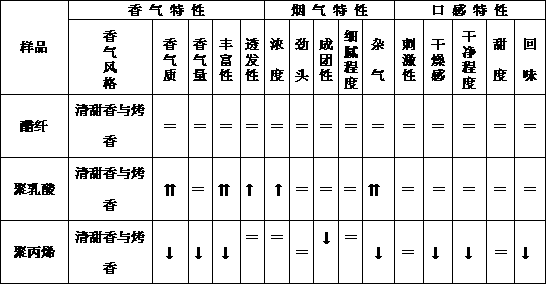

Novel production process for cut tobacco stems

InactiveCN102972856AIncrease softnessIncrease fill valueTobacco preparationTobacco treatmentAgricultural engineeringDrum drying

The invention discloses a novel production process for cut tobacco stems. The novel production process comprises the steps as follows: carrying out vacuum moisture regaining and evaporating the stems; storing the stems; heating and humidifying; straightening the stems; pressing the stems; arranging the stems; cutting the stems; feeding; expanding and drying; and perfuming. According to the novel production process, the vacuum moisture regaining and stem evaporating mode is adopted for moisture regaining of the tobacco stems, so that the impurity gases in the tobacco stems can be removed and the smoke softness is improved. The thinly pressing and cutting mode is adopted, so that the physical forms of the formed cut stems are threadlike and are closer to cut tobaccos. The flash evaporation, expansion and drum drying mode is adopted for drying of the cut stems, so that the cut stems are better in crimpiness and are closer to the form of the cut tobaccos and the filling capability of the cut stems can be improved. The cut steams produced by the production process has the advantages that the filling value is high, the impurity gases in the tobacco stems are reduced, the fragrance is increased, cigarettes can be endowed with a certain burned sweet fragrance, the physical forms of the cut stems are closer to the cut tobaccos, and the suitability is better in the cigarettes.

Owner:YUNNAN REASCEND TOBACCO TECH GRP

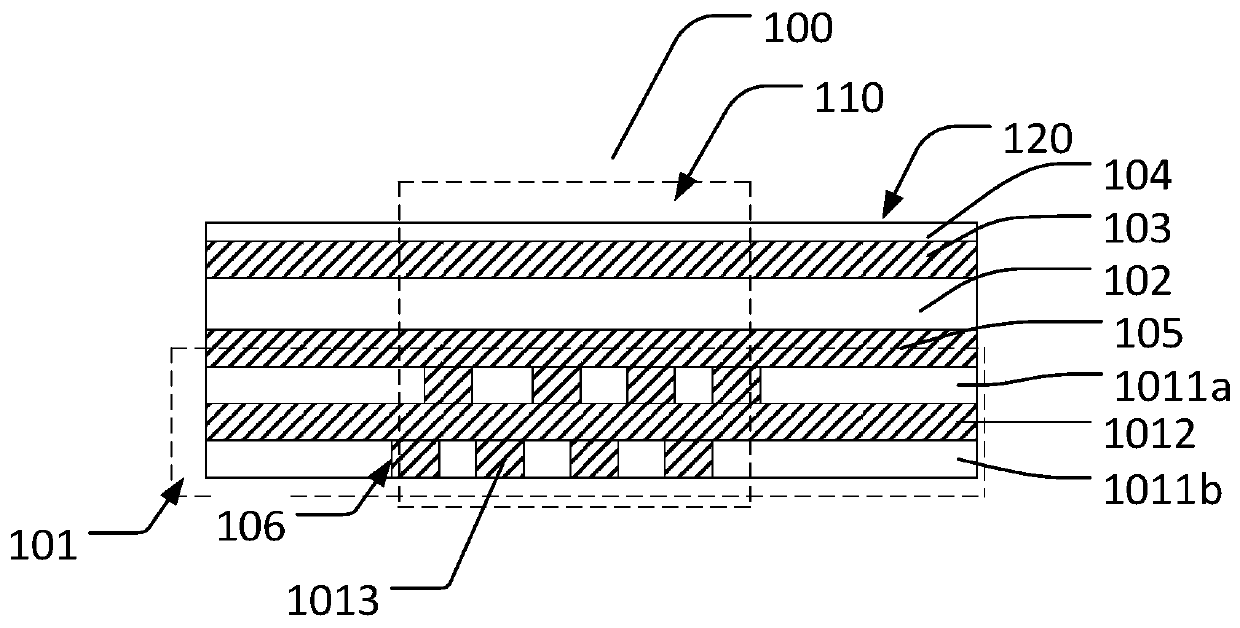

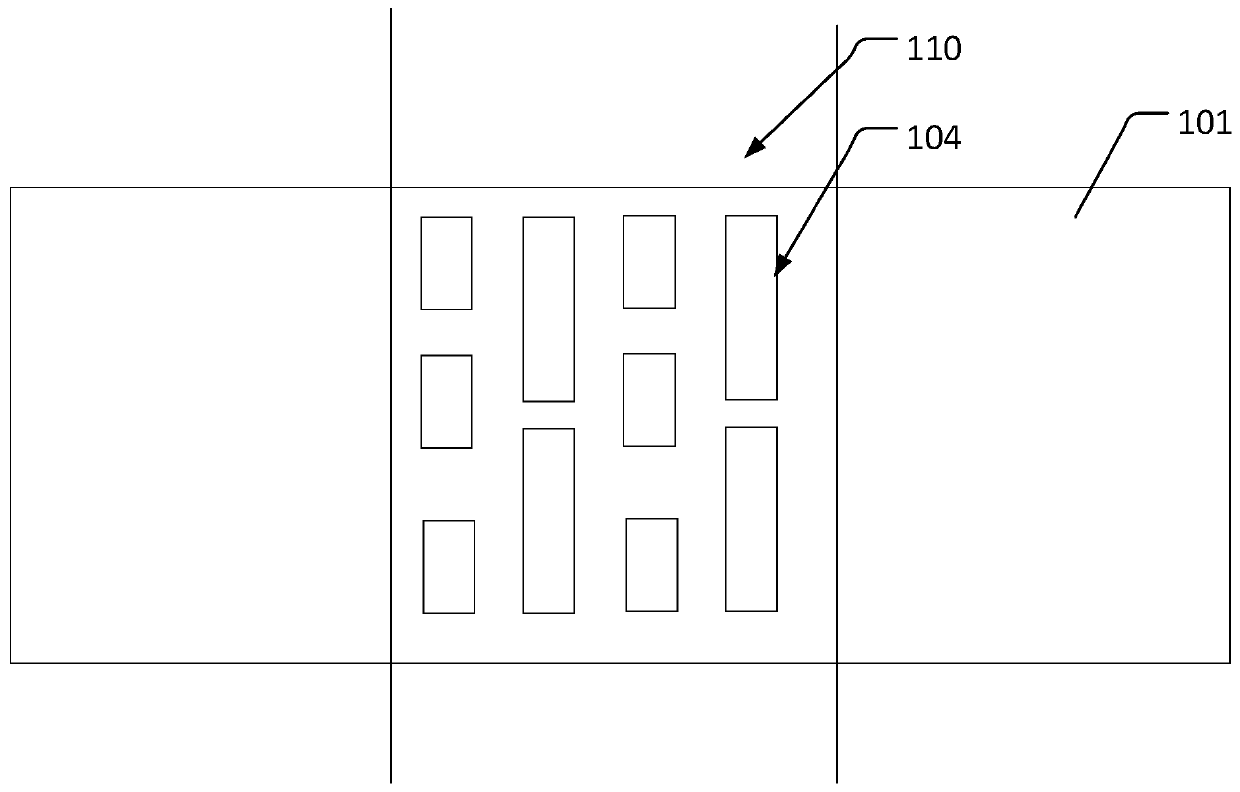

Display device

InactiveCN111312794AGood curl performanceHigh bond strengthSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringBonding strength

The invention provides a display device. The display device comprises a supporting layer, a first adhesive layer, a display panel, a fourth adhesive layer and cover plate glass. The supporting layer is designed into a sandwich structure; the supporting layer comprises at least two layers of metal sheets and a second adhesive layer clamped between the two layers of metal sheets; holes are dug in the two layers of metal sheets, and the two layers of metal sheets are filled with a third adhesive layer, so that the supporting layer has better curling performance and higher bonding strength, and the adhesive layer is effectively prevented from falling off in the bending process. The display panel can be well supported, and flexibility and rigidity are integrated.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

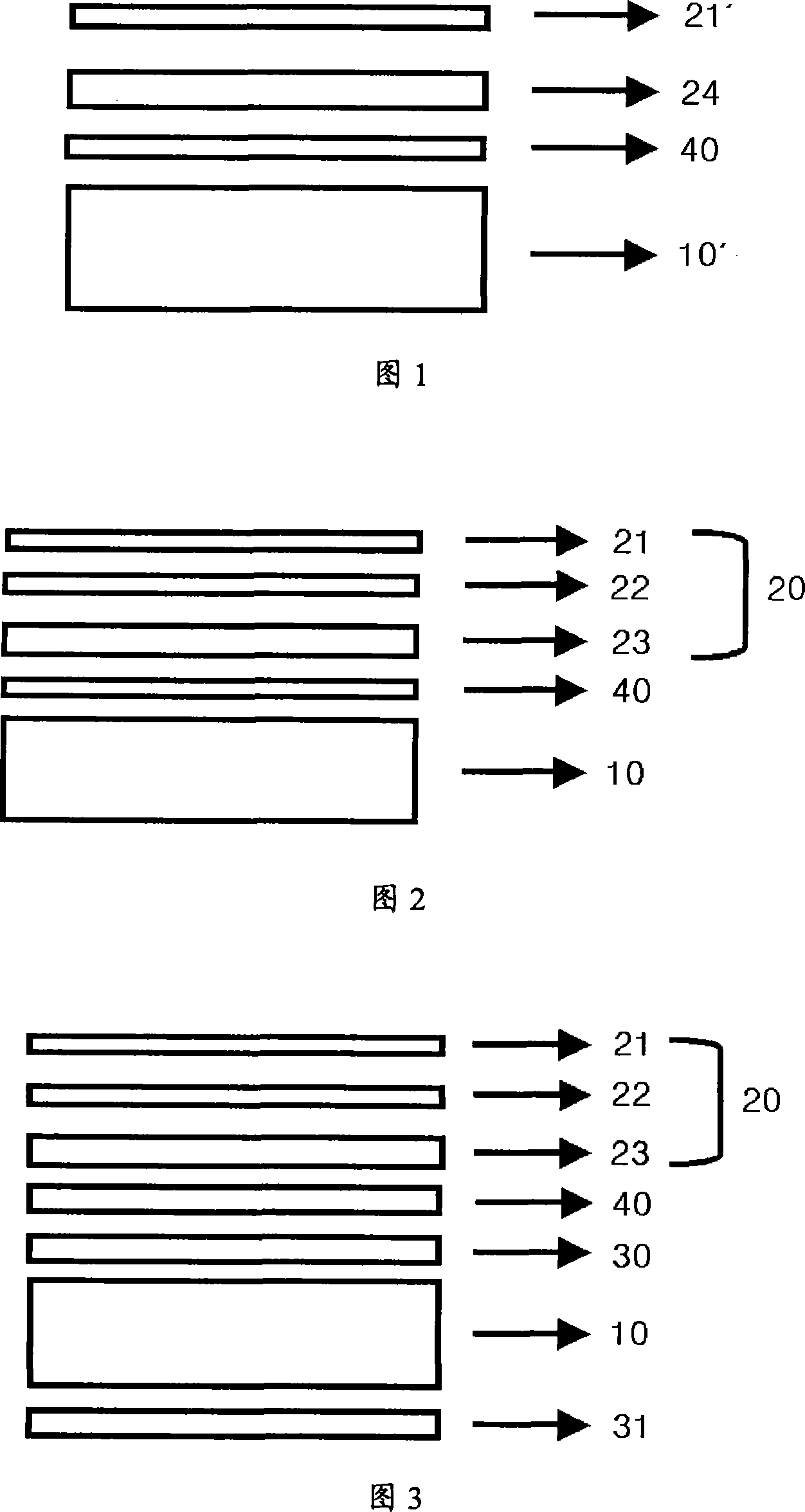

Polylactic acid/polypropylene cigarette composite tow with sheath-core structure and preparation method thereof

ActiveCN102691121AGood physical and mechanical propertiesIncrease production capacityTobacco smoke filtersFilament/thread formingPolypropyleneMelt spinning

The invention relates to a polylactic acid / polypropylene cigarette composite tow with a sheath-core structure and a preparation method thereof. The polylactic acid / polypropylene cigarette composite tow is prepared by a composite spinning technology in a melt spinning method, the section of a single prepared fiber is in a surface-core structure (the core is polypropylene, and the surface is polylactic acid), the linear density of the tow is 3.5-5.5 ktex, the monofilament linear density is 2-5 dtex, the crispation number is 18-28 / 25 mm, and the crispation index is about 0.55. Because the surface-core structure is adopted, the inside polypropylene is used as a skeleton, the composite tow can be crimped and processed for drying and shaping at the high temperature about 100 DEG C, and the cigarette tow with good crimping performance and physical and mechanical performance can be obtained; and in addition, the polylactic acid in the tow has the characteristic of biodegradation, and the environment pollution is reduced.

