Patents

Literature

208 results about "Procedure time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

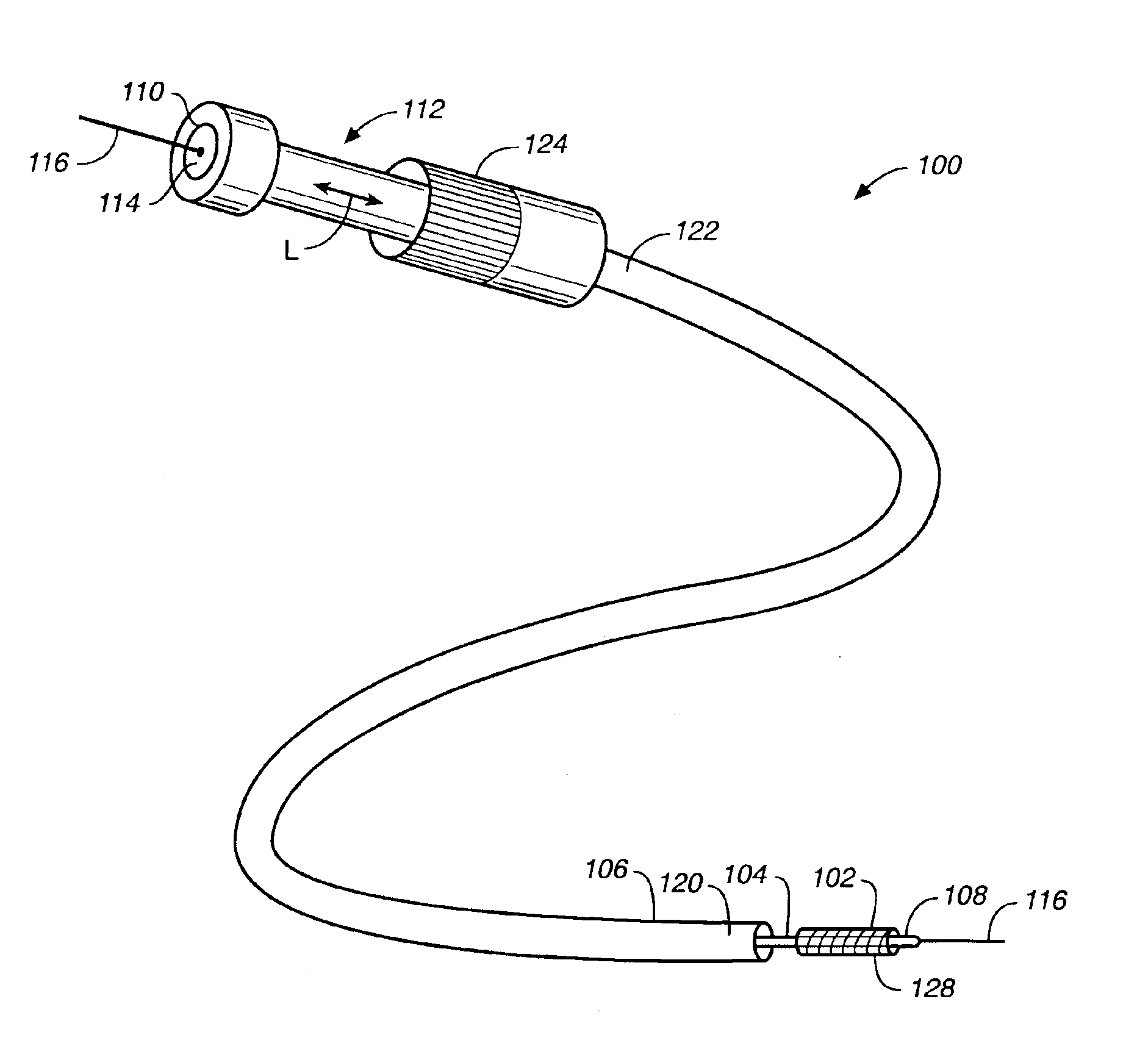

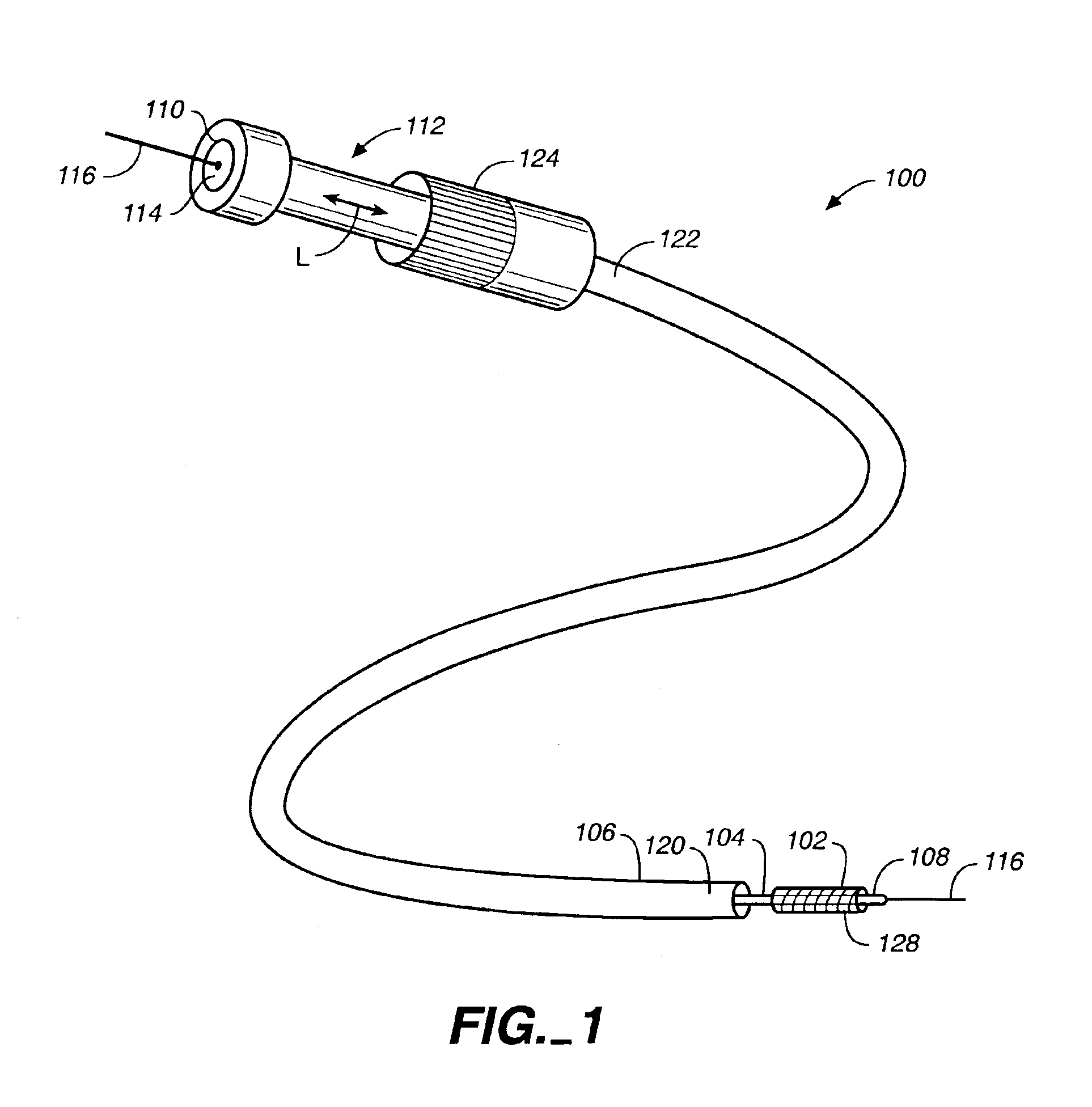

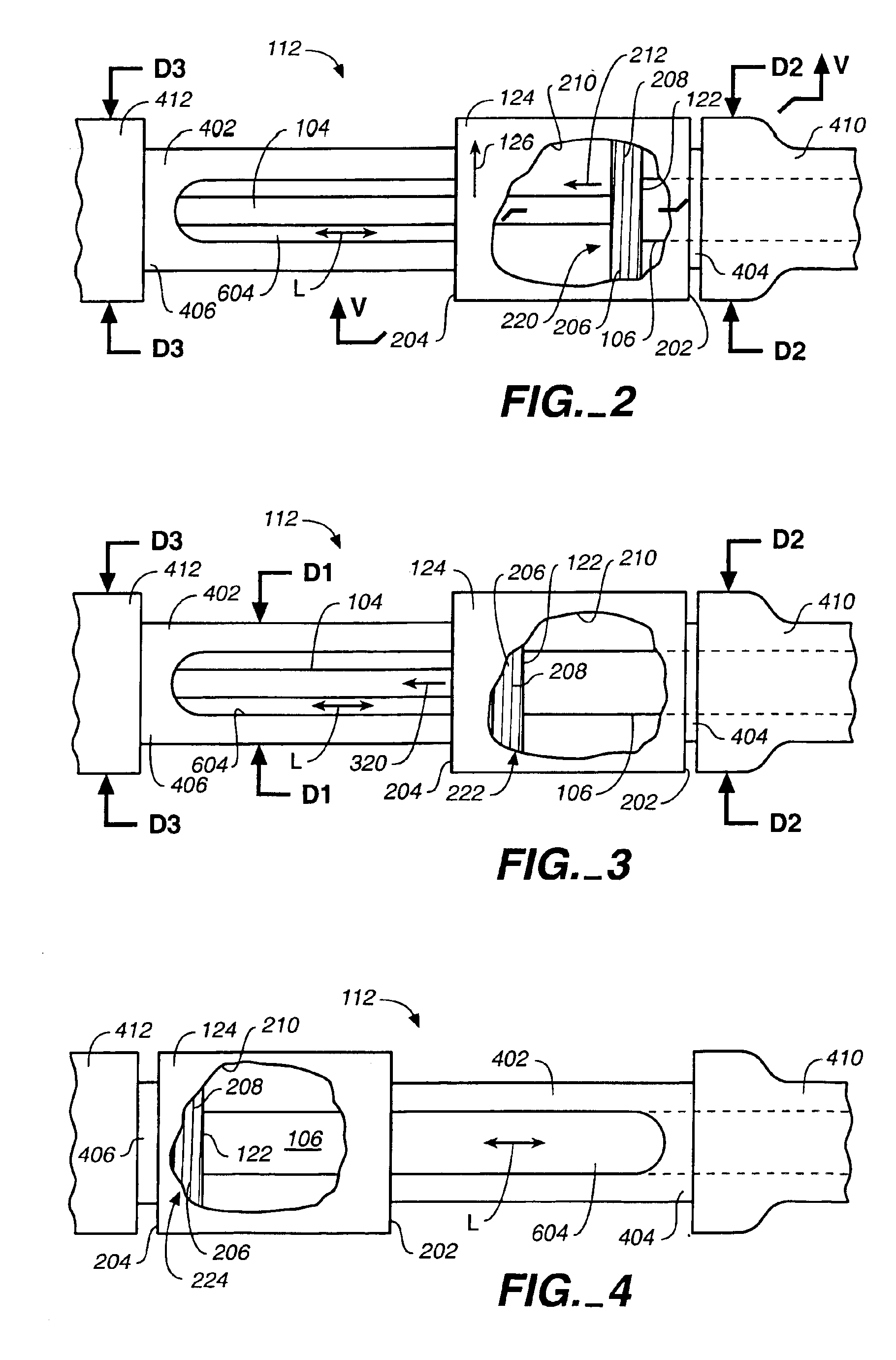

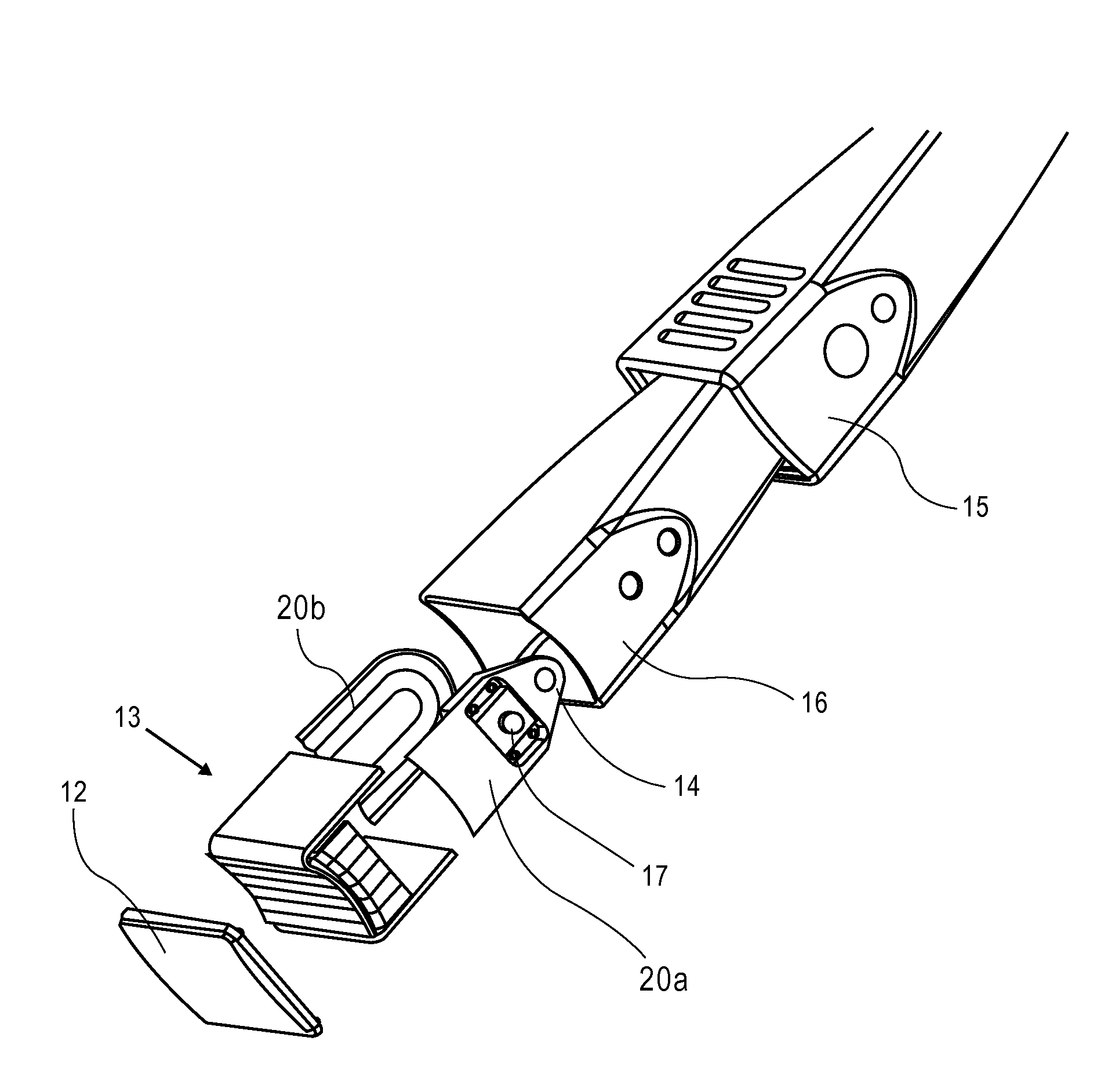

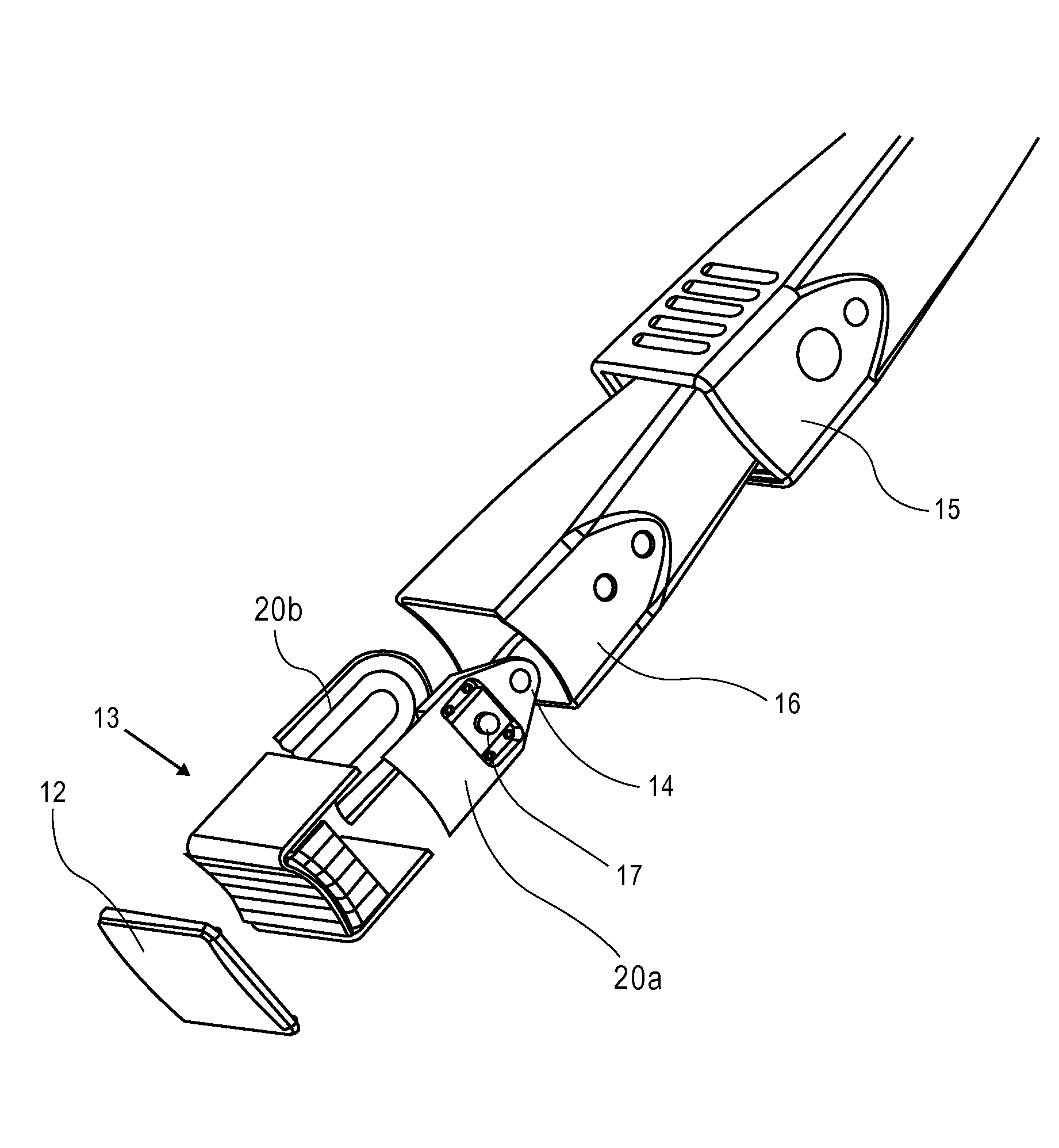

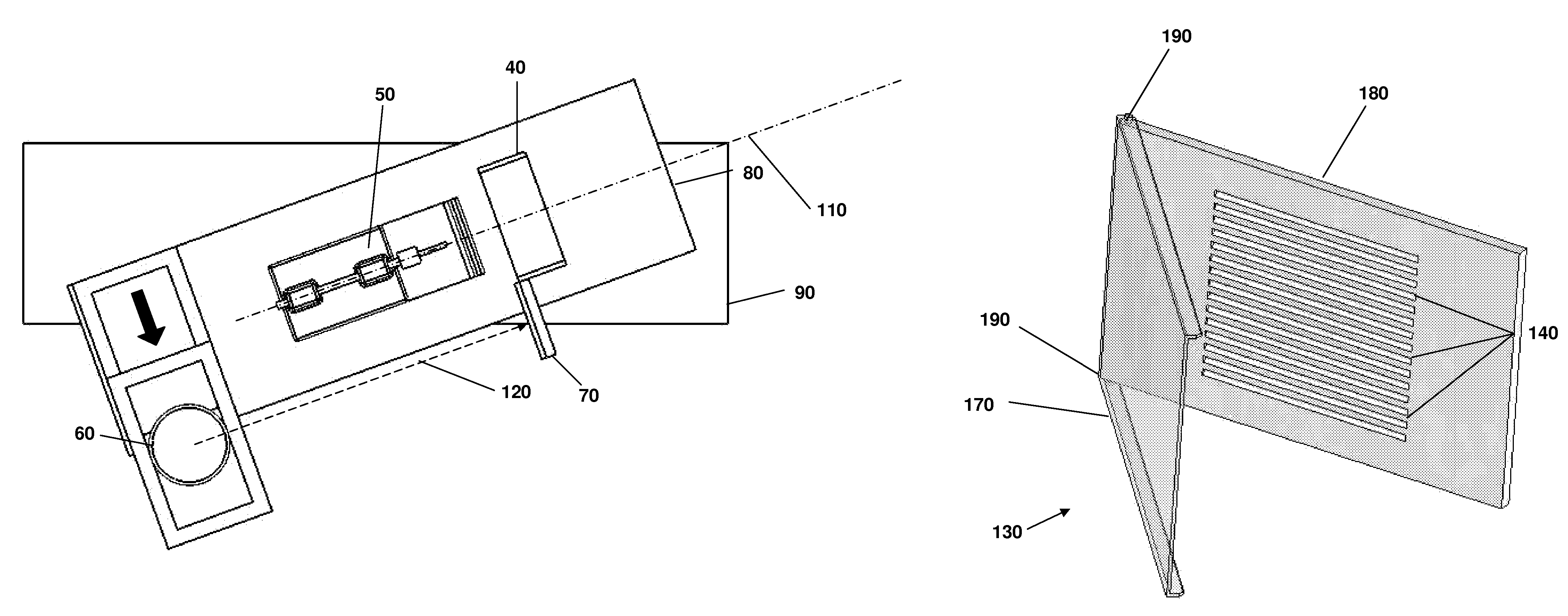

Integrated mechanical handle with quick slide mechanism

A method of deploying a prosthesis includes restraining the prosthesis within a distal end of a sheath. A slide ring of a handle is rotated to initiate retraction of the sheath. In this manner, the prosthesis is initially very gradually released. The slide ring is then slid to complete retraction of the sheath and to deploy the prosthesis. In this manner, the sheath is easily and quickly retracted thus rapidly completing deployment of the prosthesis. Rapid deployment of the prosthesis facilitates faster procedure times, thus minimizing the period of time during which blood flow is occluded.

Owner:MEDTRONIC VASCULAR INC

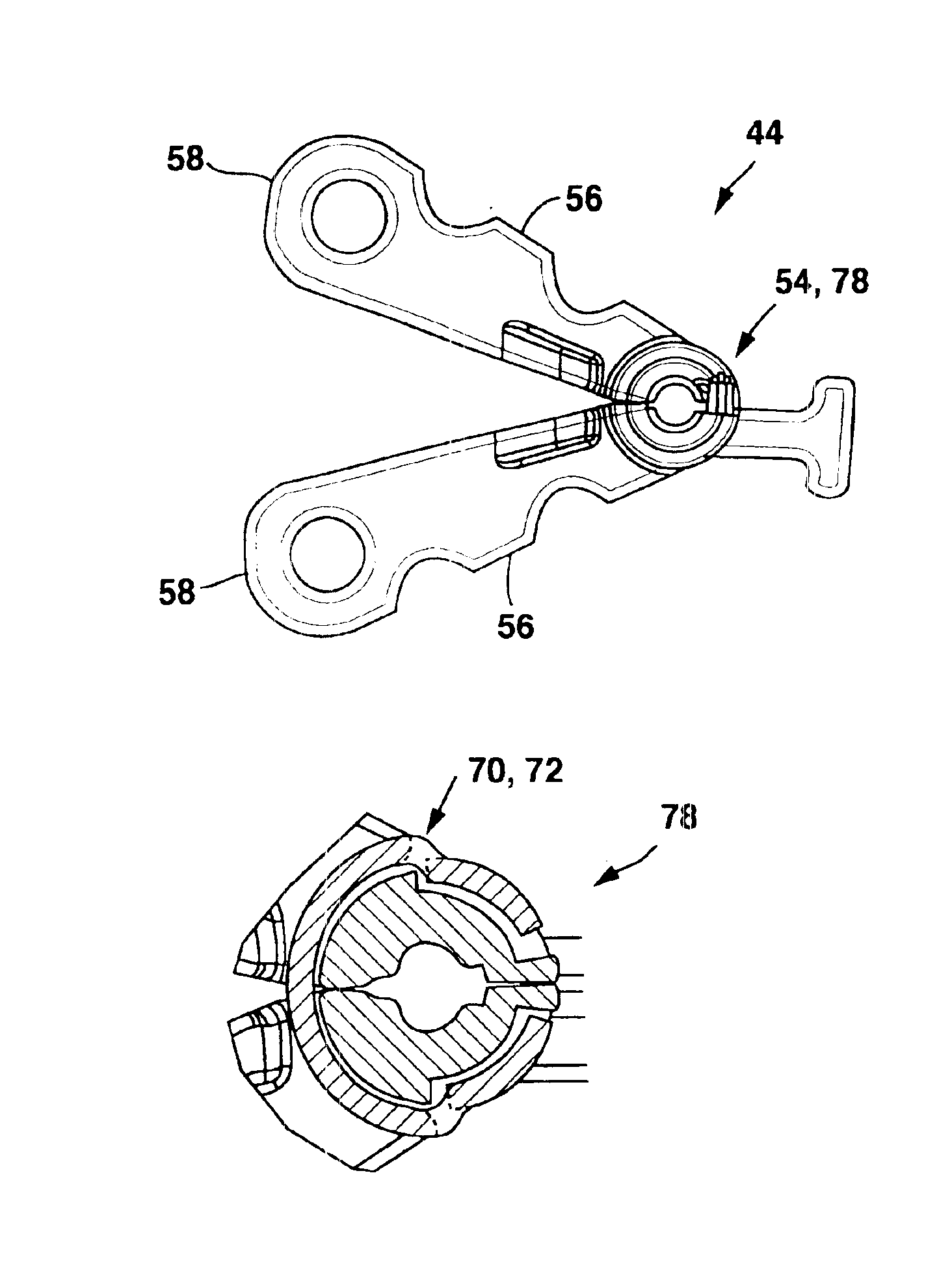

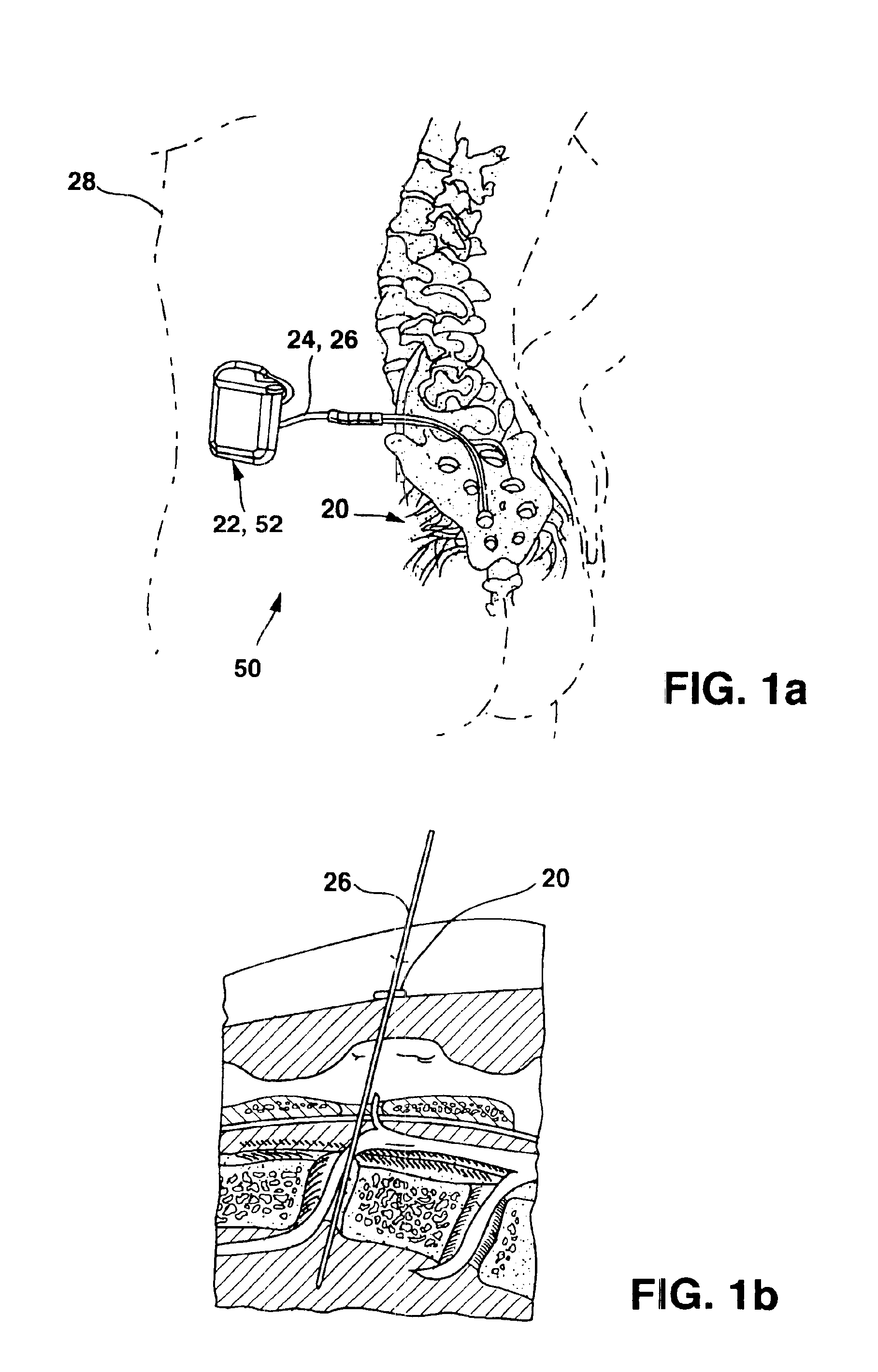

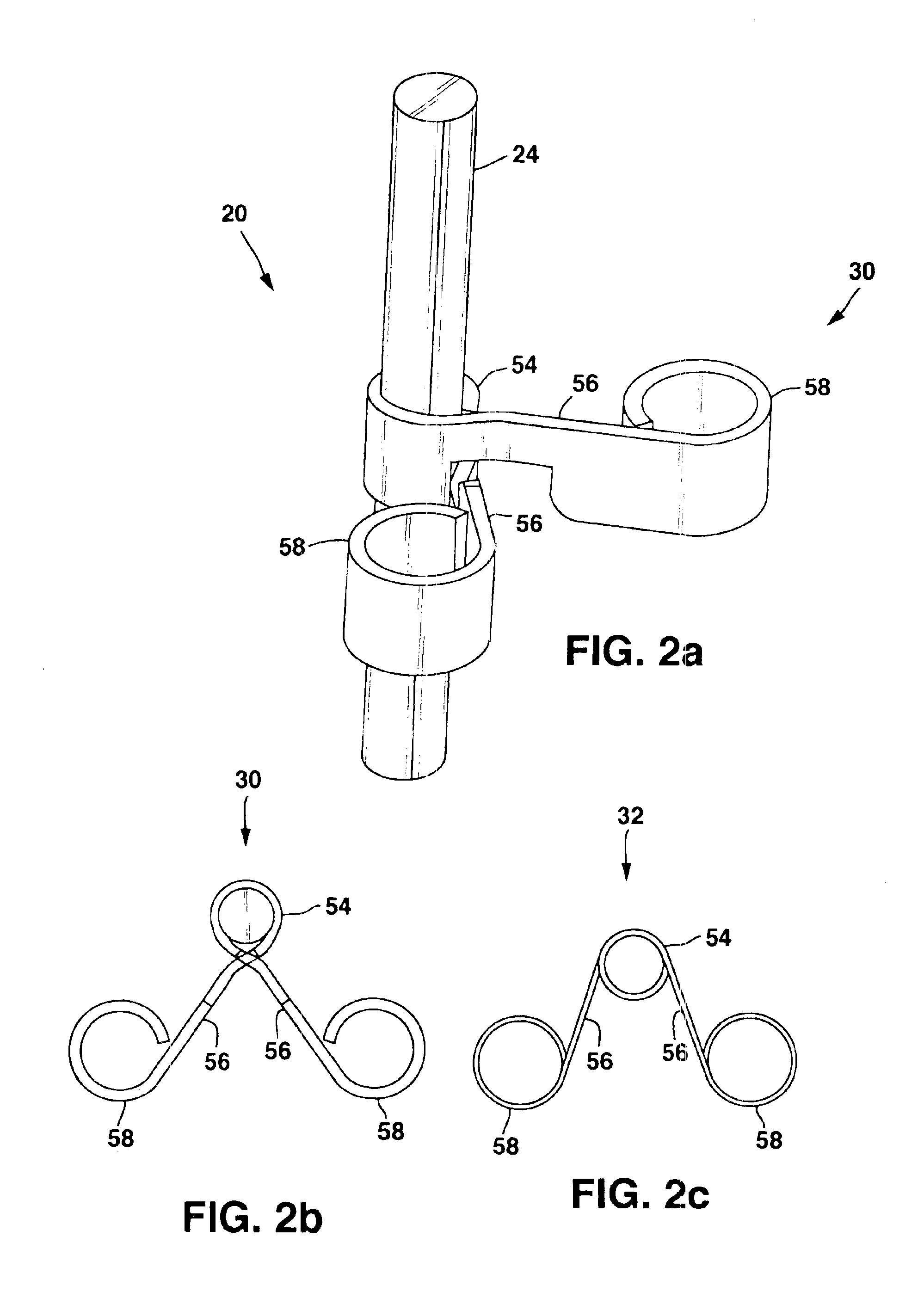

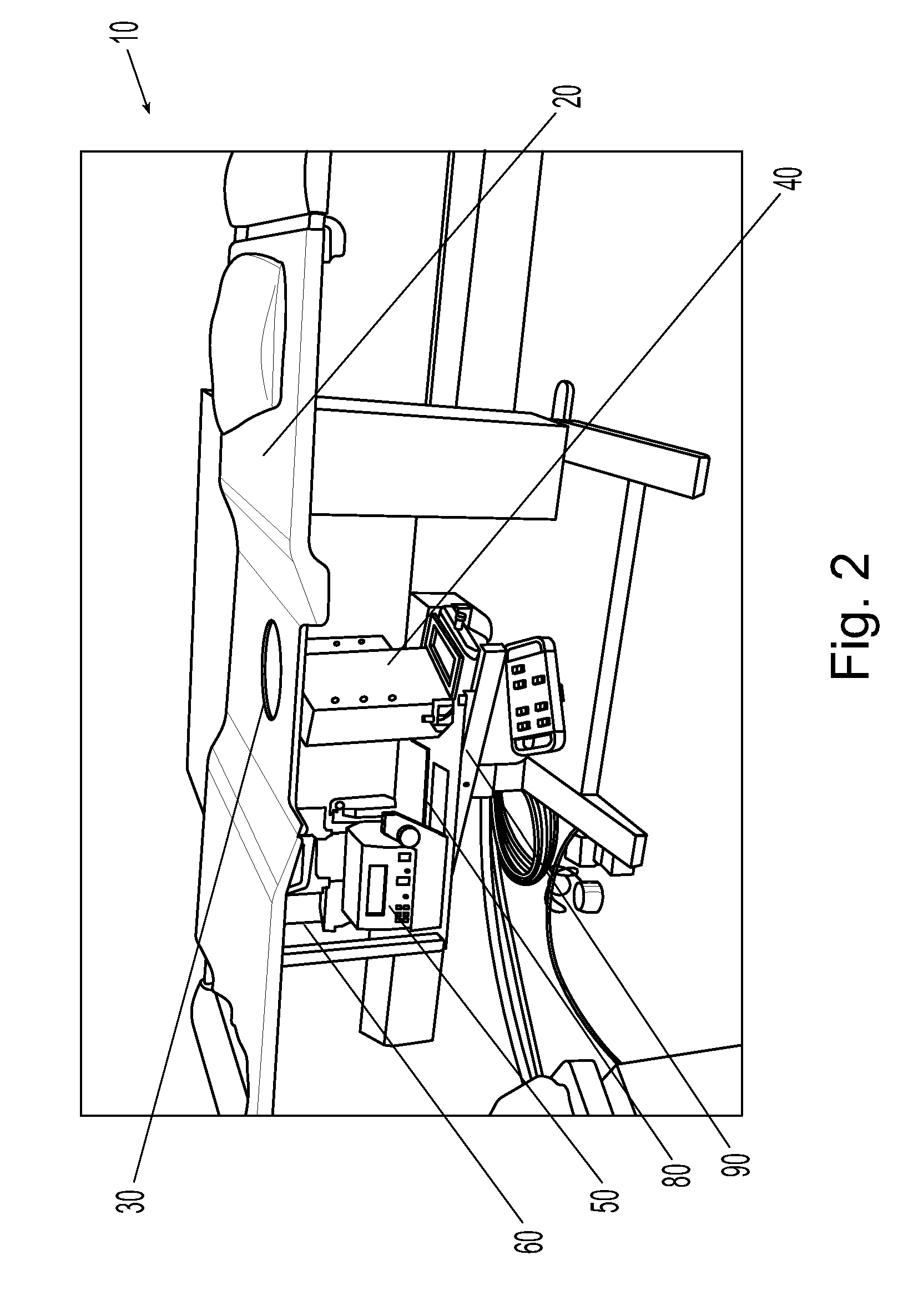

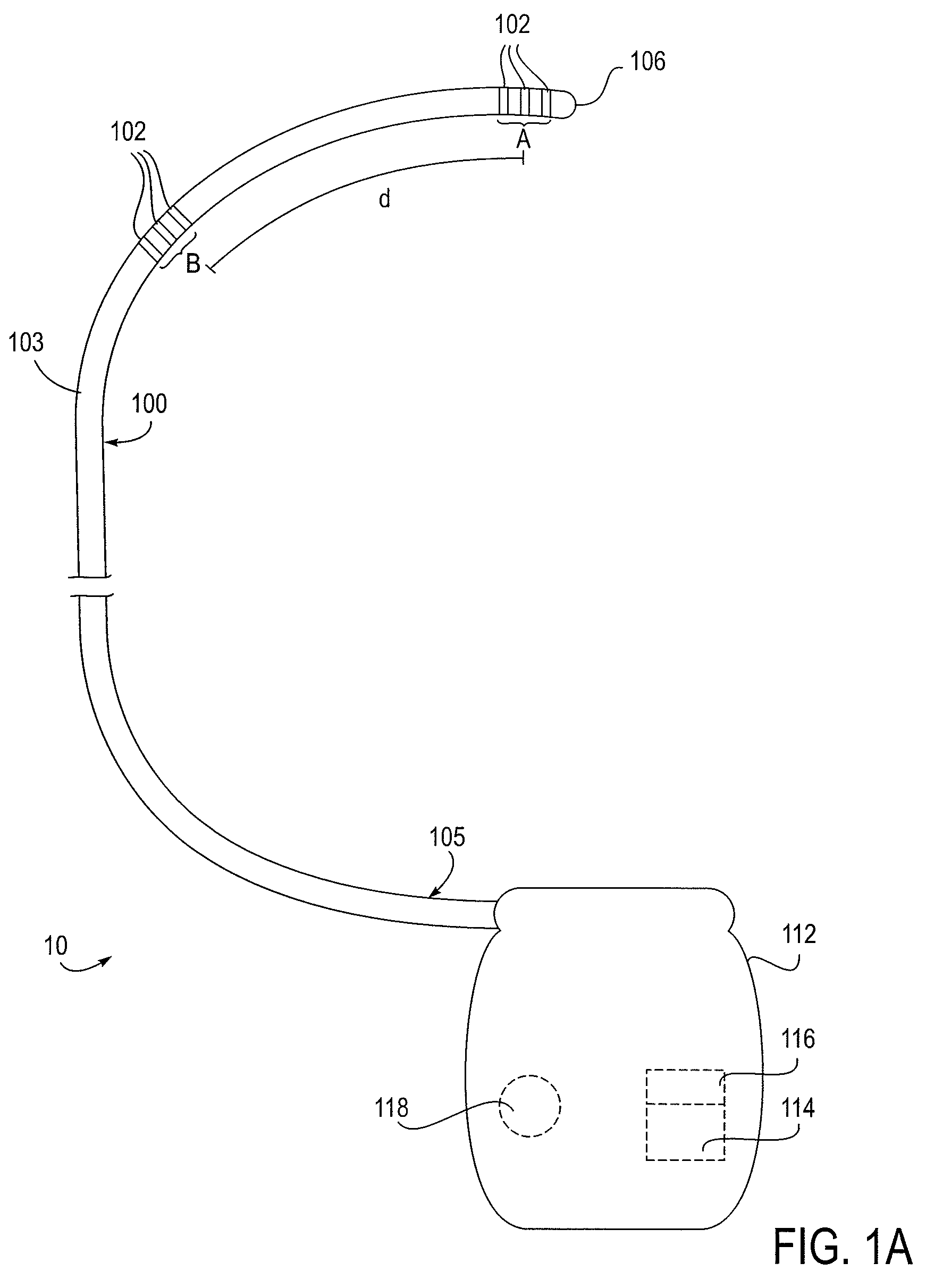

Implantable therapy delivery element adjustable anchor

InactiveUS6901287B2Facilitates invasive procedureQuick placementSpinal electrodesDiagnostic recording/measuringHuman bodySacral nerve stimulation

An implantable therapy delivery system has a therapy delivery element that is inserted or implanted into a human body and anchored or fixed to tissue to delivery a therapy to a patient. In one embodiment an implantable neurostimulator uses an electrical stimulation lead to delivery a therapy such as sacral nerve stimulation, peripheral nerve stimulation, and the like. In another embodiment the implantable therapeutic substance delivery device, also known as a drug pump, is connected to a catheter to deliver a therapy to treat conditions such as spasticity, cancer, pain, and the like. The therapy delivery element is anchored to tissue using an adjustable anchor having a therapy grip element, at least two extension elements connected to the therapy grip element, and a tissue fixation element connected to the extension elements. The extensions project substantially perpendicular in relation to the therapy delivery element and are configured to actuate the therapy grip element to an opened position and a closed position. A tissue fixation element is connected to the extensions and configured for fixation to a tissue location from an axial direction to the therapy delivery element. The adjustable anchor facilitates minimally invasive procedures, facilitates securing the therapy delivery element in the same plane as the therapy delivery element was inserted, facilitates rapid placement to reduce procedure time, and provides a wide range of other benefits. The adjustable anchor and its methods of operation have many embodiments.

