Patents

Literature

122results about How to "Strong warmth retention" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Terylene super fine denier double-faced short floss textile and production method thereof

InactiveCN101760896AAvoid churnSilkyWarp knittingHeating/cooling textile fabricsYarnTextile technology

The invention relates to the textile technology field, in particular to a terylene super fine denier double-faced short floss textile and a production method thereof; the terylene super fine denier double-faced short floss textile is characterized in that: polyester yarns or poly / nylon composite yarns with 0.42dtex and / or 0.58dtex or lower than the specification of the single-fiber fineness are adopted as felted yarn raw material, polyester FDY or polyester DTY with 55.5dtex-111dtex is used as bottom yarns; the invention further discloses a production method of the terylene super fine denier double-faced short floss textile. The terylene super fine denier double-faced short floss textile in the invention has the advantages that: 1) the textile has super smoothness, the single-fiber fineness reaches 0.42dtex and 0.58dtex, the advanced printing and dyeing process is adopted, so as to ensure the super smoothness, really achieve the purpose that the touch sense is more comfortable than the feeling of touching baby skins and have excellent fitting performance; 2) the textile has strong heat retention, the texture structure is compact and can reach 36 stitches per hour; 3) the textile has super long using cycle, the weaving structure is contact without depilation and balling-up, and the anti-tearing strength is high.

Owner:SHANGHAI WEILE TEXTILES CO LTD

Moisture-absorbing and heating alkali-free mercerized fabric and processing method of same

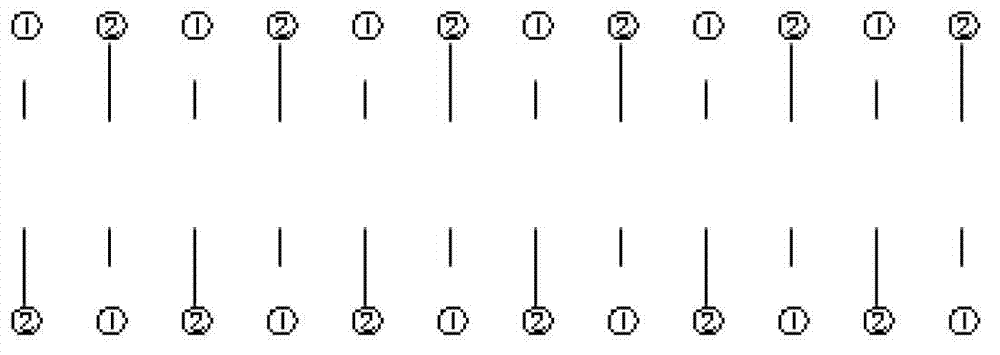

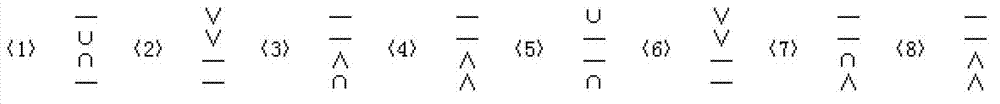

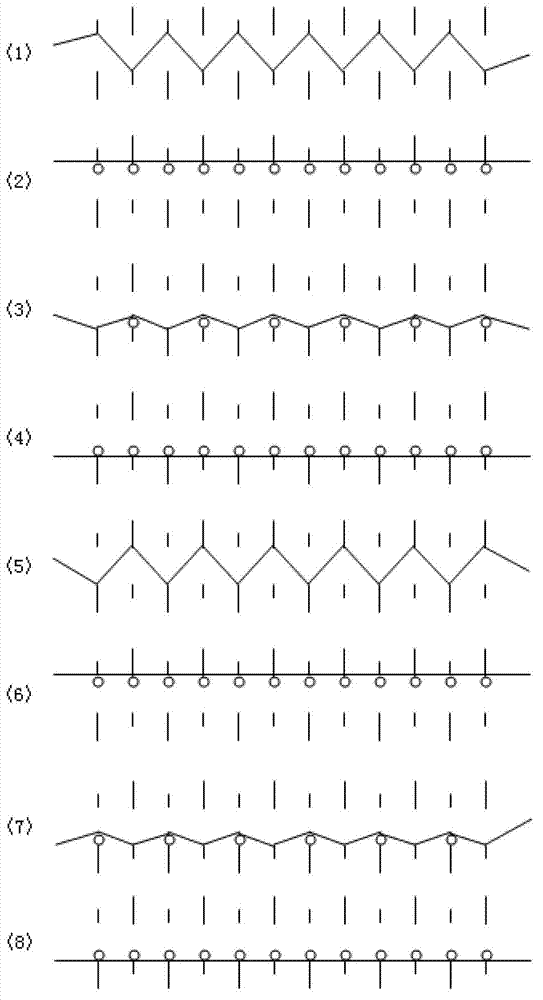

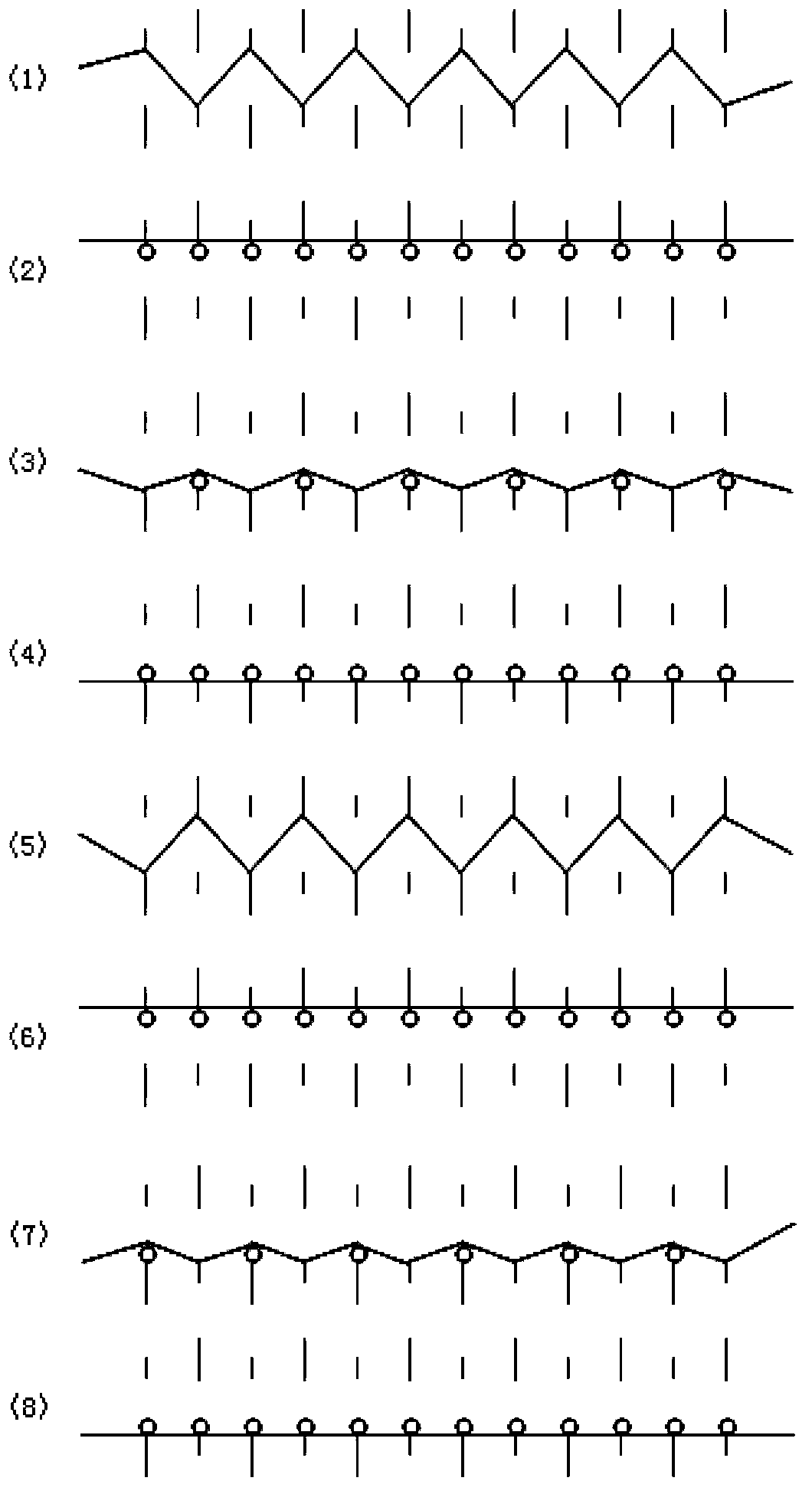

The invention discloses a moisture-absorbing and heating alkali-free mercerized fabric and a processing method of the same. The fabric has cotton on the front and moisture-absorbing and heating Heatwarm fibers on the back, and a heat insulation air layer is arranged between the front and the back of the fabric. The processing method includes the steps as follows: every two knitting needles are arranged at the top and the bottom of a two-faced machine for knitting, and linters are arranged with needles opposite to each other; during the knitting, every eight paths form a circulation, 1st and 5th paths penetrate the Heatwarm to be connected in a way that two sides are engaged, the upper and lower high-channel stitches of the 1st path are double stitched in a way that two sides are engaged and the upper and lower low-channel stitches of the 5th path are double stitched in a way that two sides are engaged, so as to knit an intermediate connecting layer; 2nd and 6th paths penetrate cotton yarns to be connected in a way that one side is engaged, and upper stitches are all looped to be knitted out of an outer layer; 3rd, 4th, 7th, 8th paths penetrate the Heatwarm to be connected in a way that one side is engaged, the lower stitch low-channel stitches of the 3rd path are double stitched and the high-channel stitches are looped, the lower stitches of the 4th and 8th paths are all looped, the lower stitch low-channel stitches of the 7th path are looped and the high-channel stitches thereof are doubled stitched, so as to be knitted out of an inner layer. The fabric has soft and smooth handfeel and silky luster after the DGF treatment through the alkali-free mercerizing finishing agent, and has the effect of moisture absorption, heating, thermal insulation and air permeability.

Owner:SHANGHAI JIALE

Wear-resisting sole material and preparation method thereof

The invention relates to a formula of a rubber sole material and an improvement of the preparation method of the rubber sole material. The wear-resisting sole material comprises the following components by weight percent: 50-60% of natural rubber 3L, 3-5% of accelerator, 40-45% of filler, 1-1.5% of hardener and 1.5-2% of vulcanizing agent, wherein the hardener is high styrene; and the acceleratoris the mixture of inorganic accelerator, polyethylene glycol, stearic acid, antioxidant and tackifier and the accelerator also contains organic accelerator which is perferably selected from accelerator D, accelerator M and accelerator DM. The sole material of the invention is prepared from good natural rubber by adding the accelerator with various functions; and the sole prepared from the material has light weight, good wear resistance, water resistance and good heat retention property and is suitable to be used as the sole of the shoe with high wear strength such as tennis shoe and outdoor sneaker.

