Patents

Literature

44results about How to "Good textile processability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bamboo-carbon viscose fibre and its production

ActiveCN101029420AEvenly dispersedHarm reductionMonocomponent cellulose artificial filamentArtifical filament manufactureViscose fiberFiber strength

A bamboo-carbon viscose fiber and its production are disclosed. It consists of bamboo pulp dregs and nano-bamboo carbon 4-30wt%, the grain size is 75-150nm, final-product fiber strength is 1.7-3.0cN / dtex, extensibility is 9-18%. It adopts viscose coagulation bath composite modifying technology, it has excellent antibacterial, far-infrared health care and deodorization functions. It has better fiber strength and spinning handling property. It's cool, refined and no environmental pollution and can be used for summer clothing production and non-woven industries.

Owner:潍坊欣龙生物材料有限公司

Preparation method and applications of isatis root extract, vitamin and protein composite microcapsule

InactiveCN105381766AEasy to takeGood textile processabilityArtificial filaments from viscoseMicroballoon preparationViscoseCellulose fiber

The invention belongs to the technical field of functional cellulose fiber, and relates to an isatis root extract, vitamin and protein composite microcapsule, which is used to prepare isatis root cellulose fiber. The preparation method comprises the following steps: adding isatis root extract and vitamins into a water solution of emulsifier, carrying out shearing emulsification to obtain a mixed emulsified solution; adding the mixed emulsified solution into a gelatin solution, then adding an Arabic gum solution, evenly mixing to form stable oil-in-water emulsion; adjusting the pH value, heating and stirring to carry out complex coacervation to obtain suspension liquid; cooling the suspension liquid, adding a curing agent, adjusting the pH value to carry out crosslinking reactions, after reactions, filtering to obtain isatis root extract, vitamin and protein composite microcapsules; adding the composite microcapsules into viscose stock solution to prepare a blended spinning liquid, and carrying out spinning through an adjusted coagulation bath. Through the micro-encapsulation, crosslinking and solidification, the loss of effective component during the processes of spinning and post treatment is reduced, and the prepared viscose has the antivirus and skincare functions.

Owner:山传雷

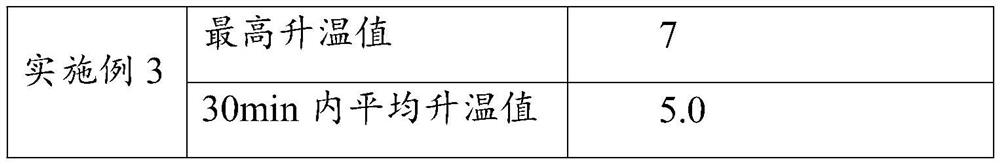

Phase transition temperature-adjusting cellulosic fiber prepared by solvent method and preparation method thereof

ActiveCN105369380AGood textile processing performanceReduce churnMonocomponent cellulose artificial filamentWet spinning methodsMacromoleculePhysical chemistry

The invention discloses phase transition temperature-adjusting cellulosic fiber prepared by a solvent method. The fiber comprises a porous material, a macromolecular phase-changing material and a substance with a far infrared absorption function, wherein mass ratio of the porous adsorption material to the substance with the far infrared absorption function to the macromolecular phase-changing material is 1-30:1-50:10-100. Melting enthalpy value of the fiber is greater than or equal to 5.5 J / g, and crystalline enthalpy value is greater than or equal to 5.3 J / g. a preparation method of the fiber comprises the following steps: preparing a composite macromolecular phase-changing porous material; preparing a spinning solution; and spinning. According to preparation of the composite macromolecular phase-changing porous material, the porous adsorption material and the substance with the far infrared absorption function are added into the molten macromolecular phase-changing material to carry out adsorption and mixing. The phase transition temperature-adjusting cellulosic fiber prepared by the method has characteristics of pollution-free production process and green and environmental-protection product. As the porous adsorption material is used to adsorb the macromolecular phase-changing material, loss during formation process is minimized, and the phase transition temperature-adjusting function of the fiber is guaranteed.

Owner:潍坊欣龙生物材料有限公司

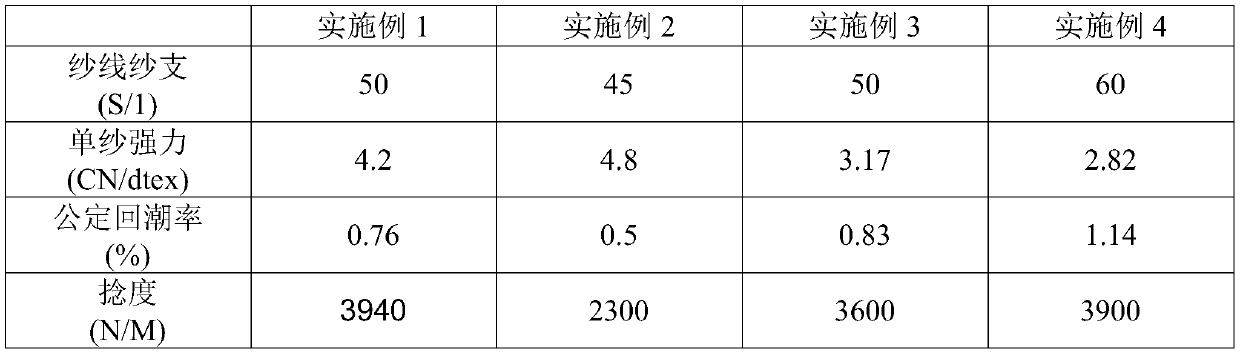

Taxus chinensis viscose blended yarn and preparation method thereof

The invention relates to a Taxus chinensis viscose blended yarn. A preparation method of the Taxus chinensis viscose blended yarn includes the following steps of cotton assorting, blowing, cotton carding, drawing, roving and yarn spinning, and is characterized in that the cotton assorting step includes: mixing 10-50% of Taxus chinensis viscose with 50-90% of blended fibers; the blowing step includes: blowing fibers obtained in the cotton assorting step on a cotton breaking machine; the cotton carding step includes: carding the blown fibers on a cotton carding machine to obtain Taxus chinensis fiber card silver; the drawing step includes: drawing the Taxus chinensis fiber card silver on a drawing machine and obtaining drawn silver fibers after drawing; the roving spinning step includes: roving the drawn silver fibers on a roving machine to obtain rovings; and the yarn spinning step includes: spinning the rovings on a spinning machine to obtain Taxus chinensis viscose blended yarns. The Taxus chinensis viscose blended yarn is made from Taxus chinensis with the anticancer function, and textiles made of the Taxus chinensis viscose blended yarns have the advantages of smoothness and fineness and has the healthcare function.

Owner:无锡红豆织造有限公司

Preparation method of temperature regulating fiber

ActiveCN104831388APhase change performance is maintained for a long timeNot easy to loseArtificial filaments from viscoseHeat-exchange elementsFiltrationKetone

The invention discloses a preparation method of a temperature regulating fiber. The method comprises the following steps: 1, carrying out two-stage dipping, squeezing, crushing, ageing, yellowing reaction, filtration, deaeration and maturation on cellulose pulp to obtain a spinning solution; 2, packaging phase change paraffin in the honeycomb micropores of a packaging material honeycomb silica to prepare phase change particles, adding an osmotic agent, an emulsifier and a ketose cross-linking agent, and uniformly mixing to prepare a phase change emulsion; 3, fully mixing the phase change emulsion with the spinning solution to prepare a phase change spinning solution, wherein the addition amount of the phase change particles is 5-25wt% of alpha-cellulose in the spinning solution; and 4, carrying out spinning formation on the phase change spinning solution, and post-processing to obtain the temperature regulating fiber. The phase change fiber prepared in the invention has the advantages of stable phase change temperature, good phase change performance, long service life and high physical and mechanical performances.

Owner:湖州珠力纳米材料科技开发有限公司

Mint-extract, menthol and cool-feeling-substance combined modification additive and application thereof

ActiveCN105332076AGood chemical stabilityLong-lasting cooling effectArtificial filaments from viscoseWet spinning methodsChemistryAnti bacterial

The invention belongs to the technical field of functional cellulosic fibers, and relates to a mint-extract, menthol and cool-feeling-substance combined modification additive. A preparing method of the mint-extract, menthol and cool-feeling-substance combined modification additive includes the steps that acrylonitrile monomers and menthol are added into an emulgator solution, and emulsification pretreatment dispersing is carried out to obtain a mixed emulsion solution of the menthol and acrylonitrile; the mixed emulsion solution is heated and stirred while initiators are dropwise added, microcapsules are prepared, and the microcapsules are dispersed into distilled water after washing and drying; cool feeling substances are added into a mint-extract solution, stirring and adsorption are carried out, cool-feeling-substance dispersion liquid with mint extract is obtained, the dispersing liquid is dried and ground, and cool-feeling substance powder with the mint extract is prepared; the menthol microcapsule slurry and the cool-feeling substance powder with the mint extract are mixed to be even, and the combined modification additive is prepared through the adsorption effect of the cool feeling substances and the protection effect of the microcapsules. Functional cellulosic fibers prepared with the combined modification additive have the lasting cool feeling effect and the anti-bacterial function.

