Dynamic dust removal water tower

A water tower and dynamic technology, applied in general water supply conservation, towers, water supply devices, etc., can solve the problems of smelly deterioration, unsafe drinking, easy accumulation of sediment, etc., and achieve the effect of low cost, simple and practical structure, and easy manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

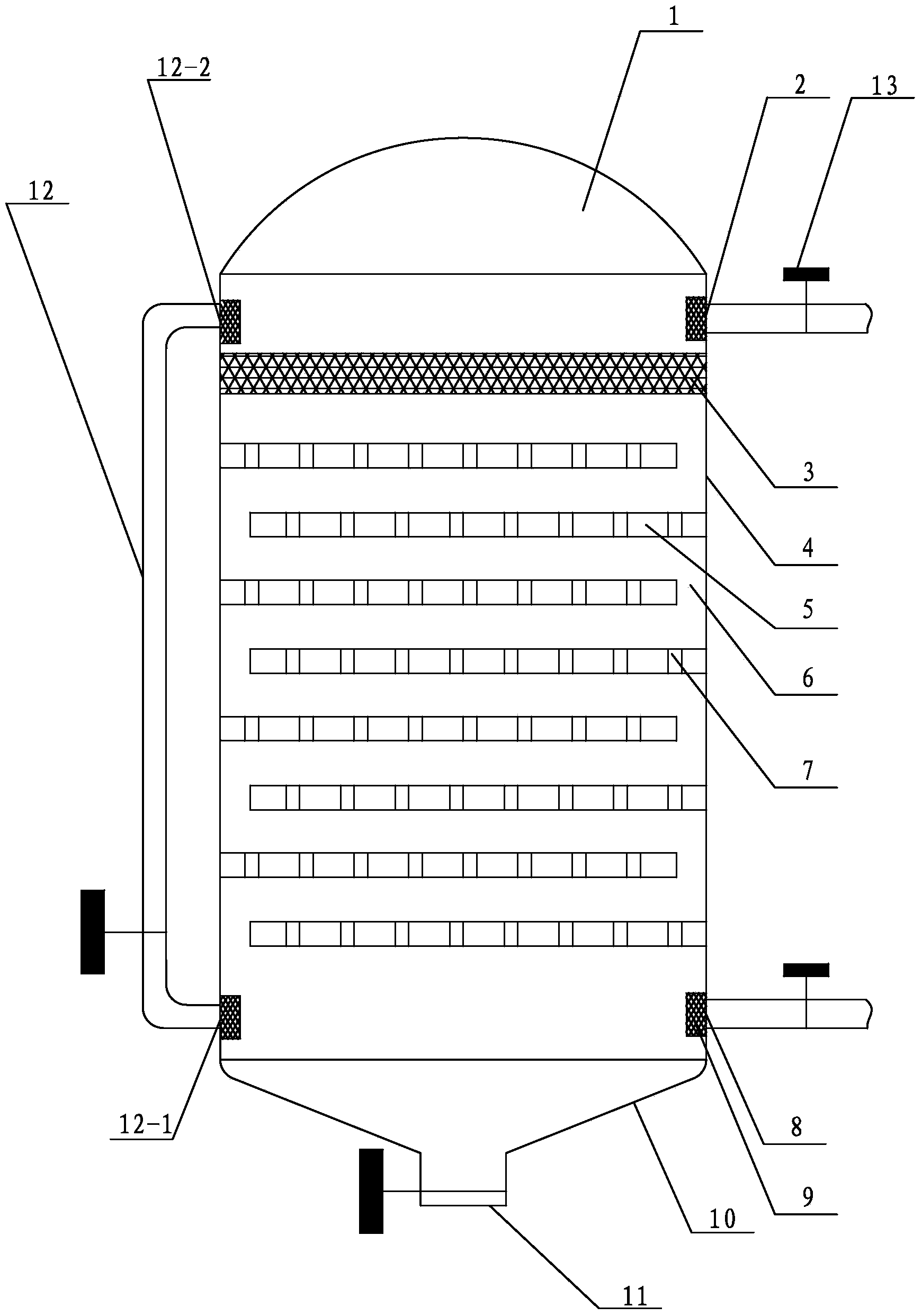

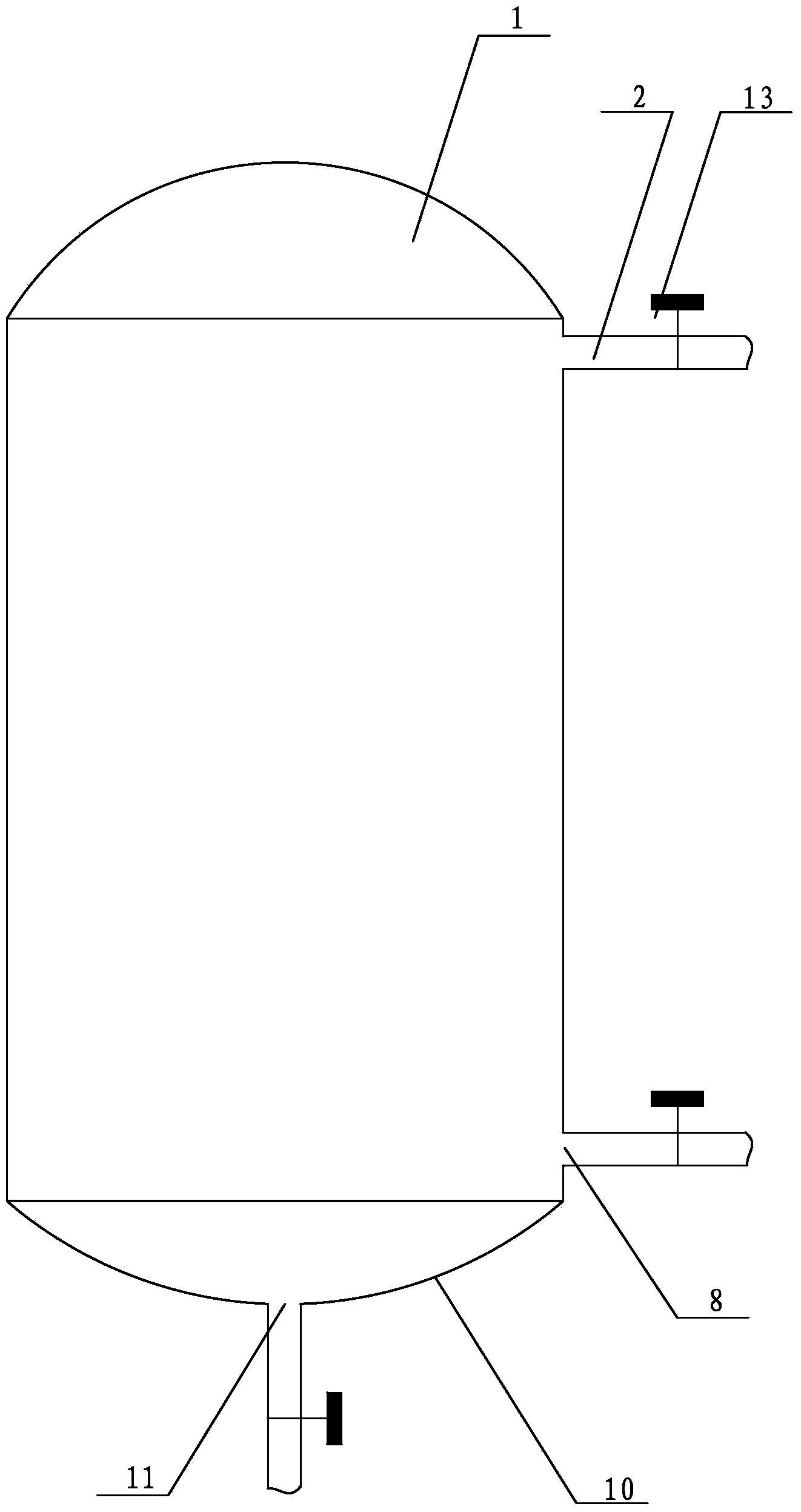

[0021] like figure 1 As shown, a dynamic dedusting water tower includes a cylinder cover 1, a cylinder body 4 and a cylinder bottom 10; the upper part of the cylinder body 4 is provided with a water inlet 2 near the cylinder cover 1; the lower part of the cylinder body 4 is close to the cylinder bottom 10 Offer water outlet 8.

[0022] The cylinder bottom 10 is set in a conical shape, and the bottom of the cylinder bottom 4 is provided with a sewage outlet 11 .