Owner:CHINADIVE WATERSPORTS INC

Multifunctional waffle cotton thermal batting and preparation method thereof

A multi-functional honeycomb cotton warm-keeping floc, which includes a surface fiber web, a middle layer fiber web, and an inner layer fiber web from top to bottom, wherein the middle layer fiber web is honeycomb cotton formed by carding and then vertically laid. The surface fiber web and the inner layer fiber web are fiber webs that are carded or air-laid and then cross-laid. An upper bonded fiber web can be added between the surface layer fiber web and the middle layer fiber web. A lower bonded fiber net can be added between the layer fiber nets, and evenly distributed thin magnets are embedded on the top surface of the middle layer fiber net. During production, each fiber web is prepared first, then compounded into one, and finally dried, cooled, and wound to obtain a finished product. This design is not only strong in warmth retention, good in elasticity, and capable of withstanding relatively large tensile forces in the horizontal direction, but also has antibacterial and magnetic therapy functions, and is easy to popularize and apply.

Owner:孙福胜

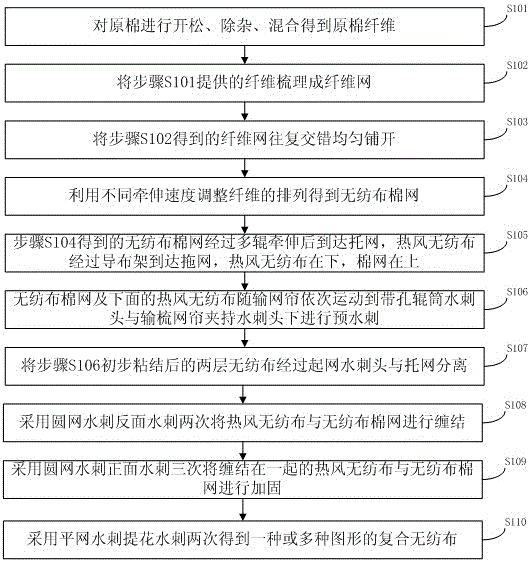

Compounding method of hot air through nonwoven fabric and all cotton nonwoven fabric and production system thereof

ActiveCN106393945AComposite process advantagesRemove the phenomenon of bleedingLamination ancillary operationsLaminationPulp and paper industryNonwoven fabric

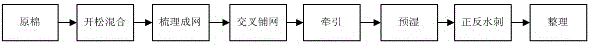

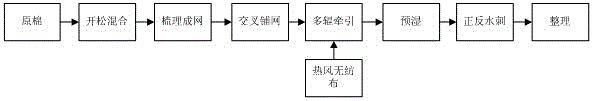

The invention discloses a compounding method of hot air through nonwoven fabric and all cotton nonwoven fabric, and belongs to the technical field of nonwoven fabric production. The method comprises the following steps: taking hot air through nonwoven fabric as the bottom layer, laminating a nonwoven fabric-cotton mesh on the hot air through fabric, and carrying out pre-wetting and front-back spunlace laminating to obtain the product. According to the method, a spunlace method is used to replace chemical adhering to compound chemical fiber nonwoven fabric and all cotton spunlace nonwoven fabric; the advantages of all cotton nonwoven fabric such as softness, water absorbing property, breathability, and the like, are preserved, at the same time, the advantages of hot air through nonwoven fabric such as high filling power, good elasticity, soft hand feeling, strong warm keeping performance, air penetrating and water penetrating performance, and the like are also preserved; moreover, the glue leakage is prevented, and the peeling strength meets the requirement.

Owner:WINNER MEDICAL (HUANGGANG) CO LTD

Long wooled tibetan carpet of yak hair or white pile

The invention relates to a Tibetan carpet, in particular to a long yak hair Tibetan carpet made by manually spinning and weaving pure yak hairs. The yarns for weaving warp threads, crossing threads and tufted surfaces of the long yak hair Tibetan carpet are pure yak hair yarns; the weaving density is 40 to 150 rows. The long yak hair Tibetan carpet has the advantages that: as the Tibetan carpet woven by unique yak hair in the Qinghai-Tibet Plateau changes the current situation that the prior Tibetan carpet is only woven by wool yarns, the woven Tibetan carpet keeps the original characteristics of good elasticity and strong warm-preservation; at the same time, as the Tibetan carpet after being woven needs no cropping and only needs to hackle the tufteds in order to extend long hairs, have the effect of simulating fur and make the Tibetan carpet more softer; and as the pure yak hair without dyeing after the cleaning treatment is adopted, the woven Tibetan carpet contains no odour of chemical dye, thereby being more environment-friendly.

Owner:QINGHAI YIYUANXIANG CARPET

Blended yarn of terylene, rabbit hair and silkworm pupa protein fiber

The invention provides blended yarn of terylene, rabbit hair and silkworm pupa protein fiber. The blended yarn comprises the following components: 65-75 weight parts of terylene, 25-35 weight parts of rabbit hair and 10-20 weight parts of silkworm pupa protein fiber. The blended yarn provided by the invention enables the characteristics of terylene, rabbit hair and silkworm pupa protein fiber to be complementary and brings the advantages thereof into play.

