Patents

Literature

132results about How to "Improve wet rubbing fastness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-temperature dyeing and finishing technology of cottonette

InactiveCN105002730AProcess temperature changeLow processing temperatureBiochemical fibre treatmentHeating/cooling textile fabricsInorganic saltsDiastase

The invention discloses a low-temperature dyeing and finishing technology of cottonette. The technology comprises the following steps: pretreatment; preshaping; modification treatment; dyeing; mordant removing; soaping; color fixing; post-treatment; drying; shaping; calendaring; rolling. According to the technology, pretreatment is carried out through the adoption of helicase and alpha-amylase, and modification treatment is carried out before dyeing, so that the property of the cottonette is fundamentally modified, and the dye-uptake of the fabric is increased; during the dyeing procedure, large quantities of alkaline substances and inorganic salt are not used, and a levelling agent, a low-temperature dyeing accelerant, a migration inhibitor and a dispersing agent are added, so that the dye uniformity is improved; during the whole dyeing process, the temperature is lower than 80 DEG C, and the dyeing process belongs to low-temperature dyeing, so that energy consumption is reduced; self-cleaning treatment is added in post-treatment, so that the self-cleaning capacity, wrinkle resistance and water washable firmness of the fabric are improved; post-treatment is carried out through the adoption of silk fibroin and sericin, so that the pilling resistance and antistatic property of the cottonette are improved; the whole technology is environment-friendly and free of pollution.

Owner:TAICANG TIANLONG CHEM FIBER

Natural dyestuff dyeing and finishing process of polyester fabric

The invention discloses a natural dyestuff dyeing and finishing process of polyester fabric. The natural dyestuff dyeing and finishing process of the polyester fabric comprises pretreatment, preshaping, modification treatment, dyeing, mordant removing, soaping, fixation, finishing, drying, shaping, calendering and winding. According to the natural dyestuff dyeing and finishing process of the polyester fabric, helicase and alhpa-amylase are adopted to conduct pretreatment, modification treatment is radically conducted on the performance of the polyester fabric through a acetic acid aqueous solution of chitosan, hydrogen peroxide and epoxy chloropropane, and the dyeing rate of the fabric is increased; in the dyeing process, a large amount of alkaline matter and inorganic salt are not used, a levelling agent and diffusant are added, the level-dyeing property is improved, natural dyestuff is used, therefore, environmental pollution is avoided, and requirements of green environmental protection are met; modification treatment and fire-retardant treatment are conducted on the fabric through montmorillonite, and the fire resistance of the fabric is high; anti-yellowing reagents are used in the preshaping and the shaping, and the final fabric is not prone to yellowing.

Owner:TAICANG CHENGLE CHEM FIBER

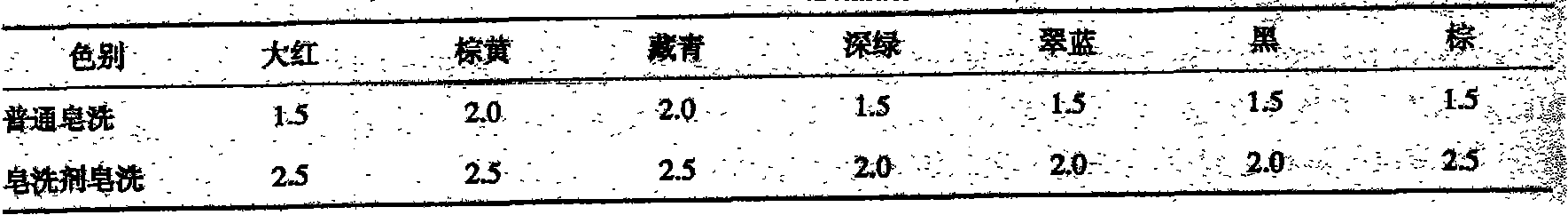

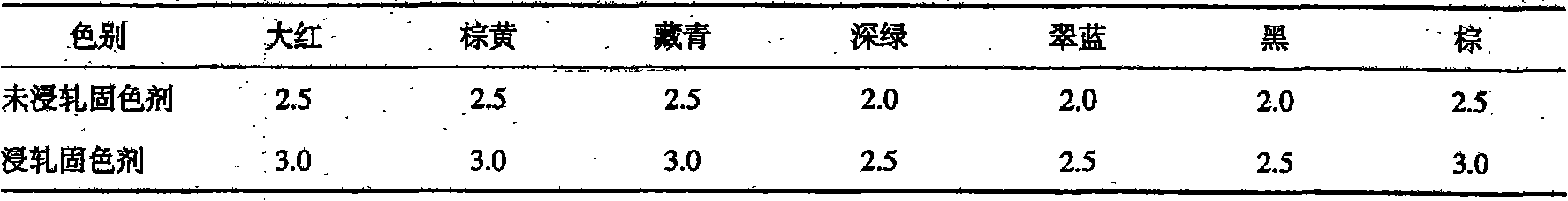

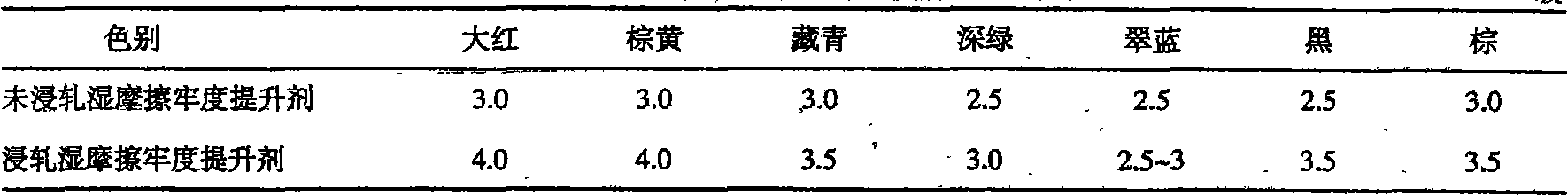

Production process for improving wet rubbing fastness of reactive dye

The invention discloses a production process for improving wet rubbing fastness of reactive dye. The process comprises the following steps: pretreating and dyeing a fabric; washing the fabric by soap; drying the fabric; padding a fixing agent; drying the fabric; padding a wet rubbing fastness improver; drying the fabric; napping the fabric; baking and stentering the fabric at 130 DEG C; carding the fabric; shearing and sewing the fabric into a finished product, wherein, the step of pretreating and dyeing the fabric comprises cold pad-batch by a refined enzyme-peroxide one bath process, open washing, dyeing and baking; the step of washing by soap adopts a LIPOTOL RK-5Z soaping agent; in the step of padding the fixing agent, the fixing agent adopts JD-427 formaldehyde-free fixing agent; and the improver in the step of padding the wet rubbing fastness improver adopts 1504 wet rubbing fastness improver. The method can save water, energy consumption and time, can thoroughly remove impurities, has small dye dosage, and can improve the wet rubbing fastness of the reactive dye.

Owner:绍兴百丽恒印染有限公司

Dyeing and finishing process for linen and cotton blended fiber fabric

InactiveCN105063998AProcess temperature changeLow processing temperaturePhysical treatmentBiochemical fibre treatmentInorganic saltsManufacturing engineering

The invention discloses a dyeing and finishing process for linen and cotton blended fiber fabric. The dyeing and finishing process comprises preprocessing, pre-sizing, modified processing, dyeing, mordant removing, soaping, color fixing, after finishing, drying, sizing, calendaring and rolling. Helicase, scouring enzyme and alpha-amylase are used for pretreatment, modification treatment is adopted before dyeing, the performance of linen and cotton blended fabric is modified fundamentally, and the dye-uptake rate is increased; the dyeing procedure does not require a large quantity of alkaline substances and inorganic salt, a leveling agent, substitutive alkali, a migration inhibitor and a dispersing agent are added, the dye uniformity is improved, environment pollution is avoided due to use of natural dye, and requirements for environmental protection are met; self-cleaning processing is added in the after finishing procedure, and the self-cleaning capacity, the crease-resistant performance, the washing resistance and the color fastness of the fabric are improved; crease-resistance finishing is added, and the crease-resistant performance of the fabric is improved; the whole process is environment-friendly and pollution-free.

