Method for preparing mesh coated with liquid silicon rubber

A technology of liquid silicone rubber and mesh, applied in fabric surface trimming, milling, textiles and papermaking, etc., can solve the problem of mesh liquid silicone rubber blockage, etc., to achieve excellent release and anti-slip properties, vapor permeability good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

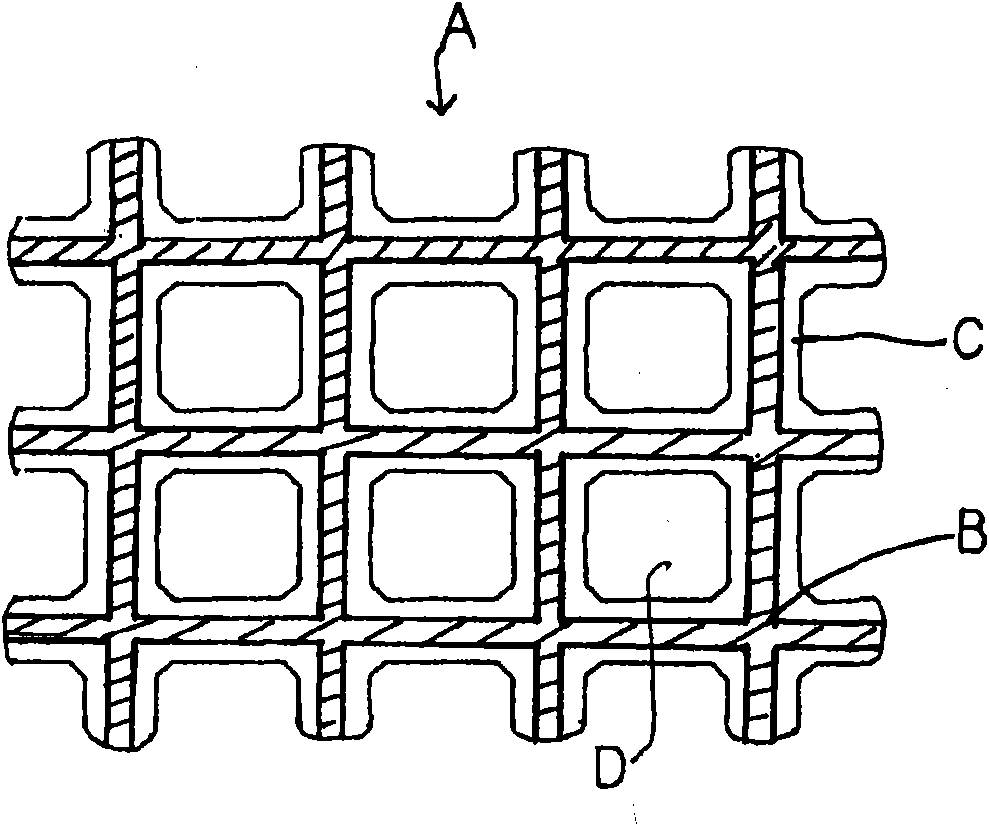

[0040] Shrinkage-resistant finishing was accomplished by immersing a mesh fabric B consisting of polyester fibers and having pores D with a maximum length of 5 mm in a pretreatment solution containing 95 g of 5 g aminosilane in water.