Owner:HAIAN COUNTY BROS SYNTHETIC FIBER

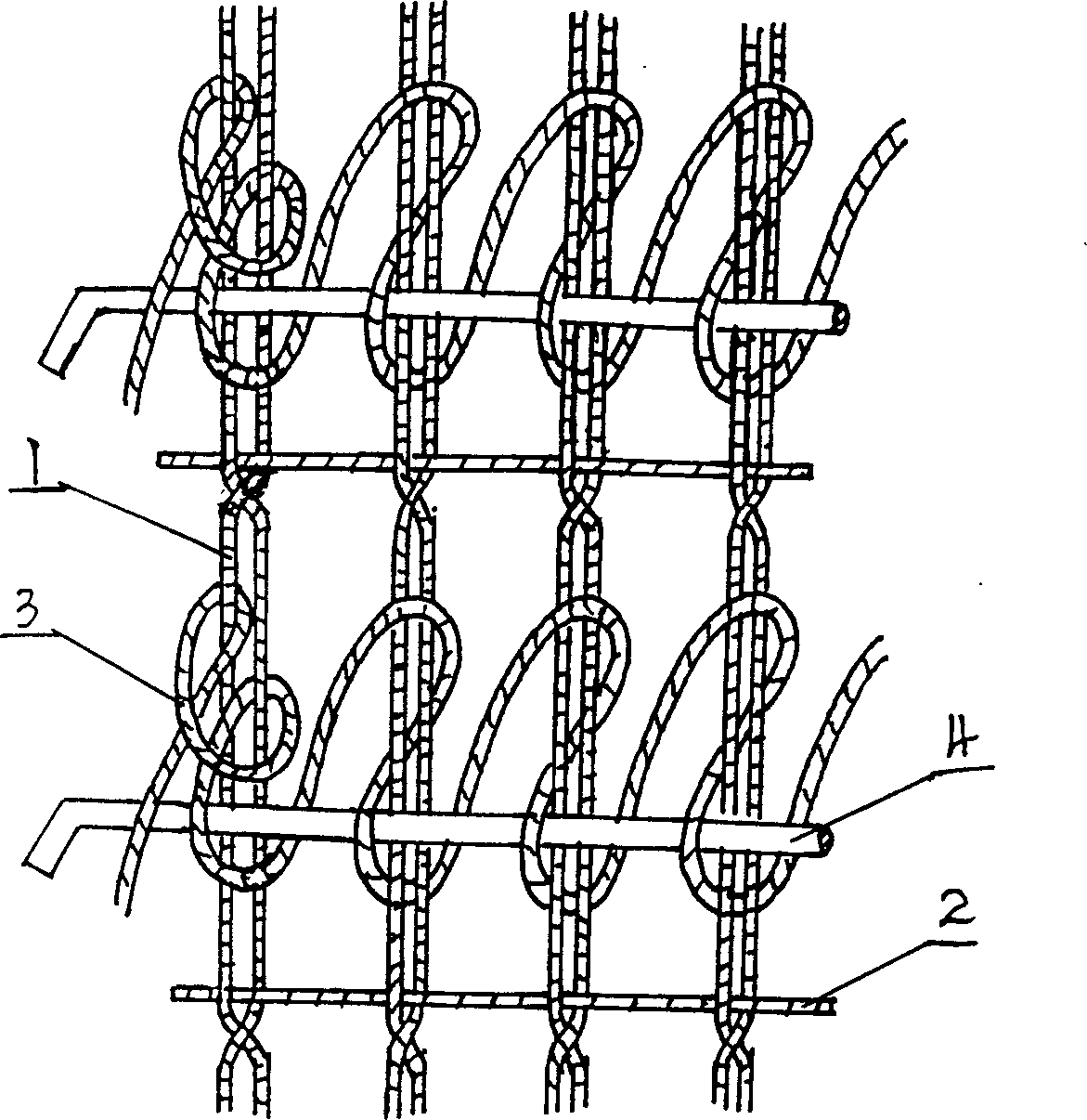

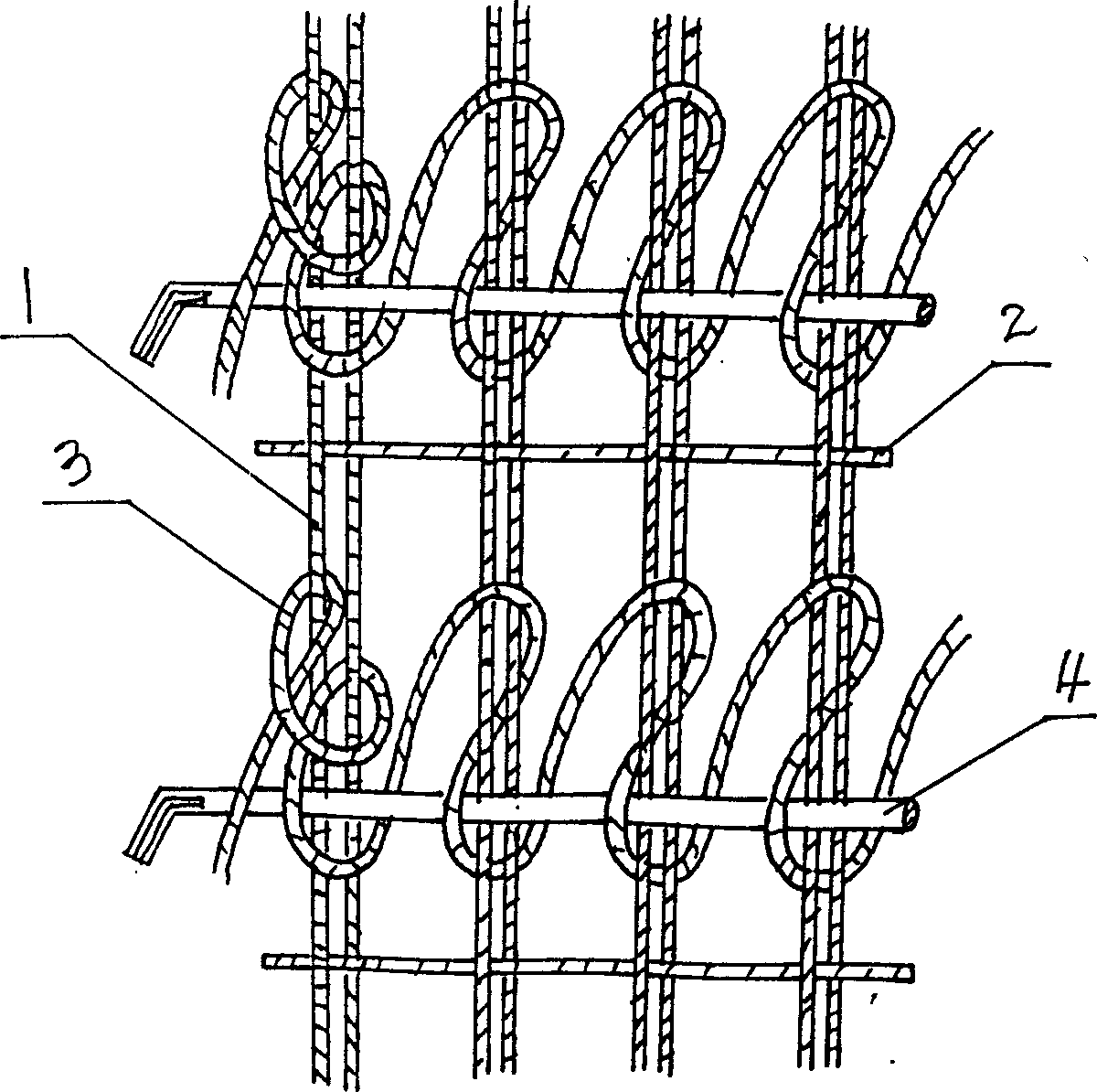

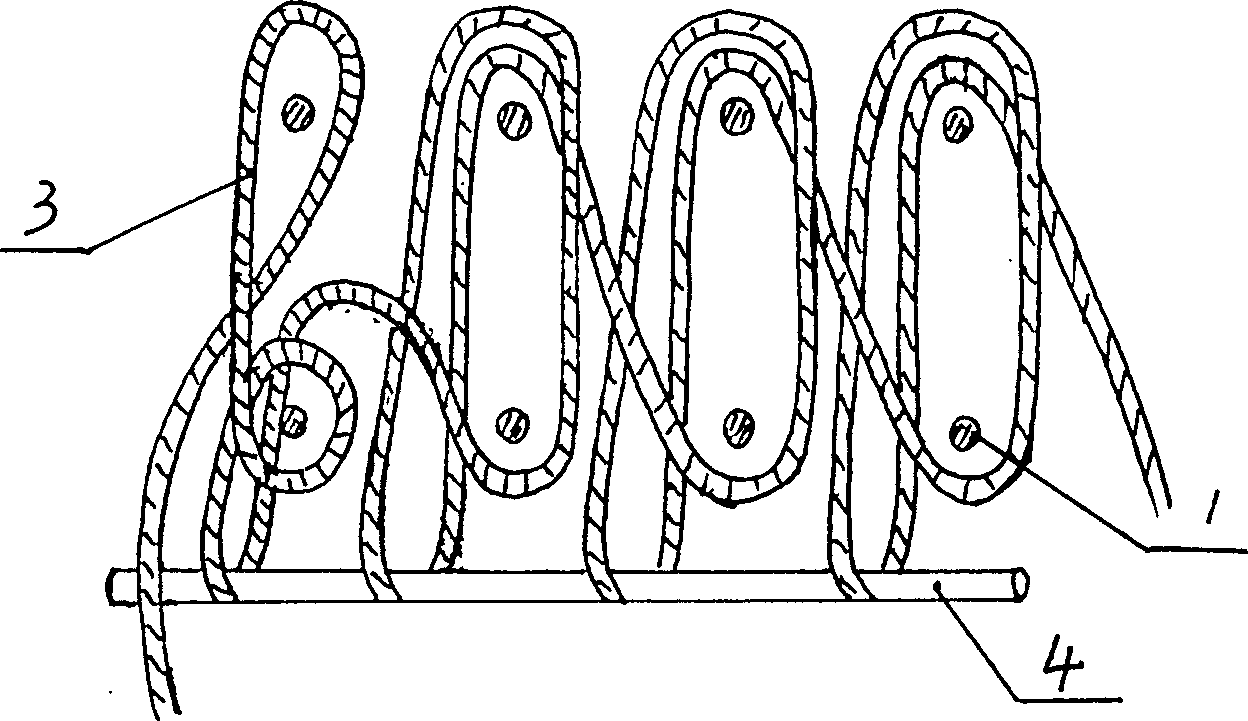

Velvet carpet and its knitting and knotting method

The present invention relates to a kind of velvet carpet and its knitting and knotting method. The woolen yarn is 9-20 count yarn of quviut, alpace, camel wool or their mixture; and the knitting density is 120-200 passages / features that. The carpet surface consists of fixed knot and knitting knot. The fixed knot is "horse's hoof tie" and the knitting knot is formed by making knitted yarn to wind around a warp yarn column, turn to form a U-shaped ring, penetrate between two warp columns and wind around a warap yarn rod. The carpet has good stereo effect, sharp layer and other advantages.

Owner:青海藏羊地毯(集团)有限公司

Warm fabric

Owner:CHANGSHU JIANHUA WEAVING

T/R elastic super-soft air knitted fabric and preparing method thereof

PendingCN107938130AElastic permanentSoft touchSucessive textile treatmentsSolvent-treatmentPolyesterYarn

The invention relates to a T / R elastic super-soft air knitted fabric and a preparing method thereof. The T / R elastic super-soft air knitted fabric comprises a fabric surface, an air layer and a bottomfabric. The fabric surface and the bottom fabric are each of a double-sided weave structure. The air layer is formed between the fabric surface and the bottom fabric. The fabric surface and the bottom fabric are formed with T / R dyed yarns and spandex stretch yarns through weft knitting. The T / R dyed yarns are dyed yarns spun from dyed polyester fibers and dyed artificial cellulose. The spandex stretch yarns are covered with the T / R dyed yarns. The air layer is woven from low-elasticity polyester filaments. The T / R elastic super-soft air knitted fabric has the advantages of being soft in handfeel, light in mass, good in drapability and strong in heat preservation performance; in the production process, the T / R elastic super-soft air knitted fabric can be obtained only through a low-temperature sizing process, lots of production cost is saved, factory benefits are improved, the influences on the environment are reduced, and the fabric has huge market prospects and social benefits.

Owner:石狮禾宝纺织有限公司

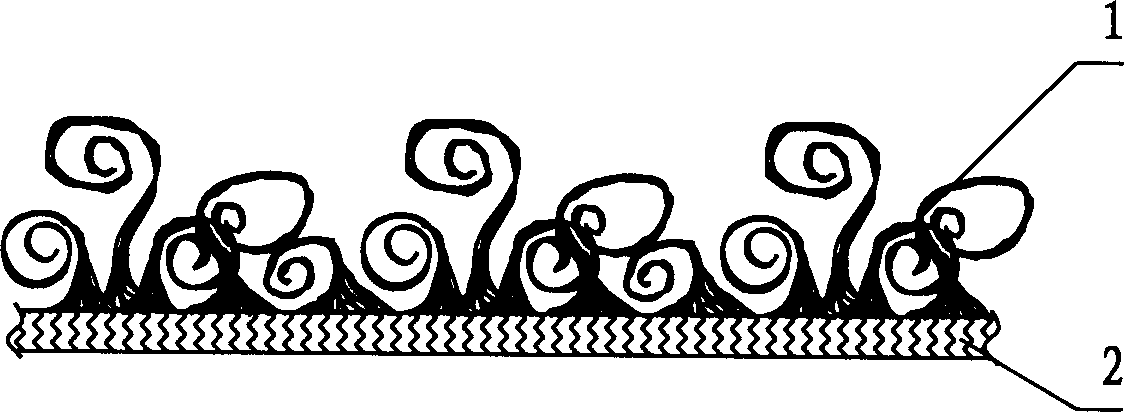

Wool-acrylic fiber cospinning pearl lint and manufacture process thereof

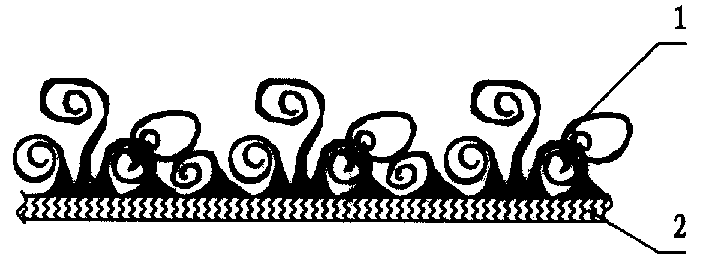

InactiveCN1423001AStrong three-dimensional senseSimple production processWeft knittingHeating/cooling textile fabricsEngineeringAcrylic fiber

The invnention is wool nitrile blending pearl lint and the manufacturing craft; it belongs to spinning product field. It includes bottom gauze layer and surface gauze layer, the surface gauze layer is closed arranged curly solid lint structure, it is at one face of bottom gauze layer, the lint is arranged on the surface of wool nitrile blending pearl line regularly or irregularly; the invention has damping, curling and drying craft after ironing and cutting craft.

