Lipoic acid tablets with few types and small dose of accessories and preparation method thereof

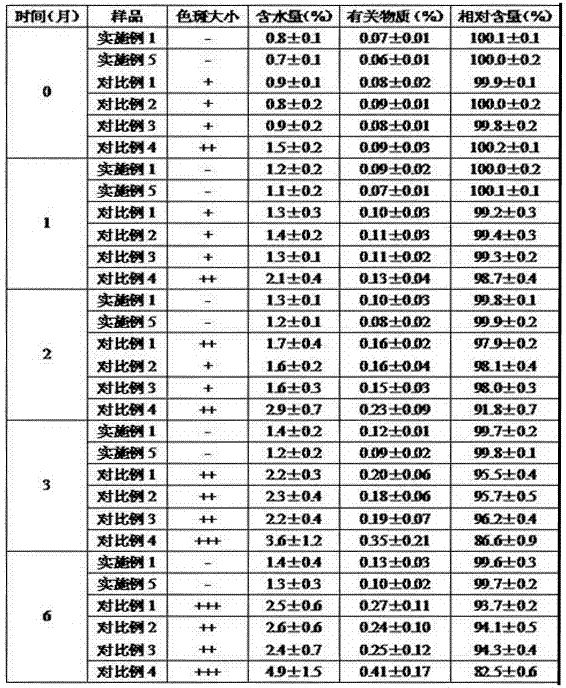

A technology of lipoic acid tablets and excipient tablets, which is applied to medical preparations with non-active ingredients, medical preparations containing active ingredients, and devices for making medicines into special physical or taking forms, etc. , easy sticking and flushing, etc., to achieve the effect of reducing the single dose, reducing the cost of raw materials, and improving chromaticity uniformity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Preparation of excipient tablets Weigh 1.5kg of starch and 0.15kg of hydroxypropyl cellulose to prepare excipient tablets with a diameter of 5mm-6mm according to the method of wet granulation and tabletting;

[0032] (2) Spray the main drug layer. Put the prepared auxiliary material tablet in a high-efficiency coating pan, weigh 8.5kg of lipoic acid and sieve it, and spray the sodium carboxymethyl cellulose solution with a concentration of 1%-1.5% with a spray gun. As a spray, spray the sieved lipoic acid powder layer by layer on the auxiliary material sheet, the rotation speed of the high-efficiency coating pan is 40 rpm, the air inlet temperature is 30°C-35°C, and the spray gun pressure is 0.4MPa. 120 layers, dried at 30°C-35°C for 35 minutes, then placed in a constant temperature room at 20°C-30°C for 6 hours to dry.

[0033]

Embodiment 2

[0035] (1) Preparation of excipient tablets Weigh 3.0kg of dextrin and 0.25kg of starch slurry to prepare excipient tablets with a diameter of 5mm-6mm by dry granulation and tabletting;

[0036] (2) Spray the main drug layer. Put the prepared auxiliary material tablet in a high-efficiency coating pan, weigh 6.5kg of lipoic acid and sieve it, and spray the sodium carboxymethyl cellulose solution with a concentration of 1%-1.5% with a spray gun. As a spray, spray the sieved lipoic acid powder layer by layer on the auxiliary material sheet, the rotation speed of the high-efficiency coating pan is 45 rpm, the air inlet temperature is 30°C-35°C, and the pressure of the spray gun is 0.5MPa. 100 layers, dried at 30°C-35°C for 45 minutes, then placed in a constant temperature room at 20°C-30°C for 8 hours to dry.

[0037]

Embodiment 3

[0039] (1) Preparation of excipient tablets Weigh 2.0kg of lactose and 0.2kg of hypromellose to prepare excipient tablets with a diameter of 5mm-6mm according to the direct powder compression method;

[0040](2) Spray the main drug layer. Put the prepared auxiliary material tablet in a high-efficiency coating pan, weigh 8.0kg of lipoic acid and sieve it, and use a spray gun to spray the sodium carboxymethyl cellulose solution with a concentration of 1%-1.5%. As a spray, spray the sieved lipoic acid powder layer by layer on the auxiliary material sheet, the rotation speed of the high-efficiency coating pan is 45 rpm, the air inlet temperature is 30°C-35°C, and the spray gun pressure is 0.45MPa. 115 layers, dried at 30°C-35°C for 40 minutes, then placed in a constant temperature room at 20°C-30°C for 7 hours to dry.

[0041]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com