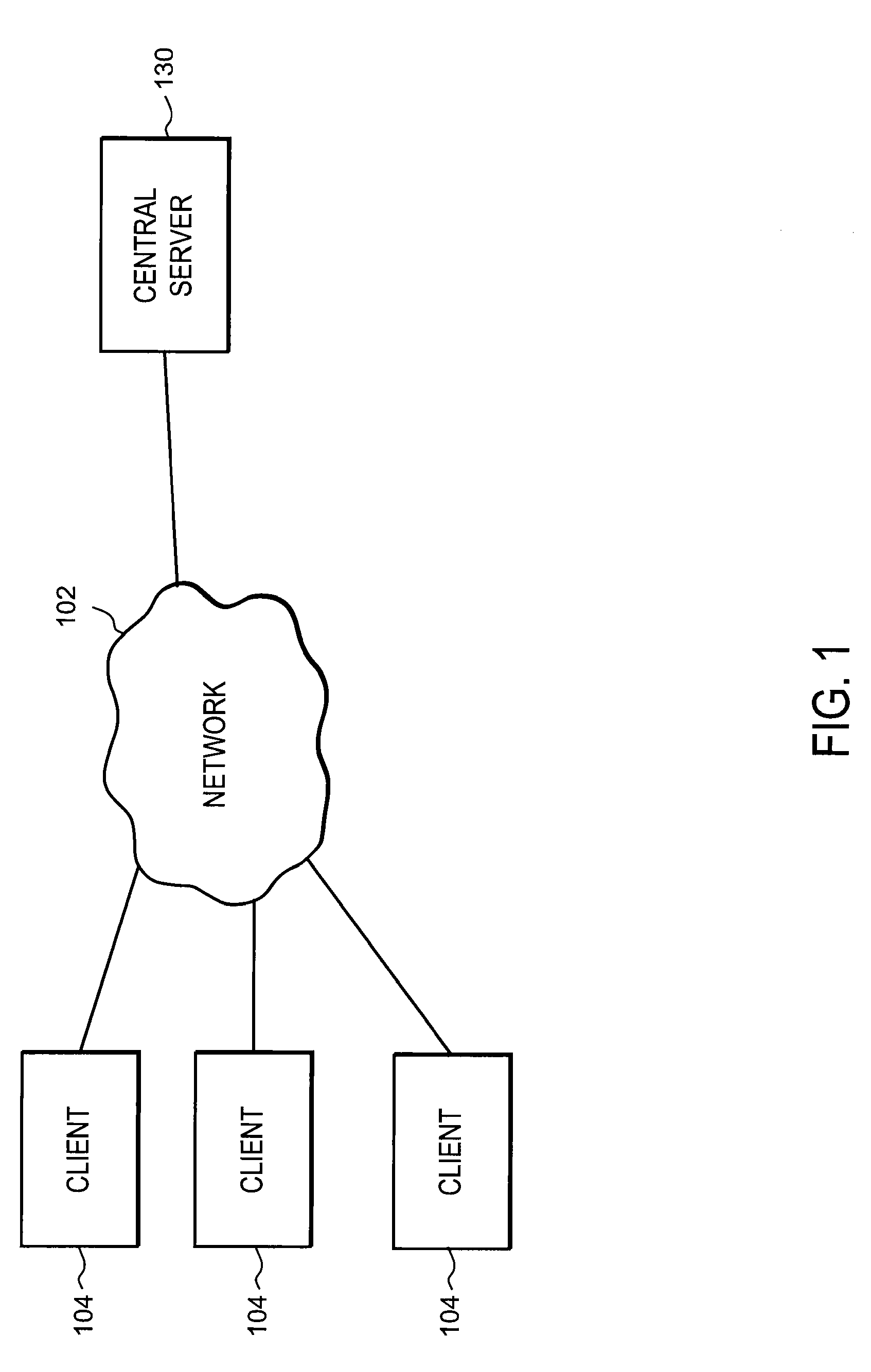

Patents

Literature

280results about "Fulling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

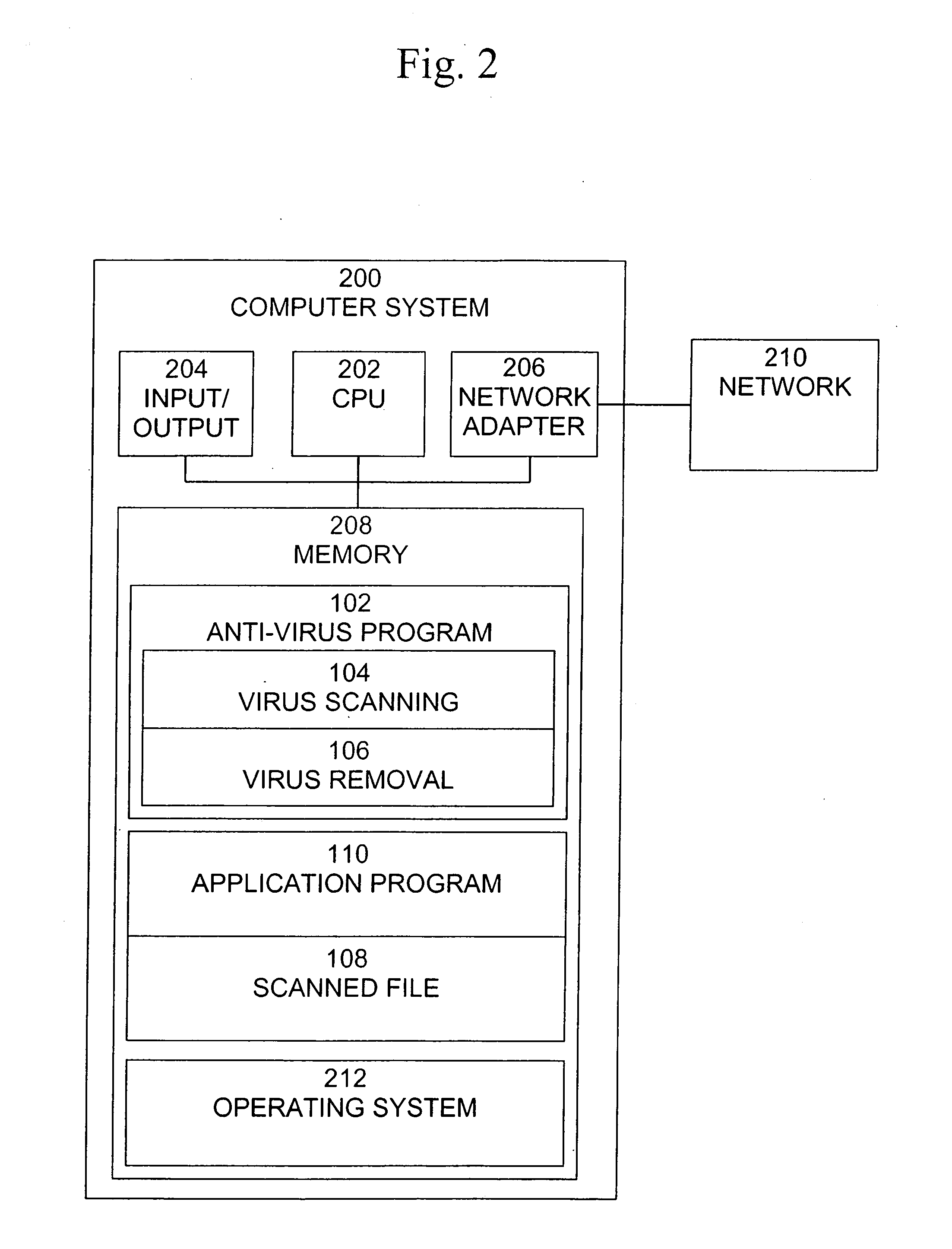

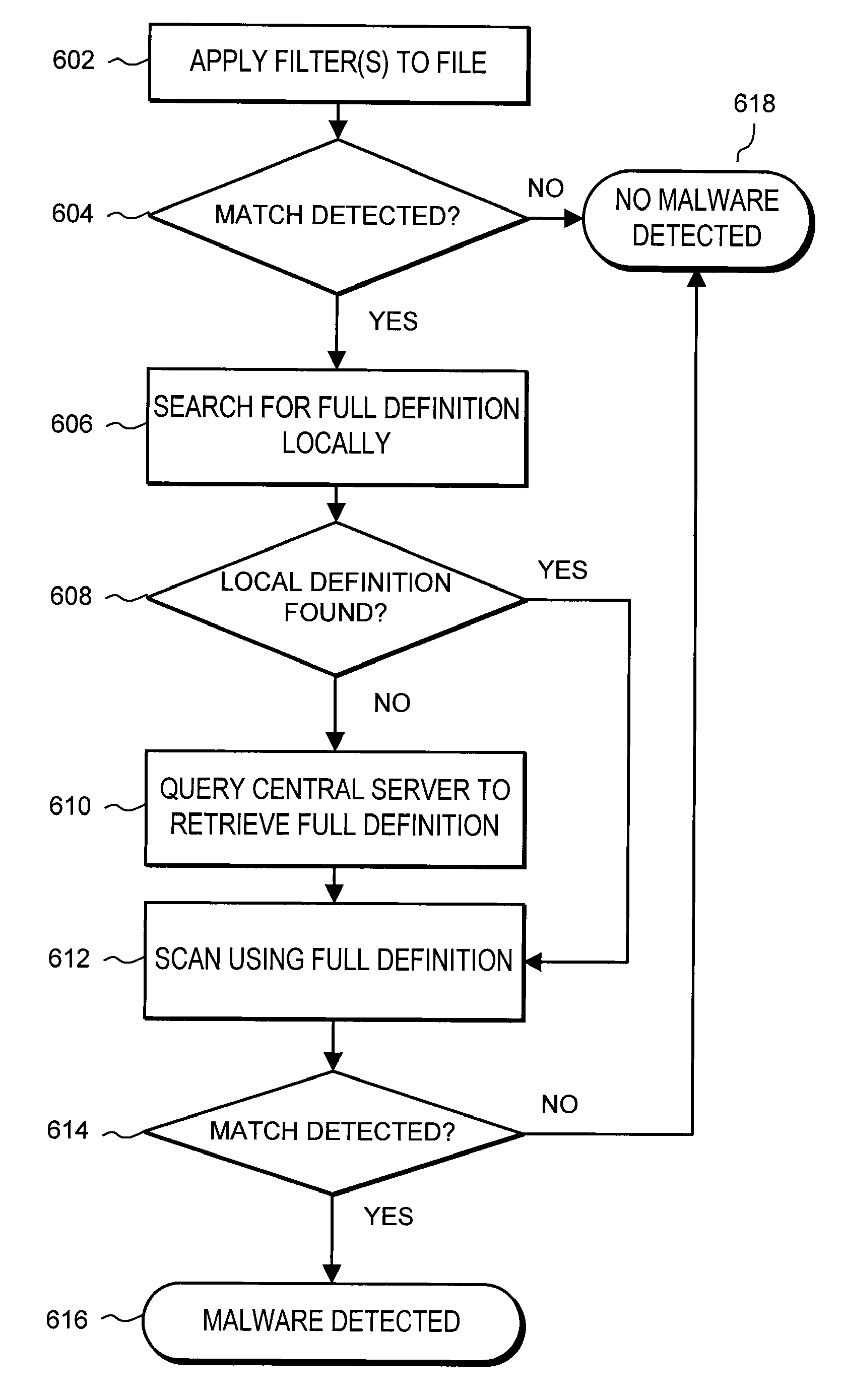

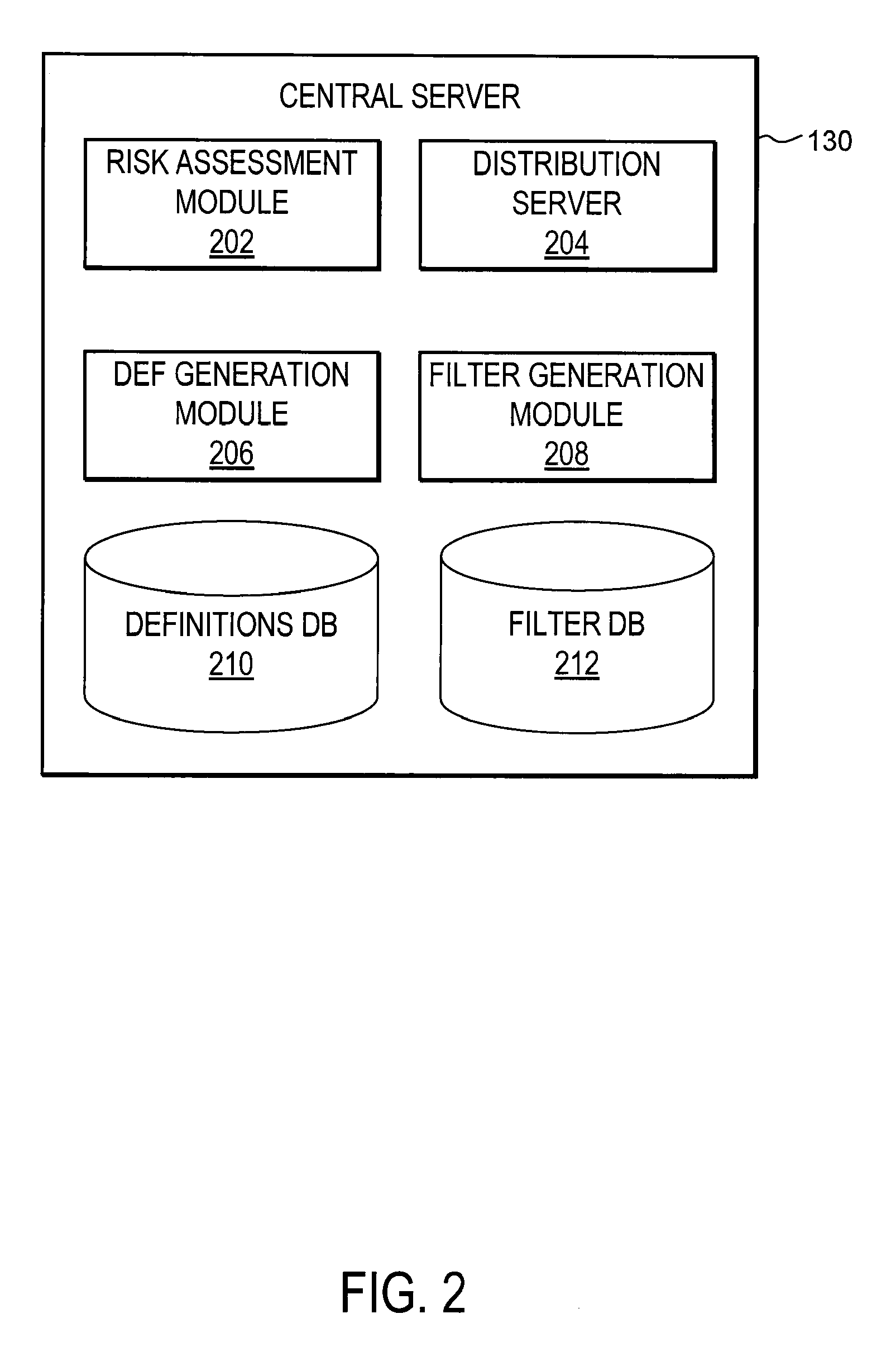

Centralized Scanner Database With Qptimal Definition Distribution Using Network Queries