Owner:ZIBO UNION PLUSH PRODS

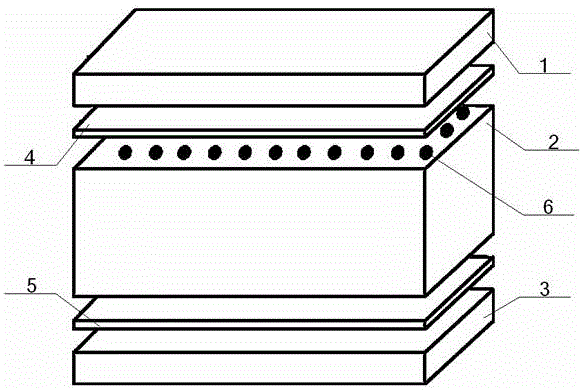

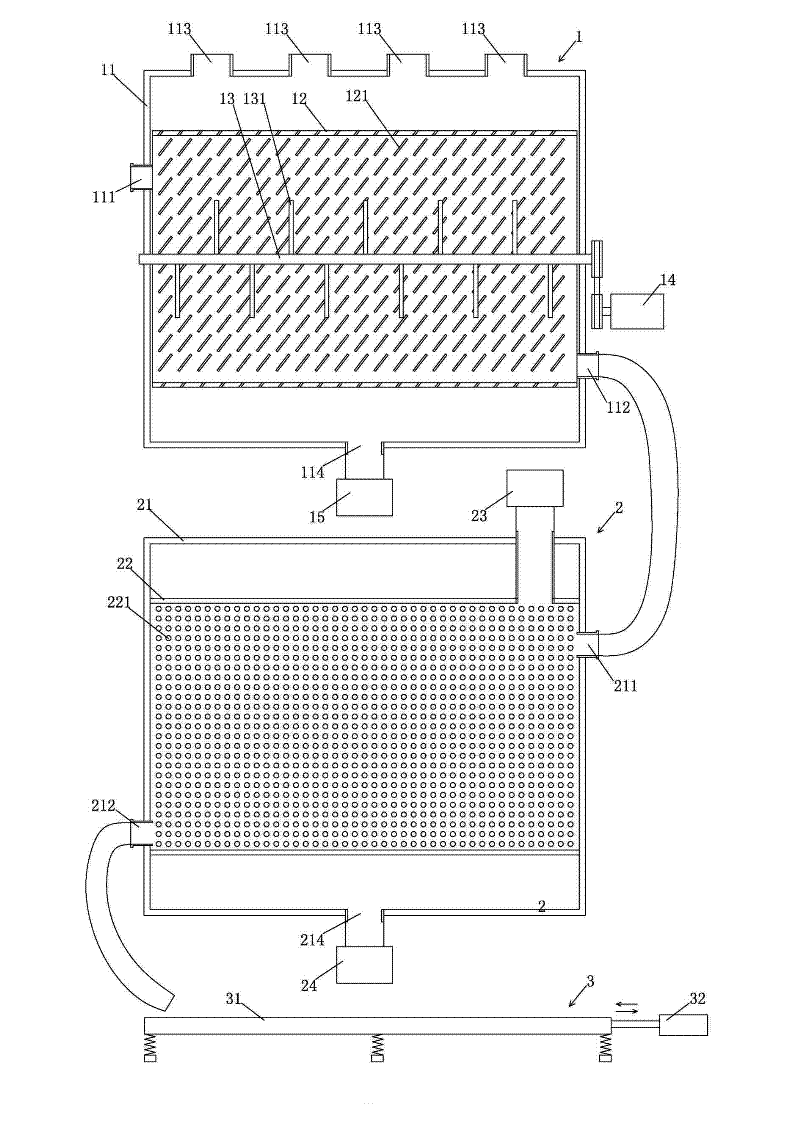

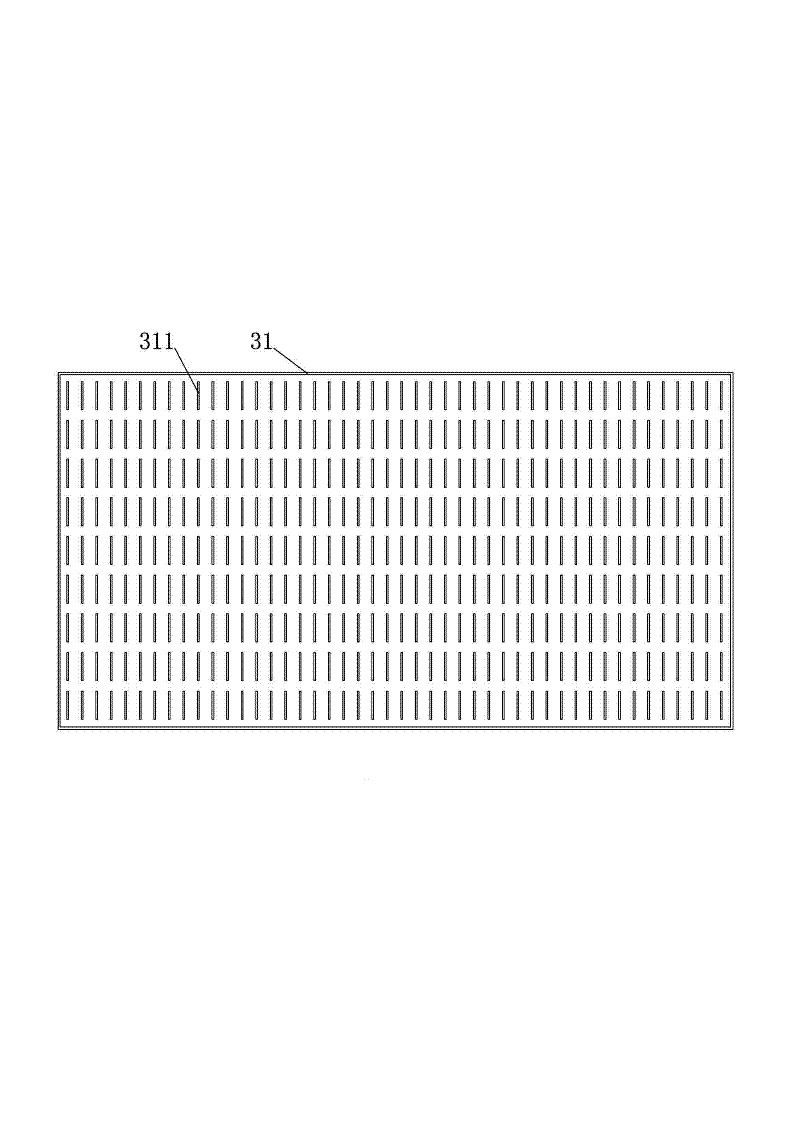

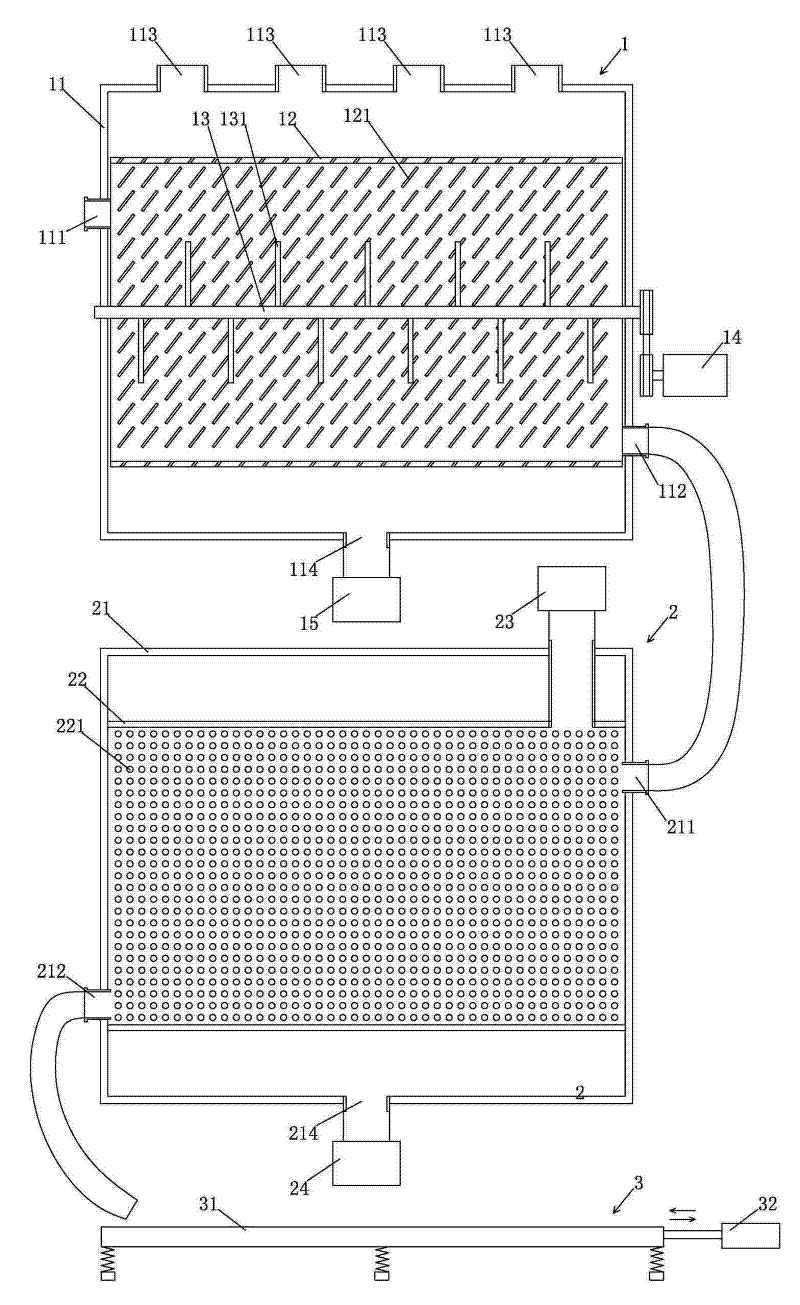

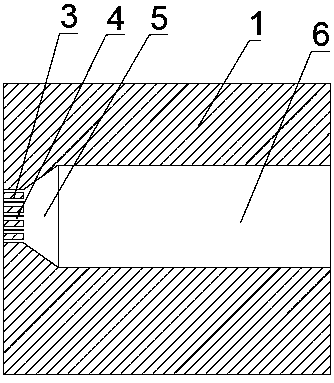

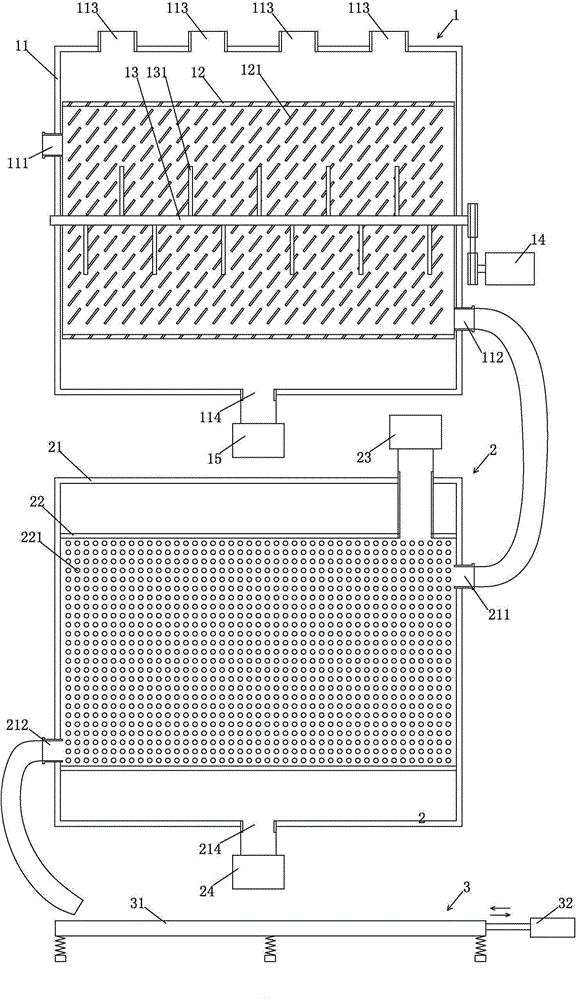

Device and method for extracting sticky down by deeply processing down

ActiveCN102242420ATo achieve the purpose of sterilization and deodorizationEliminate odorHeating/cooling textile fabricsFibre separationYarnWater vapor

The invention discloses a device and a method for extracting sticky down by deeply processing down. The device for extracting the sticky down by deeply processing the down comprises a feather yarn separation box (1), a neck feather yarn separation box (2) and a down flying yarn separation sieve (3) which are connected in turn. The method comprises the following steps of: 1) disinfecting, sterilizing and deodorizing feathers by using a high temperature of 120 DEG C generated by water vapor and pressurizing to make the feathers separated to form the down; 2) putting the down into the feather yarn separation box through a feeding hole for processing to separate feather yarns; 3) putting the down in a sieve barrel into the neck feather yarn separation box through a discharging opening for processing to separate neck feather yarns; and 4) putting the down in an inner box body into the down flying yarn separation sieve for processing to separate down flying yarns. By the device and the method, the feather yarns, the neck feather yarns and the down flying yarns can be efficiently separated to extract the sticky down with the down content of 97 percent.