Owner:MEDTRONIC INC

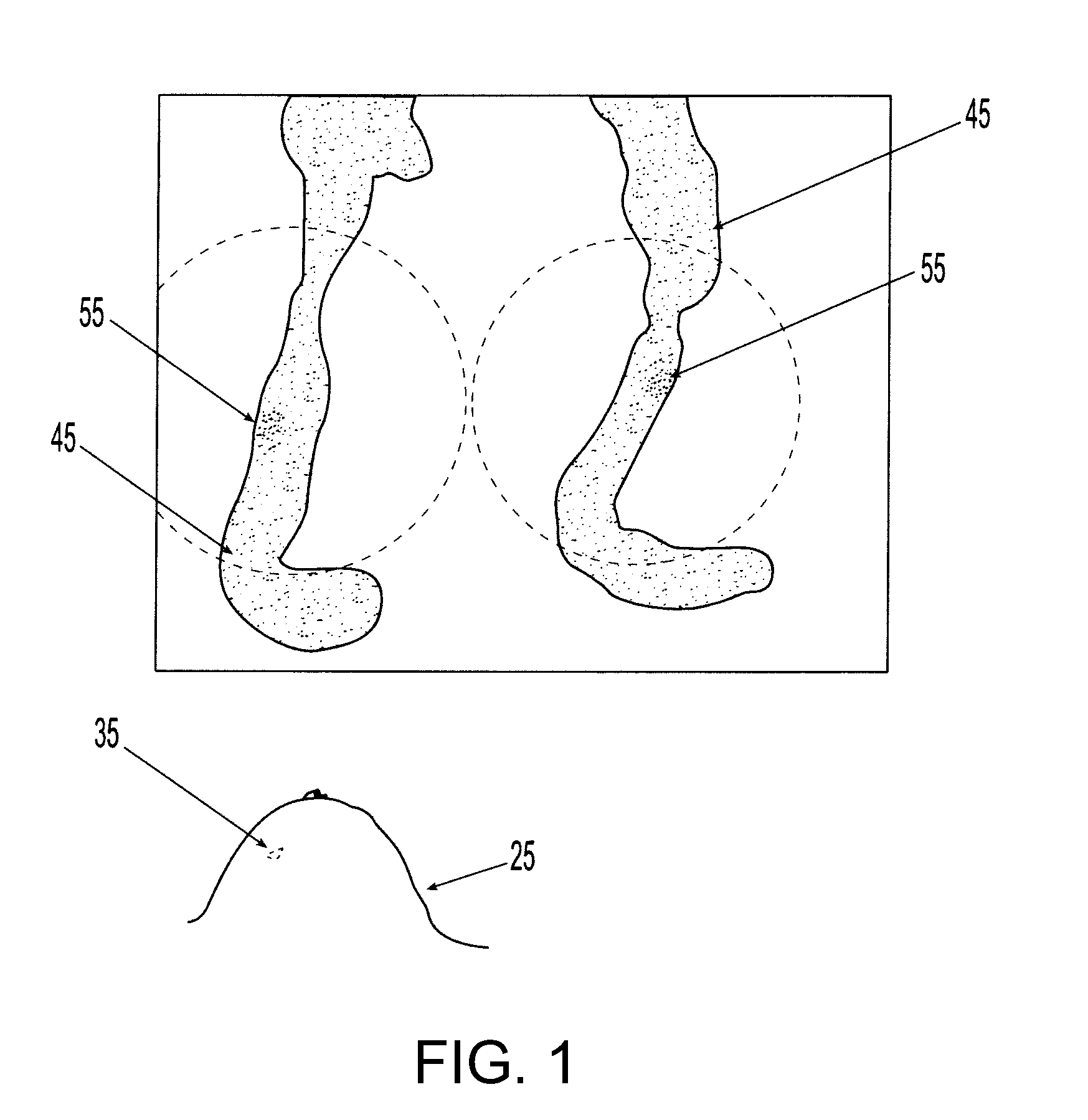

Coronary sinus cannulation

ActiveUS20080058650A1Shorten operation timeImproving procedure effectivenessSuture equipmentsGuide wiresCoronary sinusIn vivo

Coronary sinus cannulation apparatus and methods relating to tissue visualization catheters that can locate and / or cannulate a morphological feature within a body lumen, such as the coronary sinus, are described. Such devices can also perform a variety of therapeutic tissue treatments under direct in vivo visualization thereafter. Moreover, such apparatus and methods may also be utilized with guidewires to facilitate delivery into the coronary sinus to eliminate repositioning of the device and / or repeating an entire sequence of operations, consequently improving procedure effectiveness and reducing procedure time.