Owner:山传雷

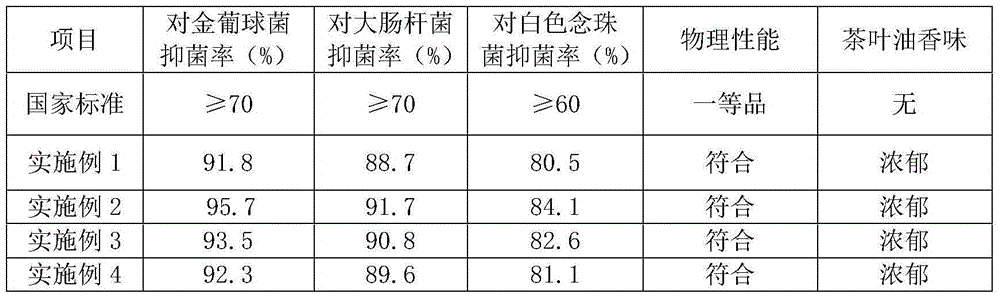

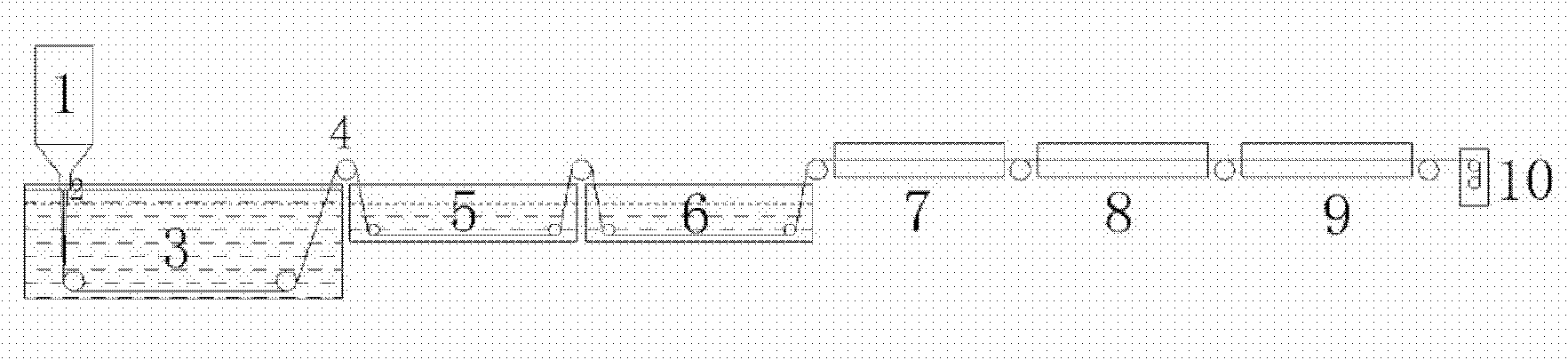

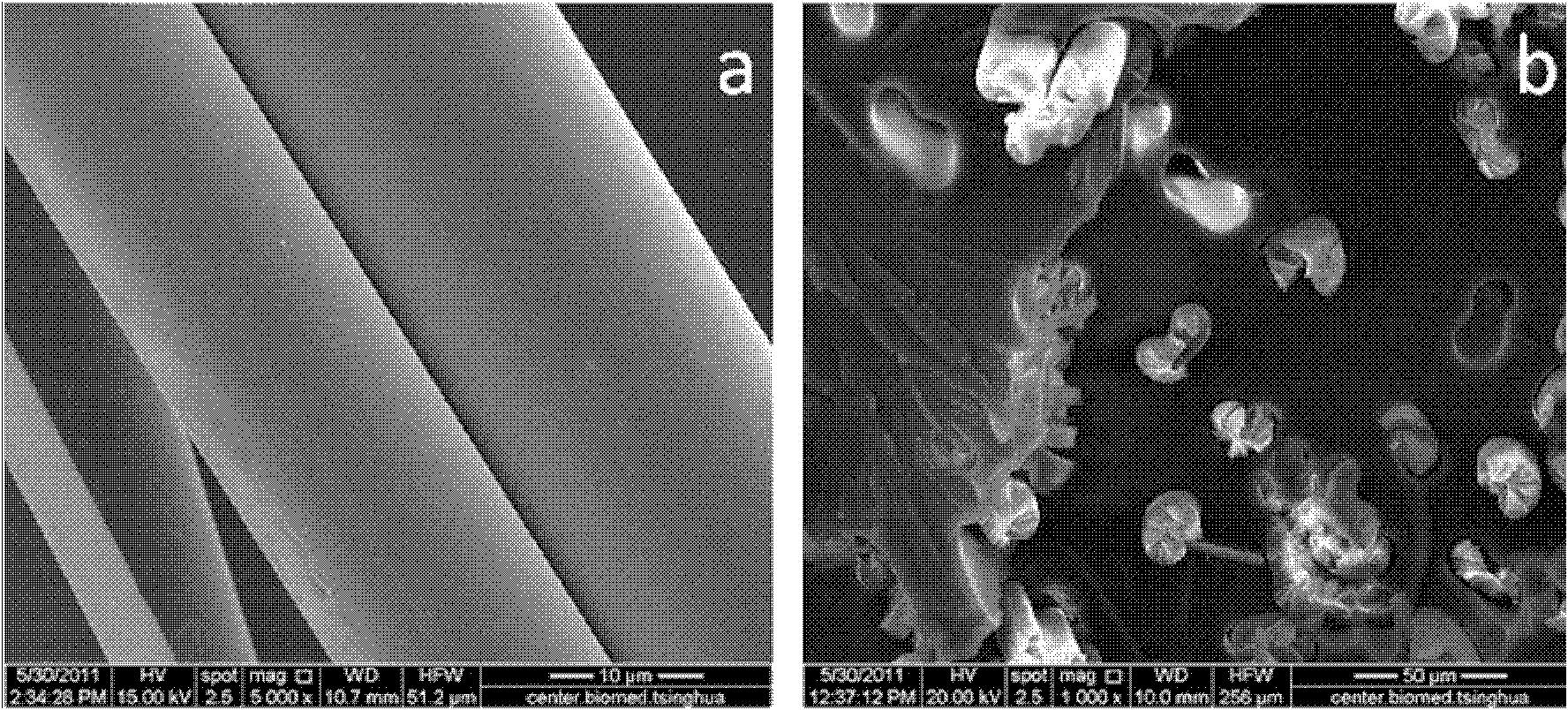

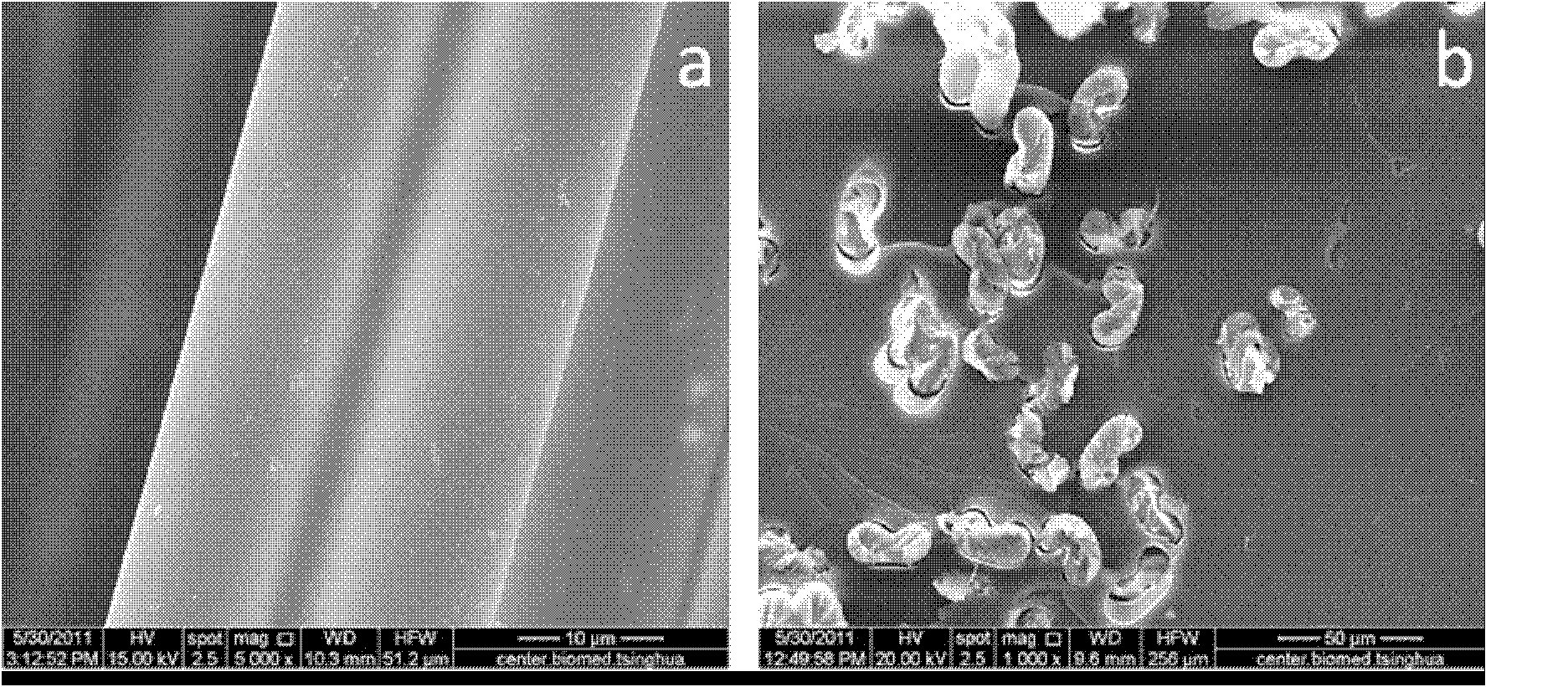

Preparation and application of tea extract oil composite modified additive

InactiveCN105113036AStable performanceChemically stableArtificial filaments from viscoseChemistryViscose fiber

The invention belongs to the technical field of functional fiber, relates to preparation and application of a tea extract oil composite modified additive, and aims to preparation of functional adhesive fiber. The preparation comprises the following steps: preparing a solid adsorbent containing a tea extract; preparing tea oil micro-capsule slurry; uniformly mixing the solid adsorbent and the tea oil micro-capsule slurry, and stirring so as to obtain a composite modified additive; preparing adhesive fiber with a tea fragrance antibacterial deodorization function, wherein preparation of the adhesive fiber comprises the following steps: preparing a commixed spinning liquid, and spinning; the prepared adhesive fiber with the tea fragrance antibacterial deodorization function comprises 1.0-11.0wt% of an adsorbent of a porous structure, 2.0-5.0wt% of a tea extract and 1.0-11.0wt% of a tea oil micro-capsule. The tea extract oil composite modified additive is stable in property, can be uniformly fused with an adhesive stock solution, and has long-lasting tea fragrance and an antibacterial deodorization function, and effective components in fiber are slightly lost in the spinning process and later treatment process.

Owner:山传雷

Germanium viscose fiber and preparation method thereof

ActiveCN102011205ASmall particle sizeHigh strengthArtificial filament washing/dryingArtificial filaments from viscoseHuman environmentZinc

The invention relates to a germanium viscose fiber, which is prepared from hemp pulp and nano germanium ores serving as raw materials, wherein the content of the nano germanium ores is 1 to 30 percent of the weight of the finished germanium viscose fiber product; the germanium viscose fiber is prepared by preparation of the germanium ore pulp, preparation of soluble viscose, preparation of germanium pulp, preparation of viscose spinning stock solution, spinning, post treatment and drying process; the hemp pulp and the nano germanium ores are used as the raw materials, the hemp pulp and the nano germanium ores serving as the raw materials are renewable resources, and the discarded fabrics of viscose fiber can be biologically degraded, so accumulative influence on the environment is not caused, and the environment is protected; the nano germanium has small grain diameter and is dispersed uniformly in the fiber; the prepared fiber product has high strength and good textile processing performance by adopting viscose and coagulating bath composite denaturation technology; and zinc sulfate with high pollution to the human environment is not used any more, so the harm to the environment is reduced in the fiber production process.