Owner:广东鸿凌羽绒有限公司

Sweater fleece falling prevention technology

InactiveCN103343434AAvoid hair lossPrevent pillingHeating/cooling textile fabricsDyeing processEngineeringSizing

The invention discloses a sweater fleece falling prevention technology. The technology comprises processes of raw material selecting, dyeing, fleece finishing and sizing. The fleece finishing process with sanding, fleecing, carding, ironing and shearing is carried out after dyeing, so that produced sweater fleeces are soft and comfortable and can be prevented from falling and piling, and moreover, the sweater cannot easily deform after being washed and has high warm-keeping performance.

Owner:罗志焯

Wool fabric

InactiveCN102943394AIncrease elasticityStrong warmth retentionTextiles and paperCamel hairWear resistant

The invention discloses a wool fabric which comprises the following raw materials in parts by weight: 40-50 parts of wool fiber, 18-22 parts of camel hair fiber, 8-10 parts of silk fiber, 6-8 parts of soybean protein fiber and 10-14 parts of lycra fiber. The wool fabric is good in elasticity, crease resistant, durable, wear resistant, excellent in heat retention property, comfortable and attractive.

Owner:HAIAN COUNTY HENGYUAN SILK FACBRICS CO LTD

Method for artificial pasture planting in greenhouses in arctic-alpine pasturing areas

ActiveCN104686187ASuitable for storageImprove palatabilityClimate change adaptationGreenhouse cultivationWood pastureElymus nutans

The invention relates to a technical method for greenhouse building, proper grass seed combining and planting and pasture harvesting and storing in arctic-alpine pasturing areas, in particular to a method for artificial pasture planting in greenhouses in arctic-alpine pasturing areas, and aims to solve the problem of shortage of fodder grass in winter and spring in the arctic-alpine areas. The whole-set method includes: providing greenhouse building parameters according to weather and soil conditions of the arctic-alpine pasturing areas and biological features of pasture; selecting three kinds of pasture including elymus nutans, elymus sibiricus and poa annua which are good in local seed introduction and domestication effect for seeding according to a proportion; performing fertilizing, irrigation management and harvesting and storing suited to local conditions and arctic-alpine weather conditions. By the method, utilization efficiency of weather resources like water, heat and light and pasture yield can be improved; fodder grass in winter and spring can be supplemented through harvesting and storing, so that economic benefit is remarkable.

Owner:INST OF ENVIRONMENT & SUSTAINABLE DEV IN AGRI CHINESE ACADEMY OF AGRI SCI

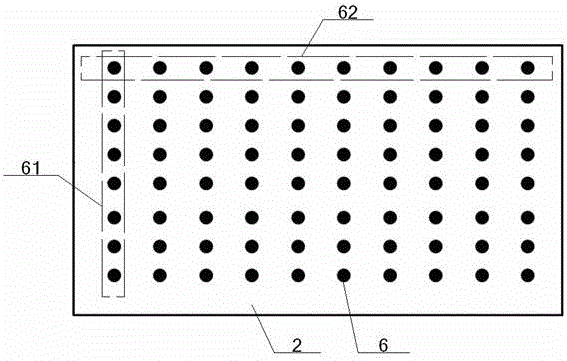

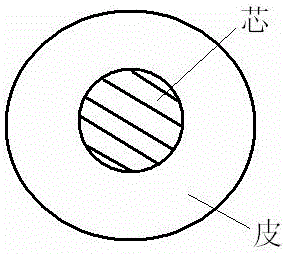

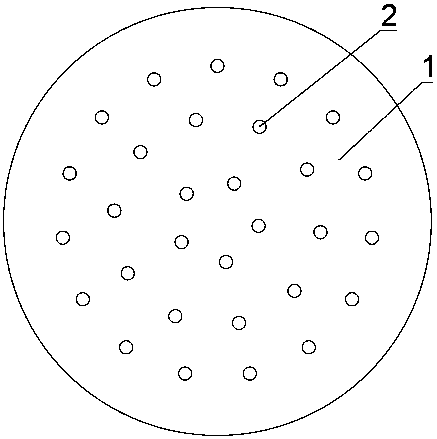

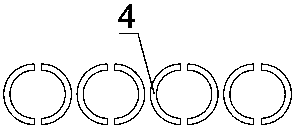

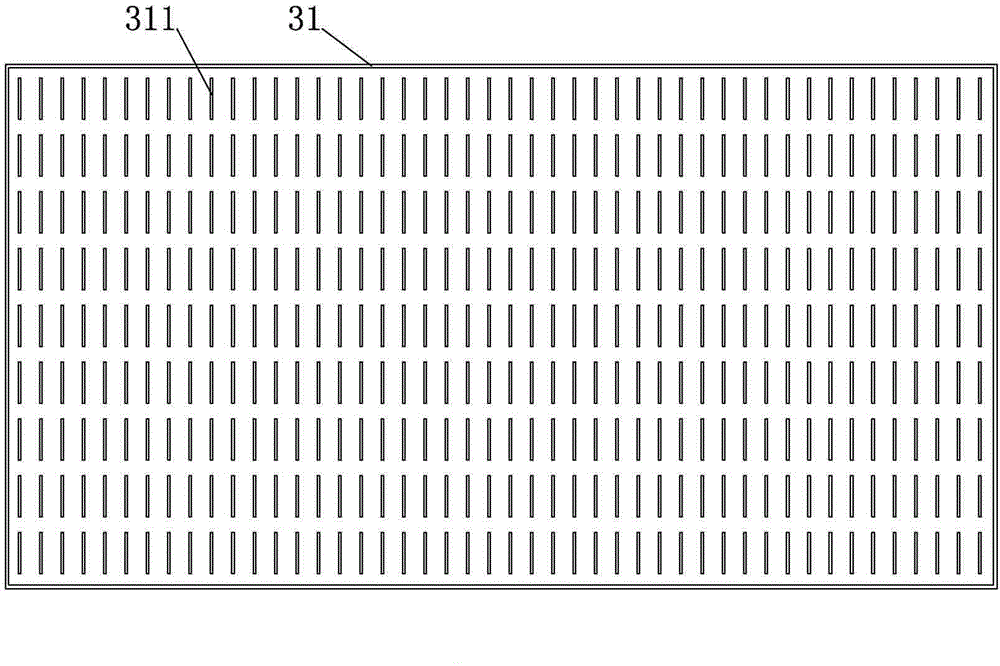

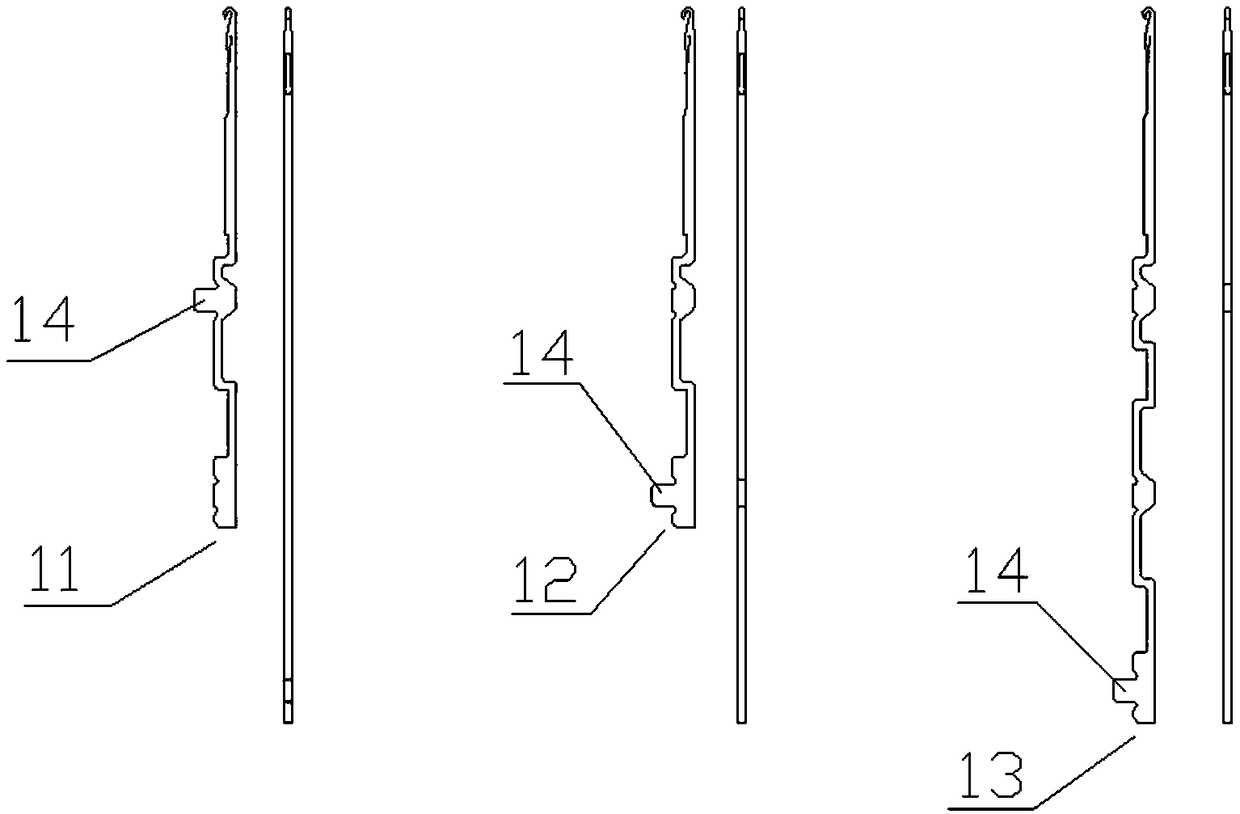

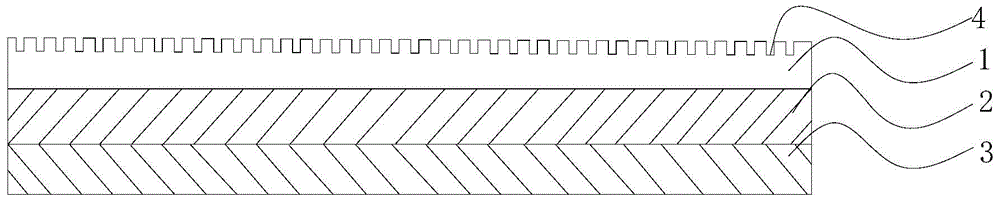

Spinneret plate for producing multi-hollow special-shaped fibers and production method

The invention relates to the technical field of fiber production, in particular to a spinneret plate for producing multi-hollow special-shaped fibers. The spinneret plate comprises a spinneret plate body, a plurality of spinneret orifices are formed in the spinneret plate body, each spinneret orifice comprises a regular porous structure located at the end, close to the raw material input end, of the spinneret plate body and a special-shaped hollow structure located at the end, close to the raw material output end, of the spinneret plate body, and the regular porous structures and the special-shaped hollow structures are communicated and are communicated with the spinneret plate body. A production method for the multi-hollow special-shaped fibers adopting the spinneret plate comprises the specific production steps of raw material screening, raw material drying, high-temperature melting, spiral extruding, spinneret plate spraying-out, cooling and oiling and wind forming. According to thespinneret plate for producing the multi-hollow special-shaped fibers and the production method, the produced multi-hollow special-shaped fibers have the advantages of being high in fluffiness, good in elasticity, high in heat retention property, soft and smooth in hand feeling, good in rebound resilience, good in spreadability and the like.

