Decorative structure

A decorative structure and decorative film technology, applied in the field of lamps or decorative parts, manufacturing decorative films of such decorative structures, can solve the problems of difficult realization of actual processes, interference of light sources, complicated structure of printed sheets, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-15 and comparative example 1-3

[0107] A laminated film having the following layer configuration was produced.

[0108] Adhesive layer (clear acrylic adhesive, 35 microns thick) / metal coating (evaporated tin layer, 0.5 microns thick) / base layer (polyurethane film, 50 microns thick) / black coloring layer (polyurethane film, 5 microns thick) / Transparent layer (transparent polyurethane film, 20 microns thick)

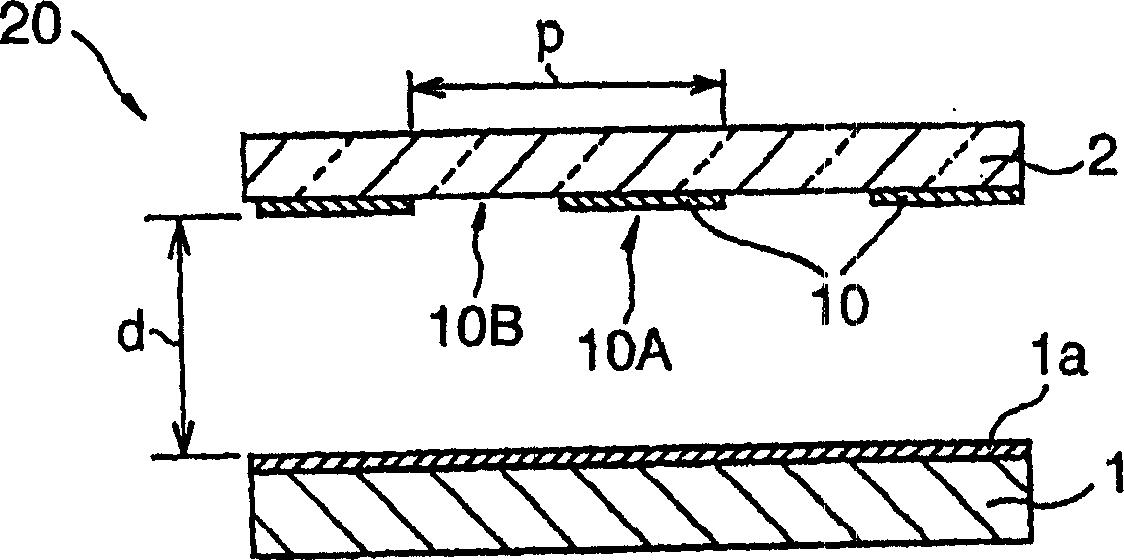

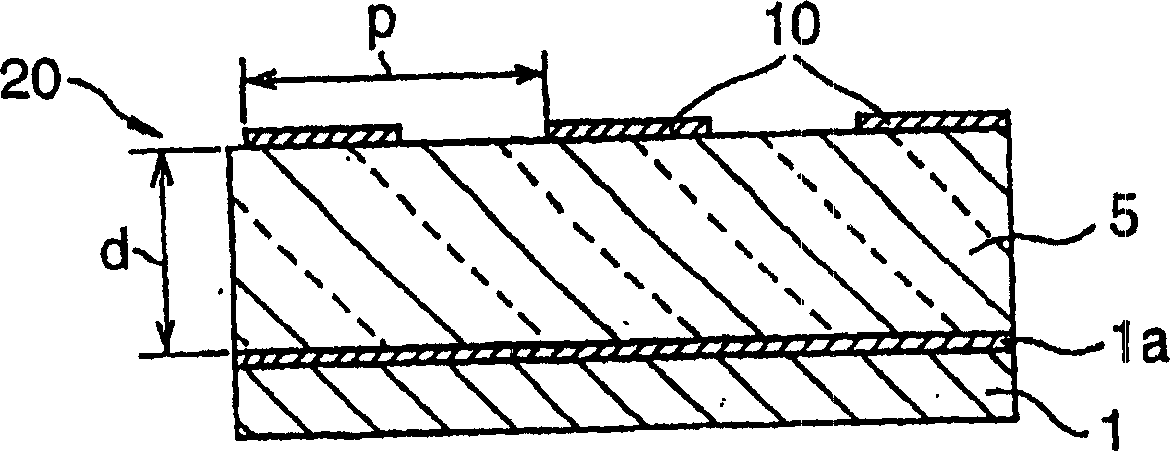

[0109] As shown in the table, the laminated film was cut into pieces of different widths, and these pieces were arranged to have different pitches (circular values in which transparent parts and light-shielding parts were repeated alternately) p, in this case Next, the sheets are integrated by a carrier tape with an adhesive. The obtained strip-shaped decorative film was pasted to a colorless and transparent acrylic sheet (2 mm thick), and pressed.

[0110] Paste the vapor-deposited aluminum film on one side of an acrylic resin plate having the same shape and size as the above-mentioned acryli...

