Delayed coking method

A delayed coking method and a technology of salt compounds, which are applied in the delayed coking field, can solve the problems of reducing the quality of petroleum coke, increasing the ash content of petroleum coke, and high desulfurization cost, reducing investment costs and operating costs, increasing the depth of cracking reaction, and reducing coke. The effect of yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

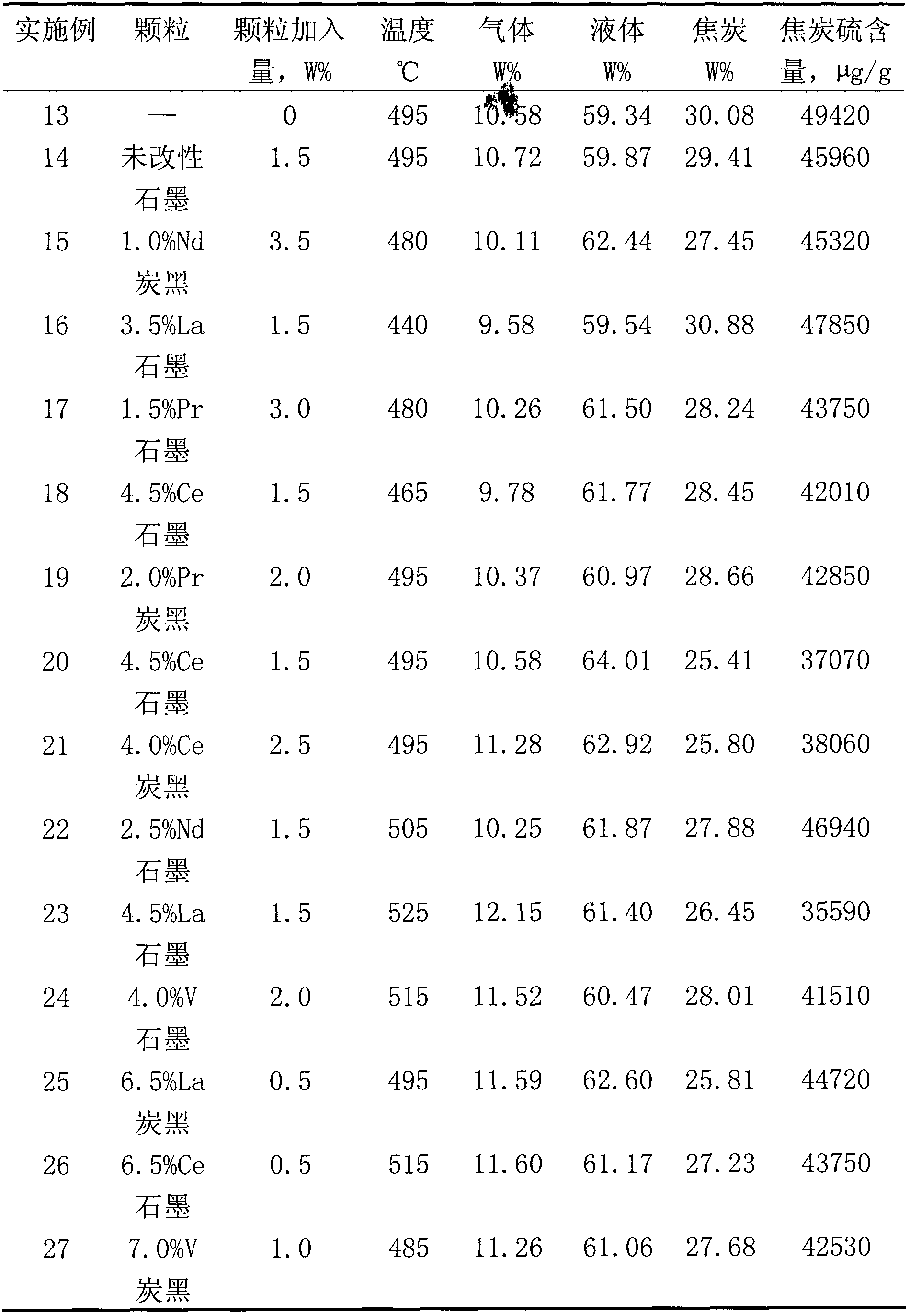

Examples

Embodiment 1

[0022] Weigh 50g of carbon black with a particle size of 60 μm and 1.0g of sodium carboxymethyl cellulose in beaker 1, and mix evenly; account for 1.0% of the weight of carbon black before modification according to the neodymium content, weigh 1.40g of neodymium in beaker 2 The content is 36% neodymium nitrate and 100g distilled water, stir to make it fully dissolved, then add the mixture of carbon black and sodium carboxymethyl cellulose in beaker 1 to beaker 2 in batches while stirring, continue to stir after adding 3 hours, standing still for 20 hours, drying at 120°C for 3 hours, and finally calcining in a muffle furnace at 550°C for 3 hours under the protection of nitrogen to obtain neodymium-modified carbon black particles.

Embodiment 2

[0024] Take by weighing 50g of graphite with a particle size of 60 μm and 1.0g of polyvinylpyrrolidone in beaker 1, and mix them evenly; Lanthanum nitrate and 100g of distilled water were stirred to fully dissolve, then the mixture of graphite and polyvinylpyrrolidone in beaker 1 was added in batches to beaker 2 under stirring, and the steps in Example 1 were repeated to obtain lanthanum-modified graphite particles .

Embodiment 3

[0026] In beaker 1, take 50g of graphite with a particle size of 60 μm and 1.0g of polyvinyl alcohol, mix evenly; calculate that praseodymium content accounts for 1.5% of the graphite weight before modification, weigh 2.08g of praseodymium content in beaker 2 and be 36% Praseodymium chloride and 100g of distilled water are stirred to fully dissolve, then the graphite and polyvinyl alcohol mixture in the beaker 1 is added in batches to the beaker 2 under stirring, and the steps in Example 1 are repeated to obtain praseodymium modified graphite particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com