Owner:潍坊欣龙生物材料有限公司

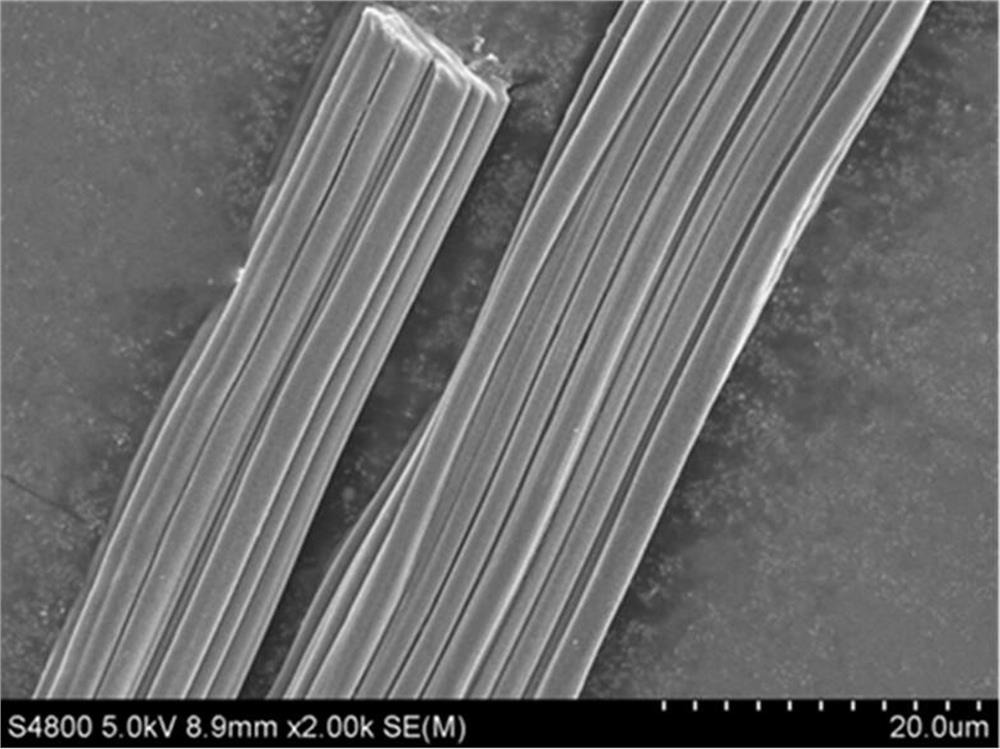

Polyimide fiber with kidney-shaped section and preparation method thereof

ActiveCN102560707AImprove production efficiencySimple preparation processSpinning solution filteringSpinning solution de-aeratingFiberConductor Coil

A polyimide fiber with kidney-shaped section and a preparation method thereof belong to the technical field of polyimide fibers. The preparation method includes: utilizing polyamide acid (PAA) solution synthesized by aromatic dianhydride and aromatic diamine to perform the wet spinning process by the aid of circular spinneret holes, adjusting spinning conditions including spinneret speed, composition, proportion and temperature of coagulating bath, the length of hydrazine and the like to obtain a PAA as-formed fiber with kidney-shaped section, then washing and drying the PAA as-formed fiber, cyclizing and drafting the same at high temperature stage by stage, and winding and the like, finally obtaining the polyimide (PI) fiber with the kidney-shaped section. The preparation method of the polyimide fiber with the kidney-shaped section has the advantages of simplicity in spinneret hole design and processing, easiness in control of spinning process, high preparation efficiency, low cost for raw materials, low energy consumption and the like and can be used for large-scale industrialized production.

Owner:BEIJING UNIV OF CHEM TECH

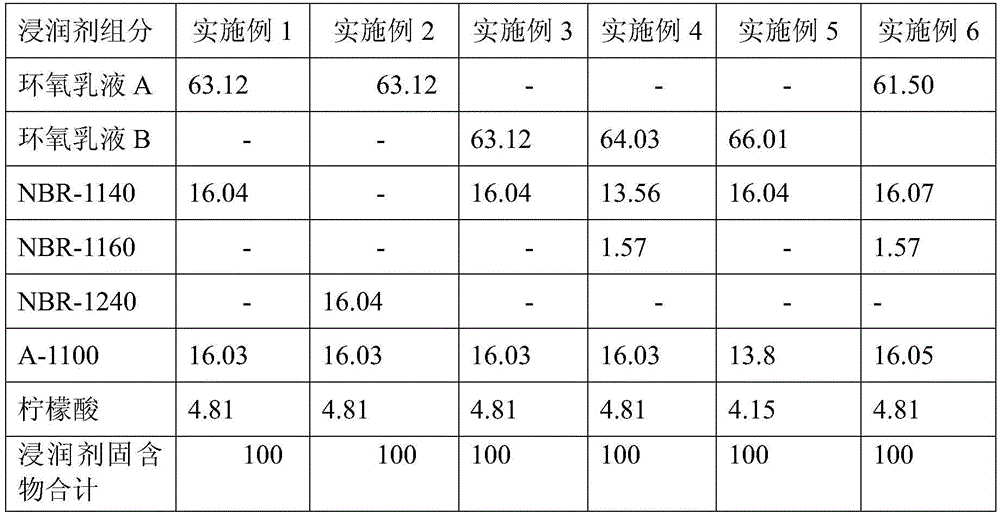

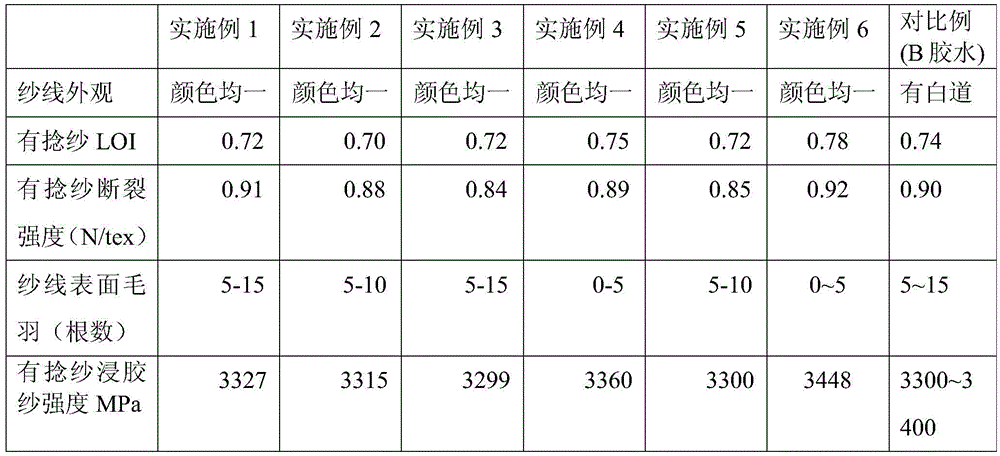

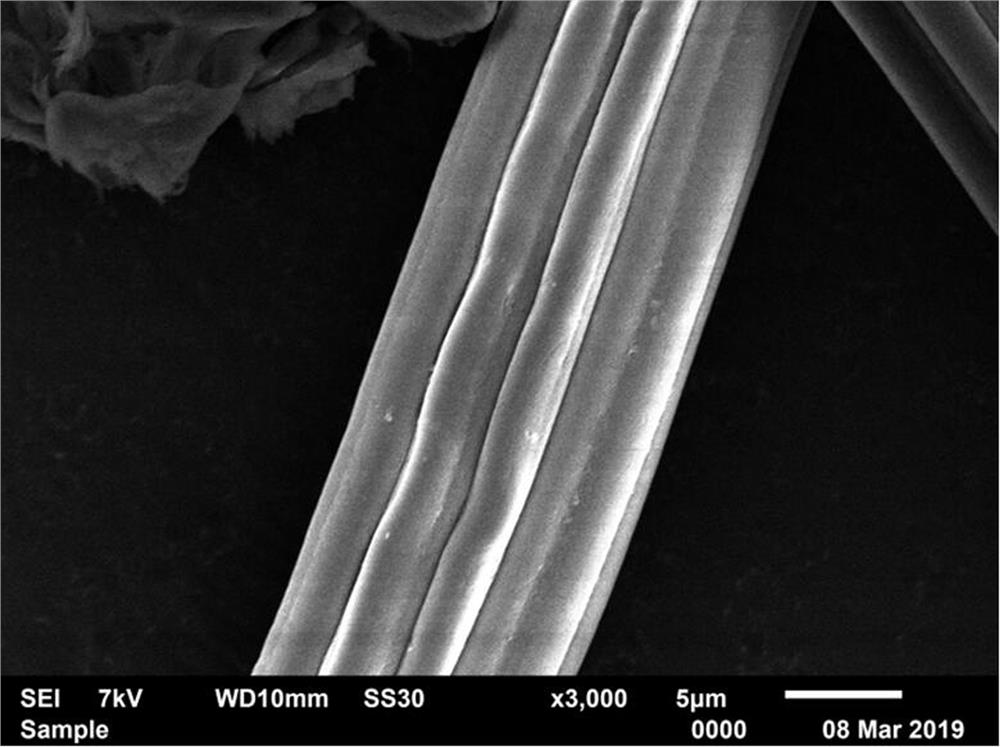

Resin compatible type glass fiber yarn impregnation agent, and preparation method thereof

The invention relates to a resin compatible type glass fiber yarn impregnation agent. The solid content of the impregnation agent accounts for 5-10% by mass of the total amount of the impregnation agent, the balance being deionized water. The solid content of the impregnation agent comprises the following components, based on the weight of the impregnation agent solid content as 100%: 50-80% of the epoxy resin emulsion, 10-25% of a non-ionic lubricant, 0-5% of a cationic lubricant, 8-20% of a silane coupling agent, and 1-6% of a pH adjusting agent. Compared with a traditional enhanced yarn impregnation agent, the impregnation agent formula has the advantage of simple composition. Mono-component epoxy resin is adopted as a film-forming agent, and two high-efficiency lubricants are combined. The impregnation agent has good compatibility with resin. With the formula, yarn strength is high. The formula also has excellent textile processing performance.

Owner:SINOMA SCI & TECH

Multifunctional vegetable regenerated cellulose fibers and preparation method thereof

InactiveCN110344130AGuaranteed stabilityGuaranteed churnMonocomponent cellulose artificial filamentMicroballoon preparationAntibiosisCellulose fiber

The invention provides multifunctional vegetable regenerated cellulose fibers and a preparation method thereof, belongs to the technical field of functional regenerated cellulose fibers, and can solvethe problems that an existing functional regenerated cellulose fiber is single in function or multifunctional, is poor in functionality, complex in preparation process, difficult in industrial production and the like. The multifunctional vegetable regenerated cellulose fibers comprise the following components in percentages by weight: 3.0-8.0wt% of a sweet basil extract and 1.72-5.22wt% of complex plant essential oil, wherein the complex plant essential oil comprises 0.69-2.09wt% of mint oil, 0.69-2.09wt% of folium artemisiae argyi essential oil and 0.34-1.04wt% of lavender essential oil. Thepreparation method disclosed by the invention can be applied to preparation of multifunctional vegetable regenerated cellulose fibers integrating functions of antibiosis, mosquito repelling, skin protection and the like, and is further applied to textiles prepared from the multifunctional vegetable regenerated cellulose fibers.

Owner:顾翚

Method for spinning blended yarns with outlast air-conditioning fibers/Newdal fibers

InactiveCN101982583AGuaranteed smooth productionRetains temperature regulating propertiesYarnFiberYarn

A method for spinning blended yarns with Outlast air-conditioning fibers / Newdal fibers is characterized by configuring the ingredients Outlast air-conditioning fibers / Newdal fibers according to the weight ratio of 95-85:5-15; opening the Outlast air-conditioning fibers and the Newdal fibers respectively and spraying antistatic agents; processing the Outlast air-conditioning fibers in a plucker, a blender, a card wire opener, a double-hopper feeder, a lap machine, a carding machine and a pre-drawing machine, and processing the Newdal fibers in the plucker, the blender and opener, a multi-bin blender, a sawblade beater type opener, the double-hopper feeder, the lap machine, the carding machine, the pre-drawing machine, a silver lap machine and a comber; and finally feeding the processed Outlast air-conditioning fibers and Newdal fibers into a drawing machine, a roving frame, a spinning frame and a bobbin winder. The method retains the temperature regulation characteristic of the Outlast air-conditioning fibers and higher strength and wet modulus, excellent breaking elongation and unique high crimp property of the Newdal fibers and ensures the products to have better spinning processibility.