Owner:INTUITIVE SURGICAL OPERATIONS INC

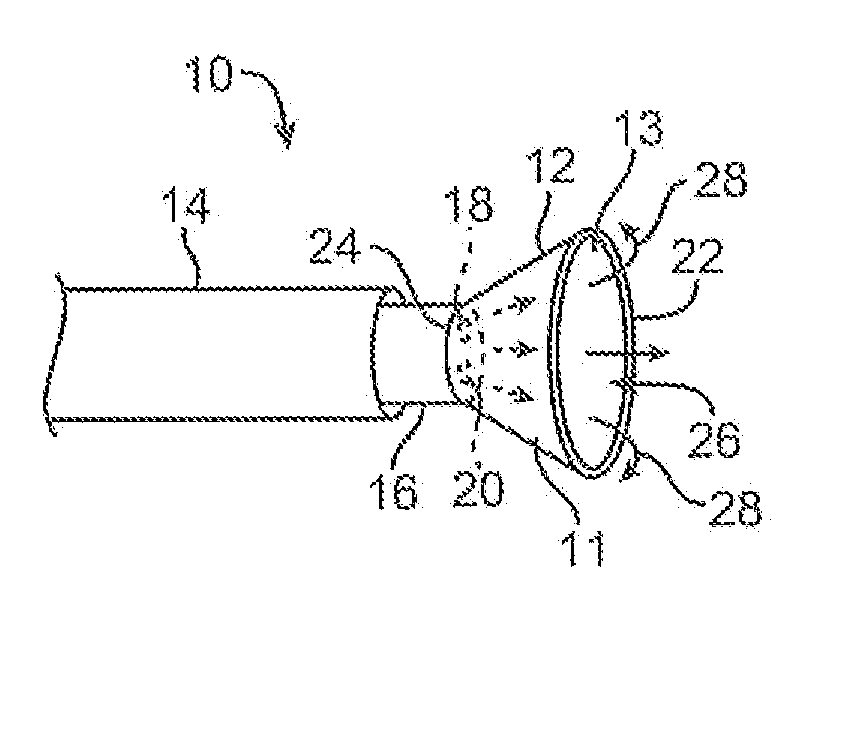

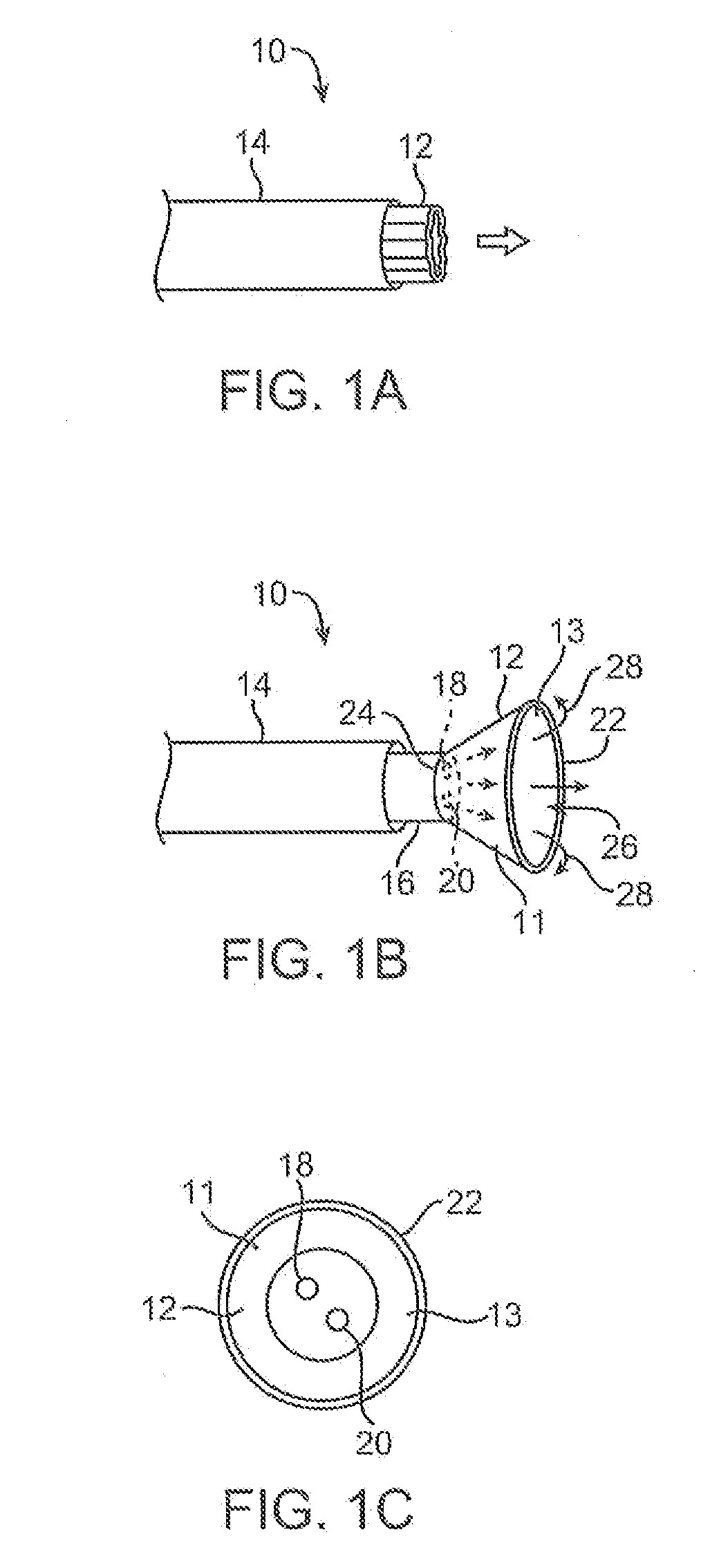

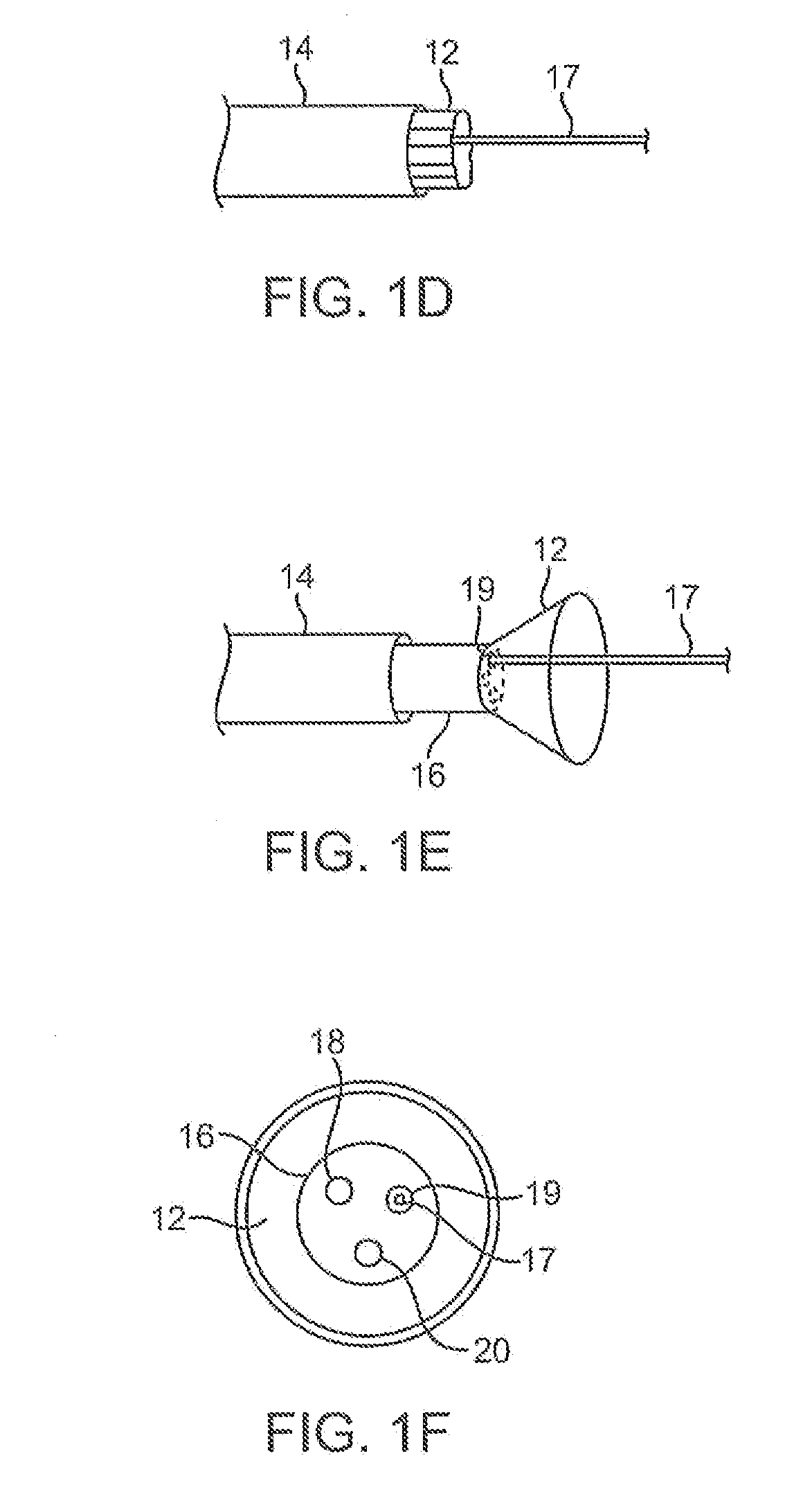

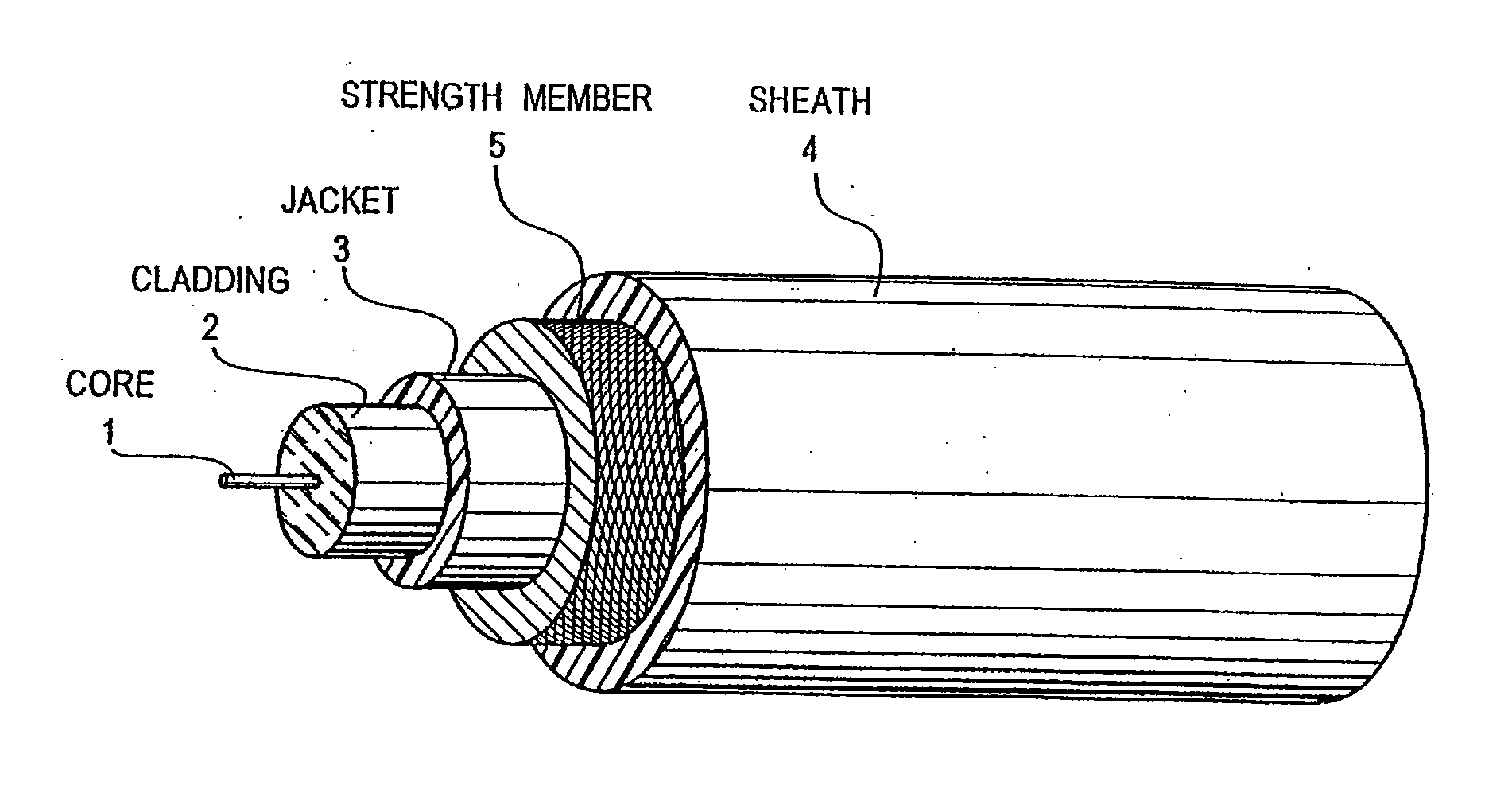

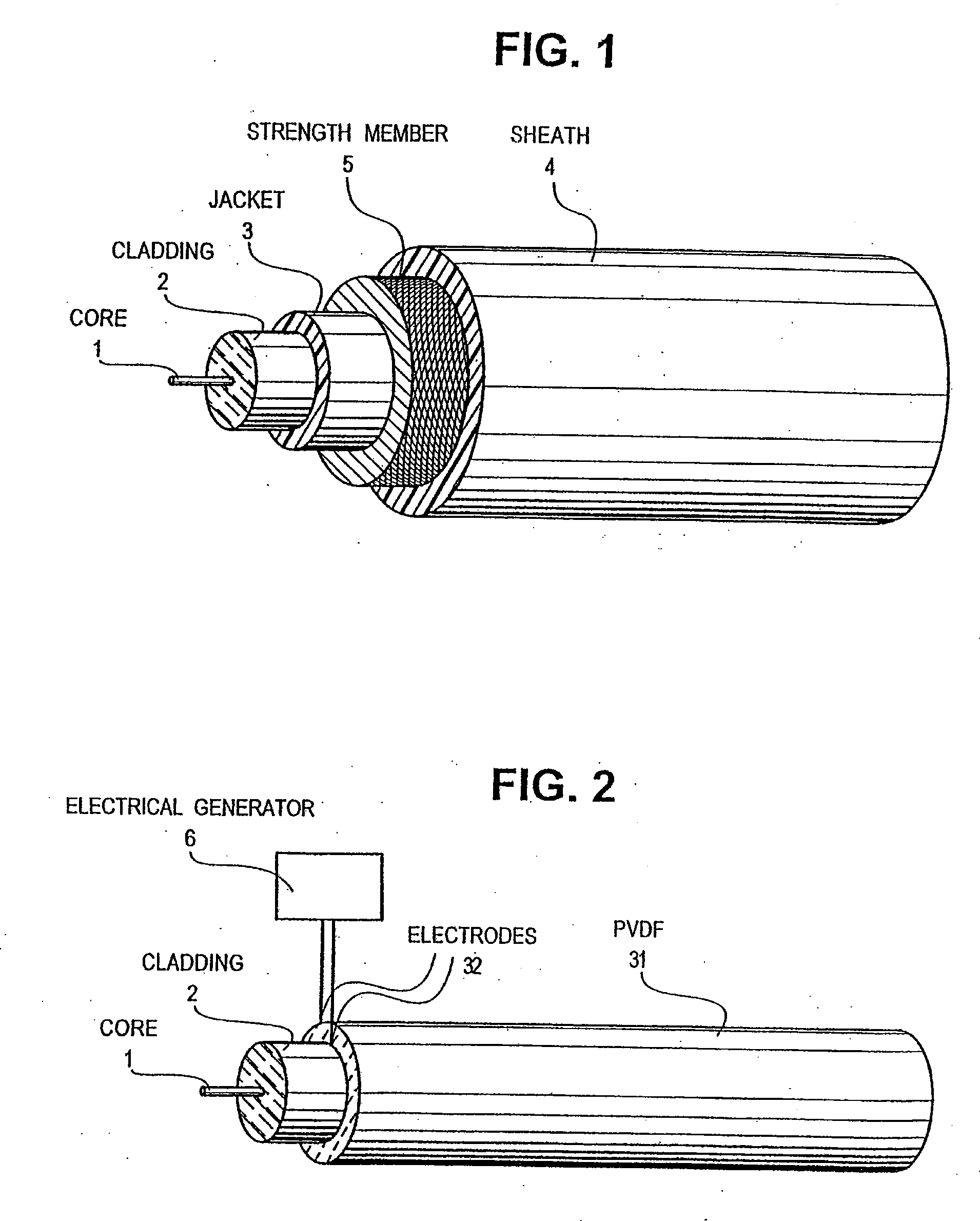

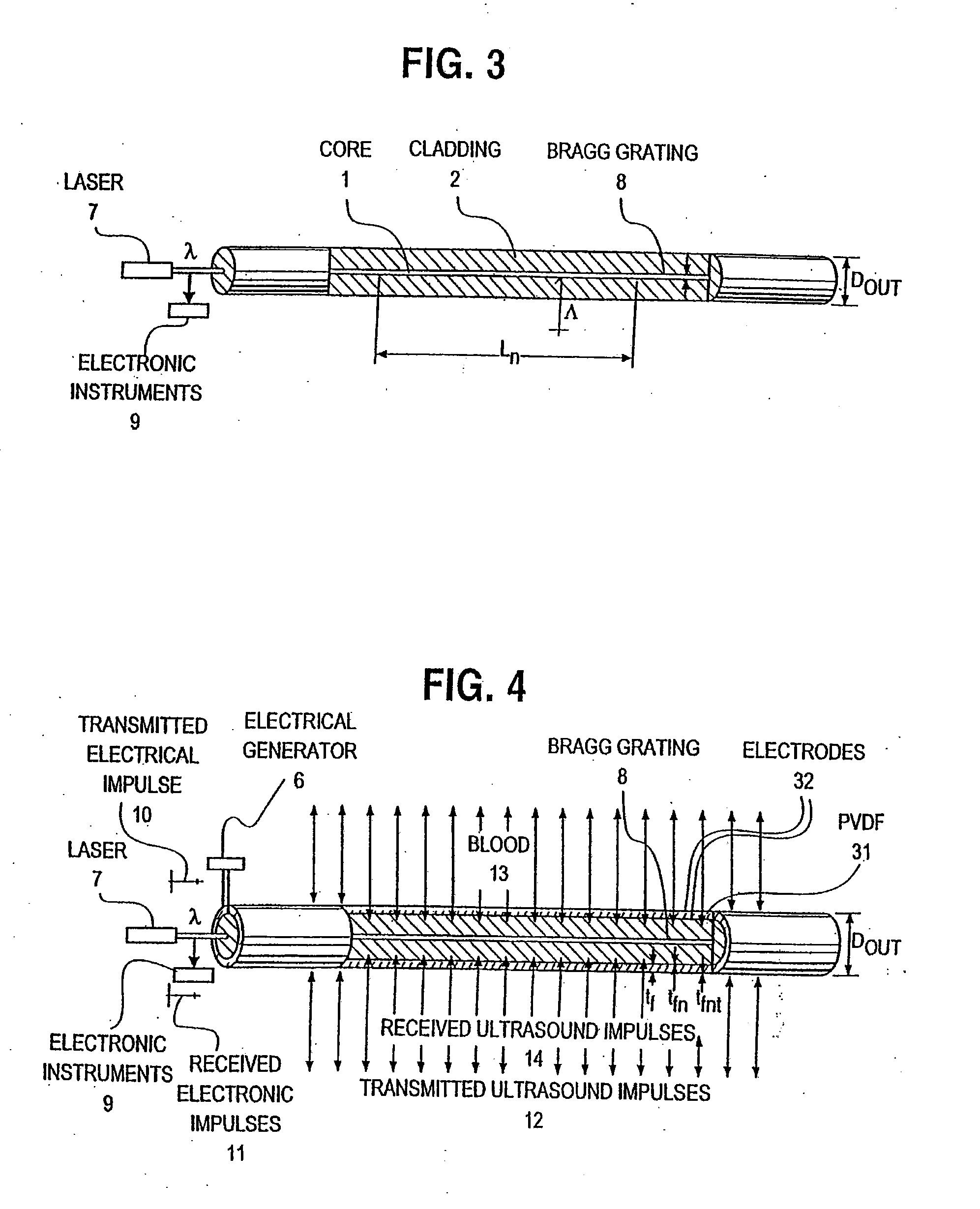

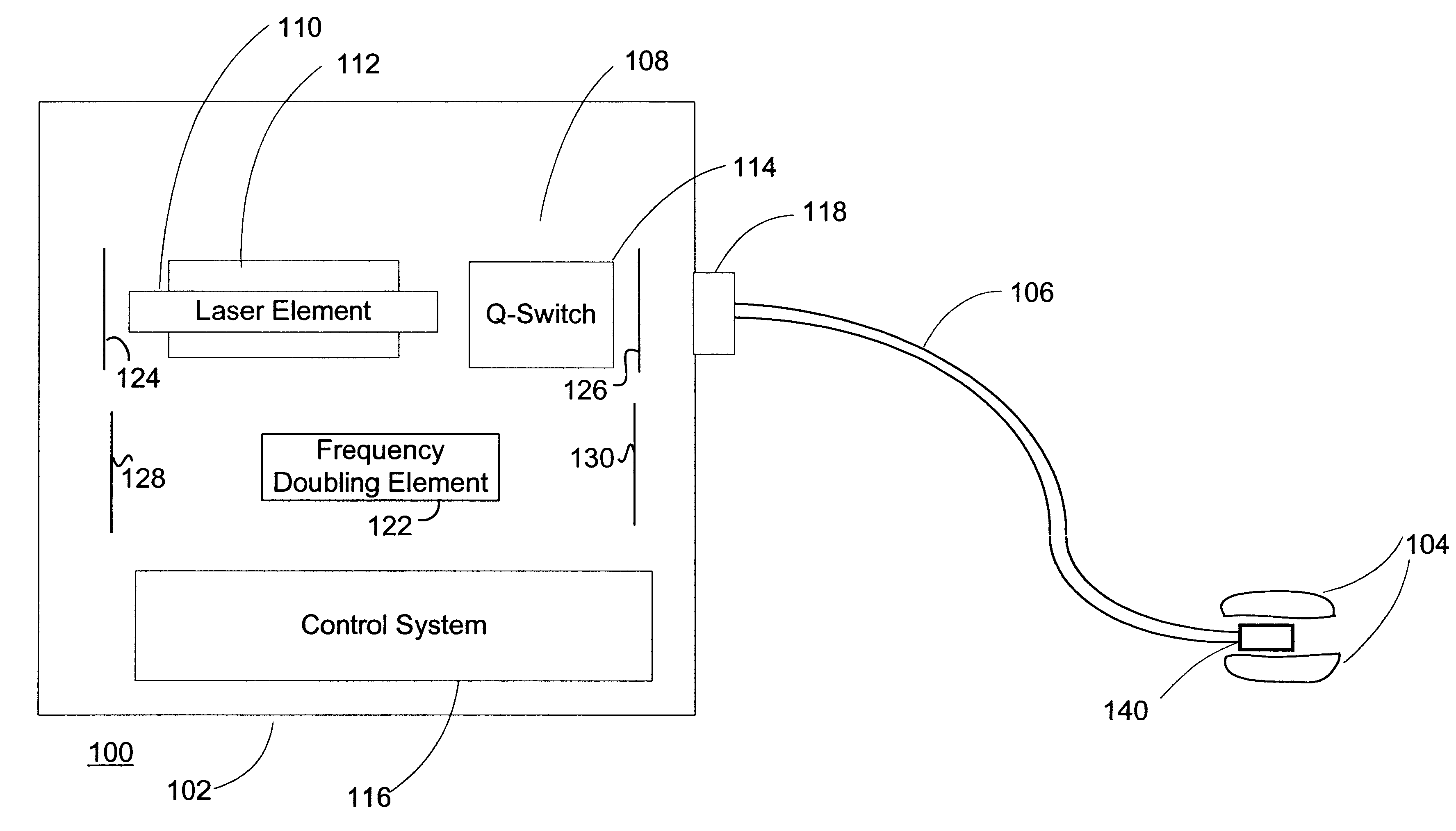

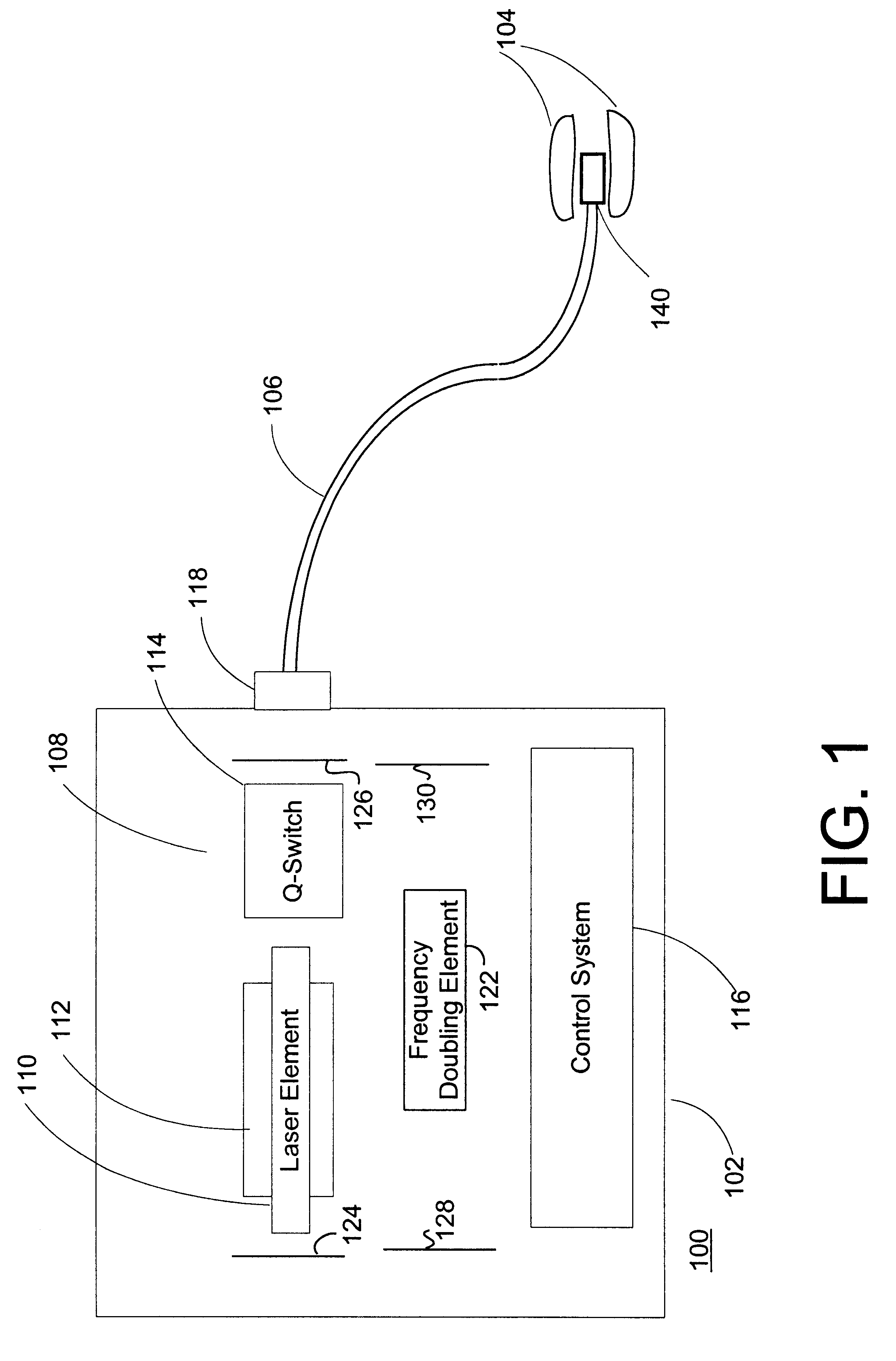

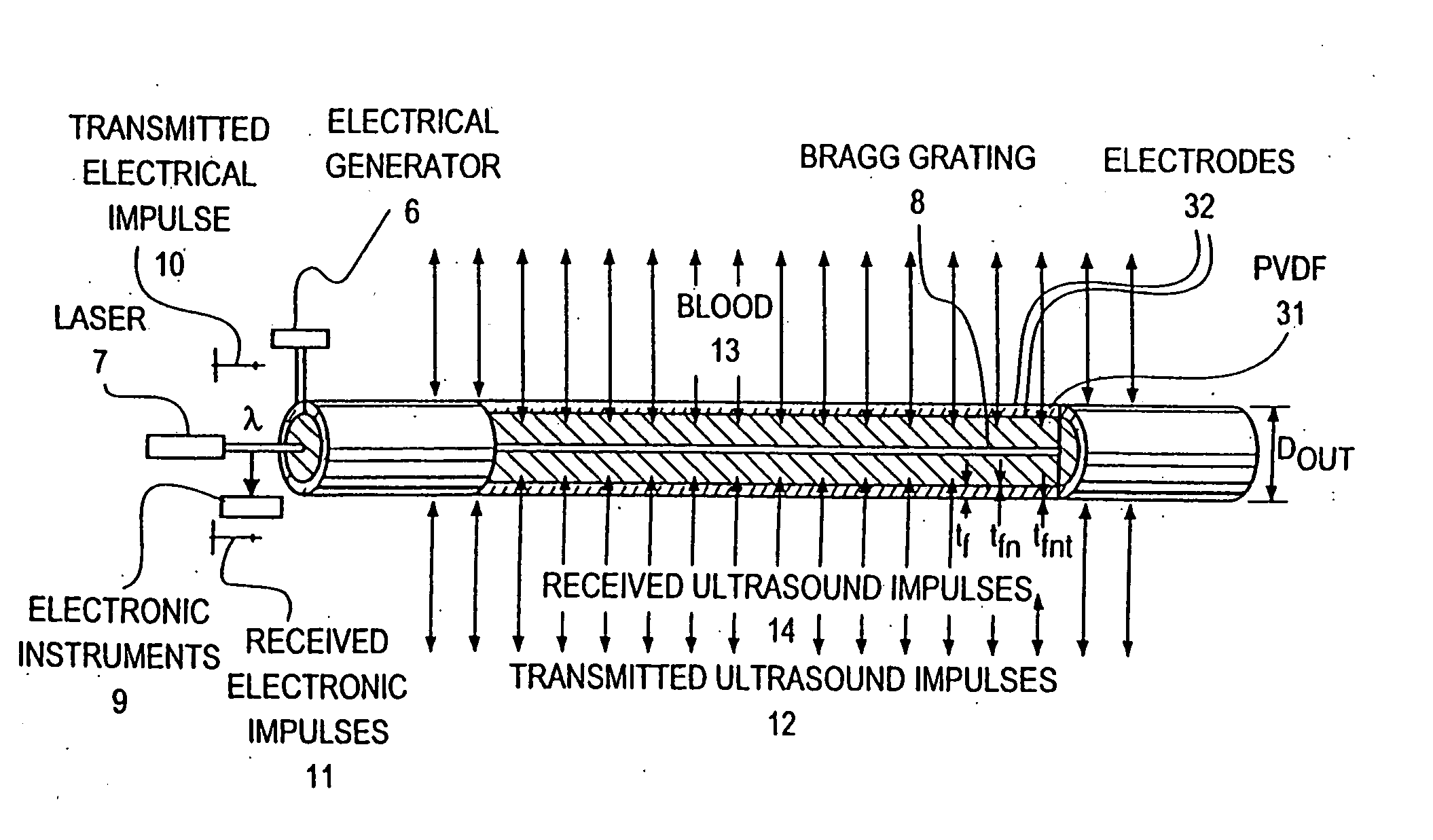

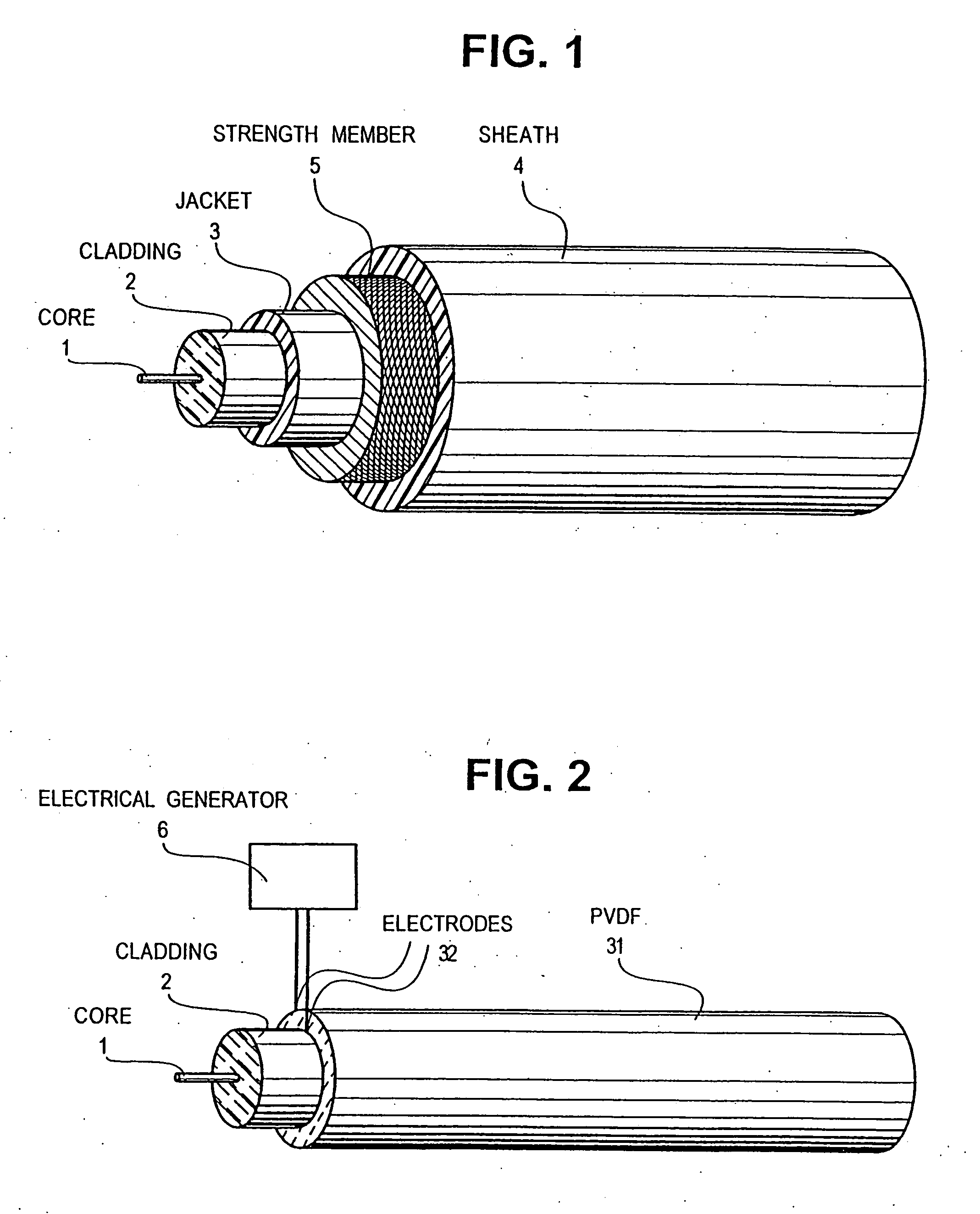

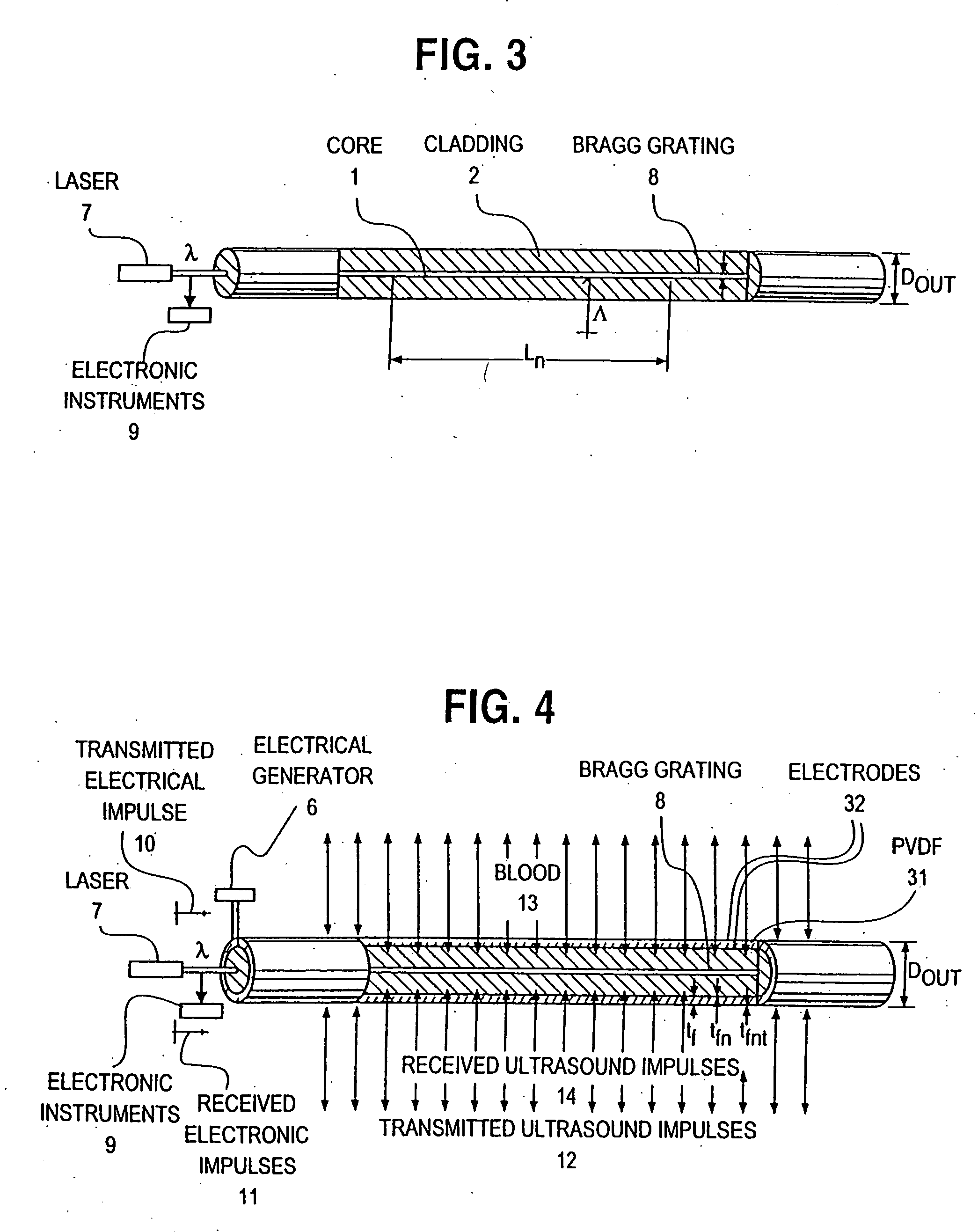

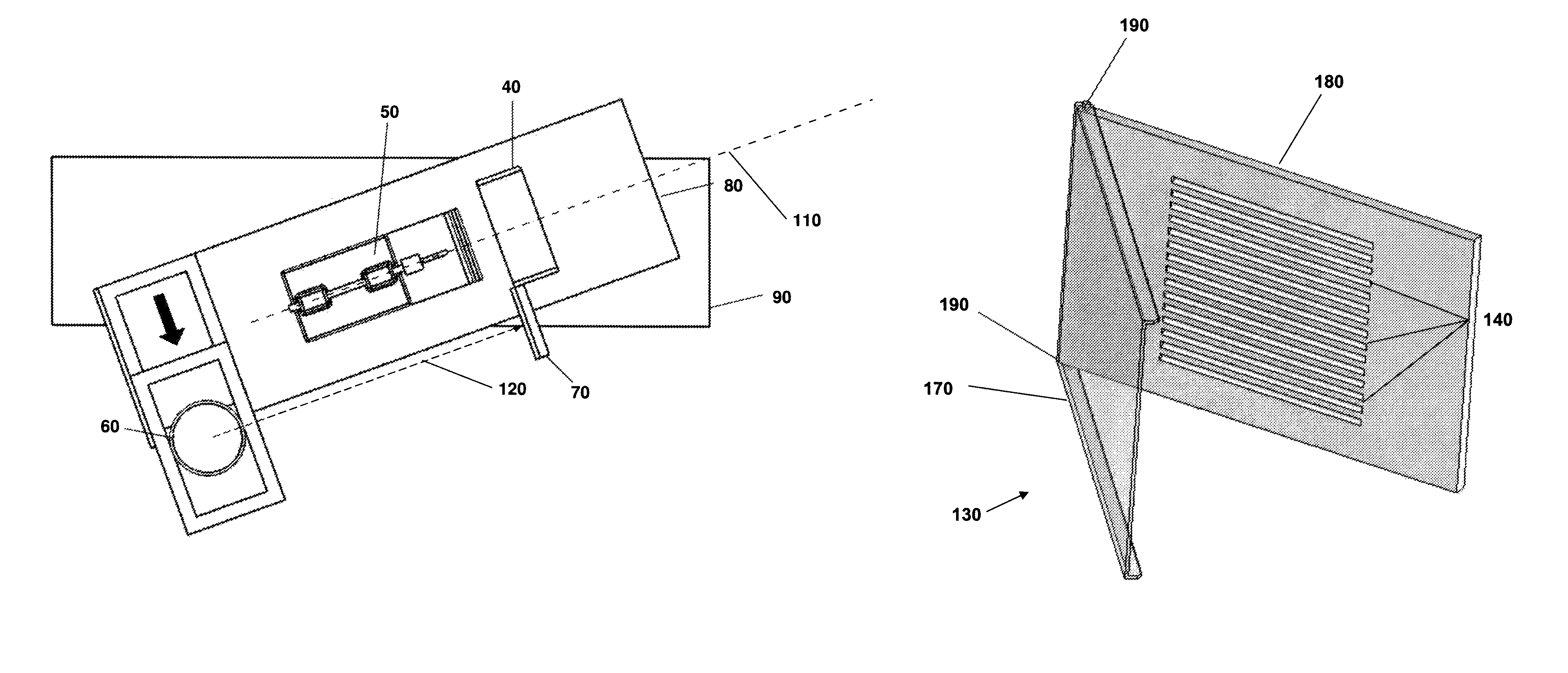

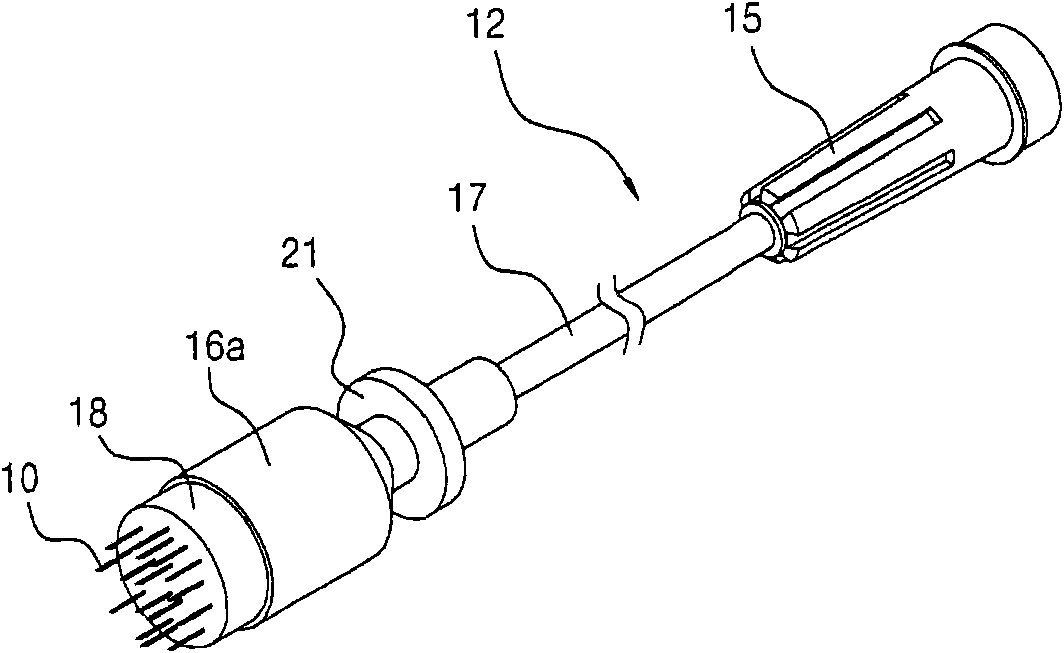

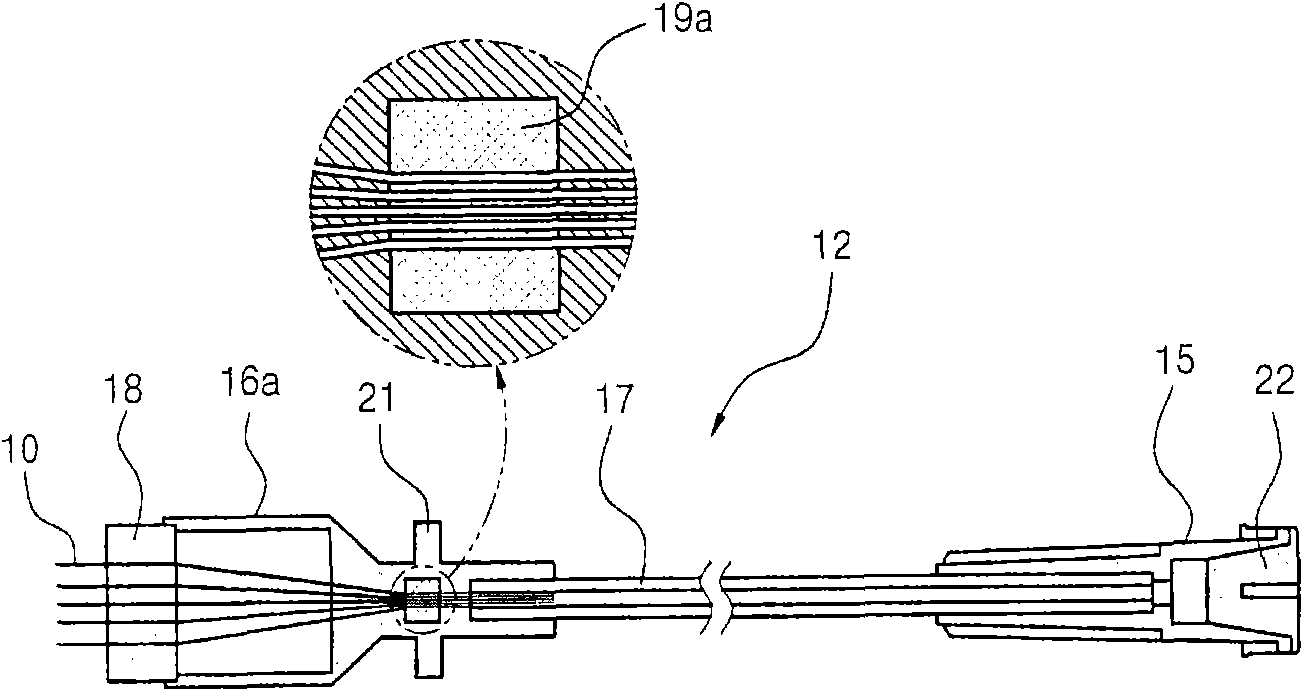

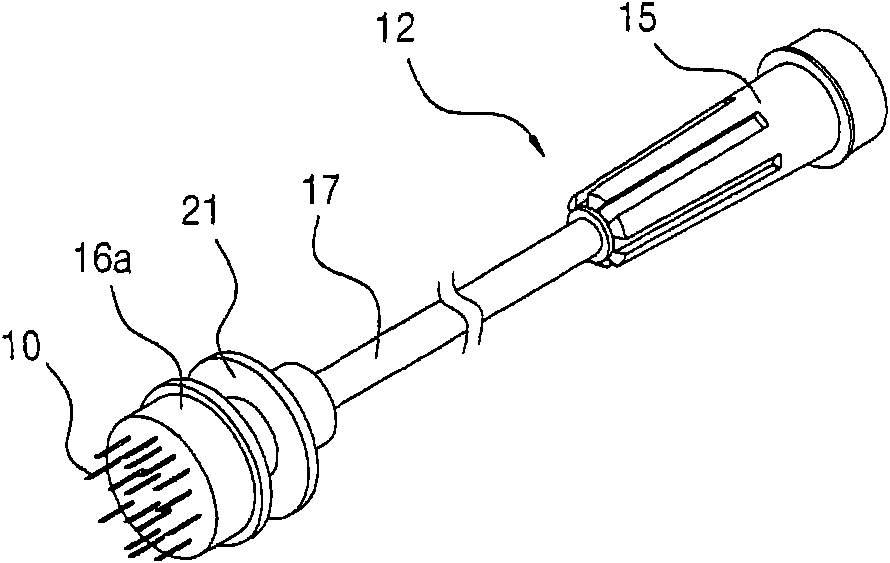

Optical-acoustic imaging device

InactiveUS20080119739A1Reduce radiation exposureShorten operation timeMaterial analysis using sonic/ultrasonic/infrasonic wavesSubsonic/sonic/ultrasonic wave measurementGratingRadiation exposure

The present invention is a guide wire imaging device for vascular or non-vascular imaging utilizing optic acoustical methods, which device has a profile of less than 1 mm in diameter. The ultrasound imaging device of the invention comprises a single mode optical fiber with at least one Bragg grating, and a piezoelectric or piezo-ceramic jacket, which device may achieve omnidirectional (360°) imaging. The imaging guide wire of the invention can function as a guide wire for vascular interventions, can enable real time imaging during balloon inflation, and stent deployment, thus will provide clinical information that is not available when catheter-based imaging systems are used. The device of the invention may enable shortened total procedure times, including the fluoroscopy time, will also reduce radiation exposure to the patient and to the operator.

Owner:PHYZHON HEALTH INC

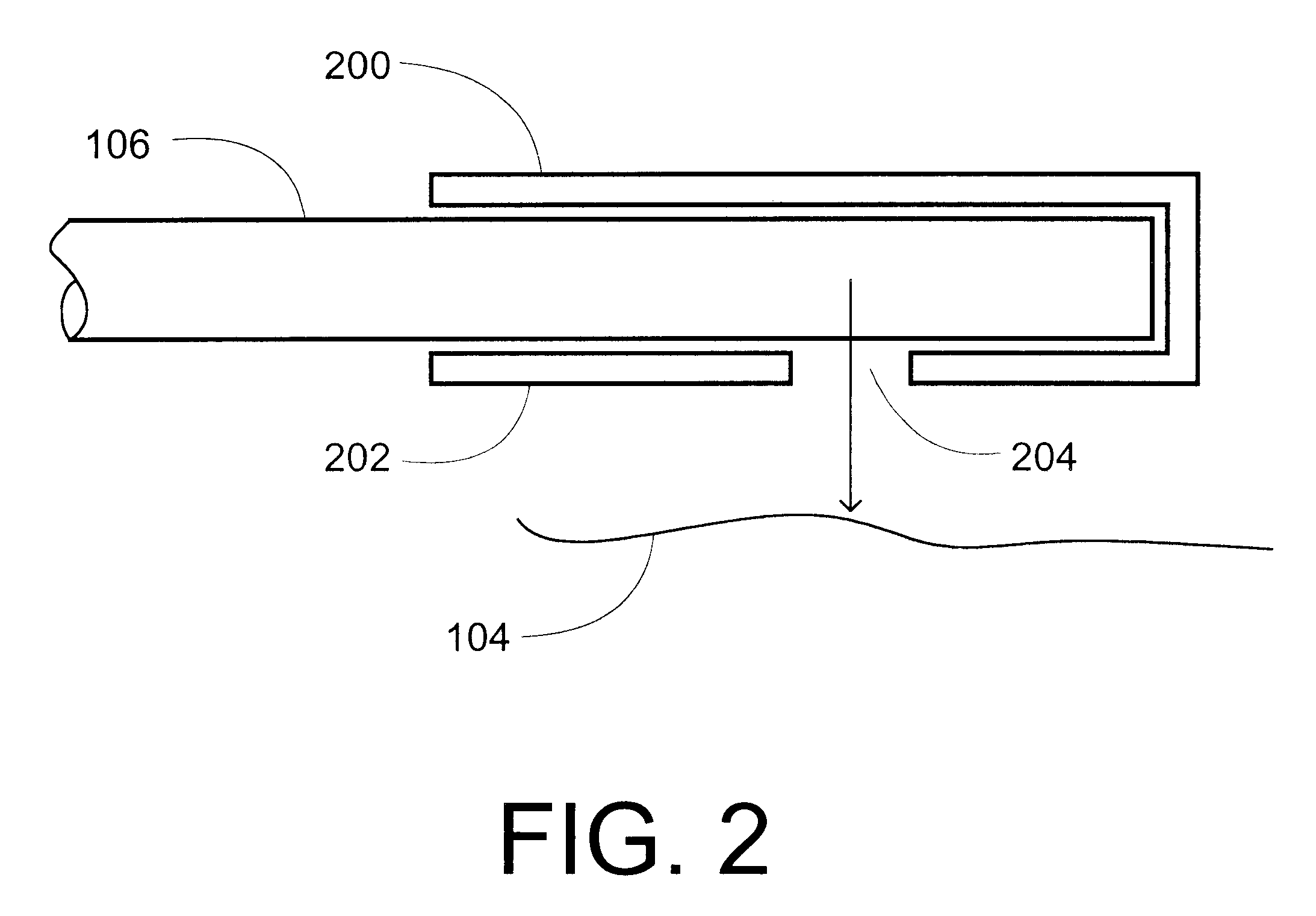

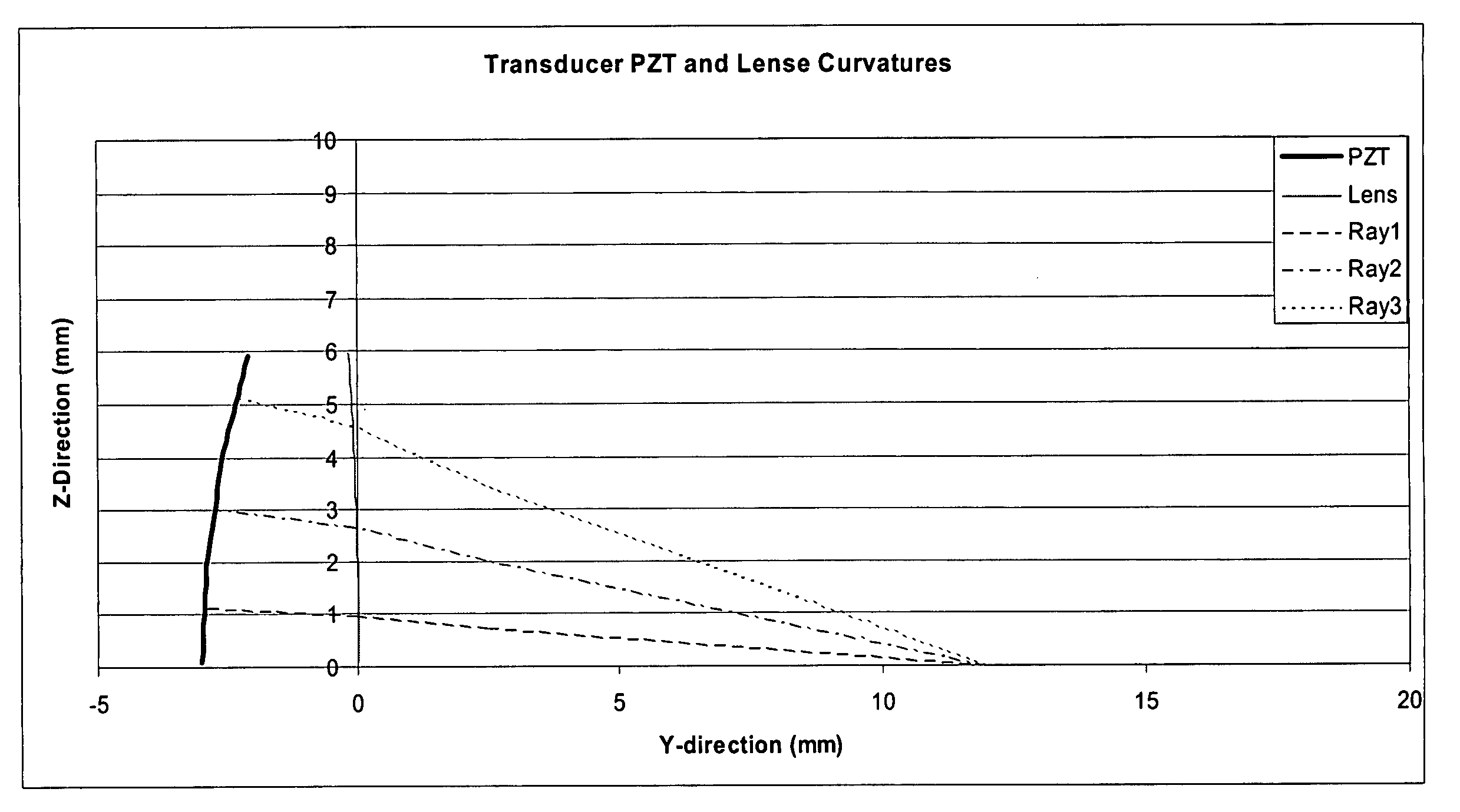

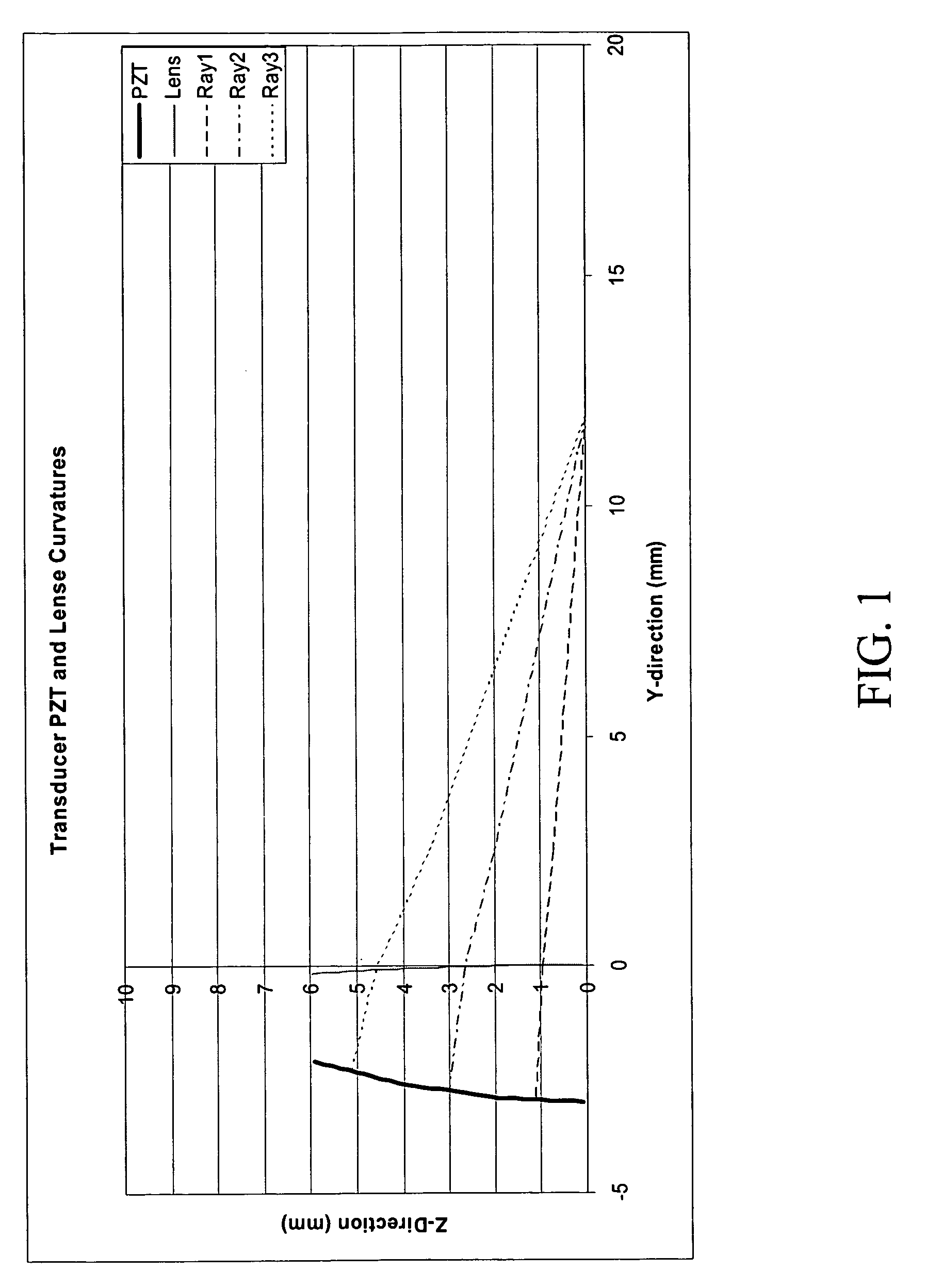

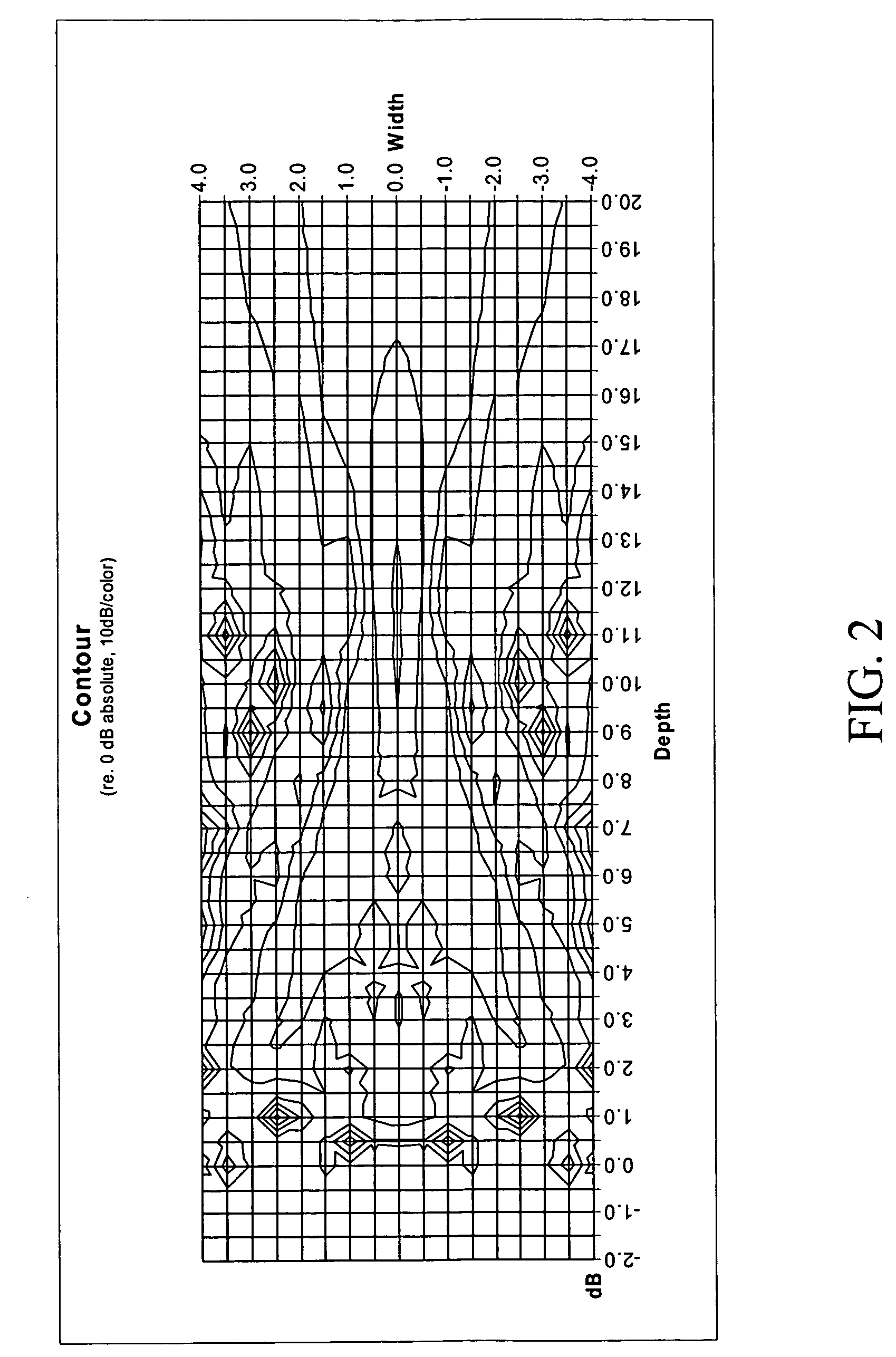

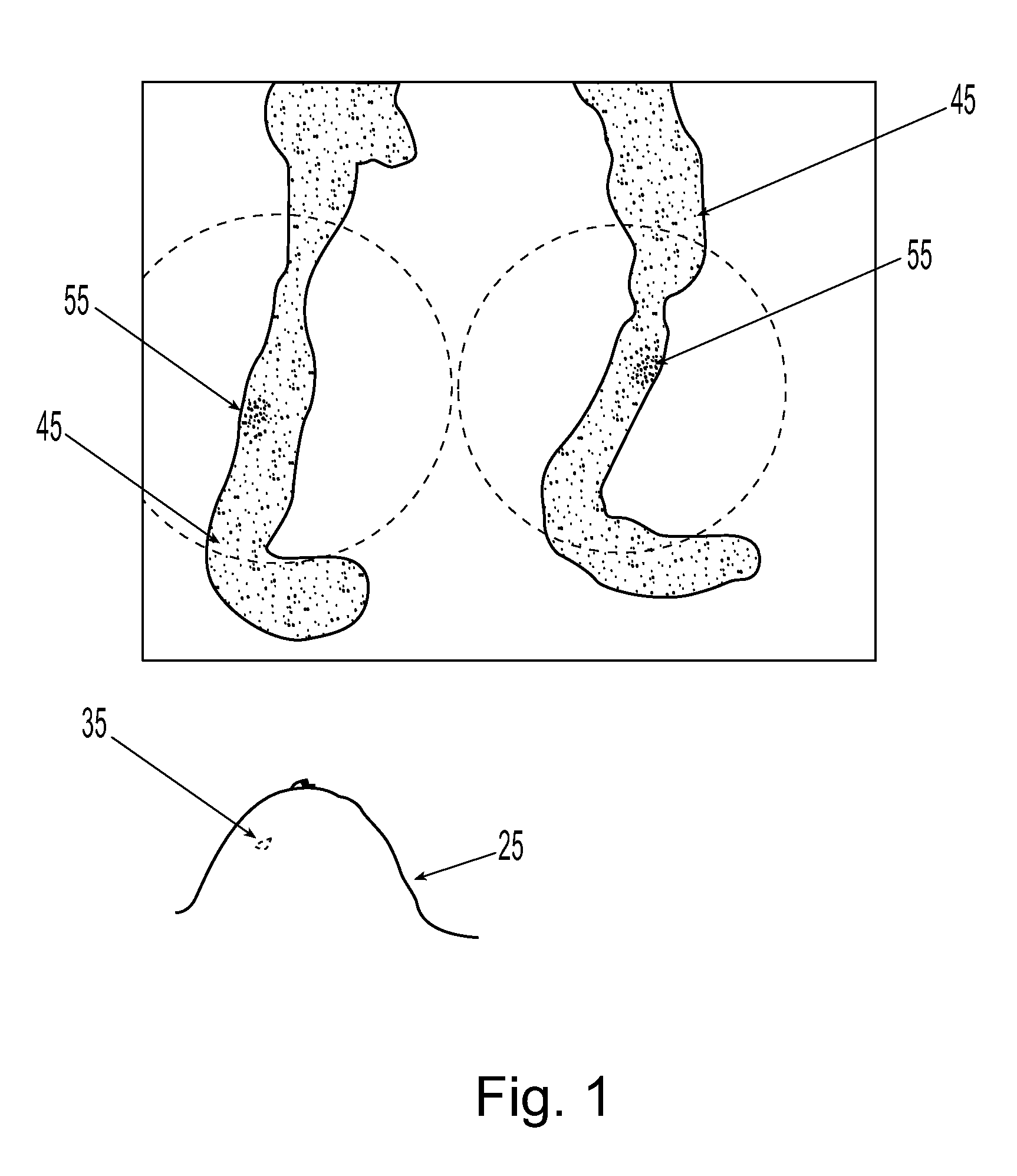

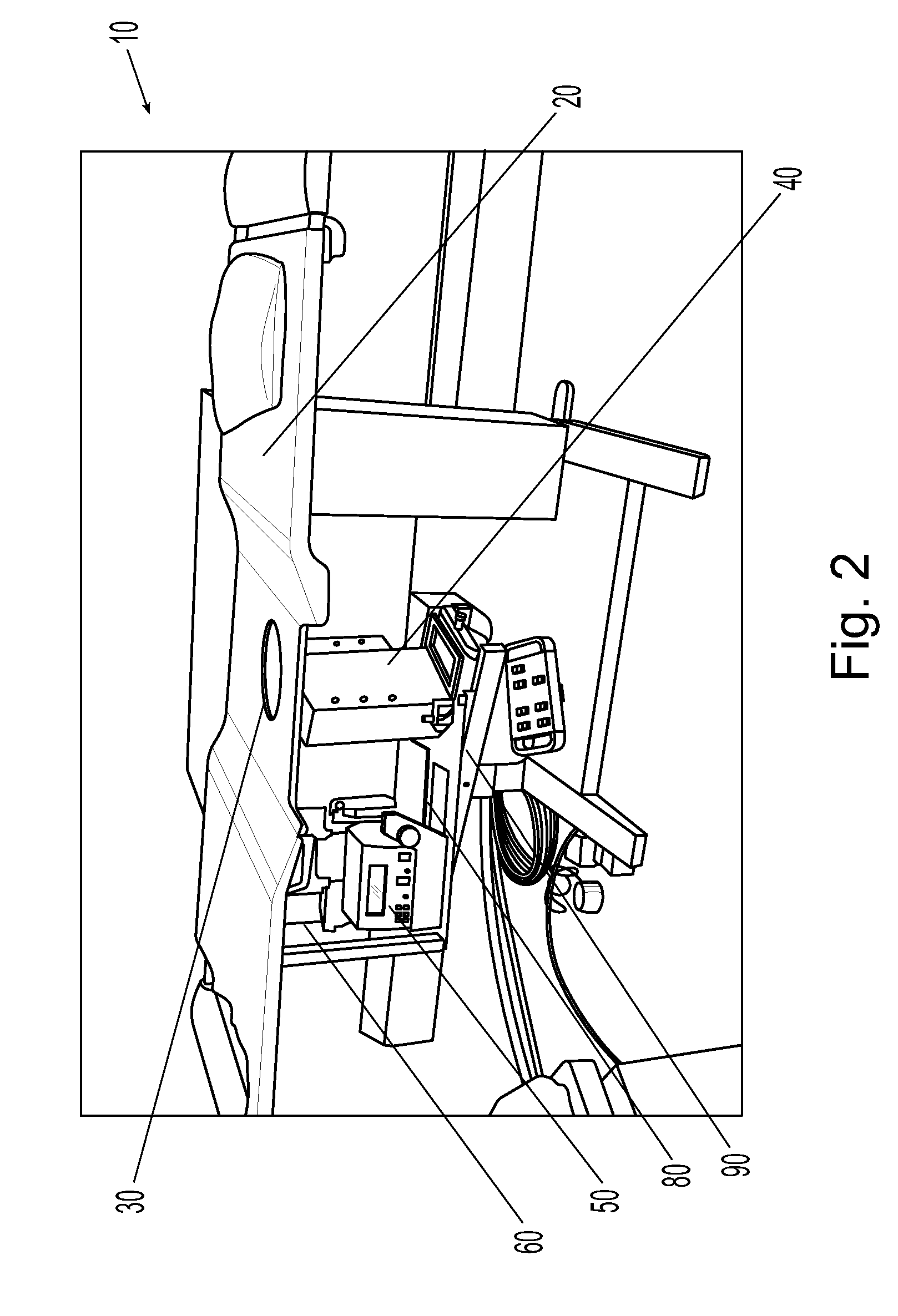

External ultrasound lipoplasty

ActiveUS20080097253A1Safer procedureUltrasonic/sonic/infrasonic diagnosticsUltrasound therapyCavitationSonification

