Recycling treatment system for cutting fluid

A technology for processing systems and cutting fluids, which is applied in the direction of lubricating compositions, etc., can solve the problems of cutting fluid waste, decreased cooling and lubrication performance of cutting fluids, and increased costs, so as to reduce production costs, avoid odor and deterioration, and prolong service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

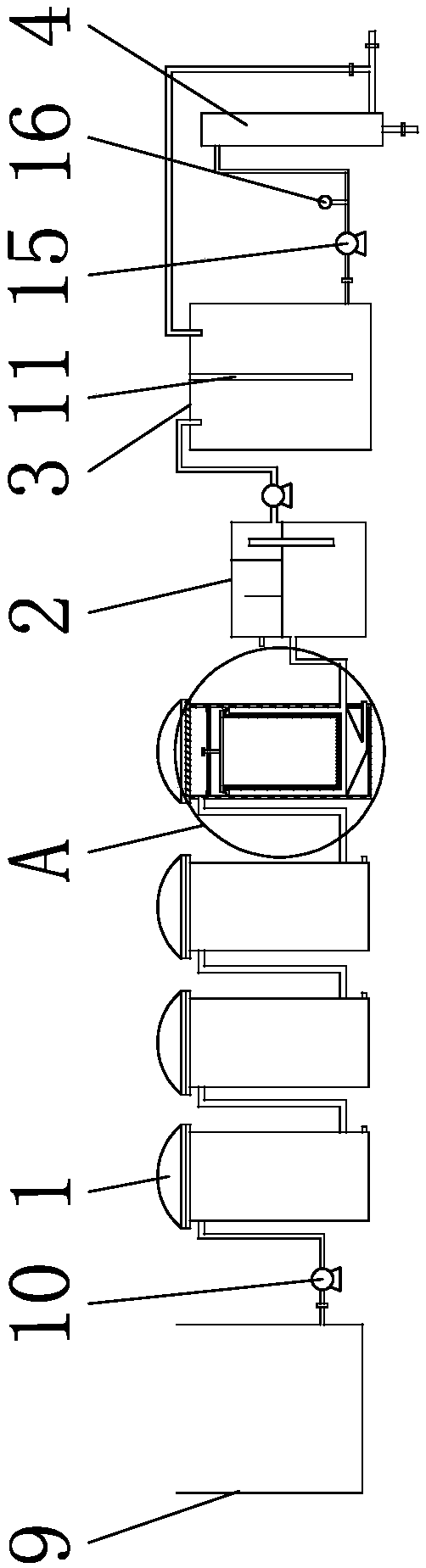

[0019] see figure 1 , a cutting fluid recycling treatment system of the present invention includes a solid-liquid separation tank 1, an oil-water separation device 2, a sterilization tank 3, and a filter tank 4 that are sequentially connected through pipelines. The solid-liquid separation tank 1 is connected with a sump 9, the sump 9 is used to collect, store and recycle cutting fluid to be processed, and a first delivery pump 10 and valve, open the valve, and the cutting fluid to be treated can be delivered to the solid-liquid separation tank 1 through the first delivery pump 10 .

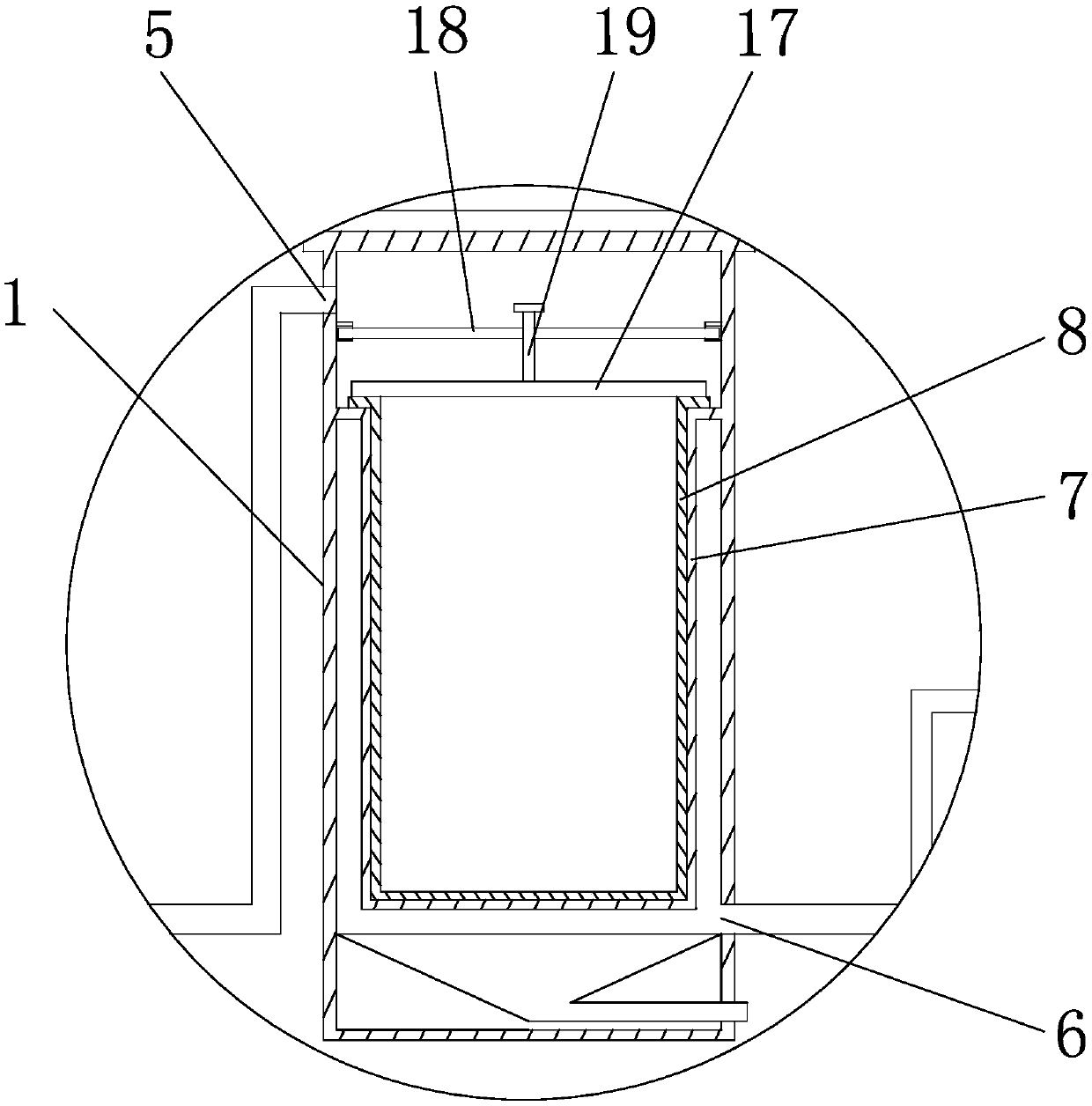

[0020] see figure 2 , the upper end of the solid-liquid separation tank 1 is provided with a liquid inlet 5, and the lower end is provided with a liquid outlet 6, and the solid-liquid separation tank 1 is provided with an annular protrusion along the circumference, and the protrusion is provided with an annular enclosure 7, an enclosure 7 The axis of the solid-liquid separation tank 1 can be pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com