Embodiment 16

[0118] A decorative film having a layer configuration as shown in Table 2 was produced. This decorative film is intended to be glued to the inside of the lampshade.

[0119] Table 2

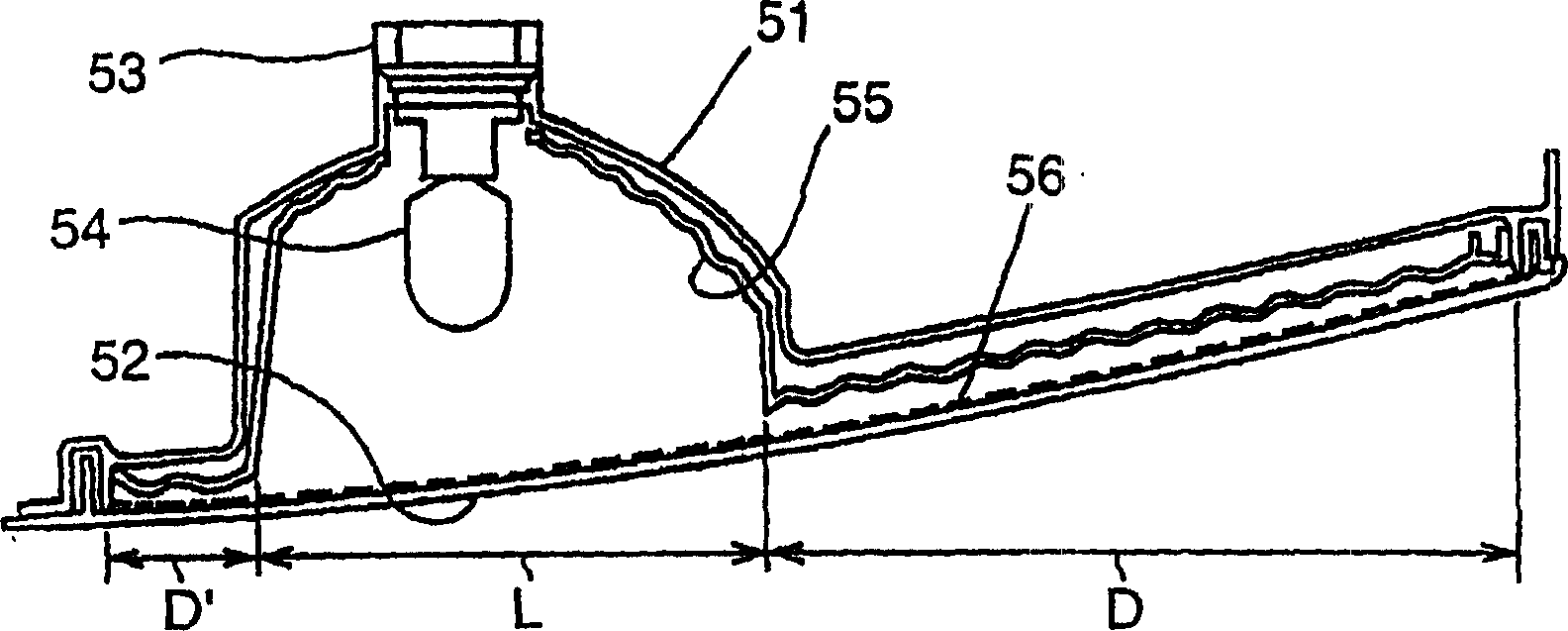

[0120] lampshade

Adhesive layer (acrylic adhesive)

40 microns thick

colorless and transparent

Metal coating (aluminized film)

0.5 microns thick

Plating color

Base layer (polyester film)

50 microns thick

colorless and transparent

Coloring layer (polyurethane)

10 microns thick

black

[0121] The coloring layer, base layer and adhesive layer were produced by using products tried in the field of vehicle exterior parts and used in actual outdoors.

[0122] The resulting laminated film was cut into pieces having a width of 4 mm, and then, the pieces were arranged at intervals of 4 mm, and under this condition, the pieces were integrated by a carrier tape having an adhesive. A decorative piece in the form of...

Embodiment 17

[0129] A decorative film having a layer configuration as shown in Table 3 was prepared. This decorative film is glued to the outside of the lampshade.

[0130] table 3

[0131] lampshade

Transparent layer (polyurethane)

30 microns thick

colorless and transparent

Base layer (polyester film)

50 microns thick

colorless and transparent

Metal coating (evaporated aluminum film)

0.5 microns thick

Plating color

Tie layer (polyurethane)

20 microns thick

colorless and transparent

Colored layer (polyurethane film)

10 microns thick

black

Adhesive layer (acrylic adhesive)

40 microns thick

colorless and transparent

[0132] The coloring layer, base layer and adhesive layer were produced by using products tried in the field of vehicle exterior parts and used in actual outdoors.

[0133] The resulting laminated film was cut into pieces having a width of 4 mm, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com