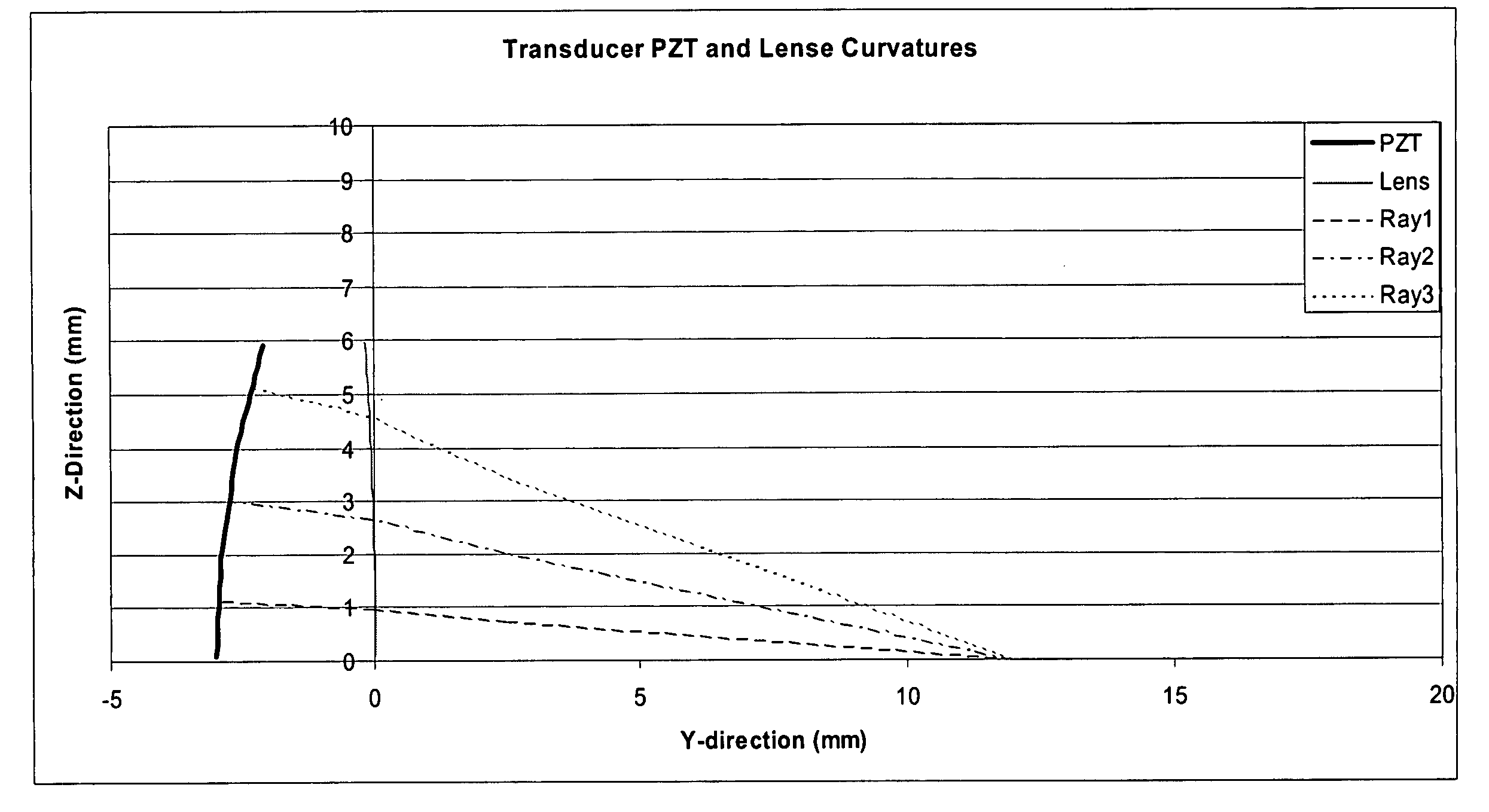

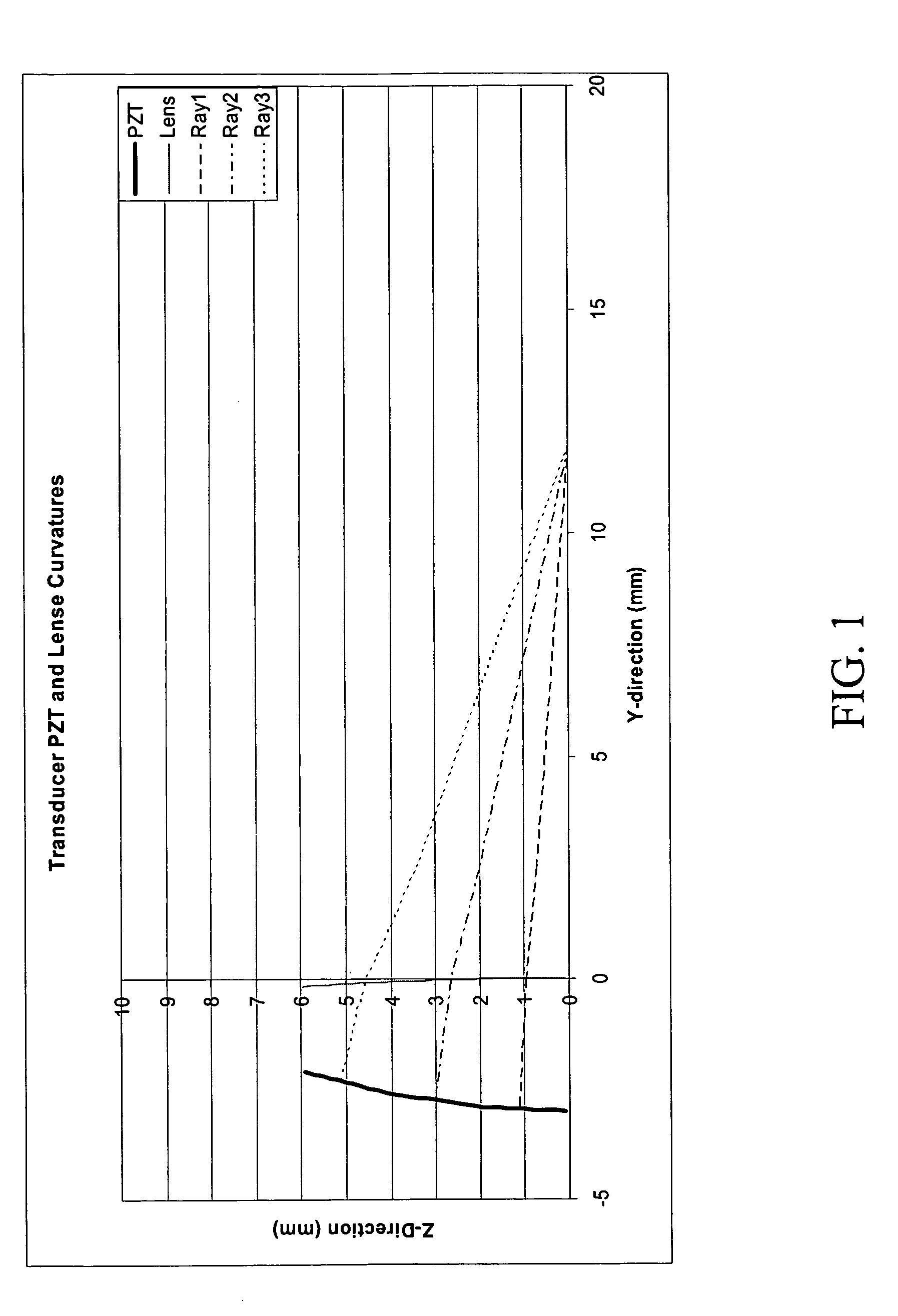

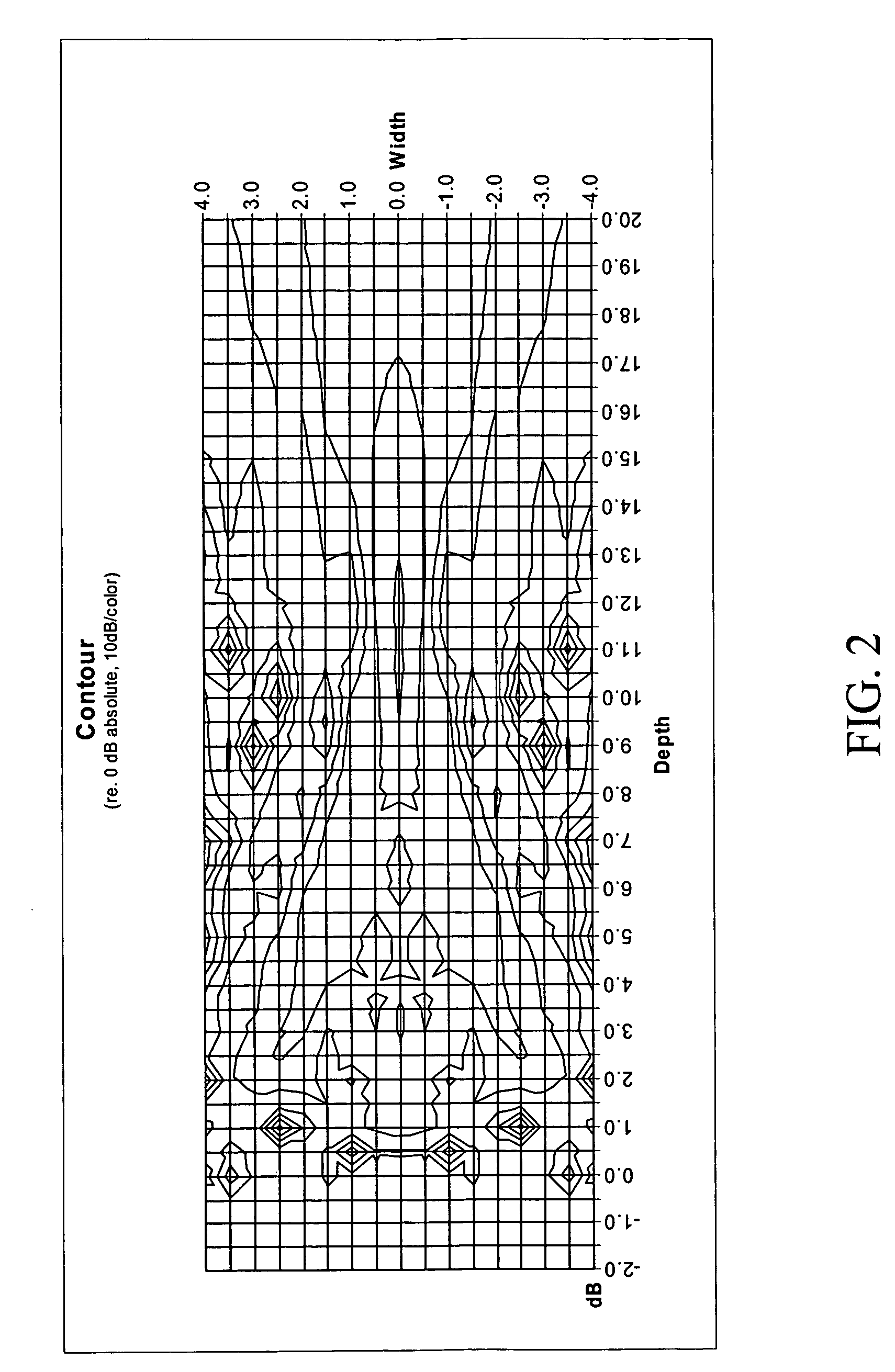

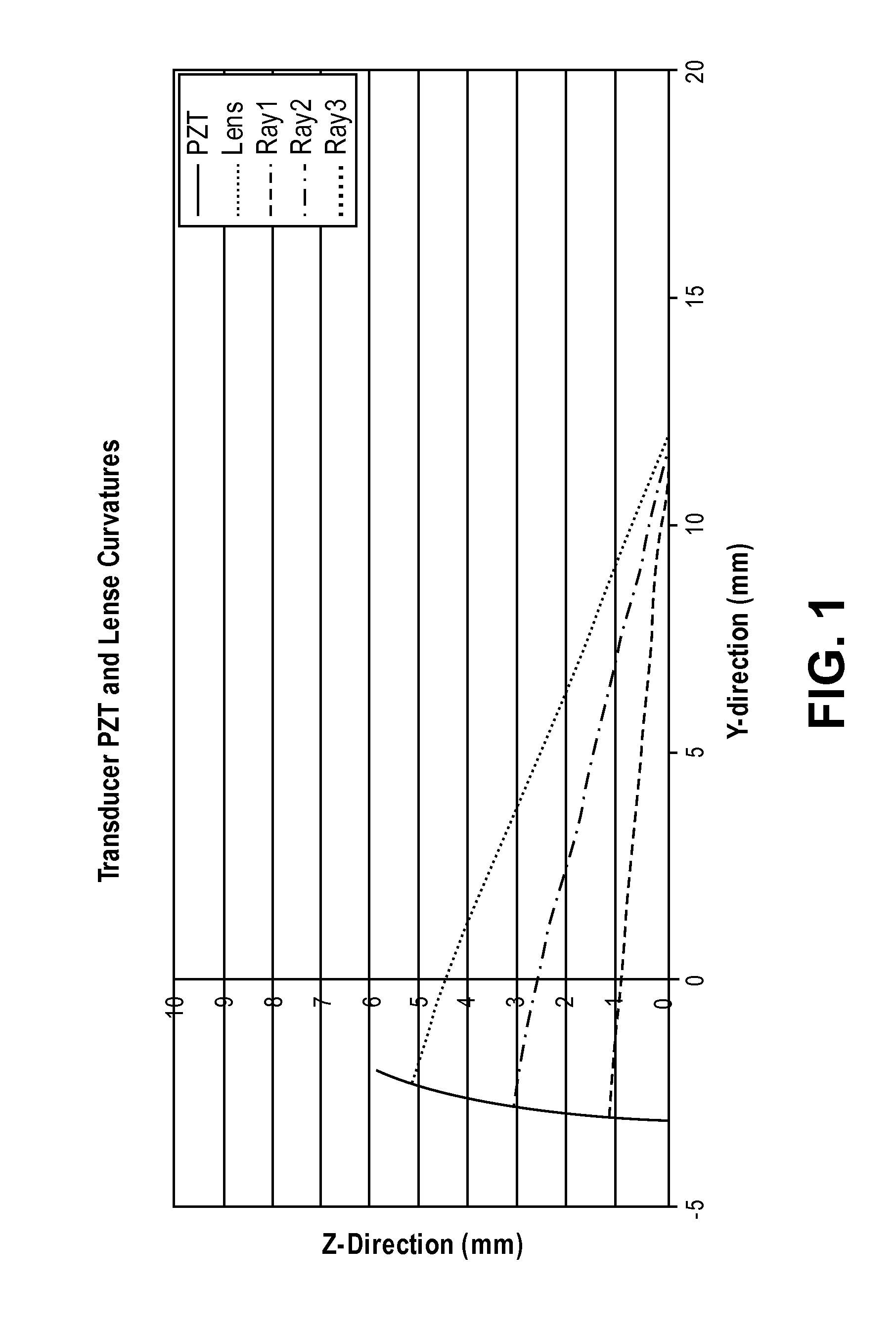

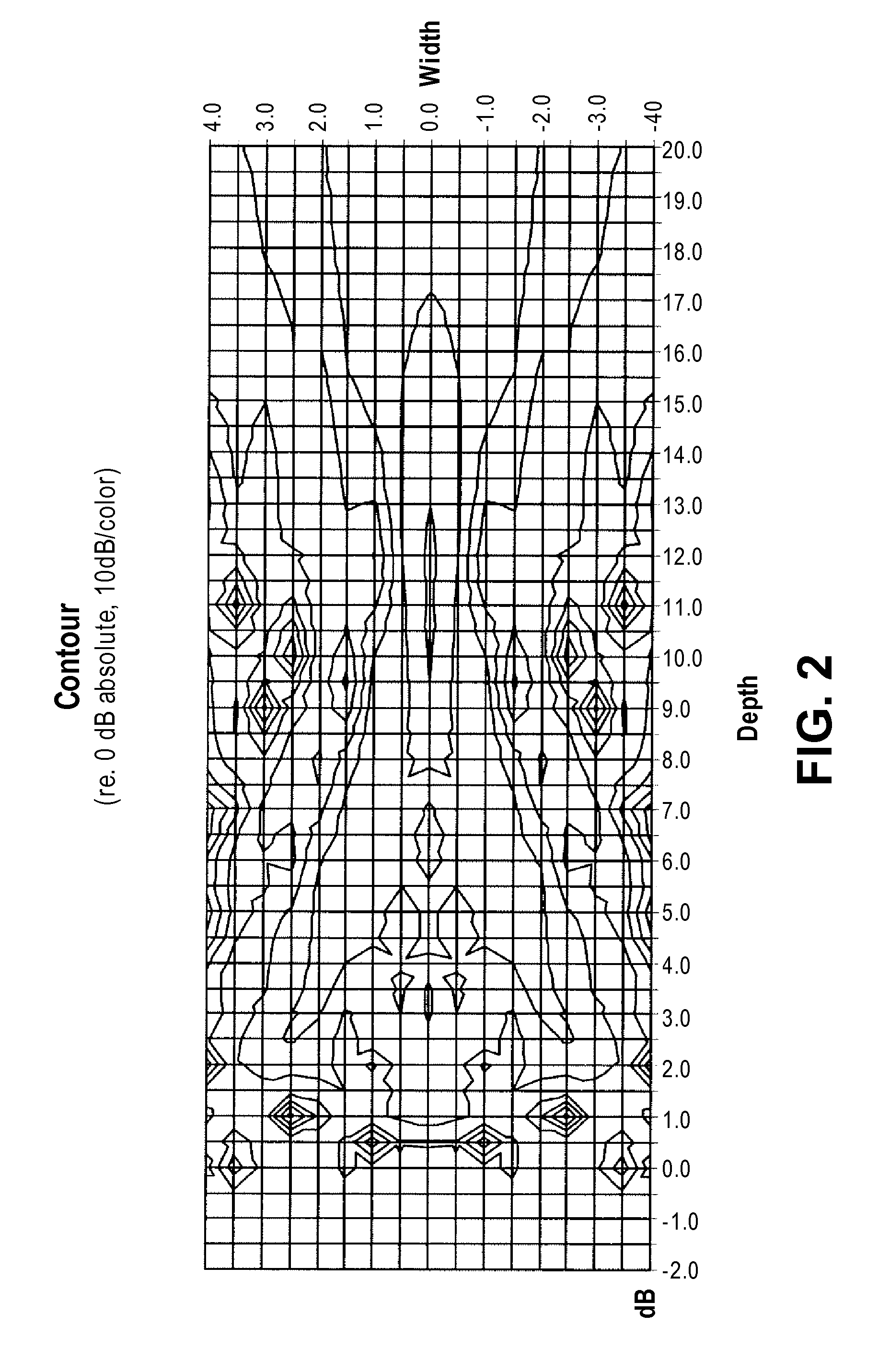

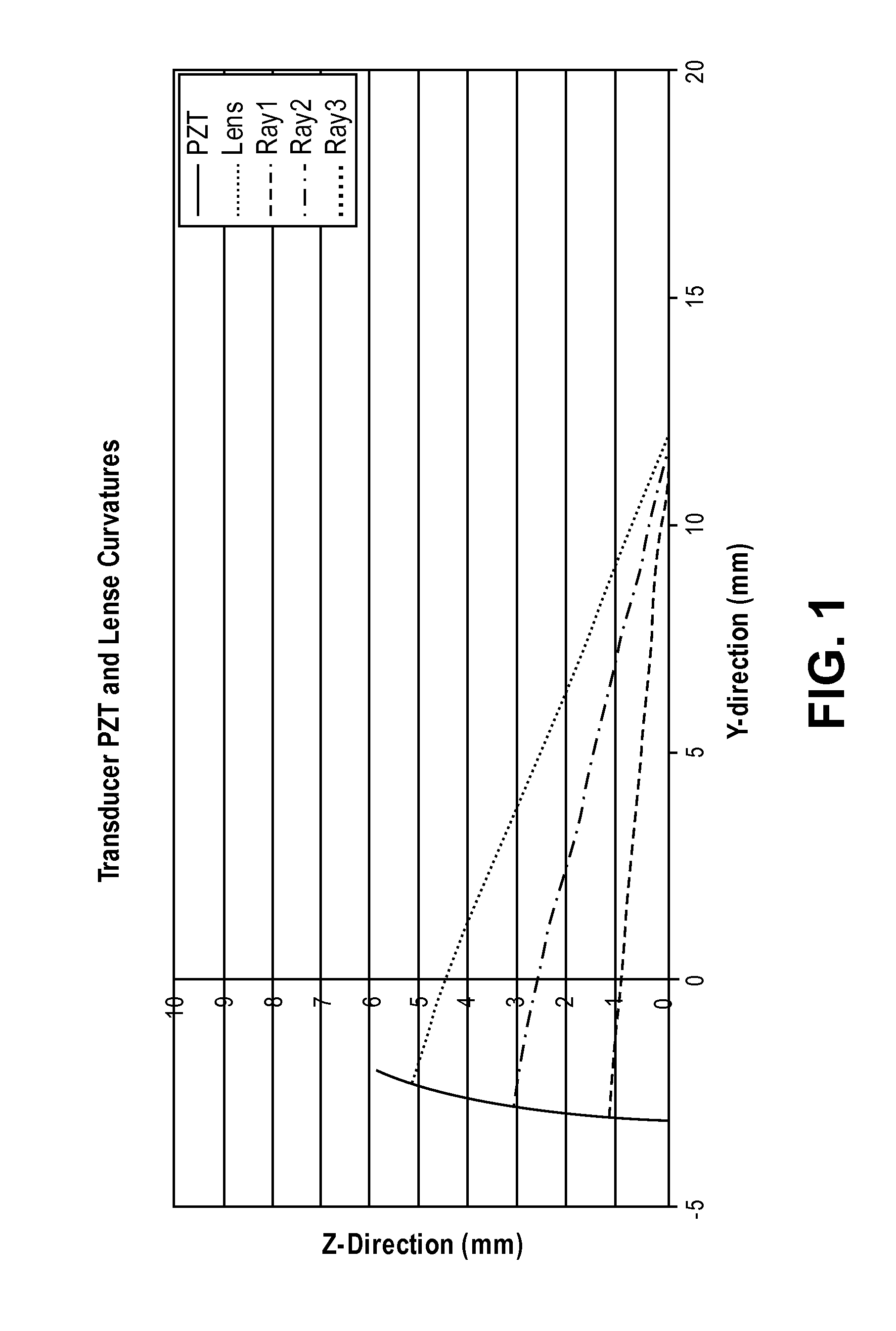

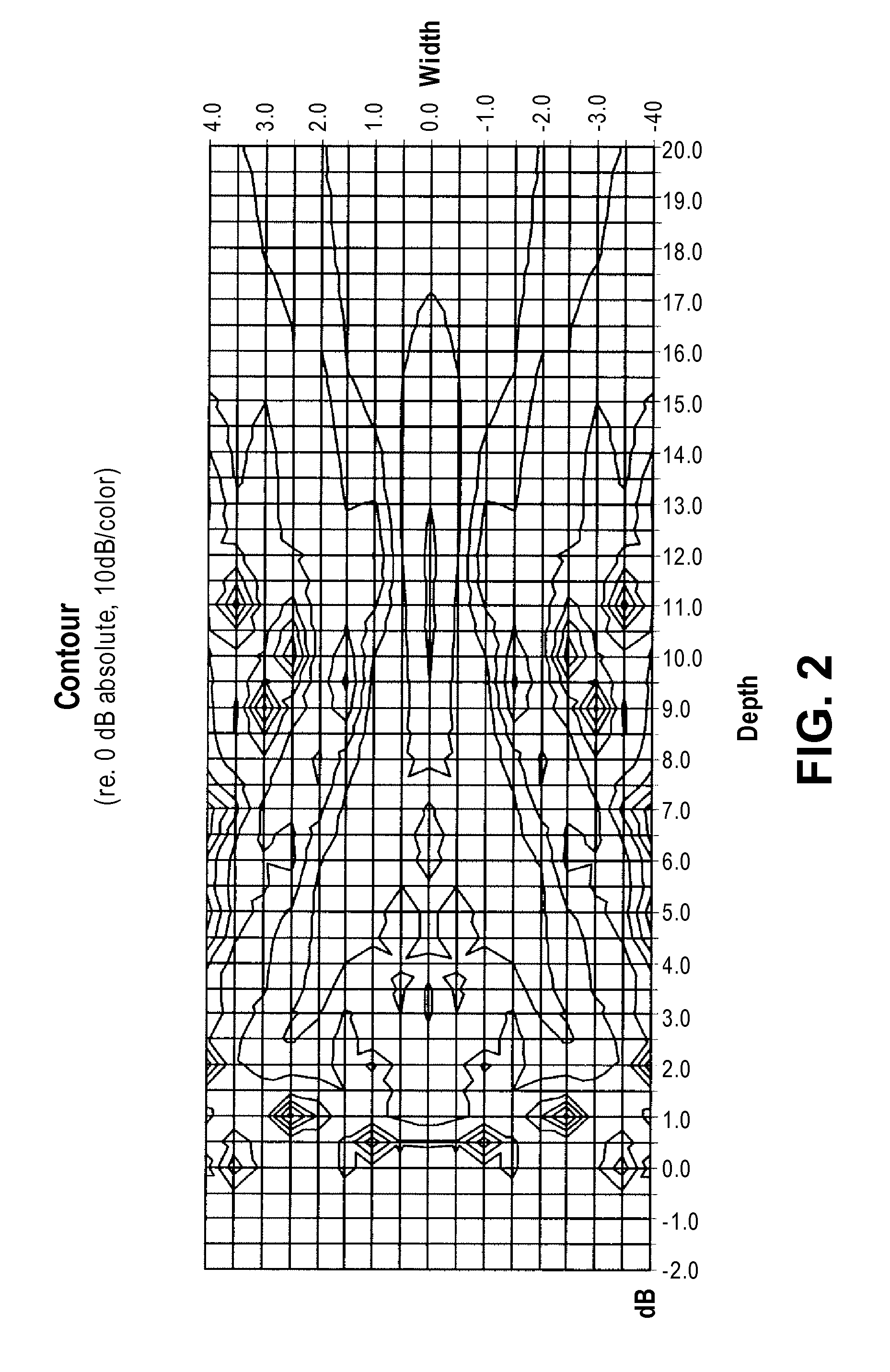

This invention relates to a non-invasive, safer alternative to current lipoplasty procedures. The preferred embodiment of the invention is a multi-channel system that focuses the low mega Hertz ultrasound at user selectable depths, where fat cells are to be emulsified. The system has independent user control of the main emulsifying property, cavitation, and thermal heating, which can independently be used for skin tightening. One part of the system is a handheld transducer, in shape similar to a typical small diagnostic ultrasound transducer. The other part of the system includes a transmitter with internal tracking of procedure time and with a disabling feature.

Owner:NIVASONIX

External ultrasound lipoplasty

InactiveUS20090227910A1Safer procedureUltrasonic/sonic/infrasonic diagnosticsUltrasound therapySonificationCavitation

This invention relates to a non-invasive, safer alternative to current lipoplasty procedures. The preferred embodiment of the invention is a multi-channel system that focuses the low mega Hertz ultrasound at user selectable depths, where fat cells are to be emulsified. The system offers independent user control of the main emulsifying property, cavitation, and thermal heating, which can independently be used for skin tightening. One part of the system is a handheld transducer, in shape similar to a typical small diagnostic ultrasound transducer. The other part of the system includes a transmitter with, for example, internal tracking of procedure time and with a disabling feature.

Owner:NIVASONIX

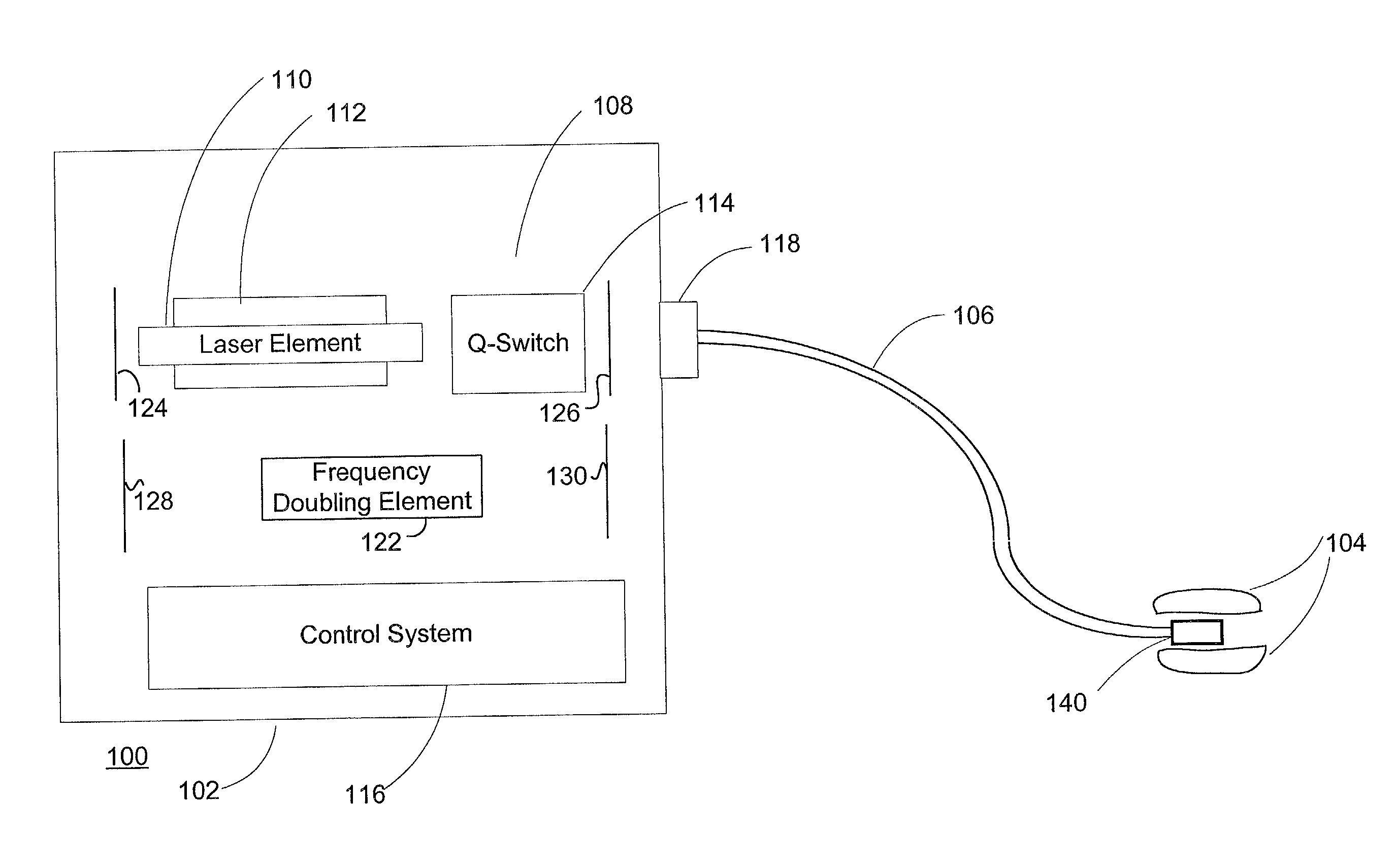

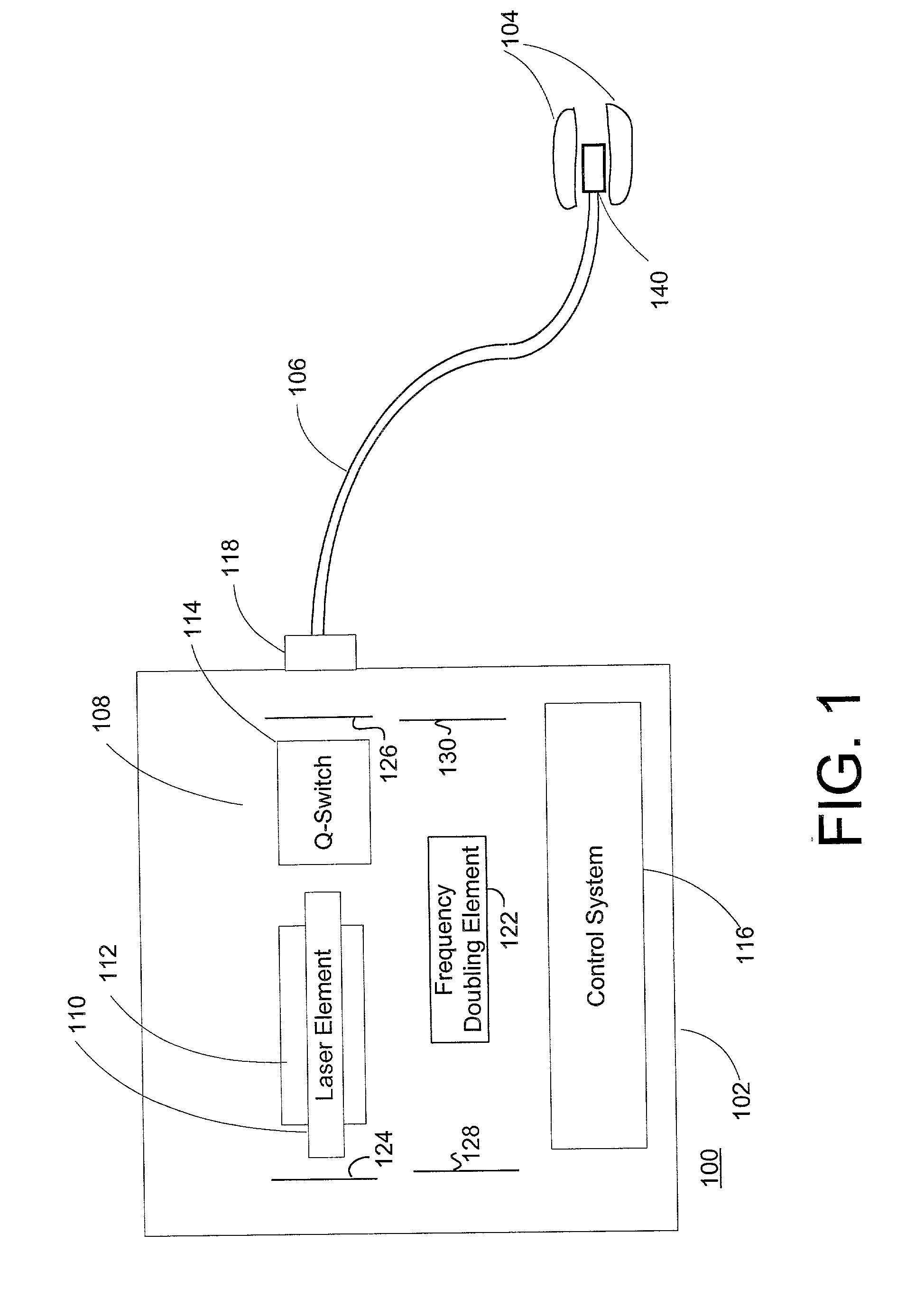

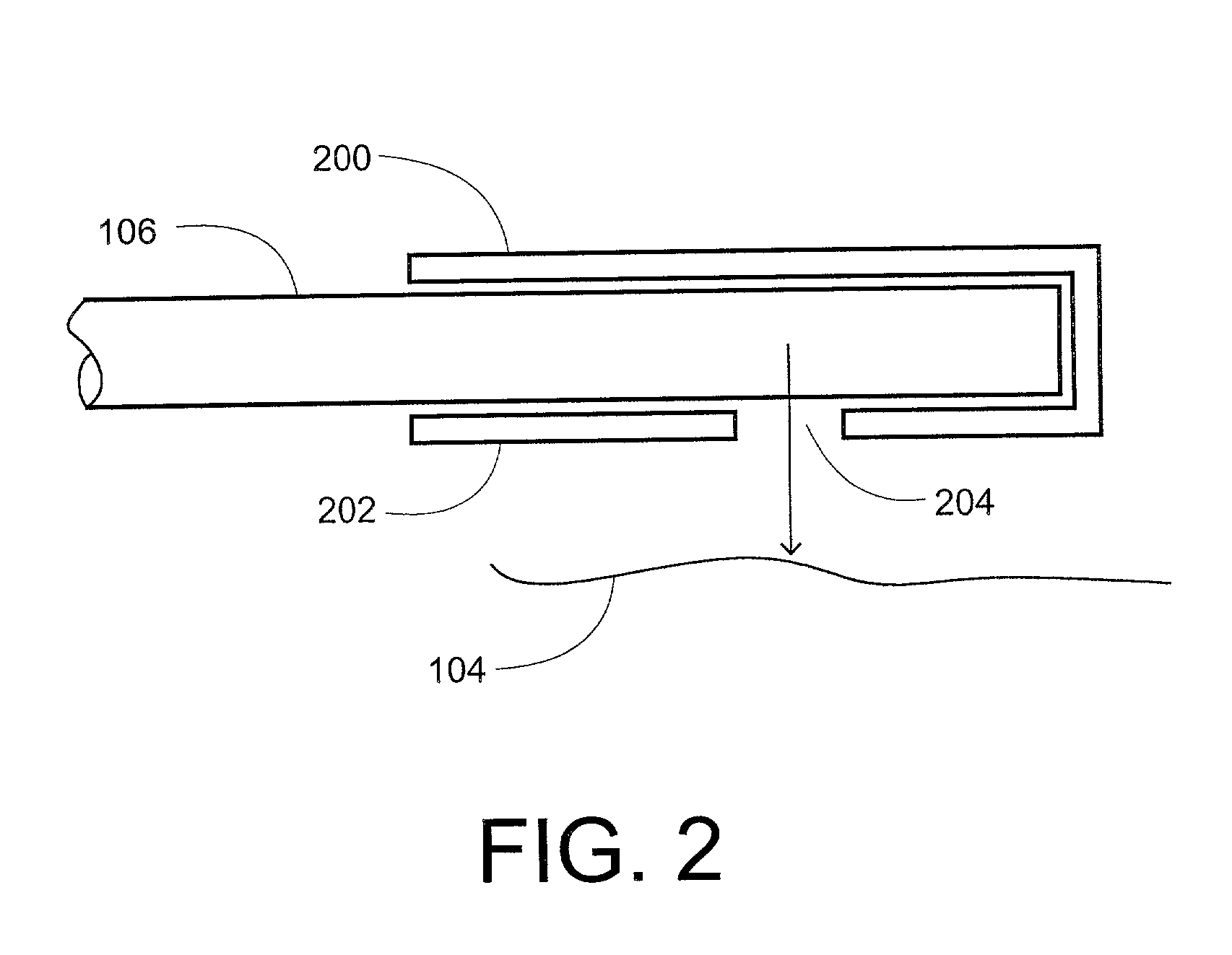

Methods for laser treatment of soft tissue

Methods are provided for treating prostate glands or other targeted soft tissue using a solid-state laser. The laser can be operated to generate a pulsed output beam having pulse durations of between 0.1 and 500 milliseconds. The output beam is delivered to the targeted tissue through an optical fiber, preferably terminating in a side-firing probe or diffusing tip. By operating the laser in a long-duration pulse mode, charring of the targeted tissue is initiated quickly, thereby increasing ablation rates and reducing overall procedure time.