Owner:TAICANG TIANLONG CHEM FIBER

Environment-friendly dyeing and finishing technology of cotton cellulose fabric

InactiveCN105002720AHigh whitenessAvoid damagePhysical treatmentBiochemical fibre treatmentEpoxyCellulose

The invention discloses an environment-friendly dyeing and finishing technology of a cotton cellulose fabric. The technology comprises the following steps: pretreatment; preshaping; modification treatment; dyeing; mordant removing; soaping; color fixing; post-treatment; drying; shaping; calendaring; rolling. According to the technology, pretreatment is carried out through the adoption of helicase and alpha-amylase, and acetic acid aqueous solution of chitosan, hydrogen peroxide and epoxy chloropropane is adopted, so that the property of the cotton cellulose fabric is fundamentally modified, and the dye-uptake of the fabric is increased; during the dyeing procedure, large quantities of alkaline substances and inorganic salt are not used, and a levelling agent and a dispersing agent are added, so that the dye uniformity is improved; natural dye is used, so that environmental pollution is avoided, and the demand of environmental protection is met; modification treatment and fire retardant treatment are carried out on the fabric through the adoption of montmorillonite, so that the fire resistance of the fabric is high; self-cleaning treatment is added in post-treatment, so that the self-cleaning capacity, wrinkle resistance and water washable firmness of the fabric are improved; the whole technology is environment-friendly and free of pollution.

Owner:TAICANG CHENGLE CHEM FIBER

Dyeing and finishing process for polyamide fabric

InactiveCN105177987AProcess temperature changeLow processing temperatureBiochemical fibre treatmentUltrasonic/sonic fibre treatmentPolyamideAmmonium chloride mixture

The invention discloses a dyeing and finishing process for polyamide fabric. The provided process comprises pretreatment, pre-setting, modified processing, dyeing, soaping, dye fixation, post-finishing, drying, setting, calendering and rolling. Supersonic waves are employed for pretreatment, fabric is subjected to low temperature plasma processing before the dyeing step, then 2,3-epoxy propyl trimethyl ammonium chloride is employed for modification processing of the fabric, the dyeing degree of the fabric is raised, and difficulty of the subsequent dyeing step is lowered. During the dyeing step, a lot of alkaline substances and inorganic salt are not used, natural dyes are employed, colophony powder is added as a dye-fixing agent, the dye-fixing effect is enhanced, environment pollution is avoided, and green environmental protection requirements are met. Montmorillonite is employed for modification processing and flame retardation processing of the fabric, and thus the flame retardation of the fabric is high. Anti-yellowing reagents are used both in the pre-setting and setting steps, and thus the final fabric is not easy to turn yellow.

Owner:TAICANG TIANLONG CHEM FIBER

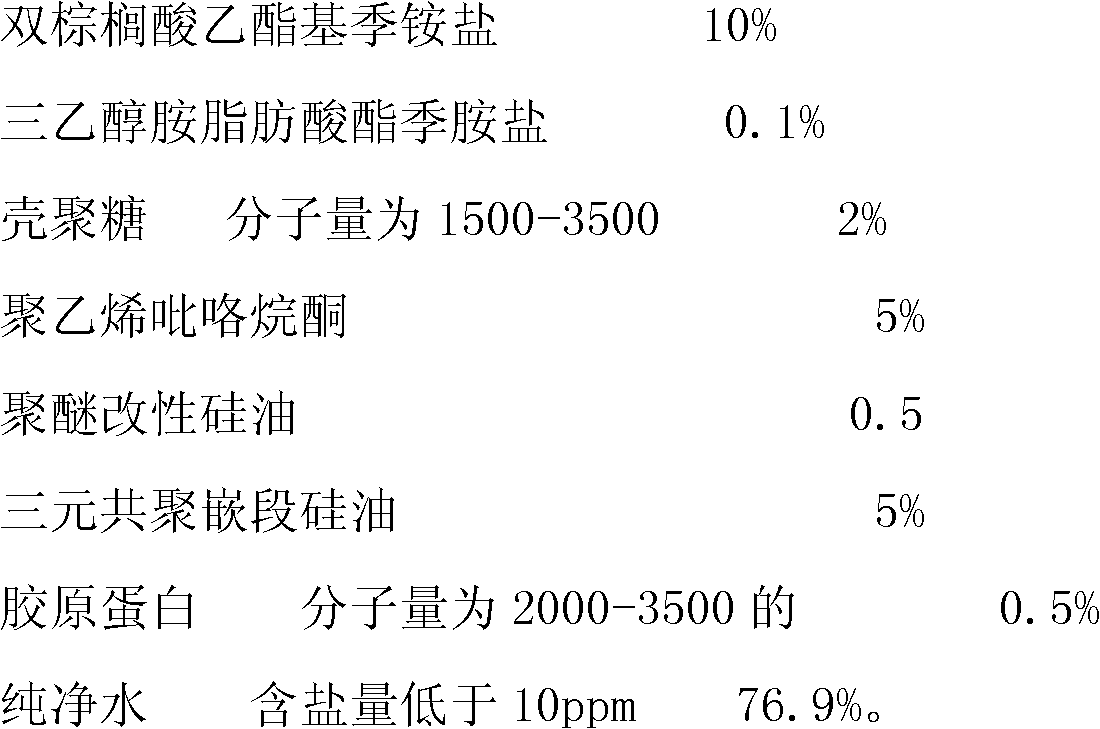

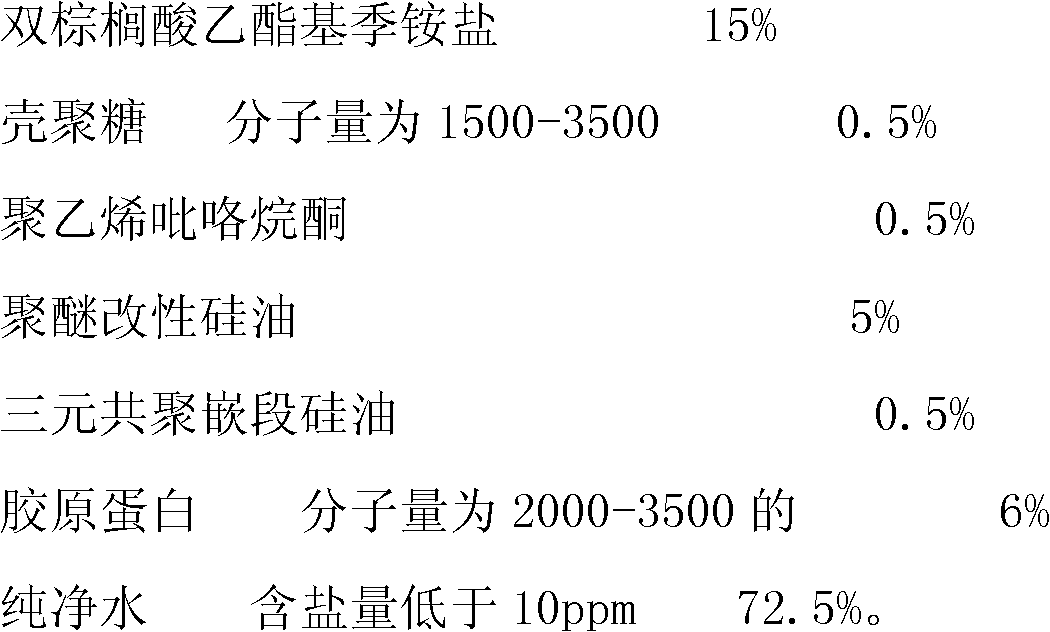

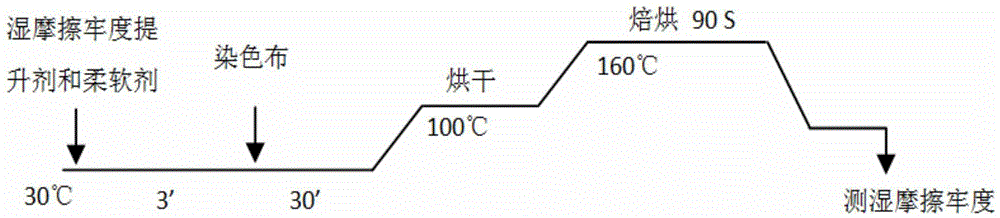

Softening agent capable of improving sublimation fastness of disperse dye and wet friction fastness of reactive dye

The invention relates to the field of textile dyeing of polyester and dark fabrics such as blended fabrics, pure cotton, adhesives and hemp, in particular to a softening agent capable of improving the sublimation fastness of a disperse dye and the wet friction fastness of a reactive dye. The softening agent is characterized by mainly comprising the following raw materials in percentage by weight: bi-ethyl palmitate based quaternary ammonium salt, triethanolamine fatty acid ester quaternary ammonium salt, chitosan, polyvinyl pyrrolidone, polyether modified silicone oil, ternary polymerization block silicon oil, collagen and purified water. Compared with the prior art, the softening agent has the advantages that the sublimation fastness of the disperse dye can be improved by 0.5 to 1 grade and the wet friction fastness of the reactive dye can be improved by 0.5 grade after the sizing of a dyed fabric; and simultaneously, the neatened fabric is endowed with elastic and exquisite handfeel, so that the fabric is high in pollution resistance, dust resistance, shrinkage resistance, pilling resistance and static electricity resistance.

