Instep shape fixing process and its special shoe last

A technology for shoe uppers and shoe lasts, applied in shoe lasts, footwear, applications, etc., can solve problems such as unsatisfactory appearance, complicated manufacturing process, and large leather damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

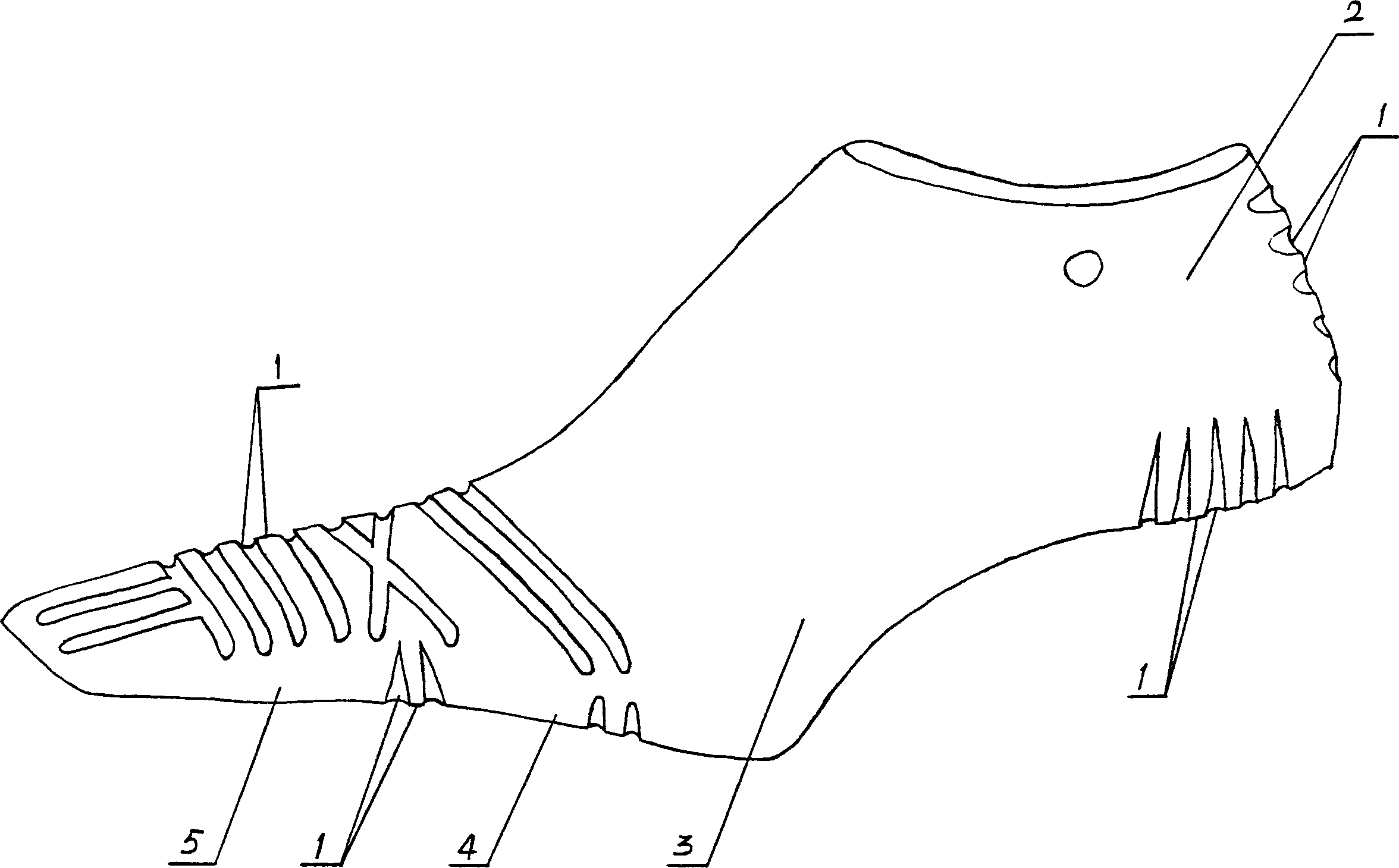

[0015] Now in conjunction with accompanying drawing of description, further illustrate the present invention.

[0016] Described a kind of vamp shaping process, concrete operation steps are as follows:

[0017] 1) Put a toe piece or brush hot melt glue on the part of the upper that needs to be shaped,

[0018] 2) Press the upper on the shoe last with concave and convex patterns, and then wrap the rope on the upper to press out the corresponding pattern, or use an outer kit that matches the structure of the shoe last with concave and convex patterns to press out the corresponding pattern. pattern,

[0019] 3) Put the vamp with the extruded three-dimensional pattern into the oven to finalize the shape, that is, complete the finalization of the vamp.

[0020] The Baotou sheet or hot-melt glue used in the above-mentioned technology, the setting temperature in the oven machine and other related technologies all belong to the existing known technology, so they will not be repeated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com