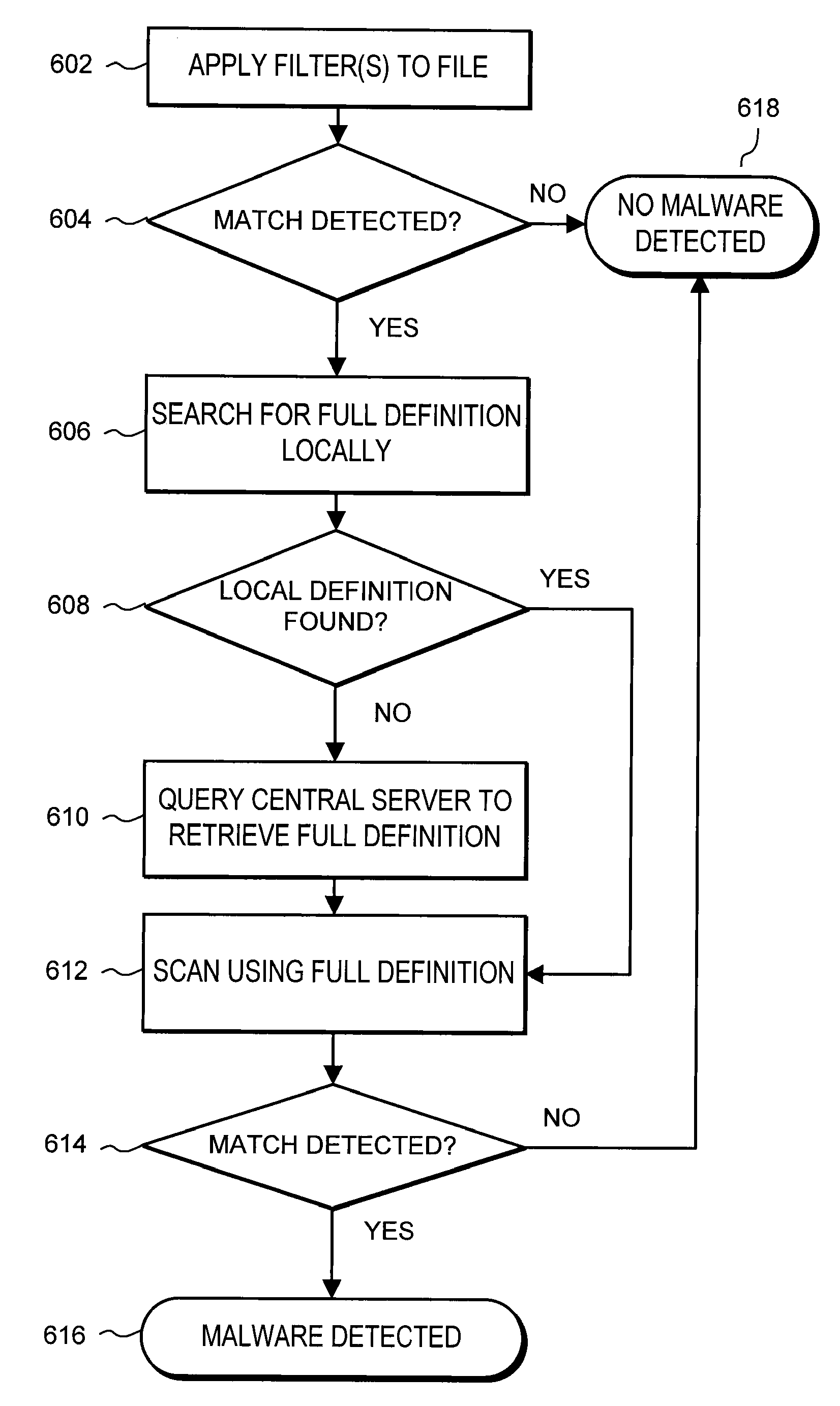

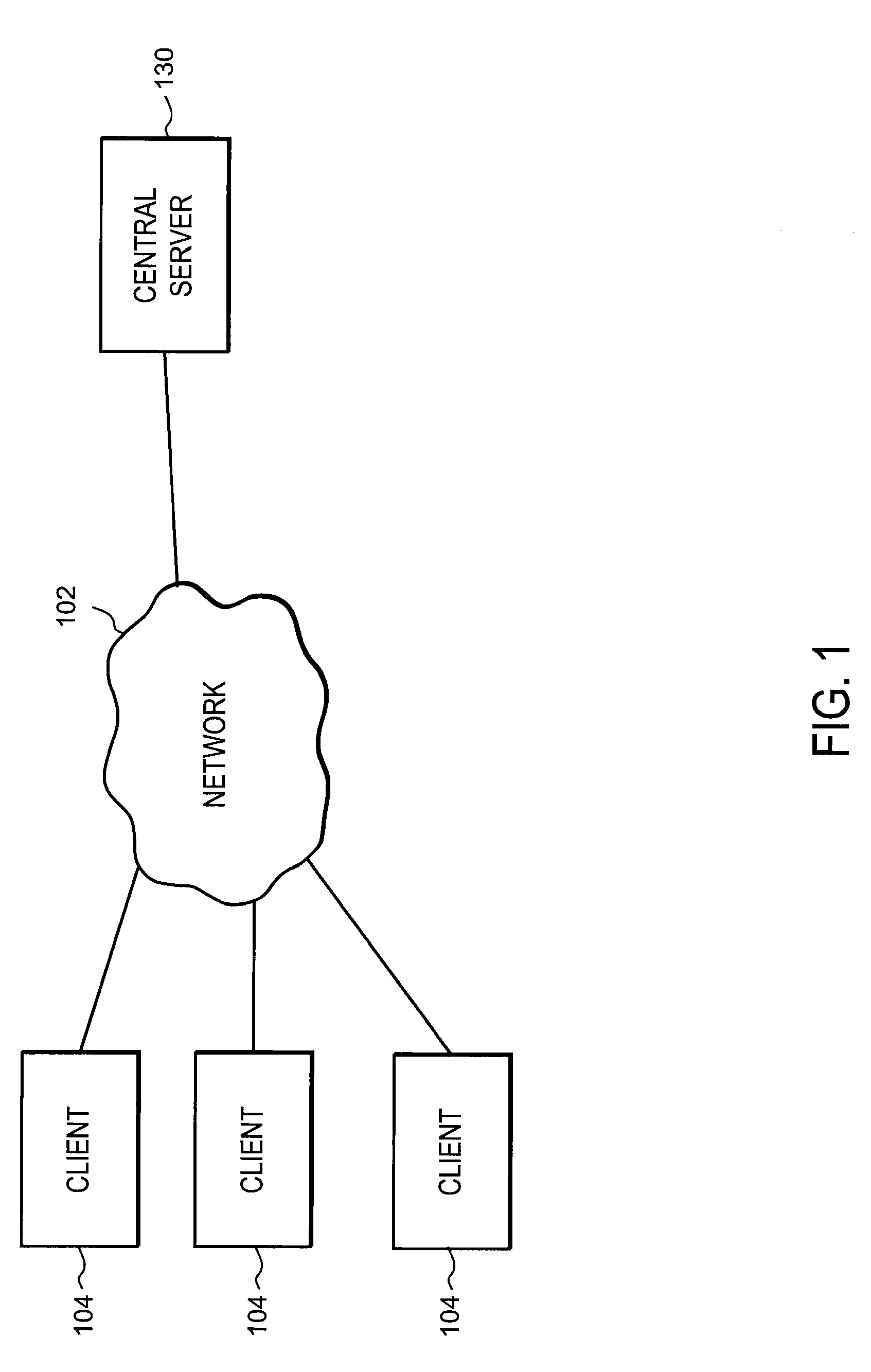

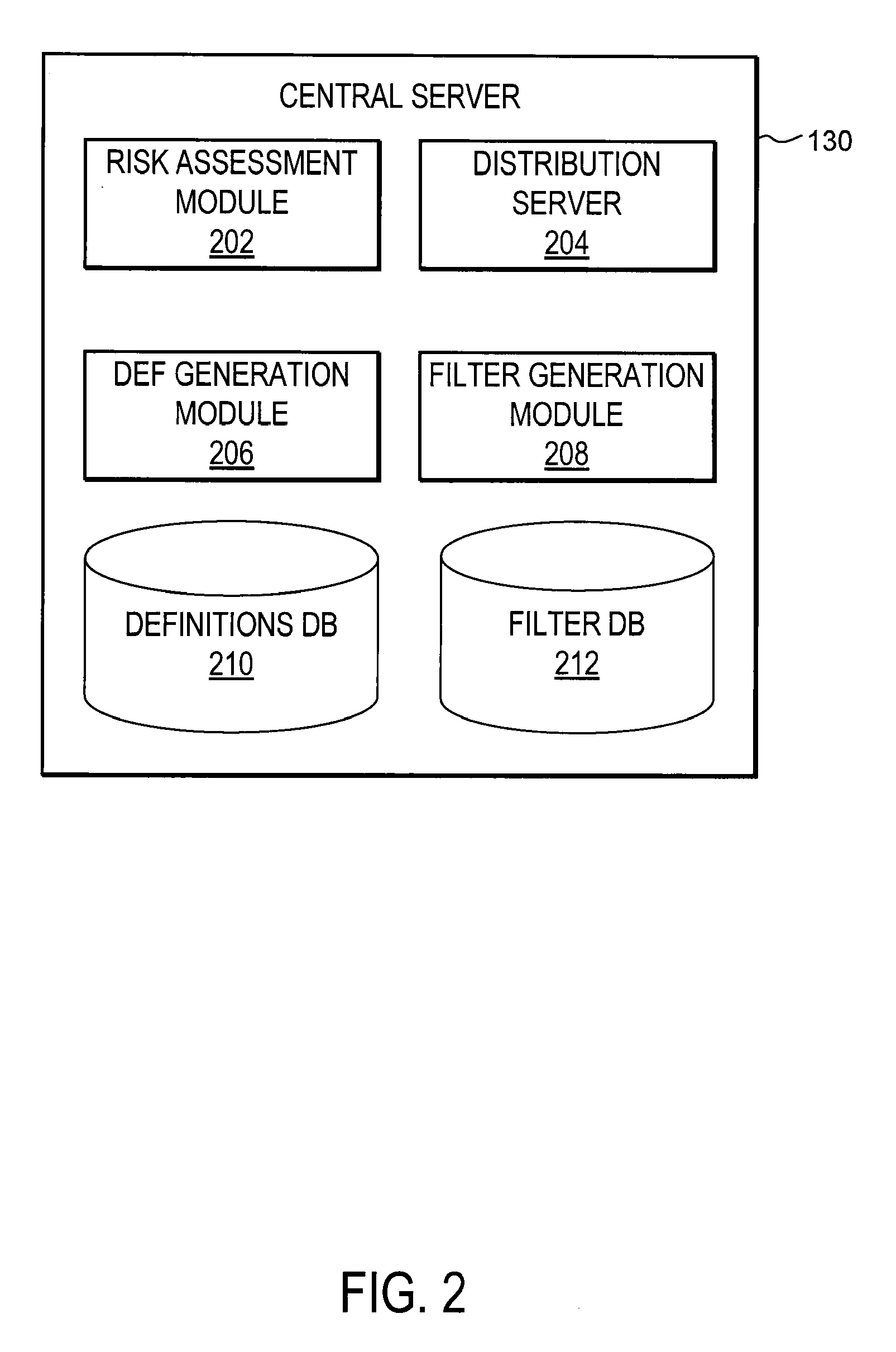

A system and method detects malware on client devices based on partially distributed malware definitions from a central server. A server stores malware definitions for known malware. The server generates one or more filters based on the malware definitions and distributes the filter(s) to client devices. The server also distributes full definitions to the clients for a subset of the most commonly detected malware. The client device scans files for malware by first applying the filter to a file. If the filter outputs a positive detection, the client scans the file using the full definition to determine if the file comprises malware. If the full definition is not stored locally by the client, the client queries the server for the definition and then continues the scanning process.

