Resin compatible type glass fiber yarn impregnation agent, and preparation method thereof

A glass fiber and sizing technology, applied in the direction of coating, can solve the problems of expensive lubricant, increased product cost, yellow yarn color, etc., and achieve the effects of good mechanical properties, good compatibility and simple components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with specific embodiment, further illustrate the present invention. It should be understood that these examples are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

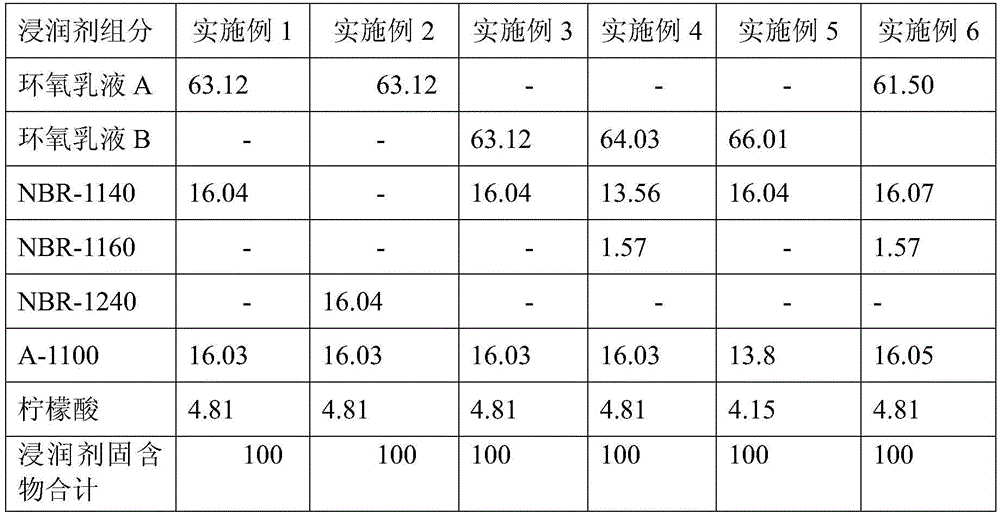

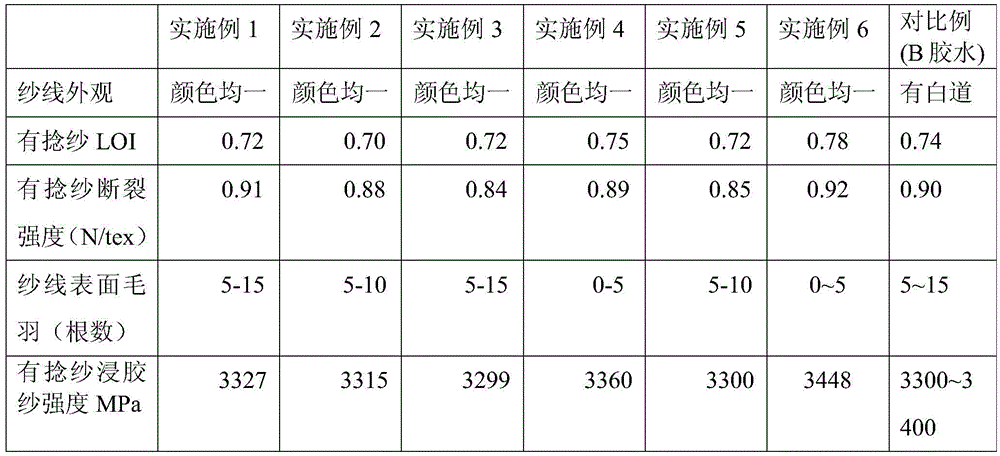

[0026] The formula of embodiment 1-6 sees the following table:

[0027]

[0028] Note: Epoxy emulsion A: epoxy equivalent is 230-270g / eq, the total amount of emulsifier in epoxy emulsion is 11% of resin weight; epoxy emulsion B: epoxy equivalent is 230-270g / eq, epoxy The total amount of emulsifier used in the emulsion was 18% by weight of the resin.

[0029] Preparation:

[0030] (1) Add water with 40% of the total amount of wetting agent to the pre-mixing container, add glacial acetic acid to adjust the pH value to 3-4, slowly add the silane coupling agent while stirring, and continue stirring until the surface of the liquid is clear and free of oil. , to obtain a silane coupling agent solution;

[0031] (2) add epo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com