Owner:江苏合吉烟用材料有限公司 +2

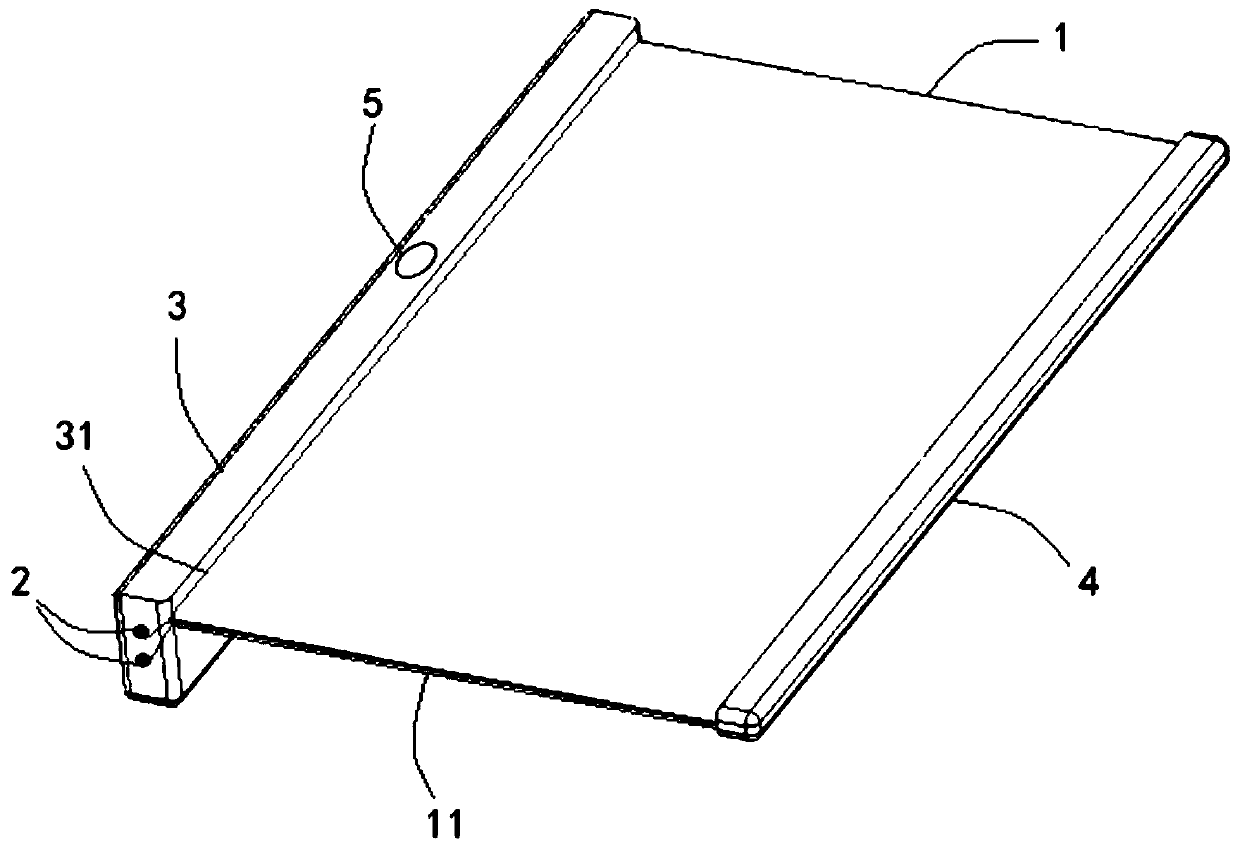

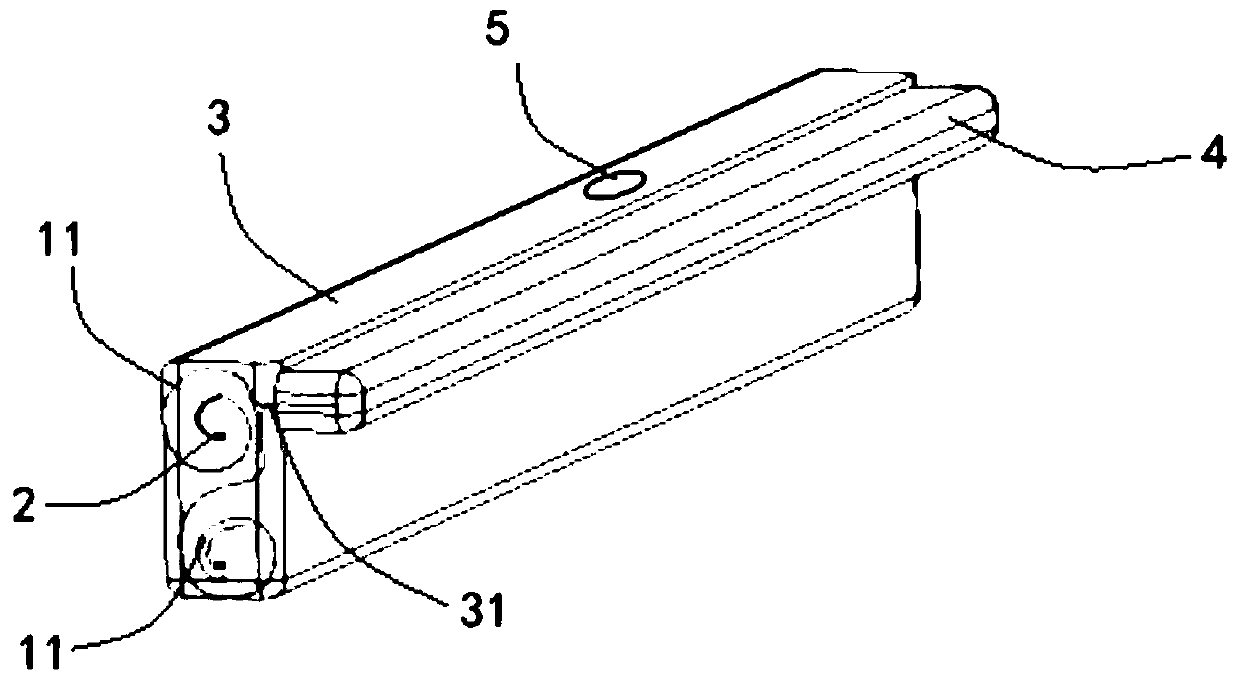

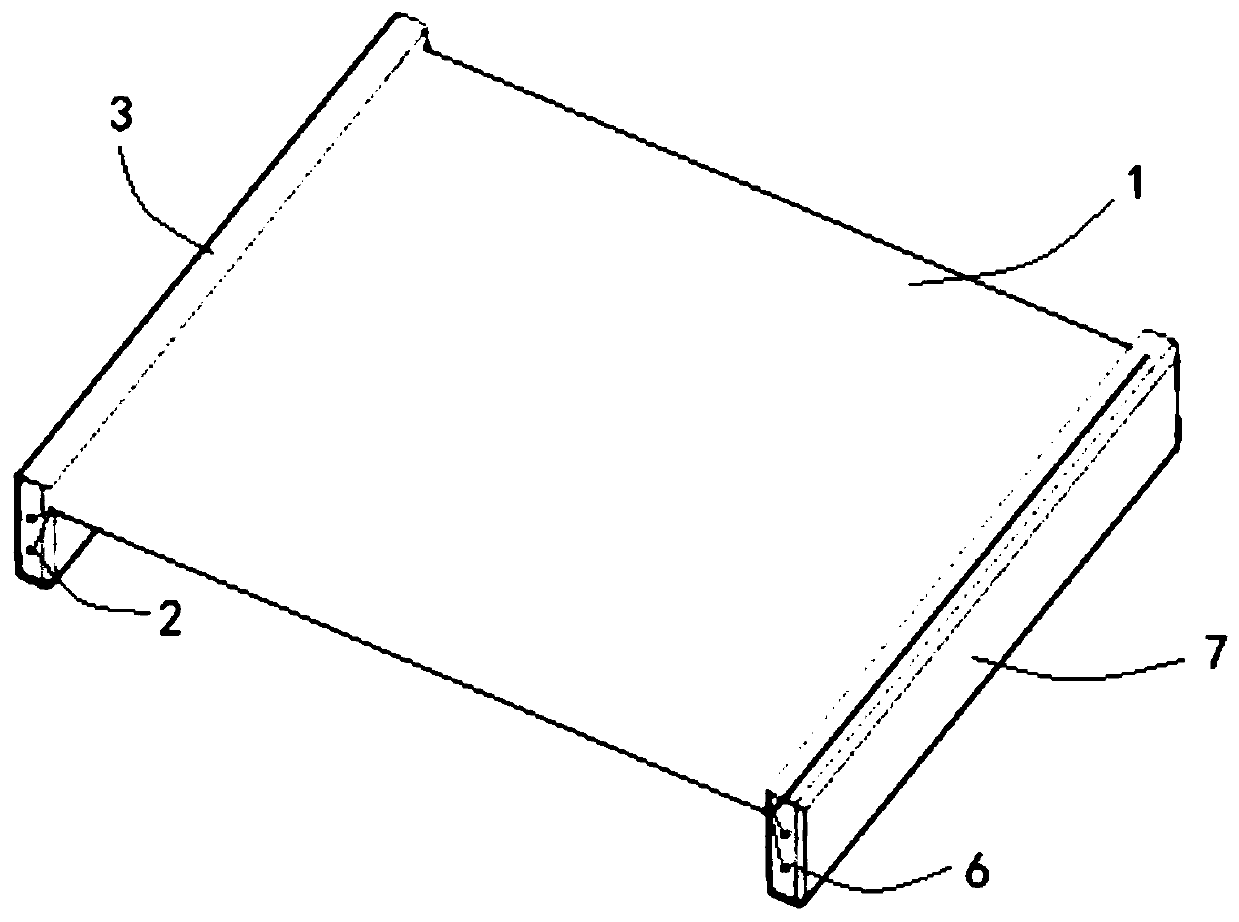

Flexible display device

ActiveCN110189634AImprove curling effectAvoid curlDigital data processing detailsIdentification meansFlexible displayComputer science

The invention discloses a flexible display device. The flexible display device comprises a flexible display screen and a plurality of first reels, and the flexible display screen comprises a pluralityof sets of flexible film layers corresponding to the multiple first reels one to one; and one end of each set of flexible film layer is connected with the first reel corresponding to the flexible film layer, so that when the flexible display screen is in a curled state, each set of flexible film layer is curled on the first reel corresponding to the set of flexible film layer, and thus the curling capacity of the flexible display screen is improved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

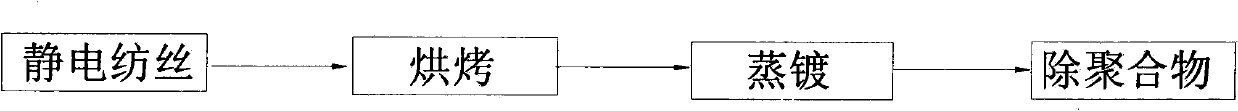

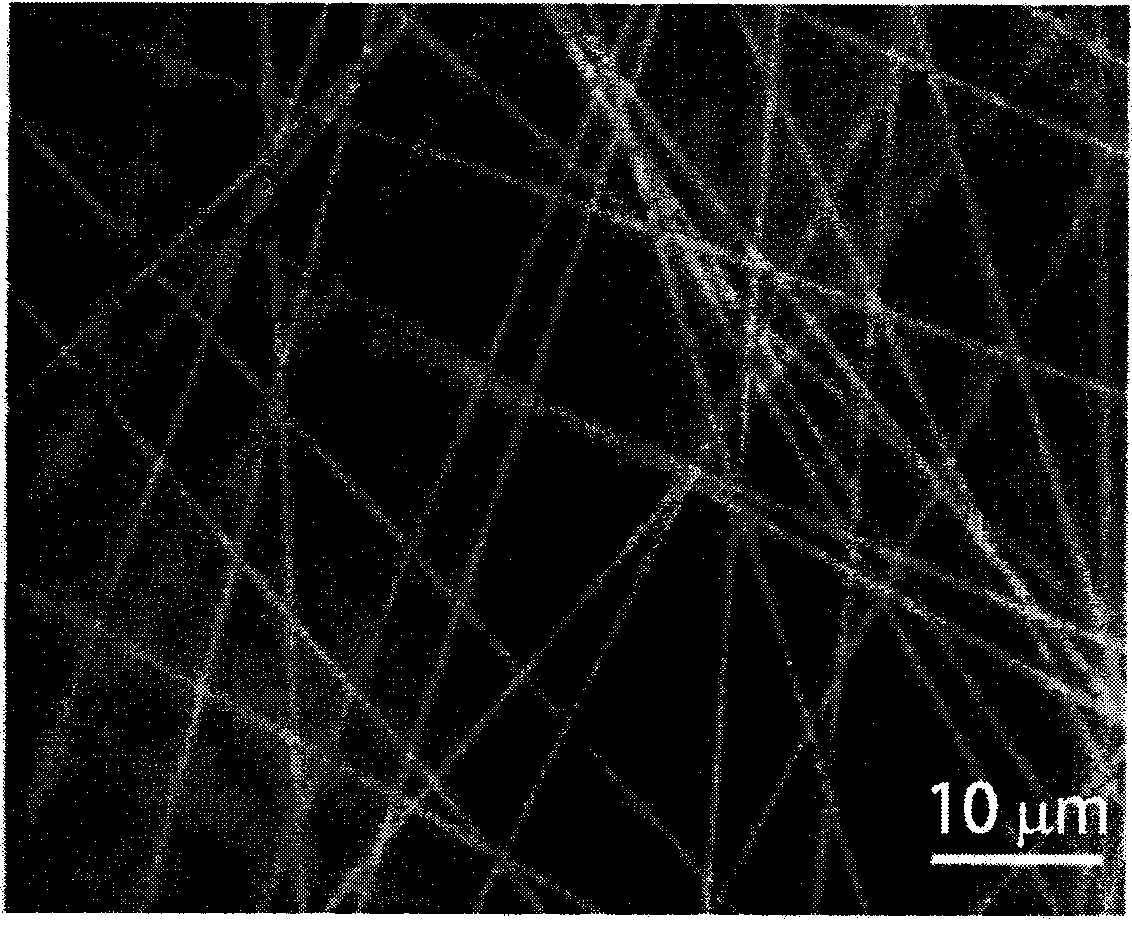

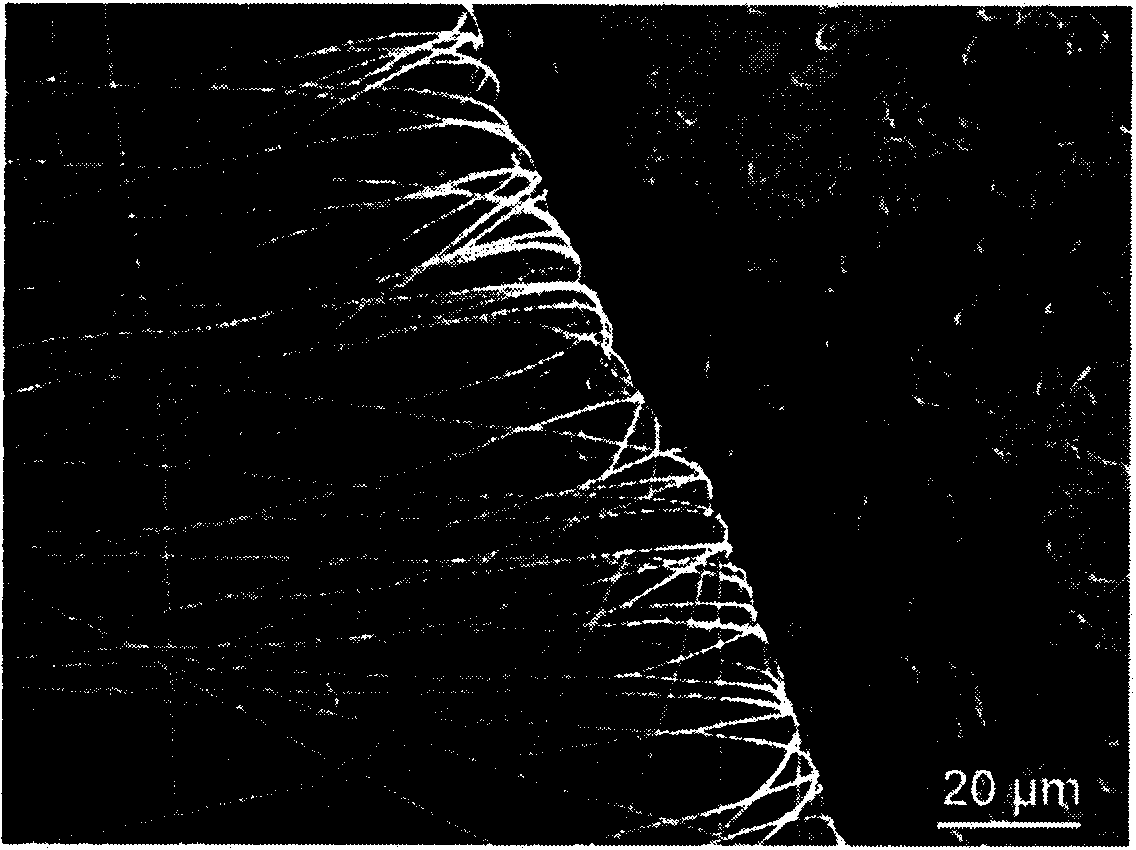

Preparation method for transparent conductive metal network

ActiveCN103628028AAchieve productionReduce energy consumptionVacuum evaporation coatingFilament/thread formingEtchingElectrospinning

The invention discloses a preparation method for a transparent conductive metal network. The preparation method comprises the following steps: a) preparing a nanofiber network through electrospinning; b) evaporating a metal layer on the nanofiber network so as to obtain a metal-polymer network complex; and c) removing a metal in the metal-polymer network complex so as to obtain the transparent conductive metal network. The invention has the following beneficial effects: downstream tedious etching and patterning processes are avoided in preparation of a conductive film prepared from the flexible transparent metal network, demands of touch screens and display panels for patterning can be directly met, and online production can be realized.