Owner:祝洪哲

Flax fabric dyeing and finishing process

InactiveCN104988768AReduce pollutionAvoid damageUltrasonic/sonic fibre treatmentDyeing processInorganic saltsMontmorillonite

The invention discloses a flax fabric dyeing and finishing process including pretreatment, pre-sizing, modification treatment, dyeing, soaping, color fixation, post-finishing, drying, sizing, calendering, and coiling. Ultrasonic waves are used for pretreatment, and at the same time, the modification treatment step is added; in the dyeing process, a large amount of alkaline substances and inorganic salts are not used, natural dyes are used, and at the same time, a colophony powder is added as a color fixing agent, so that the color fixing effect is enhanced, besides, the environmental pollution is avoided, and the requirements of environmental protection are met; montmorillonite is used for modification treatment and flame retardant treatment on the fabric, so that the flame retardancy of the fabric is high; and an anti-yellowing reagent is used in the processes of pre-sizing, sizing and post-finishing, so that a final fabric does not easily turn yellow.

Owner:太仓市宝明化纤有限公司

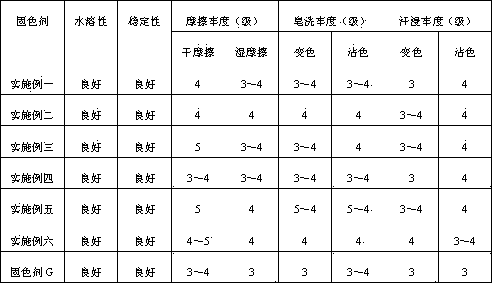

Fabric formaldehyde-free fixing agent

InactiveCN103669050AImprove color fixationHigh color fastnessDyeing processColour fastnessPolymer science

The invention discloses a fabric formaldehyde-free fixing agent. The fixing agent comprises the following raw materials in parts by mass: 10-15 parts of poly dimethyl diallyl ammonium chloride, 15-18 parts of 2-hydroxypropyltrimethyl ammonium chloride chitosan, 25-34 parts of water, 20-25 parts of ethanol and 5-10 parts of fatty alcohol polyoxyethylene ether. The fixing agent disclosed by the invention has an excellent fixation effect, and can effectively improve colour fastness of fabric dyes and wet rubbing fastness in the processes of dyeing and printing. The fabric treated by the fabric formaldehyde-free fixing agent does not discolor.

Owner:NANTONG TONGZHOU DISTRICT CHUANJIANG TOWN SUNWORLD DYNASTY HOME TEXTILE DESIGN STUDIO

Aramid fabric high-efficiency dyeing and finishing process

InactiveCN104988711AImprove hydrophilicityImprove dye uptakePhysical treatmentFibre typesInorganic saltsProcess engineering

The invention discloses an aramid fabric high-efficiency dyeing and finishing process including modification treatment, scouring and dyeing in one bath, soaping, color fixation, post-finishing, drying, sizing, calendering, and coiling. According to the dyeing and finishing process, before the dyeing process, a fabric is subjected to low temperature plasma treatment, then the fiber fabric is subjected to modification treatment with 2,3-epoxypropyltrimethylammonium chloride and chitosan, and thus the fabric dyeing degree is increased, and the difficulty of the subsequent dyeing steps is reduced; at the same time, ultrasonic treatment is adopted during modification treatment, so that the time is saved and the treatment efficiency is improved; with adopting of scouring and dyeing in one bath, the efficiency is increased, and the cost is reduced; in the dyeing process, a large amount of alkaline substances and inorganic salts are not used, natural dyes are used, and at the same time, a colophony powder is added as a color fixing agent, so that the color fixing effect is enhanced, besides, the environmental pollution is avoided, and the requirements of environmental protection are met; and with increase of anti-yellowing finishing, a final fabric does not easily turn yellow.

Owner:TAICANG SHUANGYU CHEM FIBER CO LTD

Dyeing and finishing process of polyester and cotton blended fiber fabric

InactiveCN105063997AHigh whitenessAvoid damageSucessive textile treatmentsBiochemical fibre treatmentPolyesterFiber

The invention discloses a dyeing and finishing process of polyester and cotton blended fiber fabric. The process comprises pretreatment, presetting, modification treatment, dyeing, mordant removal, soaping, color fixing, after finishing, drying, sizing, calendaring and rolling. Snailase and alpha-amylase are adopted for pretreatment, modification treatment is adopted before dyeing, the polyester and cotton blended fabric is modified fundamentally, and the dye-uptake of the fabric is increased; in the dyeing procedure, fewer alkaline substances and inorganic salt are used, a dye leveler, substitution alkali, a migration inhibitor and a diffusant are added, the dye leveling performance is improved, natural dye is used, environmental pollution is avoided, and the environment-friendly requirement is met; self-cleaning treatment is added during aftertreatment, and the self-cleaning capacity, the crease-resistant performance, the wash durability and color fastness are improved; silk fibroin and sericin are adopted for afterfinish, and the anti-pilling performance and the antistatic performance of the fabric are provided; the whole process is environment-friendly and pollution-free.

Owner:TAICANG TIANLONG CHEM FIBER

Low-temperature dyeing and finishing technology for bamboo fiber fabric

InactiveCN105019250AAvoid damageLower processing temperaturePhysical treatmentBiochemical fibre treatmentAmylaseFiber

The invention discloses a low-temperature dyeing and finishing technology for bamboo fiber fabric. The low-temperature dyeing and finishing technology includes the steps of pretreatment, preshaping, modification treatment, dyeing, mordant removal, soaping, color fixation, after finishing, drying, shaping, calendering and rolling. Helicase, scouring enzyme and alpha-amylase are adopted for pretreatment, modification treatment is adopted before dyeing, the performance of the bamboo fiber fabric is modified fundamentally, and the dye-uptake rate of the fabric is increased; as in the dyeing working procedure, alkaline substance and inorganic salts are not used in quantity, and a levelling agent is added, the dyeing levelness is improved; environment pollution is avoided by using natural dyestuff, which meets the requirement for environmental protection; as self-cleaning treatment is added in after treatment, the self-cleaning capacity, crease-resistant performance and wash-resisting firmness of the fabric are improved; crease-resistant finishing is added, and therefore the crease-resistant performance of the fabric is improved; the whole technology is environmentally friendly and free from pollution.

Owner:TAICANG TIANLONG CHEM FIBER

Formaldehyde-free fixing agent for active dye

InactiveCN102493232AHigh color fastnessLow water solubilityDyeing processPolymer chemistryFormaldehyde free

The invention discloses a formaldehyde-free fixing agent for an active dye. The formaldehyde-free fixing agent is prepared by compounding 2 to 4 compounds. The formaldehyde-free fixing agent has reactive functional groups and high cationic property, can effectively improve the dry rubbing fastness, wet rubbing fastness and color fastness to washing of fabrics dyed by the active dye, and has a little influence on the color tone of the fabrics.

