Method for increasing wet rubbing fastness of etched or sanded dark fabric

A wet rubbing fastness and sanding technology, applied in the finishing field of etched or sanded fabrics, can solve the problems of increased amount of floating fibers, decreased wet rubbing fastness, low rubbing fastness, etc., and achieves good high temperature resistance and dilution Stability, improved wet rubbing fastness, cost controllable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

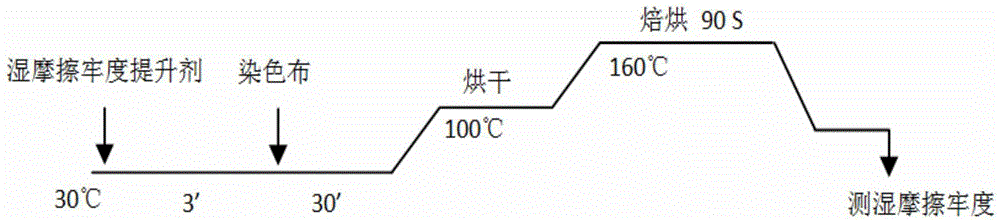

Embodiment 1

[0041] Prepare a finishing solution (the dosage of self-made wet rubbing fastness improving agent is 6% owf, pH value 6.5), heat up to 30°C and keep shaking for 3 minutes, then add black wool-etched knitted cotton-spandex cloth sample (bath ratio 1:10), shake and keep warm Finish for 30 minutes, dry (100°C), bake (160°C, 90S), and test performance (results are shown in Table 1).

[0042] Table 1

[0043] Wet rubbing fastness enhancer concentration %owf 6 Dry rubbing fastness (grade) 4-5 Wet rubbing fastness (grade) 3-4

[0044] (The dry and wet rubbing fastness of the original cloth are grade 3 and grade 2 respectively)

Embodiment 2

[0046] Prepare a finishing solution (the amount of self-made wet rubbing fastness is 8% owf, pH value 7), heat up to 30°C, heat up to 30°C and shake for 3 minutes, then add black brushed knitted cotton-spandex cloth sample (bath ratio 1:10), Shake and keep warm for 30 minutes, dry (100°C), bake (160°C, 90S), and test performance (results are shown in Table 2).

[0047] Table 2

[0048] Wet rubbing fastness enhancer concentration %owf 8 Dry rubbing fastness (grade) 5 Wet rubbing fastness (grade) 4

[0049] (The dry and wet rubbing fastness of the original cloth are grade 3 and grade 1-2 respectively)

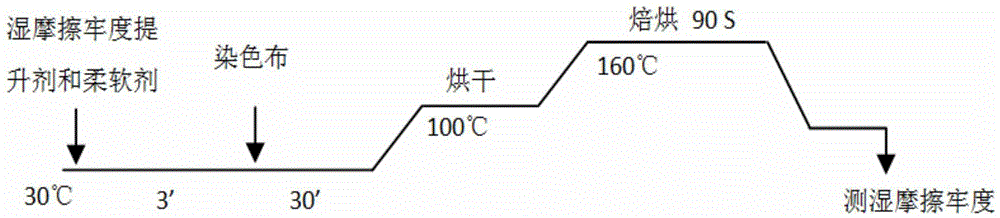

Embodiment 3

[0051] Prepare a finishing solution (self-made wet rubbing fastness of 8% owf, softener dosage of 0.5% owf, pH value 6.5), heat up to 30°C and keep warm and shake for 3 minutes, then add black wool-etched knitted cotton-spandex cloth sample (bath Ratio 1:10), shaking and heat preservation for 30 minutes, drying (100°C), baking (160°C, 90S), test performance (results are shown in Table 3)

[0052] table 3

[0053] Softener concentration %owf 0.5 Dry rubbing fastness (grade) 4-5 Wet rubbing fastness (grade) 4

[0054] (The dry and wet rubbing fastness of the original cloth are grade 3 and grade 2 respectively)

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com