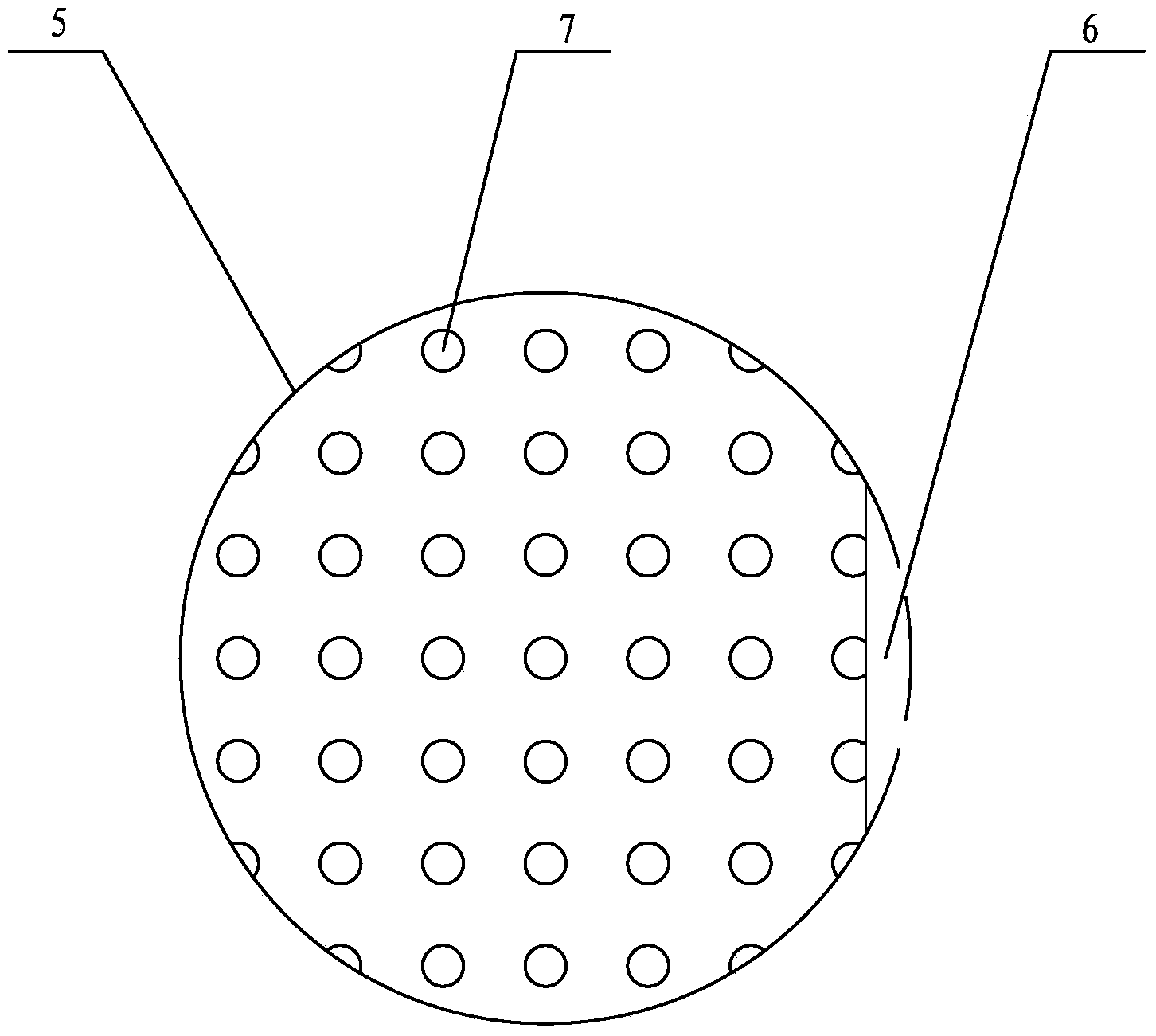

[0023] A dust removal packing layer 3 with the same cross-sectional area as the cylinder body 4 is provided below the water inlet 2; in this embodiment, the impurity removal packing layer 3 is preferably set to be a bioactivation filter material of silicon, aluminum, and oxygen lattice tetrahedrons.

[0024] The cylinder body 4 is provided with a circulating water pipe 12, the circulating water pipe 12 is provided with a circulating water outlet 12-1 and a circulating water inlet 12-2, and the circulating water outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com