Owner:新凤鸣集团股份有限公司 +1

Wool and natural fiber blended yarn

The invention relates to a textile material, in particular to a wool and natural fiber blended yarn. The wool and natural fiber blended yarn is formed by blending, by weight, 20%-28% of wool, 5%-10% of fleeces, 15%-30% of tree fiber, 20%-30% of bast fiber and the balance modal fiber. The wool and natural fiber blended yarn is formed by blending the special raw materials according to proportions, and the characteristics of all the raw material fibers are protruded; after the natural fiber and the wool are blended, the cohesive force of the yarn is increased, the hair slip phenomenon is reduced, the yarn has obdurability, and meanwhile softness and elasticity of the yarn are not lost. Meanwhile, the wool and natural fiber blended yarn has the advantages of being resistant to corrosion and bacteria, rapid in water absorption and evaporation and the like, the yarn is not prone to corrosion and moulding due to moisture accumulation, and the service life of a textile is prolonged.

Owner:TONGXIANG CITY SWEATER VOCATIONAL TECHNICAL SCHOOL

Anti-pilling flannel fabric

InactiveCN105525416AStrong warmth retentionImprove anti-pilling effectWoven fabricsFullingPolyesterYarn

The invention discloses anti-pilling flannel fabric. The anti-pilling flannel fabric is formed by interweaving upper yarn and ground yarn, wherein the upper yarn is blended yarn composed of cotton fiber and polyester fiber; the ground yarn is viscose; the cotton fiber is 35 percent to 40 percent of the mass of the upper yarn; the polyester fiber is 60 percent to 65 percent of the mass of the upper yarn; an after-finishing technology of the anti-pilling flannel fabric comprises the following steps of primary anti-pilling finishing, napping, preshrinking, drying, secondary anti-pilling finishing and forming. Through the manner, the anti-pilling flannel fabric disclosed by the invention has the advantages that the effects of softness, comfortableness and strong heat retention property are achieved, and the anti-pilling property of the flannel fabric is improved at the same time.

Owner:常熟市梅李镇赵市盛欣纺织制品厂

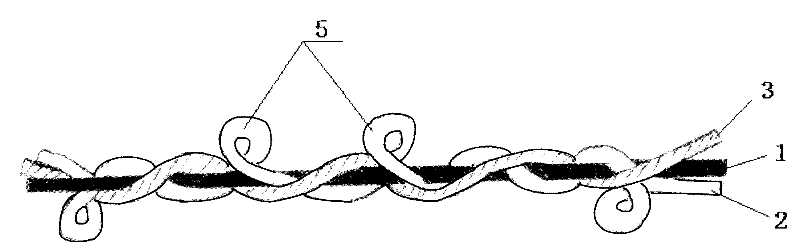

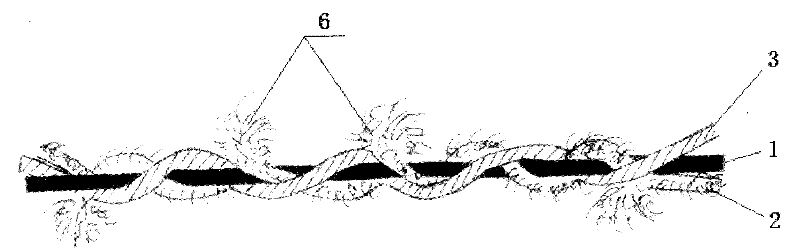

Elastic napping yarn and production method thereof

The invention discloses elastic napping yarn which comprises an inside thread, a napping thread and a coiling thread, wherein the napping thread is sequentially coiled on the inside thread in a preset twisting direction and is napped, wherein the napping thread forms a lint cluster on the inside thread at preset intervals. A production method of the elastic napping yarn comprises the following steps of: napping the snapping thread and the coiling thread, particularly cutting off the single ring of the napping thread and leading the napping thread to form the lint cluster of the napping thread, and realizing the napping of yarn. Compared with the traditional napping cloth, the cloth made of the elastic napping yarn has unique elasticity and warming retention; the problems that the traditional napping cloth has no elasticity and poor warming retention are solved; and meanwhile, a cloth cover has styles of the specific lint cluster and soft hand feeling.