Owner:CA TECH INC

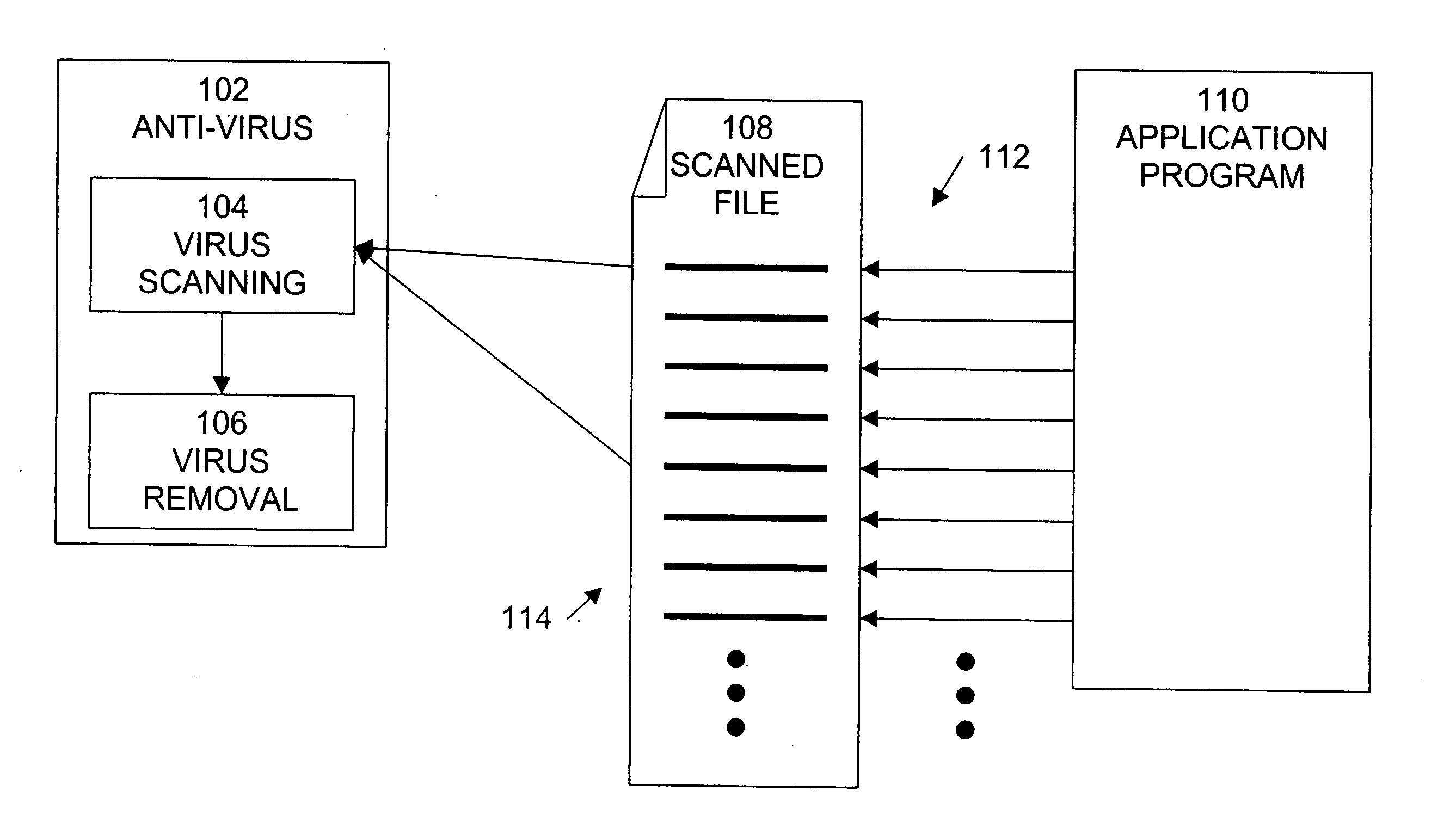

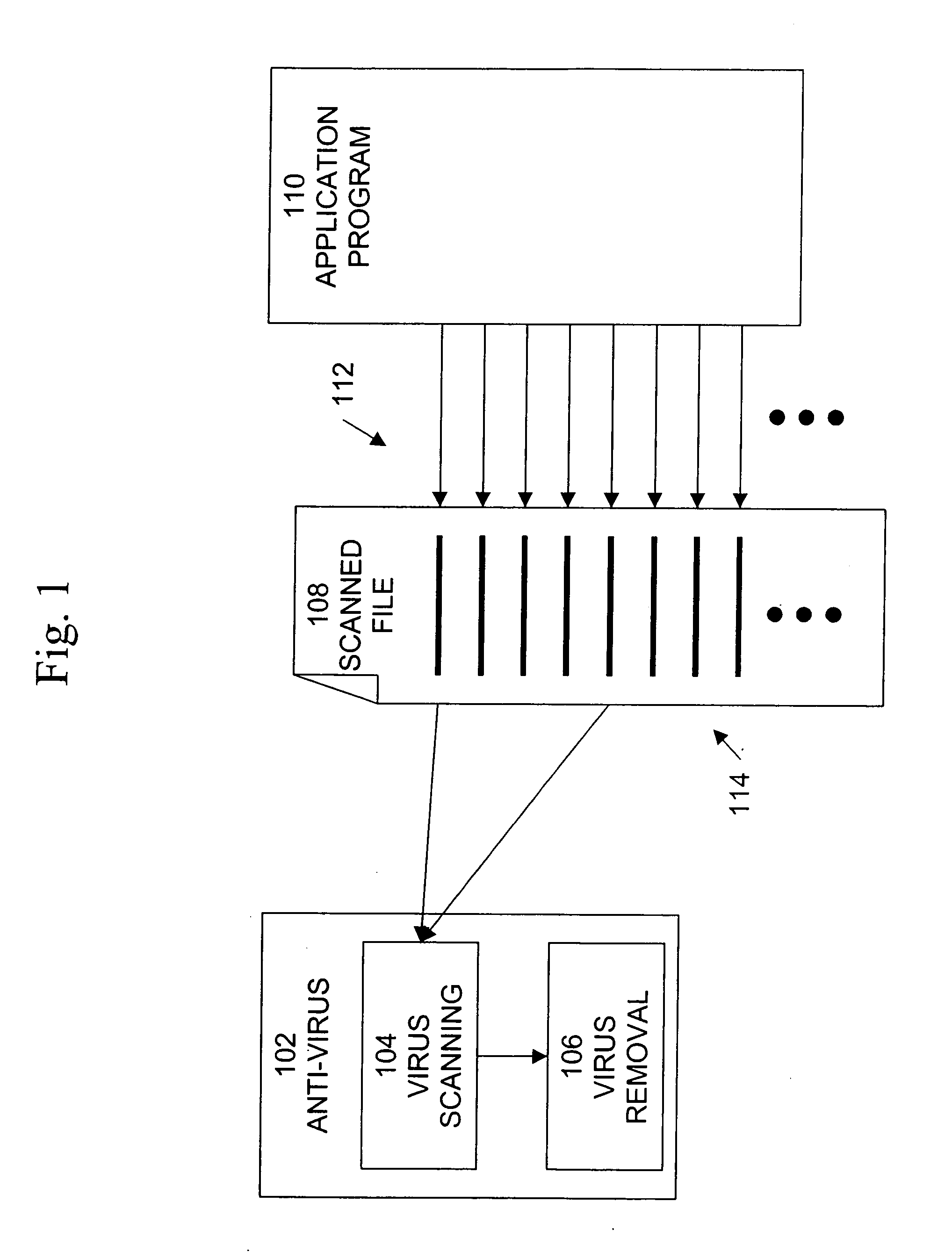

Method and system for delayed write scanning for detecting computer malwares

A method, system, and computer program product provides on-access anti-virus scanning of data files, which can be performed without introducing significant performance degradation and provides delayed file write operation scanning upon interception of a file write operation. A method of detecting a malware comprises the steps of intercepting a file access operation of the a process to a file, in response to the intercepting, waiting a time interval between the intercepting and scanning the file for a malware, and scanning the file for the malware, after waiting the time interval, wherein the process is associated with an application program and wherein the file access operation is a file write operation.

Owner:MCAFEE LLC

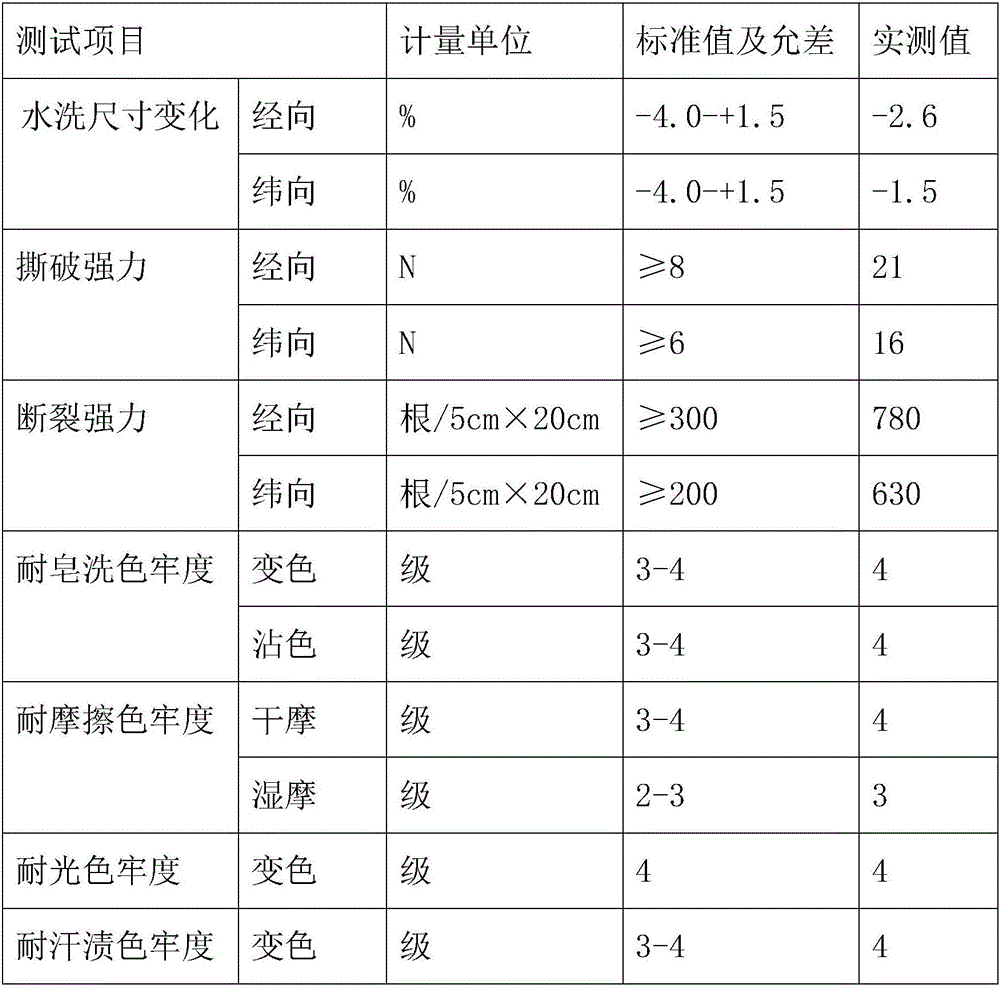

High-count pure-cotton formaldehyde-free bright adhesive interlining and production method thereof

ActiveCN104544647AImprove the quality levelReduce qualityGarmentsDyeing processColour fastnessInterlining

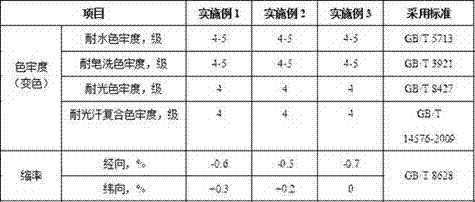

The invention discloses a high-count pure-cotton formaldehyde-free bright adhesive interlining and a production method thereof. The high-count pure-cotton formaldehyde-free bright adhesive interlining is characterized in that the surface of a coating is bright; the free formaldehyde and hydrolysis formaldehyde are less than 20mg / kg; the peeling strength of hot melt adhesive points is not less than 10N; the warp and weft water washing dimension change rate is -1.0 to 0.5%; the colorfastness to washing is not less than 4-5 levels. The adhesive interlining is free of formaldehyde, so that the processed clothes can be healthy and safe; the surface is bright, thus the quality and level are increased, and the defects such as missing point and missing coating can be easily found during appearance inspection, and as a result, the loss on degradation caused by that the defect of the adhesive interlining is not influenced before being manufactured into clothes products can be avoided for a clothes enterprise; adhesive interlining is high in peeling strength, small in wrap and weft shrinkage, and high in color fastness, so that the quality of high-level clothes cannot be decreased due to poor color fastness of the adhesive interlining; the production method is easily operated, and environmentally friendly.

Owner:NANTONG HAIHUI SCI & TECH DEV CO LTD +1

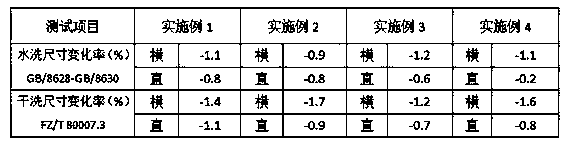

Water-soluble hot-melting adhesive interlining with very low shrinkage rate and production method thereof

ActiveCN103478937AEnvironmental protection is goodEasy to operateLiquid surface applicatorsGarmentsInterliningSolubility

The invention discloses a water-soluble hot-melting adhesive interlining with very low shrinkage rate and a production method thereof. Dimensional change rate in the warp and weft direction after washing is -0.6%-0.5%. After the hot-melting adhesive interlining is combined with fabric through pressing, time for separating the hot-melting adhesive interlining from the fabric in 35-DEG C water is less than 15 seconds. Free and hydrolyzing formaldehyde is equal to or less than 35 mg / kg. The production method sequentially includes seam inverting, singeing, desizing, scouring, bleaching, secondary bleaching or dyeing, post-processing, liquid ammonia finishing, shrink resistant finishing, mechanical pre-shrinking and powder dot coating. The shrinkage rate in the warp and weft direction is low, water-solubility is good, the free and hydrolyzing formaldehyde amount is the minimum, and the production method is easy to operate.

Owner:NANTONG HAIHUI SCI & TECH DEV CO LTD +1

High-quality wide bamboo fiber woven fabric and production method thereof

ActiveCN105177819ASimple production processEasy to operateSucessive textile treatmentsLiquid/gas/vapor removalFiberEngineering

The invention discloses high-quality wide bamboo fiber woven fabric and a production method thereof. The production method includes the steps of singeing, preprocessing, dyeing, shrink-resistant finishing, anti-pilling finishing, mechanical pre-shrinking, inspection and package. The dyeing technology is carried out on a large-capacity jig dyeing machine. The production technology is simple, operation is convenient, product performance is excellent, the warp and weft direction washing dimension change of the fabric ranges from -3% to 1.0%, the anti-pilling level is larger than or equal to the third to fourth level, and color fastness is larger than or equal to the fourth level.

Owner:NANTONG JINSHAIDA SPECIAL FAB CO LTD

Method for dyeing and finishing polyester and nylon composite filament corduroy

InactiveCN102605584ADamage intensityHigh strengthSolvent-treatmentFibre typesDisperse dyeNylon material

The invention discloses a method for dyeing and finishing polyester and nylon composite filament corduroy, which comprises the following processes: checking a gray fabric; sewing the gray fabric; pre-shrinking in full width; splitting; pre-shaping; dyeing; soft finishing shaping; and packaging an end product, wherein a full width water washing machine is used for performing the process of pre-shrinking in full width; the process of splitting is performed according to a thermal treatment method and an alkali treatment method; during the process of pre-shaping, the temperature is 195 DEG C-200 DEG C and an assembly line turning speed is 30m / min-35m / min; dye liquor in the process of dyeing is aqueous solution of disperse dye or mixed aqueous solution of disperse dye and acidic dye; and the process of the soft finishing shaping is as follows: the corduroy passes through a material chute containing 10-15g / l softening agent aqueous solution, and then the corduroy is dried and shaped at high temperature, wherein the drying temperature is 165 DEG C-175 DEG C, the assembly line turning speed is 30m / min-35m / min and the softening agent is an organic silicon softening agent. The end product prepared according to the method provided by the invention has the advantages of high strength, full and mild velvet feeling, excellent shape-keeping property, convenience in washing and finishing, uniform dyeing effect, and capability of obtaining specific gigging effects such as frostwork or polyester peach skin, and the like.

Owner:杭州天宇印染有限公司

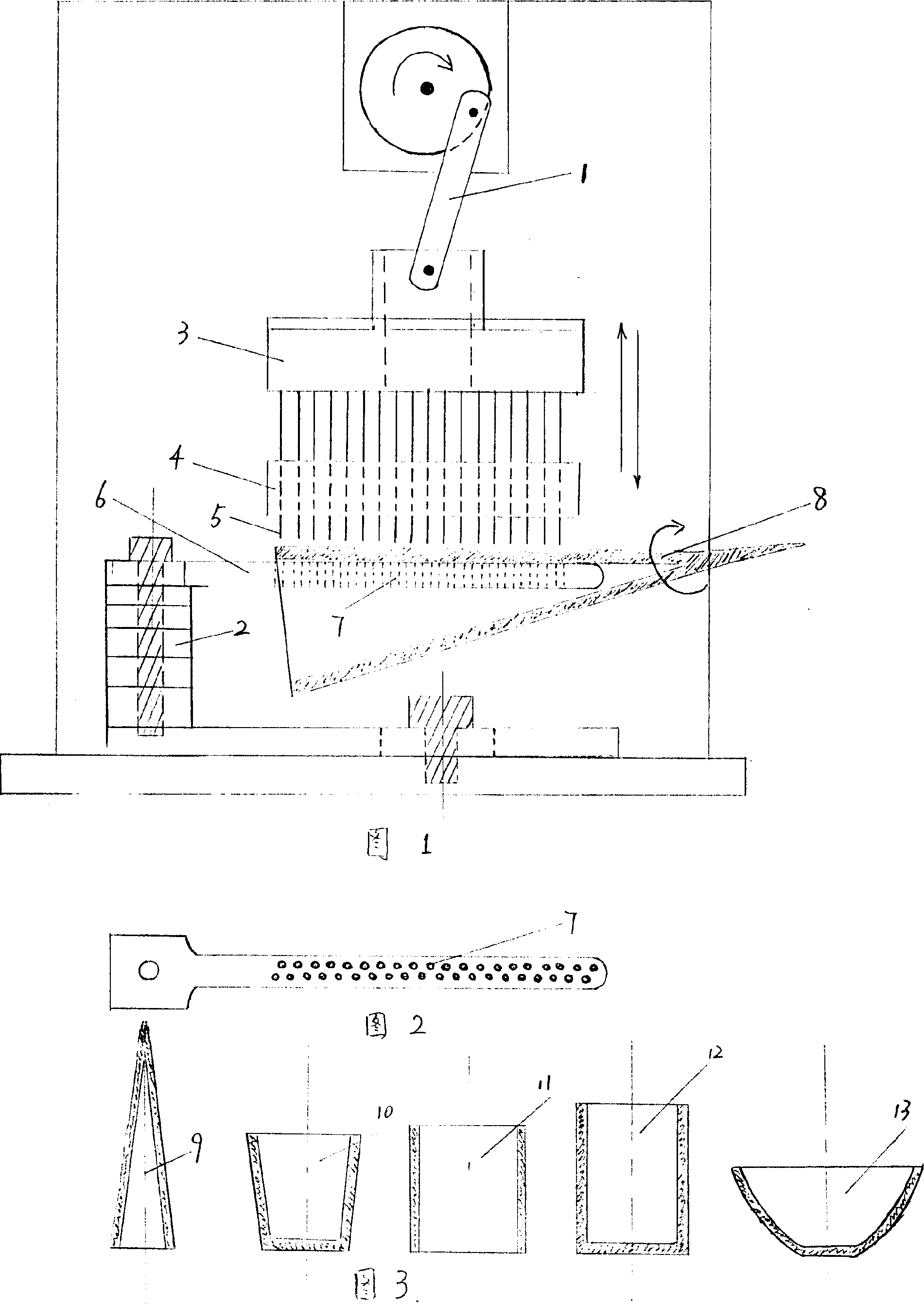

Production process of irregular cylindrical wool felt

InactiveCN101021032AHigh strengthGood surface effectNeedling machinesFelting apparatusEngineeringAbnormal shaped

Owner:胡海波

Production method of methanal-free purified-cotton woven adhesive interlining

ActiveCN103462264AStrong damageSmall dimensional change rate after washingGarmentsDyeing processCross-linkInterlining

The invention discloses a production method of a methanal-free purified-cotton woven adhesive interlining. The production method comprises the steps of pretreatment and mechanical shrunk finish; in the step of pretreatment, a cold pad-batch pretreatment production process is adopted, dyeing is performed by adopting a cold pad-batch dyeing production process with reactive dyes, glyoxal is taken as an anti-wrinkling finishing agent, a low-temperature tide-state cross-linked production process is adopted, hot melt powder with high bonding strength is adopted for powder point coating, and the number of coatings is controlled, so that after a combined sample is baked, the stripping strength is not less than 15N; in the step of mechanical shrunk finish for fabric subjected to powder point coating, the preshrunk quantity is controlled so as to ensure that after finishing, dimensional changes after laundering, in warp and weft directions, of the adhesive interlining are not less than -0.8 percent. According to the production method, a cold pad-batch process is adopted to perform the pretreatment, the dyeing and the shrink resistant finish, energy-saving and environment-friendly effects are realized, and the produced purified-cotton woven adhesive interlining does not release methanal, is barely damaged by strong force and is small in the dimensional changes after laundering.

