Polyphenylene sulfide short fiber spinning oil and preparation method thereof

A technology of spinning oil and polyphenylene sulfide, which is applied in the field of polyphenylene sulfide short fiber spinning oil and its preparation, can solve the problem of affecting the spinning performance and processing performance of polyphenylene sulfide, limiting polyphenylene sulfide Short fiber development and other issues can be improved to improve uneven drafting and curling effects, reduce fuzz, and improve product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 35% by weight (the same below) of antistatic agent C 18 Alkyl phosphate potassium salt, 20% smoothing agent 150N, 25% coagulant C 12 Fatty alcohol polyoxyethylene ether, 15% emulsifier octanol high molecular weight block polyether (M is about 3000) pumped into the reactor, heated to 60 ° C, stirred evenly, and then adjusted 5% by weight Agent C 5 The fatty alcohol is pumped into the reactor, stirred for 2 hours, cooled, discharged, and packaged to obtain the polyphenylene sulfide short fiber spinning oil.

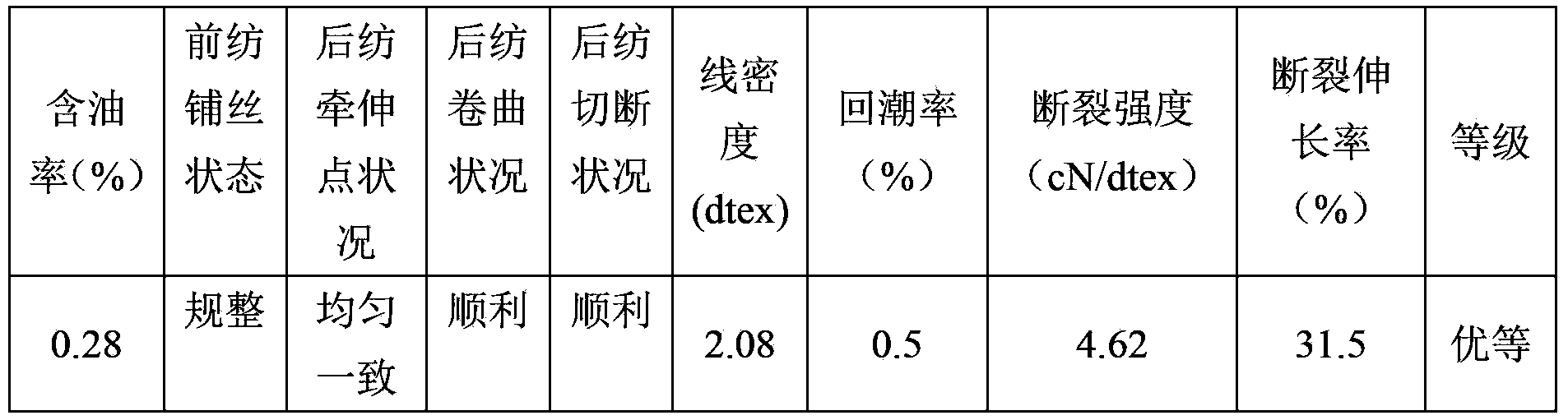

[0023] The oil was tested for spinning application, and the results are shown in Table 1.

[0024] The spinning application test data table of the oil agent obtained in table 1 embodiment 1

[0025]

Embodiment 2

[0027] The two-component antistatic agent of 46% by weight (the same below) (wherein, C 18 Alkyl Phosphate Potassium Salt 30%, C 18 Alkyl dimethyl betaine 16%), mix and stir and heat up to 35°C, then add 22% smoothing agent C 8 Fatty acid polyoxyethylene ether, 18% coagulant C 18 Aliphatic amine polyoxyethylene ether, 9% emulsifier amyl alcohol high molecular weight block polyether (M is about 3000) is pumped into the reaction kettle, heated to 65°C, stirred evenly, and then 5% regulator C 5 The fatty acid is pumped into the reactor, stirred for 3 hours, cooled, discharged, and packaged to obtain the polyphenylene sulfide staple fiber spinning oil.