Owner:苏州冷石纳米材料科技有限公司

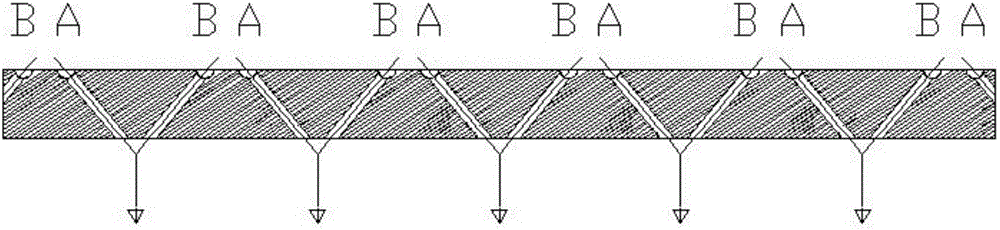

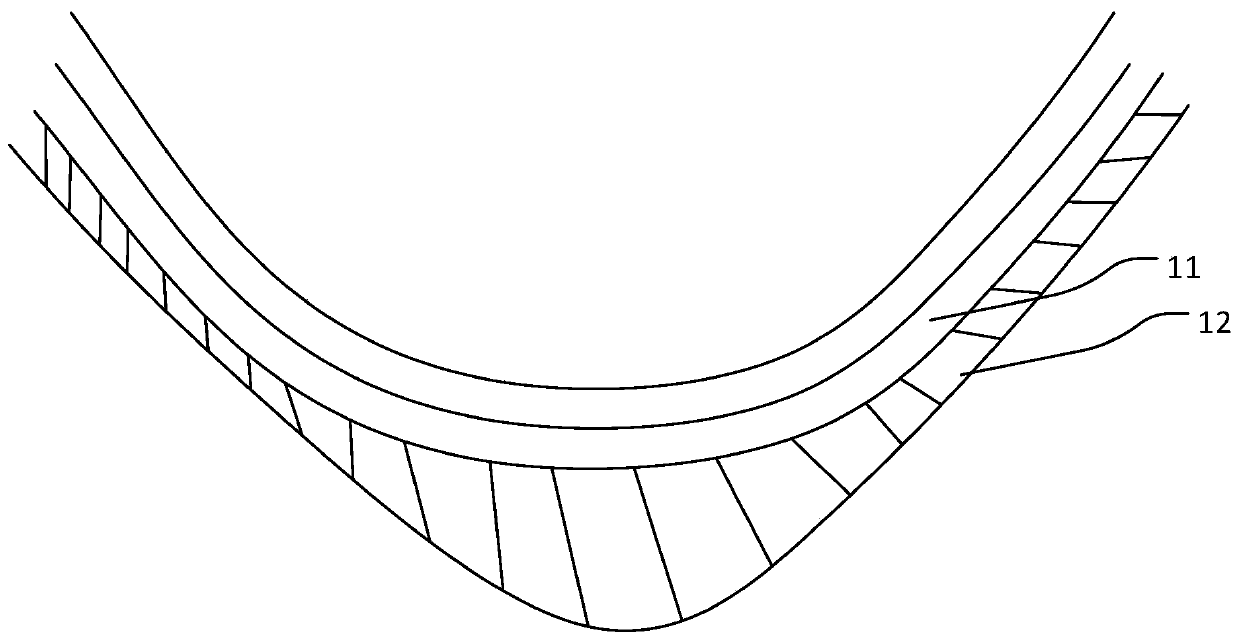

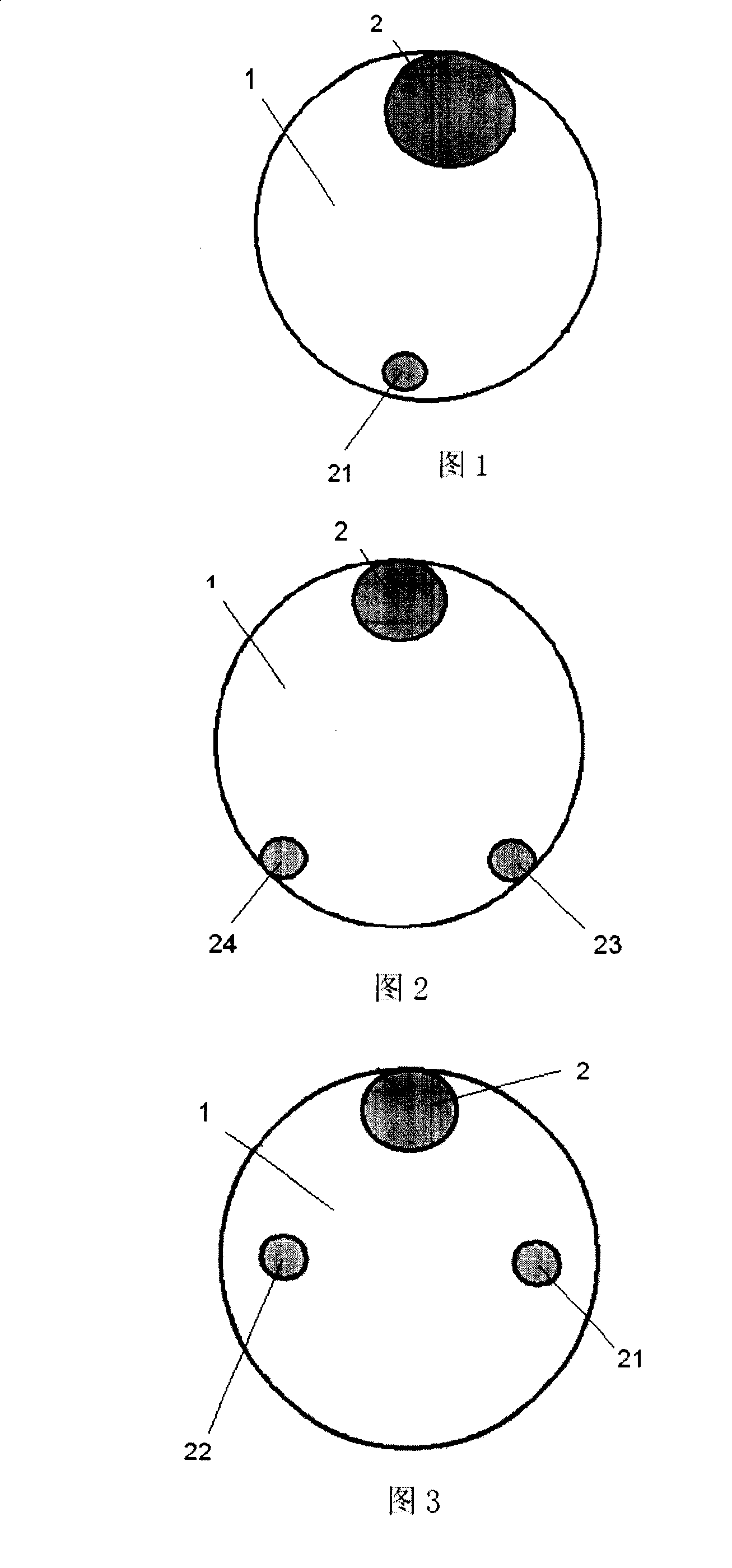

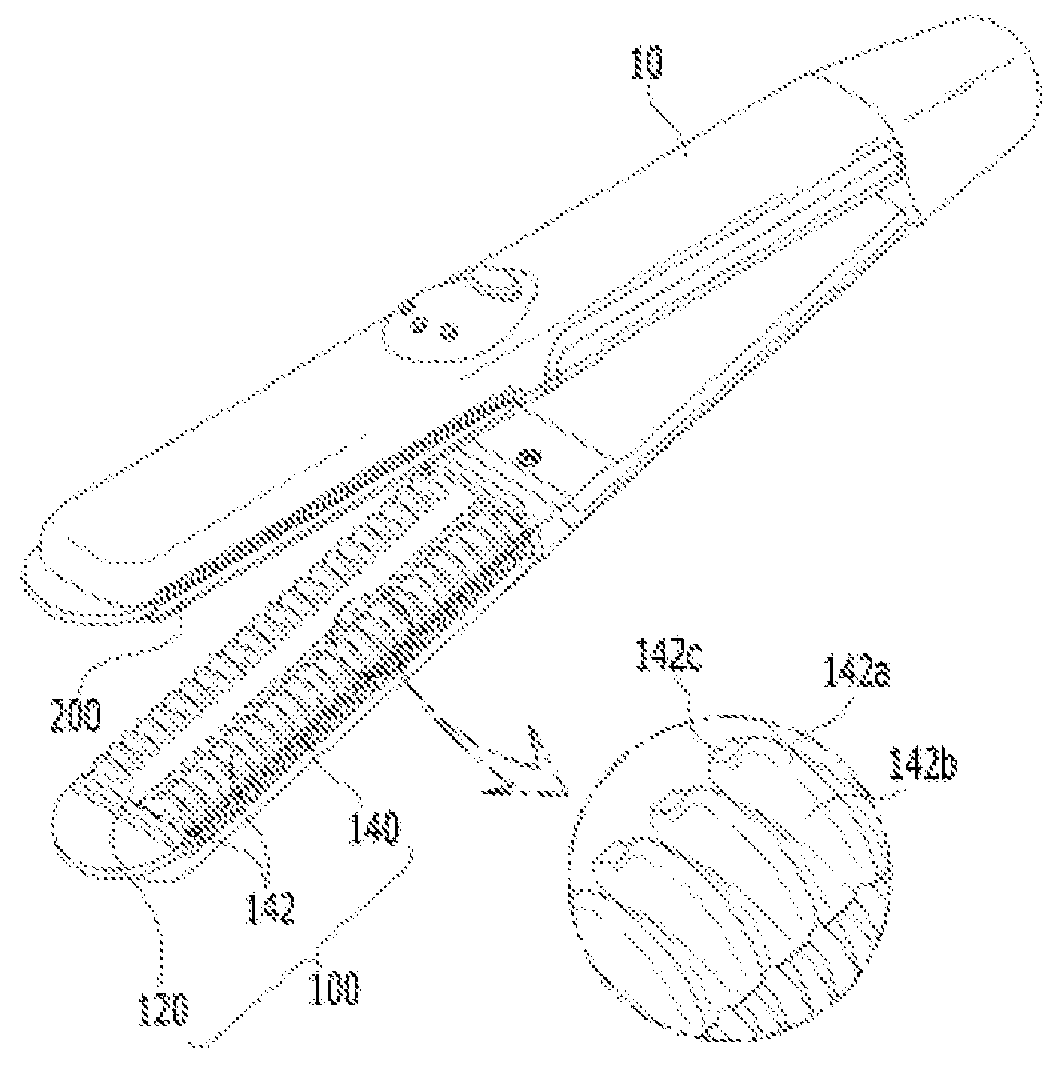

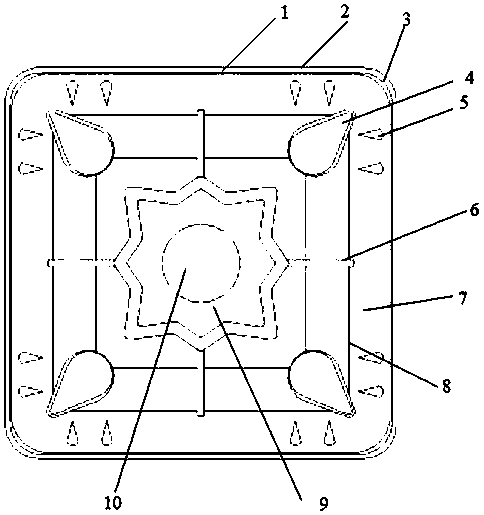

Three-dimensional crimp fibre

ActiveCN101230498AImprove curling effectImprove spinnabilityMonocomponent cellulose artificial filamentFilament/thread formingFiberPolymer science

The invention provides a three-dimensional crimped fiber and consists of a first polymer component and a second polymer component. The second polymer is at least two discontinuous regions on the cross section of the fiber. At least two discontinuous regions of the second polymer are distributed in the first component or at least part of the two discontinuous regions is connected with the first component to form at least three separate regions. The regions formed by the first polymer component and the second polymer component respectively present an unsymmetrical mechanical structure. The technical proposal relieve the strict restrictions for the melt viscosity of the two components in the process of preparing the three-dimensional crimped composite fiber as well as the problem of the bend angle, and greatly widens the restrictions for the melt apparent viscosity difference and spinnability of the two components in the process of spinning the other sections. Simultaneously, the crimped property of the three-dimensional crimped composite fiber is equal to or better than the core-shift sheath-core fiber.

Owner:CHINESE TEXTILE ACAD

Polylactic acid filter stick paper element and manufacturing method thereof

ActiveCN104532386AStrong recycling abilityPromote degradationFilament forming substance formingArtificial filament physical treatmentPolymer scienceCellulose acetate

The invention relates to a polylactic acid filter stick paper element and a manufacturing method thereof, in particular relates to a biodegradable polylactic acid filter stick paper element and a preparation method thereof, and belongs to the technical fields of tobacco tar filter elements and manufacturing methods. The polylactic acid filter stick paper element is prepared from the following raw materials in parts by weight by virtue of melt spinning: 100 parts of polylactic acid and 5-15 parts of a bonding agent, wherein a crystallization nucleating agent accounts for 0.15-0.5% of the mass percentage of polylactic acid; the ratio of a laevo isomer in the polylactic acid is 95-99%; the crystallization nucleating agent is a mixture of a substituted aryl lithium phosphate salt Na-03 and nano calcium carbonate, the substituted aryl lithium phosphate salt Na-03 accounts for 0.10-0.30% of the mass of the polylactic acid, and the nano calcium carbonate accounts for 0.05-0.2% of the mass of the polylactic acid. The materials used by the paper element are rich in resource, the manufacturing cost is low, the curling property index, tensile strength, filtration efficiency and quality characteristic of the filter stick paper element prepared by the method are close to those of cellulose acetate smoke filter material, and the polylactic acid filter stick paper element is biodegradable.