Owner:BOSTON SCI SCIMED INC

External ultrasound lipoplasty

InactiveUS7955281B2Safer procedureUltrasonic/sonic/infrasonic diagnosticsUltrasound therapyCavitationSonification

This invention relates to a non-invasive, safer alternative to current lipoplasty procedures. The preferred embodiment of the invention is a multi-channel system that focuses the low mega Hertz ultrasound at user selectable depths, where fat cells are to be emulsified. The system has independent user control of the main emulsifying property, cavitation, and thermal heating, which can independently be used for skin tightening. One part of the system is a handheld transducer, in shape similar to a typical small diagnostic ultrasound transducer. The other part of the system includes a transmitter with internal tracking of procedure time and with a disabling feature.

Owner:NIVASONIX

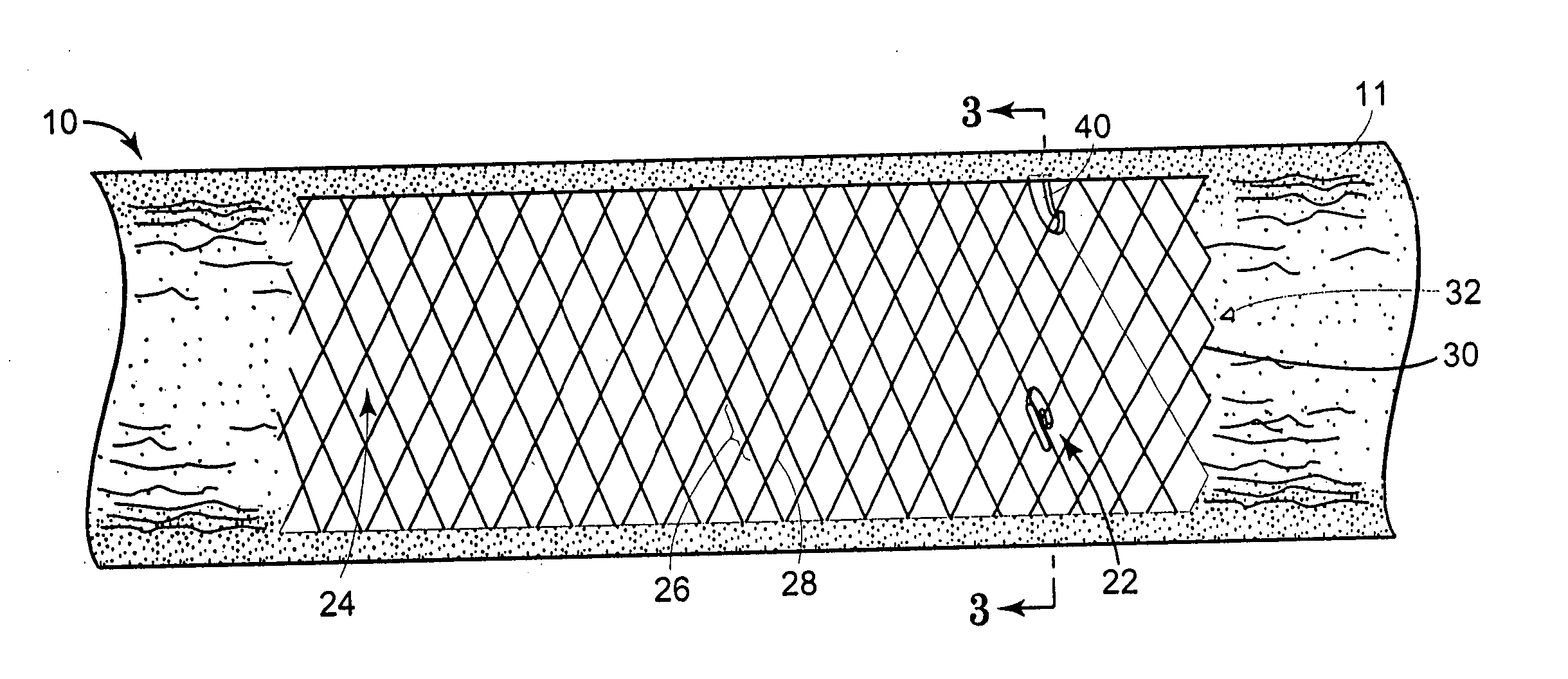

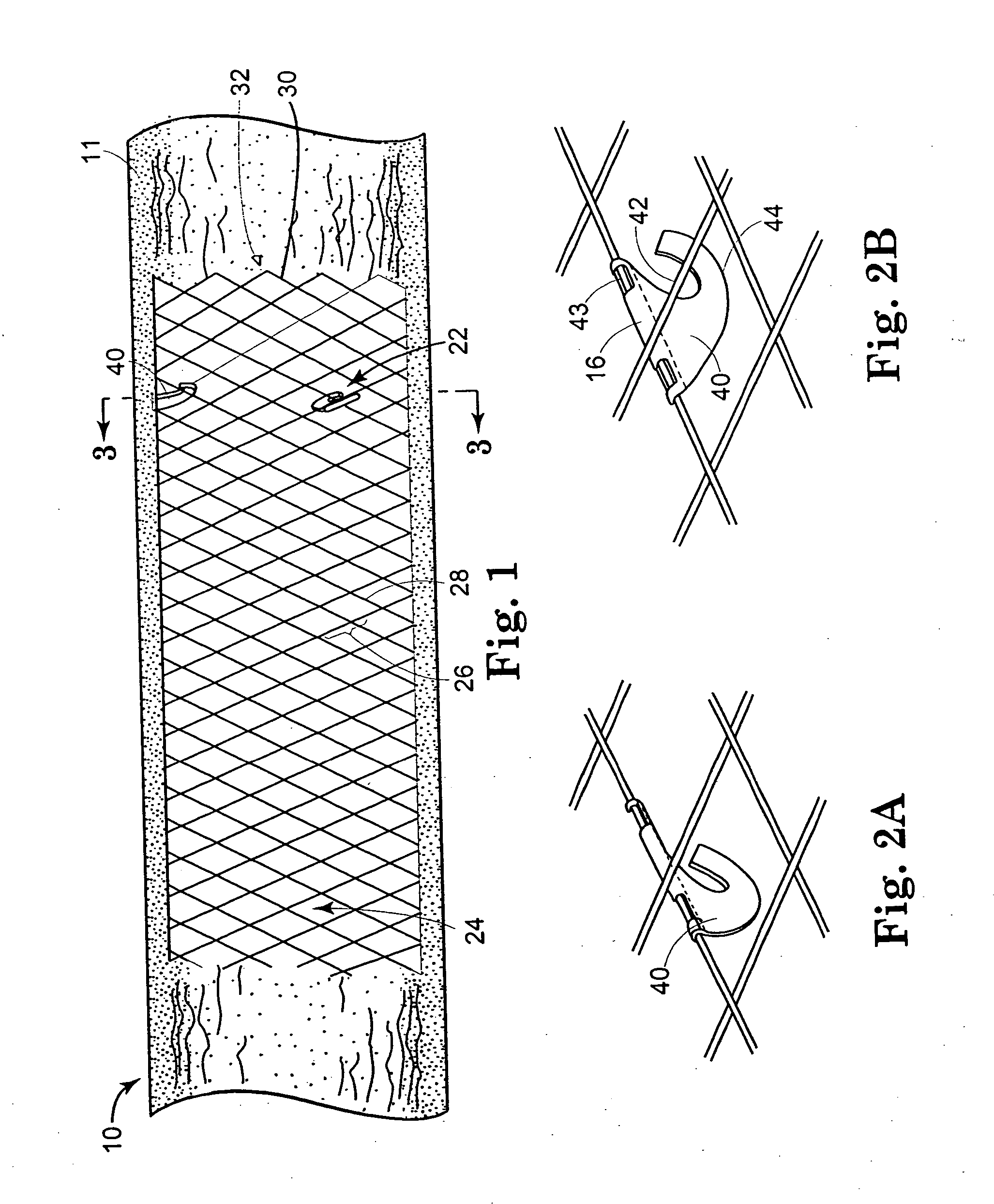

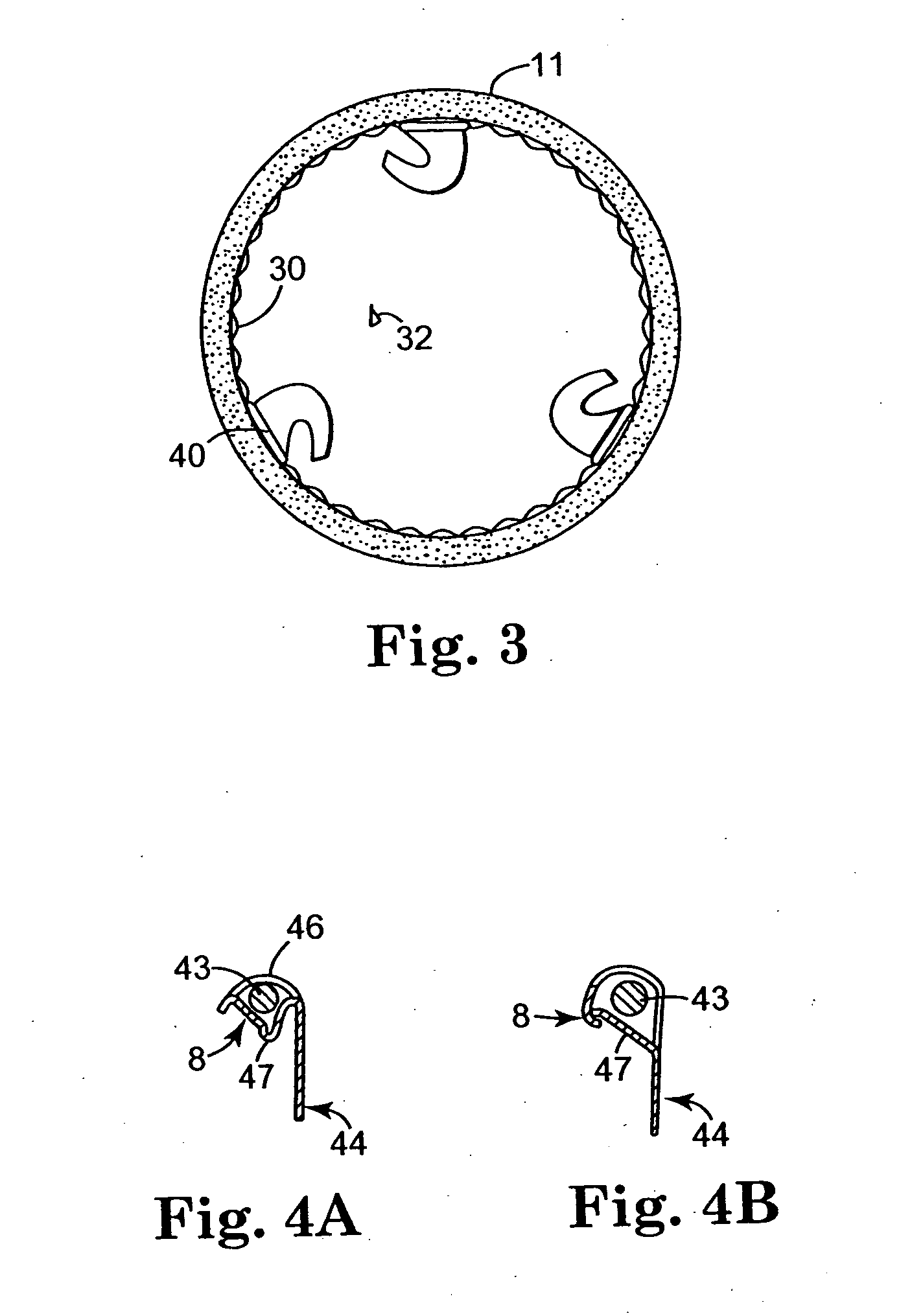

Retrievable stent and method of use thereof

A removable stent system and method for extraction of a removable stent from a target site is disclosed. The removable stent includes a removable stent having a collapsible end and a collapsing element configured for coupling with a removal tool. The collapsing element can be configured as a lasso or can be movable between two positions when deployed at a target site in vivo. The removable stent overcomes disadvantages and limitations of previous types of stents as well as overcoming complications during or following stent deployment in vivo. The removable stent further includes features that increase its ease of use and reduce the maneuvering required of devices or tools used to remove the stent. This then decreases the amount of effort required by the physician, the procedure time, and the level of discomfort experienced by a patient during the procedure.

Owner:BOLEA STEPHEN L +5

External ultrasound lipoplasty

InactiveUS8262591B2Safer procedureUltrasonic/sonic/infrasonic diagnosticsUltrasound therapyCavitationSonification

This invention relates to a non-invasive, safer alternative to current lipoplasty procedures. The preferred embodiment of the invention is a multi-channel system that focuses the low mega Hertz ultrasound at user selectable depths, where fat cells are to be emulsified. The system offers independent user control of the main emulsifying property, cavitation, and thermal heating, which can independently be used for skin tightening. One part of the system is a handheld transducer, in shape similar to a typical small diagnostic ultrasound transducer. The other part of the system includes a transmitter with, for example, internal tracking of procedure time and with a disabling feature.

Owner:NIVASONIX

Optical-acoustic imaging device

InactiveUS20040082844A1Shorten operation timeReduce radiation exposureMaterial analysis using sonic/ultrasonic/infrasonic wavesSubsonic/sonic/ultrasonic wave measurementGratingRadiation exposure

The present invention is a guide wire imaging device for vascular or non-vascular imaging utilizing optic acoustical methods, which device has a profile of less than 1 mm in diameter. The ultrasound imaging device of the invention comprises a single mode optical fiber with at least one Bragg grating, and a piezoelectric or piezo-ceramic jacket, which device may achieve omnidirectional (360°) imaging. The imaging guide wire of the invention can function as a guide wire for vascular interventions, can enable real time imaging during balloon inflation, and stent deployment, thus will provide clinical information that is not available when catheter-based imaging systems are used. The device of the invention may enable shortened total procedure times, including the fluoroscopy time, will also reduce radiation exposure to the patient and to the operator.

Owner:PHYZHON HEALTH INC

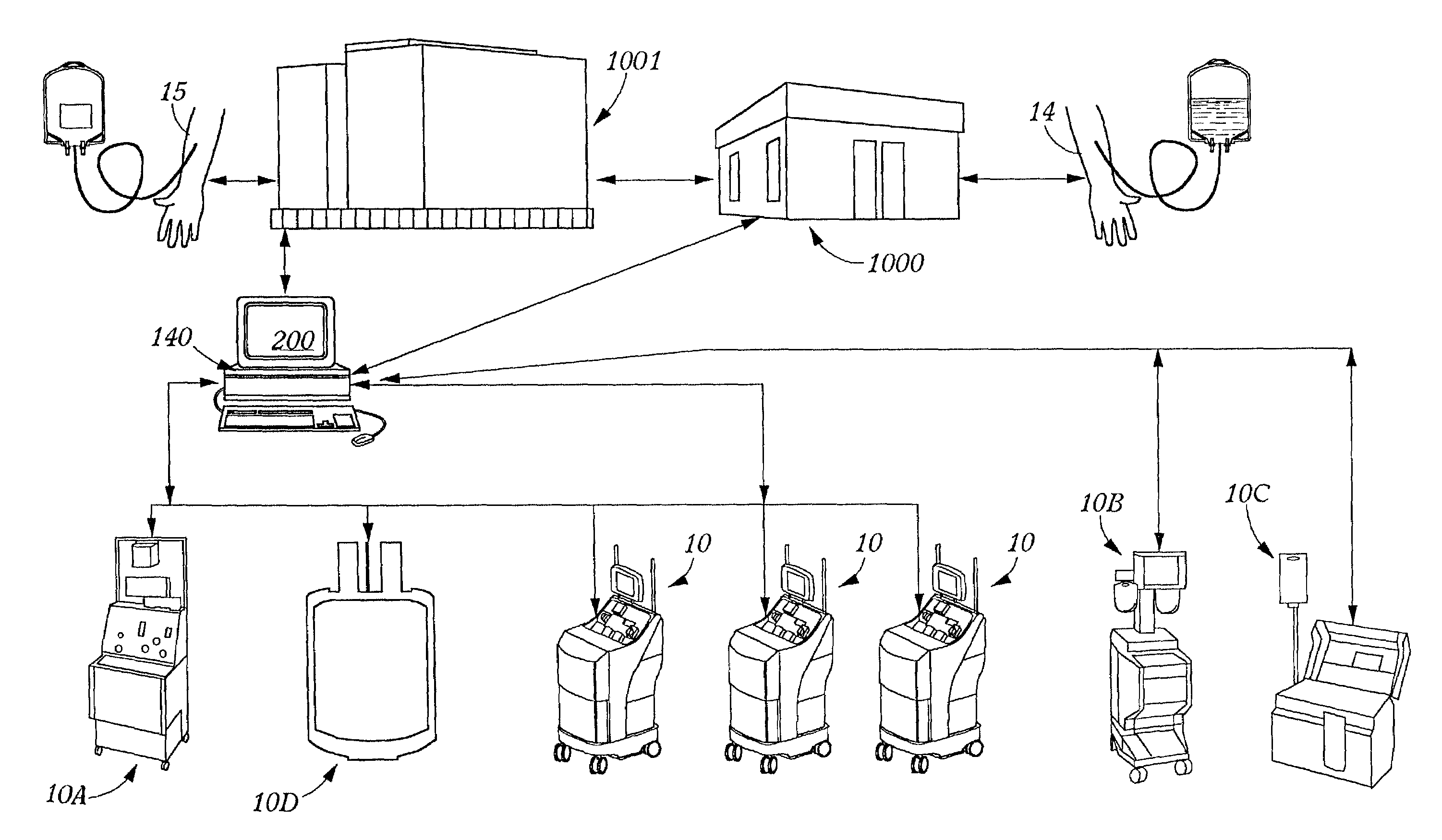

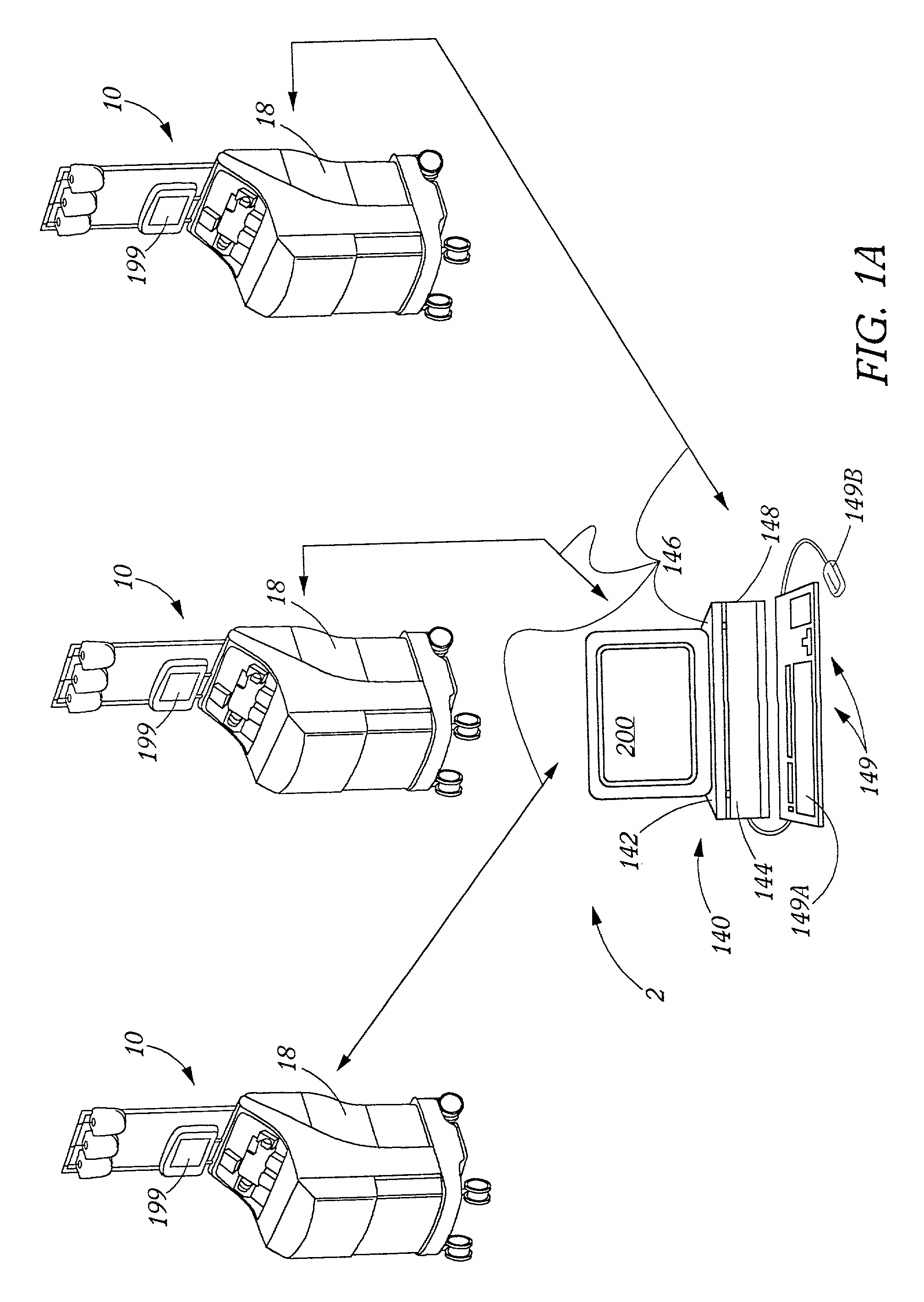

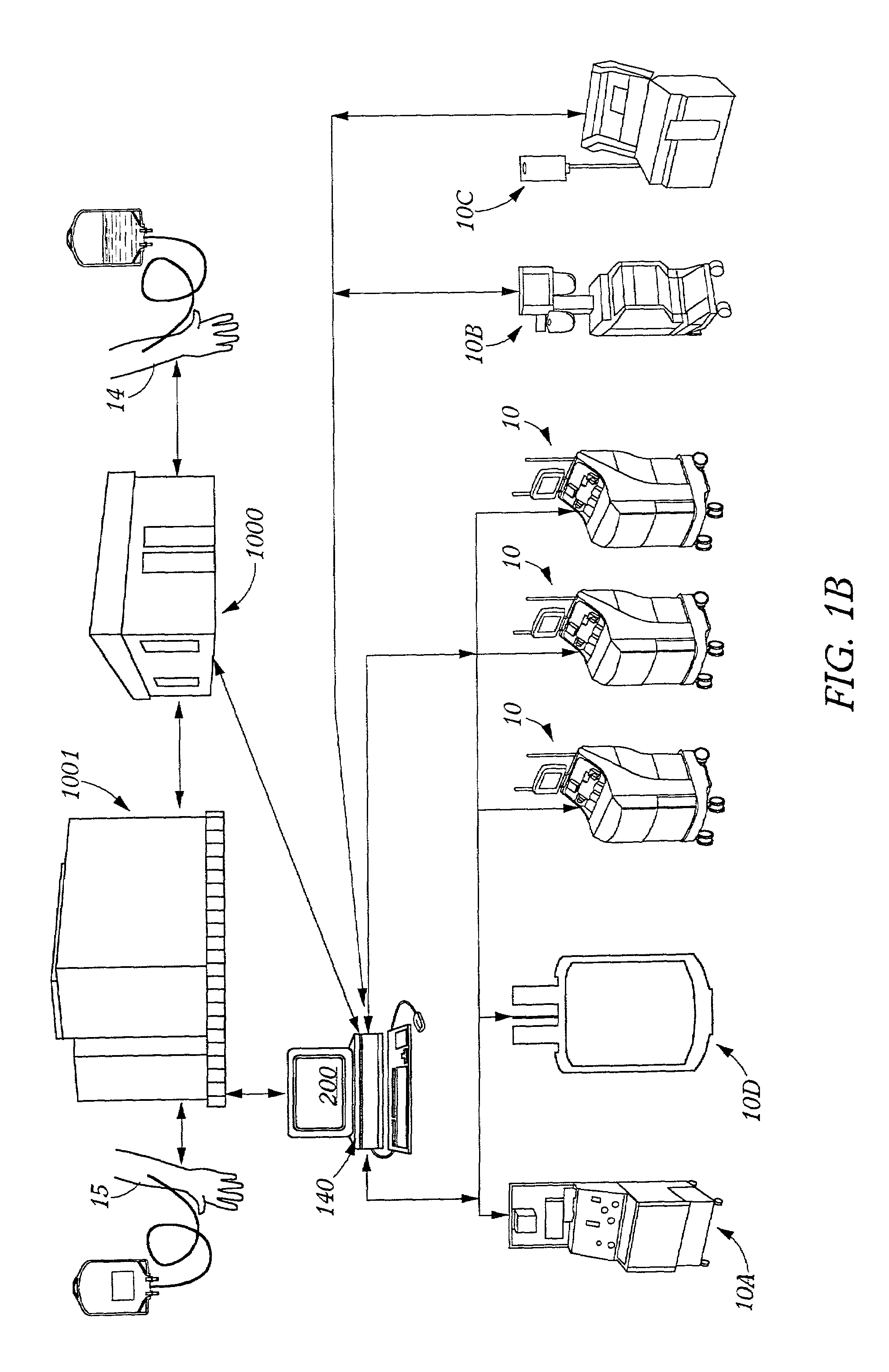

Extracorporeal blood processing information management system

ActiveUS7072769B2Simplified storage and controlEase and optimize and operationMechanical/radiation/invasive therapiesOther blood circulation devicesBlood componentCollection system

A blood component collection system with manipulation and optimization capabilities. In one embodiment, process parameters are derived from an input / configured predetermined blood component yield and which is based upon the maximization of at least one process parameter. Thereafter, the blood component collection procedure is performed with these derived process control parameters. In another embodiment, process parameters are derived from an input total procedure time from a maximized value for at least one of the other process control parameters so as to maximize blood component yield in this fixed time. Thereafter, the blood component collection procedure is performed with these derived parameters.

Owner:TERUMO BCT

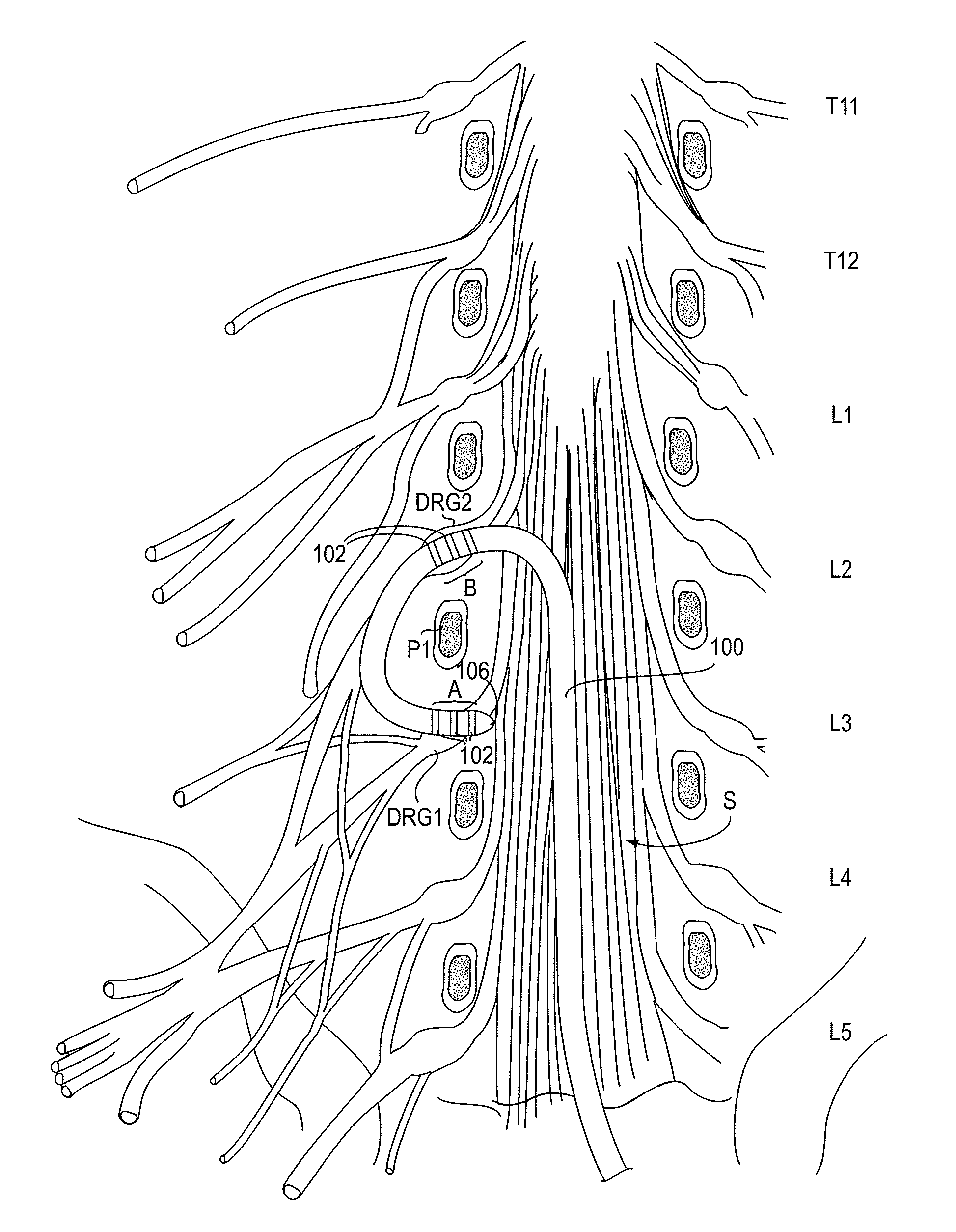

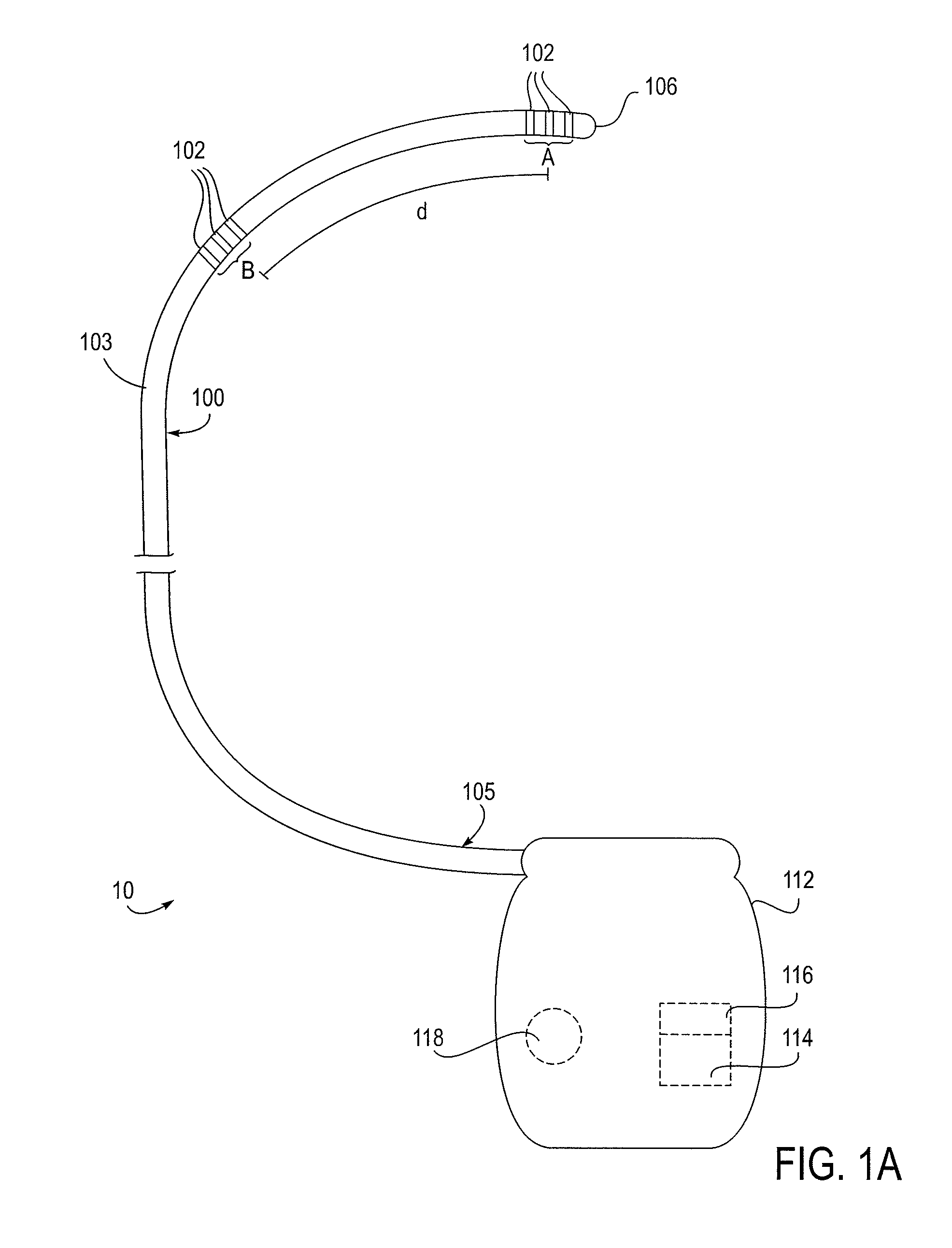

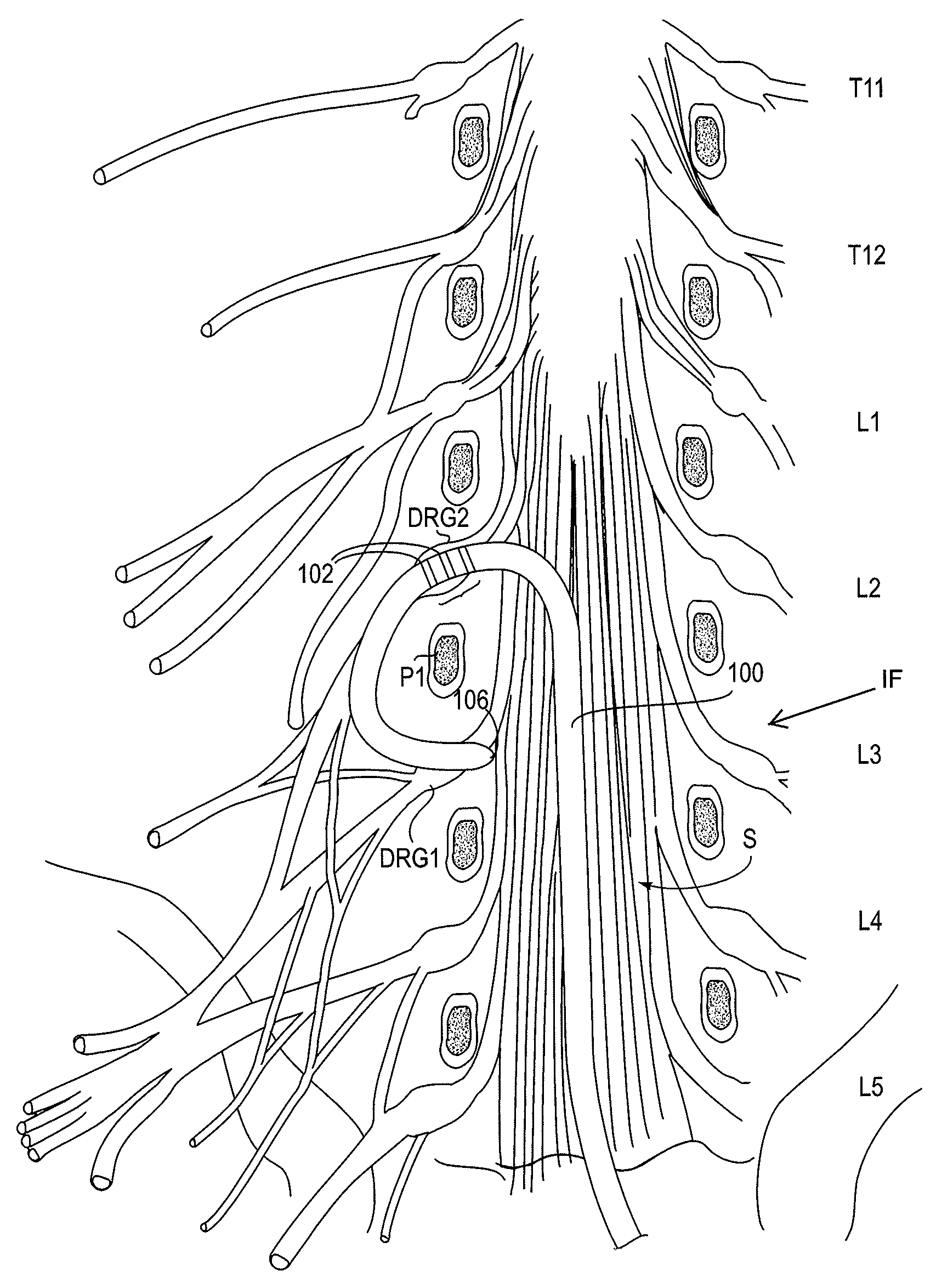

Methods, systems and devices for neuromodulating spinal anatomy

ActiveUS20100292769A1Minimizing complicationMinimize side effectsSpinal electrodesExternal electrodesSide effectSpinal anatomy

Devices, systems and methods for treating pain or other conditions while minimizing possible complications and side effects. Treatment typically includes electrical stimulation and / or delivery of pharmacological or other agents with the use of a lead or catheter. The devices, systems and methods provide improved anchoring which reduces migration of the lead yet allows for easy repositioning or removal of the lead if desired. The devices, systems and methods also provide for simultaneous treatment of multiple targeted anatomies. This shortens procedure time and allows for less access points, such as needle sticks to the epidural space, which in turn reduces complications, such as cerebral spinal fluid leaks, patient soreness and recovery time. Other possible complications related to the placement of multiple devices are also reduced.