Owner:SUZHOU UNIV

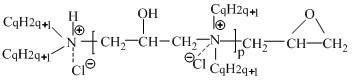

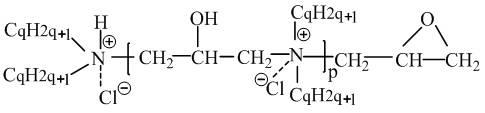

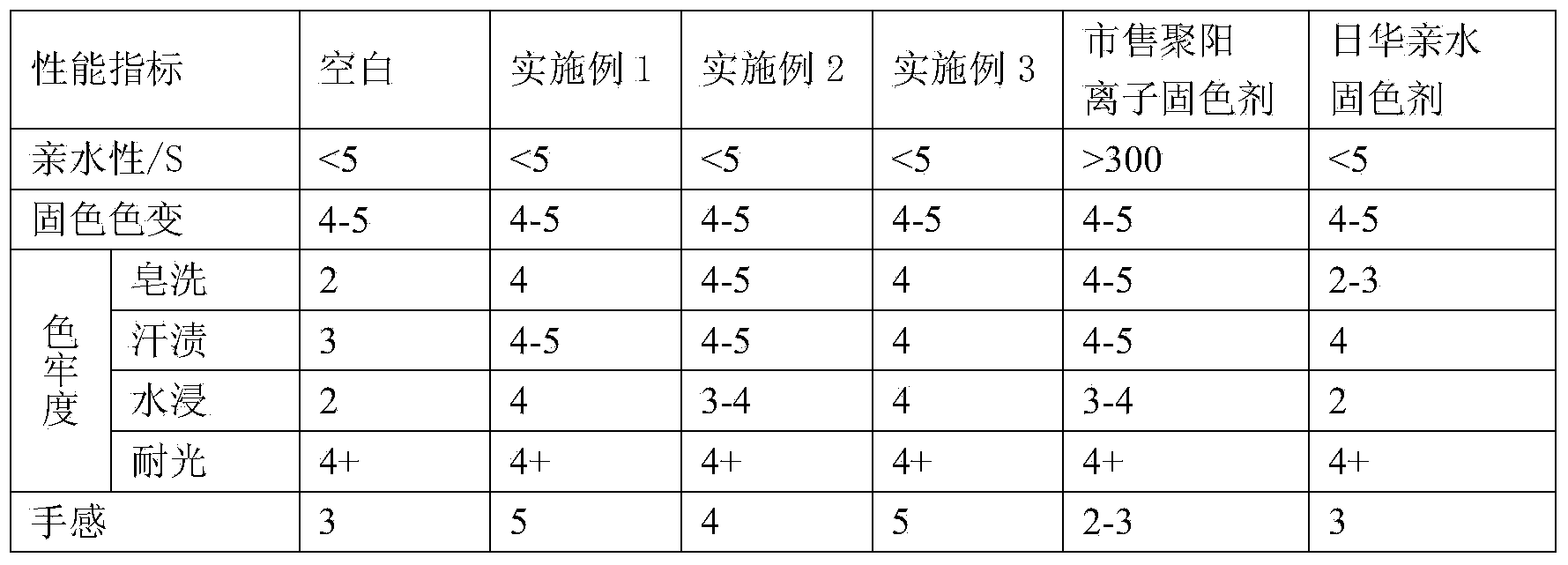

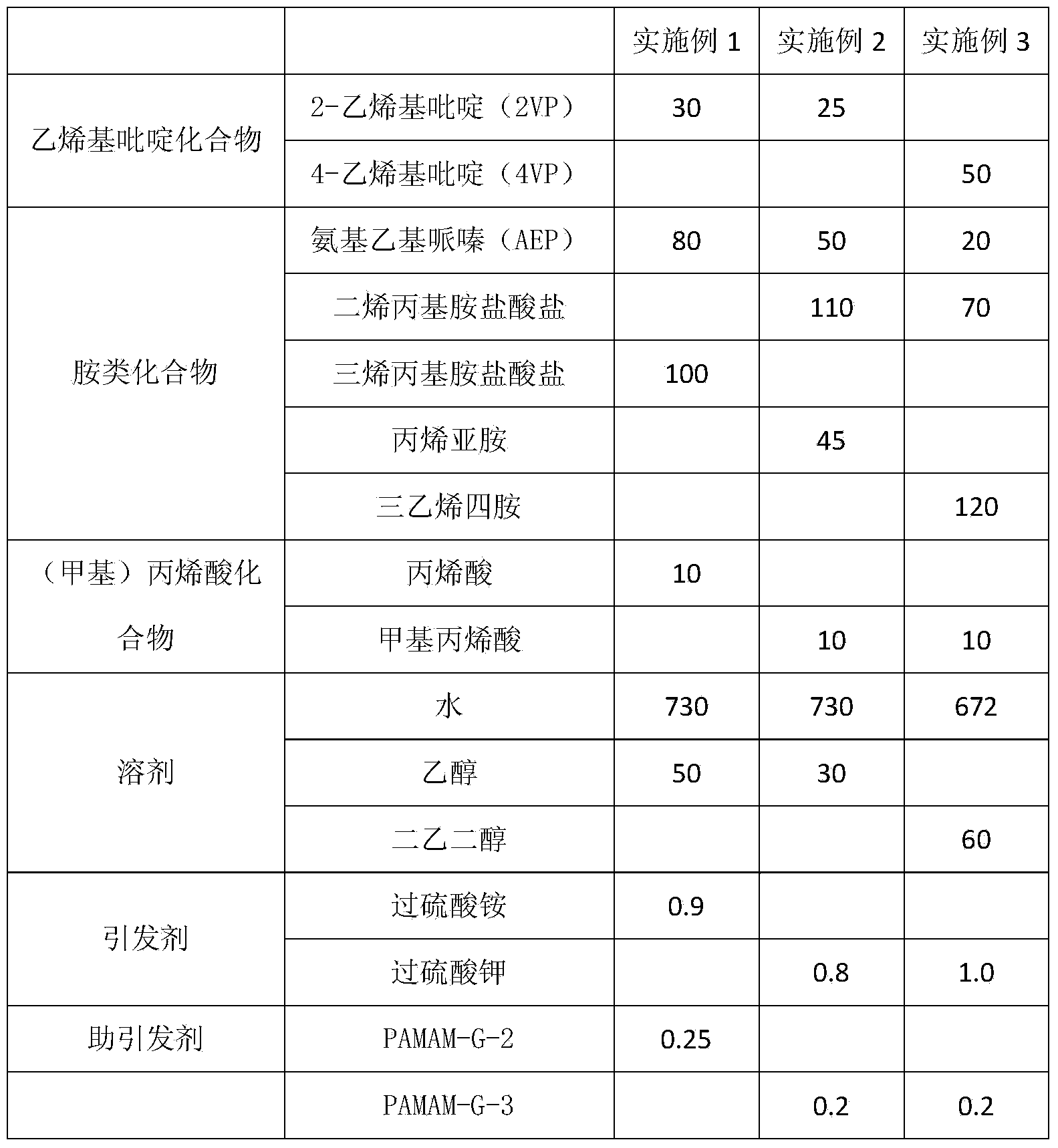

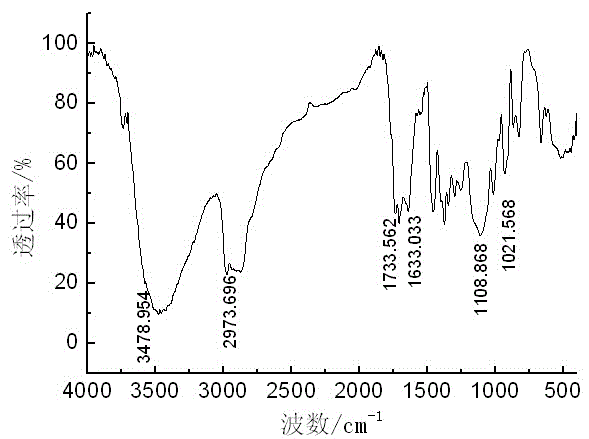

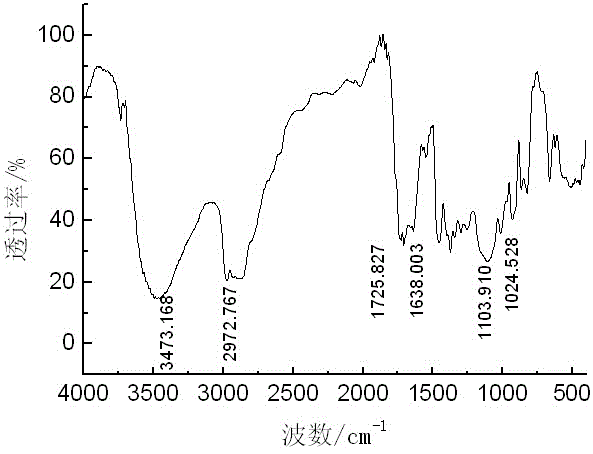

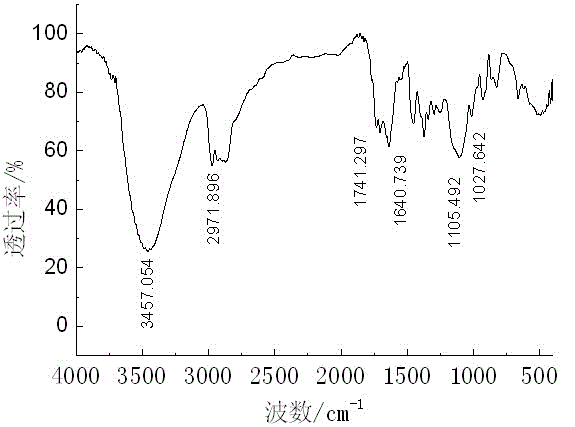

Preparation method for hydrophilic dye-fixing agent for reactive dyeing

ActiveCN104313926ADoes not affect hydrophilicityDoes not affect the feelDyeing processRadical initiatorDyeing

The invention relates to a preparation method for a hydrophilic dye-fixing agent for reactive dyeing. According to the method, vinylpyridine, amine monomers and acrylate monomers have a polymerization reaction when radical initiators and assisting initiators exist, and the hydrophilic dye-fixing agent is obtained. The hydrophilic dye-fixing agent prepared with the method has an excellent dye-fixing effect, meanwhile, the hygroscopicity and the hydrophilia of cotton fabric are not affected, and a good hand feeling is achieved.