Owner:HONGTA TOBACCO GRP

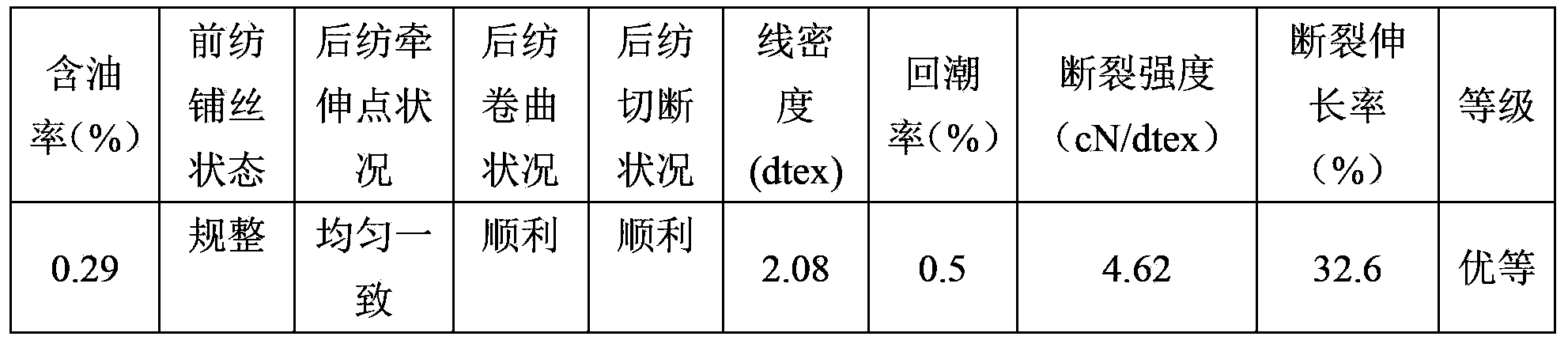

Hard coating film and flexible display having the same

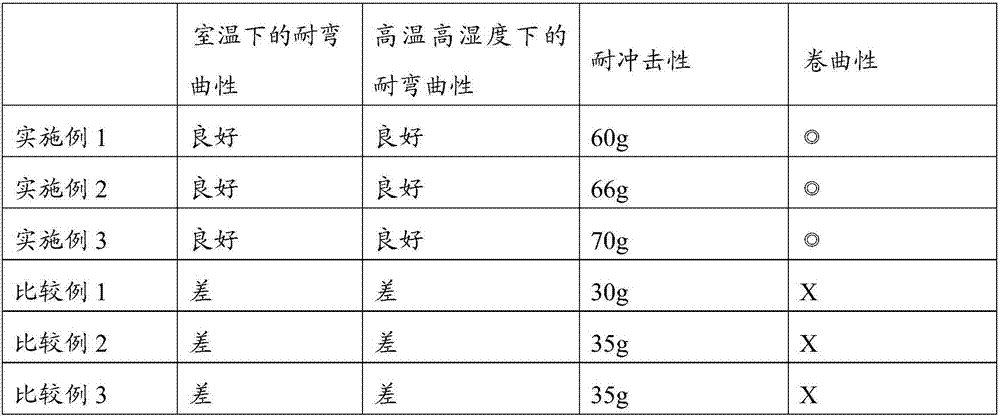

ActiveCN107402414AImprove impact resistanceImprove curling effectPolarising elementsPretreated surfacesPolymer scienceOligomer

Owner:DONGWOO FINE CHEM CO LTD

Preparation for all-metaposition aromatic polyamide fibre

ActiveCN101275308AImprove heat resistanceImprove flame retardant performanceWet spinning methodsSpinning solutions preparationYarnFiber

The invention relates to a full interposition aromatic polysulfonamides fibre production method, which includes three steps: the spinning serous producing, wet method spinning and post treatment. The spinning serous producing includes the following steps: dissolving 3' 3-diaminodiphenyl sulphone in an organic polar solvent, cooling to -20-20 EDG C; adding metaphenylene dimethylamine acyl with the same molecular of 3' 3-diaminodiphenyl sulphone for executing polymerization reaction; and then adding inorganic base with the same molecular of 3' 3-diaminodiphenyl sulphone for executing neutralization reaction with the hydrogenchloride produced in the polymerization reaction, thereby manufacturing spinning slurry with 10%-20% of dry content. The fabre obtained by the invention method, has largely improved curl performance compared with the conventional aromatic polysulfonamides fibre, obviously improves the elongation at break and improves the resultant yarn leptogenesis.

Owner:中芳新材料有限公司

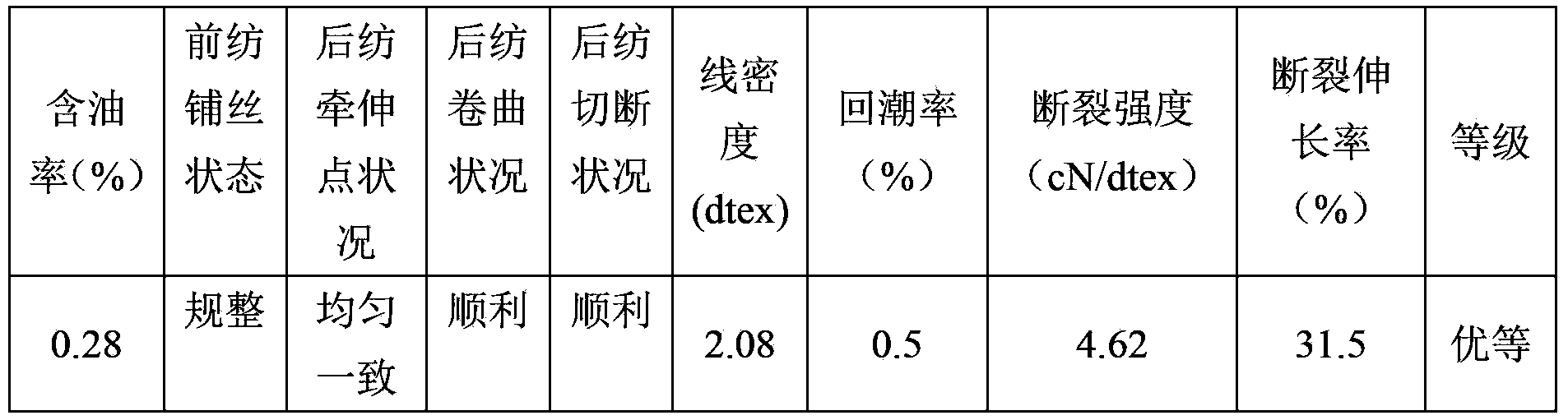

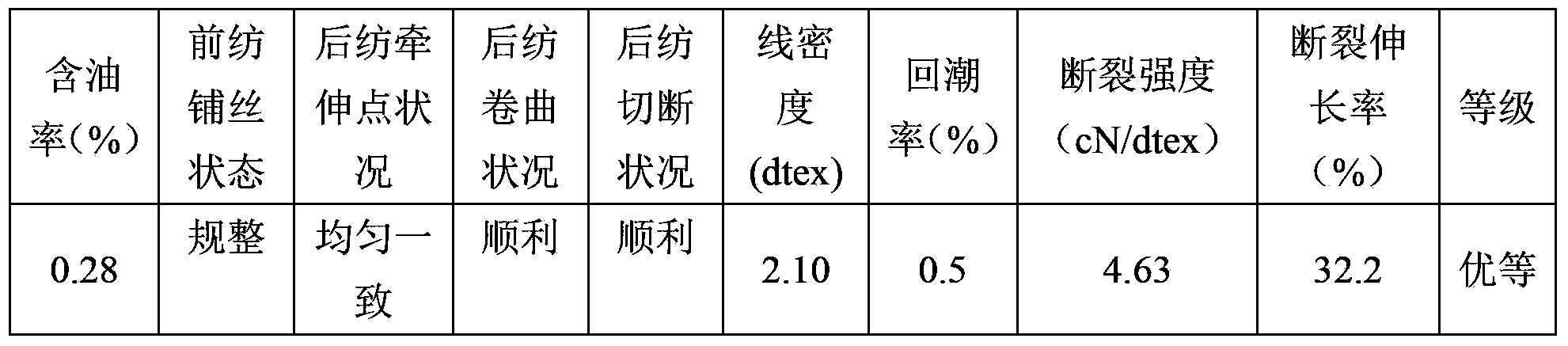

Polyphenylene sulfide short fiber spinning oil and preparation method thereof

ActiveCN103409855ASuitable for antistaticSuitable smoothnessSynthetic polymer filament chemical after-treatmentSpin effectAntistatic agent

The invention discloses a polyphenylene sulfide short fiber spinning oil and a preparation method thereof. The polyphenylene sulfide short fiber spinning oil comprises the following compound raw materials by weight percentage: 25-50 percent of antistat, 15-25 percent of smoothing agent, 18-35 percent of saturant, 5-20 percent of emulsifier and 2-8 percent of modifier. According to the weight percentage of each raw material component, the accurately metered antistat, smoothing agent, saturant, and emulsifier are pumped into a reaction pot, heated to 50-80 DEG C, and uniformly mixed; the modifier is pumped into the reaction pot, agitated for 1-3 h, cooled, filtered, unloaded and packaged. The polyphenylene sulfide short fiber spinning oil has good anti-static electricity performance, smoothness, saturation and the like, is uniform and stable in oil loading, can ensure smooth operation of spinning production and postprocessing working procedure, and satisfies production requirements on spinning effect and the mechanical performance of the fiber.

Owner:天津工大纺织助剂有限公司

Breathable and moisture permeable biodegradable thermal insulating flakes and preparation method thereof

InactiveCN108265395AGood moisture absorption and releasePromote degradationNon-woven fabricsFiberDesorption

The invention provides breathable and moisture permeable biodegradable thermal insulating flakes and a preparation method thereof. The thermal insulating flakes use Viloft fiber as the floc main bodyand three-dimensional crimped hollow fiber and far-infrared fiber as skeleton; ES fiber is made of hot adhesive by hot melt bonding. The present invention is a method of processing a thermal insulating flake using a nonwoven technique. The method uses a variety of different types and functions of new fibers, so that the flakes aggregate the good moisture absorption and desorption of viloft fibers,the curling properties of three-dimensional crimped hollow fibers and the health care function of far-infrared fibers. The invention has certain environmental protection property, and most of the products are biodegradable under certain conditions after the product is discarded.

Owner:HENAN INST OF ENG

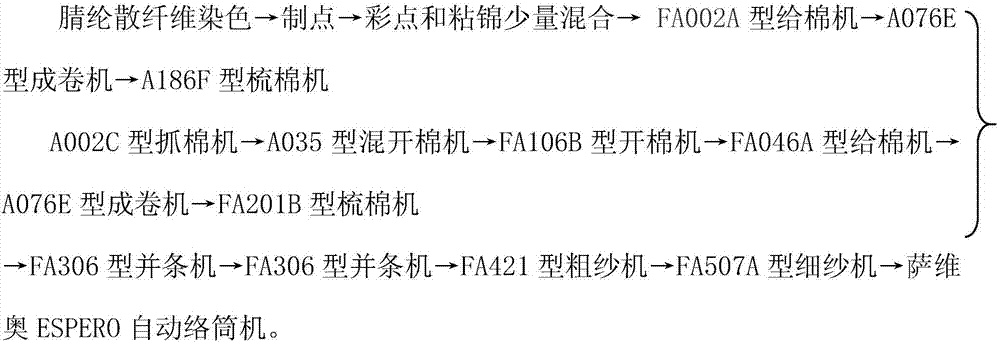

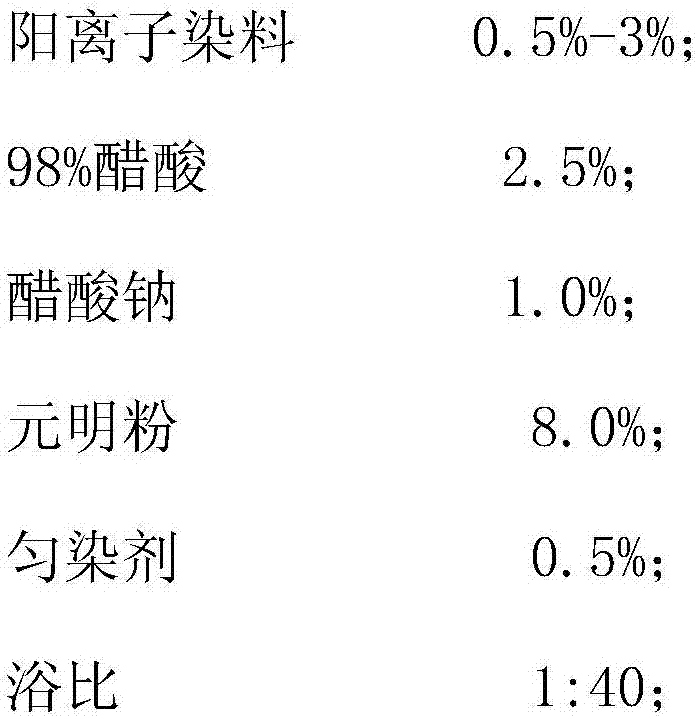

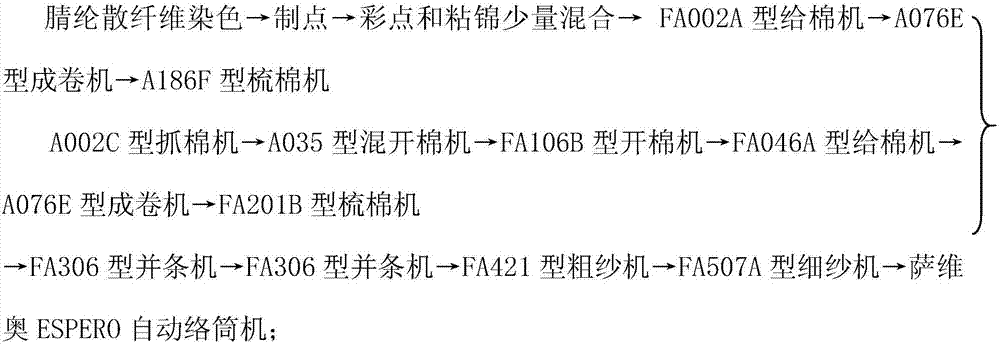

Method for producing PBT (Polythylene Terephthalate) color point core spun yarns

The invention discloses a method for producing PBT (Polythylene Terephthalate) color point core spun yarns. The method comprises the following steps: selecting yarn materials; performing process procedures of the PBT color point core spun yarns; implementing the specific production process. According to the method disclosed by the invention, acrylic fibers serve as raw materials of the points, the color point has rich colors, the color is bright, the stereoscopic impression is excellent, and the price can be saved by 20000 Yuan per tonnage compared with that of common chinlon points. A waterproof agent is diluted according to a ratio and uniformly sprayed onto the points, and the points are dried and roasted at a high temperature, so that the colored point achieves a water-repellent effect, the colored points are prevented from being loosened in the subsequent processing procedure, staining of dyes on the color points is reduced in the dyeing process, the shape and brightness of the color points can be guaranteed, and the quality of the yarns is improved. The PBT serves as the core yarn, viscose cotton serves as an outer packaging material, and the problems that the spandex core-spun yarns are poor in acid resistance and chlorine resistance and have non-ideal dyeing effect are solved. The color point core spun yarns produced by the method disclosed by the invention are excellent in fluffiness and crimpiness and high in elasticity and shape stability and have hand feel of cashmere.

