Vortex spinning compound sunscreen fabric

A vortex spinning and fabric technology, applied in the field of fabrics, can solve the problems of airtightness and washing resistance of fabrics, loss of anti-ultraviolet effect, easy washing off of coatings, etc., and achieves good moisture absorption and dehumidification effect and good anti-ultraviolet performance. , Good stereoscopic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

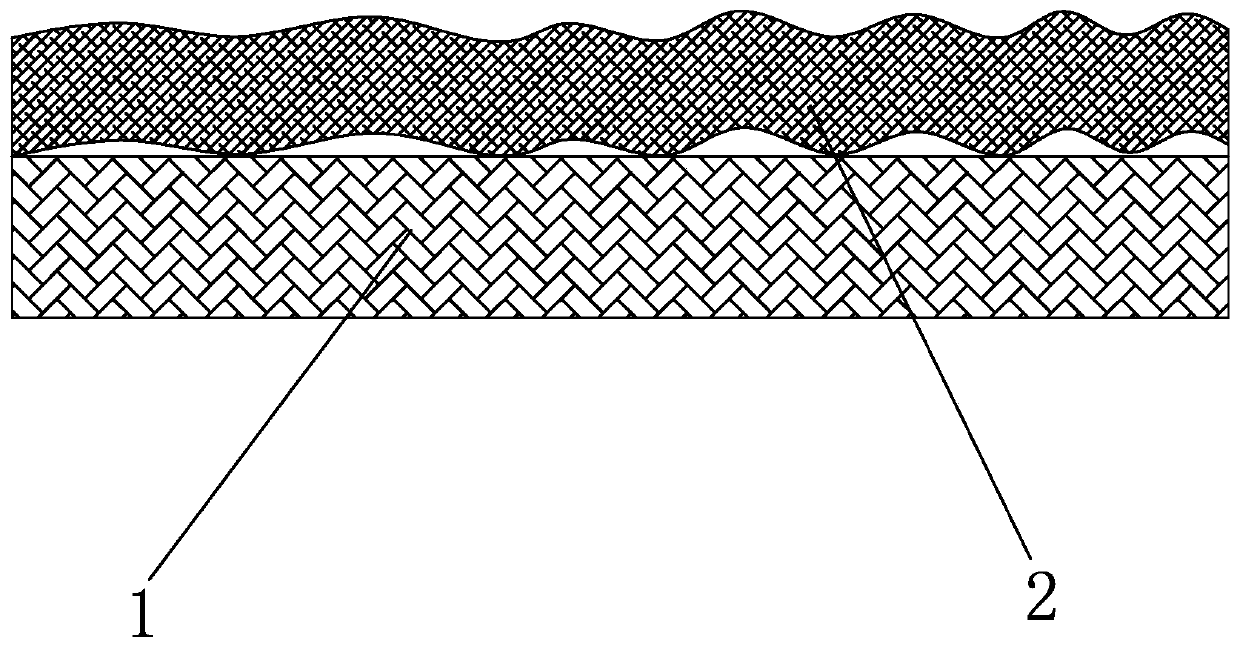

[0019] combine figure 1 , the invention discloses a vortex spinning composite sunscreen fabric, comprising an inner fabric 1 and an outer fabric 2 . The inner layer fabric 1 and the outer layer fabric 2 are stitched by spandex filaments, and the outer layer fabric 2 is stacked on the outside of the inner layer fabric 1 . The inner layer fabric 1 of the present invention is smooth and comfortable, and has a good touch feeling, and the outer layer fabric 2 is light and slightly wrinkled, and has a good appearance effect. The outer fabric 2 is woven with a twill weave structure. The warp yarn of the outer layer fabric 2 is untwisted coffee charcoal core-spun yarn. The weft yarn of the outer layer fabric 2 is a strongly twisted polyester shrinkage yarn. The core yarn of the coffee charcoal core-spun yarn is polyester filament with special-shaped cross-section, the outer fiber of the coffee charcoal core-spun yarn is coffee charcoal staple fiber, and the coffee charcoal staple f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com