Owner:TC1 LLC

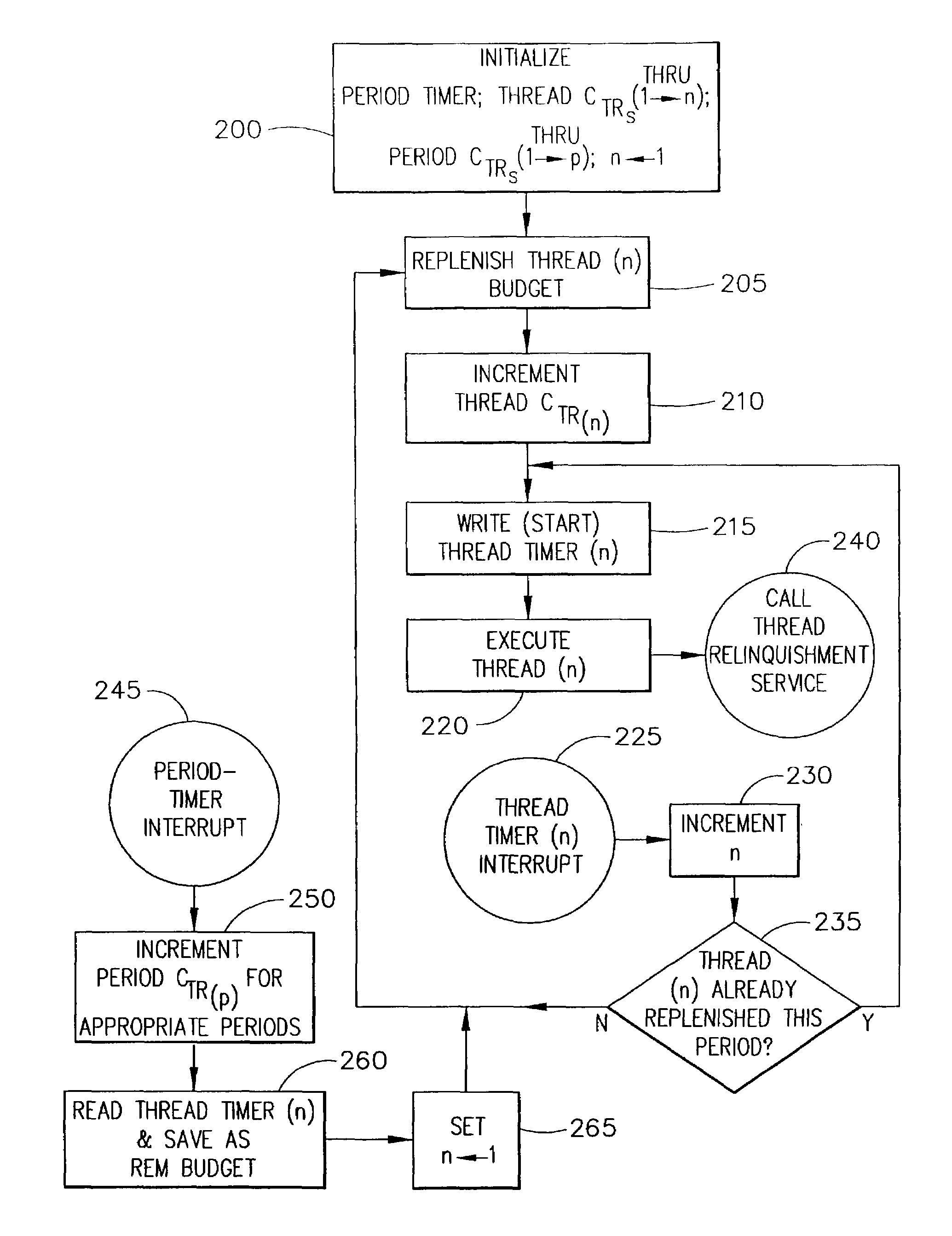

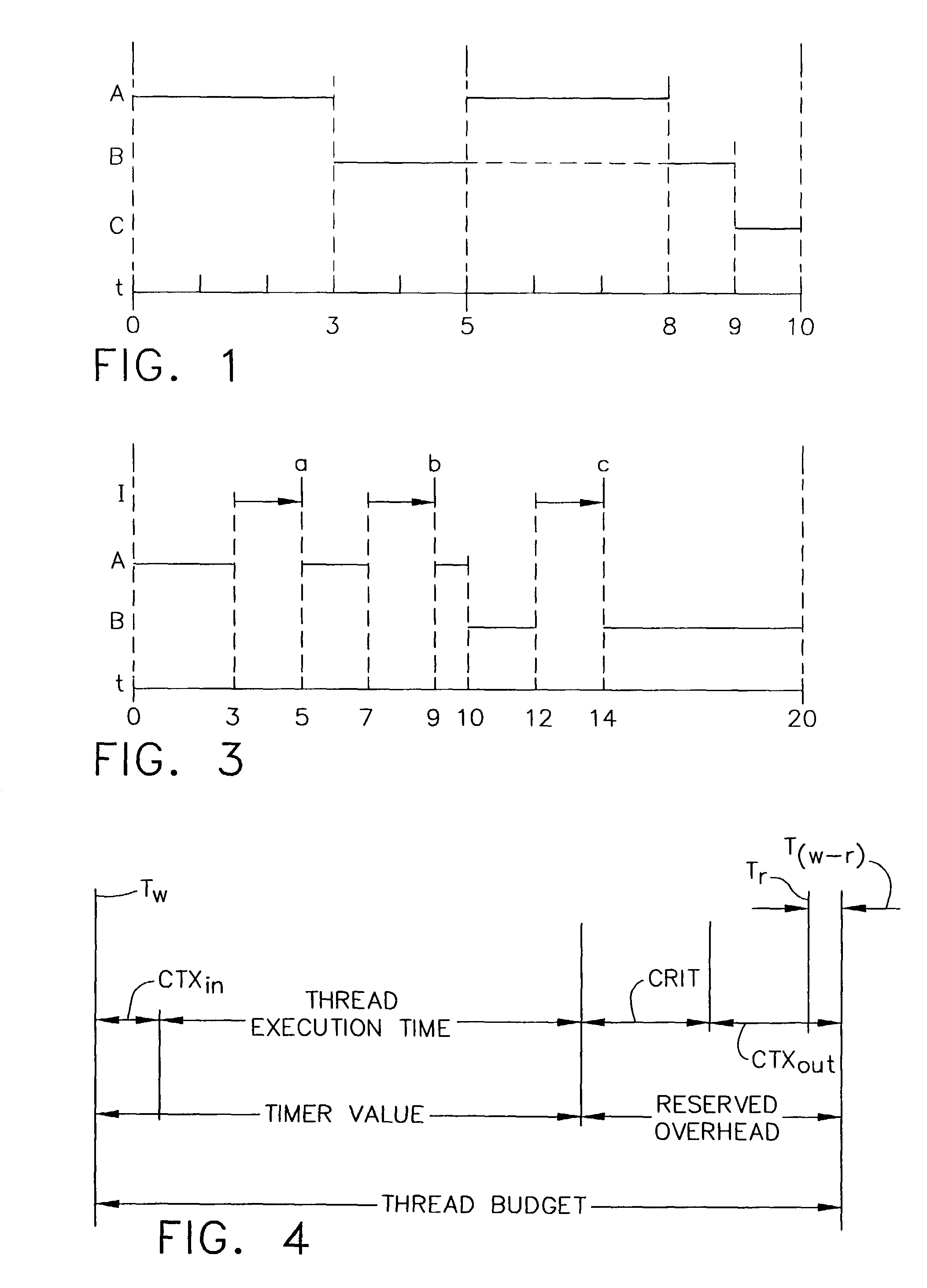

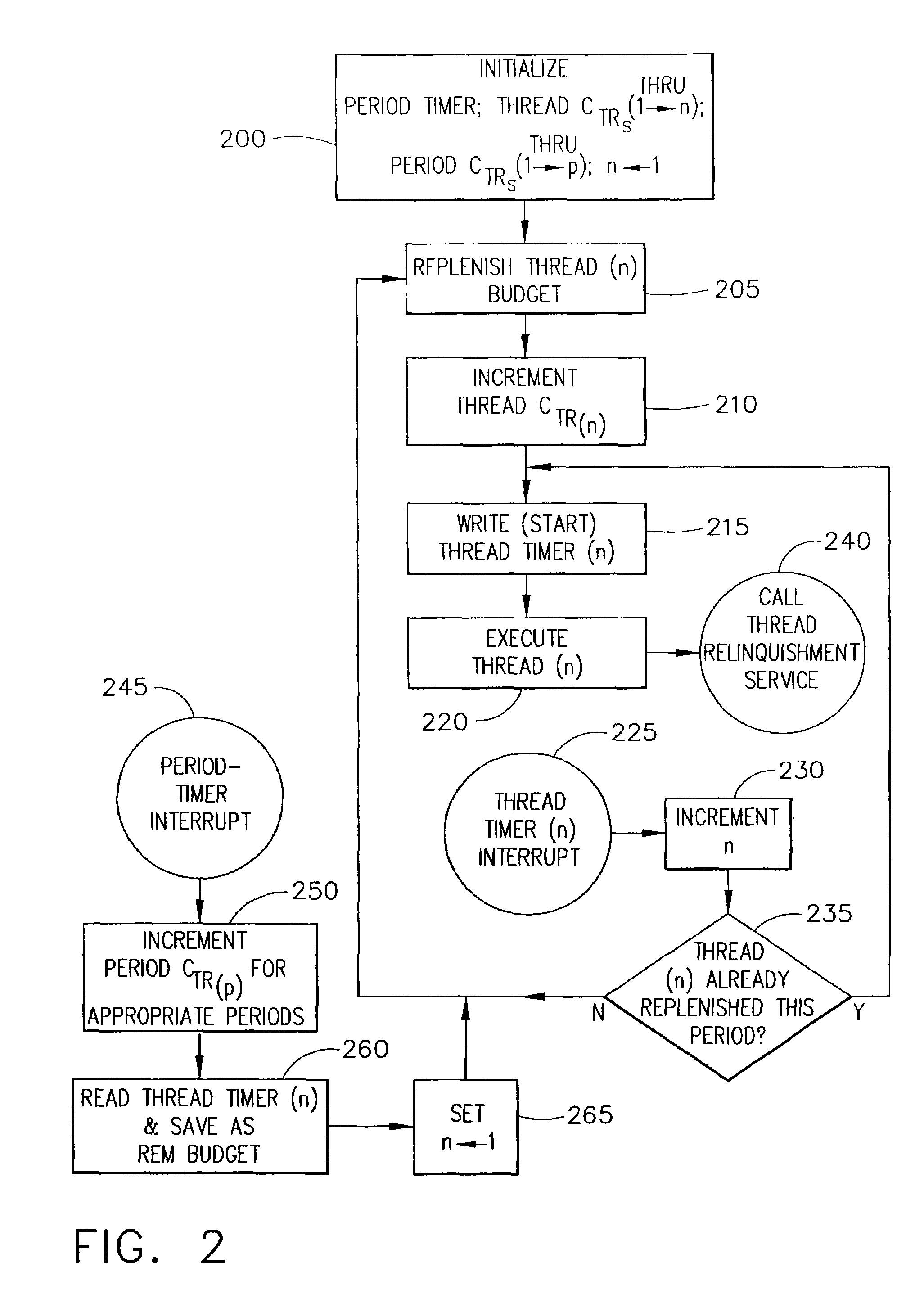

System and method for robust time partitioning of tasks in a real-time computing environment

InactiveUS7207042B2Eliminate needSimplifies enforcementProgram initiation/switchingResource allocationOperational systemApplication software

A time-partitioned system for accounting for processor time consumed by operating system services provided on behalf of an application runs in a real-time environment. The time utilized by the operating system is treated as application processing time, rather than viewing the resultant processor time consumed as an operating system overhead. Each application consists of one or more threads. A time budget is assigned to each thread and to each interrupt. The processor time consumed by the operating system when executing on behalf of a thread or interrupt is charged back to the application or interrupt as part of the application's time budget. Operating system overheads and processor interrupts are thus accounted for accurately enough to determine a schedule for the applications that is enforceable by the operating system at run time.

Owner:HONEYWELL INT INC

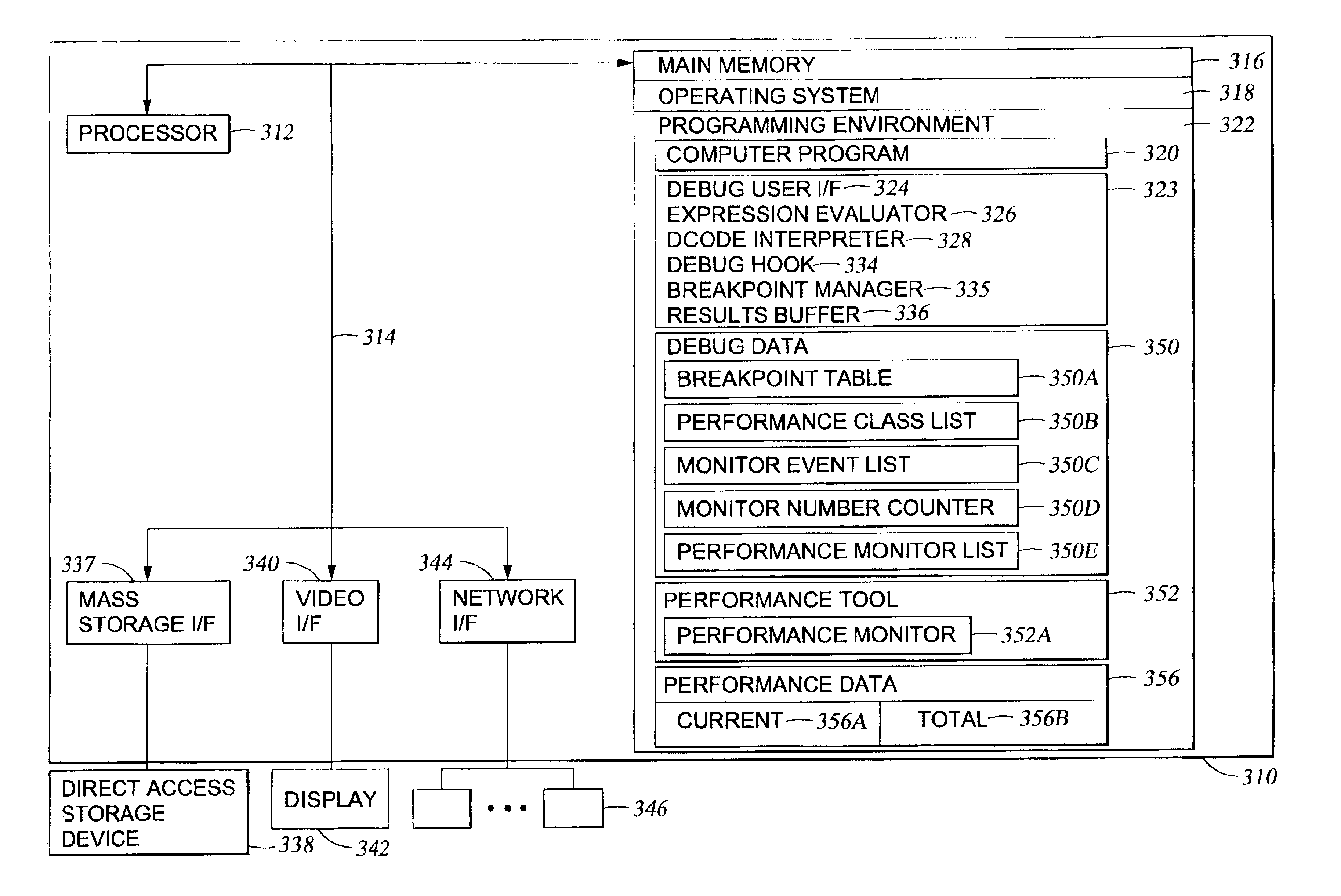

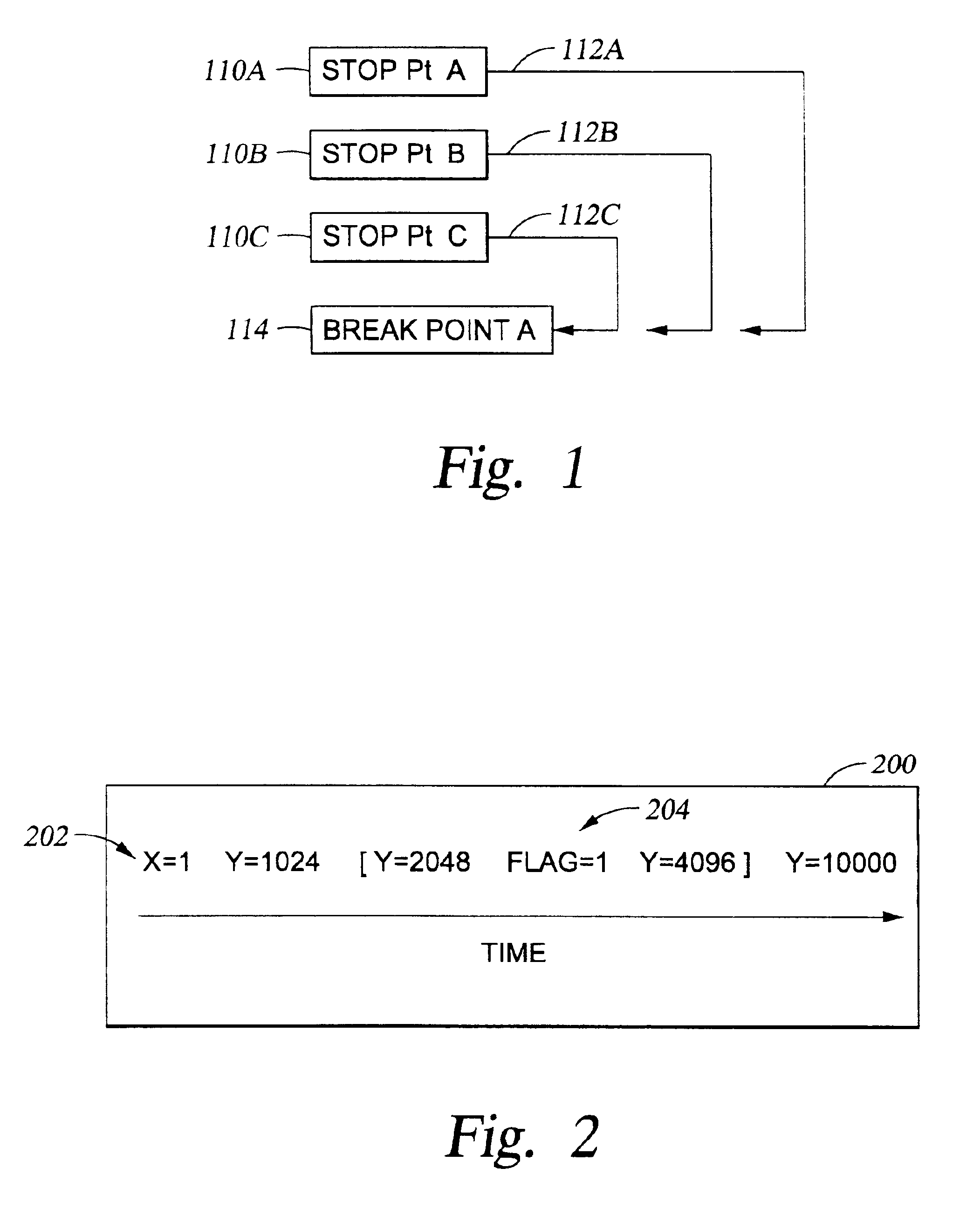

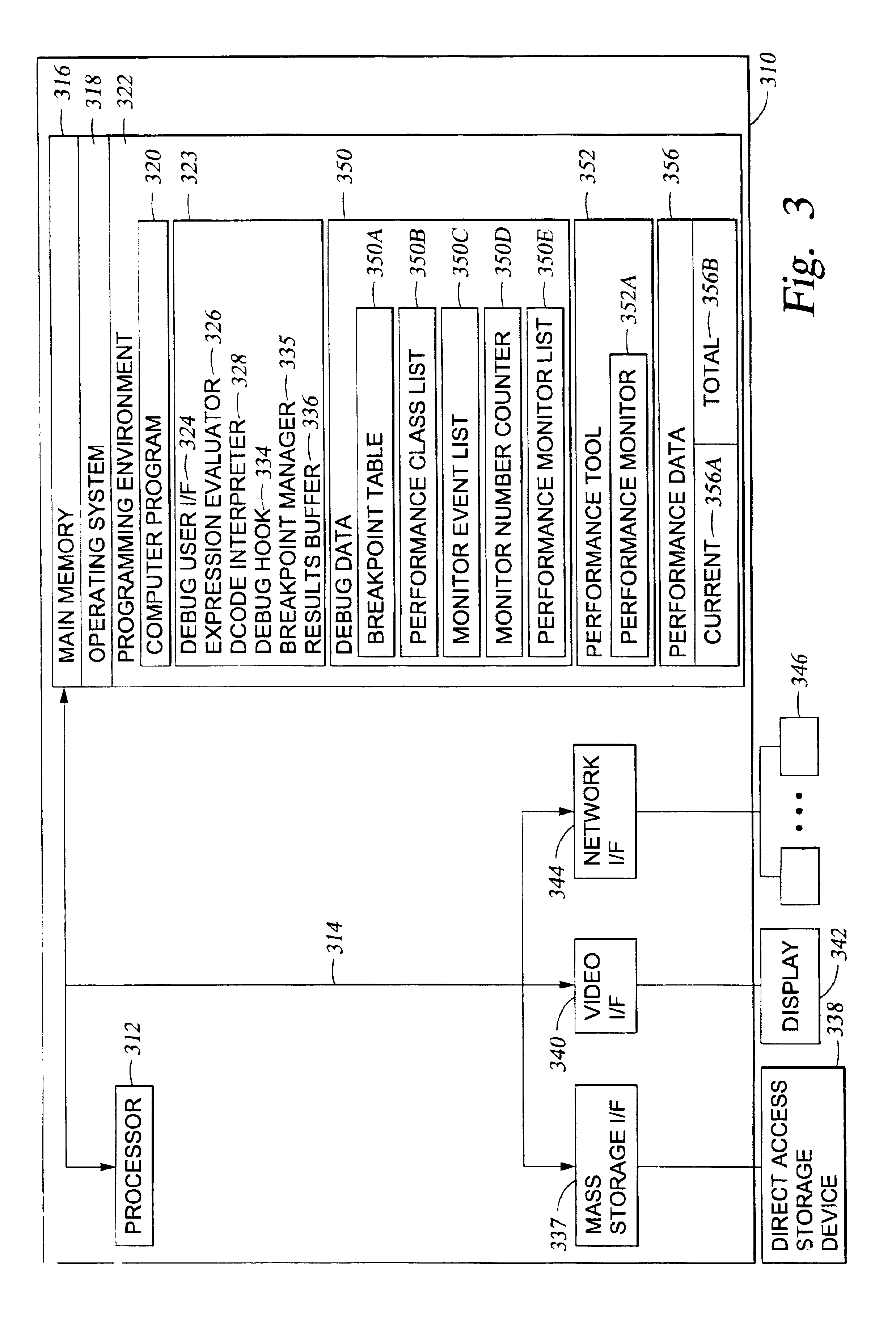

Debugger program time monitor

Apparatus, methods and articles of manufacture for collecting performance data in a debugger environment. In one embodiment, performance data is collected and associated with a breakpoint. The performance data may then be displayed to a user in a meaningful way. In one embodiment, a user is provided with performance data for the last execution path resulting in terminating at a breakpoint, regardless of an origination point of the execution path. In another embodiment, a user is provided with the collective performance data for any execution path terminating at a breakpoint. In still another embodiment, a user is provided with a historical account for a particular execution path using cumulative data for that path. Still another embodiment provides a debugger configured to track performance data based on variable values.

Owner:IBM CORP

Methods for laser treatment of soft tissue

Methods are provided for treating prostate glands or other targeted soft tissue using a solid-state laser. The laser can be operated to generate a pulsed output beam having pulse durations of between 0.1 and 500 milliseconds. The output beam is delivered to the targeted tissue through an optical fiber, preferably terminating in a side-firing probe or diffusing tip. By operating the laser in a long-duration pulse mode, charring of the targeted tissue is initiated quickly, thereby increasing ablation rates and reducing overall procedure time.

Owner:BOSTON SCI SCIMED INC

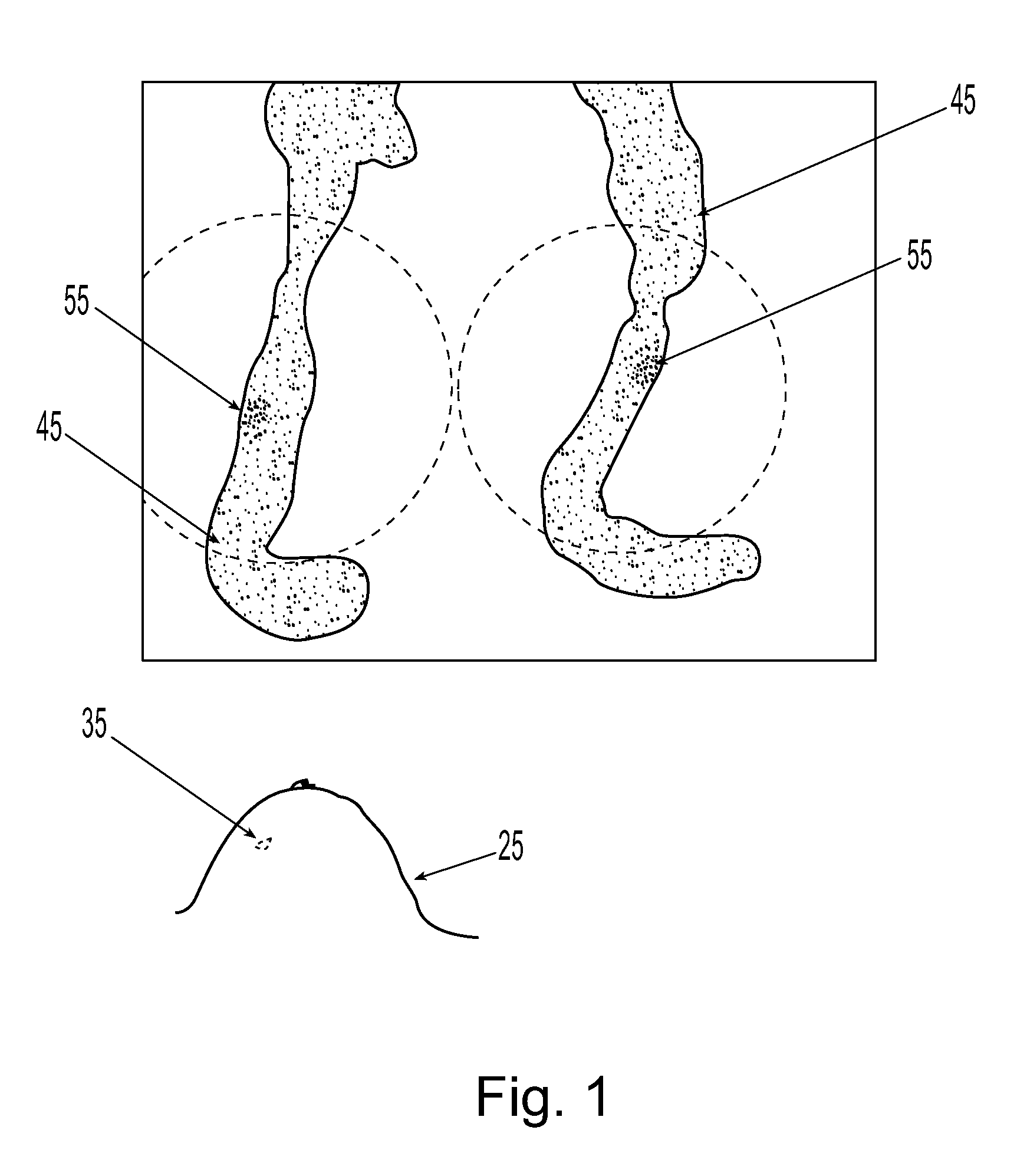

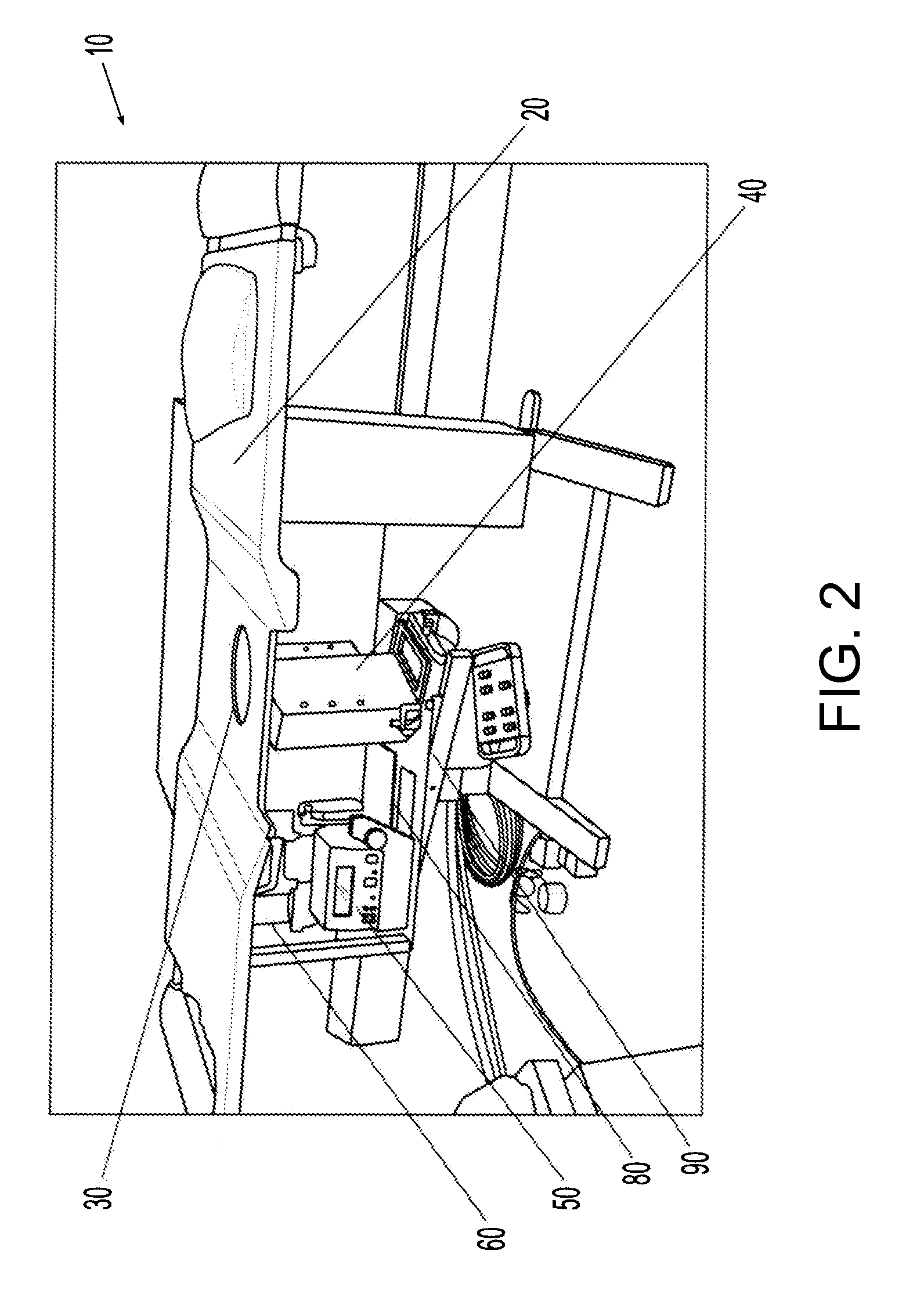

System and apparatus for rapid stereotactic breast biopsy analysis

InactiveUS7715523B2Rapid productionImprove toleranceVaccination/ovulation diagnosticsPatient positioning for diagnosticsDigital imagingBleeding complication

A stereotactic breast biopsy apparatus and system that may comprise an x-ray source, a digital imaging receptor, and a biopsy specimen cassette, wherein the x-ray source is provided with a means for displacing the beam axis of the x-ray source from a working biopsy corridor beam axis to permit an unobstructed illumination of the biopsy specimen and thereby produce biopsy x-ray images directly in the procedure room for immediate analysis. Some examples of the benefits may be, but are not limited to, a more rapid analysis of biopsy specimen digital images, post-processing image capability, and decreased procedure time and diminution of patient bleeding complications and needle discomfort.

Owner:LAFFERTY PETER R

Methods, systems and devices for neuromodulating spinal anatomy

ActiveUS9259569B2Minimally invasivePromote migrationSpinal electrodesExternal electrodesSide effectSpinal anatomy

Devices, systems and methods for treating pain or other conditions while minimizing possible complications and side effects. Treatment typically includes electrical stimulation and / or delivery of pharmacological or other agents with the use of a lead or catheter. The devices, systems and methods provide improved anchoring which reduces migration of the lead yet allows for easy repositioning or removal of the lead if desired. The devices, systems and methods also provide for simultaneous treatment of multiple targeted anatomies. This shortens procedure time and allows for less access points, such as needle sticks to the epidural space, which in turn reduces complications, such as cerebral spinal fluid leaks, patient soreness and recovery time. Other possible complications related to the placement of multiple devices are also reduced.