Owner:IANGSU COLLEGE OF ENG & TECH

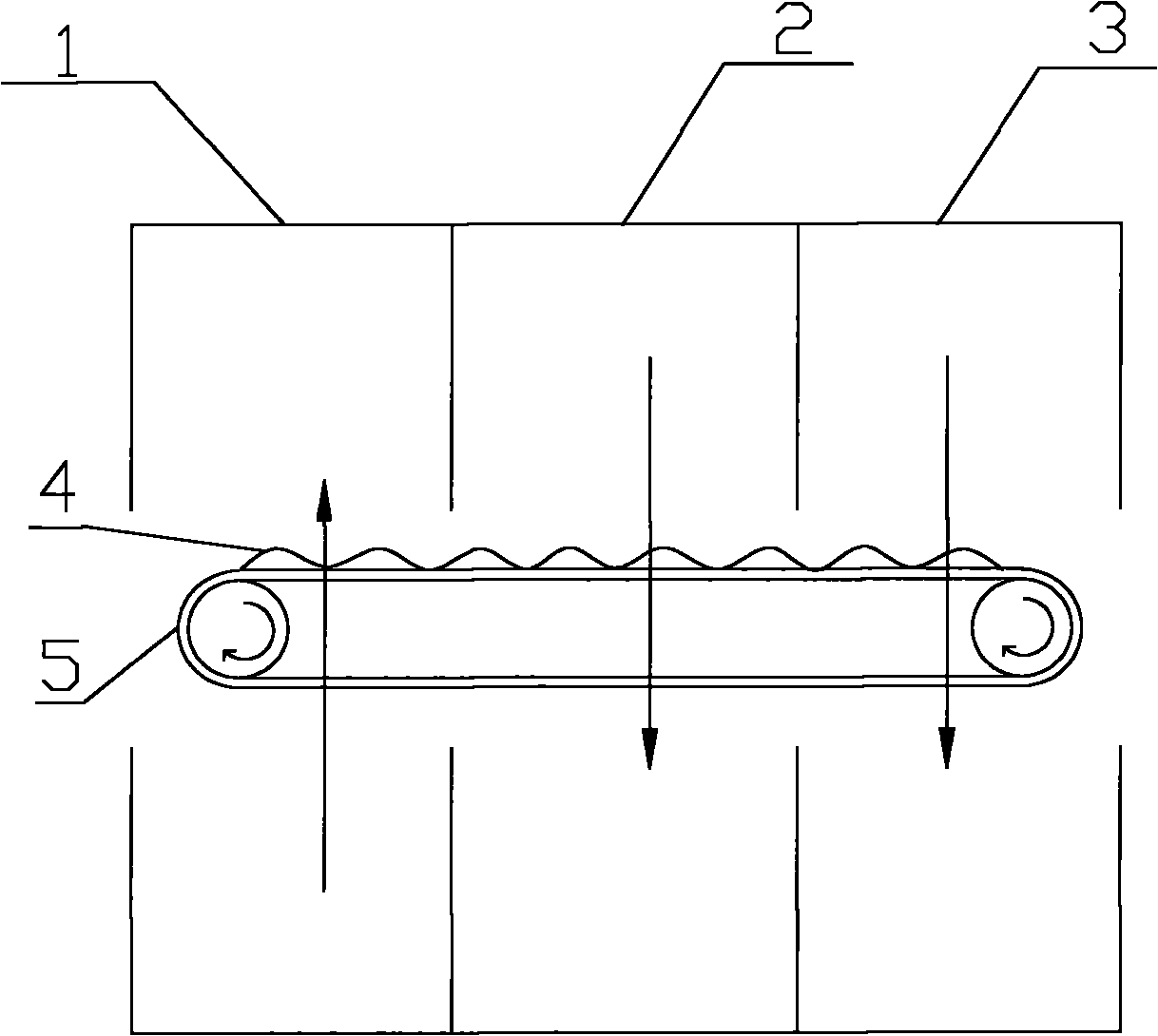

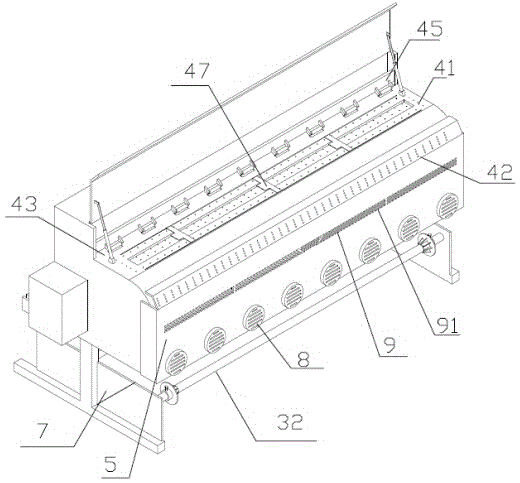

Preparation method of ultrahigh molecular weight polyethylene (UHMWPE) short fibers

InactiveCN102115937AAvoid localized heatStable mechanical propertiesDrying solid materials with heatSevering to form staple fibresFiberPolymer science

The invention provides a preparation method of ultrahigh molecular weight polyethylene (UHMWPE) short fibers, comprising the following steps: preheating UHMWPE long fibers at 40-60 DEG C; curling the preheated UHMWPE long fibers; sequentially carrying out first-stage drying, second-stage drying and third-stage drying on the curled UHMWPE long fibers, wherein in the first-stage drying, hot wind isblown to the UHMWPE long fibers in a direction from the bottom up, in the second-stage drying, the hot wind is blown to the UHMWPE long fibers in a direction from the top down, and the in the third-stage drying, the hot wind is blown to the UHMWPE long fibers in a direction from the top down; and cutting the dried UHMWPE long fibers into short fibers of 50-100mm. An anti-spike fabric prepared from the UHMWPE short fibers prepared in the invention has the advantages of uniform mechanical property and higher anti-spike grade.

Owner:杨珍芬

Wood flooring laminated with high pressure veneer and impregnated low weight printing paper

InactiveCN101006234AImprove surface strengthGood printabilityCovering/liningsSpecial ornamental structuresThermoplasticWood veneer

Disclosed herein is a UV surface-coated laminate wood flooring for an under-floor heating system comprising a back-grooved base, an adhesive layer and a printed wood veneer layer wherein the printed wood veneer layer is produced by impregnating and coating a low-basis weight printed paper with a thermoplastic or thermosetting resin, integrally forming the paper layer with a low-price reinforcing layer by pressing under high pressure, treating the surface of the paper layer with an acryl based primer, and coating the primer-treated paper layer with a solvent-free type UV coating paint, and wherein the back-grooved base and the printed wood veneer layer are adhered to each other by the adhesive layer.

Owner:LG CHEM LTD

Tow with high crimp index for polylactic acid cigarette and preparation method for tow

InactiveCN102704030AHigh crystallinityImprove thermal performanceTobacco smoke filtersMelt spinning methodsPolymer scienceSilicic acid

The invention discloses a tow with a high crimp index for a polylactic acid cigarette and a preparation method for the tow. The tow is prepared from the following raw materials by a melt spinning method: 99-100 percent by weight of polylactic acid, 0.1-0.5 percent by weight of nanoscale titanium dioxide, 0.1-0.5 percent by weight of hydrated magnesium silicate ultrafine powder, wherein the linear density of the tow is 3.5-5.0 ktex, the linear density of a single filament is 2-5 dtex, the crimp number is 18-28 / 25 mm and the crimp index is 0.45-0.65. According to the tow and the preparation method disclosed by the invention, a nucleating agent is added into a polylactic acid raw material, so that the crystallization rate is increased and the crystallinity degree and the thermal performance of fibers are improved, and further the crimp temperature in the subsequent spinning crimp work procedures is increased to 85-95DEG C and the crimp performance is improved; and the crimp index of the whole tow is improved to about 0.55. The tow with high crimp index for the polylactic acid cigarette has better crimp performance; and under the same conditions, unit weight tows can be used for preparing more filter rods, and thus the economic benefits are increased.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC +2

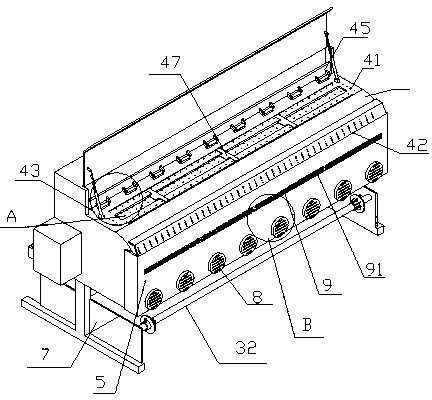

Digital printing machine for wide Dacron wall cloth

ActiveCN104228341AAdapt to the needs of multiple processesHigh thermal efficiencyTypewritersOther printing apparatusPulp and paper industryDigital printing

The invention relates to the field of printing equipment, in particular to a digital printing machine for wide Dacron wall cloth. According to the following technical scheme, the digital printing machine for the wide Dacron wall cloth comprises a rack, a printing device arranged on the rack, a conveying device and a heating device arranged on the rack, the heating device comprises a fixing zone, a low-temperature preheating zone and a medium-temperature fixation zone, and the fixing zone, the low-temperature preheating zone and the medium-temperature fixation zone are sequentially connected to the rack in the conveying direction of the wide Dacron wall cloth and located between an unreeling roller and a reeling roller. According to the digital printing machine for the wide Dacron wall cloth, the structure is simple and implementation is facilitated; the digital printing machine comprises the conveying device and the heating device, the wide Dacron wall cloth can be conveyed flatly, force is borne evenly, and the process requirements for low-temperature color development, medium-temperature fixation and drying and heat dissipation of the wide Dacron wall cloth can be met.

Owner:山东万众纬业新材料科技有限公司

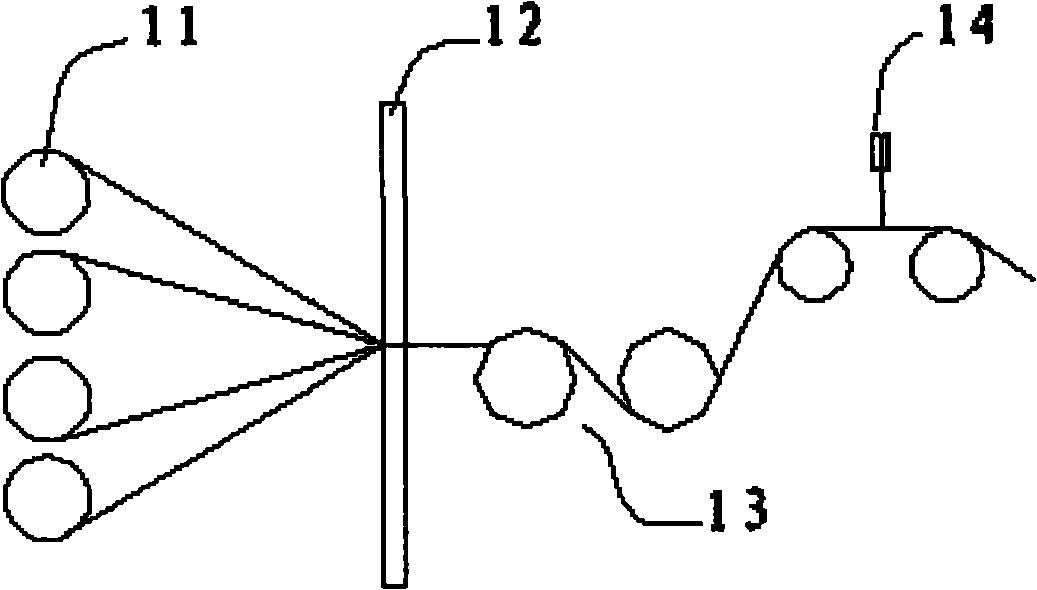

Method for spinning blended yarns with outlast air-conditioning fibers/Newdal fibers

InactiveCN101982583AGuaranteed smooth productionRetains temperature regulating propertiesYarnFiberYarn

A method for spinning blended yarns with Outlast air-conditioning fibers / Newdal fibers is characterized by configuring the ingredients Outlast air-conditioning fibers / Newdal fibers according to the weight ratio of 95-85:5-15; opening the Outlast air-conditioning fibers and the Newdal fibers respectively and spraying antistatic agents; processing the Outlast air-conditioning fibers in a plucker, a blender, a card wire opener, a double-hopper feeder, a lap machine, a carding machine and a pre-drawing machine, and processing the Newdal fibers in the plucker, the blender and opener, a multi-bin blender, a sawblade beater type opener, the double-hopper feeder, the lap machine, the carding machine, the pre-drawing machine, a silver lap machine and a comber; and finally feeding the processed Outlast air-conditioning fibers and Newdal fibers into a drawing machine, a roving frame, a spinning frame and a bobbin winder. The method retains the temperature regulation characteristic of the Outlast air-conditioning fibers and higher strength and wet modulus, excellent breaking elongation and unique high crimp property of the Newdal fibers and ensures the products to have better spinning processibility.

Owner:山东昊龙集团有限公司

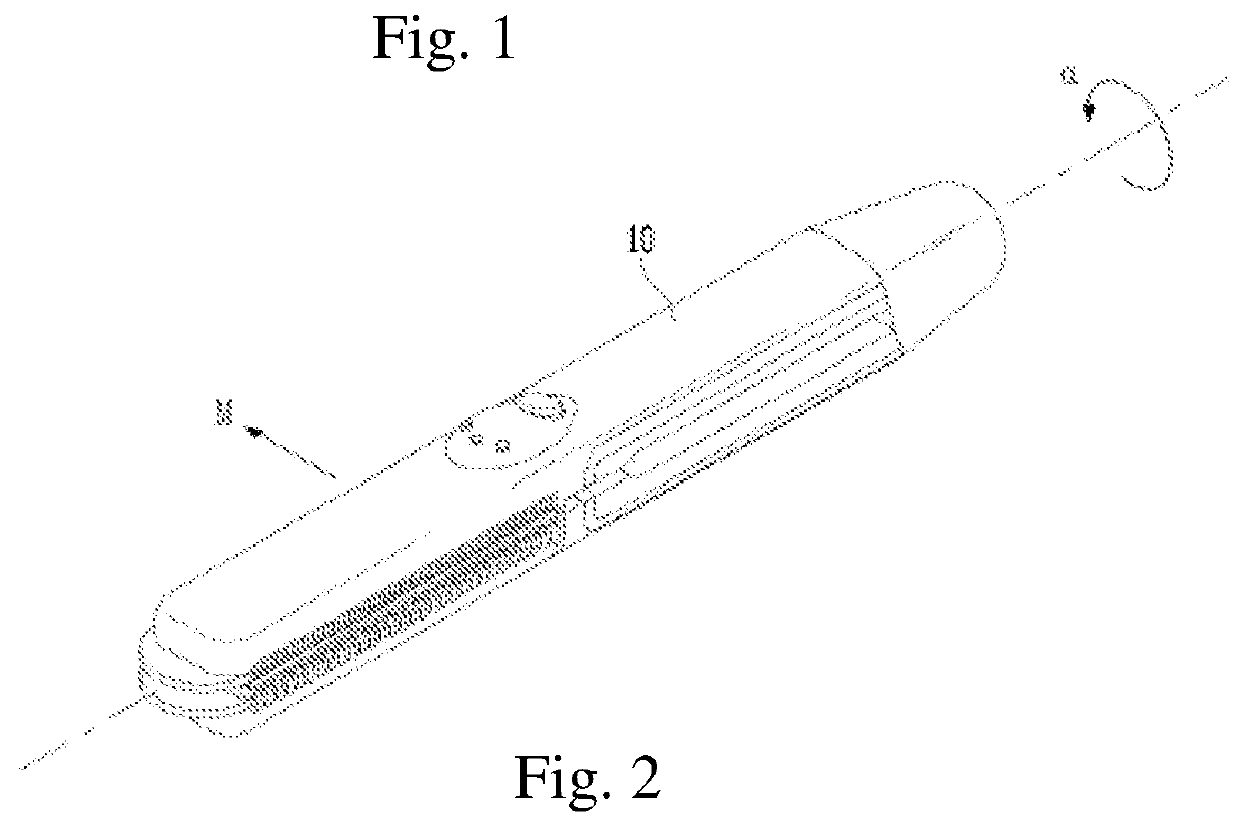

Hair iron

InactiveUS20180177273A1Good hair conditionImprove curling effectCurling-ironsCurling-tongsEngineeringMechanical engineering

Owner:JEONG KWONRYOUL

Wool/crotalaria sp./mulberry silk/cotton/polyester fiber blended fabric and preparation method thereof

The invention relates to a wool / crotalaria sp. / mulberry silk / cotton / polyester fiber blended fabric. The fabric comprises the following material components in percentage by weight: 28% of wool fiber, 35% of crotalaria sp. fiber, 17% of polyester fiber, 18% of cotton fiber and 3% of mulberry silk. The method includes the steps of: 1, top dying process of the cotton fiber and the crotalaria sp. Fiber; 2, dying and re-combing process of the wool fiber, the polyester fiber and the mulberry silk fiber; 3, spinning process; 4 weaving process; 5, dying and finishing process; the spinning process includes: mixing and performing primary gilling, secondary gilling, third gilling and fourth gilling on products prepared by the dying and re-combing process of the wool fiber, the polyester fiber and the mulberry silk fiber, then being subjected to primary roving, secondary roving and spinning processes together with yarn prepared by the top dying process of the cotton fiber and the crotalaria sp. Fiber, when a double-steel wire hook is adopted in the spinning process. The fabric achieves the purpose of being breathable, antibacterial and health-care, and meanwhile meets the requirements on various technical indexes of spring and summer fabrics.