Owner:山东昊龙集团有限公司

Preparation method of taxus chinensis viscose fibers

InactiveCN102586918AMoisture wickingHas functional health effectsArtificial filaments from viscoseCellulose material pulpingFunctional healthTaxus mairei

The invention relates to a preparation method of taxus chinensis viscose fibers. The preparation method is characterized by comprising the following technological steps of: tabletting a taxus chinensis raw material, washing tablets in hot water, and placing the tablets in an alkali liquor for stewing; continuously washing the tablets in hot water after stewing; beating the tablets in a beating machine to obtain pulp, and desanding the pulp; concentrating the pulp in a thickner after desanding, and bleaching the concentrated pulp; continuously concentrating the bleached pulp, manufacturing paper with pulp after concentration, and obtaining the taxus chinensis pulp; soaking the taxus chinensis pulp in a NaOH solution, squeezing after soaking to obtain fine materials, carrying out yellowing treatment on the fin materials to obtain mucilage glue, spinning the mucilage glue in a spinning coagulating bath, and obtaining the taxus chinensis viscose fibers. Taxus chinensis with the anti-cancer effect adopted in the preparation method is made into the taxus chinensis viscose fibers; the taxus chinensis viscose fibers have good spinning processability; manufactured textiles has the advantages of smoothness, fineness and the like, has the functional health-care effect and is beneficial to promoting the sleep.

Owner:WUXI HODOHOME GARMENT

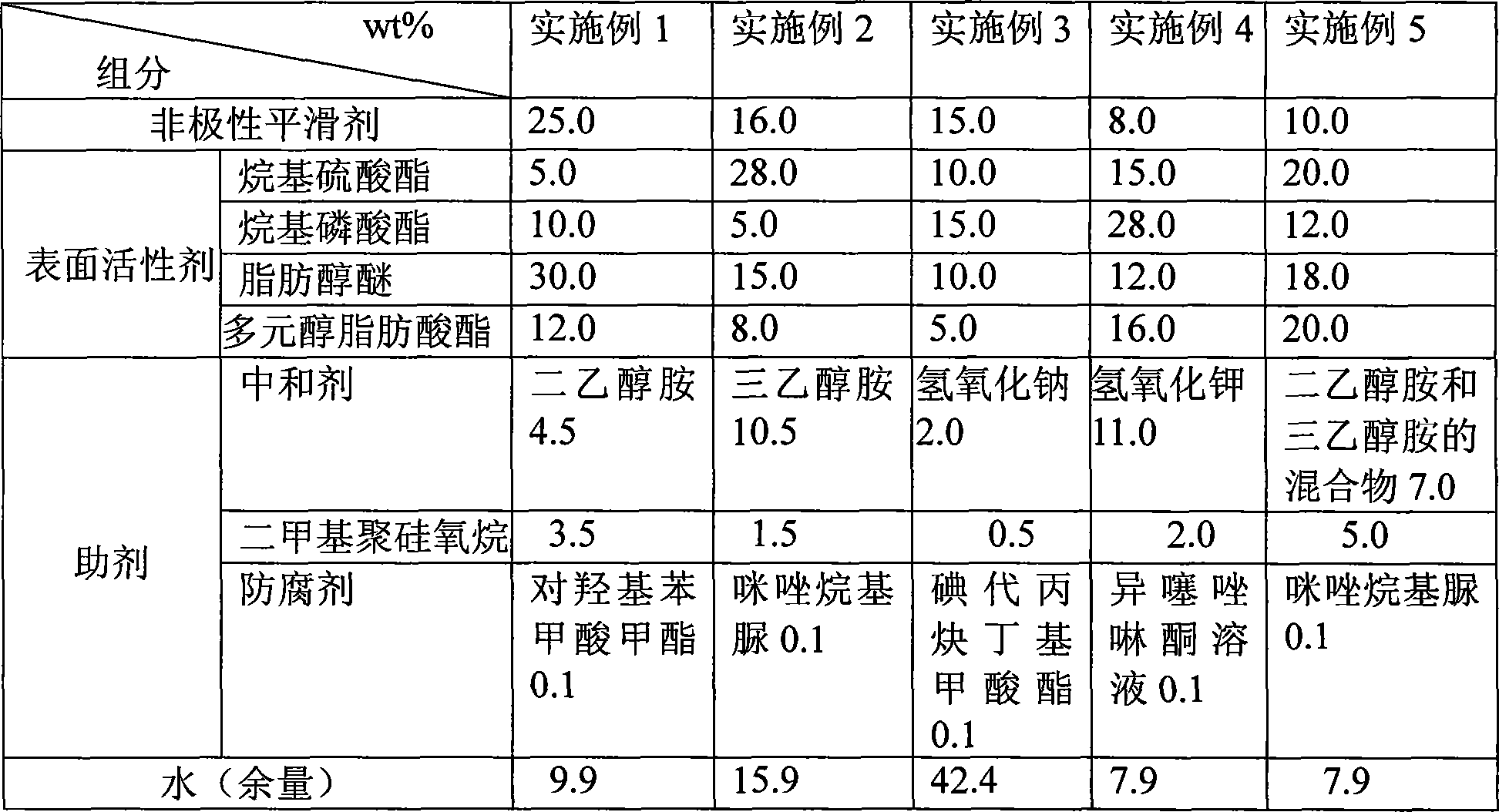

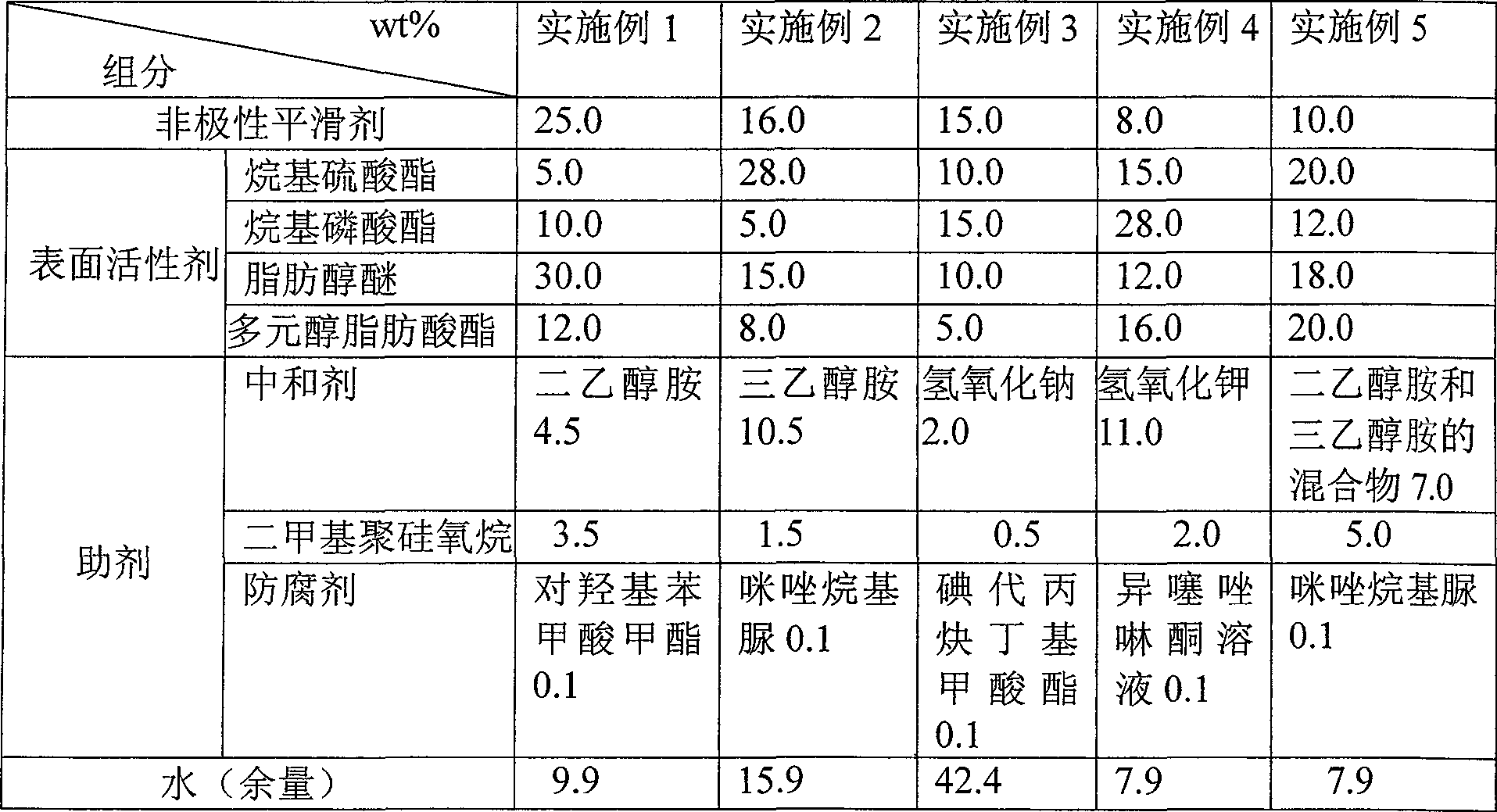

Vinylon pure-spinning fibre oil solution and preparing method thereof

The present invention provides a vinylon pure fiber oil solution and its preparation method, it consists of non-polar smoothing agent, surfactant, additives and water and the content of each component as follows: non-polar smoothing agent : 8 - 25%; surfactant: sulfate 5 - 28%, phosphate 5 - 28%, polyols fatty acid ester 5 - 20%, aliphatic alcohol ether 10-30%; auxiliaries: neutralizer 2-11%, macromolecular organosilicon polymer 0. 5-5. 0%, preservatives 0. 1%; cushion for water; both according to the percentage of weight. Because the oil solution in the invention does not contain alkylphenol category surfactants, so it reduces environmental pollution. The fiber treated by the oil solution in the invention has good smooth, wolliness, suitable graded property, antistatic property and so on, so the fiber can pass the subsequent processes smoothly and the spinnability is good; it also can adapt the craft condition of fiber production widely, such as heat-resistant, oxidation resistance, corrosion resistance and it can prevent oil solution degeneration and bad odor caused bacteria multiplying. The preparation method of the present invention is simple and need not heating in preparation.