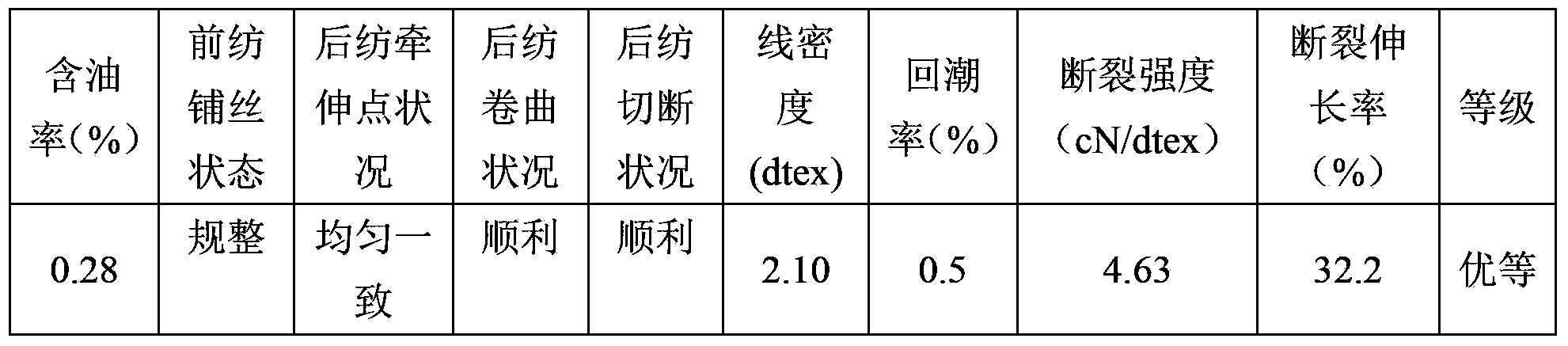

[0028] The oil agent was tested for spinning application, and the results are shown in Table 2.

[0029] The spinning application test data table of the oil agent gained in table 2 embodiment 2

[0030]

Embodiment 3

[0032] 28% by weight (the same below) of two-component antistatic agent (wherein, C 12 Alkyl Phosphate Potassium Salt 25%, C 12 Alkyl dimethyl betaine 3%) mixing and stirring to raise the temperature to 35°C, then add 22% smoothing agent, the smoothing agent component is 18% C 8 Fatty alcohol polyoxyethylene ether and 4% C 8 The mixture composed of fatty acid polyoxyethylene ether, continue to stir and heat up to 45 ° C, add 32% coagulant castor oil polyoxyethylene ether (EO is 20), 10% emulsifier sorbitan polyoxyethylene ether pumped into the reaction kettle , heated to 70 ° C, stirred evenly, and then pumped 8% modifier modified silicone oil into the reaction kettle, stirred for 1 hour, cooled, discharged, and packaged to obtain polyphenylene sulfide short fiber spinning oil.

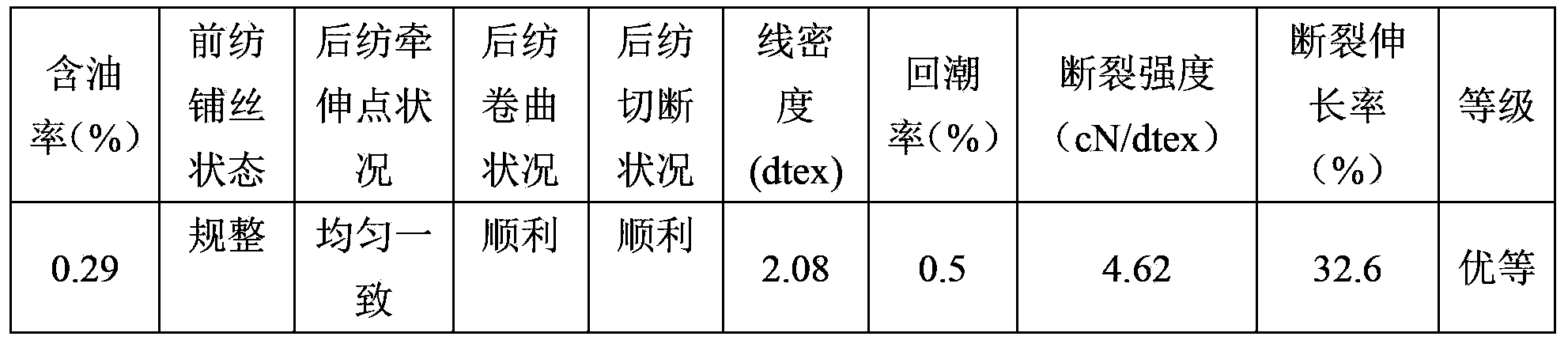

[0033] The oil agent was tested for spinning application, and the results are shown in Table 3.

[0034] The spinning application test data sheet of table 3 embodiment 3 gained oil agent

[0035] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com