Owner:江苏华西村纺织服装有限公司

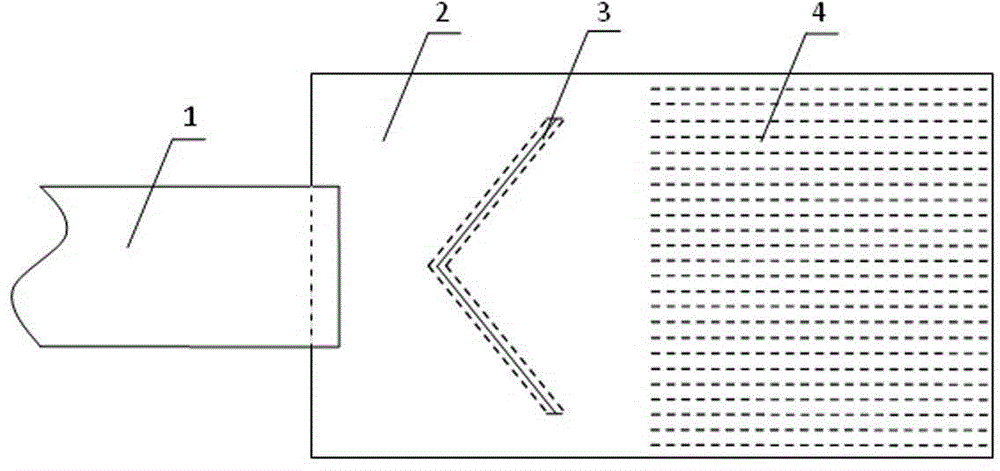

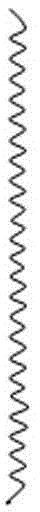

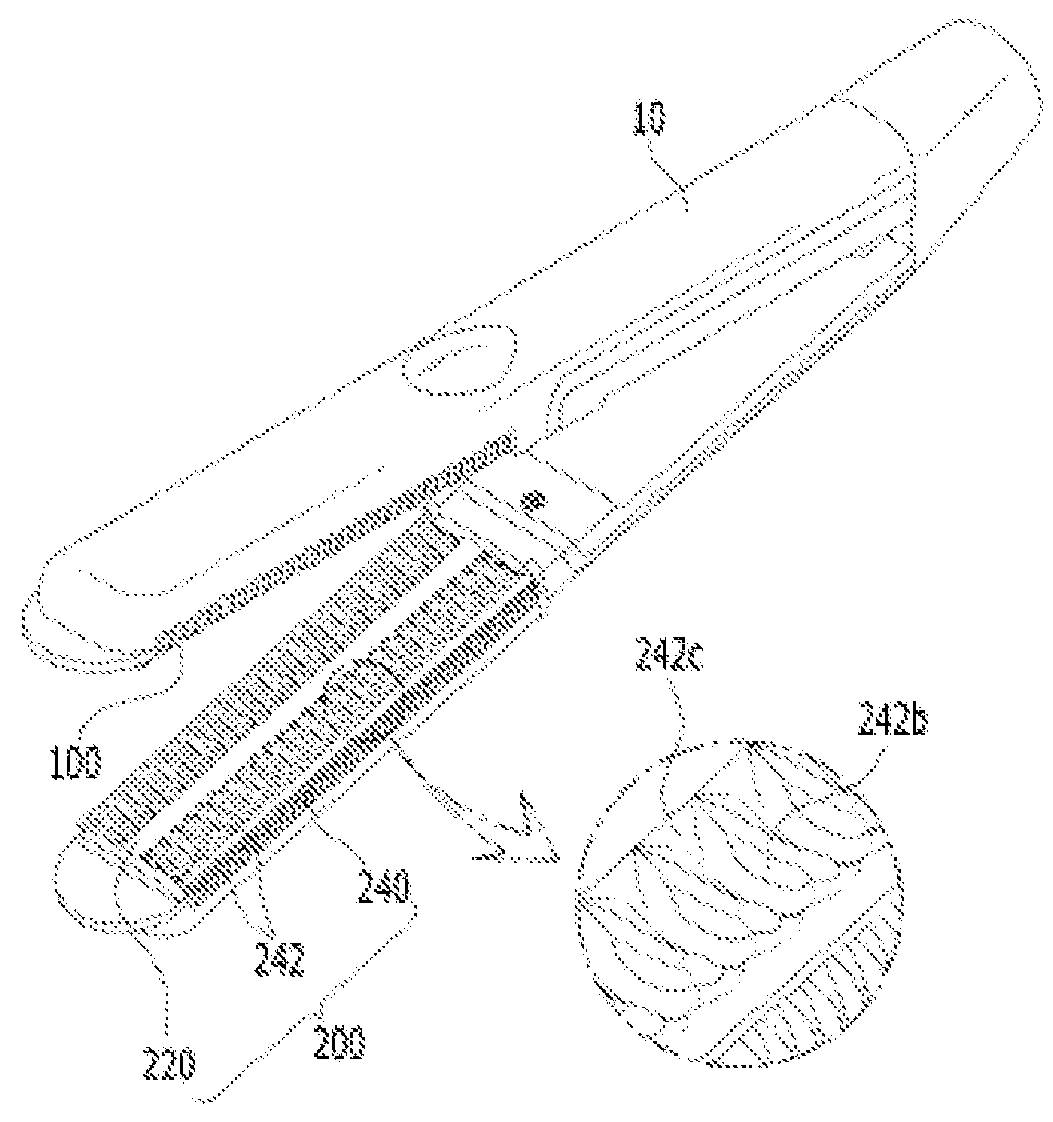

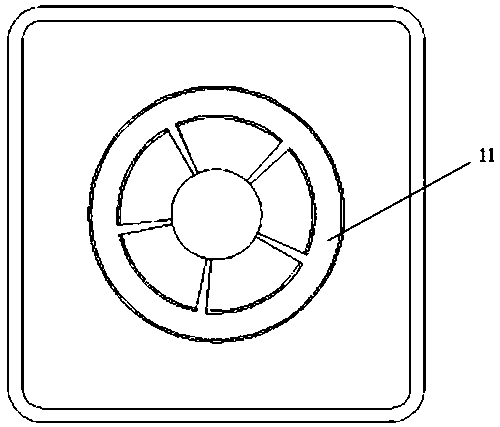

Large-diameter polymer bent filament and production method thereof

ActiveCN103741253AHigh strengthImprove curling effectElectroconductive/antistatic filament manufactureFilament forming substance formingPolyethylene terephthalate glycolPolymer science

The invention discloses a large-diameter polymer bent filament. The large-diameter polymer bent filament is composed of a polymer and a master batch, wherein the weight percent of the polymer is 95-100% and the weight percent of nano powder is 0-5%; the polymer is composed of one or more of polyethylene terephthalate, polytrimethylene terephthalate, polybutylene terephthalate and polypropylene; the master batch is a nano calcium carbonate master batch or a nano titanium dioxide master batch; the filament is 0.05-2mm in diameter or equivalent diameter; the monofilament intensity is more than or equal to 3.0CN / dtex; the elongation at break of the monofilament is 15-35%; the bending rate is 25-35%; the bending stability is more than or equal to 85%. The large-diameter polymer bent filament has the advantages of simple process, convenience in operation and wide application range; the formed fiber has the characteristics of high tenacity, excellent bending performance and high uniformity and the like.