Owner:徐元萍 +1

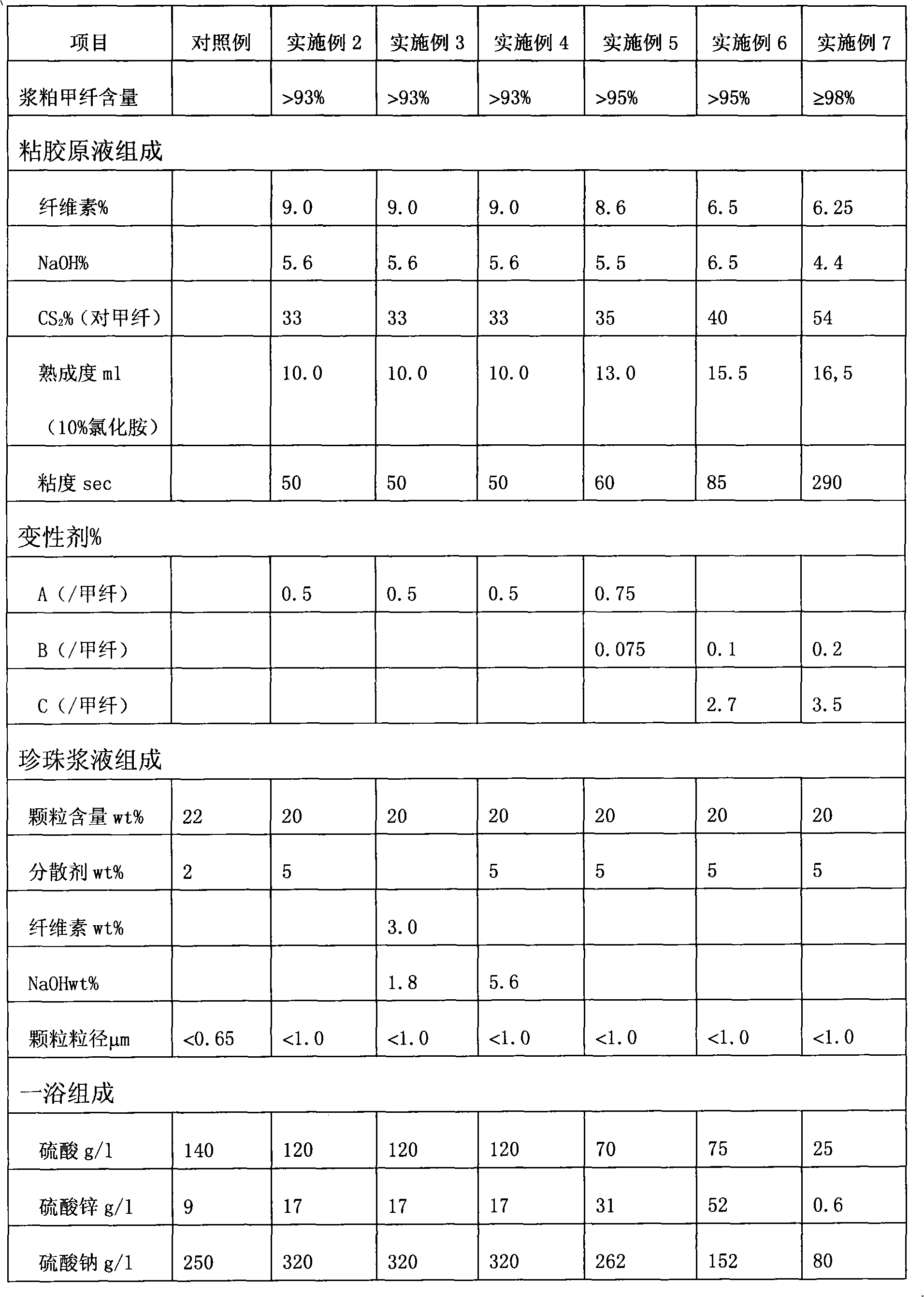

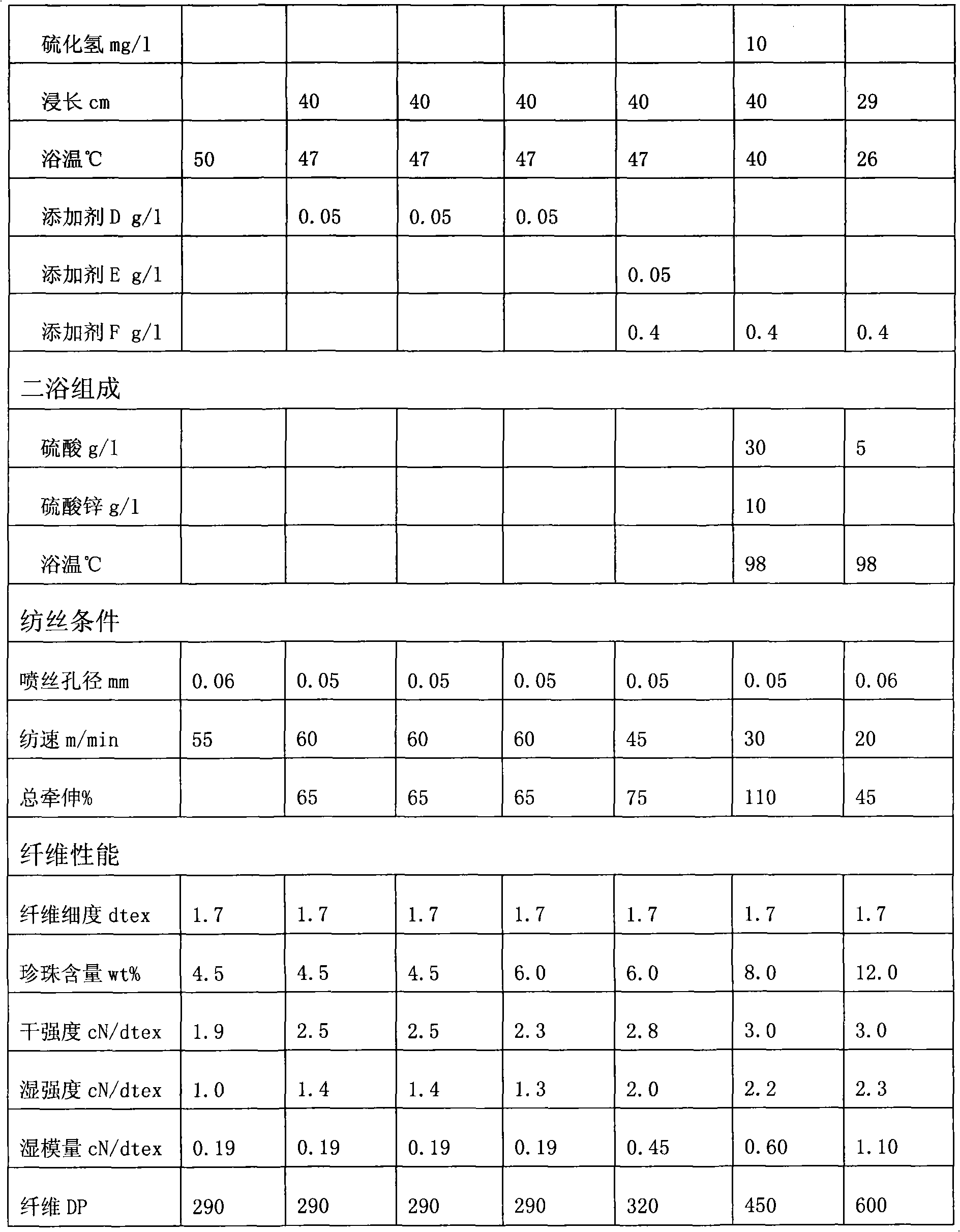

Improved viscose fiber containing pearl particles and manufacturing method thereof

InactiveCN101514496ASolve washing deformationSolve wrinkleMonocomponent cellulose artificial filamentSpinning solutions preparationCellulosePolymer science

The invention relates to improved viscose fiber containing pearl particles and a manufacturing method thereof. The fiber is reinforced, high-wet-modulus or rich and strong viscose fiber, the total amount of the fiber comprises 0.1 to 15.0 weight percents of the pearl particles, 0.2 to 6.0 weight percent of denaturant, and 79.0 to 99.7 weight percents of cellulose, the dry rupture strength of the fiber is more than or equal to 2.2 cN / dtex, and the wet rupture strength of the fiber is more than or equal to 1.2 cN / dtex. The mixture of one or more components selected from the copolymer of fatty amines, polyamines compounds, alcohol amine, polyoxyethylene and the aliphatic amine thereof, fatty acid, fatty alcohol, amide condensation compounds, ethylene oxide and propylene oxide, quaternary ammonium, pyrrolidine dithiocarbamate, dithioglycol, imidazole and derivatives thereof, is adopted as the denaturant. The manufacturing method for the fiber comprises the steps of: (1) the preparation of a viscose stock solution; (2) the preparation of slurry of the pearl particles; (3) the injection mixing of the slurry of the pearl particles and the viscose stock solution through a pre-spinning injection system; (4) spinning; and (5) post-treatment.