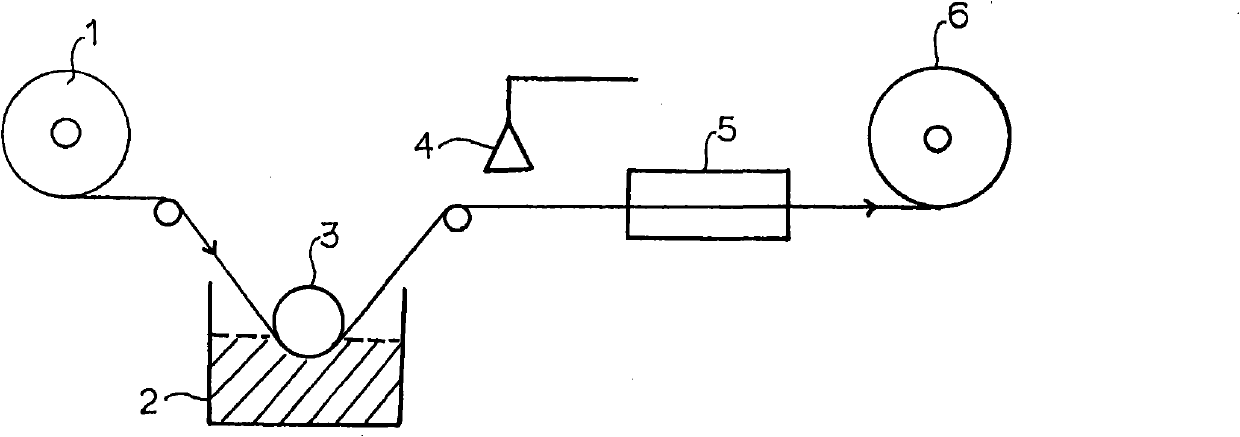

[0041] Subsequently, a liquid silicone rubber composition comprising 94% by weight of an addition-type liquid silicone rubber having a viscosity of 3,000 centipoise was applied to the preshrunk-treated mesh fabric B by intermittent knife coating. , 5.0% by weight of pigment, 0.5% by weight of fused silica and 0.5% by weight of methylvinyl hydrogen polysiloxane; subsequently, before the liquid silicone rubber composition is dried, the liquid silicone rubber coated with The mesh fabric of the composition is subjected to hot air injection. Finally, the dried product was dried at 80° C. for 3 minutes and then at 200° C. for 4 minutes, thereby preparing a coated web.

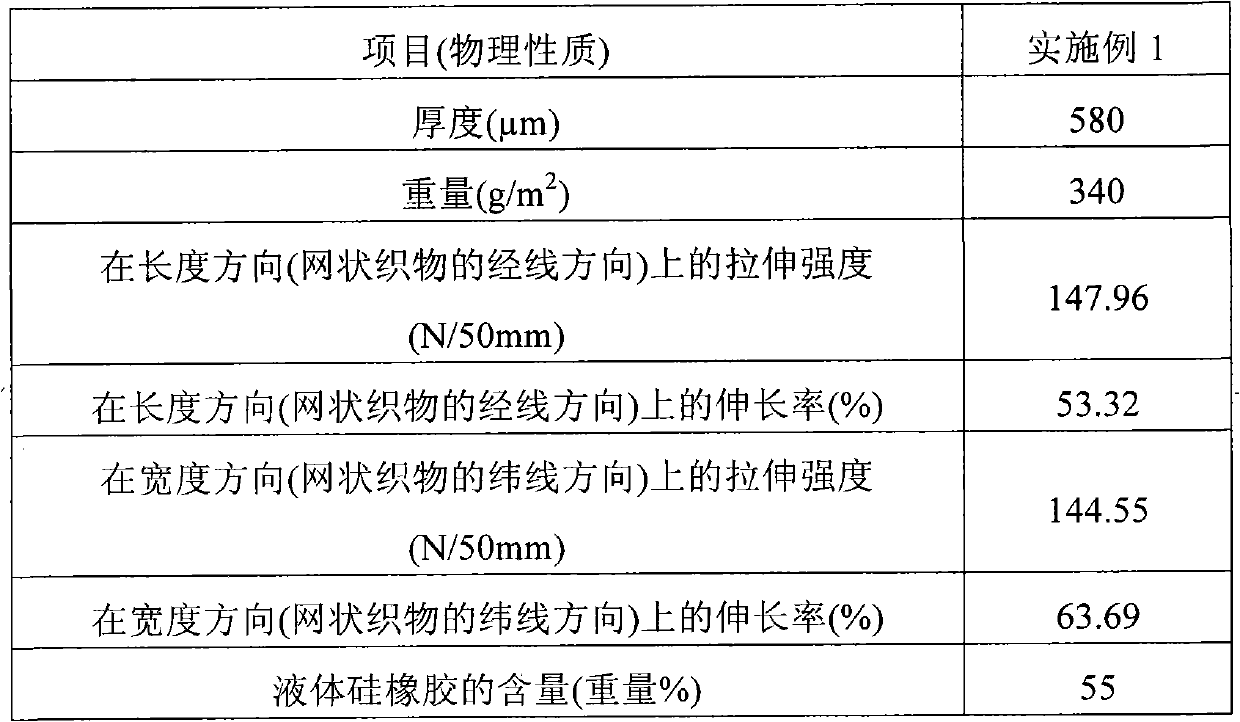

[0042] Physical property evaluations were performed on the coated webs and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com