Owner:NANTONG NTEC MONOFILAMENT TECH CO LTD

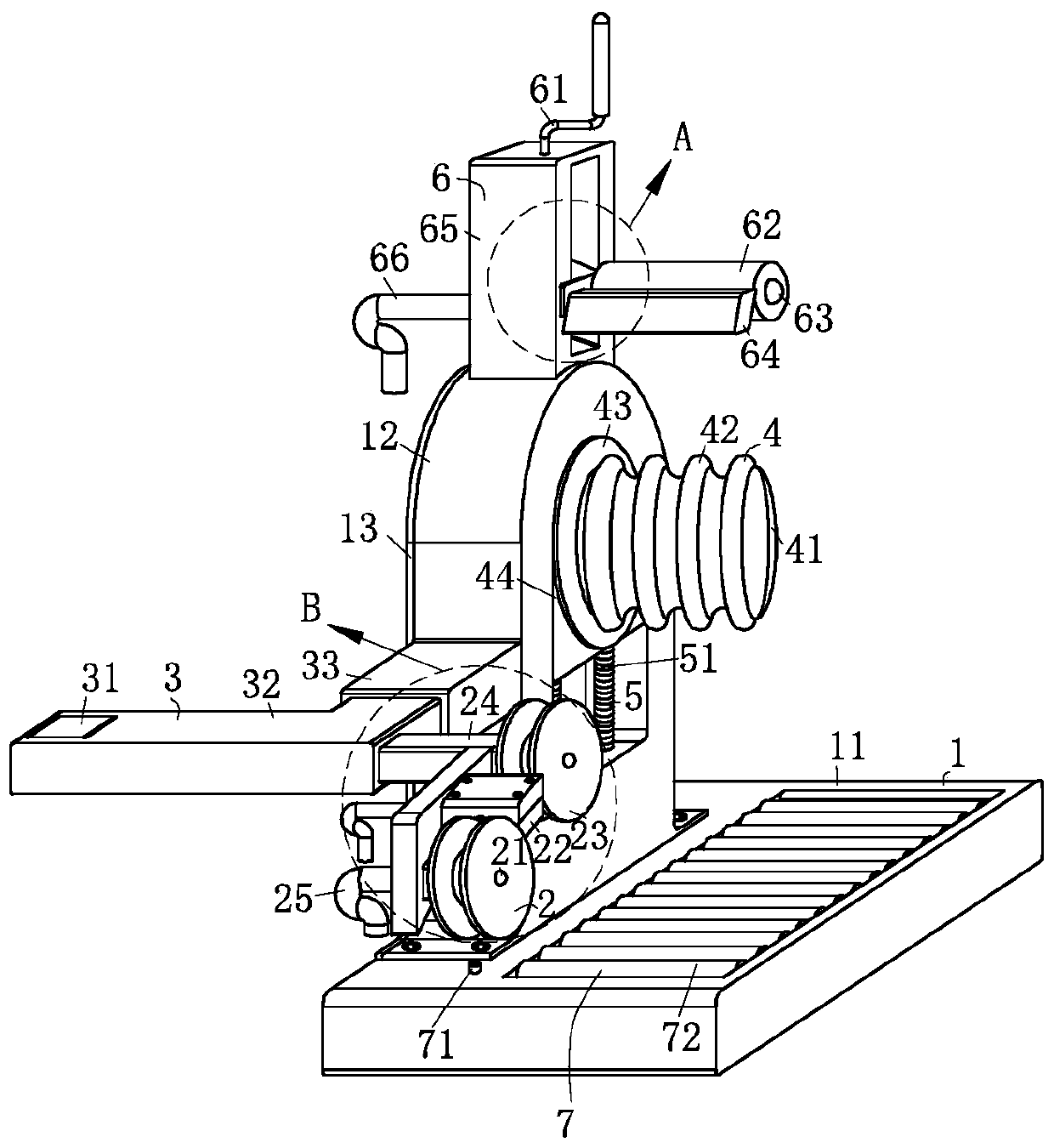

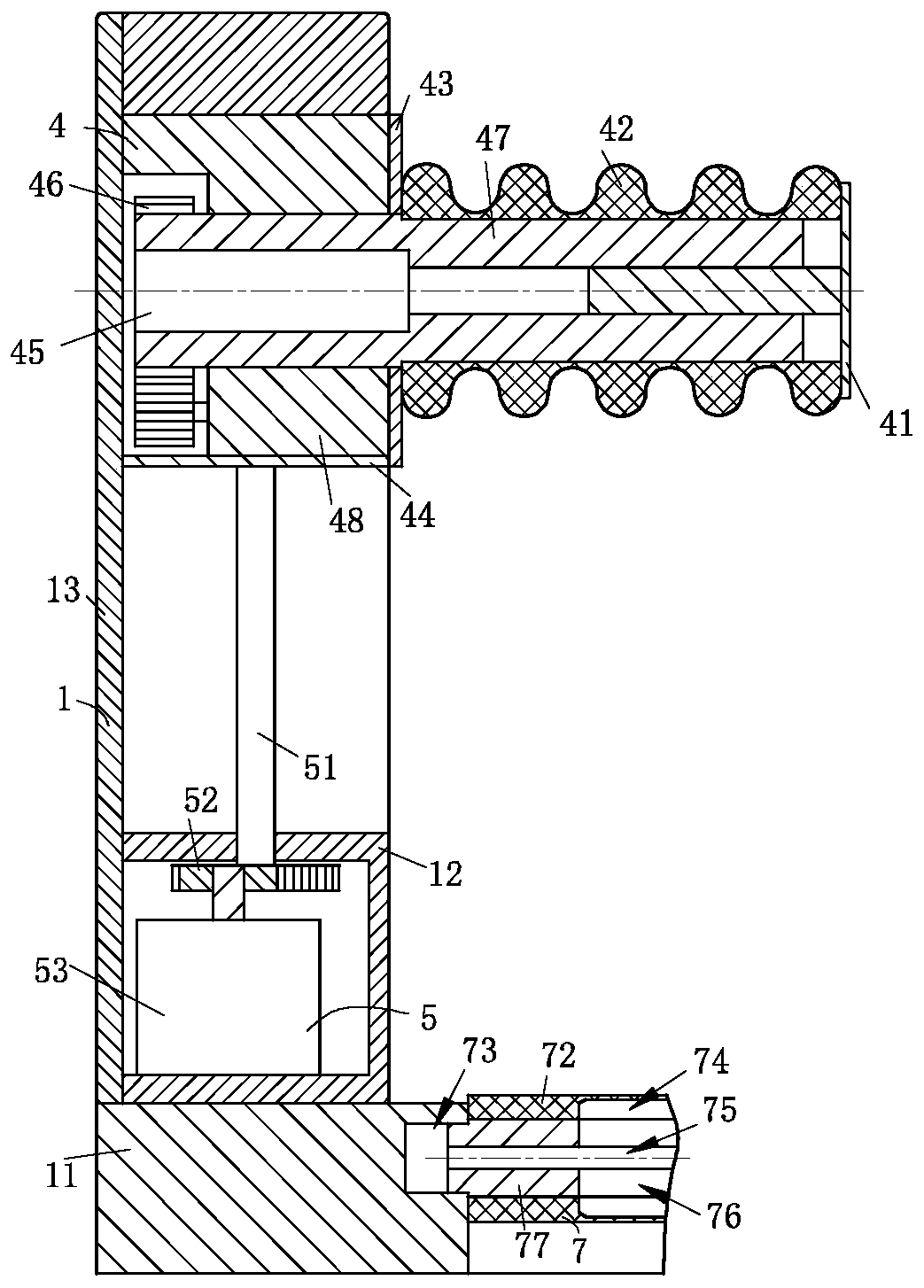

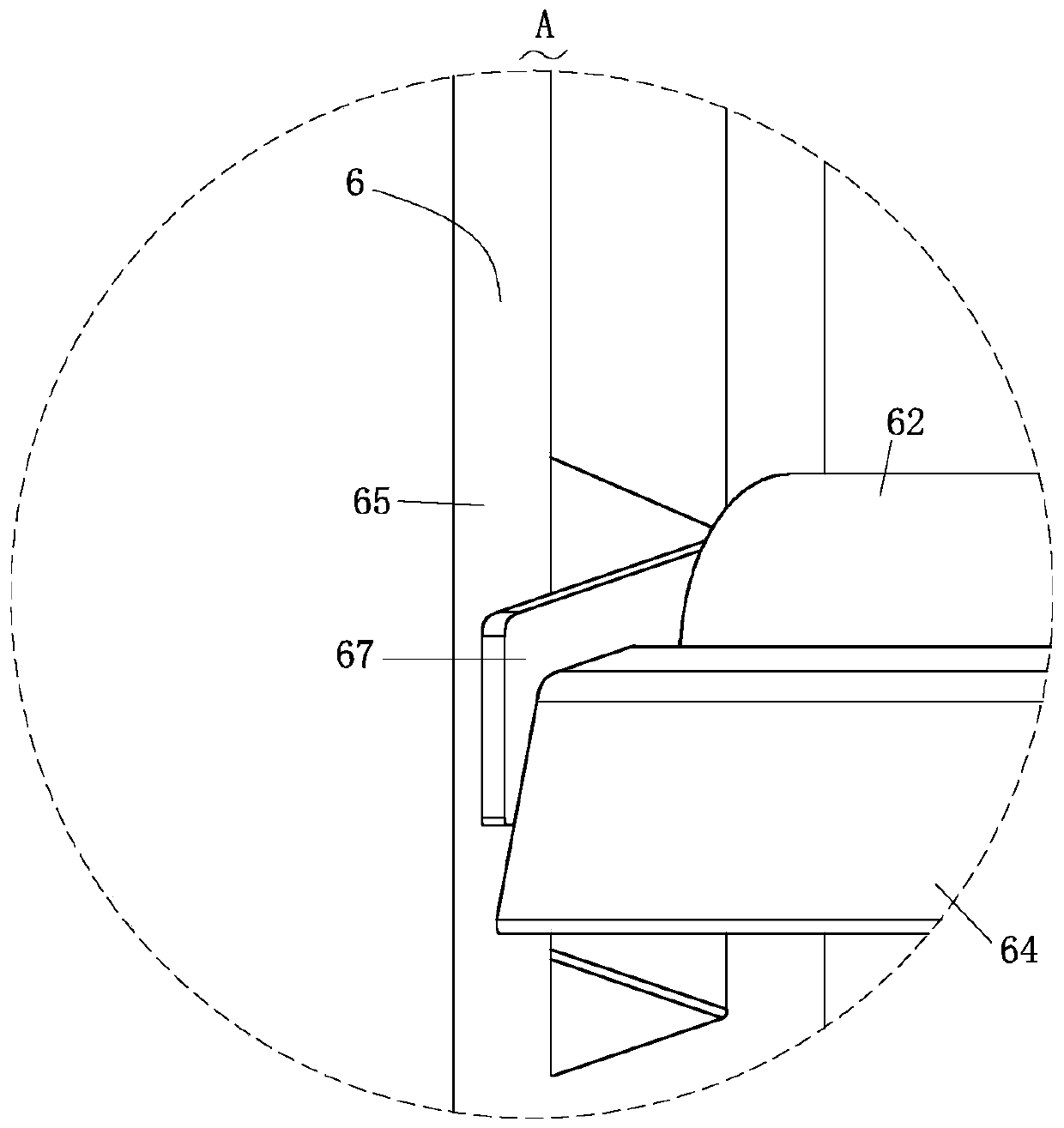

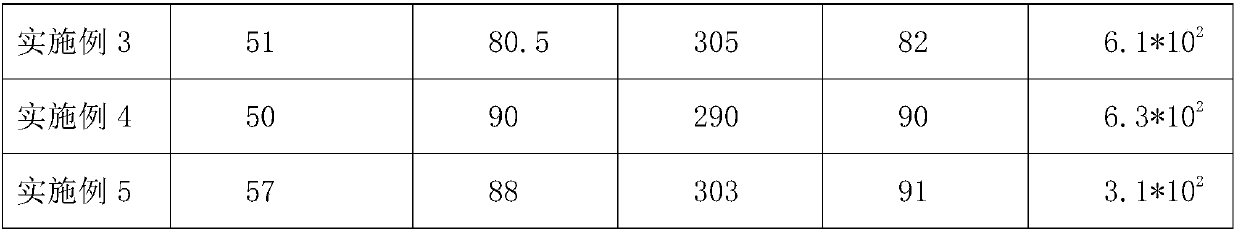

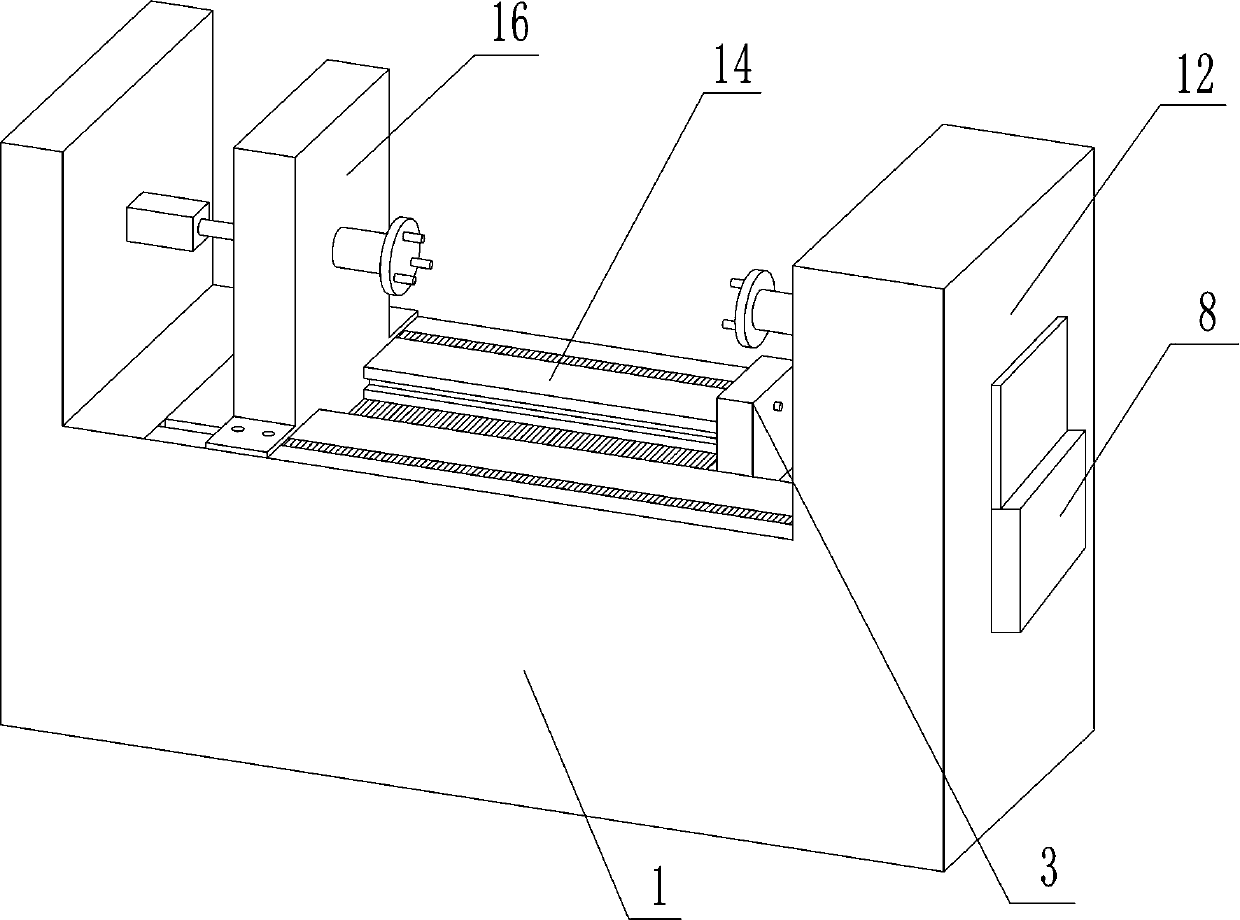

Cable manufacturing equipment

ActiveCN110422702AEasy to placeEasy to rollFilament handlingCable/conductor manufactureConductor CoilMechanical engineering