Owner:NANTONG HAIHUI SCI & TECH DEV CO LTD +1

Centralized scanner database with optimal definition distribution using network queries

A system and method detects malware on client devices based on partially distributed malware definitions from a central server. A server stores malware definitions for known malware. The server generates one or more filters based on the malware definitions and distributes the filter(s) to client devices. The server also distributes full definitions to the clients for a subset of the most commonly detected malware. The client device scans files for malware by first applying the filter to a file. If the filter outputs a positive detection, the client scans the file using the full definition to determine if the file comprises malware. If the full definition is not stored locally by the client, the client queries the server for the definition and then continues the scanning process.

Owner:CA TECH INC

Dyeing and finishing method of CVC (chief value of cotton) dyster fabric

The invention discloses a dyeing and finishing method of a CVC (chief value of cotton) dyster fabric. The dyeing and finishing method comprises the following steps of S1, pretreatment; S2, dyeing; S3, post-finishing, wherein the pretreatment includes singeing, desizing, enzyme washing and mercerizing; the dyeing includes polyester dyeing, and cotton dyeing; the post-finishing includes tentering, pre-reduction, weft straightening, and shaping. The dyeing and finishing method of the CVC dyster fabric has the advantages that the method is simple, and the quality is stable; the hand feel of the fabric is soft, the dyeing cloth surface is full and uniform, the color is uniform, the texture is tight, and the elasticity is realized.

Owner:ANHUI YAYUAN PRINTING & DYEING CO LTD

Production process of four-side elastic fabric

ActiveCN107460602AAvoid easy swellingAvoid deformationFabric breaking/softeningHeating/cooling textile fabricsColour fastnessYarn

The invention relates to a production process of a four-side elastic fabric, and belongs to the field of textiles. The invention comprises the steps of weaving, pretreatment, mechanical softening finishing, grey fabric premolding, two bath method dyeing, low-temperature heat setting, and preshrinking, the front face of the four-side elastic fabric renders nylon yarn, and the opposite face renders high humidity modulus fiber yarn. According to the production process of the four-side elastic fabric, the technical problems existing in the fabric of the present technology are solved by means of coordination between reasonable fiber and tissue structures, adjustment of procedures and processes, and reasonable selection of dye materials, so that the obtained four-side elastic fabric not only is comfortable and wearable, but also has good color fastness and stable shrinkage rate.

Owner:LILANG CHINA

Method for thinning aggregate of water-absorbent material and thin aggregate of water-absorbent material obtained using the method

InactiveUS20120231946A1Easy to thinEasy to transformOther chemical processesFibre treatmentFiberPolymer science

A method for thinning an aggregate of water-absorbent materials. An aggregate of water-absorbent materials includes hydrophilic fibers and superabsorbent polymer particles and has a thickness direction. Steam at a temperature corresponding to water's boiling point or higher is ejected to the aggregate while the aggregate is compressed in the thickness direction.

Owner:UNI CHARM CORP

Milling process of cashmere sweater product

The invention discloses a milling process of a cashmere sweater product. The milling process comprises the following steps: preparing, immersing, milling, immersing, rinsing, dehydrating, drying over a fire, shaping by steam pressing and packaging. By simplifying the processing step, the milling time of the cashmere sweater is shortened, and the production efficiency is improved; meanwhile, the cashmere sweater product processed by the milling process disclosed by the invention is soft in hand feeling and attractive in appearance, so that the milling process is beneficial to improvement of the economic benefit; due to the adoption of an added quality inspecting step, a production process of the cashmere sweater product can be controlled effectively and the yield of the product is effectively improved.

Owner:TAICANG SHARTEX SHENTAI SWEATER

Multilayer thermal knitted fabric and method for processing same

InactiveCN107964808AElasticWith far infrared heatingWeft knittingHeating/cooling textile fabricsComposite functionMoisture absorption

The invention discloses a method for processing a multilayer thermal knitted fabric (Smart Thermal). The method includes processing steps of 'sandwich' multilayer weaving, automatic scutching and rolling, pre-shrinking, preliminary type approval, pretreatment, dyeing, hydrophilic soft finishing, dehydrating and drying and type approval. The method has the advantages that the multilayer thermal knitted fabric is a comprehensive thermal fabric as compared with an existing product with a single thermal function and comprises independent heating materials with moisture absorption heating and far infrared heating functions, large quantities of thermal elements are added into the multilayer thermal knitted fabric in the design, heat of garments can be locked in the multilayer thermal knitted fabric to be fed to human bodies, and accordingly the multilayer thermal knitted fabric is a comprehensive thermal product in the true sense; the multilayer thermal knitted fabric produced by the aid ofthe method is soft and comfortable, is high in elasticity, has diversified far infrared heating, natural antibacterial, moisture absorption heating and heat storage thermal composite functions, has amoderate thickness and is suitable for diversified thermal garment styles.

Owner:SHENGZHOU SHENGTAI KNITTING

High-count, high-mesh and pure-cotton weaving adhesive interlining and production method thereof

ActiveCN104544648ASolve the problem of weft shift and weft skewSolve the problem of easy seepageFibre treatmentGarmentsInterliningEngineering

The invention discloses a high-count, high-mesh and pure-cotton weaving adhesive interlining and production method thereof. The interlining comprises 80s warp and weft yarn counts; when in powder point coating, a 38-mesh engraving roller is utilized for processing the coating; the warp and weft water washing dimension change rate is -0.5 to 0.5%; the free formaldehyde and hydrolysis formaldehyde are not greater than 30mg / kg; the peeling strength of the adhesive interlining is not less than 8N. The production method comprises steps of inverting suturing a gray fabric; singeing; performing cold pad-batch pretreating; performing cold pad-batch dyeing; arranging with resin, performing powder point coating; mechanically pre-retracting; inspecting the quality and packing into boxes. The high-count, high-mesh and pure-cotton weaving adhesive interlining is high in hand feeling, small in free formaldehyde and hydrolysis formaldehyde, small in water washing dimension change rate, and suitable for silk and other high-level thin suit-dresses.

Owner:NANTONG HAIHUI SCI & TECH DEV CO LTD +1

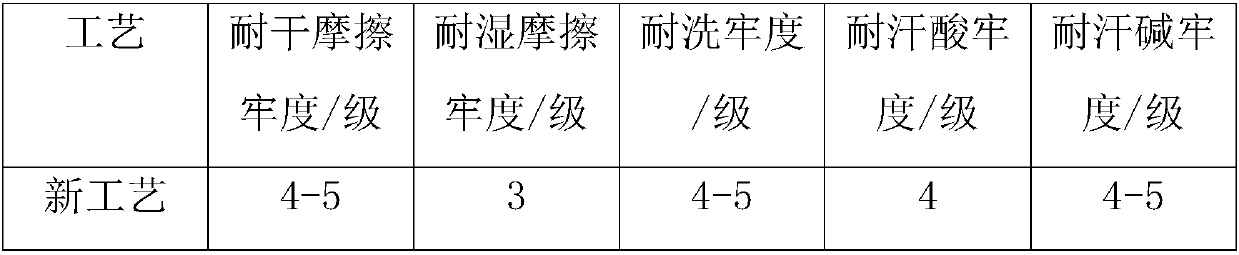

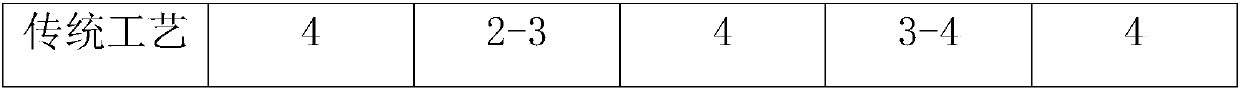

Process method for improving woven dark cloth wet rubbing fastness

ActiveCN107916518AImprove wet rubbing fastnessTightly bondedTextile storage in superimposed formLiquid/gas/vapor open-width material treatmentSurface finishProduct inspection

The invention discloses a process method, and particularly relates to a process method for improving woven dark cloth wet rubbing fastness. The process method includes the steps: (1) cloth distribution; singeing, cooling reaction and desizing; scouring and bleaching; mercerizing; pad dyeing or jig dyeing; wet rubbing fastness improver and auxiliary selection and preparation; wet rubbing fastness improver finishing; over-soft sizing; pre-shrinking; finished product inspection. According to the process method for improving the woven dark cloth wet rubbing fastness, production processes of all procedures are controlled, the capillary effect of a fabric is effectively improved, the surface finish degree of the fabric is improved, friction resistance is reduced, surface dyeing is decreased by strengthening soaping and washing after dyeing, wet rubbing fastness improvers of waterborne polyurethane complexes (Jiangxi Luxi County Xianghua Fine Chemical Co., Ltd., similarly hereinafter) are added after dyeing, under the assistant effects of assistant stabilizers 203 and cracking agents 109, the process method effectively solves the problem that oil floating points are generated in continuous production for 2000 meters or more when single wet rubbing fastness improvers are added in the past, the wet rubbing fastness of dark dyed cloth is improved by one level or more, corresponding washing fastness is improved, pH (potential of hydrogen) values meet requirements, continuous production and product quality are ensured, and a cloth surface has a certain color-deepening effect and softening effect, so that customer satisfaction is achieved.

Owner:佛山市顺德金纺集团有限公司

Wool/cashmere/modal/mulberry silk/antimicrobial polypropylene blended yarn weaved fabric and manufacturing method

The invention relates to wool / cashmere / modal / mulberry silk / antimicrobial polypropylene blended yarn weaved fabric. The fabric comprises, by mass, 63% of wool fibers, 7% of cashmere fibers, 14% of modal fibers, 10% of mulberry silk fibers and 6% of antimicrobial polypropylene fibers. The fabric is formed by interweaving warps and wefts, wherein the warps are worsted yarns of the wool fibers and the mulberry silk fibers, and the wefts are semi-worsted yarns of the wool fibers, the modal fibers and the antimicrobial polypropylene fibers. The method includes the first step of top dyeing, the second step of spinning, the third step of weaving and the fourth step of dyeing and finishing. The spinning twist of the wefts is controlled to be 700-1100 twists per meter. The obtained fabric integrates fluffiness of wool, smoothness of cashmere, and gloss and smoothness of spun silk, is soft and smooth in hand touch and rich in elasticity, and is the first choice for making men and women high-grade clothes.

Owner:江苏华西村纺织服装有限公司

Full-tencel mini-jacquard fabric and manufacturing method thereof

InactiveCN104831557AStrong and goodImprove performance shortcomingsMercerisingDry-cleaning apparatus for textilesFiberEngineering

The present invention discloses a full-tencel mini-jacquard fabric and a manufacturing method thereof, wherein the warp yarn and the weft yarn of the fabric adopt tencel fibers. According to the present invention, the unique characteristics of bacterial inhibiting, fiber stiffness and good strength of the tencel fibers are utilized to replace the full-cotton fabric so as to ensure the characteristics of the mini-jacquard fabric while improve the performance disadvantages of the full-cotton fabric.