Owner:NINGBO E & F TEXTLE

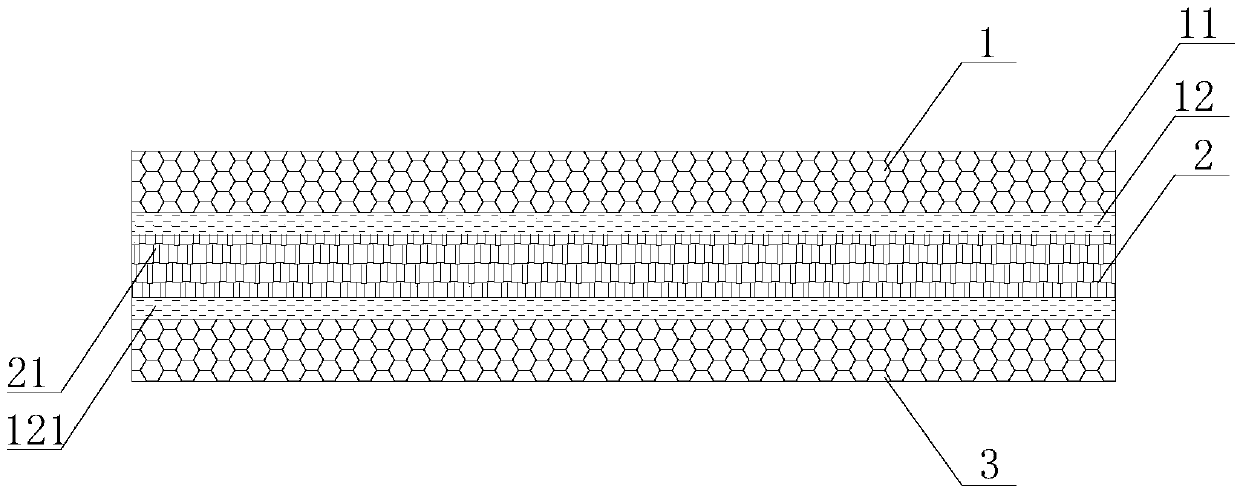

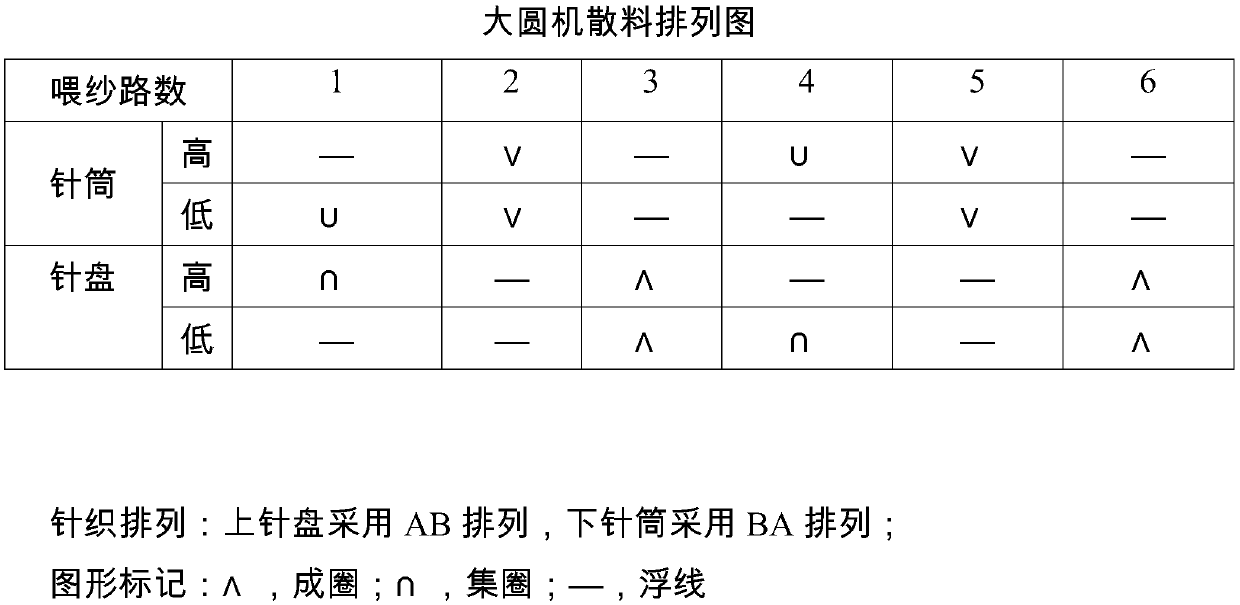

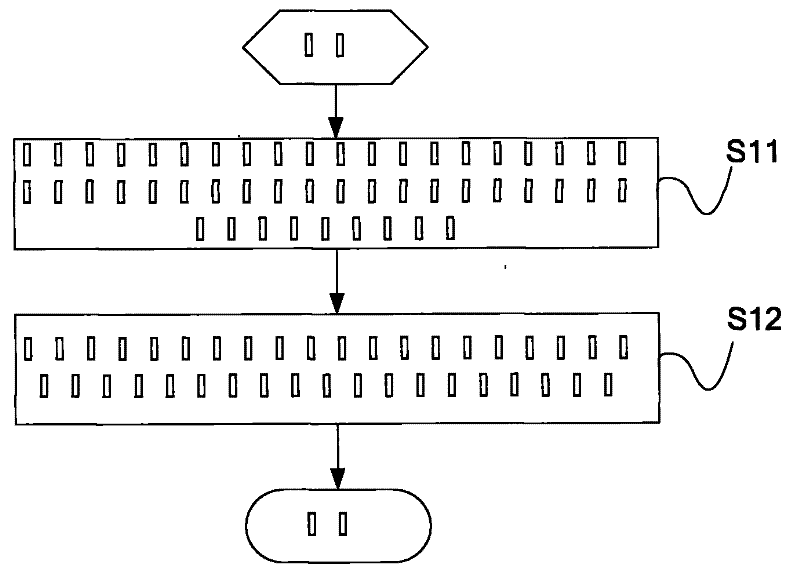

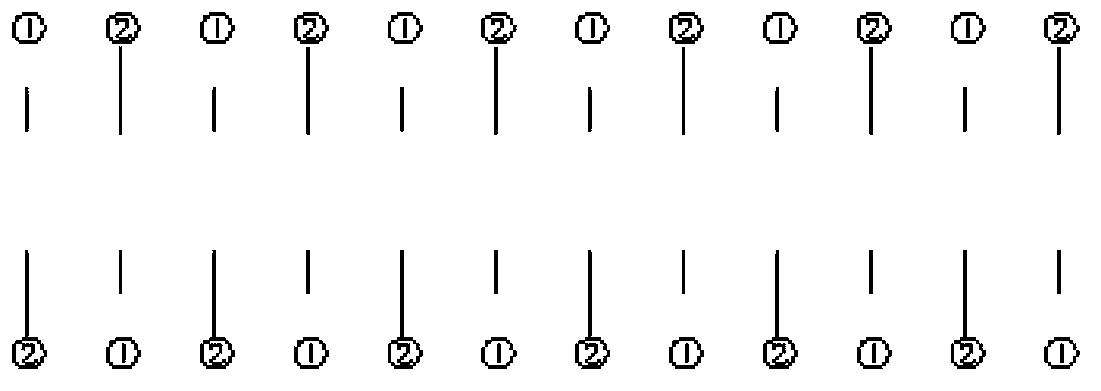

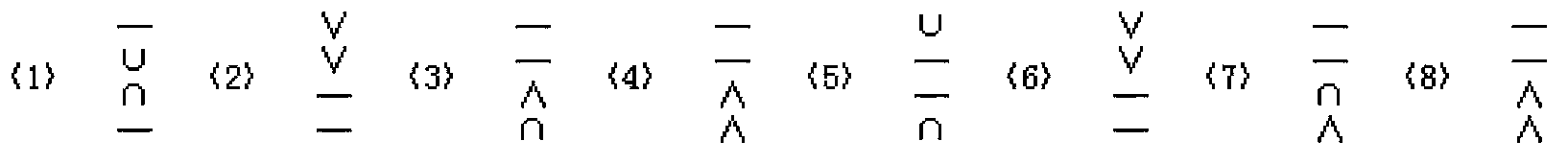

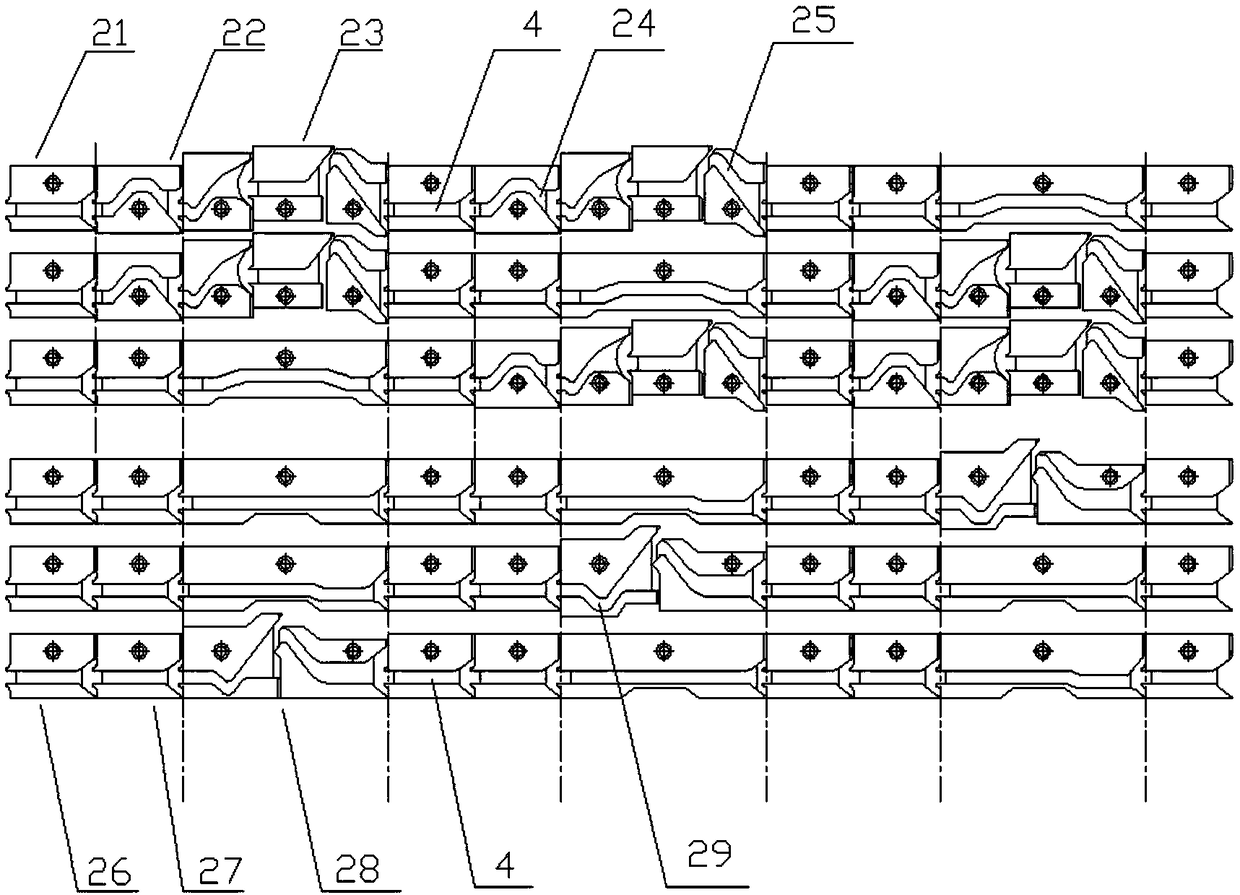

Moisture-absorbing and heating alkali-free mercerized fabric and processing method of same

The invention discloses a moisture-absorbing and heating alkali-free mercerized fabric and a processing method of the same. The fabric has cotton on the front and moisture-absorbing and heating Heatwarm fibers on the back, and a heat insulation air layer is arranged between the front and the back of the fabric. The processing method includes the steps as follows: every two knitting needles are arranged at the top and the bottom of a two-faced machine for knitting, and linters are arranged with needles opposite to each other; during the knitting, every eight paths form a circulation, 1st and 5th paths penetrate the Heatwarm to be connected in a way that two sides are engaged, the upper and lower high-channel stitches of the 1st path are double stitched in a way that two sides are engaged and the upper and lower low-channel stitches of the 5th path are double stitched in a way that two sides are engaged, so as to knit an intermediate connecting layer; 2nd and 6th paths penetrate cotton yarns to be connected in a way that one side is engaged, and upper stitches are all looped to be knitted out of an outer layer; 3rd, 4th, 7th, 8th paths penetrate the Heatwarm to be connected in a way that one side is engaged, the lower stitch low-channel stitches of the 3rd path are double stitched and the high-channel stitches are looped, the lower stitches of the 4th and 8th paths are all looped, the lower stitch low-channel stitches of the 7th path are looped and the high-channel stitches thereof are doubled stitched, so as to be knitted out of an inner layer. The fabric has soft and smooth handfeel and silky luster after the DGF treatment through the alkali-free mercerizing finishing agent, and has the effect of moisture absorption, heating, thermal insulation and air permeability.

Owner:SHANGHAI JIALE

Antibacterial woolen sweater

InactiveCN103284340AImprove featuresAntibacterial hasProtective garmentSpecial outerwear garmentsYarnFiber

Owner:太仓市隆丝达针织时装有限责任公司

Device and method for extracting sticky down by deeply processing down

ActiveCN102242420BTo achieve the purpose of sterilization and deodorizationEliminate odorHeating/cooling textile fabricsFibre separationYarnWater vapor

The invention discloses a device and a method for extracting sticky down by deeply processing down. The device for extracting the sticky down by deeply processing the down comprises a feather yarn separation box (1), a neck feather yarn separation box (2) and a down flying yarn separation sieve (3) which are connected in turn. The method comprises the following steps of: 1) disinfecting, sterilizing and deodorizing feathers by using a high temperature of 120 DEG C generated by water vapor and pressurizing to make the feathers separated to form the down; 2) putting the down into the feather yarn separation box through a feeding hole for processing to separate feather yarns; 3) putting the down in a sieve barrel into the neck feather yarn separation box through a discharging opening for processing to separate neck feather yarns; and 4) putting the down in an inner box body into the down flying yarn separation sieve for processing to separate down flying yarns. By the device and the method, the feather yarns, the neck feather yarns and the down flying yarns can be efficiently separated to extract the sticky down with the down content of 97 percent.

