Vinylon pure-spinning fibre oil solution and preparing method thereof

A fiber oil, vinylon technology, applied in the field of vinylon pure spinning fiber oil, can solve the problems of equipment corrosion, environmental protection pressure, high biological toxicity, etc., to reduce production and use costs, reduce environmental pollution, preparation method simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

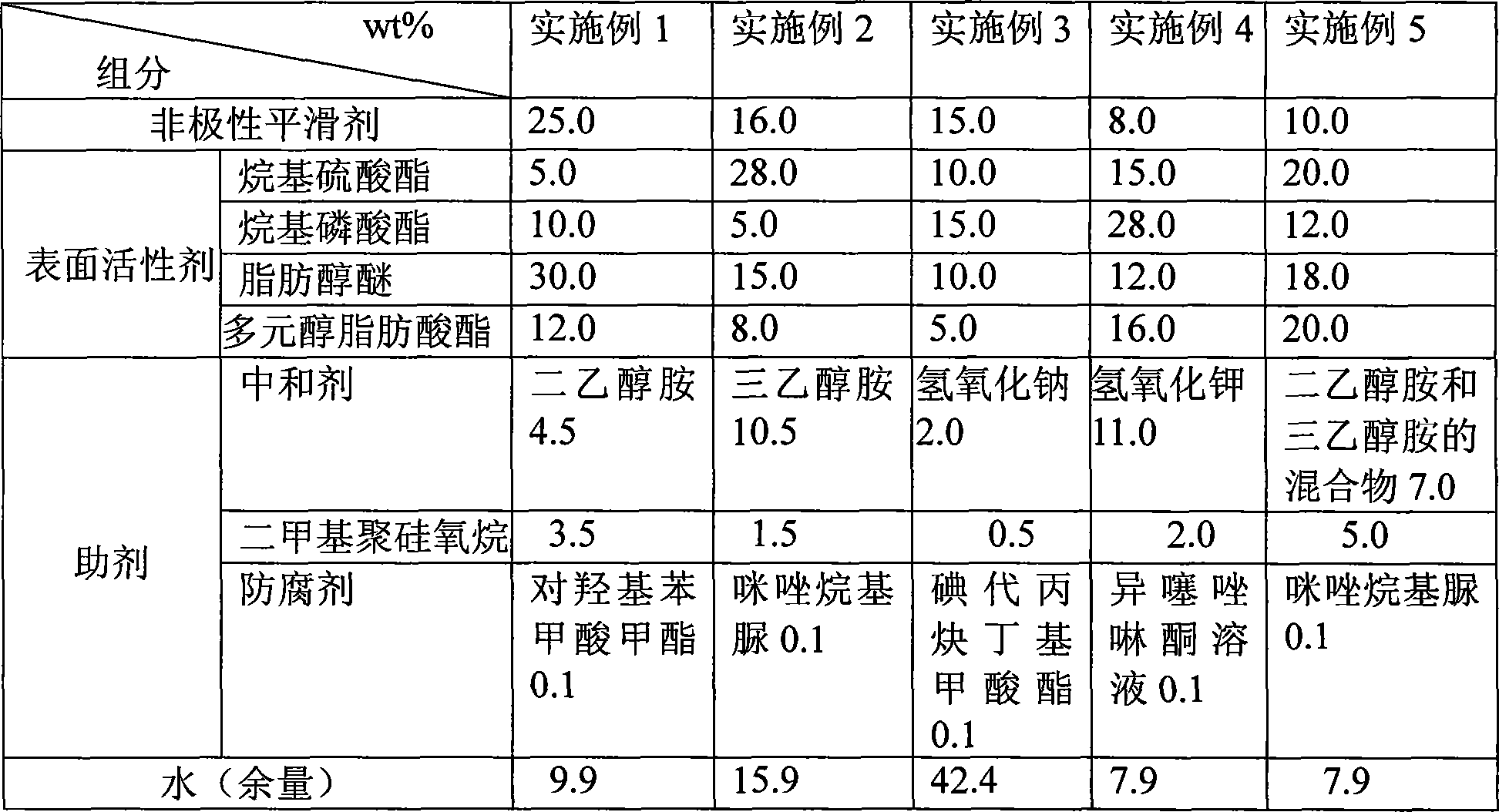

[0018] Embodiment 1: a kind of vinylon pure spinning fiber oil, it is made up of nonpolar smoothing agent, surfactant, auxiliary agent and water, and its proportioning is shown in Table 2. Among them: non-polar smoothing agent is refined mineral oil; among surfactants: the general chemical formula of alkyl sulfate is RO-(CH 2 CH 2 O) n -SO 3 Na, R is alkyl C8-C12, average n=2; the general chemical formula of alkyl phosphate is (RO) x -O=P(OH) y , R is alkyl C8-C12, x=1-2, y=1-2; the general chemical formula of polyol fatty acid ester is R1COOR2, R1 is C12-C16 alkyl, R2 is sorbitol; fatty alcohol ether The general chemical formula is RO-(CH 2 CH 2 O) n H, R are alkyl C12-C14, average n=7-15. The preparation steps of the above-mentioned vinylon pure spinning fiber oil agent are as follows: first, the above-mentioned refined mineral oil as a non-polar smoothing agent and each component of the surfactant are sequentially added to the container and stirred evenly, and then ...

Embodiment 2

[0019] Embodiment 2: A kind of vinylon pure spinning fiber oil, the distribution ratio of each component is shown in Table 2. Among them: the general chemical formula of non-polar smoothing agent is RH, and R is the alkyl group of C8-C19; Among the surfactants: the chemical general formula of alkyl sulfate is RO-(CH 2 CH 2 O) n -SO 3 Na, R is alkyl C13-C18, average n=3; the general chemical formula of alkyl phosphate is (RO) x -O=P(OH) y , R is alkyl C13-C16, x=1-2, y=1-2; the general chemical formula of polyol fatty acid ester is R1COOR2, R1 is the alkenyl of C17-C22, R2 is glycerol; fatty alcohol ether The general chemical formula is RO-(CH 2 CH 2 O) n H, R are alkyl C15-C18, average n=16-21. Its preparation steps are with embodiment 1.

Embodiment 3

[0020] Embodiment 3: A kind of vinylon pure spinning fiber oil, the distribution ratio of each component is shown in Table 2. Among them: the general chemical formula of non-polar smoothing agent is RH, and R is the cycloalkyl group of C20-C30; Among the surfactants: the chemical general formula of alkyl sulfate is RO-(CH 2 CH 2 O) n -SO 3 Na, R is alkyl C6-C10, n=0; the general chemical formula of alkyl phosphate is (RO) x -O=P(OH) y , R is alkyl C6-C10, x=1-2, y=1-2; the general chemical formula of polyol fatty acid ester is R1COOR2, R1 is C17-C22 alkyl, R2 is polyhydric alcohol; fatty alcohol ether The general chemical formula is RO-(CH 2 CH 2 O) n H, R are alkyl C8-C10, average n=22-28. Its preparation steps are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com