Owner:江苏英瑞世家实业有限公司

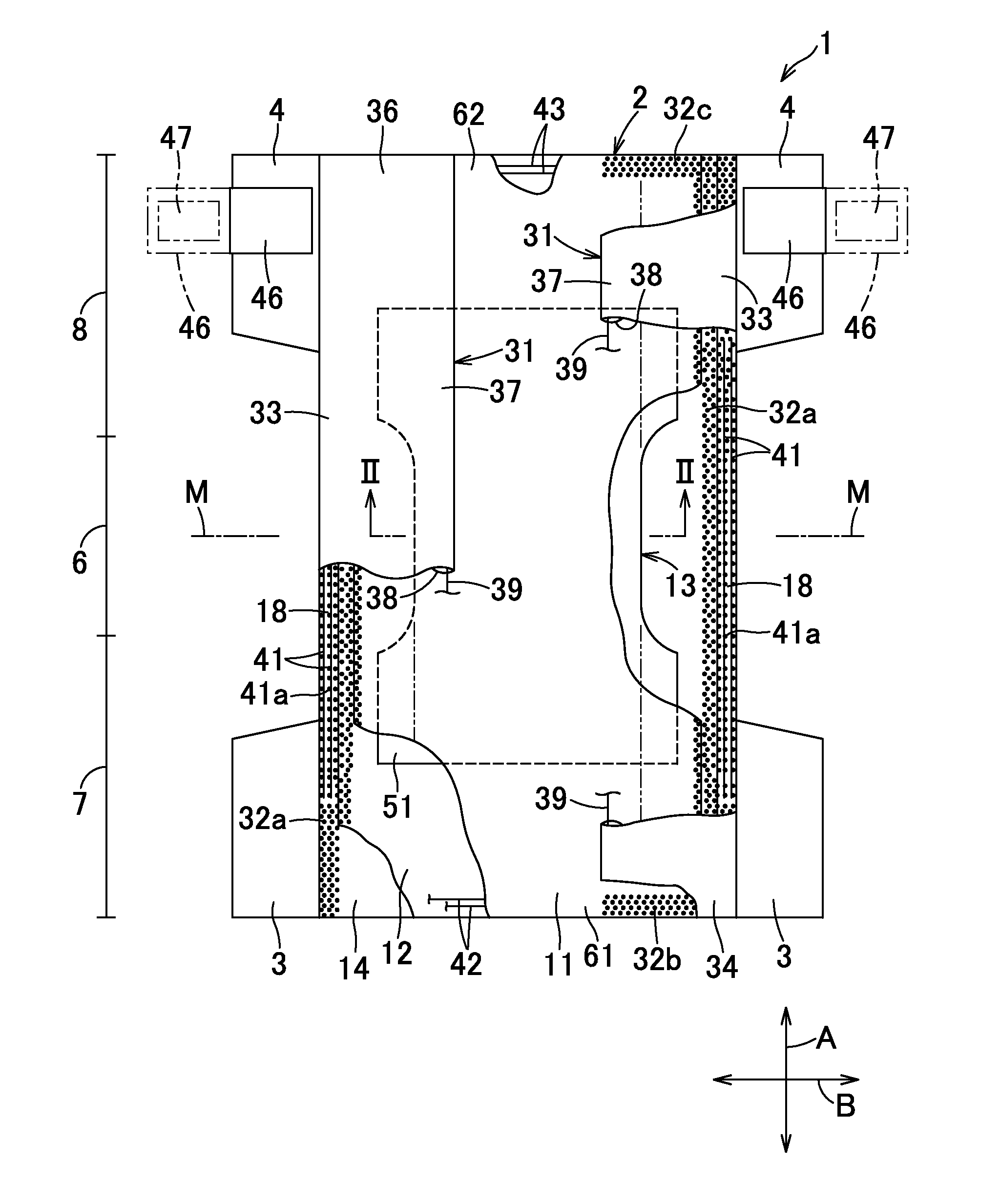

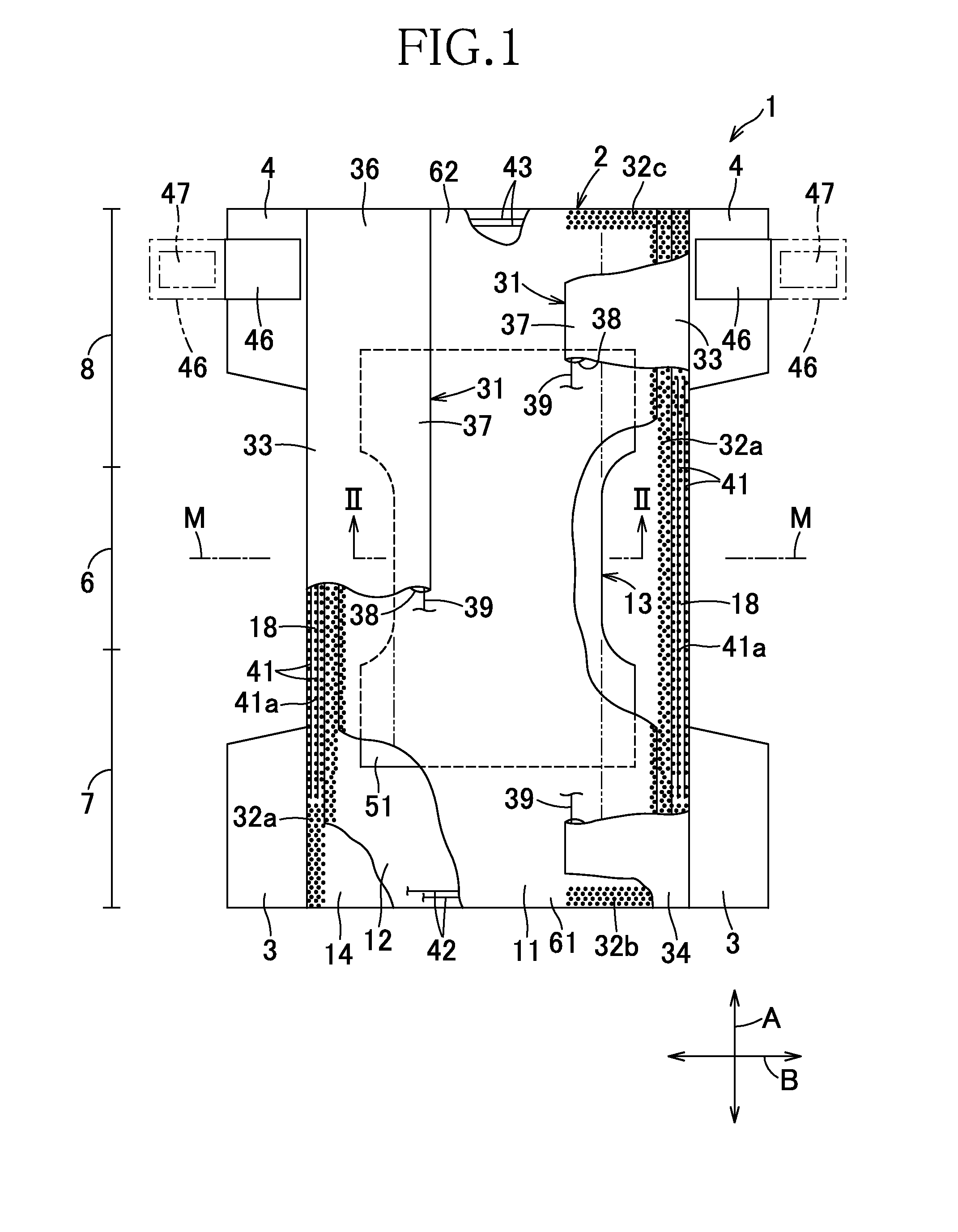

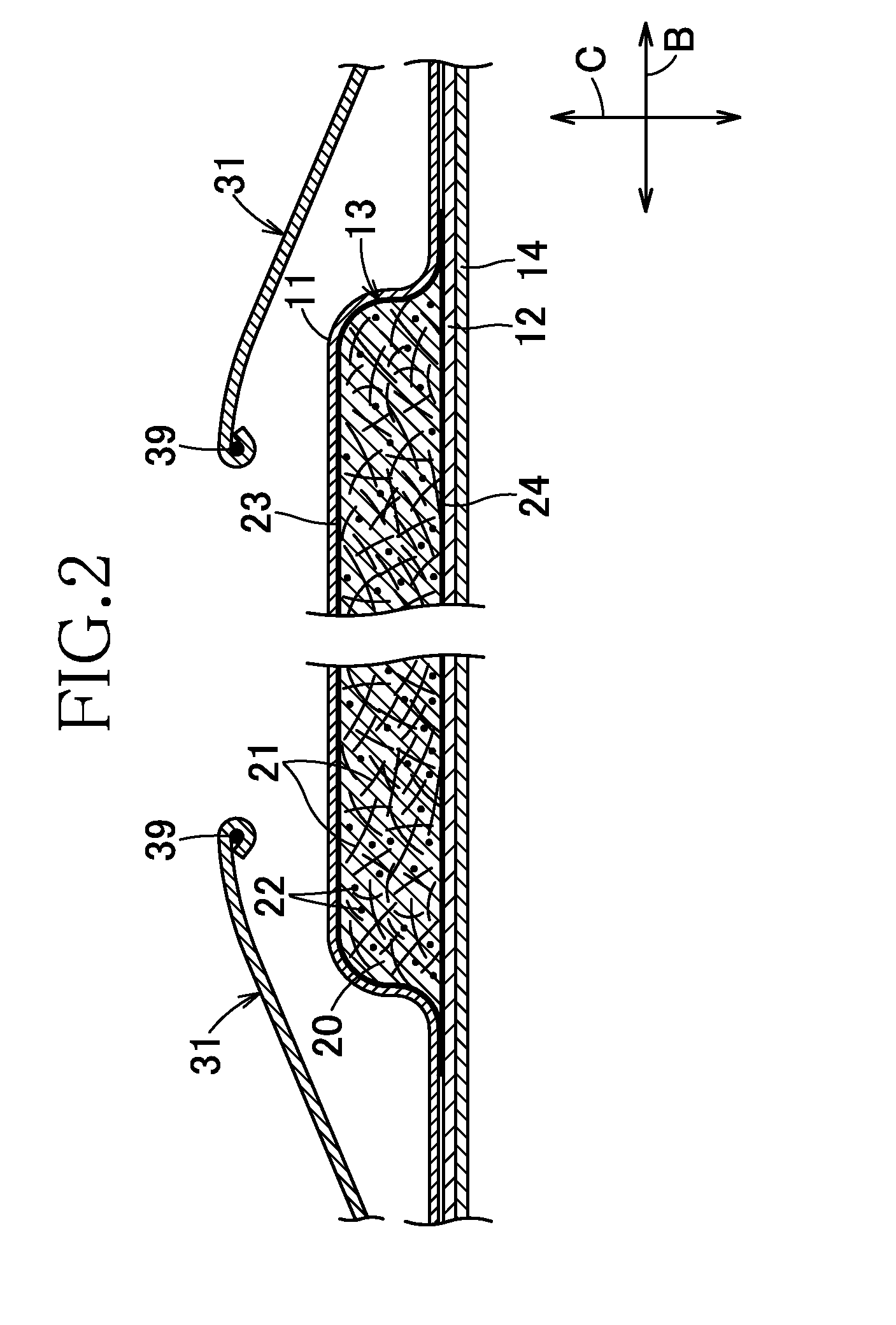

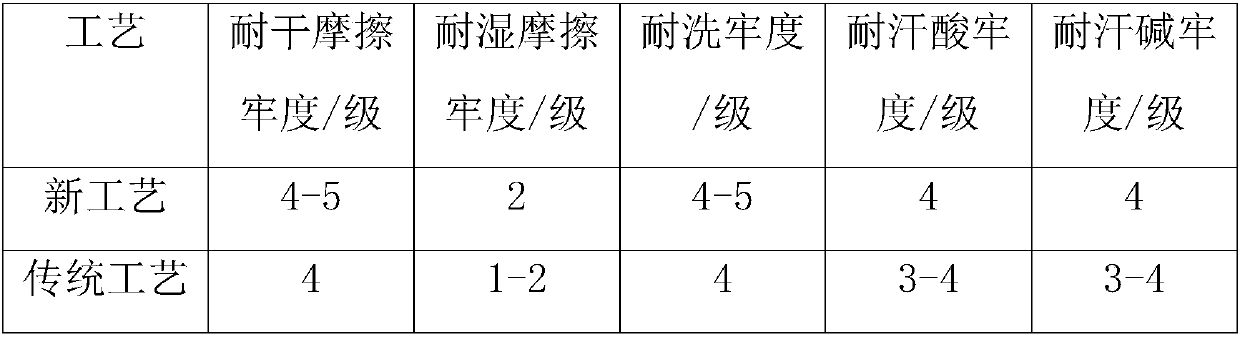

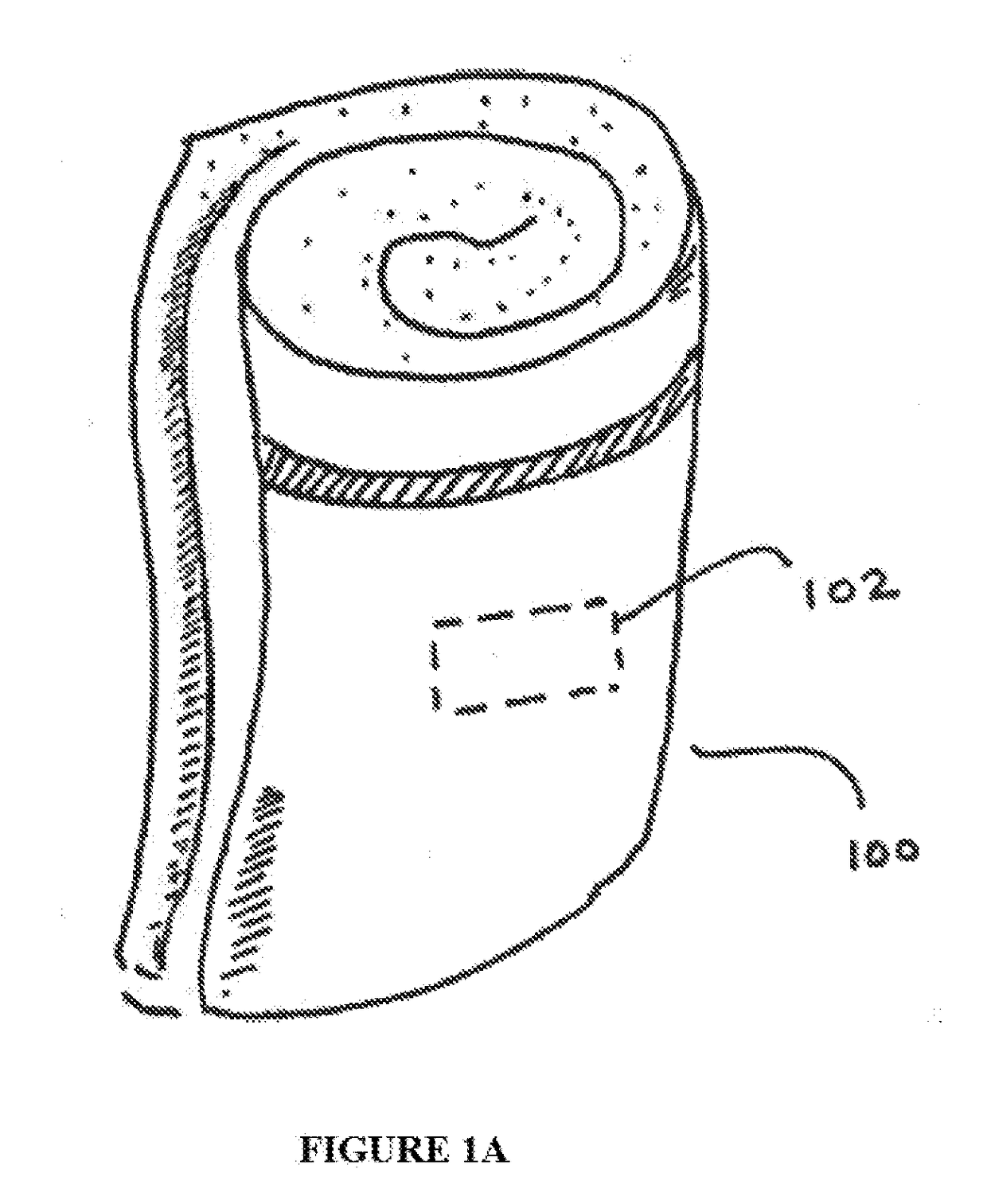

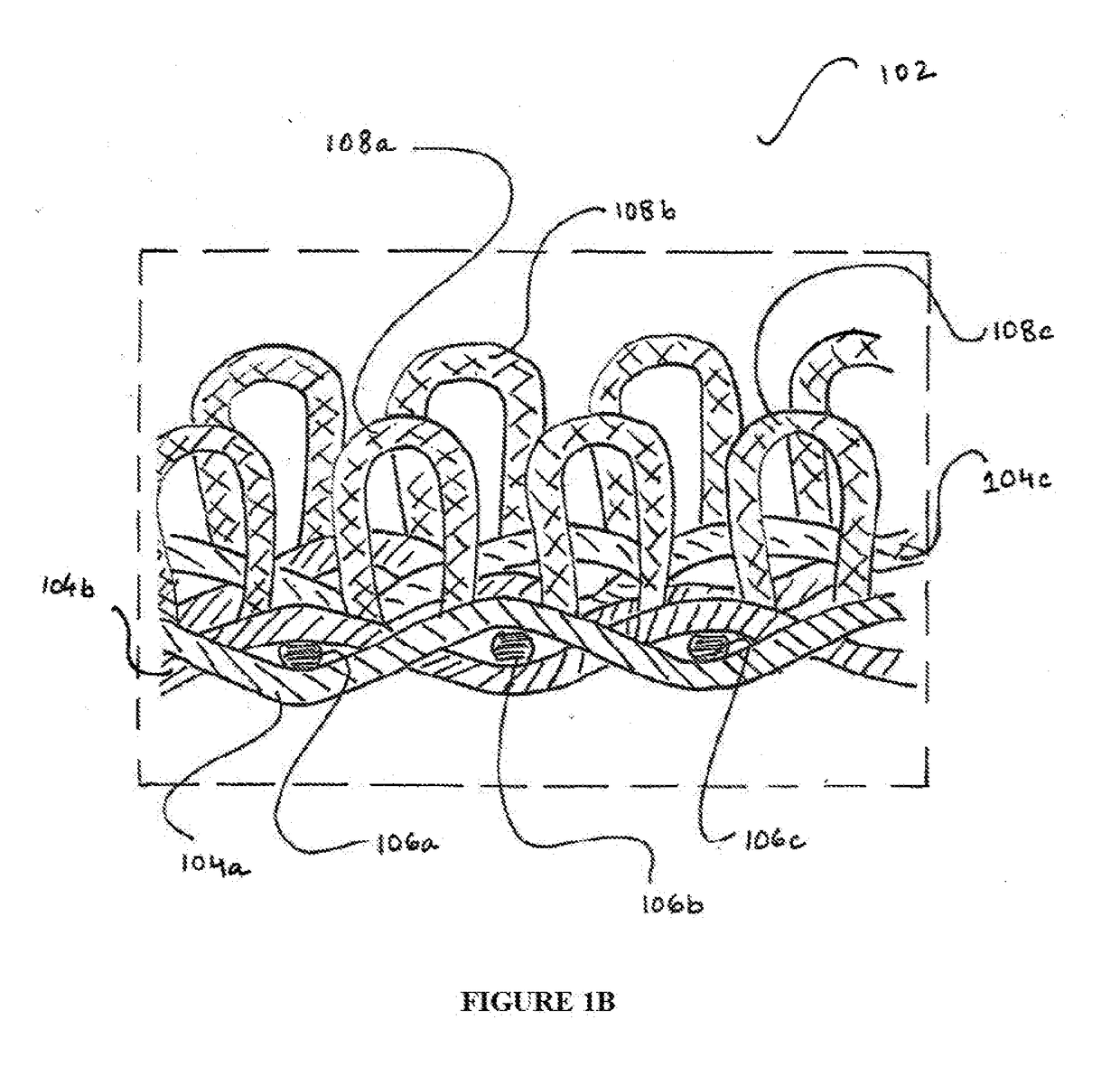

Fabric and method of manufacturing fabric

The present invention relates to textile fabrics and methods of manufacturing textile fabrics. Particularly, the invention comprises a method of producing a fabric, comprising the steps of (i) blending chemo mechanically felting fibers with non-felting fibers into a blended feed material, (ii) spinning the blended feed material into a blended yarn, (iii) producing a fabric comprising the blended yarn, (iv) subjecting the fabric to a first fabric treatment comprising a mechanical felting treatment; and (v) subjecting the fabric to a second fabric treatment comprising a chemical treatment of the fabric with an alkali, wherein the ratio of weight of the alkali to dry fabric weight is between 0.02 and 0.05, thereby obtaining increased air space in the resultant fabric.