Owner:SHANGHAI ARGUS NEW MATERIAL CO LTD

Dyeing and finishing process for modal fabric

InactiveCN104975499AReduce pollutionAvoid damageBiochemical fibre treatmentHeating/cooling textile fabricsInorganic saltsProcess engineering

The invention discloses a dyeing and finishing process for modal fabric. The process comprises the procedures of pretreatment, pre-setting, modification treatment, dyeing, soaping, fixation, after-finishing, drying, sizing, calendering and rolling. According to the invention, pretreatment is carried out by adopting ultrasonic wave, and a step of modification treatment is added; in the dyeing procedure, a base substituent SA is used, use of a large quantity of alkaline substances and inorganic salt is avoided, nature dye is adopted, and colophony powder is added as a fixing agent, so that the color fixing effect is enhanced, environmental pollution is avoided, and the requirement of green environmental protection is met; furthermore, montmorillonoid is adopted to carry out modification treatment and flame retardant treatment on the fabric, so that the flame retardancy of the fabric is high. According to the invention, a yellowing-resisting reagent is used in the procedures of pre-setting, sizing and after-finishing, so that the final fabric cannot become yellow easily.

Owner:TAICANG CHENGLE CHEM FIBER

Method for preparing acrylate printing adhesive

InactiveCN102108110AGood flexibilityImprove wet rubbing fastnessEster polymer adhesivesDyeing processAdhesiveAmmonia

The invention discloses a method for preparing an acrylate printing adhesive, which is prepared by the following steps: (1) weighing a common monomer, a special monomer, an emulsifier, an initiator and deionized water in a mixing ratio; (2) mixing 40 to 60 percent of deionized water weighed in the mixing ratio, 40 to 60 percent of emulsifier weighed in the mixing ratio and 40 to 60 percent of initiator weighed in the mixing ratio to prepare liquid I; (3) mixing the common monomer and the special monomer, which are weighed in the mixing ratio, with 60 to 40 percent of deionized water, 60 to 40 percent of emulsifier and 60 to 40 percent of initiator, stirring and emulsifying to prepared liquid II; (4) dripping the liquid II into the liquid I; (5) after the liquid II is dripped, stirring, keeping temperature for reaction and obtaining an initial product of the acrylate printing adhesive; and (6) dripping ammonia water into the initial product of the acrylate printing adhesive to regulating the pH value of the initial product of the acrylate printing adhesive to 6.5 to 7.5, and filtering to obtain the acrylate printing adhesive product. The adhesive prepared by the method has high performance, and the environmental-protection problem in the synthesis and use processes of the adhesive is solved.

Owner:金华金龙助剂厂

Moisture-absorption and sweat-releasing finishing agent for chinlon, and preparation method thereof

The invention relates to a moisture-absorption and sweat-releasing finishing agent for chinlon, and a preparation method thereof. The finishing agent is non-ionic type polyetheramide copolymer, and the aqueous solution is yellow to deep yellow liquid. The finishing agent has a polyether chain section, so that the finished chinlon textile has excellent moisture absorption and fast drying properties; the molecular structure of the finishing agent comprises an amide chain section formed by adipic acid and hexanediamine, by utilizing the structure similarity principle, the amide chain section in the molecular structure of the finishing agent and the fiber molecular chain of chinlon form co-crystallizing under the high-temperature baking condition and are inlaid on the surface of the fabric, so that the finished chinlon fabric has durable moisture absorption and fast drying properties; the reactive functional group in molecules of the finishing agent can generate crosslinking film forming action in the baking and finishing processes, the moisture absorption and fast drying durability and dry-wet friction fastness of the finished fabric can be further enhanced on the basis of co-crystallizing action. In addition, the hand feeling of the fabric can be favorably improved by the organosilicon chain section in the molecular structure of the finishing agent and the methyl in the polyether chain section.

Owner:SUZHOU UNIV

High-fixation high-flame retardation polyester fabric dyeing and finishing technology

InactiveCN105113286AProcess temperature changeLow processing temperatureFibre typesUltrasonic/sonic fibre treatmentPolyesterFlame resistance

The invention discloses a high-fixation high-flame retardation polyester fabric dyeing and finishing technology. The technology comprises pre-treatment, pre-setting, modification treatment, dyeing, soaping, dye fixation, after finishing, drying, setting, calendering and rolling. Supersonic wave is used for pre-treatment and a modification treatment process is used. In dyeing, a lot of alkaline substances and inorganic salts are avoided, natural dye is adopted and colophony powder is used as a dye-fixing agent so that dye fixation effects are improved, environmental pollution is avoided and environmental protection requirements are satisfied. Through modification and flame retardation treatment on the fabric by montmorillonite, fabric fire resistance is high. Through the dyeing and finishing technology, the high-fixation high-flame retardation polyester fabric is obtained.

Owner:太仓市宝明化纤有限公司

Polyamide fabric modifying, dyeing and finishing process

InactiveCN105019266AProcess temperature changeLow processing temperatureBiochemical fibre treatmentFibre typesPolyamideDyeing

The invention discloses a polyamide fabric modifying, dyeing and finishing process. The process comprises the steps of pretreatment, pre-setting, modification treatment, dyeing, soaping, color fixing, after treatment, drying, setting, calendering and rolling. Helicase and alpha-amylase are adopted for carrying out pretreatment, mixed liquor of nanometer titanium dioxide, gamma-(2, 3-epoxypropoxy) trimethoxypropylsilane and caprolactam is adopted for modifying performance of polyamide fabric fundamentally, and the dye-uptake rate of the fabric is increased; in the dyeing working procedure, a large number of alkaline substances and inorganic salts are not used, a leveling agent and a dispersing agent are added, and dyeing levelness is improved; meanwhile, as rosin powder is added to serve as a color fixing agent, the color fixing effect is enhanced, environmental pollution is avoided, and the requirement for environmental protection is met; moreover, montmorillonite is adopted for carrying out modifying and flame retarding on the fabric, and therefore the fire retarding property of the fabric is high; anti-yellowing reagents are used in the presetting and setting steps, and therefore the final fabric is not prone to yellowing.

Owner:TAICANG CHENGLE CHEM FIBER

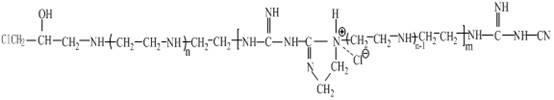

Micro-crosslinking type poly(methacryloxyethyltrimethyl ammonium chloride) modified color fixing agent and preparation method thereof

The invention relates to the technical field of color fixing agents and provides a micro-crosslinking type poly(methacryloxyethyltrimethyl ammonium chloride) modified color fixing agent which is capable of well improving the fastness of the textile to wet rubbing and the color fastness of the textile to washing. The micro-crosslinking type poly(methacryloxyethyltrimethyl ammonium chloride) modified color fixing agent comprises the following raw material components in parts by weight: 50-60 parts of methacryloxyethyltrimethyl ammonium chloride, 0.25-5 parts of epoxy compound, 0.1-2 parts of crosslinking agent, 0.02-0.3 part of initiator and 35-45 parts of deionized water, wherein the methacryloxyethyltrimethyl ammonium chloride is a water solution with a weight percent concentration of 65-98 percent. Meanwhile, the invention provides a preparation method of the micro-crosslinking type poly(methacryloxyethyltrimethyl ammonium chloride) modified color fixing agent.

