Breathable and moisture permeable biodegradable thermal insulating flakes and preparation method thereof

A biodegradable and flake technology, applied in the field of non-woven fabrics, can solve the problems of poor hygroscopicity and difficult biodegradation of thermal flakes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

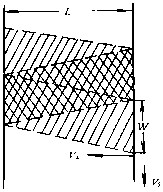

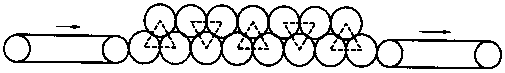

Image

Examples

Embodiment 1

[0025] A breathable and moisture-permeable biodegradable warm-keeping floc, which is processed by hot-melt bonding of Viloft fibers, three-dimensional crimped hollow fibers, and far-infrared fibers. Among them, the proportion of various fibers is: Viloft fiber 50%, three-dimensional crimped hollow fiber 25%, far-infrared fiber 5%, ES fiber 20%.

[0026] The Viloft fiber is the main body of the floc, the three-dimensional crimped hollow fiber and the far-infrared fiber are the skeleton, and the ES fiber is the thermal adhesive.

[0027] The length of the Viloft fiber is 38mm, and the linear density is 2.4dtex; the length of the three-dimensional crimped hollow fiber is 51mm, and the linear density is 6.67dtex; the length of the far-infrared fiber is 51mm, and the linear density is 5.6dtex; the length of the ES fiber is 51mm, Line density 2.2dtex.

[0028] (1) Select Viloft fiber, three-dimensional crimped hollow fiber, far-infrared fiber, and ES fiber as raw materials accordin...

Embodiment 2

[0036] A breathable and moisture-permeable biodegradable thermal insulation wadding. The thermal insulation wadding is made of Viloft fiber as the main material, three-dimensional crimped hollow fiber and far-infrared fiber as the skeleton, and ES fiber as thermal adhesive through hot-melt bonding. Among them, the proportion of various fibers is: Viloft fiber 35%, three-dimensional crimped hollow fiber 20%, far-infrared fiber 10%, ES fiber 35%.

[0037] The length of the Viloft fiber is 38mm, and the linear density is 2.4dtex; the length of the three-dimensional crimped hollow fiber is 38mm, and the linear density is 3.33~6.67dtex; the length of the far-infrared fiber is 34mm, and the linear density is 2.7dtex; the length of the ES fiber is 38 mm, linear density 2.2 dtex.

[0038] (1) Select Viloft fiber, three-dimensional crimped hollow fiber, far-infrared fiber, and ES fiber as raw materials according to the above mass ratio; Viloft fiber is the main body of floc, the three-...

Embodiment 3

[0046] A breathable and moisture-permeable biodegradable thermal insulation wadding. The thermal insulation wadding is made of Viloft fiber as the main material, three-dimensional crimped hollow fiber and far-infrared fiber as the skeleton, and ES fiber as thermal adhesive through hot-melt bonding. Among them, the proportion of various fibers is: Viloft fiber 60%, three-dimensional crimped hollow fiber 20%, far-infrared fiber 5%, ES fiber 15%.

[0047] The length of the Viloft fiber is 45 mm, and the linear density is 2.4 dtex; the length of the three-dimensional crimped hollow fiber is 45 mm, and the linear density is 4.55 dtex; the length of the far-infrared fiber is 50 mm, and the linear density is 4.5 dtex; the length of the ES fiber is 45 mm. mm, linear density 2.2 dtex.

[0048] (1) Select Viloft fiber, three-dimensional crimped hollow fiber, far-infrared fiber, and ES fiber as raw materials according to the above mass ratio; Viloft fiber is the main body of floc, the th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com