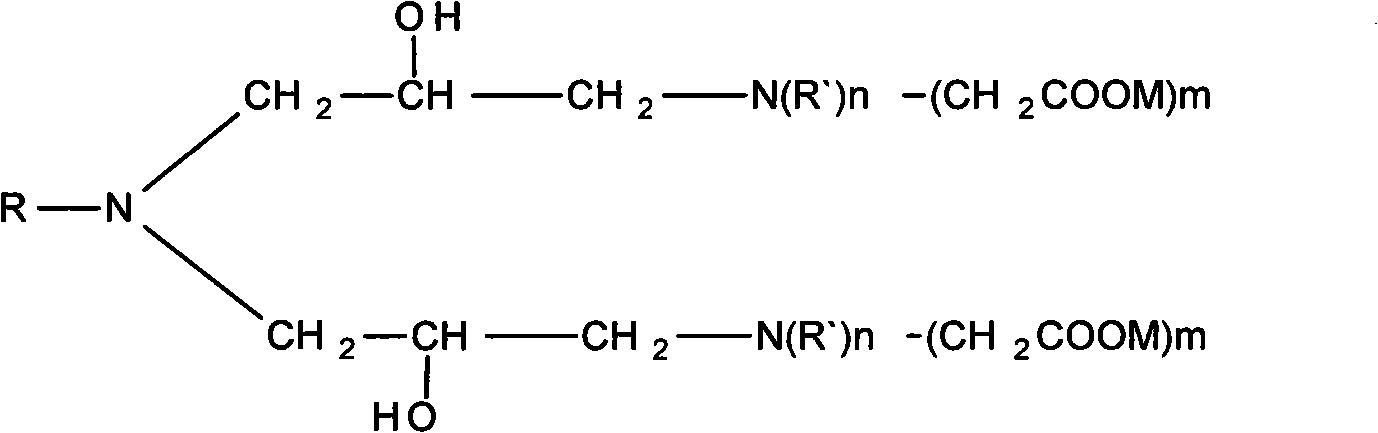

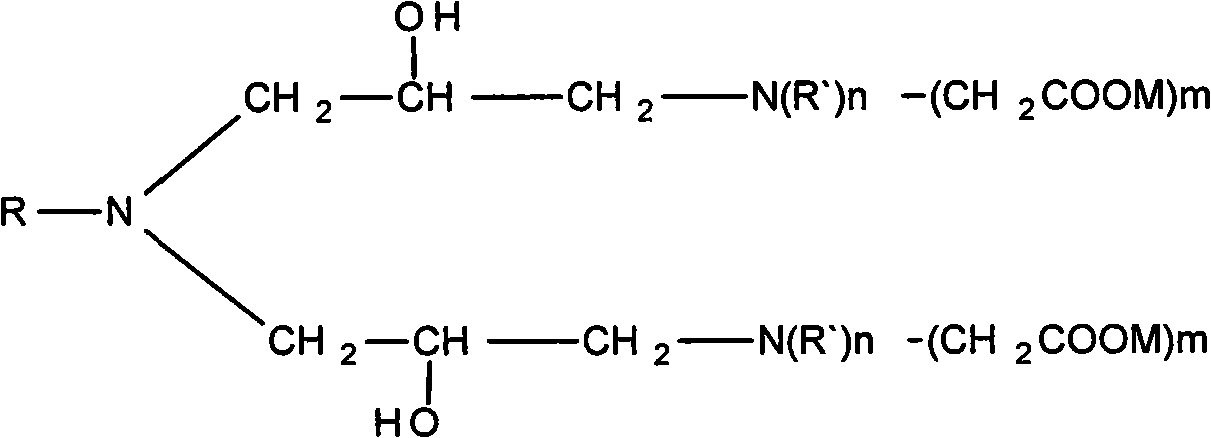

Leveling and deepening fixing agent and preparation method thereof

A color-fixing agent and organic solvent technology, which is applied in the field of dyeing and darkening color-fixing agent and its preparation in leather dyeing and fatliquoring process. Low tension and good wetting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