Owner:TRIDENT

Method for processing health-care type cotton and graphene nylon interwoven silk shirt fabric

ActiveCN106835445AGentrificationRealize healthcareSingeingLiquid/gas/vapor treatment of indefinite length materialsCombingCotton fibre

The invention discloses a method for processing a health-care type cotton and graphene nylon interwoven silk shirt fabric. According to the health-care type cotton and graphene nylon interwoven silk shirt fabric, low-tex combed cotton yarn is interwoven with graphene nylon filaments after being dyed to form greige, and then the high-grade health-care type shirt fabric is obtained after silk-like finishing. The method specifically includes the following steps that the low-tex combed cotton yarn serving as warp yarn is subjected to dyeing, spooling and yarn beam warping in sequence and then is prepared into warp beams by slashing, the warp beams are interwoven with graphene nylon filaments on a gripper loom to produce the greige, and the greige is subjected to fabric finishing, desizing and silk-like finishing in sequence to obtain the finished high-grade health-care type shirt fabric product. The health-care type cotton and graphene nylon interwoven silk shirt fabric prepared by the method is smooth in cloth cover, has multiple health care functions of resisting and inhibiting bacteria, achieving low-temperature far infrared heating, deodorization and adsorption and the like and is easy to clean. The method can give full play to the multiple superior health-care functions of graphene nylon fibers in the aspect of resisting and inhibiting bacteria, achieving low-temperature far infrared heating, deodorization and adsorption and the like, moreover, the good wearing comfortableness of cotton fibers is gave full play to, and the high grade and the health care function of the shirt fabric can be achieved.

Owner:IANGSU COLLEGE OF ENG & TECH

Processing method for yak wool sweater

InactiveCN102450748AFull display of excellent characteristicsImprove qualityWeft knittingGarmentsFiberEngineering

The invention relates to a processing method for a yak wool sweater, comprising the steps of selecting fibers raw materials, blending furs, checking, spinning, weaving by a flat knitting machine, checking by a lamp, milling, mothproof finishing, checking by a lamp, nailing a lock hole, eliminating impurities, steaming and setting, finishing, packaging and warehousing. The suede and the hand feeling of the product provided in the invention is similar to cashmeres; the yak wool sweater is fine, smooth and soft, comfortable to wear and has strong warming and lower cost, so the better properties of the yak wool are completely displayed; and the sweater has promotional value.

Owner:CHANGSHU XINTEDU GARMENTS

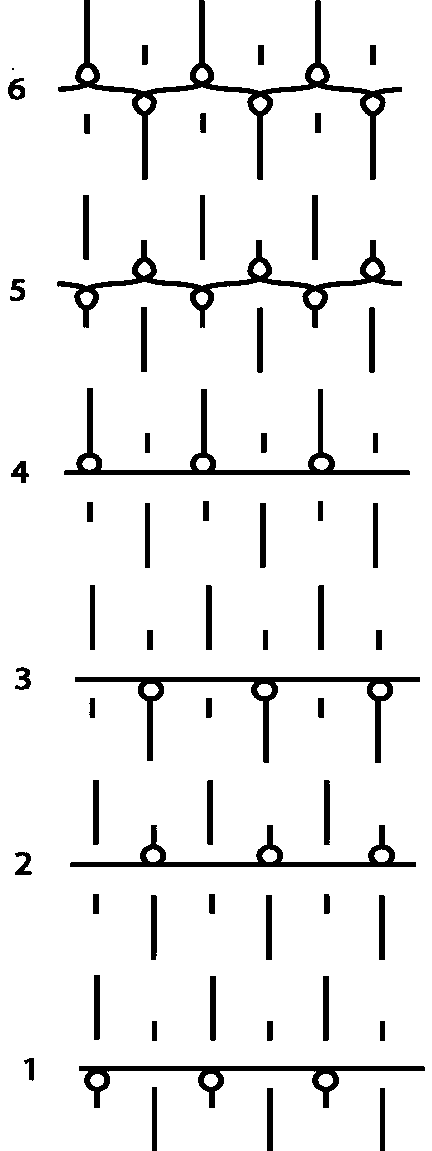

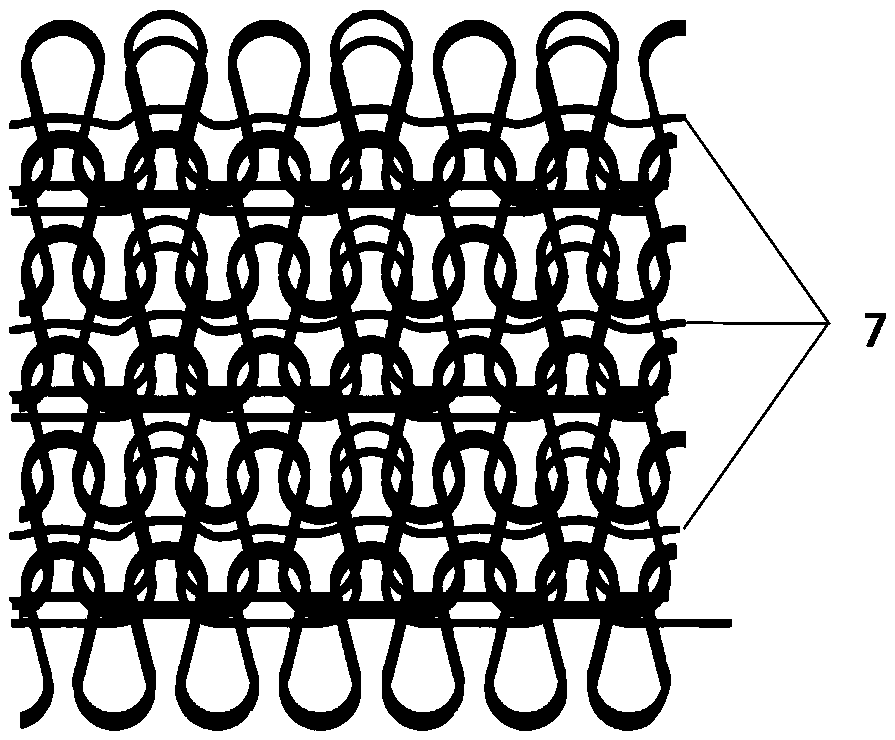

High-heat preservation air-layer wool fabric and process thereof

The invention relates to the field of textile and apparel, in particular to a high-heat preservation air-layer wool fabric. The wool fabric is selected for knitting, six-way knitting in a double-needle disc coiling mode with upper and lower needle discs is adopted, the air layer is formed in the middle of the fabric, hollow polyester yarn is introduced at the same time in the air layer, while theair storage capacity is greatly improved, the air is made to be still in the fabric, air convection is weakened, the heat preservation of the fabric is enhanced obviously, and the heat preservation iscomparable to that of a down product. The invention also provides a preparation method for the above fabric. A loom-state fabric is firstly subjected to polar fleece processing before a fulling process, a mode of primary fulling, singeing and secondary fulling is adopted, the wool feel is more uniform, plump and compact, shearing is carried out after further heat setting, the wool feel on the front is short and dense, the wool feel on the back is relatively thick, and while the heat preservation is ensured, the fabric style and the hand feel are both excellent.

Owner:LILANG CHINA

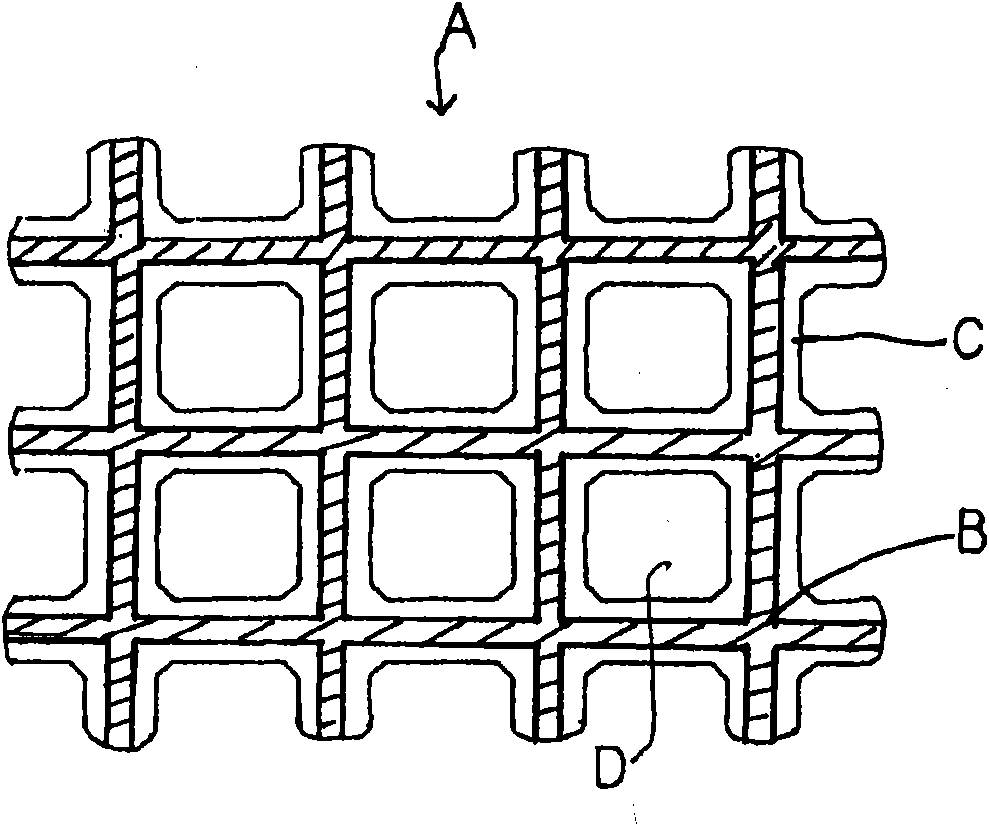

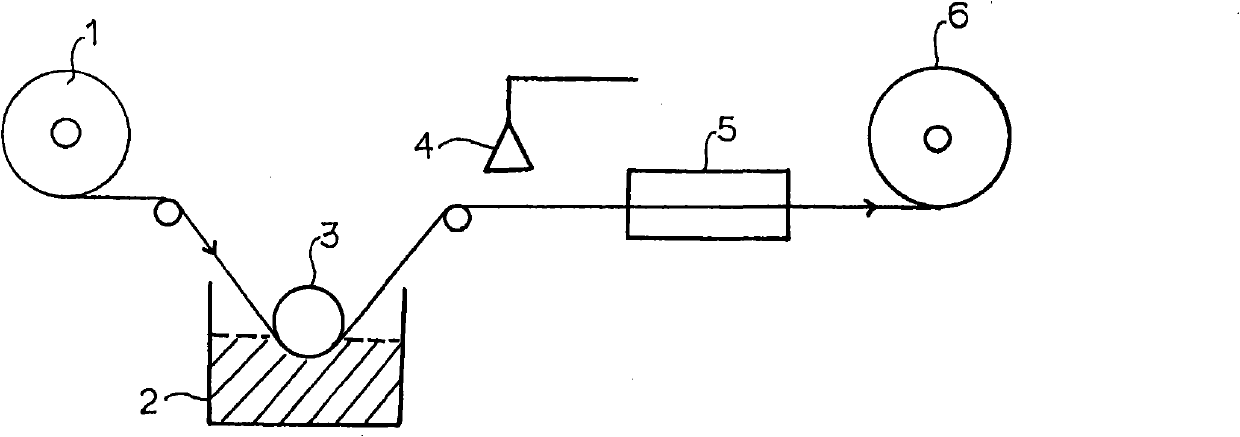

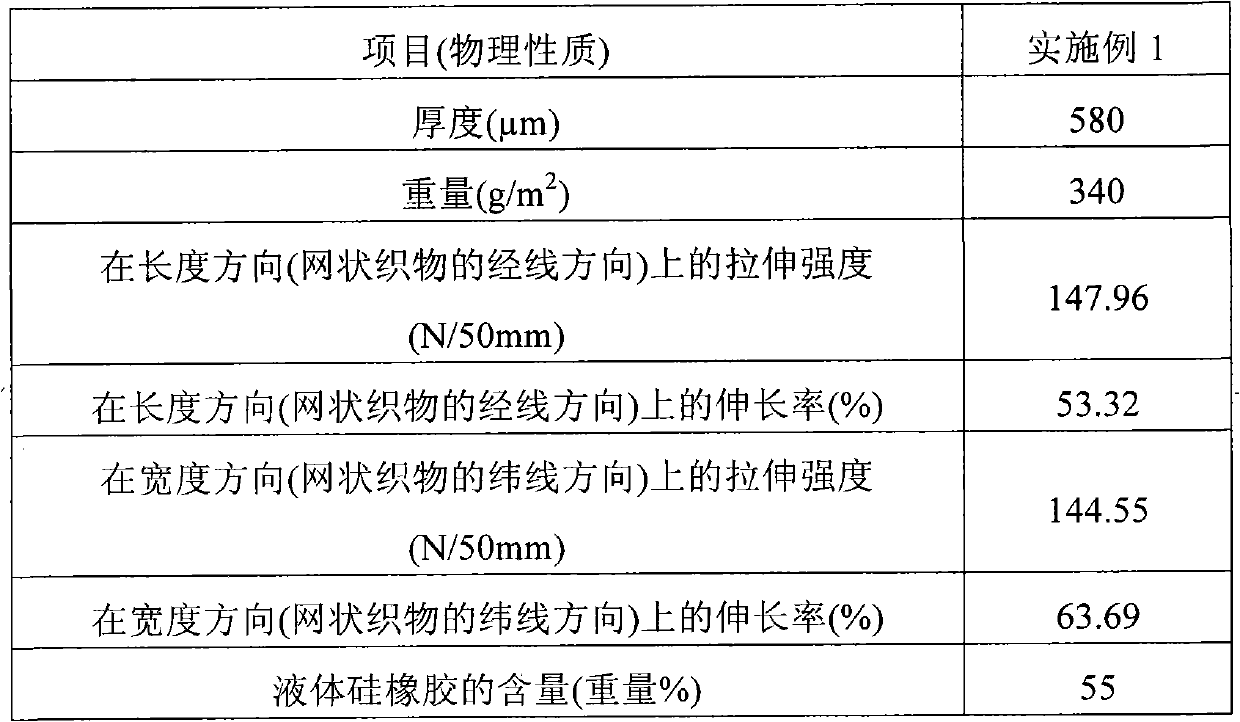

Method for preparing mesh coated with liquid silicon rubber

InactiveCN102561047AGood bottom separationFacilitated releaseSynthetic fibresFullingPolymer scienceViscosity

The invention discloses a method for preparing mesh coated with liquid silicon rubber. The method comprises the following steps: (i) mesh fabrics, in which holes are formed, are subjected to shrink-resistant treatment; (ii) liquid silicon rubber composition, of which the viscosity is 300-500,000 centipoises, is coated on the shrink-resistant treated mesh fabrics; and (iii) before the liquid silicon rubber composition is dried, air is injected to the mesh fabrics coated with the liquid silicon rubber composition. With excellent releasing property, the disclosed mesh coated with the liquid silicon rubber is used as linings of steamed dishes; and with excellent anti-skid property, the mesh can be used for manufacturing each kind of anti-slid mat using the coated mesh.

Owner:KOREA TACONIC

Production process of clean appearance pure cotton and cotton blended knitted fabric

ActiveCN111118719ARaise the gradeIncrease added valueTextile storage in superimposed formWeft knittingDye absorptionIndustrial engineering

The invention provides a production process of a clean appearance pure cotton and cotton blended knitted fabric. The production process includes the following operation steps of singeing, alkali shrinking, stacking, dyeing and shaping; specifically, the pure cotton and cotton blended knitted fabric is subjected to singeing by a full width singeing machine with double burners on the cloth cover and a single burner at the fabric bottom; the singed cotton and cotton blended knitted fabric is subjected to alkali shrinkage treatment through an alkali shrinking machine and rolled up to a cloth rack; the fabric on the cloth rack is stacked after sealing packaging; after stacking is ended, the fabric is washed and then subjected to conventional dyeing, and dewatering and drying are carried out after dyeing is completed; and after drying is carried out, the fabric is shaped and made soft, and finally the fabric is discharged from the machine in a shaped mode. Through reasonable improvement ofthe process and parameters, the dye absorption capacity of cotton knitted fabrics is effectively improved, the tightness of the fabric is conducive to achieving low shrinkage rate of a finished product, the fabric cover is less in hairiness and shiny, the resilience and stiffness-smooth are significantly improved, the cost performance is high, and the market demands are met.