Owner:上海士林纤维材料有限公司

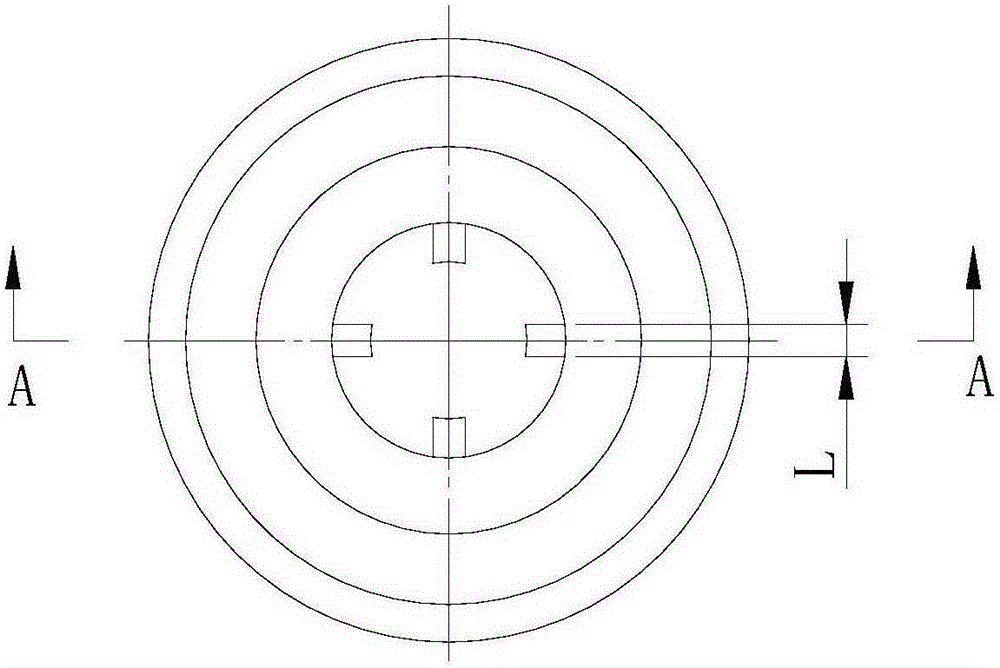

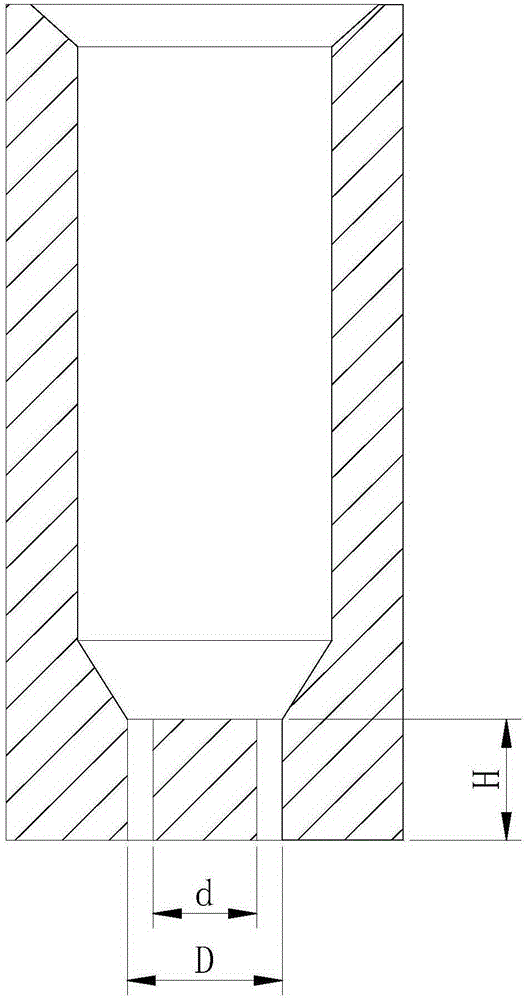

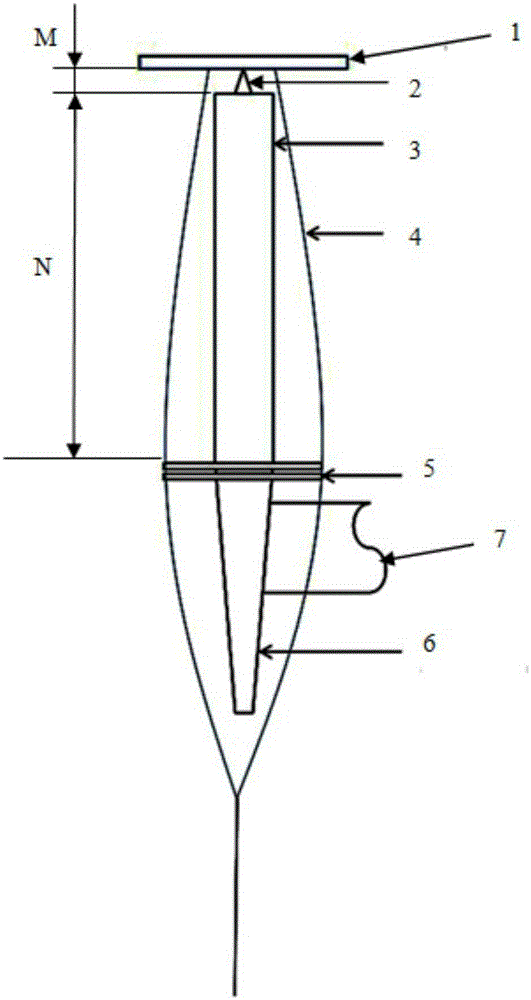

Production method for fine denier hollow short fiber

ActiveCN105220251AControl outer diameter uniformityHigh control precisionHollow filament manufactureArtificial filament washing/dryingPolyesterHeat setting

The invention provides a production method for fine denier hollow short fibers. A melt direct spinning technology is used, so that lightweight hollow polyester short fibers can be used in the conventional field of spinning, and market requirement for producing relative thin textiles is satisfied. The production method uses the melt direct spinning technology. After a melt enters a spinning manifold, through extrusion by a spinneret orifice on a spinneret plate, a melt trickle is formed. A chimney fan on the middle part of the melt trickle blows out cross air blow from inside to outside, to cool and solidify the melt trickle, and a nascent fiber is formed. Through oil applying bundling, traction, two-stage stretching, heat setting, crimping, and drying, the nascent fiber is obtained after cutting. Each spinneret orifice comprises four micropores uniformly distributed on a same circumference. When the melt passes through the spinneret orifice, temperature of spinning is 288-290 DEG C. the distance M between the upper end of a blowing column and the spinneret plate is 80-150 mm. Total height N of the blowing column is 850 mm. Cross air blow speed is 0.75-1.50 m / s. The cross air blow speed increases linearly on the height direction of the blowing column, the air blow speed is low close to the spinneret plate end, and wind temperature is 20-23 DEG C.

Owner:JIANGSU JIANGNAN HIGH POLYMER FIBER

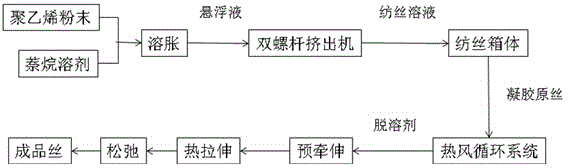

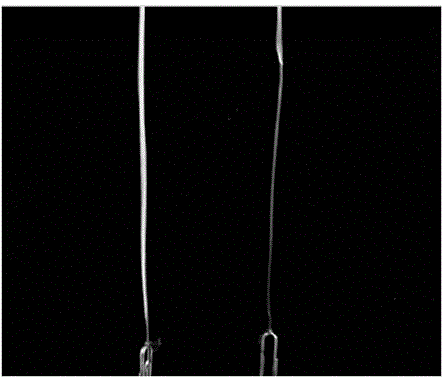

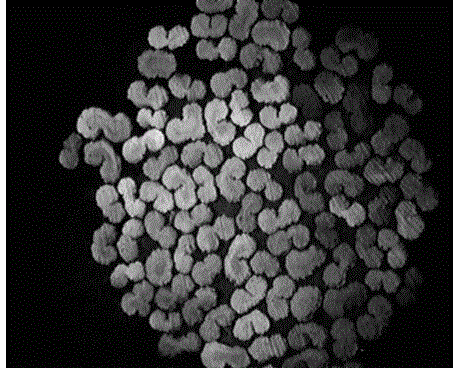

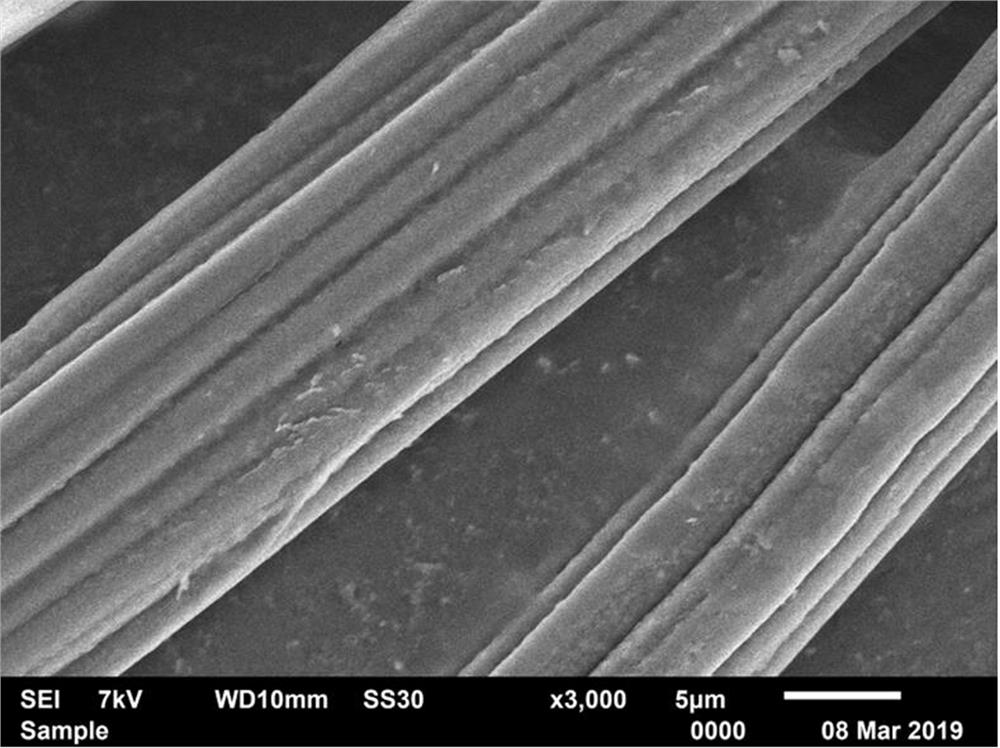

A preparing method of a polyethylene fine-denier moisture-conducting fiber

InactiveCN106032583AImprove performanceSoft and comfortableDry spinning methodsMonocomponent polyolefin artificial filamentConventional polyethyleneWind circulation

A preparing method of a polyethylene fine-denier moisture-conducting fiber is disclosed. The polyethylene fine-denier moisture-conductive fiber the fineness of which ranges from 22 dtex to 1776 dtex is obtained by swelling ultra-high-molecular-weight polyethylene used for fiber and having a molecular weight of 4-8 million in decalin to obtain a suspension, dissolving and shearing through a twin-screw extruder to allow polyethylene macromolecular chains to be fully untwisted to form a uniform spinning solution, spinning through a spinneret plat, removing the decalin in a silk bundle in a hot-wind circulation system, pre-stretching, performing one or more thermal stretch steps and performing one or more loosing steps. The hot-wind circulation system is a sealed heating chamber having nitrogen circulated therein. The polyethylene fine-denier moisture-conductive fiber is lighter, thinner and softer than conventional polyethylene fibers, maintains high-strength and high-modulus characters. The cross section of the fiber has an oval shape, an egg shape, a dog bone shape, a bean shape or other special shapes. The fiber is provided with micro grooves and slots at the axial direction. Moisture-conducting performance of the fiber is obviously improved than that of wet-process fibers. The fiber is obviously improved in wearability, and fabric of the fiber has moisture conducting and rapidly drying and refreshing properties.