Owner:FUJIAN QINGYUAN TECH

Efficient dyeing and finishing process for chemical fiber fabric

InactiveCN104975498AImprove hydrophilicityImprove dye uptakeHeating/cooling textile fabricsDry-cleaning apparatus for textilesInorganic saltsFiber

The invention discloses an efficient dyeing and finishing process for a chemical fiber fabric, which comprises the procedures of modification treatment, one-bath scouring dyeing, soaping, fixation, after finishing, drying, sizing, calendering and rolling. According to the invention, pretreatment is carried out by adopting ultrasonic wave; before the procedure of dyeing, the fabric is subjected to low-temperature plasma treatment, and then 2, 3-glycidyl trimethyl ammonium chloride is adopted for carrying out modification treatment on the fiber fabric, so that the degree of dyeing of the fabric is increased, and the difficulty of subsequent dyeing step is lowered; since one-bath scouring dyeing is adopted, the efficiency is increased, and the cost is lowered; in the dyeing procedure, use of a large quantity of alkaline substances and inorganic salt is avoided, nature dye is adopted, and colophony powder is added as a fixing agent, so that the color fixing effect is enhanced, environmental pollution is avoided, and the requirement of green environmental protection is met; furthermore, montmorillonoid is adopted to carry out flame retardant treatment on the fabric, so that the flame retardancy of the fabric is high. According to the invention, a yellowing-resisting reagent is used in the procedure of sizing, so that the final fabric cannot become yellow easily.

Owner:TAICANG TIANLONG CHEM FIBER

Preparing method for room temperature curing non-isocyanate waterborne polyurethane-based macromolecular dye

ActiveCN105219125AImprove water resistanceImprove thermal stabilityOrganic dyesDyeing processMechanical propertyCarbonate

Owner:JIANGNAN UNIV

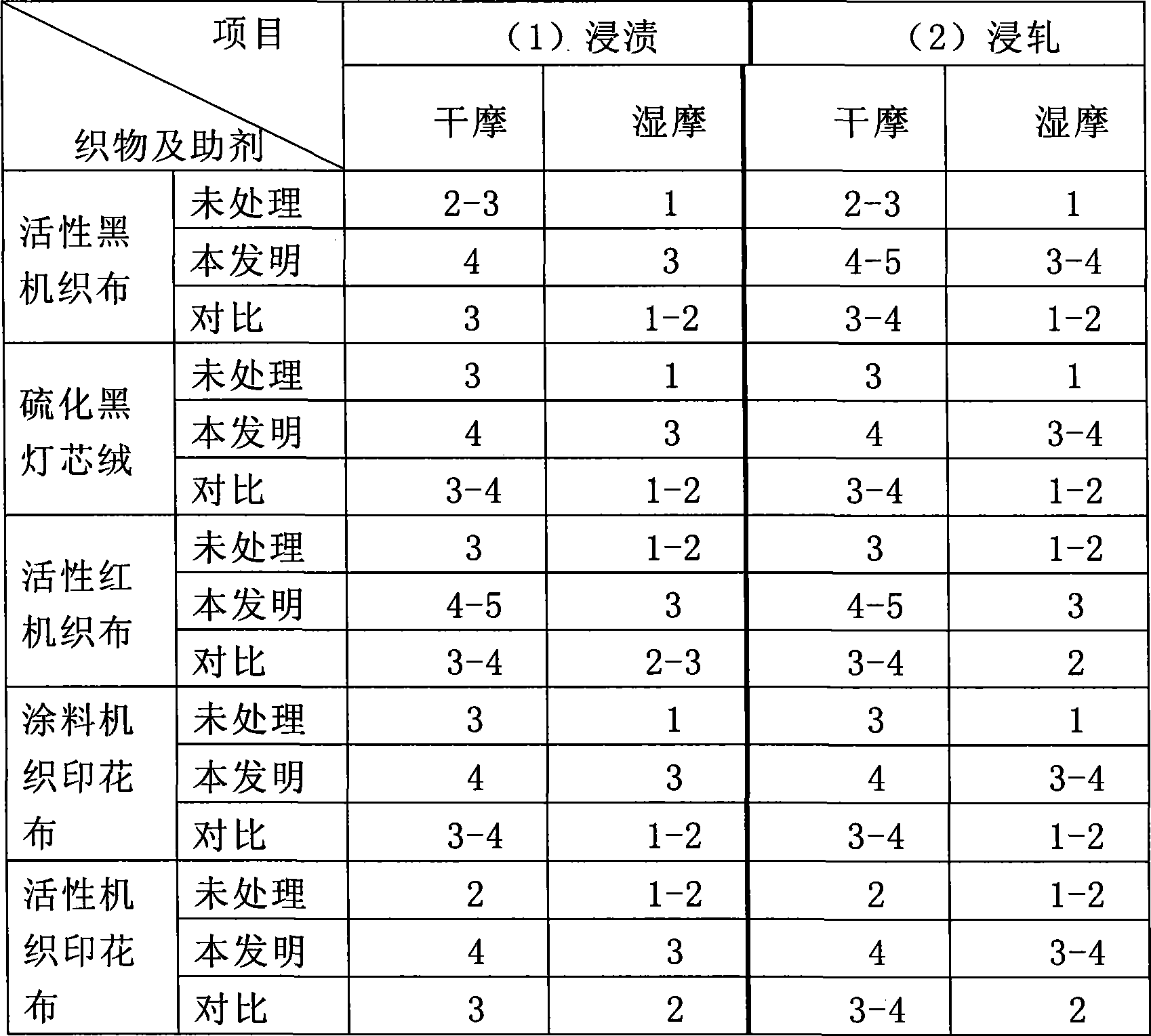

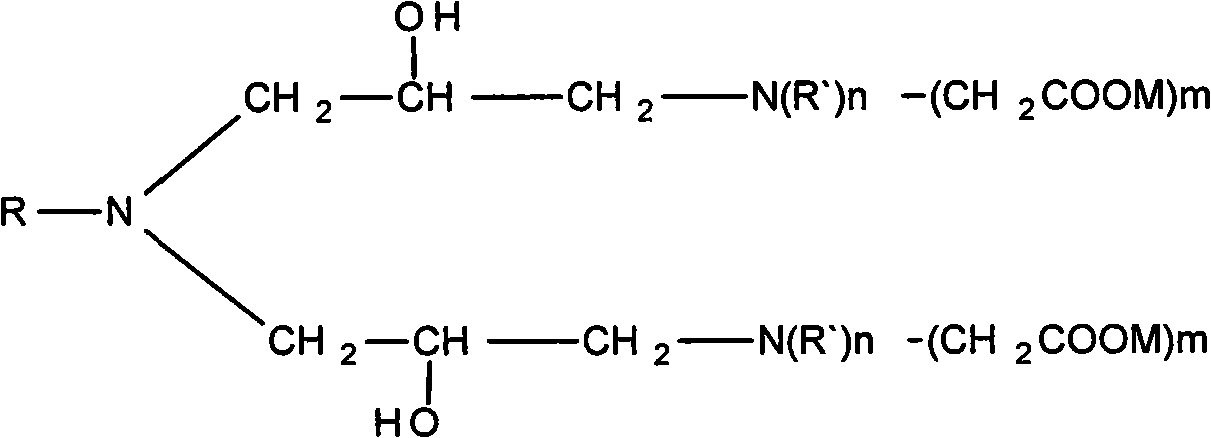

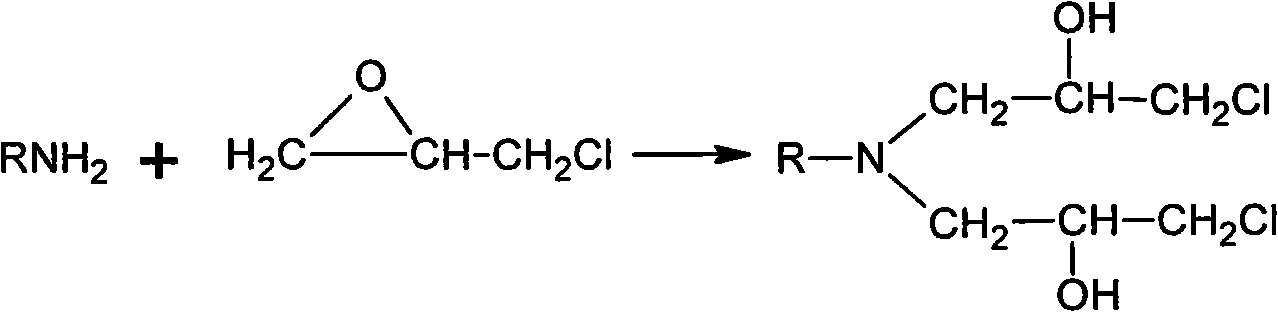

Wet friction fastness improving agent for dyeing fabric

InactiveCN101503860AImprove wet rubbing fastnessShade has no effectFibre treatmentPolypropyleneSilicone oil

The invention relates to an auxiliary agent in the printing and dyeing industry, in particular to a wet rubbing fastness improver for dyed fabric, which is characterized in that the wet rubbing fastness improver is nonionic polymer, of which the main component is polyether compound containing water; the wet rubbing fastness improver is formed by copolymerizing 10 to 30 portions of low-hydro silicone oil, 30 to 60 portions of polyurethane prepolymer and 20 to 40 portions of polypropylene ester copolymer under the conditions of catalyzing and heating; and the portion is weight portion. The wet rubbing fastness improver can improve the wet rubbing fastness of the fabric dyed by direct, active, acid and other dyes by 2 to 3 level to reach above 3 level, has no influence on the tone of the dyed fabric basically, does not influence the light fastness and chlorine fastness, and improves the perspiration-light fastness.