Owner:盐城福汇纺织有限公司

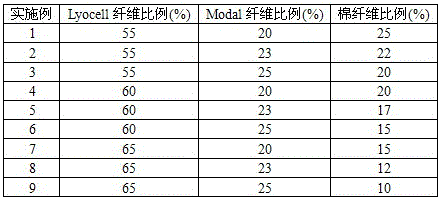

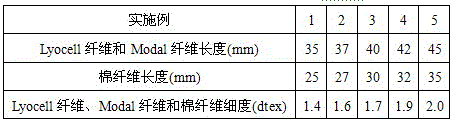

Home textile fabric and blending method thereof

InactiveCN105696163ANot easy to fadeFeel smoothDry-cleaning apparatus for textilesBleaching apparatusFiberEngineering

The invention discloses a home textile fabric and a blending method thereof.The home textile fabric is formed by blending the three raw materials including Lyocell fibers, Modal fibers and cotton fibers, the number of warp / weft yarns is 80, the warp density is 182 root / inch, the weft density is 120 root / inch, and the fabric weave and is satin weave.The gold matching mode of the three raw materials including the Lyocell fibers, the Modal fibers and the cotton fibers is determined, the home textile fabric produced adopting the matching has the advantages of Lyocell, Modal and cotton, does not easily fade, is green and healthy, good in air permeability and smooth in hand feeling, is environmentally friendly, absorbs and releases sweat, has a pleasant soft touch feeling and a drape effect and also has unique silk surface gloss, and the manufacturing cost is reduced.The detected values of the home textile fabric produced by adopting a home textile fabric blending production process reach the class-II ko-Tex Standard 100.

Owner:ZHENGZHOU DEHUI TEXTILE CO LTD

Method for producing worsted fabrics with carved patterns

ActiveCN103710807ASpecial drapabilityFeel slipperyTextile storage in wounded formPattern makingPersonalizationWorsted

The invention relates to a method for producing worsted fabrics with carved patterns. The method is characterized by comprising the following the steps of milling, inflaming retarding treatment, napping, decatizing and pattern carving. The worsted fabrics manufactured through the production method have the advantages that because fabric bodies are blended, counts, gram weight and colors can meet production requirements of customers; the worsted fabrics can be designed according to pattern types provided by the customers, and fabric bodies of one piece of clothing can be produced as well; the fabric bodies have special draping, good hand feeling, even, fine and smooth woolen cloth faces, and the taste and fashions of a wearer can be better embodied when the wearer wears clothes made of the worsted fabrics; requirements for personalization are met.

Owner:HEILAN HOME

Hand knitting cashmere yarn felting technology

This invention discloses a kind of technology to handle the cashmere yarn, especially the fulling technology of hand-knitting cashmere yarn, it includes the following steps in proper order: washing treatment of the hand-knitting cashmere yarn , clean treatment, the light fulling treatment, soft treatment, dehydration treatment, drying, dampening treatment, since the fulling treatment of the cashmere yarn is dyed by the now available color dye equipment under rational sticky condition, it has the merits that it is easy to operate, it is easy to control, the production cost is low, the handle cashmere yarn is soft and smooth , has the body bone , elastic, the surface shows a layer of short cashmere, the outward appearance is fine , the handle is thick and soft, the color and the lustre is gentle.

Owner:王启发

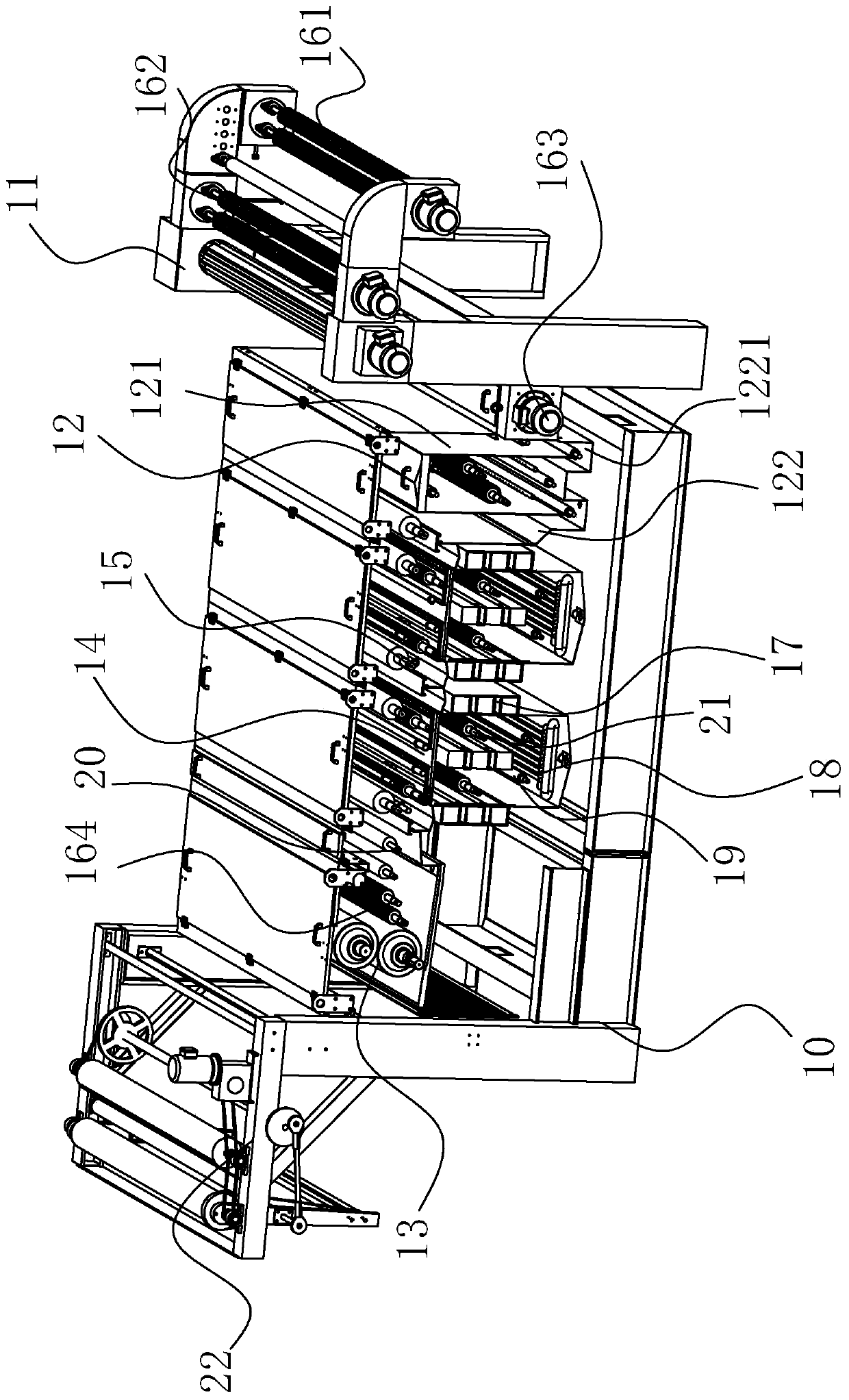

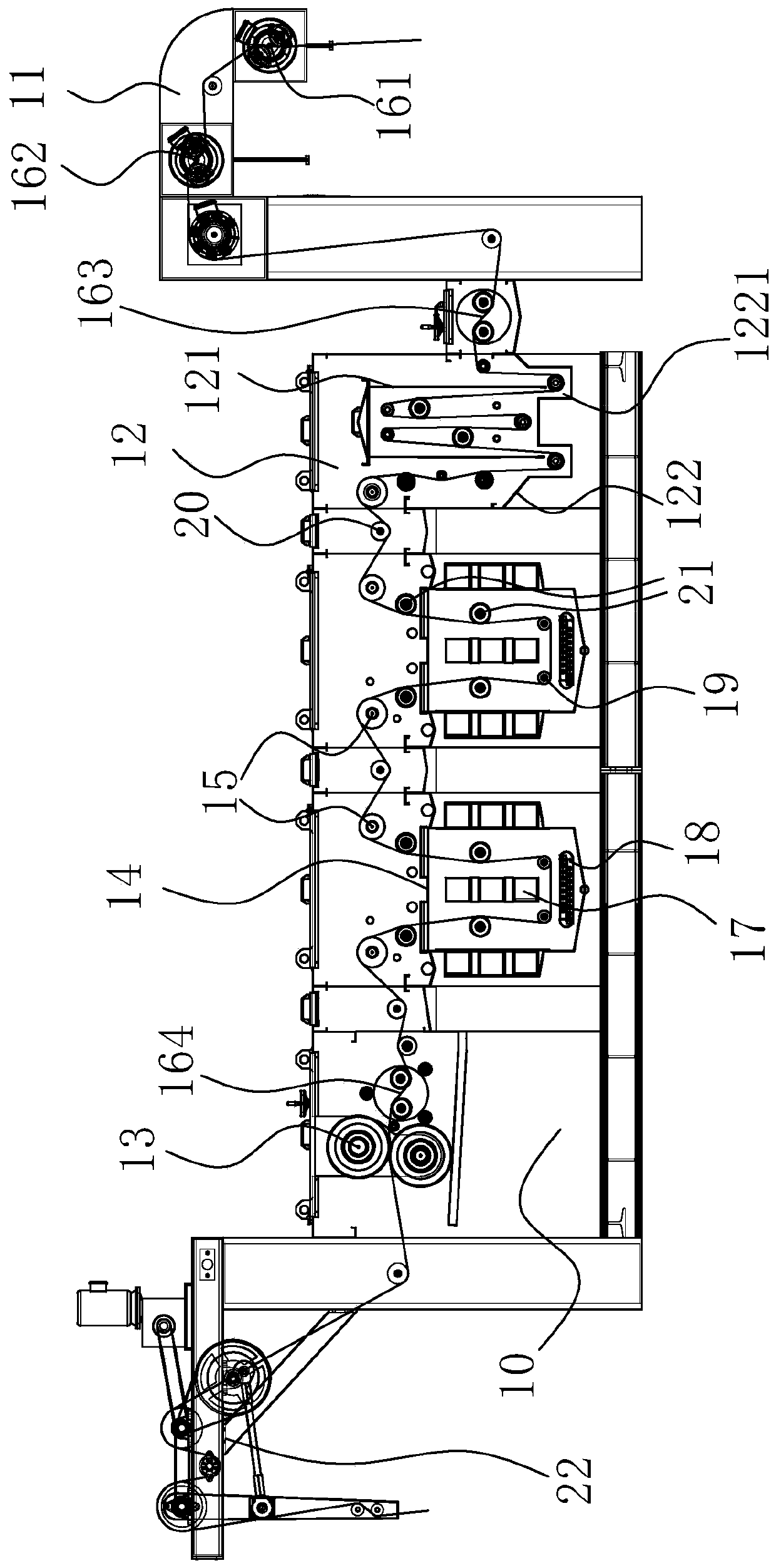

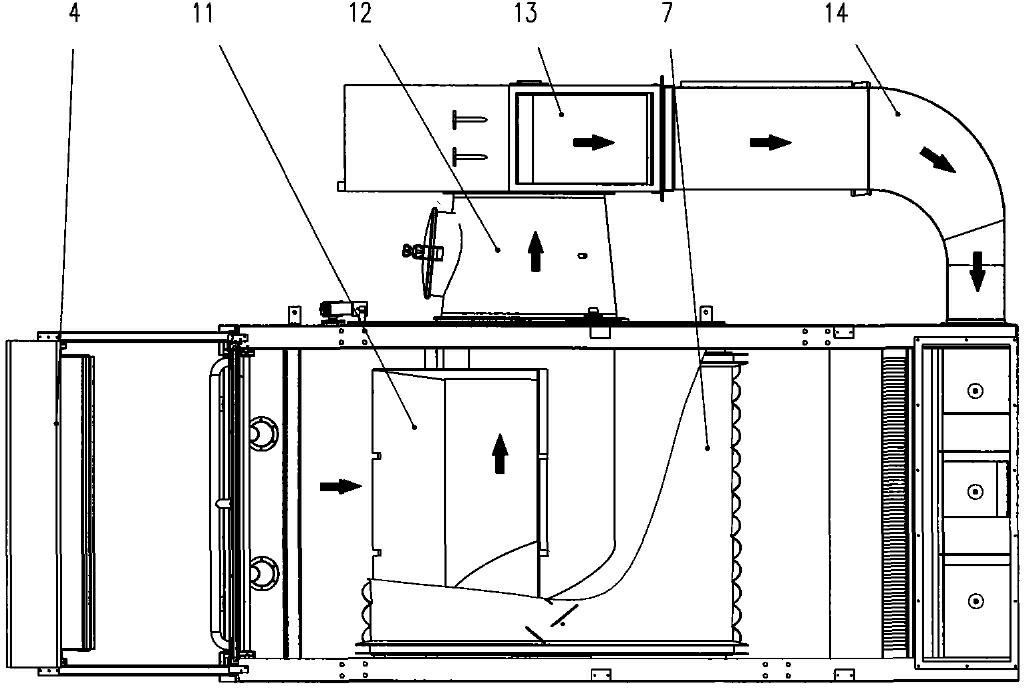

Multi-U-shaped-trough water washing machine

PendingCN110952242AQuality improvementFully contactedSucessive textile treatmentsTextile treatment machine arrangementsProcess engineeringMechanical engineering