Owner:广东鸿凌羽绒有限公司

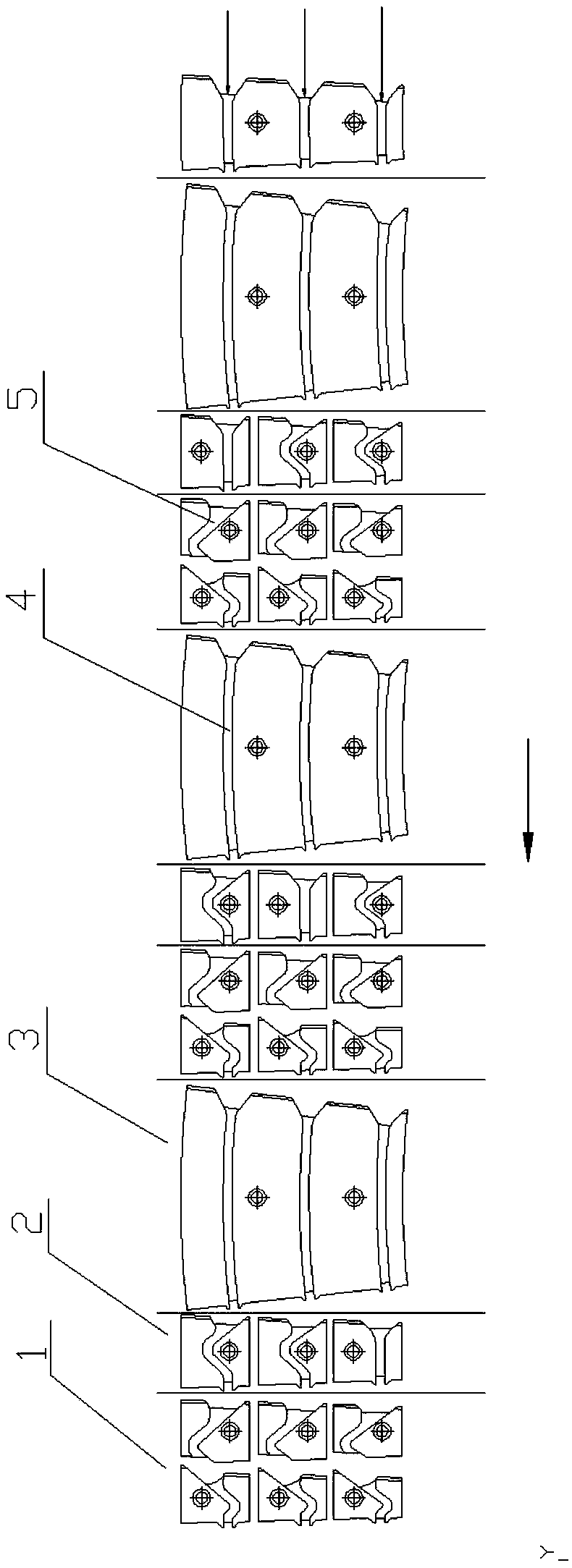

Anti-package loop pile cutting circular machine for double-face knitting

The invention relates to an anti-package loop pile cutting circular machine for double-face knitting. The anti-package loop pile cutting circular machine comprises an upper needle disc and a lower needle cylinder, needle grooves are formed in the upper needle disc, and knitting needles are mounted in the needle grooves; bush hook grooves are formed in the lower needle cylinder, and bush hook assemblies are mounted in the bush hook grooves; needle cams which control the movement rails of the knitting needles are arranged on the upper portion of the upper needle disc and form an annular cam combination in the circumferential direction of the upper needle disc, and cutter cams and hook cams which control the movement rails of the bush hook assemblies are arranged outside the lower needle cylinder and form a cylindrical cam combination around the outer cylinder wall of the lower needle cylinder; sinker grooves are further formed in the upper needle disc, sinkers for pushing away cut fluffare mounted in the sinker grooves, and sinker cams which control the movement rails of the sinkers are arranged on the upper portion of the upper needle disc. The anti-package loop pile cutting circular machine has a double-face knitting technology through special array modes of the cams, and can knit special knitted fabric with increased wool surface density, thick and solid double-surface backing fabric and high heat preservation.

Owner:LIANYUNGANG YUANFENG MACHINERY

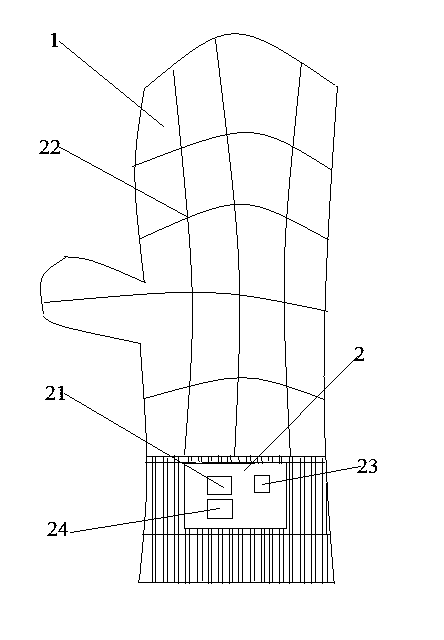

Chargeable warm-keeping glove

InactiveCN103653425ASimple structureReasonable designProtective garmentBamboo charcoalElectrical and Electronics engineering

The invention discloses a chargeable warm-keeping glove which comprises a glove body and a heating body. The glove body is of a double-layer structure including an outer layer and an inner layer, the outer layer is made of waterproof and windproof materials, and the inner layer is made of bamboo charcoal fiber shell fabrics. The heating body comprises a charging plug, a heating sheet, a switch and a storage battery. The heating sheet is arranged between the outer layer and the inner layer of the glove body. The charging plug, the switch and the storage battery are arranged at the wrist of the glove body, and are electrically connected. By means of the method, the chargeable warm-keeping glove is simple in structure, convenient to use, practical, safe, reliable and capable of producing heat while keeping warm, and people can feel more comfortable and warmer when wearing the glove.

Owner:SUZHOU HEMAS DRESS

Kendir farinfrared health-care material

A health-care far-infrared kender fabric is prepared from kender yarn (50-75%), polypropylene fibre as functional fibre (20-40%) and polyurethane fibre (5-10%) through interweaving. Its advantages are more health-care functions, good softness, no deformation, no generation of static electricity, and high elasticity, thermal insulation and moisture permeability.

Owner:天津市天益华泰科技发展有限公司

Antibacterial warm-keeping cotton fiber with seaweed carbon fibers added and preparation method of cotton fiber

InactiveCN104357949AInsufficient improvementSimple processConjugated cellulose/protein artificial filamentsSpinning solutions preparationCarbon fibersAdditive ingredient

The invention discloses an antibacterial warm-keeping cotton fiber with seaweed carbon fibers added. The cotton fiber is characterized by being prepared from raw materials in parts by weight as follows: 20-30 parts of cotton fibers, 12-14 parts of coconut cotton fibers, 10-13 parts of bamboo fibers, 12-14 parts of the seaweed carbon fibers, 9-11 parts of wool fibers, 2-4 parts of xanthan gum, 4-6 parts of a hydroxyl silicone oil emulsion, 8-10 parts of potato straw, 1.2-2.4 parts of zirconium phosphate, 0.4-0.8 parts of sodium sulfite, 22-25 parts of ethylene glycol butyl ether, 15-18 parts of tetraethyl orthosilicate, 2-3 parts of Chinese angelica, 1-3 parts of poria cocos, 3-5 parts of Chinese magnoliavine fruits, 110-120 parts of 1-butyl-3-ethylimidazolium dibutyl phosphate, 105-100 parts of 1-butyl-3-methylimidazolium acetate, 4-6 parts of an additive and a proper amount of water. The cotton fiber is simple in process and convenient to operate, the seaweed carbon fibers are added, and far infrared rays beneficial to human bodies can be released; meanwhile, other animal and plant fibers and Chinese herbal medicine ingredients are also added, so that defects of natural cotton fibers are overcome, and the cotton fiber has the advantages of bacterium resistance, mildew prevention, high toughness, high strength, high warm-keeping property and the like.

Owner:安徽颍元农业科技股份有限公司

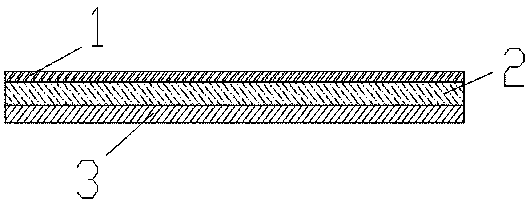

Multifunctional wind-preventing and warmth-keeping fabric

InactiveCN103445366AImprove wind resistanceStrong warmth retentionSynthetic resin layered productsProtective garmentPolyvinyl chlorideMaterials science

The invention discloses multifunctional wind-preventing and warmth-keeping fabric which comprises a surface protecting layer and an inner soft warmth-keeping layer. The surface protecting layer is covered on the upper surface of the inner soft warmth-keeping layer and comprises a nonwoven base layer and a PU (poly urethane) coating on the surface of the nonwoven base layer, the nonwoven base layer is formed by blending polyester fibers with polyamide fibers according to a certain proportion, and the inner soft warmth-keeping layer is formed by blending polyvinyl chloride fibers with cotton fibers according to a certain proportion. By the above mode, the multifunctional wind-preventing and warmth-keeping fabric is good in wind-preventing performance, high in warmth-keeping capability and soft in texture, and clothes made by the multifunctional wind-preventing and warmth-keeping fabric are relatively light and suitable for being worn in windy or cold days.

Owner:吴江市锦邦纺织品有限公司

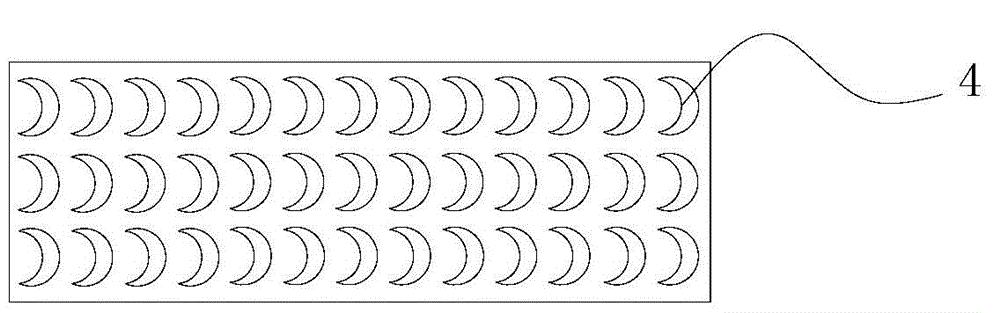

Soft cotton non-woven fabric and preparation method thereof

ActiveCN104963093ABetter air permeabilityImprove bulkNon-woven fabricsWoven fabricPuncture resistance

The invention discloses soft cotton non-woven fabric and a preparation method thereof. The soft cotton non-woven fabric sequentially comprises a first hot-air non-woven fabric layer, an elastic non-woven fabric layer and a second hot-air non-woven fabric layer; the first hot-air non-woven fabric layer and / or the second hot-air non-woven fabric layer are / is provided with multiple rows of crescent embossments sunk in the thickness direction, the elastic non-woven fabric layer is composed of chopped fibers where a Vistamaxx special elastic body and modified polypropylene fibers are added, and the chopped fibers are arranged to be of a multilayer structure in the transverse direction and in the longitudinal direction alternately; according to the crescent embossments of the soft cotton non-woven fabric, the non-woven fabric is not prone to deforming, the breathability is good, filling power is high, the hand feel is soft, meanwhile due to the fact that the Vistamaxx special elastic body is added into the elastic non-woven fabric layer, high elasticity, high transparency, high puncture resistance, tear resistance and terrific tactility can be achieved for the non-woven fabric, and due to the fact that the modified polypropylene fibers are added, the non-woven fabric is soft in hand feel. According to the soft cotton non-woven fabric, the elasticity is high, the filling power is high, the breathability is good, the hand feel is soft, and the non-woven fabric is not prone to deforming.

Owner:JIANGSU SHENGFANG NANO MATERIAL TECH CO LTD

Nanometer hydrophobic and oleophobic clothes fabric

The invention discloses nanometer hydrophobic and oleophobic clothes fabric. The nanometer hydrophobic and oleophobic clothes fabric comprises a fabric body formed by weaving warp yarn and weft yarn, the warp yarn is formed by weaving chitin fibers and shape memory fibers, and the weft yarn is formed by blending nanocomposites and acetate cellosilk. The nanometer hydrophobic and oleophobic clothes fabric has the advantages of being good in air permeability, resistant to washing, free of toxicity, safe to use and great in warm-keeping property.

Owner:TAICANG SHENGDANRONG CLOTHING CO LTD

Multifunctional down jacket

Owner:JIANGSU JINYANG LEATHER & DOWN PROD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com