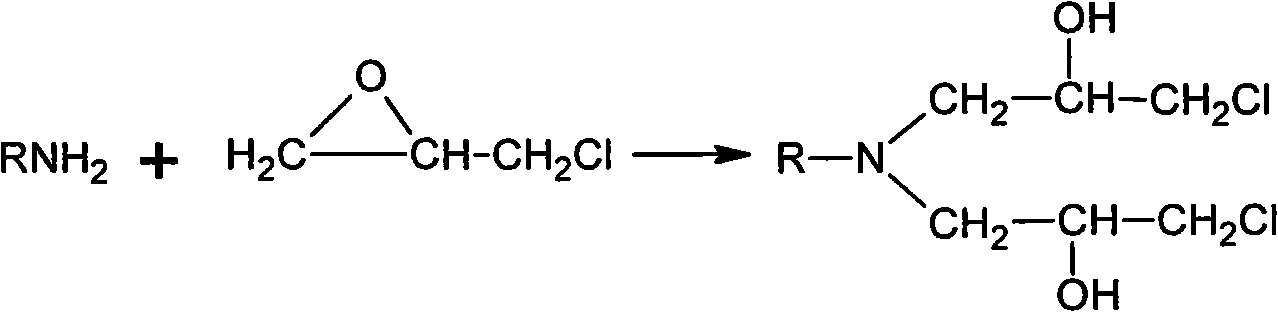

Embodiment 1

[0037] Add 18.5g of dodecylamine and 30g of absolute ethanol into a dry four-necked glass flask equipped with a stirrer and a condenser, raise the temperature to 30°C, wait for the dodecylamine to melt, and after stirring evenly, slowly add epichlorohydrin dropwise. 18.5g, and then heat preservation reaction for 12h to obtain intermediate I. The temperature of the reaction system was raised to 60°C, 12.2 g of ethanolamine was added dropwise, and then the temperature was raised to 80°C, and the intermediate II was obtained by reacting for 6 hours. Cool the reaction system to 60°C, add 60g of chloroacetic acid aqueous solution (20g of chloroacetic acid + 40g of water) dropwise, and then add dropwise of 48g of sodium hydroxide aqueous solution (16g of sodium hydroxide + 32g of water), and raise the temperature to 80°C after the dropwise addition , Reaction 4h. After the reaction, the temperature was lowered to 60° C., and 96.8 g of water was added to adjust the active substance ...

Embodiment 2

[0039] Add 9.25g of dodecylamine, 13.5g of octadecylamine and 40g of absolute ethanol into a dry four-necked glass flask equipped with a stirrer and a condenser, raise the temperature to 55°C, wait until the long-chain fatty amine is melted, stir evenly, slowly Add 18.5 g of epichlorohydrin °C dropwise, and then keep warm for 6 hours to obtain intermediate I. The temperature of the reaction system was raised to 60°C, 12.2 g of ethanolamine was added dropwise, and then the temperature was raised to 80°C, and the intermediate II was obtained by reacting for 6 hours. Cool the reaction system to 60°C, add 60g of chloroacetic acid aqueous solution (20g of chloroacetic acid + 40g of water) dropwise, and then add dropwise of 48g of sodium hydroxide aqueous solution (16g of sodium hydroxide + 32g of water), and raise the temperature to 80°C after the dropwise addition , Reaction 4h. After the reaction, the temperature was lowered to 60° C., and 96.0 g of water was added to adjust the...

Embodiment 3

[0041] Add 18.5g of dodecylamine and 35g of absolute ethanol into a dry four-necked glass flask equipped with a stirrer and a condenser, raise the temperature to 30°C, wait for the long-chain fatty amine to melt, and after stirring evenly, slowly add epichlorohydrin dropwise ℃ 19.5g, and then keep warm for 12h to obtain intermediate I. The temperature of the reaction system was raised to 60°C, 6.51 g of monomethylamine was added dropwise, and then the temperature was raised to 70°C, and the reaction was carried out for 8 hours to obtain intermediate II. Cool the reaction system to 60°C, add 59.8g of chloroacetic acid aqueous solution (19.8g of chloroacetic acid + 40g of water) dropwise, and then add 46.8g of sodium hydroxide aqueous solution (16.8g of sodium hydroxide + 30g of water) dropwise. Raise the temperature to 80°C and react for 4h. After the reaction, the temperature was lowered to 60° C., and 38.7 g of water was added to adjust the active substance content to 30%, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com