Owner:SCHIAOMIE TECH CO LTD

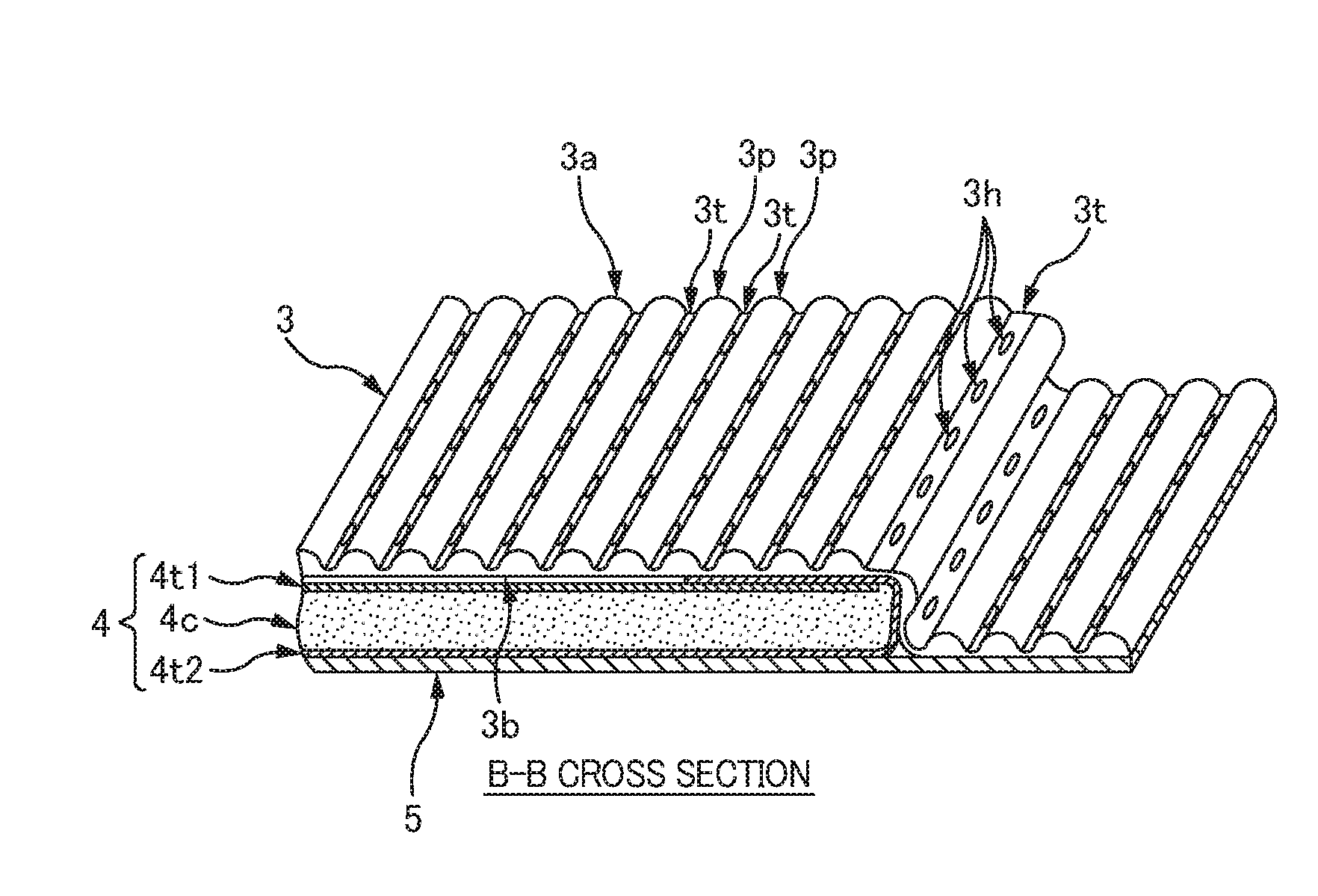

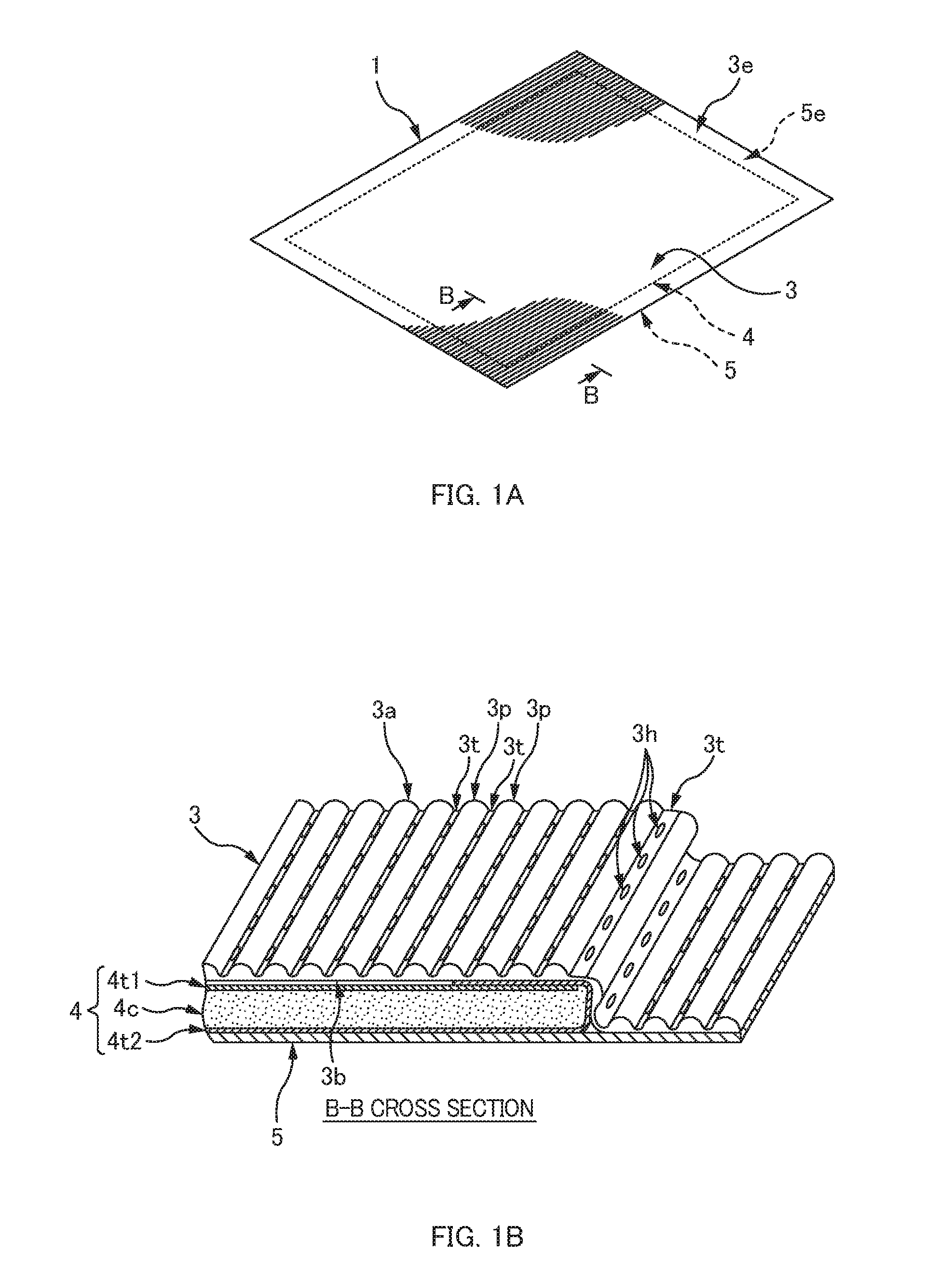

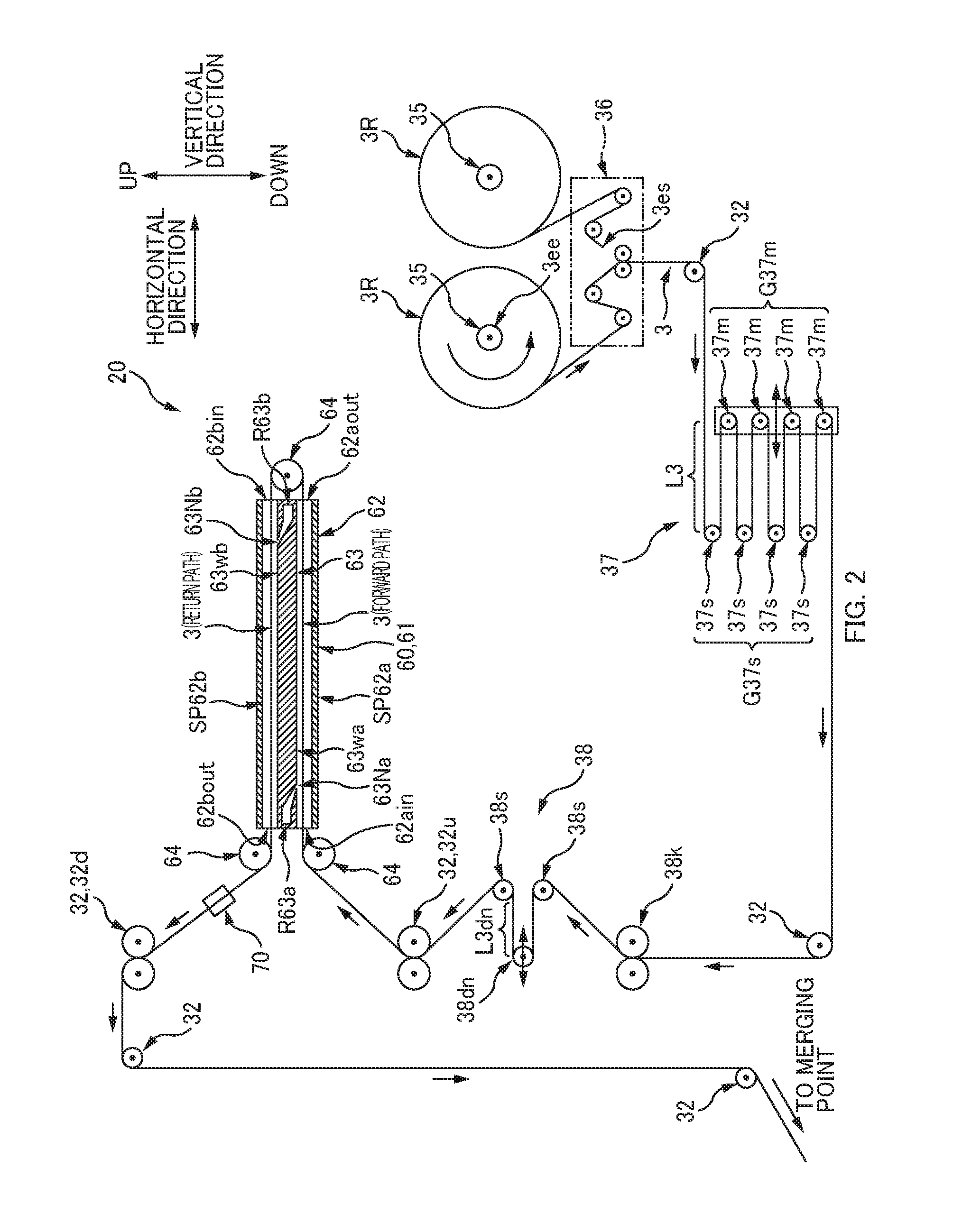

Bulkiness recovery apparatus and bulkiness recovery method for nonwoven fabric

InactiveUS20160251780A1Suppress mutationHeating/cooling textile fabricsNon-woven fabricsRecovery methodProcess engineering

There is provided a bulkiness recovery apparatus for nonwoven fabric, the apparatus being for recovering bulkiness of the nonwoven fabric by blowing hot air to heat the nonwoven fabric. The apparatus includes: a conveying section that conveys the nonwoven fabric along a conveying direction, the nonwoven fabric being continuous in the conveying direction; a heating section that heats the nonwoven fabric by blowing the hot air to the nonwoven fabric being conveyed; a width sensor that measures a widthwise dimension of the nonwoven fabric at a position downstream from the heating section in the conveying direction, and that outputs information concerning the widthwise dimension; and a controller that controls at least either one of the heating section and the conveying section based on the information that has been output from the width sensor.

Owner:UNI CHARM CORP

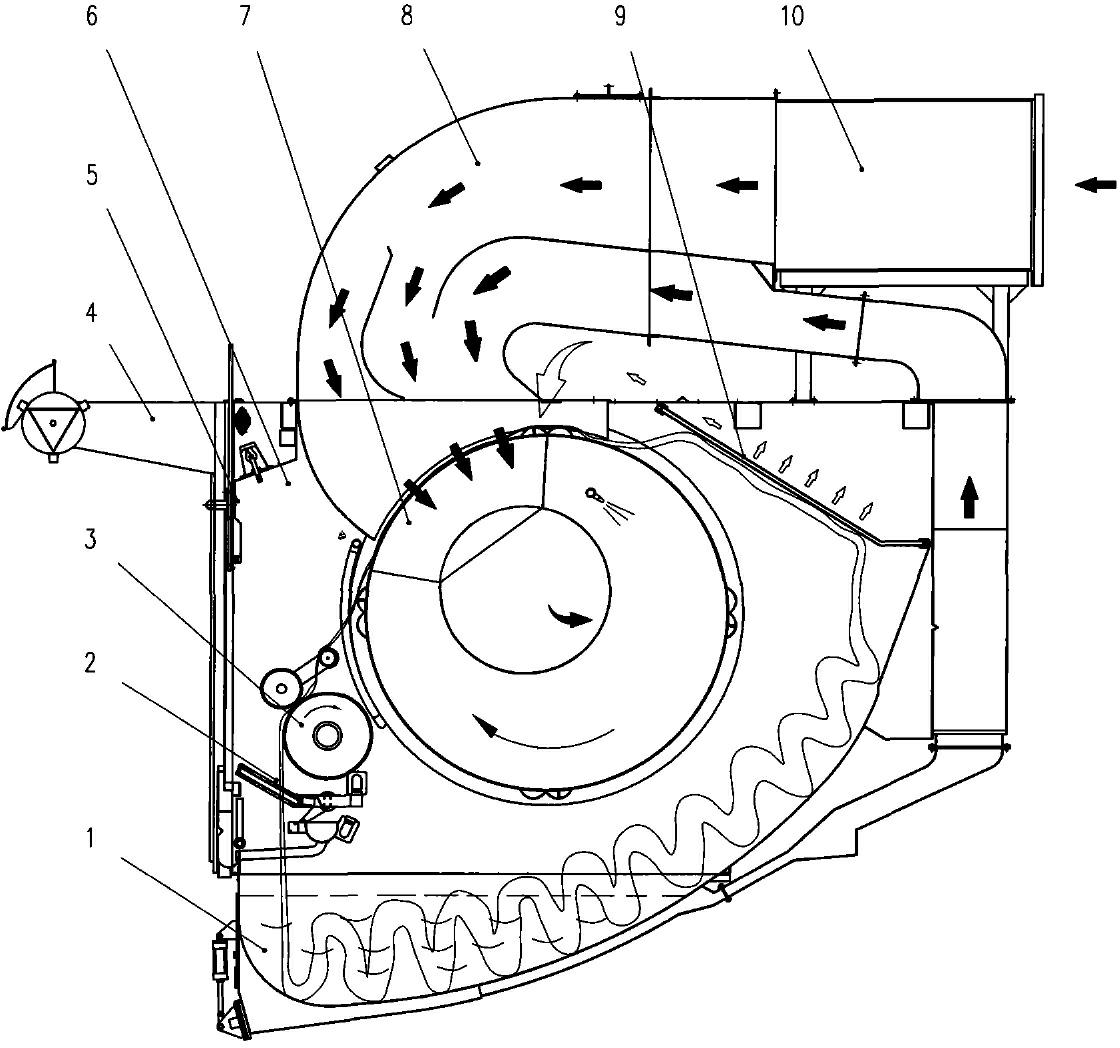

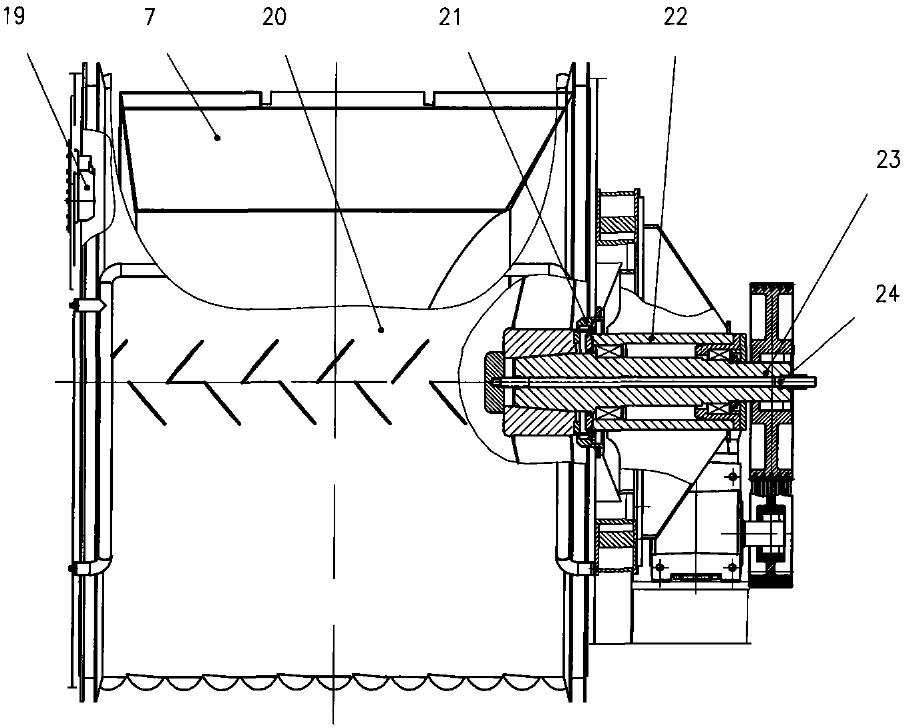

Roller for multifunctional fulling-softening finisher

The invention discloses a roller for a multifunctional fulling-softening finisher, which is arranged in a box body of the multifunctional fulling-softening finisher and can rotate at high speed under the drive of a driving device. The roller is characterized in that holes are uniformly distributed in the wall of the roller; and the roller is also provided with an airflow circulating device which is used for inspiring air from the inner side and spraying the airflow on the outer surface of the airflow circulating device from a return air port above the roller by a circulating pipeline. By using the softening finisher disclosed by the invention, the problems of washing, softening and the like of light and thin fabrics made of cotton, cambric, wool, silk, chemical fibers and the like, and knitwear are effectively solved. On the aspect of post-treatment procedures of fulling, softening, drying and the like of the fabrics, the treatment efficiency is increased, and the treatment cost and environmental pollution are reduced.

Owner:TAIAN COMPANION MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com