Owner:TC1 LLC

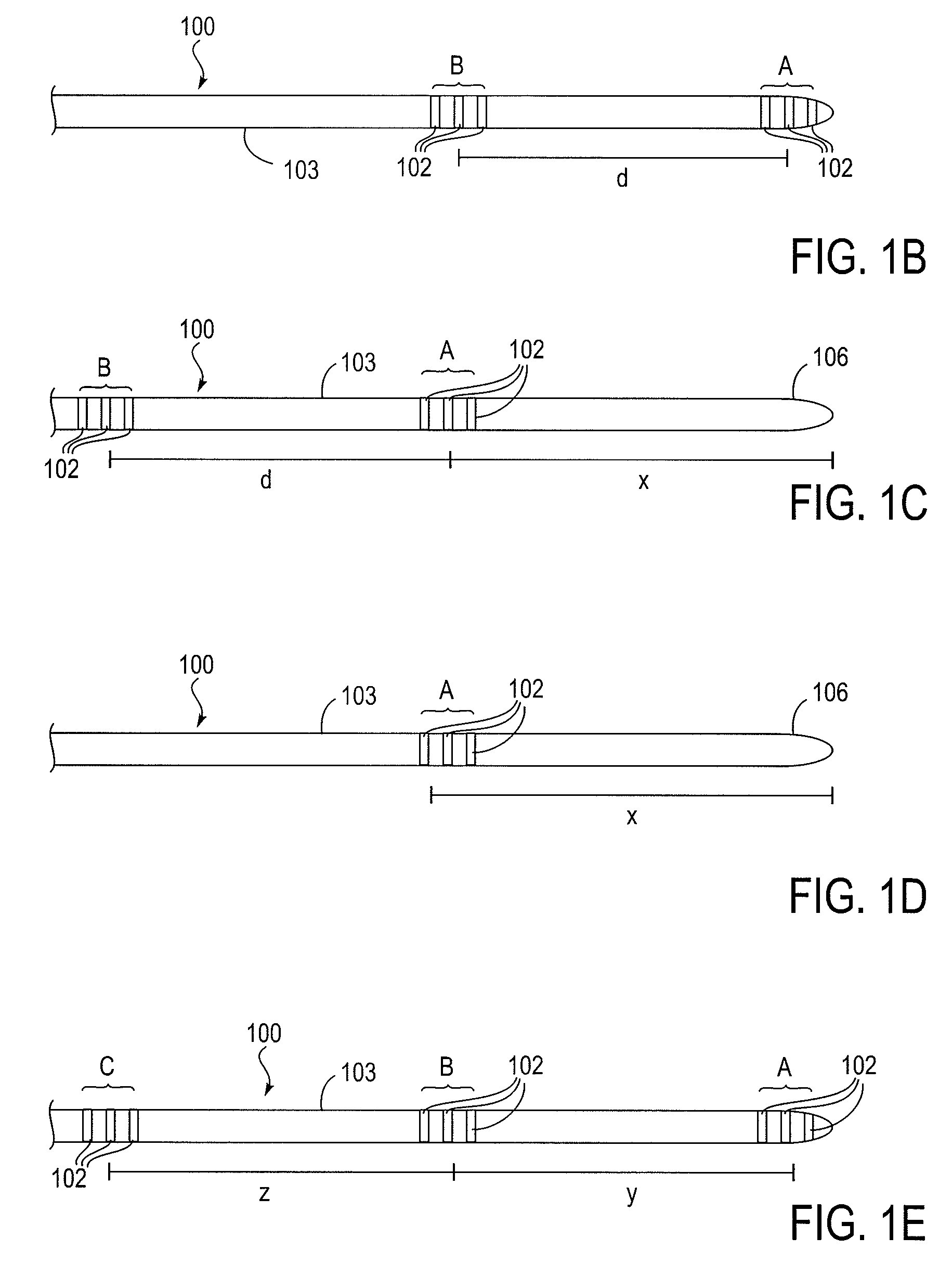

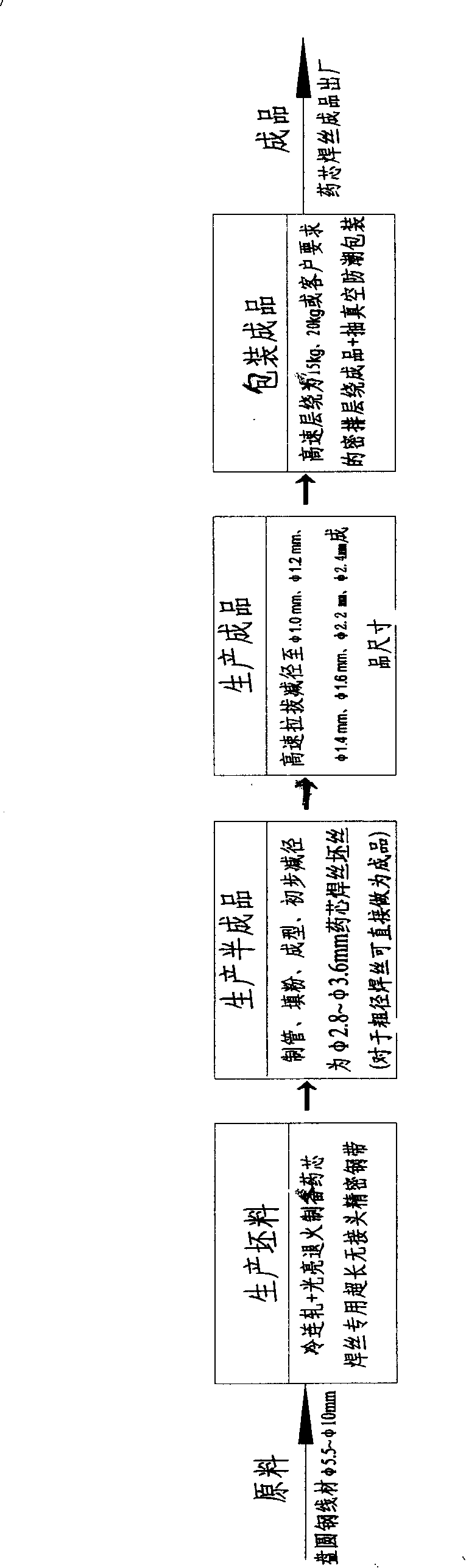

Technique for manufacturing flux-cored wire from disk round steel wire bar

InactiveCN101239430ASufficient bending radiusPrevent space warpingFurnace typesRollsFill rateBreakage rate

A technique for producing flux-cored wires by using disc round steel wire bars is characterized by comprising following steps: using disc round steel wire bars as raw materials; producing accurate steel bands used for flux-cored wires exclusively; producing semi-finished products which are flux-cored wire blank tubes by using accurate steel bands; producing termination products by drafting to reduce the diameter thereof with a high speed; packaging the termination products by winding with a high speed. The advantages of the invention are: the invented technique uses high-speed hot-rolling disc round steel wire bars to replace broad cold-rolled steel strip, so that the raw material cost is reduced greatly; the continuous overlong endless accurate steel bands are used to save assistant procedure time for welding steel band joints, reduce end breakage rate during rolling and drafting procedures, improve continuous operation rate, and further reduce production cost; the invented technique uses high-speed accurate cold tandem rolling machine group to solve the problem that the sheet iron rolling precision is difficult to be controlled when rolling flux-cored wires by using disc round steel wire bars directly, and the filling precision is improved greatly since size accuracy of the flux-cored wire exclusive use accurate steel bands is high.

Owner:TIANJIN SAINTEAGLE WELDING CO LTD

System and apparatus for rapid stereotactic breast biopsy analysis

InactiveUS8503602B2Rapid productionImprove toleranceVaccination/ovulation diagnosticsPatient positioning for diagnosticsBleeding complicationDigital imaging

A stereotactic breast biopsy apparatus and system that may comprise an x-ray source, a digital imaging receptor, and a biopsy specimen cassette, wherein the digital imaging receptor is adjustably secured to the apparatus to permit an unobstructed illumination of the biopsy specimen and thereby produce biopsy x-ray images directly in the procedure room for immediate analysis. Some examples of the benefits may be, but are not limited to, a more rapid analysis of biopsy specimen digital images, post-processing image capability, and decreased procedure time and diminution of patient bleeding complications and needle discomfort.

Owner:LAFFERTY PETER R

Fluid packing forming device and method thereof

ActiveCN101337593AImprove stabilityAvoid pollutionWrappingPackaging under vacuum/special atmosphereManufacturing cost reductionProduct gas

The invention relates to a fluid encapsulation forming device and a method thereof. An upper thin film and a lower thin film are respectively placed on a middle die seat and a lower die seat, fluid is infused into the lower die seat, through sealing a vacuum cavity body where the middle die seat and the lower die seat are positioned through a valve, the gas in the vacuum cavity body can be extracted by using a vacuum pump unit to form a state close to the vacuum state, and by performing hot pressure sealing to the vertically butted sealing seats formed by the middle die seat and the lower die seat, one-time sealing is performed to the circumferences of the upper thin film and the lower thin film under the state close to the vacuum state to cause the fluid to be clad, and no bubbles remain in the fluid. The fluid encapsulation forming device and the method thereof have the advantages of avoiding pollution, enhancing stability of the finished product, reducing working procedure time and reducing manufacturing cost.

Owner:陈惠美

System and apparatus for rapid stereotactic breast biopsy analysis

InactiveUS20080081984A1Rapid productionImprove tolerancePatient positioning for diagnosticsVaccination/ovulation diagnosticsDigital imagingBleeding complication

A stereotactic breast biopsy apparatus and system that may comprise an x-ray source, a digital imaging receptor, and a biopsy specimen cassette, wherein the x-ray source is provided with a means for displacing the beam axis of the x-ray source from a working biopsy corridor beam axis to permit an unobstructed illumination of the biopsy specimen and thereby produce biopsy x-ray images directly in the procedure room for immediate analysis. Some examples of the benefits may be, but are not limited to, a more rapid analysis of biopsy specimen digital images, post-processing image capability, and decreased procedure time and diminution of patient bleeding complications and needle discomfort.

Owner:LAFFERTY PETER R

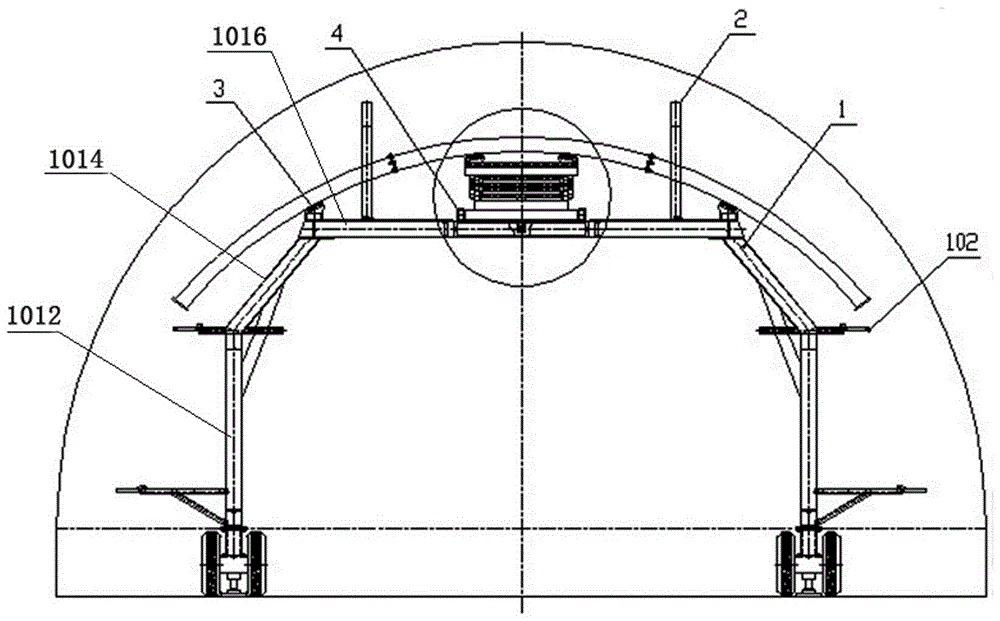

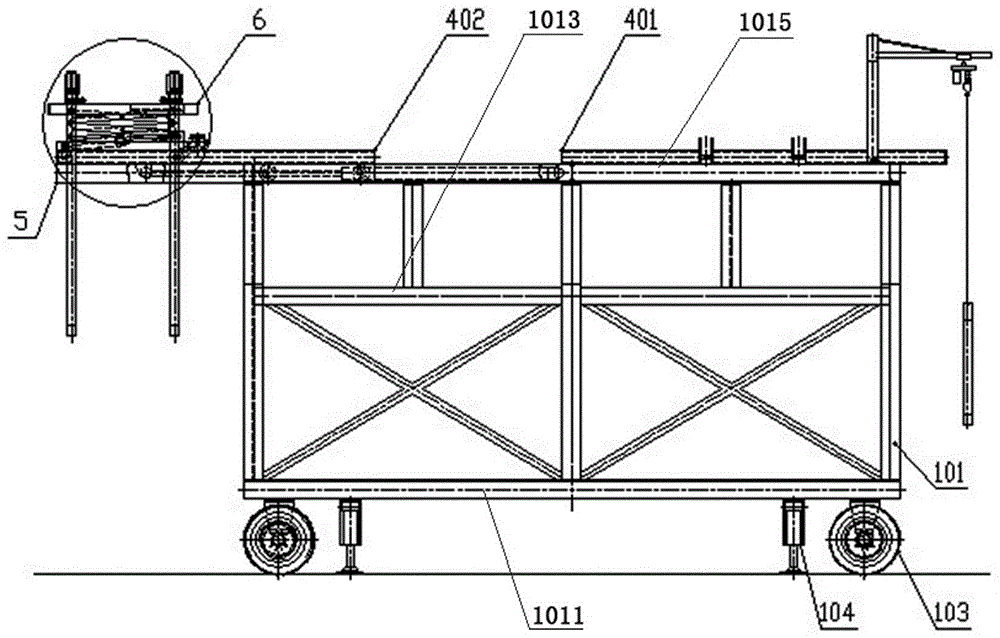

Door frame type multi-functional support trolley for tunnel

ActiveCN106837392AStable supportMeet the installation requirementsUnderground chambersTunnel liningBogieEngineering

The invention discloses a door frame type multi-functional support trolley for a tunnel. The door frame type multi-functional support trolley for the tunnel comprises a door frame and a working platform. The top end of the door frame is provided with a sliding groove track and an arch centering mounting device. The arch centering mounting device comprises a traveling bogie and a lifting device, wherein the traveling bogie is capable of moving backward and forward on the sliding groove track. The lower side of the lifting deviceis fixed to the traveling bogie. The left side and the right side of the lifting device are provided with left-right moving mechanisms and left-right moving tracks for the left-right moving mechanisms to move correspondingly. The left-right moving mechanisms are provided with transportation supports. The sliding groove track comprises a fixed sliding groove track and a movable sliding groove track with the same gauge. The fixed sliding groove track is fixed to the rear of the top end of the door frame and the tail end of the fixed sliding groove track is beyond the tail end of the door frame. The movable sliding groove track is fixed to a sliding platform in the middle of the front of the top end of the door frame. The rear end of the sliding platform is hinged to one end of a sliding cylinder, and the other end of the sliding cylinder is hinged to the door frame. According to the door frame type multi-functional support trolley for the tunnel, the arch centering mounting requirements of a micro-step excavation and support construction method of very weak surrounding rock can be met, and the working procedure time occupied by the arch centering mounting is shortened.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

Multi injection microneedle theraphy system

InactiveCN101557848AImprove absorption rateReduce processing timeAutomatic syringesMicroneedlesMulti injectionHuman skin

Owner:株式会社艾莫克尔

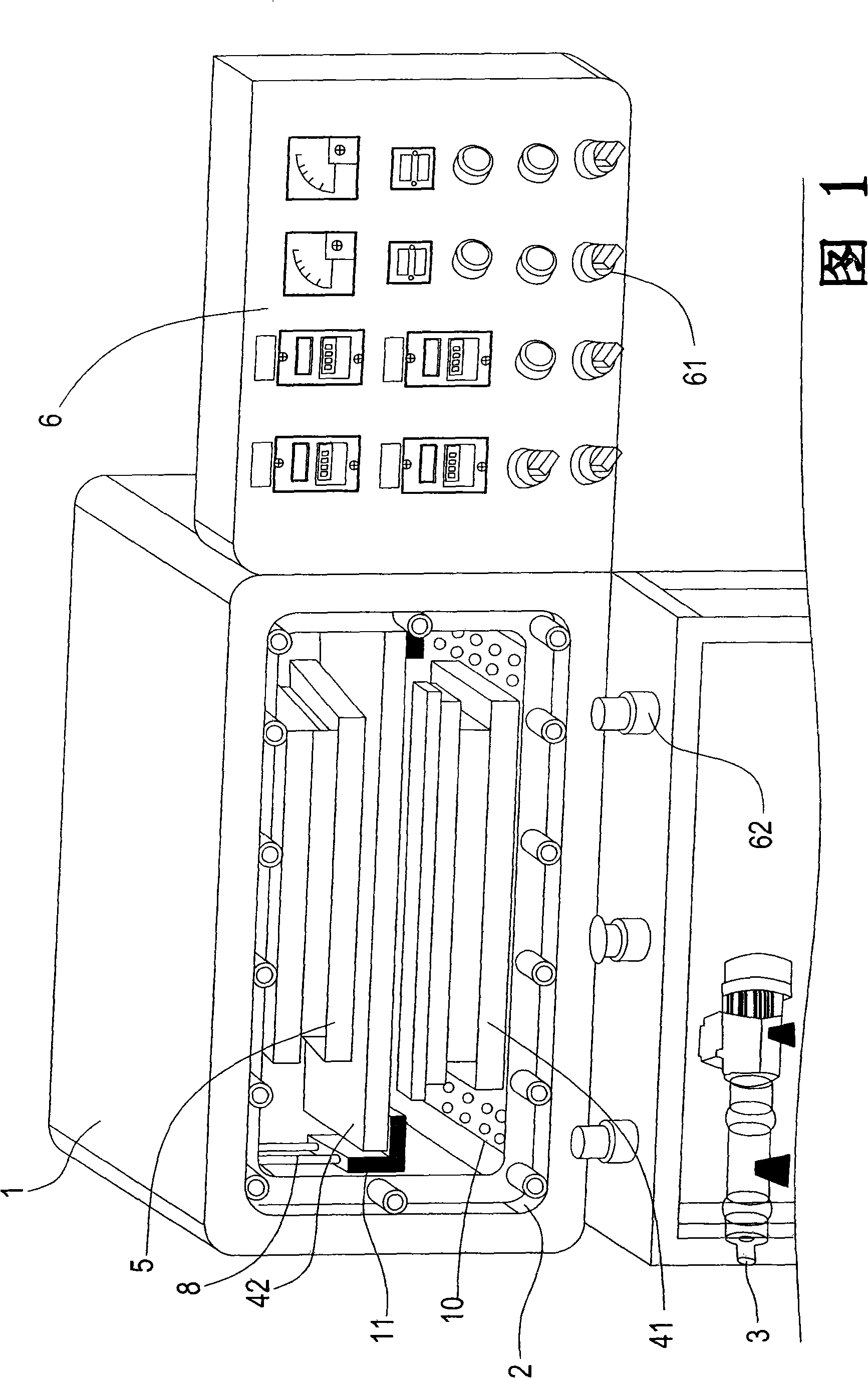

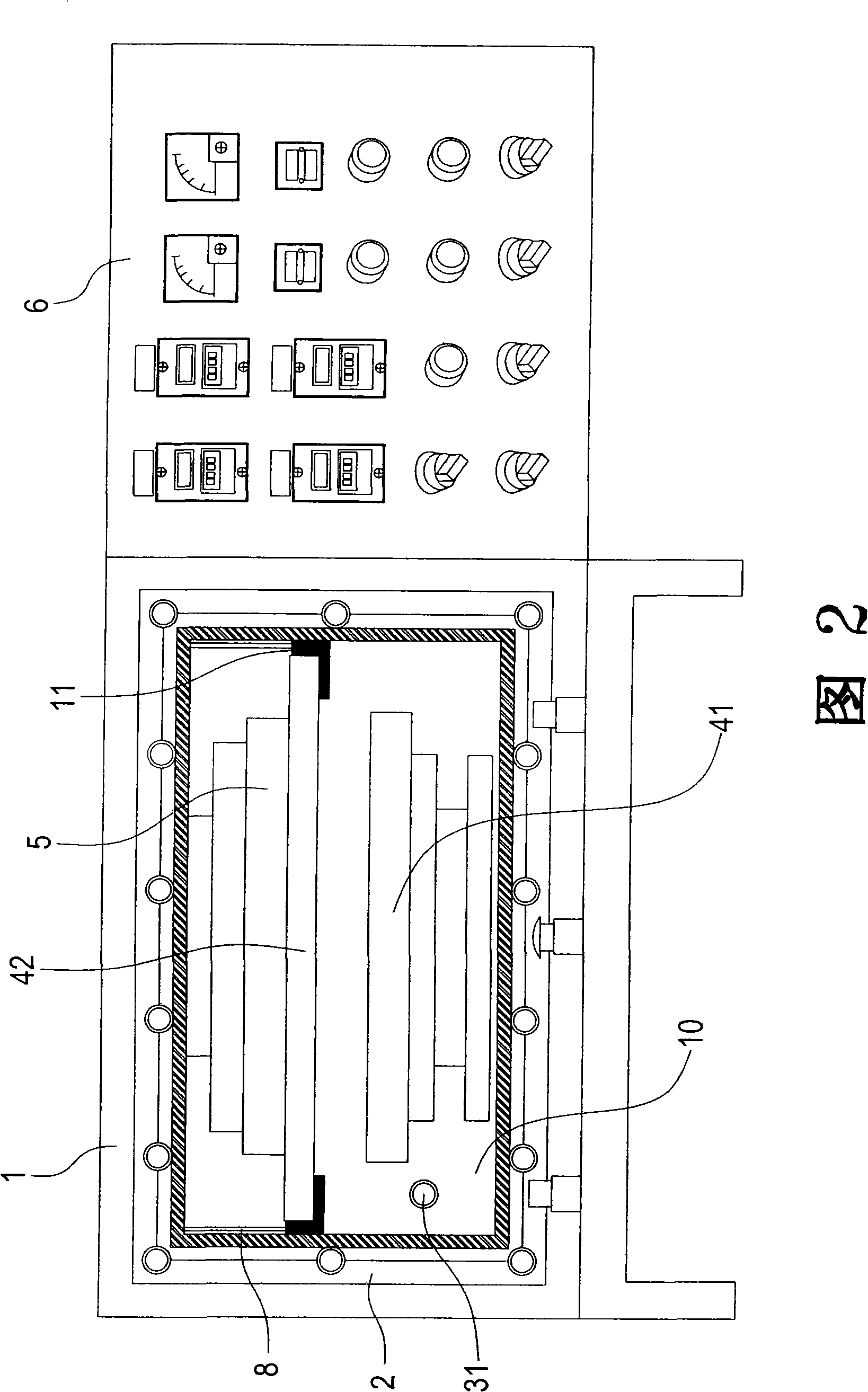

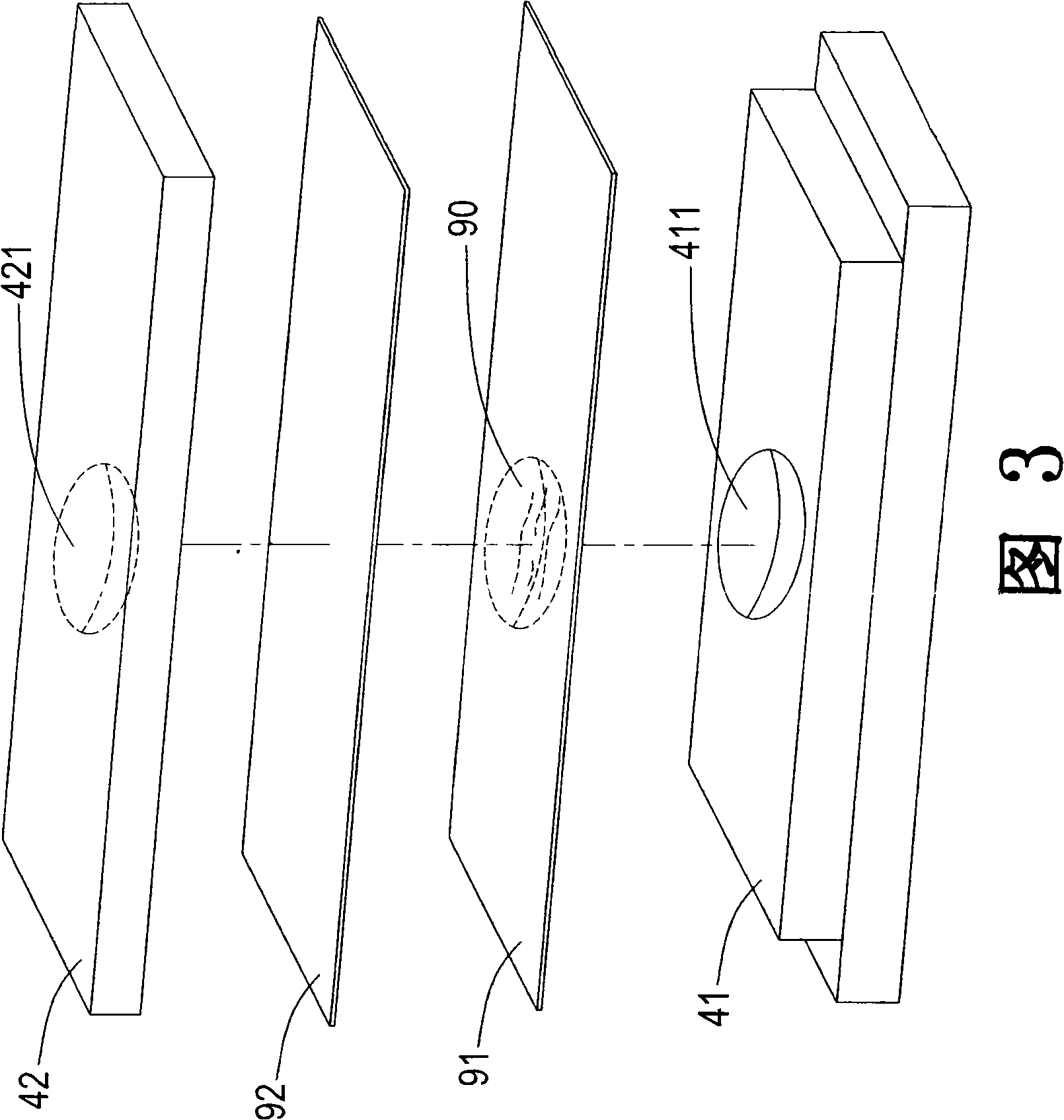

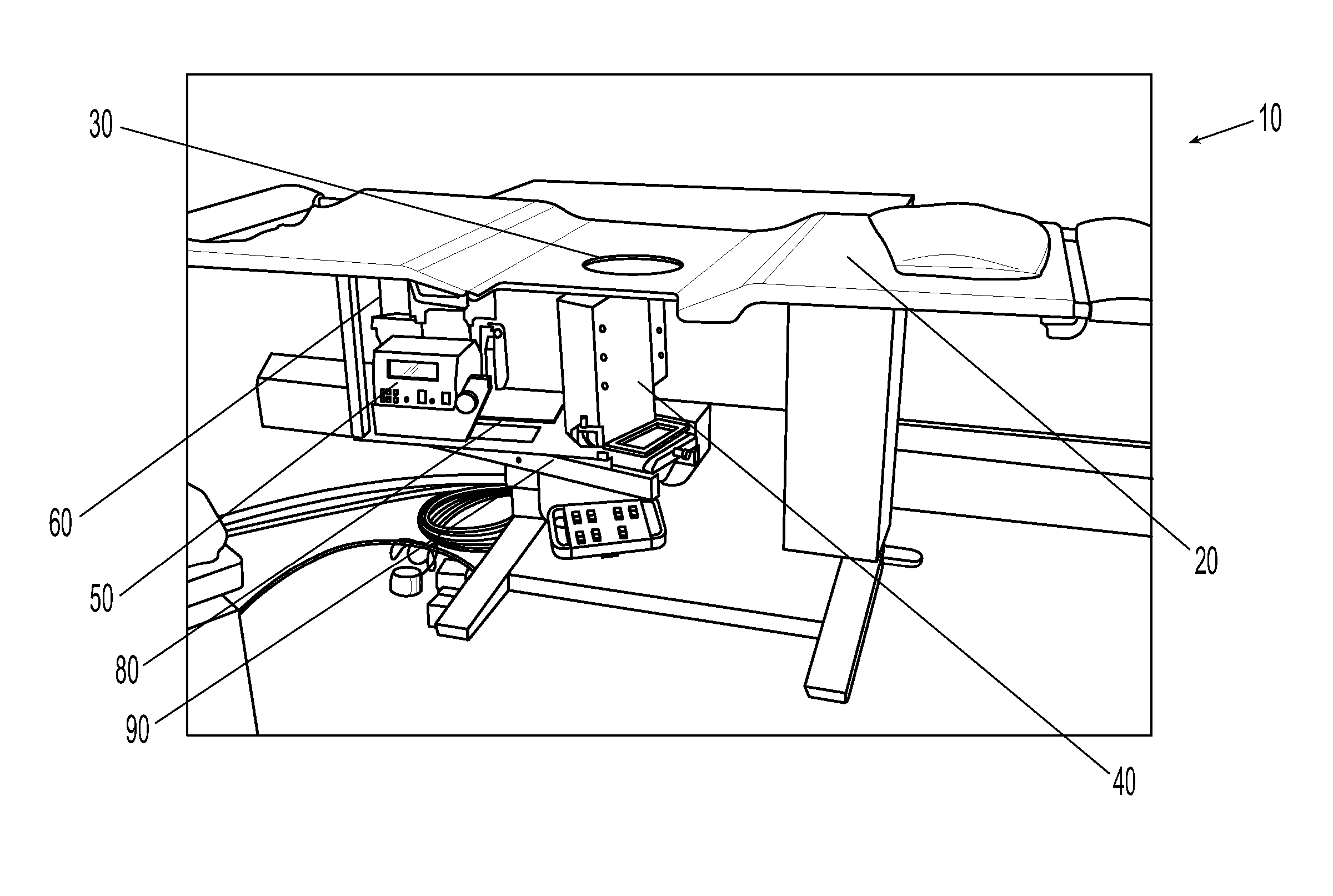

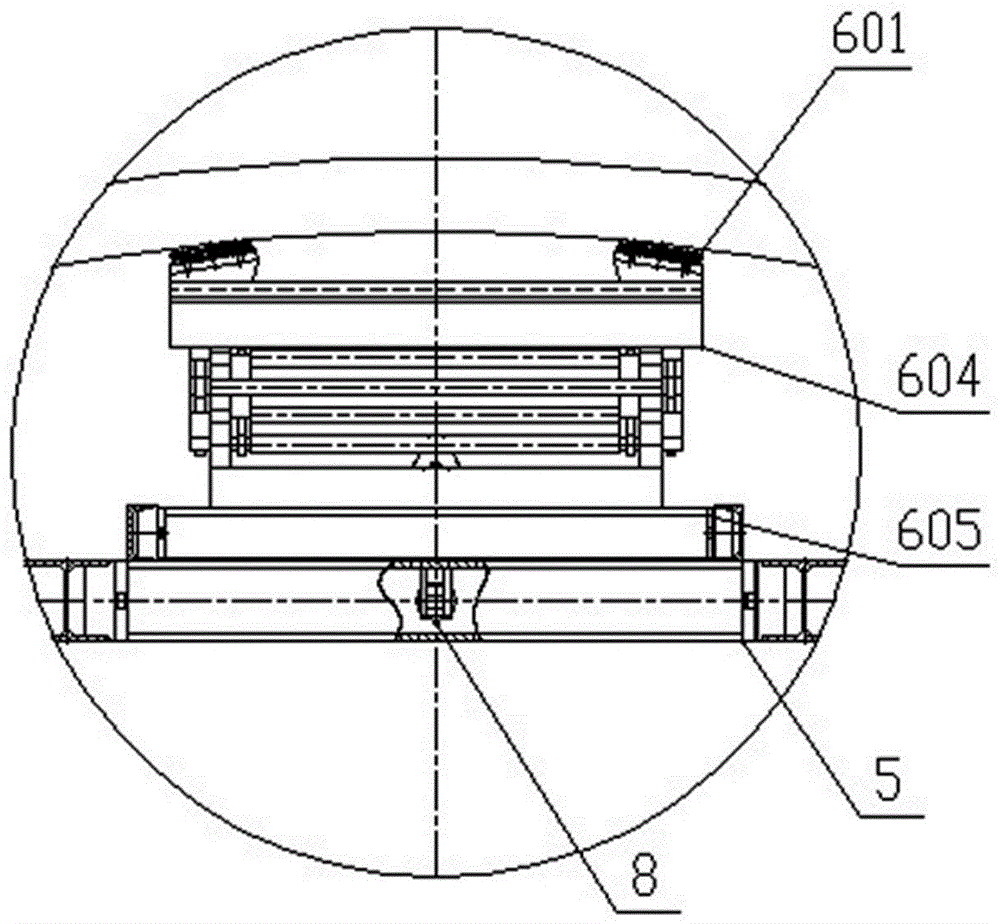

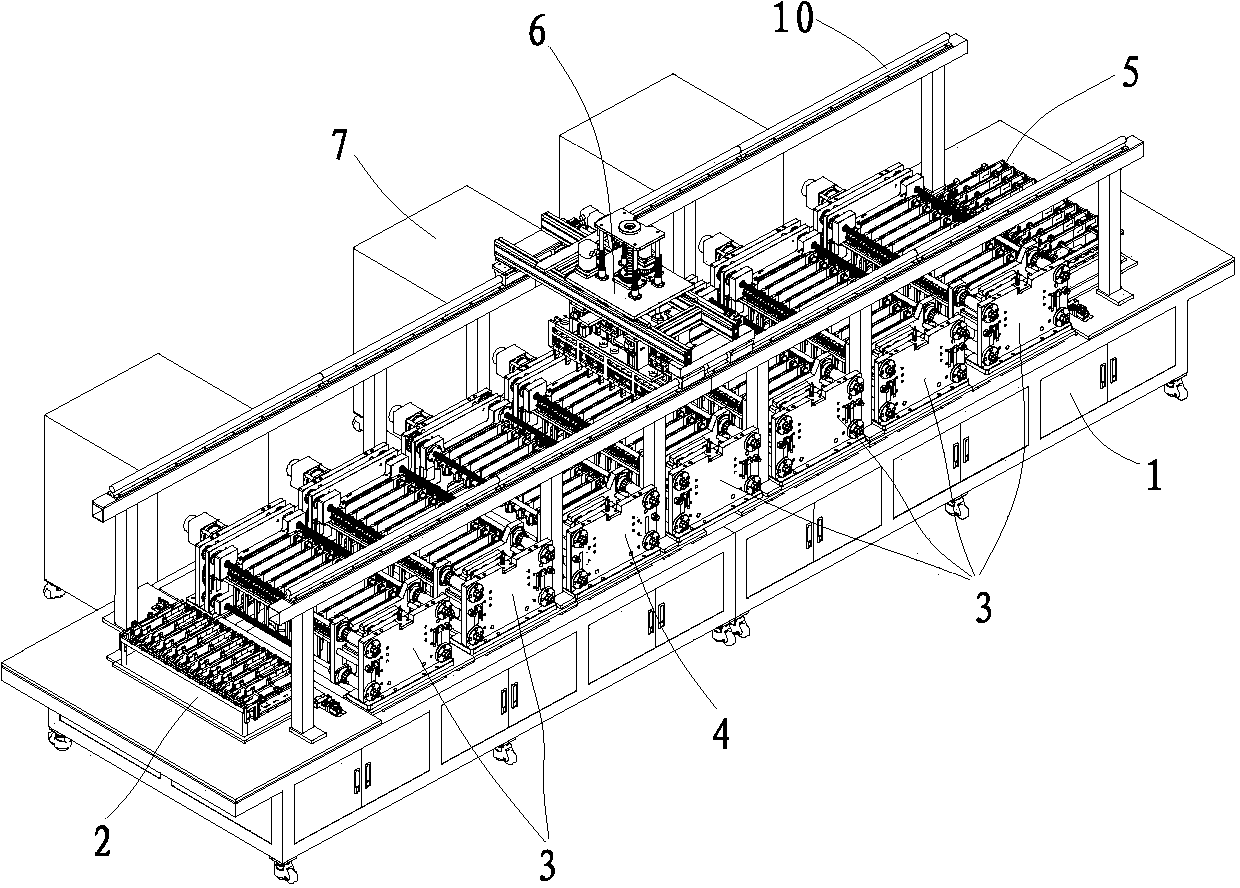

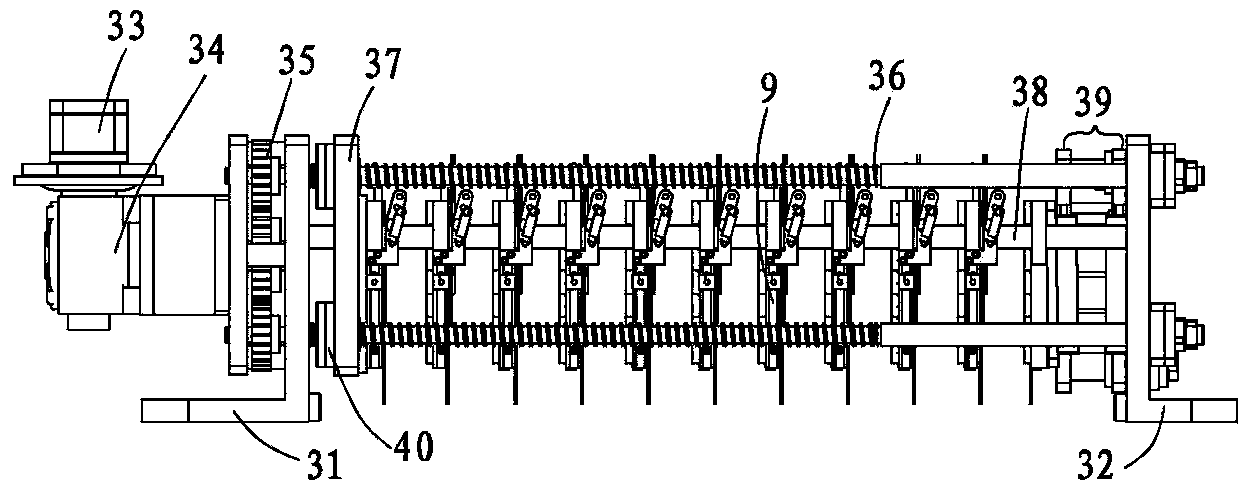

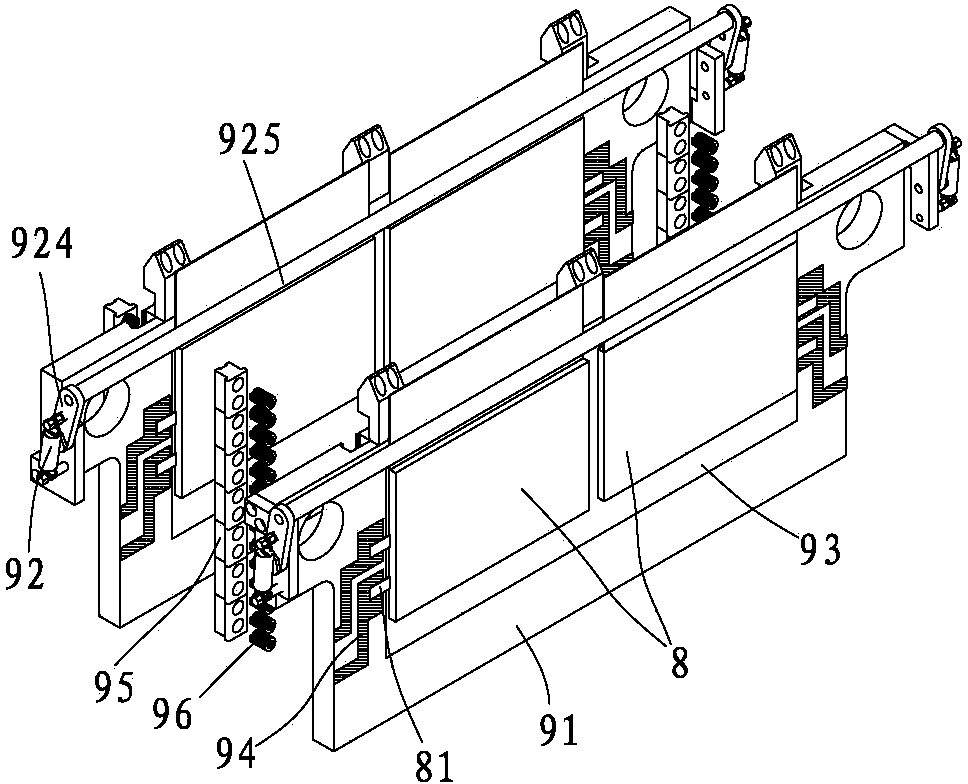

Lithium ion battery hot and cold-press formation equipment

ActiveCN103811816AWill not affect performanceSolve handling problemsFinal product manufactureElectrolyte accumulators manufactureEngineeringManipulator

The invention belongs to the technical field of battery manufacturing equipment and in particular relates to lithium ion battery hot and cold-press formation equipment. The lithium ion battery hot and cold-press formation equipment comprises a stander, a material loading tray, a hot-press formation clamp, a cold-press clamp, a material unloading tray, a manipulator and a formation cabinet, wherein the material loading tray, the hot-press formation clamp, the cold-press clamp, the material unloading tray and the manipulator are arranged on the stander; the formation cabinet is electrically connected with the hot-press formation clamp; the cold-press clamp and the hot-press formation clamp comprise laminated plates; the laminated plates are in contact with a battery, and included angles formed between the contact surfaces of the laminated plates and the horizontal plane are 90+ / -0.5 degrees; the manipulator can catch the battery at a time and move among the material loading tray, the hot-press formation clamp, the cold press clamp and the material unloading tray. The equipment integrates three working procedures, namely formation, hot press and cold press, on the battery, so that the time of all the working procedures is shortened; meanwhile, the formation and hot press working procedures on the battery are integrated into the same hot-press formation clamp, so that the working procedure is simplified, and the unnecessary working procedure time is shortened; furthermore, the usability of the battery cannot be affected.