Owner:重庆燕牌电线电缆有限公司

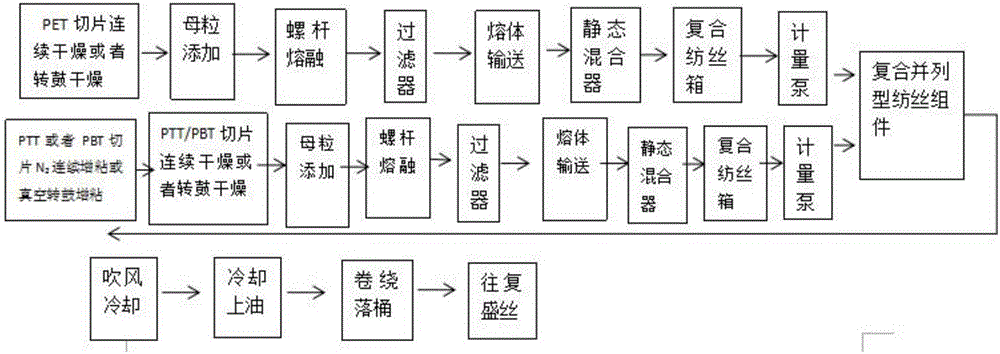

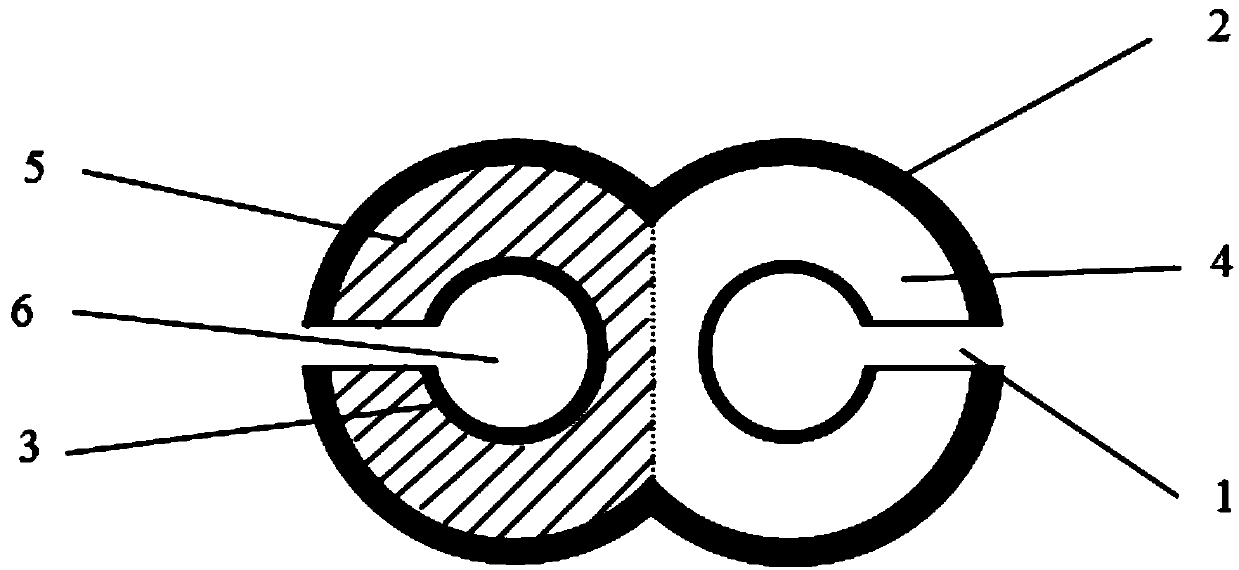

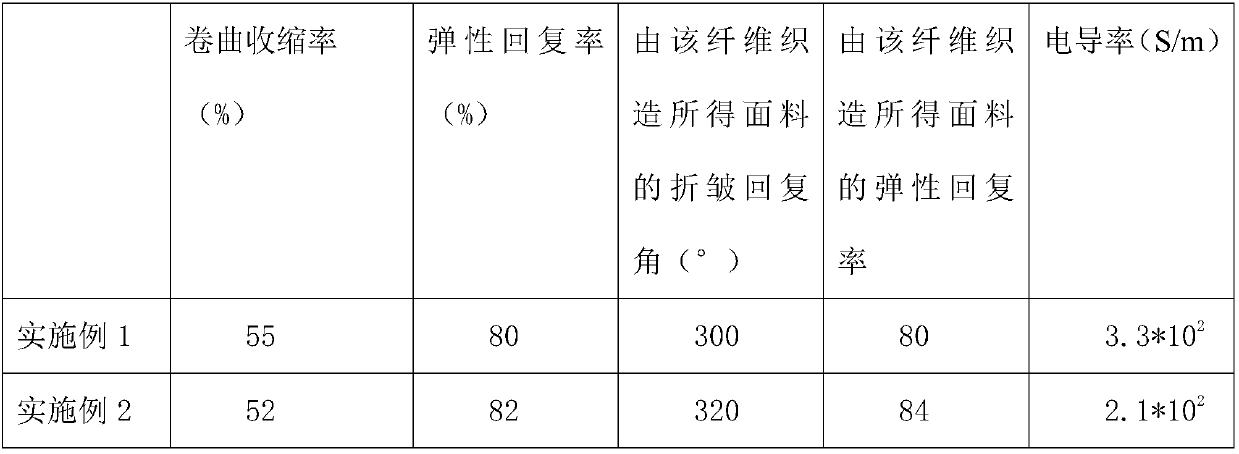

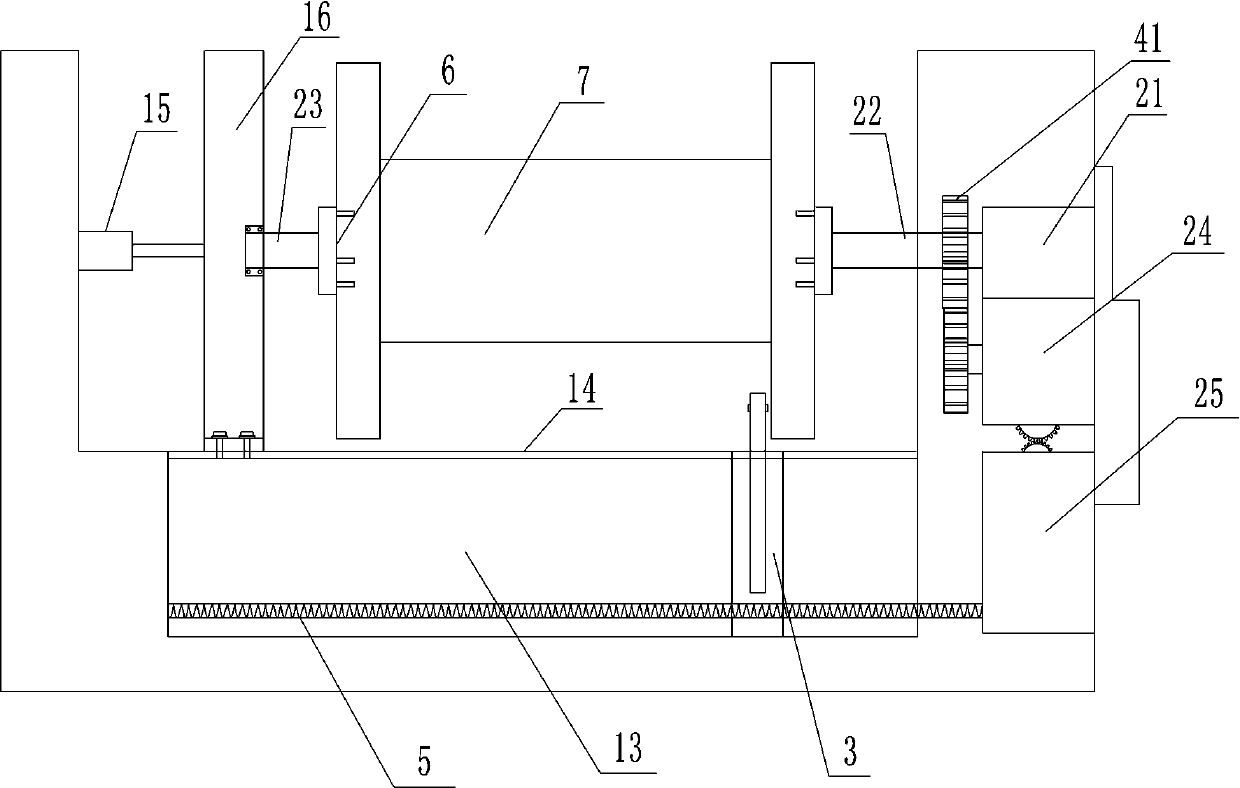

Conductive hollow double-ingredient parallel composite fiber and preparation method thereof

InactiveCN109518454AIncrease surface areaSolve the problem of easy falling offHollow filament manufactureMelt spinning methodsAdditive ingredientElectrical resistivity and conductivity

The invention relates to the technical field of synthetic fiber, in particular to a conductive hollow double-ingredient parallel composite fiber and a preparation method thereof. The composite fiber is formed by two ingredients of an ingredient A and an ingredient B in parallel; the double-ingredient cross section of the composite fiber is in a transverse eight shape or a dumbbell shape or a bielliptic shape or a double square shape or an I shape; hollow structures are respectively arranged in double ingredients of the composite fiber. The composite fiber and the preparation method have the advantages that the conductive hollow double-ingredient parallel composite fiber has inner and outer double conductive layers in parallel double conductive structures; due to the existence of the doubleconductive layers, a synergistic effect is achieved; the surface area of the conductive layer is greatly increased; high conductivity can be provided; the conductivity is 10 to 104S / m; the compositefiber hollow structure provides an inner conductive layer; the composite fiber is communicated with an outer opening in the drying process for contraction and closing, so that the problem that conductive particles attached on a conduction and coating electric layer at the inner surface of the composite fiber can easily fall off is solved.

Owner:LANGSHA KNITTING

Hairdressing agent with Chinese traditional medicine as main material and method for preparing the same

Disclosed is a hairdressing agent with Chinese traditional medicine as main material and method for preparing, wherein the hair-waving agent comprises agent 1 and agent 2, the agent 1 employs cystinic acid as the reducing agent, sodium hydrogen sulfite as auxiliary reducing agent, traditional Chinese medicinal clove as penetrating agent, while the agent 2 employs hydrogen peroxide and belamcanda rhizome as combination oxidizing agent, clove as penetrating agent. The two portions of the agent are prepared separately and used in combination.

Owner:SHANGHAI JIAO TONG UNIV

Metal sheath mineral insulated cable uniform rolling device and application method

PendingCN111591834AAvoid damageSolve the unstable center of gravityFilament handlingElectric machineGear wheel

The invention discloses a metal sheath mineral insulated cable uniform rolling device and an application method. A workbench and a power box are included. A wiring groove and a lead screw are arrangedin the workbench, and a wiring box is arranged on the lead screw. One side surface of the workbench is connected with a limiting plate through an air cylinder. A motor, a gear speed changing box anda gear reversing device are arranged in the power box, and cooperation with a cable disc is achieved through a rotation shaft and a chuck structure at one end of the rotation shaft. The single motor is adopted in the device to drive the cable disc and a wiring device, a cable penetrates through the uniform-speed moving wiring device to be wound around the cable disc, and uniform wiring is achieved; long-cable multi-time reciprocated wiring is achieved through cooperation of the wiring device and the reversing device; an arc penetration groove is formed in the wiring box and used for pre-reeling, the problems that the existing equipment wiring position is fixed, winding is uneven, and consequently the gravity center of a cable disc is not stable and the problem that since pre-reeling cannotbe conducted, an outer sheath of a metal sheath cable is broken and torn are solved; and the characteristics that wiring is uniform, the reeling effect is good, and the cable can be protected againstdamage are achieved.

Owner:YICHANG HONGQI ZHONGTAI CABLE CO LTD

Heavy type cutting rotary turning and milling composite blade

InactiveCN108655427AImprove impact resistanceStable cutting processMilling cuttersCutting insertsSet screwEdge strength

A blade is mainly applied to the field of heavy type cutting, and the problems that during heavy type machining of large special-shaped pieces, since the cutting parameters are large and the machinedcomponent surface state is complex, the blade is likely to vibrate, and failures happen need to be solved. For the large special-shaped piece machining complex work condition, a heavy type cutting rotary turning and milling composite blade is developed and designed. The blade is provided with a linear cutting edge and an arc cutting edge; and meanwhile, the large parameters during heavy type cutting are considered, so that negative chamfer is designed, and the cutting edge strength of the blade can be improved. Streamline protrusions and conical abrasion reducing protrusions are designed on the upper cutter face, and during machining, the functions that the cutting temperature is reduced and scrap rolling and discharging are assisted can be achieved, and meanwhile the anti-vibration capability of the blade is improved. An octangle groove and a set screw hole are designed in the geometric center of the blade, an annular heat dissipation groove is designed in the bottom, the blade and air contact area can be increased while cutting fluid is stored, the heat dissipation function is achieved during blade cutting, and meanwhile the blade strength is improved. The whole blade structure is complete, the production cost is low, and the heavy type cutting rotary turning and milling composite blade is suitable for being used for heavy type turning and milling machining.

Owner:HARBIN UNIV OF SCI & TECH

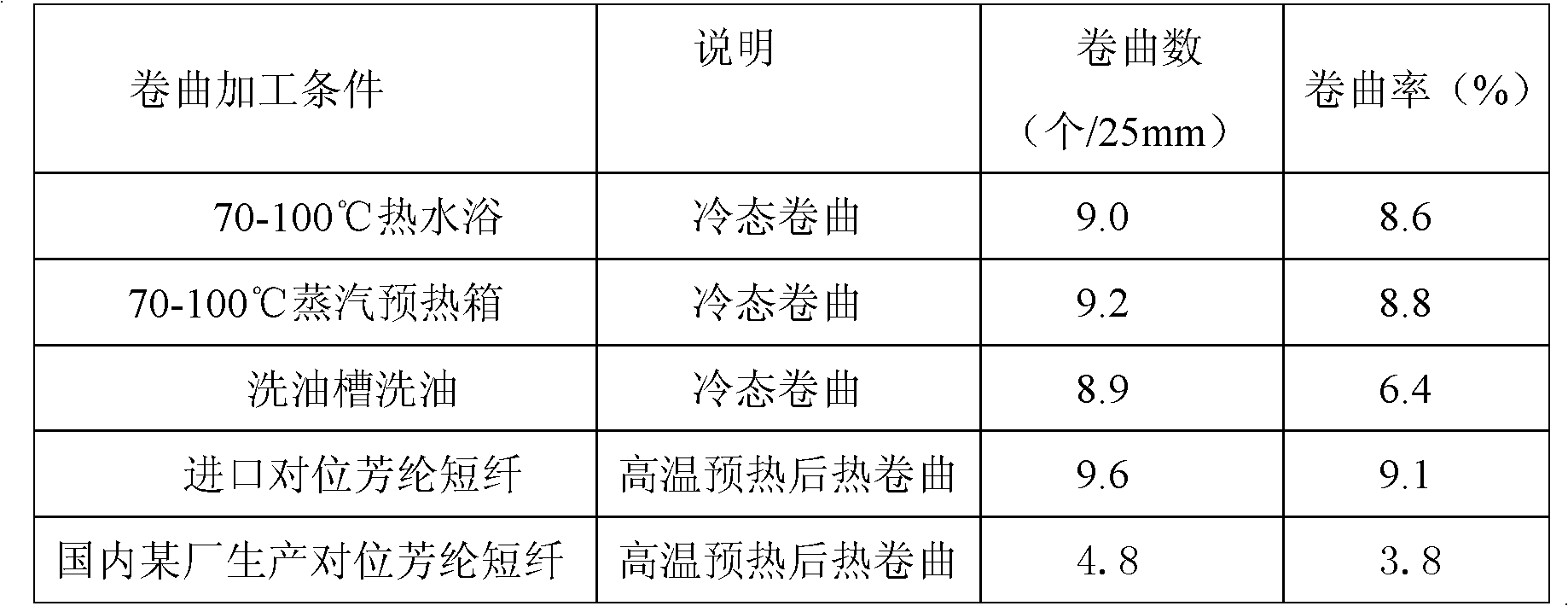

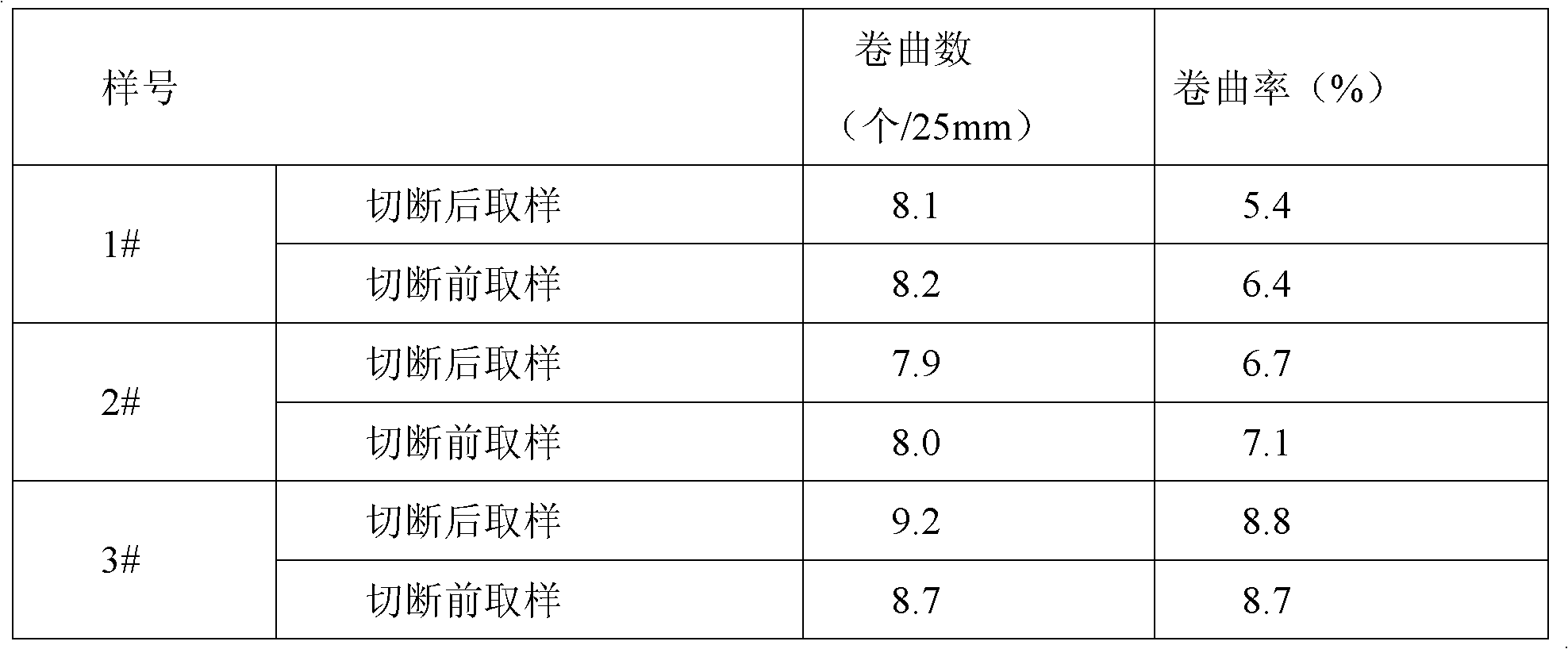

Method for curling para-position aramid short fibers

The invention discloses a cold-state curling method for producing para-position aramid short fibers. The method comprises the following steps of: bunching aramid filaments, washing by the oil washing of an oil washing tank or hot water bath or a low-pressure steam heat box, and curling the softened aramid filaments in a mechanical stuffing curling box; after curling the aramid filaments, drying the curled fibers in a drying oven at the temperature of between 80 and 140 DEG C; and performing tensioning, and cutting the fibers off in a cut-off machine to obtain the para-position aramid short fibers with high curling performance. According to the method, before entering the curling box, the fibers are not needed to be subjected to high-temperature preheating treatment at the temperature which is higher than the glass transition temperature of 340 DEG C of the fibers so as to soften molecular chain segments, the fibers are not needed to be heated at high temperature in the curling box, and the curled fibers are not needed to be subjected to high-temperature setting of about 340 DEG C.

Owner:CHINA PETROLEUM & CHEM CORP +1

A digital printing machine for wide-width polyester wall covering

ActiveCN104228341BAdapt to the needs of multiple processesHigh thermal efficiencyTypewritersOther printing apparatusPolyesterPolymer science

The invention relates to the field of printing equipment, in particular to a digital printing machine for wide-width polyester wall coverings. The above technical purpose of the present invention is achieved through the following technical solutions: a digital printing machine for wide-width polyester wall coverings, including a frame, a printing device on the frame, a transmission device and a The heating device on the frame, the heating device includes a fixed area and a low-temperature preheating area connected to the frame in sequence according to the conveying direction of the polyester wall covering and located between the unwinding drum and the winding drum And medium temperature fixing area. The purpose of the present invention is to provide a digital printing machine for wide-width polyester wall covering, which has a simple structure and is convenient for implementation. Wide-width polyester wall coverings require low-temperature color development, medium-temperature color fixation, and drying and heat dissipation.

Owner:南京裂潭科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com