Owner:上海德桑精细化工有限公司

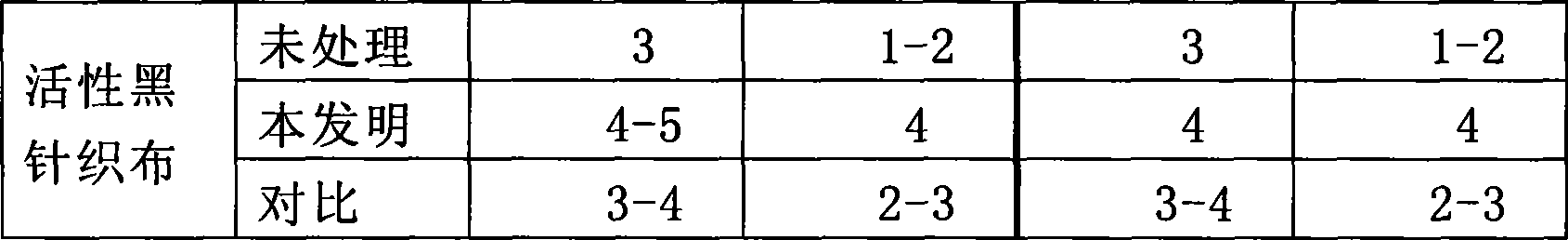

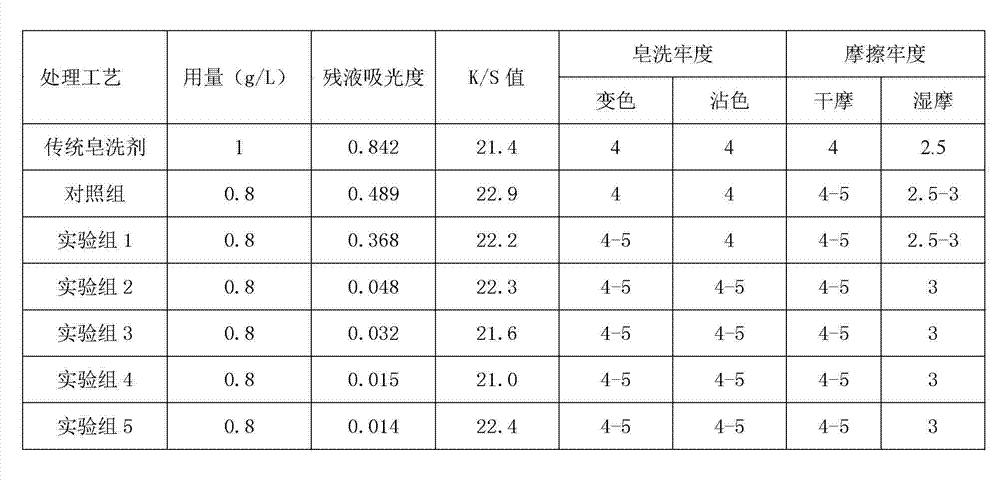

Soaping compound enzyme and application method thereof

ActiveCN102899195AImprove soaping effectLow absorbanceBiochemical fibre treatmentOrganic non-surface-active detergent compositionsTrisodium citrateChemistry

The invention relates to soaping compound enzyme and an application method thereof. The soaping compound enzyme comprises laccase, persulfate and PVP (polyvinylpyrrolidone), and sodium citrate is also added in the soaping compound enzyme. The soaping compound enzyme comprises the following compositions in percentage by mass: 55-80 of the laccase, 15-30 % of the persulfate, 4-10 % of the PVP, and 1-5 % of the sodium citrate. In the soaping compound enzyme disclosed in the invention, cooperative anxoaction can be generated between the sodium citrate and the laccase as well as between the persulfate and the PVP, and thus the whole soaping effect of the soaping compound enzyme is greatly increased. Compared with the traditional soaping technology, according to the soaping compound enzyme disclosed by the invention, the absorbance of raffinate after soaping is obviously reduced, the clarity is increased, and thus the treating difficulty of sewage is reduced; the fastness to wet rubbing of a cloth sample after soaping in increased by 0.5-1 level, and the soaping fastness is increased by 0.5 level; and three washing procedures are saved, 30% of the water consumption is saved, 30% of the procedure time is saved, the production cost is greatly reduced, and the environment pollution is reduced.

Owner:QINGDAO VLAND BIOTECH GRP

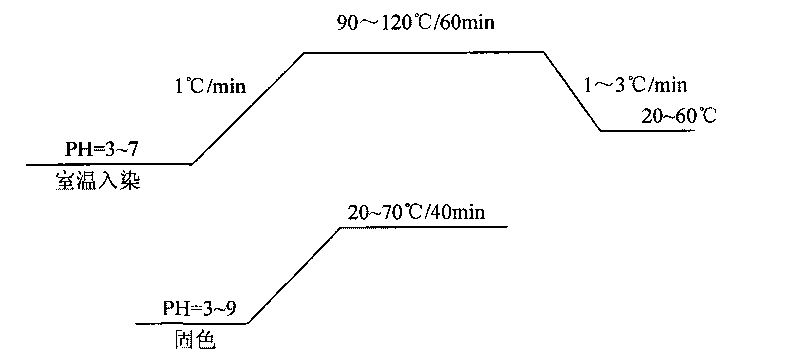

Reactive dyes dyeing method of beam shaped superfine fiber PU synthetic leather

The invention relates to a reactive dyes dyeing method of a beam shaped superfine fiber PU synthetic leather, which is realized through the following technical proposals: in the proportion of 2 percent to 5 percent (owf), at the bath ratio of 1 : 15 to 30, the PH valve is 3 to 7, wool reactive dyes A is heated to 90 to 120 Degrees Celsius from the room temperature at the speed of 0.3-2Degrees Celsius / min, then the temperature is preserved 10 to 70 min, then the temperature is decreased to 20 to 60 Degrees Celsius at the speed of 1 to 3 Degrees Celsius / min. Then the PH valve is adjusted to 3 to 9 and the color is fixed for 20 to 60 min at the temperature of 20 to 70 Degrees Celsius, at last the beam shaped superfine fiber PU synthetic leather is dyed. The invention has the beneficial effects: compared with the traditional dyeing method which uses acid dyes and neutral dyes, the dyeing depth, the color uniformity as well as the dry rubbing fastness of the wool reactive dyes dyeing of the beam shaped superfine fiber PU synthetic leather are almost the same, the wet rubbing fastness is higher about 1 to 2 grades, the dyeing waste water does not contain heavy metal ions, thereby the invention is environment-friendly.

Owner:HUAFON MICROFIBER SHANGHAI

Fabric fixative

The invention discloses a fabric fixative which is prepared from the following raw materials in parts by mass: 20-25 parts of acrylate, 30-35 parts of acetic acid, 20-25 parts of epoxy chloropropane, 2-3 parts of sodium silicate, 5-10 parts of fatty alcohol polyethenoxy ether, 20-25 parts of ethanol, 5-10 parts of hydroxypropyltrimethylammonium chloride chitosan, 10-15 parts of deionized water and 3-5 parts of octadecyldimethyl amine. The fabric fixative has excellent color fixation effect, and can effectively enhance the color fastness of the fabric dye and fastness to wet rubbing in the printing and dyeing process; and the treated fabric can not generate discoloration.