Owner:NINGDE AMPEREX TECH

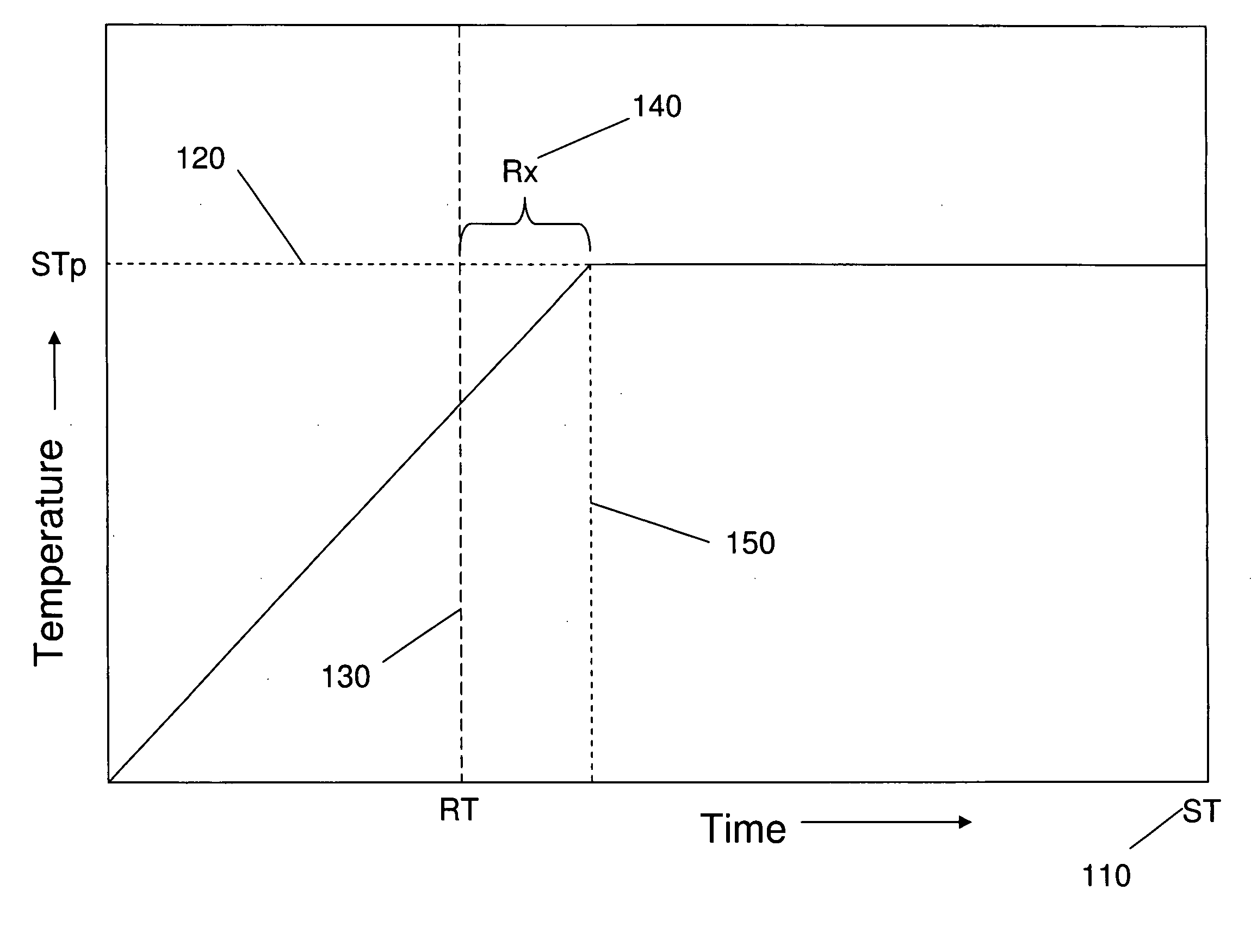

Electrosurgical method

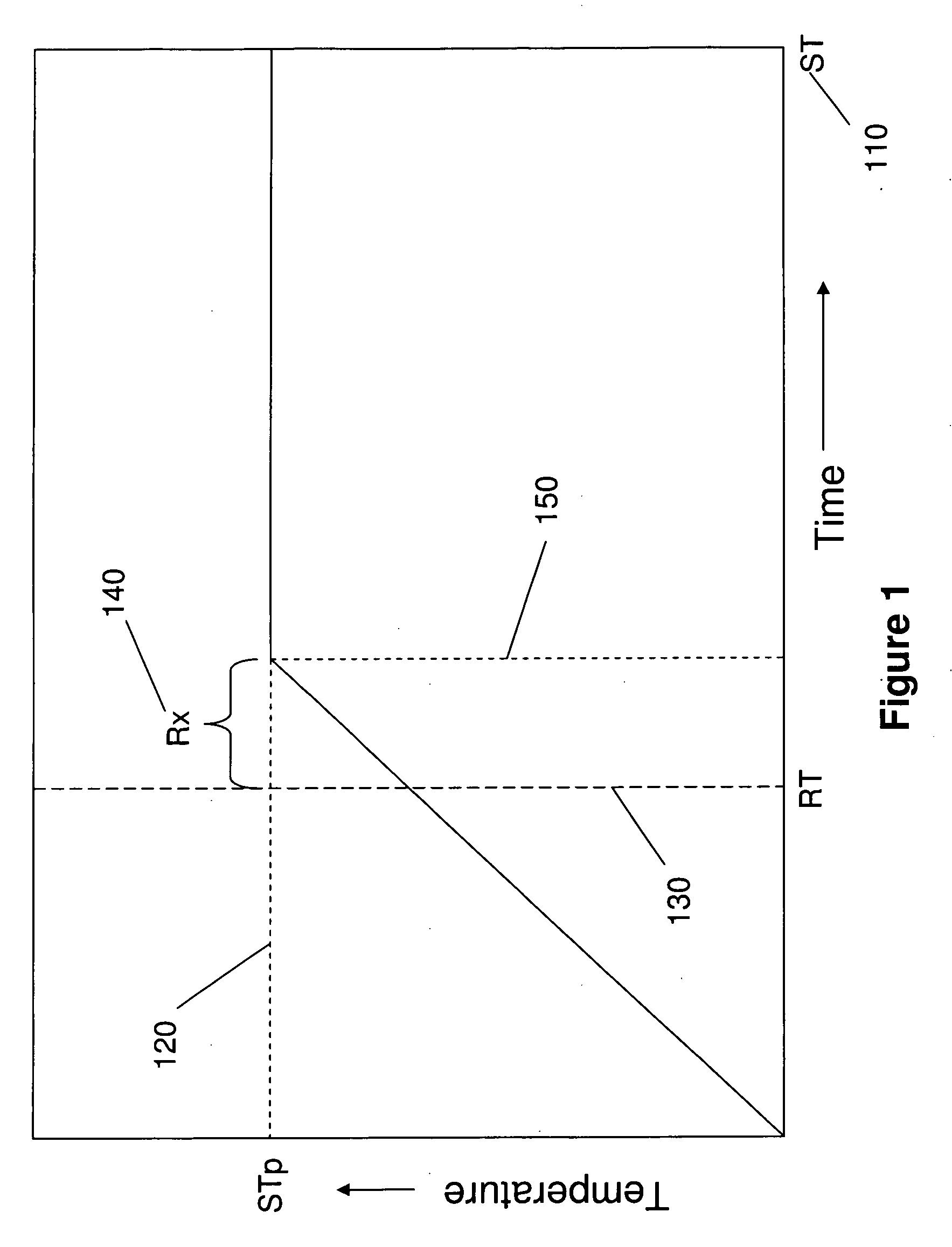

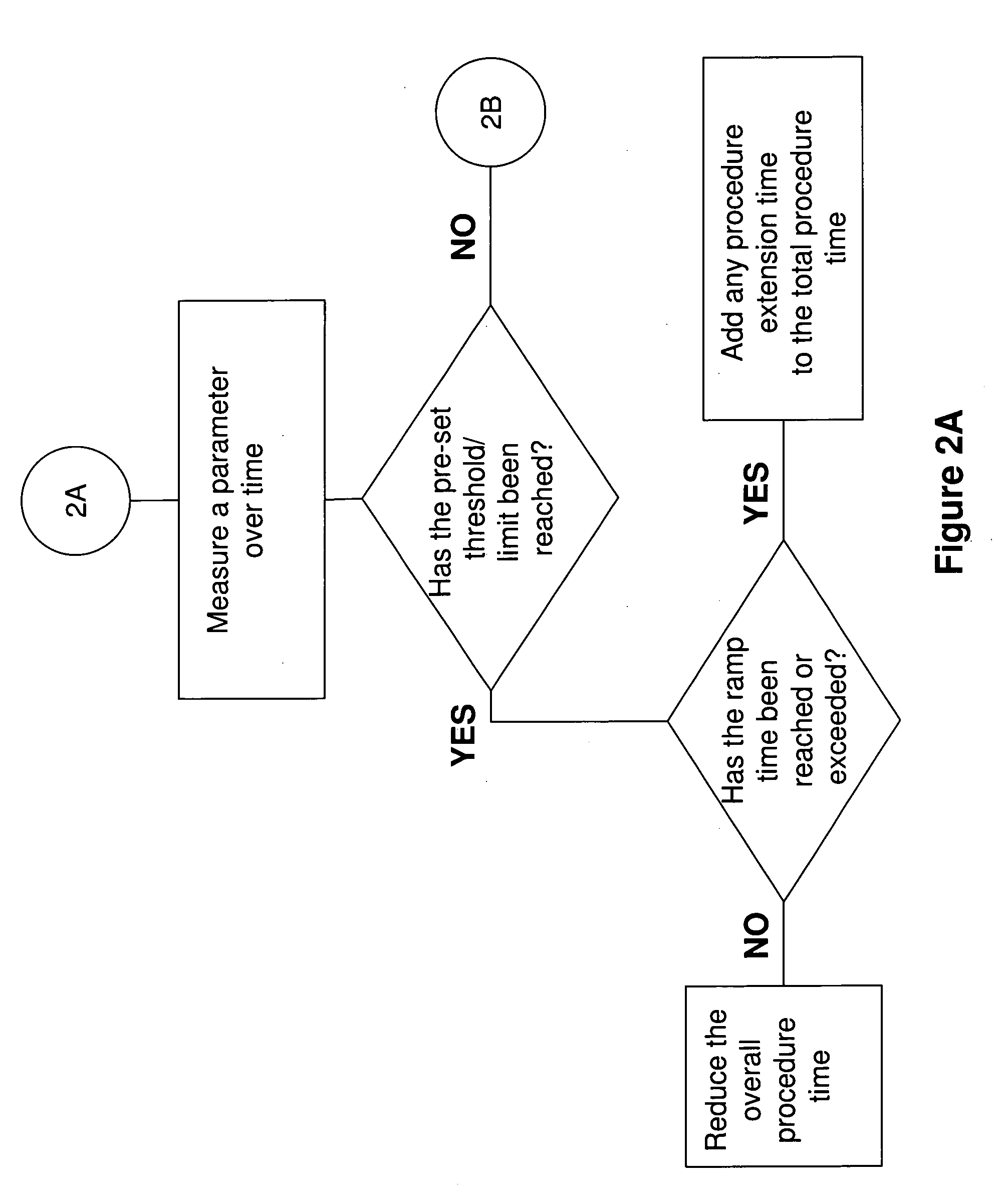

Methods are disclosed for delivering energy to a body of a human or animal during a treatment procedure using an electrosurgical generator, a pre-set overall procedure time being defined for the treatment procedure, a ramp time being defined for a parameter to reach a pre-set threshold during the treatment procedure, the method comprising: measuring the parameter over time; and if the parameter has not substantially reached the pre-set threshold by the ramp time, setting a procedure extension time responsive to the time difference between the ramp time and the time at which the pre-set threshold was reached, and extending the overall procedure time by the procedure extension time.

Owner:AVENT INC

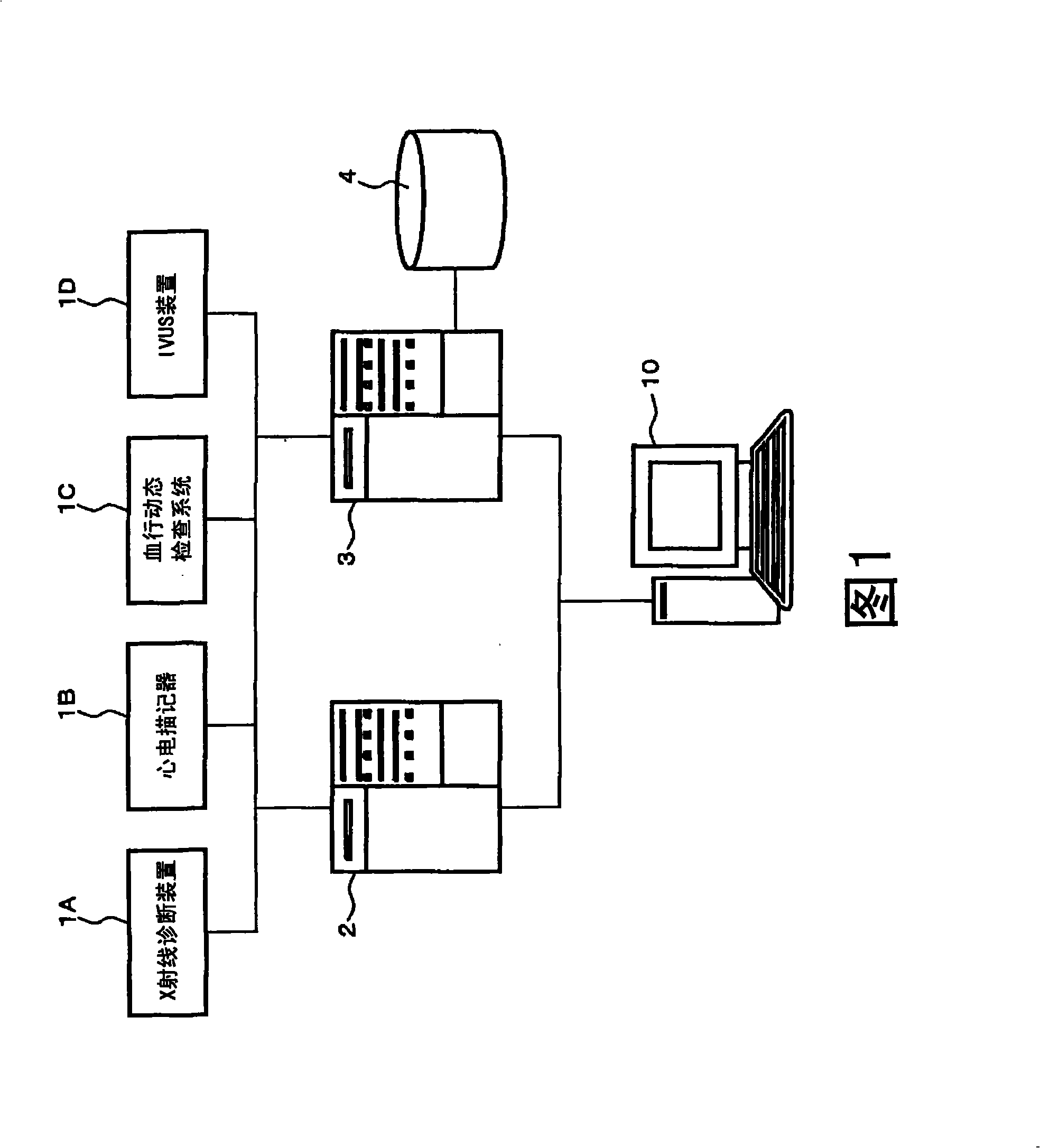

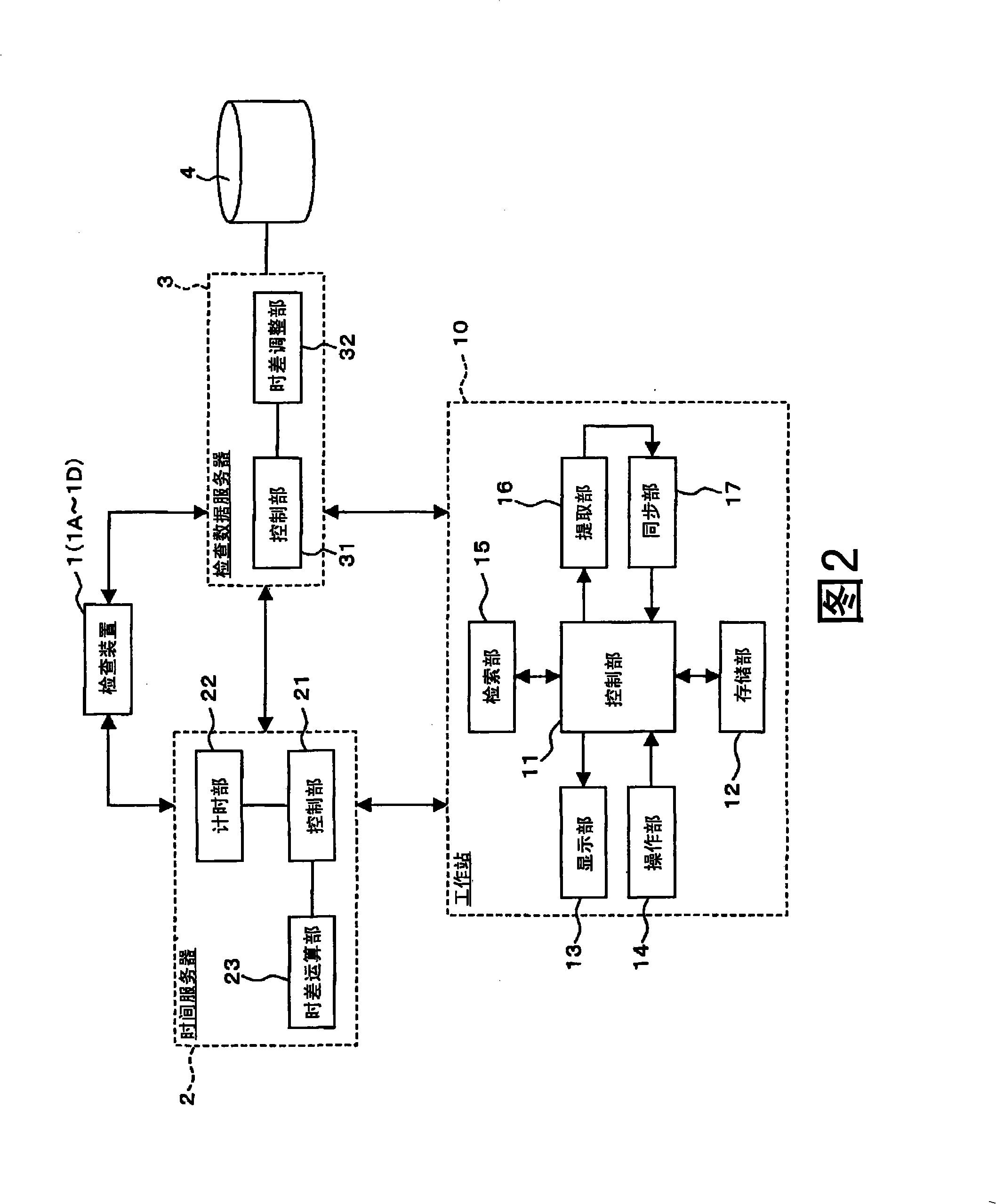

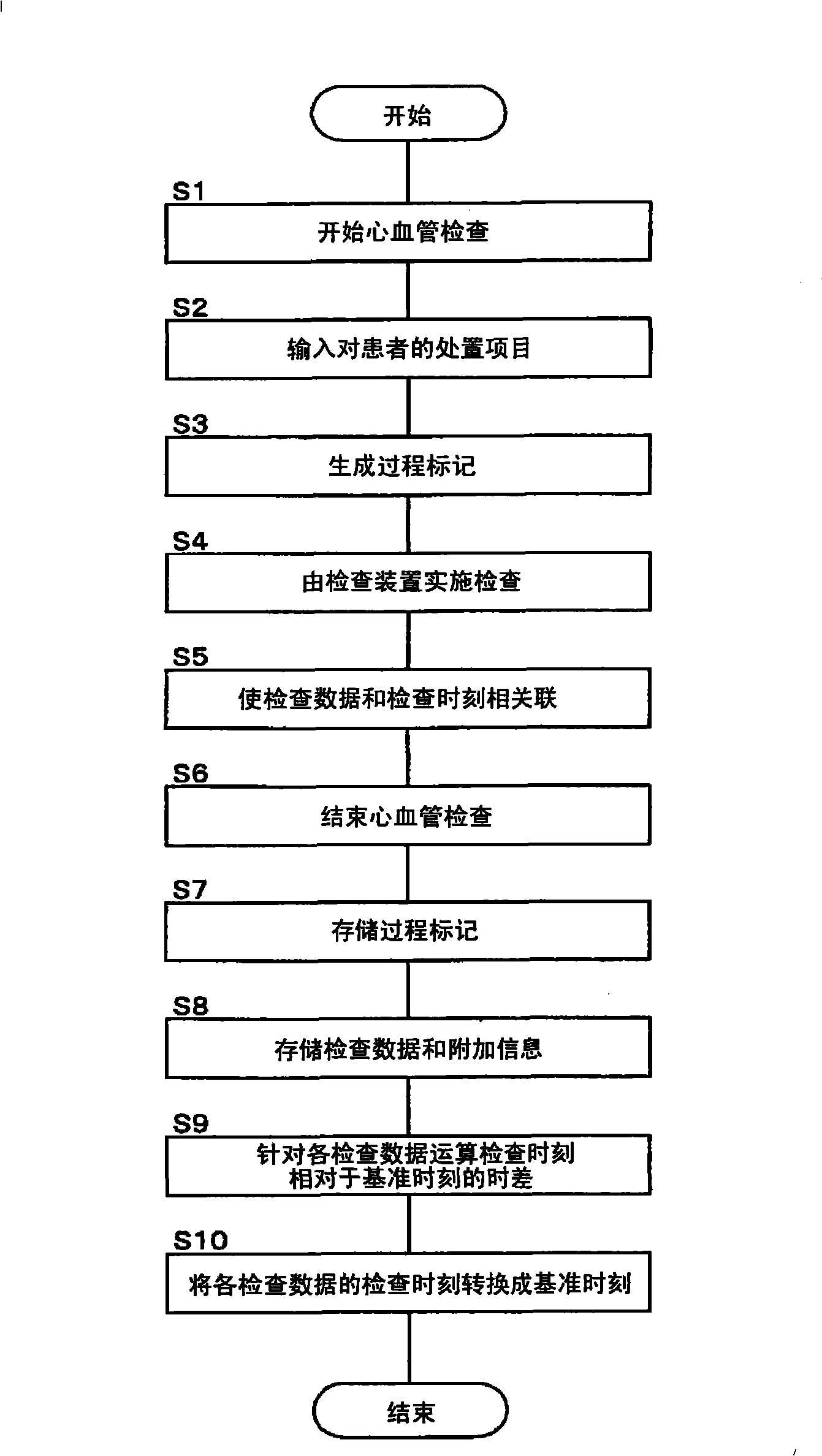

Examination-data processing apparatus and examination system

InactiveCN101317786APromote reproductionUltrasonic/sonic/infrasonic diagnosticsSurgeryWorkstationComputer science

The invention provides an examination data processing apparatus and examination system reproducing a plurality of examination data acquired by examination synchronously in an easy way. An examination system comprises an examination apparatus (1) and a workstation (10). The examination apparatus (1) executes an examination on a patient to acquire a plurality of examination data and acquire an examination time of each examination data. The workstation (10) creates a procedure log that associates a procedure item executed on the patient with a procedure time thereof. The workstation (10) displays a chronological display screen (100) on a display (13) based on the procedure log and an examination time. An operator operates an operation part (14) to designate a procedure item in the chronological display screen (100). The workstation (10) extracts partial data within a range that corresponds to the designated procedure item from each of the examination data based on the examination time and the procedure log, and synchronizes and displays the extracted partial data on the display (13).

Owner:KK TOSHIBA +1

Method for biological detoxication of pretreated lignocellulose biomass

InactiveCN102191279AAvoid inhibitionRealize industrializationBiofuelsMicroorganism based processesCelluloseWater content

The invention relates to a method for biological detoxication of pretreated lignocellulose biomass, which comprises the following steps: step one, performing pretreatment for preparation of raw materials; and step two, performing biological detoxication and fermentation: inoculating fungi Amorphotheca resinae ZN1 by using PDA as a medium, followed by cultivation at a temperature of 20 to 30 DEG C; performing elution to obtain A. resinae ZN1 spores, inserting the A. resinae ZN1 spores into the pretreated lignocellulose biomass raw materials, and carrying out cultivation until the growing of mycelia, so that a first order seed is obtained; and inserting the first order seed into the raw materials, wherein the water content is 10 to 90%, adjusting the pH of the raw materials to 4 to 7, and then carrying out cultivation for 1 to 7 days at a temperature of 20 to 40 DEG C. The method for biological detoxication of the pretreated lignocellulose biomass provided in the invention has advantages of simple operation and low requirement for equipment. Furthermore, various mainly inhibitors produced during the pretreatment processing can be degraded. Therefore, the continuity of simultaneous saccharification and fermentation of high-solid content can be ensured, processing steps can be reduced, and working procedure time can be shorten and working procedure cost can be reduced.

Owner:EAST CHINA UNIV OF SCI & TECH

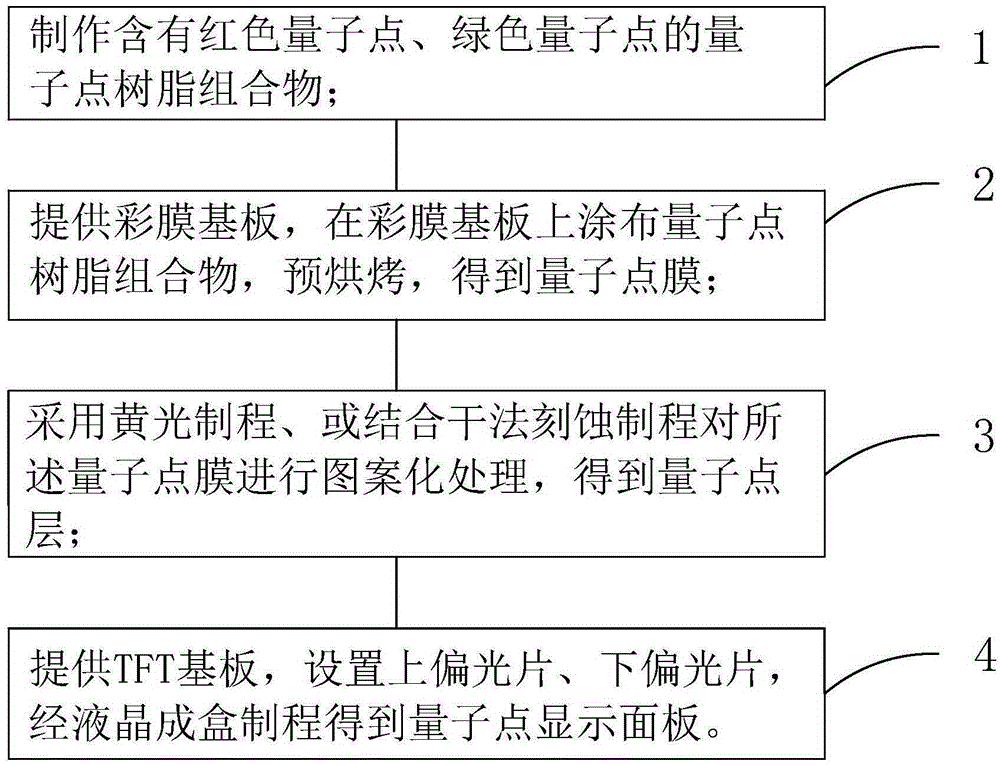

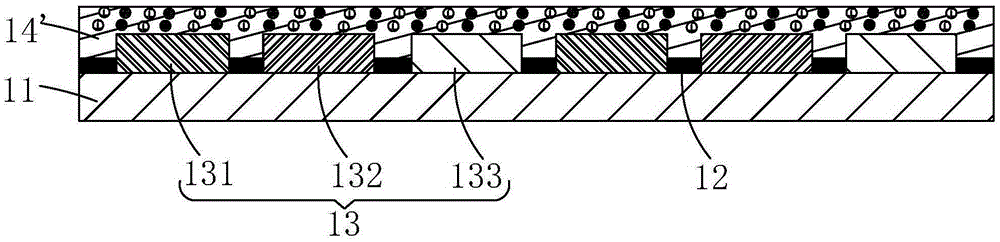

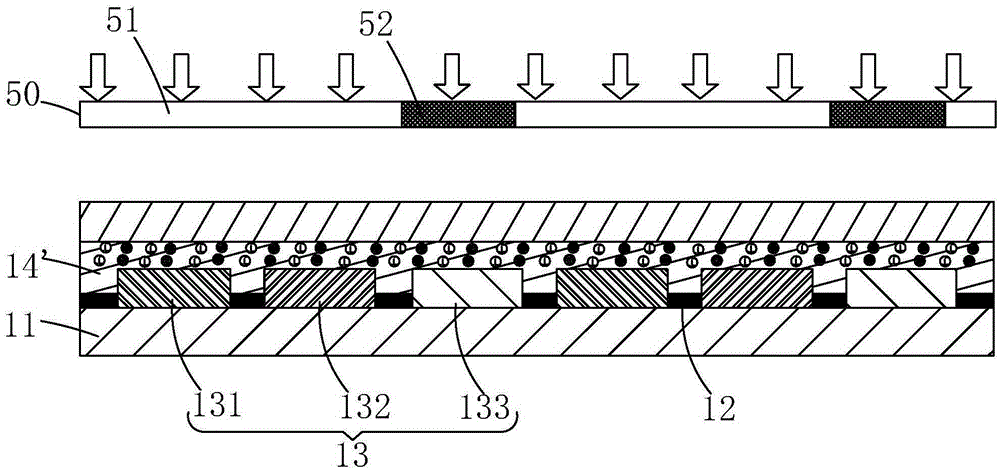

Manufacturing method for quantum dot display panel

ActiveCN105319765AImprove coloring performanceSimple preparation processLiquid surface applicatorsStatic indicating devicesSurface finishGamut

The invention provides a manufacturing method for a quantum dot display panel. By means of the existing yellow light manufacturing procedure of a color light filter or in combination with the dry method etching manufacturing procedure, a resin composition containing red and green quantum dots for surface finish is manufactured to obtain a quantum dot layer with an exquisite graph structure. Compared with other existing manufacturing method for the quantum dot display panel, the manufacturing method has the advantages that the raw material preparing and manufacturing process is simple, the graph resolution is high, the display panel can be manufactured on a large scale, cost and manufacturing procedure time are saved, the quantum dots are guided into the color light filter structure, color saturation and color gamut of a display device can be effectively promoted, and the color expressive ability of the display panel is enhanced.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

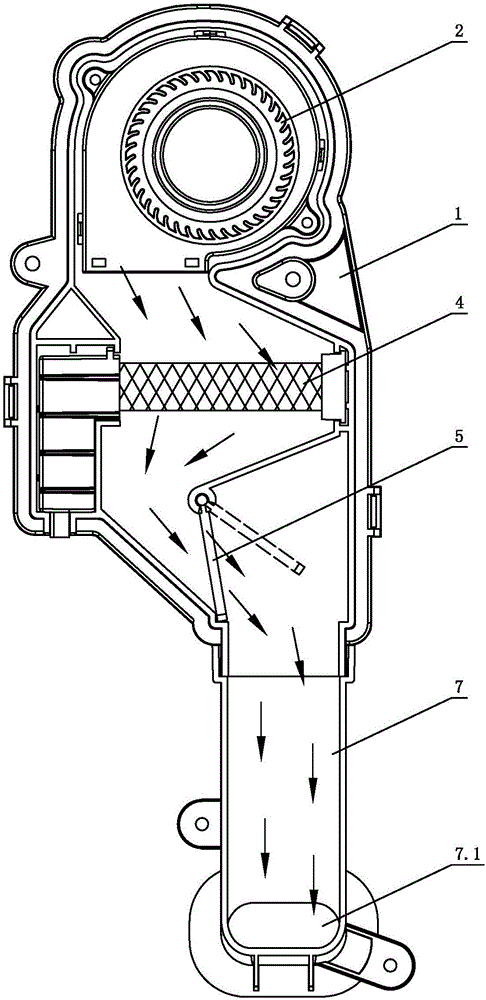

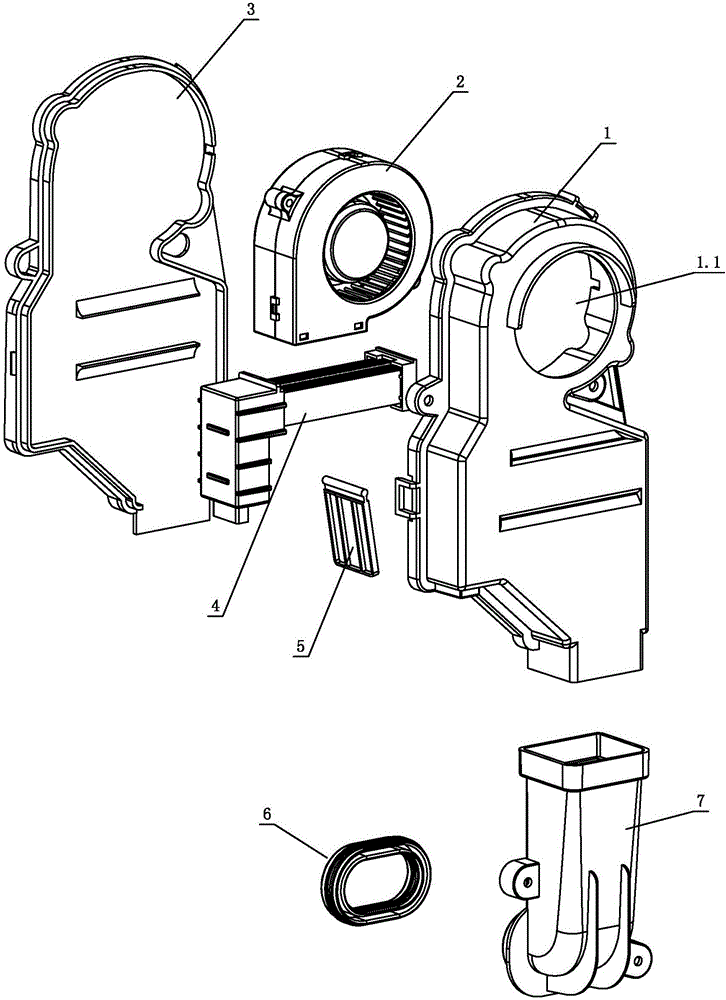

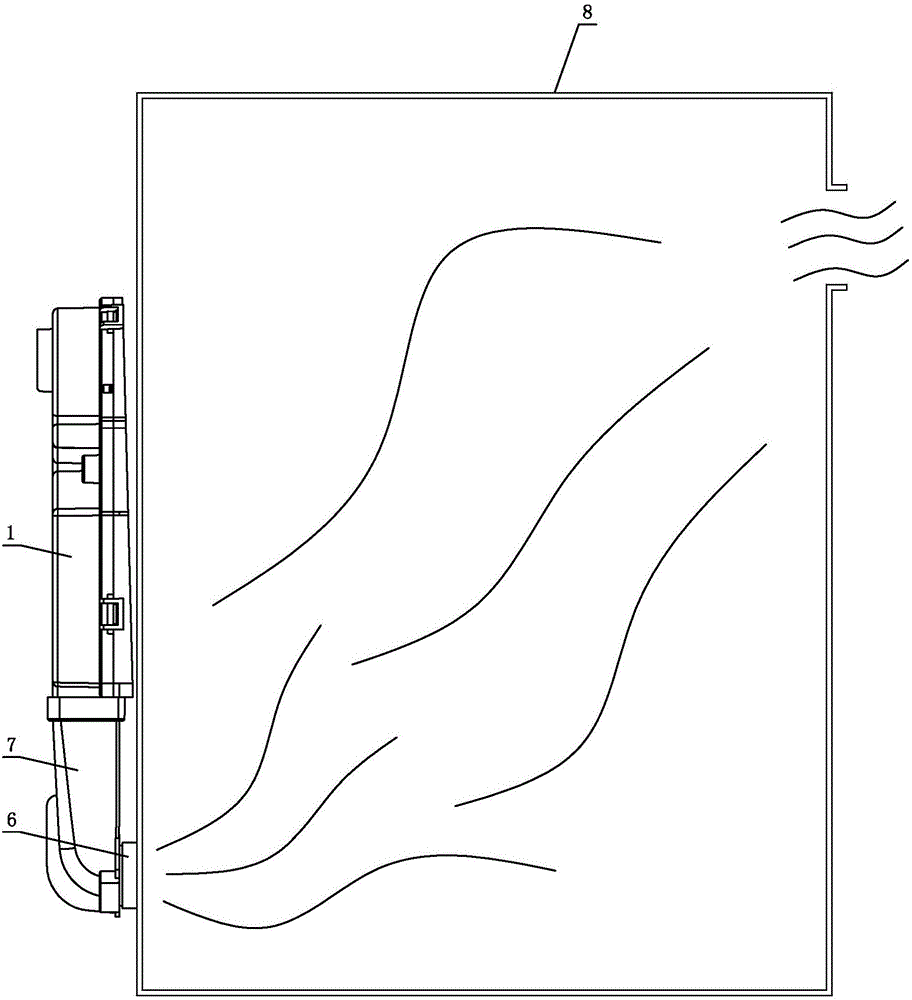

Fan drying device of dish washing machine

InactiveCN106073682APrevent leakageHeatingTableware washing/rinsing machine detailsDrying timeMechanical engineering

The invention relates to a fan drying device of a dish washing machine. The fan drying device comprises a casing assembly arranged on an inner liner, wherein an air passage communicating with the outside and an inner cavity of the inner liner is arranged in the casing assembly; a fan and a heating assembly are arranged on the fan; a blocking sheet used for automatically starting and closing the air passage is also arranged on the air passage; the blocking sheet closes the air passage at least under the gravity effect, and opens the air passage at least under the wind force effect. Through the matched work of the fan and the heating assembly, hot air can be blown into the inner cavity of the inner liner; the effect of heating tableware and air in the inner cavity of the inner liner is achieved, so that the drying temperature is raised; the drying time is reduced; the drying efficiency is improved; in addition, through the arrangement of the blocking sheet, the automatic starting and closing function is realized on the air passage; when the fan does not work, the external leakage of steam can be prevented. The fan drying device has the following beneficial effects that 1, at the same installing temperature, a better drying effect is provided; 2, due to the setting of the how air blowing function, the drying work can be completed in short time; the procedure time is shortened; the drying efficiency is improved.

Owner:GUANGDONG GALANZ GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com