Polylactic acid/polypropylene cigarette composite tow with sheath-core structure and preparation method thereof

A technology of composite tow and polylactic acid, applied in the direction of conjugated synthetic polymer artificial filament, application, tobacco, etc., can solve the problems of polylactic acid tobacco tow performance deterioration, low rod yield, and reduced economic benefits , to achieve excellent physical and mechanical properties, improve production capacity, and improve economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

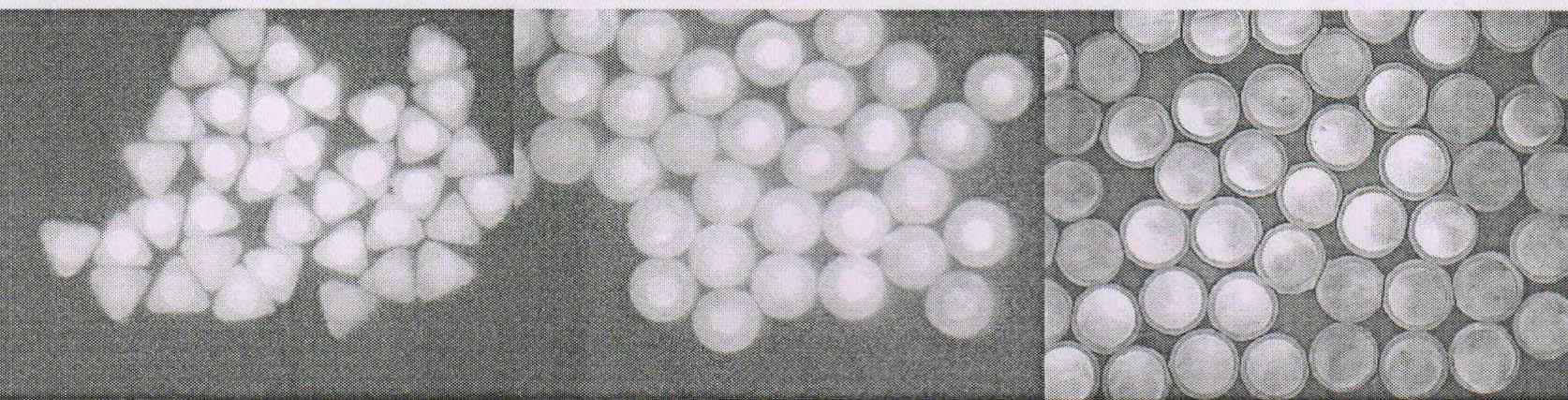

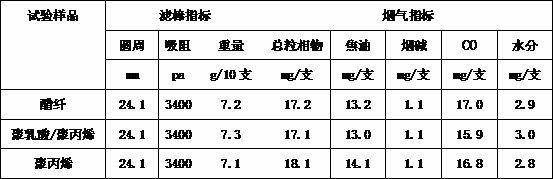

Embodiment 1

[0029] Select a polylactic acid resin with a melt index of 2.68g / 10min and a melting point of 169°C, and dry it at 80°C for 8 hours with a vacuum drum dryer, and the moisture content is less than 100ppm; melt the dried above-mentioned raw materials at 210°C, Filtration, quantitative input into the composite spinning assembly through the metering pump, at the same time, the polypropylene resin (melt index is 26g / 10min) is sent to another set of spinning system, melted at 265 ℃, filtered, quantitative input into the composite spinning component through the metering pump The wire assembly, the weight-component ratio of the two materials is 50:50 (polylactic acid: polypropylene), the number of spinneret holes is 11400, and the shape of the spinneret holes is triangular; it is cooled and formed by cooling air at 11°C, and passed through the upper The tanker coats the oil on the surface of the tow; the tow is wound up at a winding speed of 650m / min and temporarily stored in the silk ...

Embodiment 2

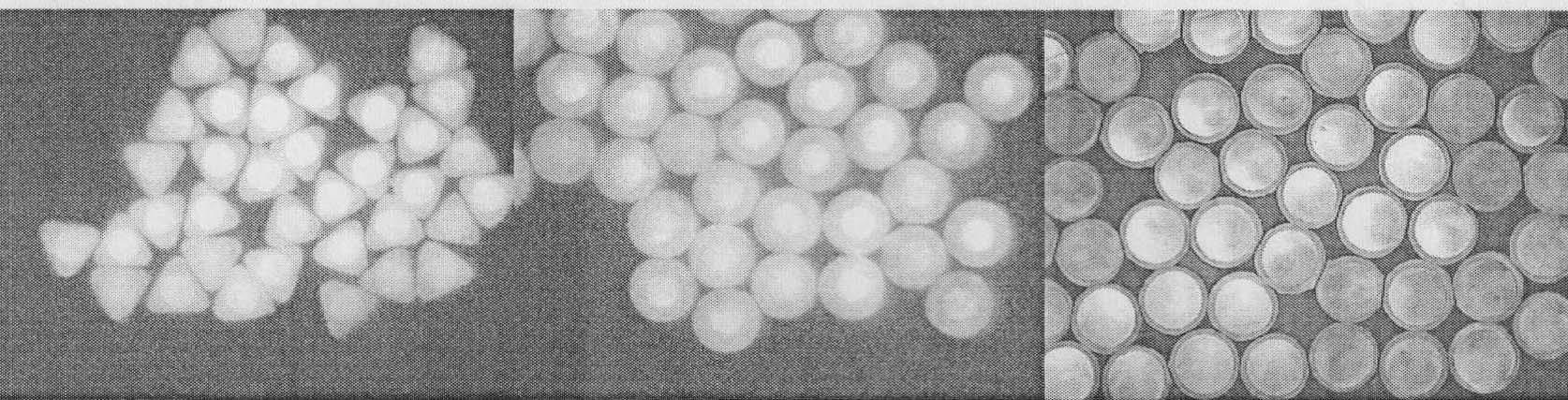

[0031] Select a polylactic acid resin with a melt index of 2.43g / 10min and a melting point of 167°C, and dry it at 80°C for 8 hours with a vacuum drum dryer, and the moisture content is less than 100ppm; melt the dried above-mentioned raw materials at 215°C, Filtration, quantitative input into the composite spinning assembly through the metering pump, at the same time, the polypropylene resin (melt index is 26g / 10min) is sent to another set of spinning system, melted at 260 ℃, filtered, quantitative input into the composite spinning component through the metering pump The weight component ratio of the two materials is 70:30 (polylactic acid: polypropylene), the number of spinneret holes is 13,200, and the shape of the spinneret holes is round; the cooling air at 11°C is used for cooling and molding, and the upper The tanker coats the oil on the surface of the tow; the tow is wound up at a winding speed of 500m / min and temporarily stored in the silk barrel. The tow is drawn in ...

Embodiment 3

[0033] Select a polylactic acid resin with a melt index of 2.72g / 10min and a melting point of 168°C, and dry it at 80°C for 8 hours with a vacuum drum dryer, and the moisture content is less than 100ppm; melt the dried above raw materials at 210°C, Filtration, quantitative input into the composite spinning assembly through the metering pump, at the same time, the polypropylene resin (melt index is 26g / 10min) is sent to another set of spinning system, melted at 270 ℃, filtered, quantitative input into the composite spinning component through the metering pump The wire component, the weight component ratio of the two materials is 25:75 (polylactic acid: polypropylene), the number of spinneret holes is 13200, and the shape of the spinneret holes is round; it is cooled and formed by cooling air at 11°C, and passed through the upper The oil tanker coats the oil on the surface of the tow; after winding the tow at a winding speed of 550m / min, it is temporarily stored in the silk barre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com