High-purity iron p-toluenesulfonate preparation method

A technology of ferric p-toluenesulfonate and p-toluenesulfonic acid, which is applied in the field of electronic chemicals, can solve the problems of shortening the service life of electrolytic capacitors, corrosion of oxide films by chloride ions, and difficulty in removing anions, and achieves high solubility and clean process. , the effect of low moisture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

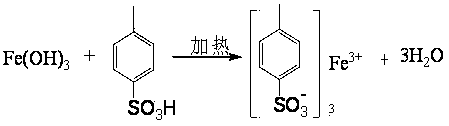

Image

Examples

Embodiment 1

[0025] Add 1000g of deionized water, 500g of p-toluenesulfonic acid and 100g of ferric hydroxide into a 2000ml flask, heat the reaction temperature at 100-104°C, react for 5h, cool and filter. The filtrate was spray-dried to obtain 450 g of solids. Karl Fischer detected moisture<0.2%, particle size<25um, no chloride ions were detected, no nitrate ions were detected, and sulfate ions were 2ppm.

Embodiment 2

[0027] Add 500g of deionized water, 500g of p-toluenesulfonic acid and 100g of ferric hydroxide into a 2000ml flask, heat the reaction temperature at 105-110°C, react for 3h, cool and replenish water and filter. The filtrate was spray-dried to obtain 430 g of solids. Karl Fischer detected moisture<0.2%, particle size<25um, no chloride ions were detected, no nitrate ions were detected, and sulfate ions were 2ppm.

Embodiment 3

[0029] Add 100g of deionized water, 500g of p-toluenesulfonic acid and 100g of ferric hydroxide into a 2000ml flask, heat the reaction temperature at 115-120°C, react for 2h, cool and replenish water and filter. The filtrate was spray-dried to obtain 380 g of solids. Karl Fischer detected moisture <0.2%, particle size <25um, no chloride ions, no nitrate ions, and 3 ppm sulfate ions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com