Owner:CHINA PETROLEUM & CHEM CORP +1

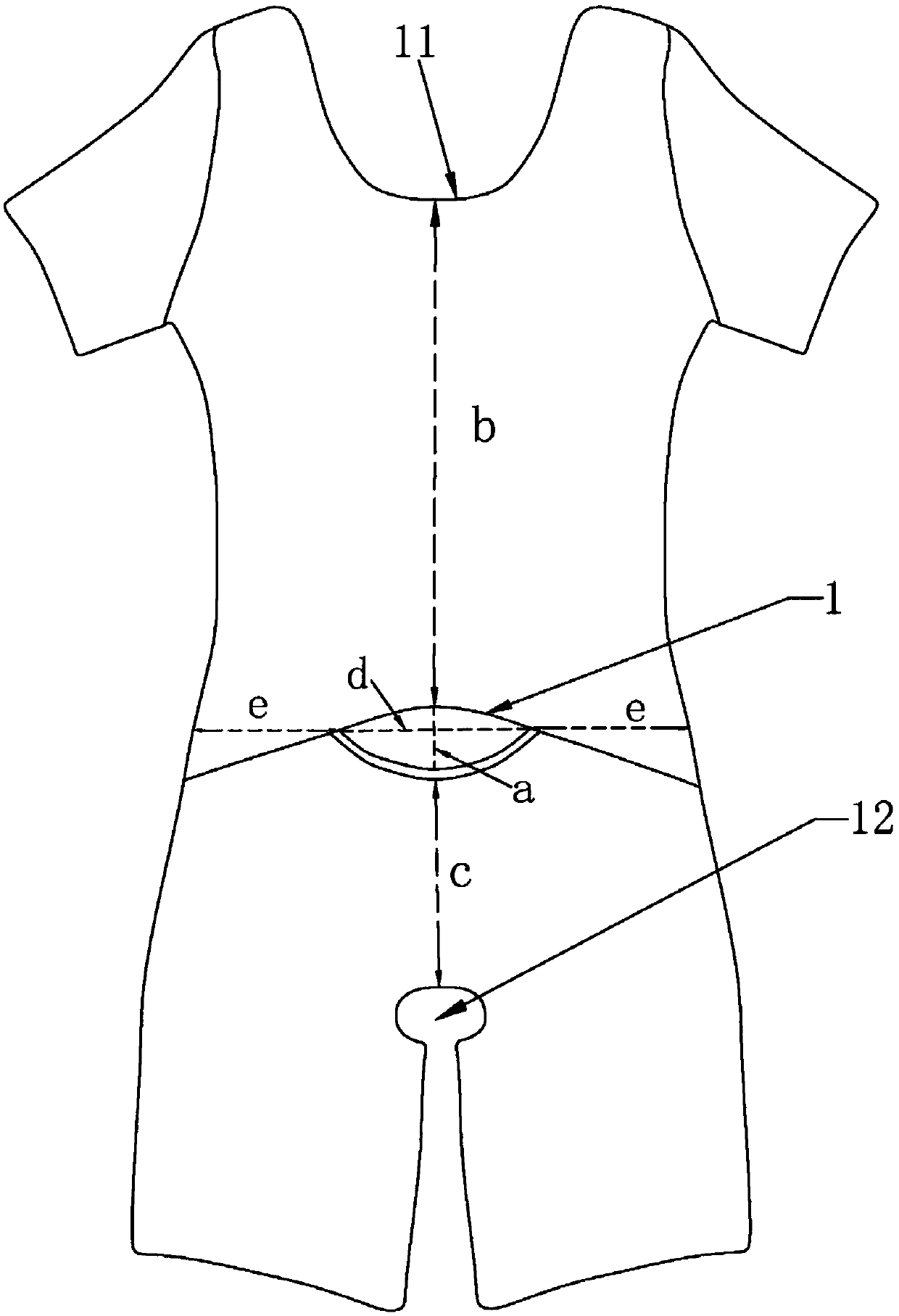

Far infrared seamless corset

ActiveCN109090720AImprove stabilityImprove spinnabilityElectroconductive/antistatic filament manufactureGirdlesFiberLength wave

The invention relates to the technical field of corsets, in particular to a far infrared seamless corset. The far infrared seamless corset is formed by seamless weaving of far infrared fiber. The farinfrared fiber is obtained by far infrared master batches, and the far infrared master batches are a mixture formed by far infrared mixed powder, a composite polymer and auxiliaries with the weight ratio being 4-8:100:0.5-2. The far infrared seamless corset is prepared by weaving far infrared fiber, far infrared ray is released, the mixing ratio of the far infrared fiber far infrared mixed powder,the composite polymer and a polymerization inhibitor is strictly controlled, the released far infrared wavelength is matched with the wavelength range of the human body, the absorption function of the human body is good, the far infrared fiber achieves the antibacterial, heat preservation and healthcare effects, and the effects of eliminating fatigue, promoting blood circulation, dispelling coldness, improving immunity and beautifying the features and achieving skin protection are achieved.

Owner:HONGJI UNDERWEAR CO LTD

Multilayer composite felt for filtration

InactiveCN107744690ALow densityLow thermal conductivityDispersed particle filtrationMembrane filtersGlass fiberSurface layer

The invention discloses a multilayer composite felt for filtration. The multilayer composite felt for filtration includes a base cloth, a first filter layer and a second filter layer which are arranged in sequence, the base cloth is obtained through hybrid braiding of polyphenylene sulfide fibers and glass fibers and is positioned at the outermost layer, the first filter layer is made of a composite felt of glass fibers with the diameter being 0.5-3 [mu]m and glass fibers with the diameter being 20-50 [mu]m and is placed on the upper surface layer of the base cloth, and the second filter layeris made of an ultrafine glass fiber and polytetrafluoroethylene fiber composite felt and is placed on the upper surface layer of the first filter layer. The multilayer composite felt for filtration fully performs the respective performance advantages of the glass fibers, polytetrafluoroethylene and polyphenylene sulfide fibers, covers the mutual shortages, and has very good comprehensive effectsdue to performance synergism, so a novel filtering material having excellent high temperature resistance, excellent chemical corrosion resistance, good mechanical performances and excellent wear resistance is obtained.

Owner:宿迁空天新材料有限公司

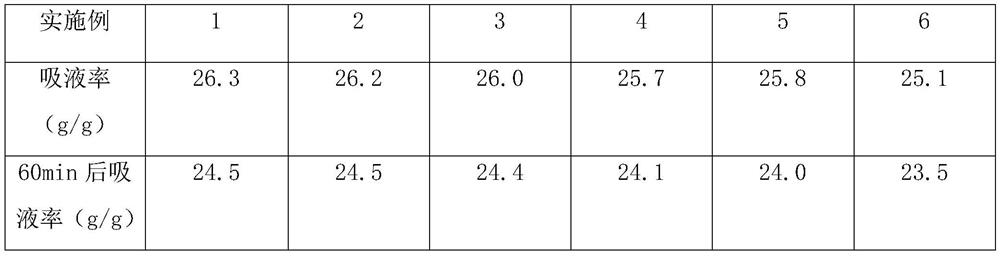

Binchotan composite modified nano platinum bamboo pulp fiber for mask base cloth and preparation method of Binchotan composite modified nano platinum bamboo pulp fiber

ActiveCN113638069AFeel goodGood hygroscopicityMonocomponent cellulose artificial filamentWet spinning methodsPolymer scienceSpinning

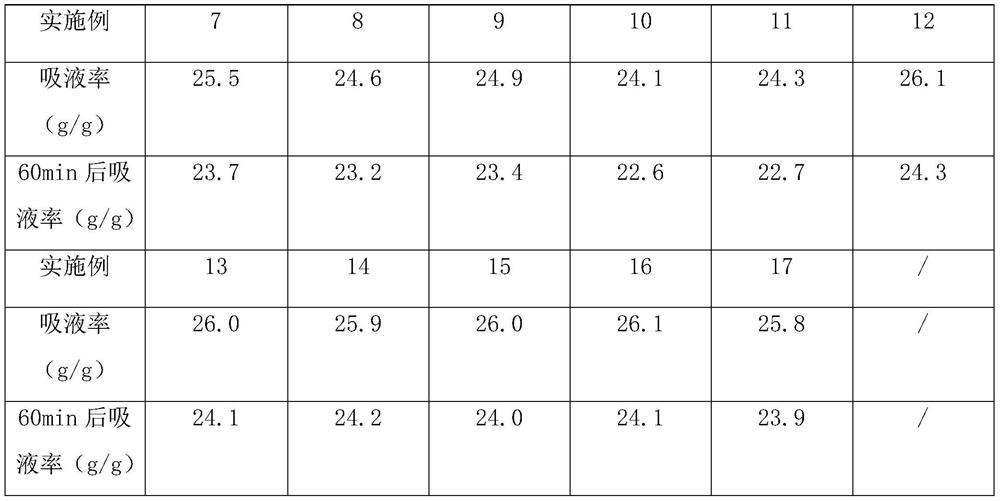

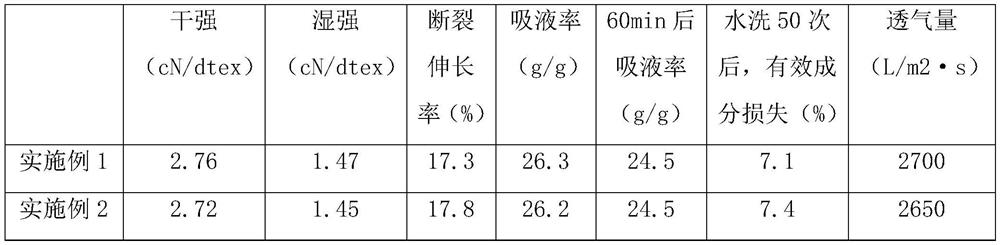

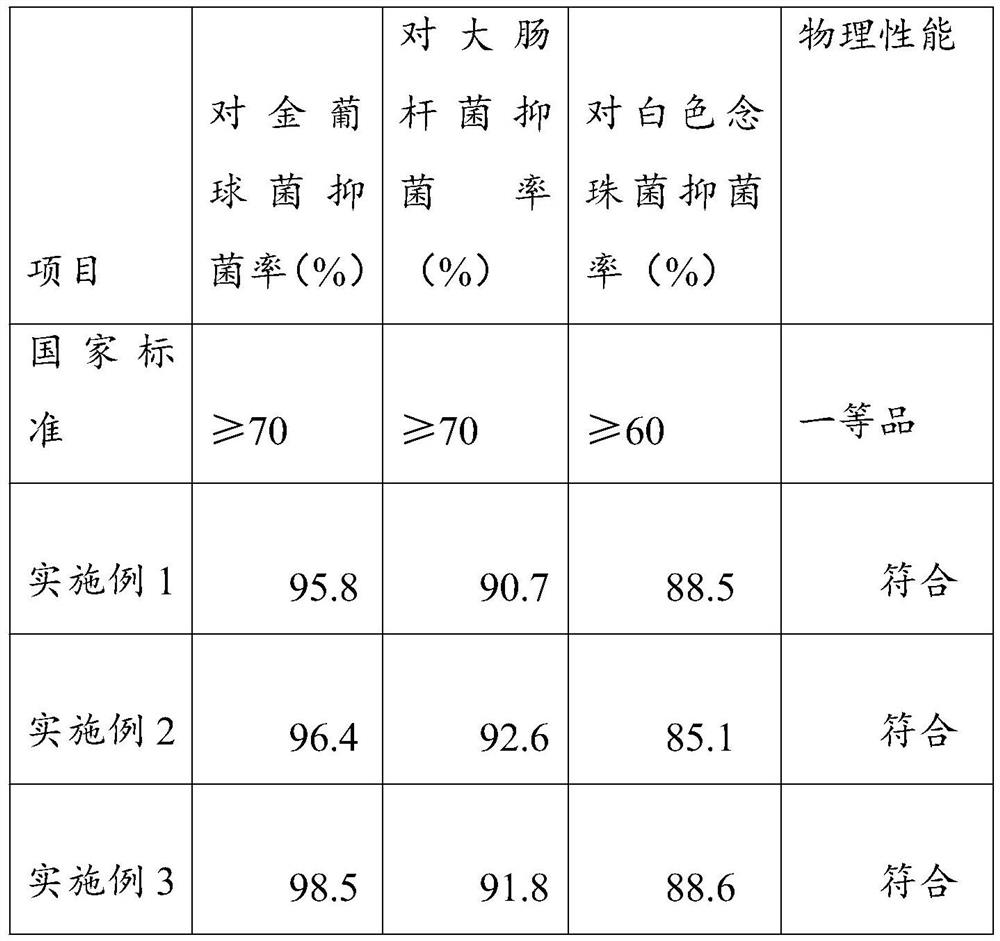

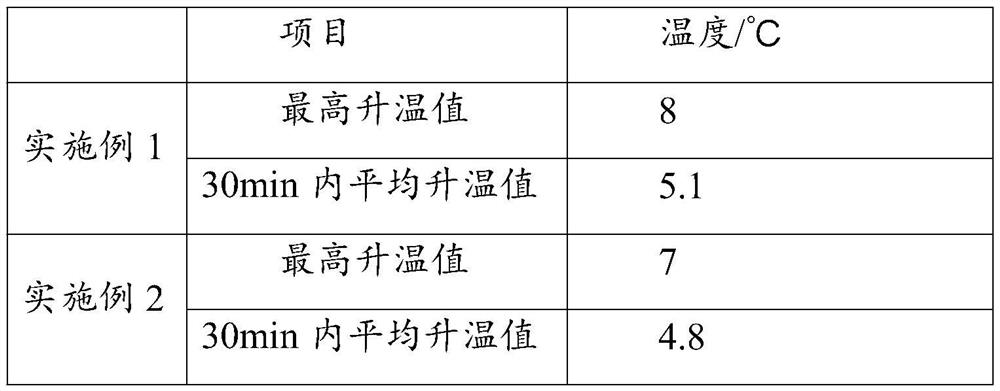

The invention provides binchotan composite modified nano platinum bamboo pulp fiber for mask base cloth and a preparation method of the binchotan composite modified nano platinum bamboo pulp fiber. The preparation method comprises the steps of preparation of binchotan composite modified nano platinum pulp, preparation of a spinning solution, blending, spinning and aftertreatment. The fiber prepared by the method has good antibacterial, far infrared emission, anti-oxidation and negative ion release effects, is high in skin dirt adsorption capacity and good in fiber biocompatibility, and is natural and degradable; and the liquid absorption performance is good, the liquid absorption rate reaches 24.1-26.3 g / g, the liquid absorption content is 21.6-23.5 g / g after 60 min, the loss rate is low, and the durability is high. The pulp with relatively high polymerization degree is adopted, binchotan micro-powder and nano platinum particles are combined with a bamboo regenerated cellulose spinning solution through a special process by the method, the binchotan micro-powder and nano platinum are uniformly distributed in the prepared fiber, and the dispersity of the fiber is improved without adopting a traditional chemical dispersing agent, so that the safety of the fiber is improved, and the irritation to the skin is avoided.