Owner:桑达化工(南通)有限公司

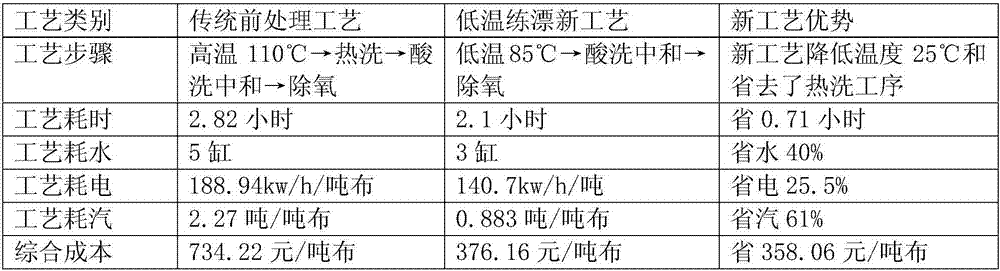

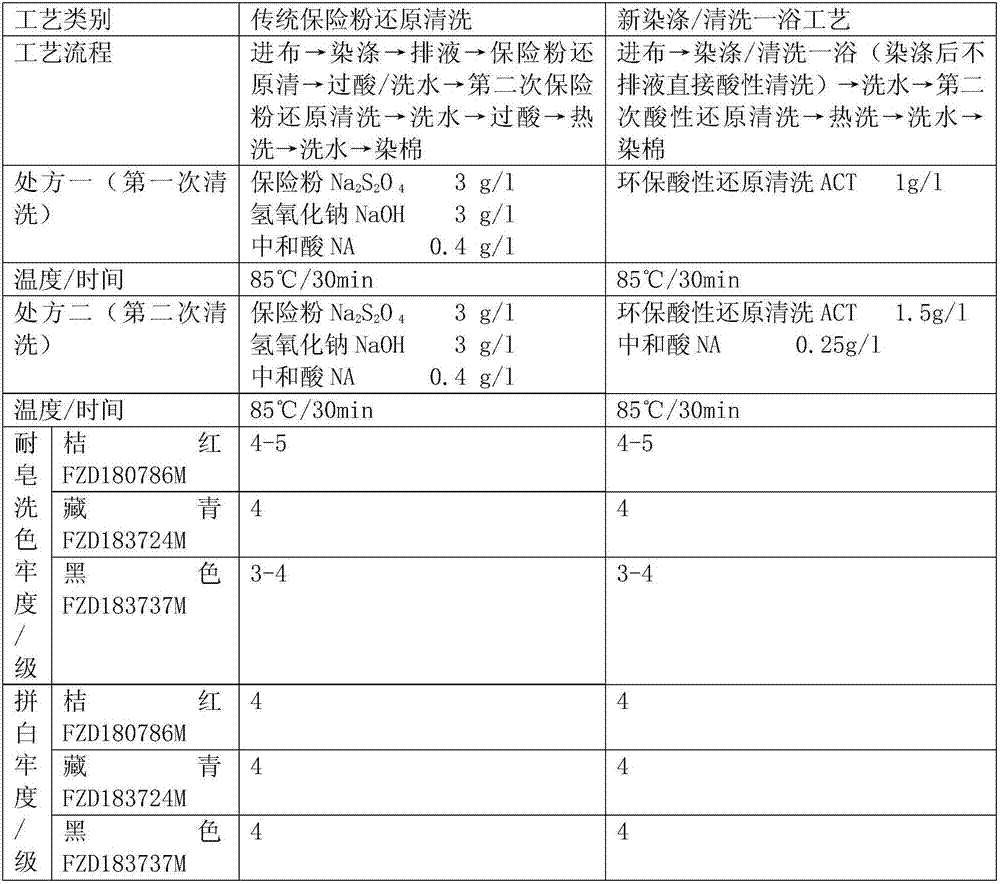

School uniform fabric production technology

InactiveCN106868894AReduce consumptionReduce pollutionDry-cleaning apparatus for textilesGrip property fibresWoolPolyester

The invention discloses a school uniform fabric production technology. The technology comprises pretreatment, polyester dyeing, first reduction cleaning, drainage, hot washing, water washing, second reduction cleaning, hot washing, cotton dyeing, fixation, softening, scutching wool washing machine-based water washing, drying, setting, detection, final inspection, and packaging / warehousing. A low temperature scouring and bleaching agent TF-189 is used, a treatment temperature is reduced by 25 DEG C from a high temperature 110 DEG C to a low temperature of 85 DEG C, a hot washing process is avoided, after treatment, whiteness, hair effects and dyeing effects are similar to those of the traditional oxygen bleaching process, energy consumption is reduced, polyester dying and reduction cleaning processes are combined because of the complementarity, the traditional sodium hydrosulfite alkaline reduction cleaning method is replaced by the technology provided by the invention, sodium hydrosulfite-caused pollution and damage are reduced, environmental friendliness is realized and energy saving and emission reduction effects are obtained.

Owner:FUJIAN FYNEX TEXTILE SCI & TECH

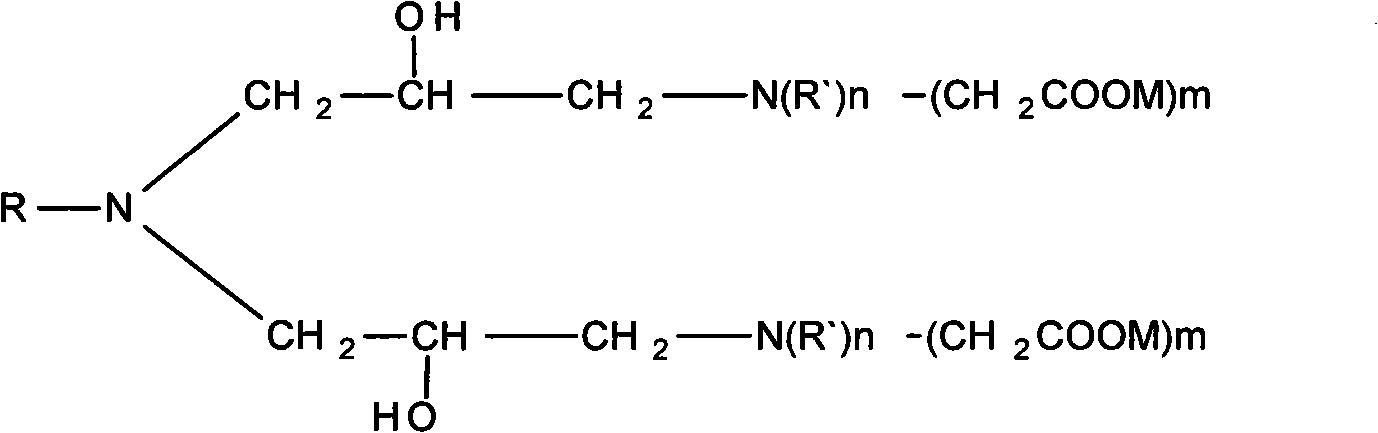

Leveling and deepening fixing agent and preparation method thereof

The invention discloses a leveling and deepening fixing agent and a preparation method thereof. The leather leveling and deepening fixing agent is a dyeing assistant with the functions of leveling, deepening and fixing colors, and an assistant molecule comprises the groups of -NR2, -NH2, -NHR, -COONa, and the like and is a compound with an amphoteric structure. Under an alkaline condition, the molecule carries negative charge and has a leveling function for dyeing acid dye, the auxochromic groups of -NR2, -NH2, -NHR, and the like on the assistant molecule act on the dye to deepen the color andplay a deepening function. Under an acidic condition, the groups of -NR2, -NH2, -NHR, and the like have positive charge and play a fixing function for the acid dye. The assistant is a multifunctionalproduct, can play the functions of leveling, deepening and fixing colors for dying leather and can simplify a leather preparing technology.

Owner:WENZHOU UNIVERSITY

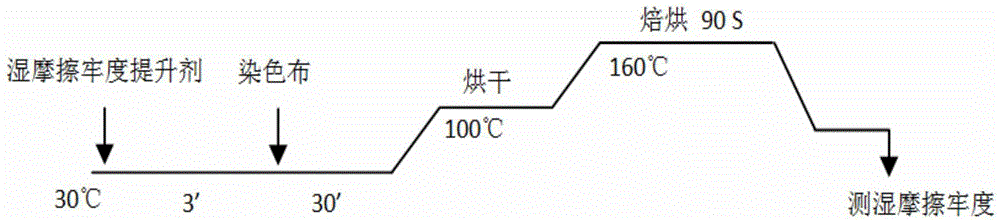

Method for increasing wet rubbing fastness of etched or sanded dark fabric

InactiveCN104611957AImprove high temperature resistanceImprove stabilityFibre treatmentDyeing processRubbingMaterials science

The invention relates to a method for increasing wet rubbing fastness of an etched or sanded dark fabric. The method comprises steps as follows: a finishing liquid is prepared and then heated to 30 DEG C, the etched or sanded dark fabric is added, the bath ratio is 1:(7-10), vibration heat-insulation finishing is performed for 20-30 min, and drying and baking are performed. The method is simple and convenient to operate, equipment is not required to be added, and the cost is controllable.

Owner:DONGHUA UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com