Lithium ion battery hot and cold-press formation equipment

A lithium-ion battery and formation equipment technology, applied in the direction of non-aqueous electrolyte battery, electrolyte battery manufacturing, sustainable manufacturing/processing, etc., can solve the problems of heat loss, energy waste, time-consuming and other problems of formation fixtures, and avoid handling problems, The effect of reducing the process time and simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention and its beneficial effects will be described in detail below in conjunction with the accompanying drawings and specific embodiments, but the embodiments of the present invention are not limited thereto.

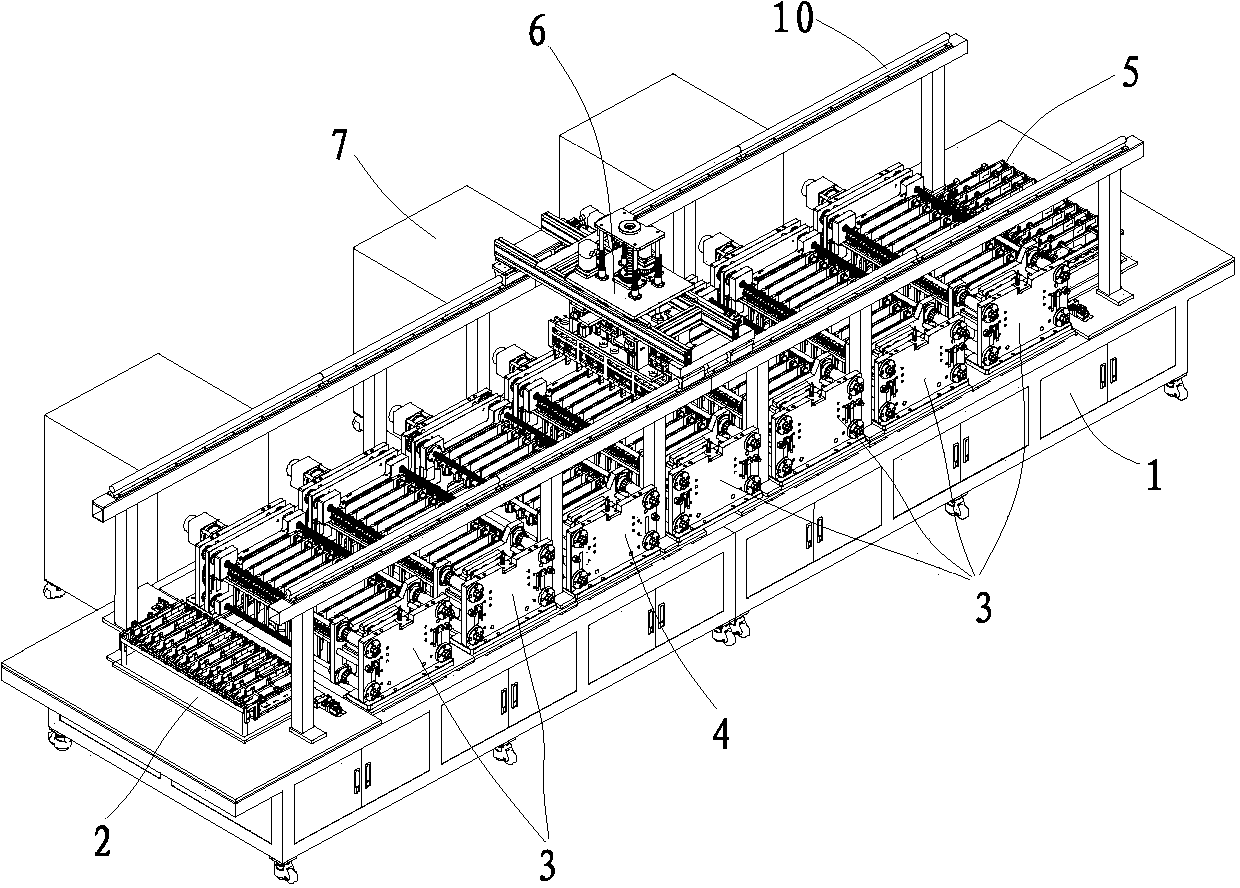

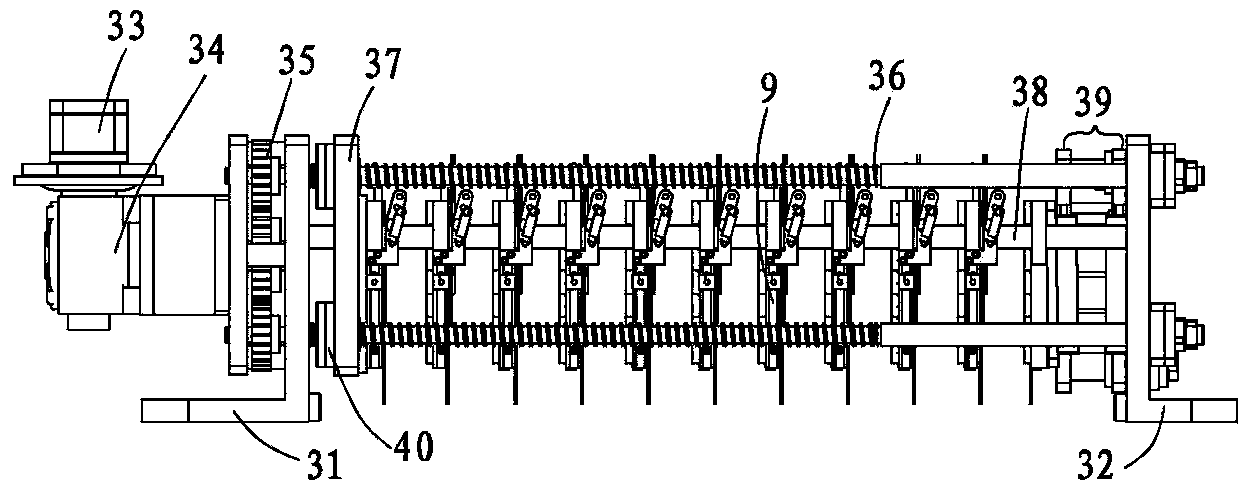

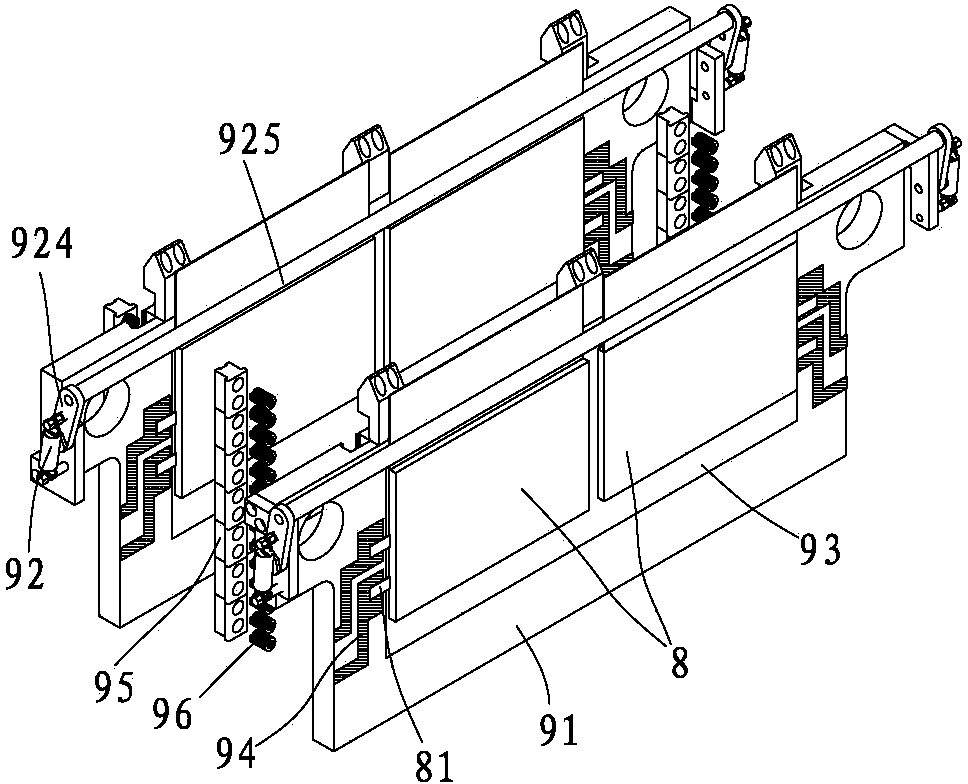

[0039] refer to Figure 1 to Figure 11 , a lithium ion battery hot and cold pressing forming equipment, comprising a frame 1, a feeding tray 2, a hot pressing forming fixture 3, a cold pressing fixture 4, a blanking tray 5, a manipulator 6 and a forming cabinet 7, a loading tray 2, The hot-pressing fixture 3, the cold-pressing fixture 4, the blanking tray 5 and the manipulator 6 are all set on the frame 1, and the cold-pressing fixture 4 and the hot-pressing fixture 3 both include a laminate 9, and the laminate 9 is in contact with the lithium-ion battery 8 And the angle between its contact surface and the horizontal plane is 90°±0.5°. Preferably, the laminate 9 is in contact with the battery and its contact surface is perpendicular to the horizon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com