Owner:山东银鹰化纤有限公司

Preparation method of moisture-absorbing heating fiber containing plant extract and having antibacterial function

PendingCN114000224ANo addedNo heavy metalsElectroconductive/antistatic filament manufactureConjugated cellulose/protein artificial filamentsSpinningFiber bundle

The invention discloses a preparation method of moisture-absorbing heating fibers containing plant extracts and having an antibacterial function, which comprises the following steps: step 1, preparation of a spinning solution: mixing cellulose pulp with alpha cellulose according to a weight ratio of 1: 2, then adding 10-18% of a composite modified additive, stirring at a high speed by using a stirrer to realize blending to prepare a blended spinning solution, and standing, defoaming, and ripening for later use; and 2) spinning and forming: in which the spinning solution obtained in the first step is treated through a metering pump and a filter, the spinning speed is preset, the spinning solution is sprayed out through a spinning nozzle, enters a coagulating bath and reacts with reagents in the coagulating bath to be cured, and formed fiber bundles need to be stretched through a drafting roller firstly and then subjected to post-processing treatment. The product is fine, soft, moisture-preserving, breathable, non-irritating to skin affinity, excellent in moisture absorption and heating performance and antibacterial property, green, environment-friendly, biodegradable, free of heavy metals and harmful chemicals, safe and non-dissolving out; and the fiber has high moisture regain and high hygroscopicity.

Owner:江苏康溢臣生命科技有限公司

Preparation method of multifunctional viscose fiber containing barley proteins

InactiveCN112160036AHas antibacterial propertiesFunctionalMonocomponent cellulose artificial filamentCellulose pulpAnti bacterial

The invention discloses a preparation method of a multifunctional viscose fiber containing barley proteins, and belongs to the preparation of functional regenerated cellulose. According to the preparation method, cellulose pulp, modified zeolite, a wheat protein extract, an aqueous solution of cationic cellulose and the like are taken as main raw materials, firstly, in-situ loading is carried outon the barley protein extract by adopting the modified zeolite, and then drying and grinding are carried out on the zeolite adsorbing the extract to prepare a modified functional agent; and then the modified functional agent is mixed with a plant protein solution and finally blended with a viscose stock solution, and the multifunctional viscose fiber containing the plant proteins and having antibacterial, moisture-absorbing and heating functions are prepared through a wet spinning process.

Owner:江苏康溢臣生命科技有限公司

Protein/cellulose fiber preparation method based on cellulase activation treatment

ActiveCN110331584BImprove mechanical propertiesEasy to takeBiochemical treatment with enzymes/microorganismsVegetal fibresPolymer scienceCellulose fiber

The invention relates to a protein / cellulose fiber preparation method based on cellulase activation treatment, which uses protein powder and cellulose fiber as raw materials, and performs alkyl glycoside pretreatment and cellulase activation on the cellulose fiber in sequence, and then A protein / cellulose fiber with a protein content of 1-5% is prepared by grafting proteins with a cross-linking agent polyvinyl glycidyl ether. Based on the specificity, high efficiency, green environmental protection and other characteristics of cellulase, the present invention not only has a protein / cellulose fiber protein grafting efficiency > 50%, but also has excellent mechanical properties of the fiber, excellent wearing performance, and relatively high textile processing performance. it is good.

Owner:TAIYUAN UNIV OF TECH

Preparation method of functional viscose fiber containing green alga protein algae extract

InactiveCN112144135AHas antibacterial functionEasy to takeArtificial filaments from viscoseSpinningCellulose pulp

The invention discloses a preparation method of a functional viscose fiber containing a green alga protein algae extract, and belongs to the technical field of preparation of functional regenerated cellulose. The preparation method of the functional viscose fiber comprises the following steps by taking cellulose pulp, modified rare earth, an aqueous solution of an algae extract and the like as main raw materials, firstly, carrying out in-situ loading on the algae extract by adopting the modified rare earth, then drying and grinding the rare earth adsorbed with the extract to prepare a modifiedfunctional agent, and blending the modified functional agent with a viscose stock solution, so that viscose fibers containing algae glycoprotein, trehalose and the like and having an antibacterial function are prepared through a wet spinning process.

Owner:江苏康溢臣生命科技有限公司

Taxus chinensis environment-friendly antibacterial anti-mite wadding and preparation method thereof

InactiveCN110629404AFluffy goodStrong warmth retentionMechanical cleaningPressure cleaningPolyesterFunctional health

The invention belongs to the technical field of textile materials, and particularly relates to a Taxus chinensis environment-friendly antibacterial anti-mite wadding and a preparation method thereof.The Taxus chinensis wadding provided by the invention comprises, by mass, 15-60% of Taxus chinensis viscose fibers and 40-85% of a fiber mixture, wherein the fiber mixture includes two or more of cotton fibers, composite antibacterial agent finished viscose fibers, natural mineral fibers, modal fibers, heat-melting silk polyester fibers or wool fibers. The steps of material mixing, air suction, carding, laying, hot melting, post-ironing, cooling, cutting and the like are performed to obtain the prepared Taxus chinensis wadding having multiple layers, good fluffy property, strong heat retentionproperty and good resilience, having the functions of bacteria inhibiting, mite preventing, moisture absorbing, sweat discharging, natural health care and static electricity preventing, having the characteristics of smoothness, fineness, coolness and the like, having a functional health care effect, and being beneficial to promoting sleep.

Owner:HODO GRP WUXI TEXTILE

Cool viscose and preparation method thereof

ActiveCN101805934BEvenly dispersedGood dispersionArtificial filaments from viscosePerspirationUltraviolet radiation

The invention relates to cool viscose which contains mica powder accounting for 3 to 20 wt% of fiber dry basis. The preparation method comprises the steps of: (1) adding surfactant and dispersing agents into the mica bodies to prepare mica slurry with the concentration of 16% to 30 wt%; (2) preparing mucilage glue using bamboo pulp as a raw material, and adding dissolution denaturant in the step of dissolution; (3) mixing the mica slurry with the dissolved mucilage glue with the weight of 5 to 10 times that of the mica slurry; (4) adding the mica slurry after secondary preparation into the ripening mucilage glue according to proportion and stirring uniformly, and then continuously defoaming and filtering to obtain a spinning solution through; and (5) spinning and forming the spinning solution in a coagulating bath with spinning denaturant and spinning dispersing agents, and preparing the cool viscose after sliver drawing and post treatment. The product of the invention has the healthcare effects of ultraviolet radiation resistance, moisture absorption, perspiration removal, and far infrared healthcare, and is specially suitable for producing clothing products of summer clothes.

Owner:潍坊欣龙生物材料有限公司

Preparation method of multifunctional viscose fiber containing vegetable protein

InactiveCN112126998AEasy to keepImprove distributionArtificial filaments from viscoseSpinningAnti bacterial

The invention discloses a preparation method of multifunctional viscose fiber containing vegetable protein, and belongs to the technical field of preparation of functional regenerated cellulose fiber.The preparation method comprises the following steps that firstly, in-situ loading is conducted on a lotus seed pot extract and a lotus leaf extract by adopting modified zeolite, then zeolite after adsorbing the extracts is dried and ground to prepare a modified functional agent, then the modifying agent is mixed with a vegetable protein solution, and finally a mixture is blended with a viscose stock solution to obtain the multifunctional viscose fiber. The viscose fiber which contains the vegetable protein and has antiviral and antibacterial functions is prepared by a wet spinning process.

Owner:江苏康溢臣生命科技有限公司

Germanium viscose fiber and preparation method thereof

ActiveCN102011205BHave a cumulative effectSmall particle sizeArtificial filament washing/dryingArtificial filaments from viscoseSulfateHuman environment

Owner:潍坊欣龙生物材料有限公司

Vinylon pure-spinning fibre oil solution and preparing method thereof

InactiveCN100510241CReduce pollutionAvoid smelly and spoiledFibre typesPhosphoric Acid EstersActive agent

The invention provides a vinylon pure spinning fiber oil and its preparation method, which is composed of non-polar smoothing agent, surfactant, auxiliary agent and water, wherein the content of each component is: non-polar smoothing agent: 8-25%; in surfactants: 5-28% sulfate esters, 5-28% phosphate esters, 5-20% polyol fatty acid esters, 10-30% fatty alcohol ethers; in additives: neutralizer 2 ~11%, high molecular silicone polymer 0.5~5.0%, preservative 0.1%; the balance is water; all are calculated by weight percentage. Since the oil agent of the invention does not contain alkylphenol surfactants, environmental pollution is reduced. The fiber product treated with the oil agent of the present invention has good smoothness, softness, suitable cohesion (or clustering property), antistatic property, etc., so that the fiber can pass through various post-processing procedures smoothly, and has good spinnability; Moreover, it can be widely adapted to the process conditions of fiber production, such as heat resistance, oxidation resistance, corrosion resistance, and prevention of oily odor and deterioration caused by bacterial reproduction. The preparation method in the present invention is simple and does not need heating during preparation.

Owner:徐元萍 +1

Superfine denier yew yarn

The invention provides a superfine denier yew yarn. The yarn is a blend of yew fiber and superfine denier polyester staple fiber. In part by weight, the weight ratio of the yew fiber in the yarn is 5-20%, and the weight ratio of the superfine denier polyester staple fiber in the yarn is 80-90%. The superfine denier yew yarn is obtained by blending the yew fiber and the superfine denier polyester staple fiber, and the textile machinability is good. Meanwhile, the textile made of the superfine denier yew yarn has the characteristics of smoothness, delicacy, strength, elasticity, luster and moisture absorption ability, can meet the crisp requirement of outerwear fabric, and can be used to make the outerwear fabric. Thus, the application of the yew yarn on the outerwear fabric is widened.

Owner:JIANGSU HONGDOU INDUSTRIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com