Technique for manufacturing flux-cored wire from disk round steel wire bar

A technology of flux-cored welding wire and round steel, which is used in manufacturing tools, welding media, metal rolling, etc., can solve the problems of high price of wide-width cold-rolled coils, not too high line speed, and increased wear of welding torch nozzles. Achieve the effect of improving the continuous operation rate of equipment, saving auxiliary process time, and reducing raw material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

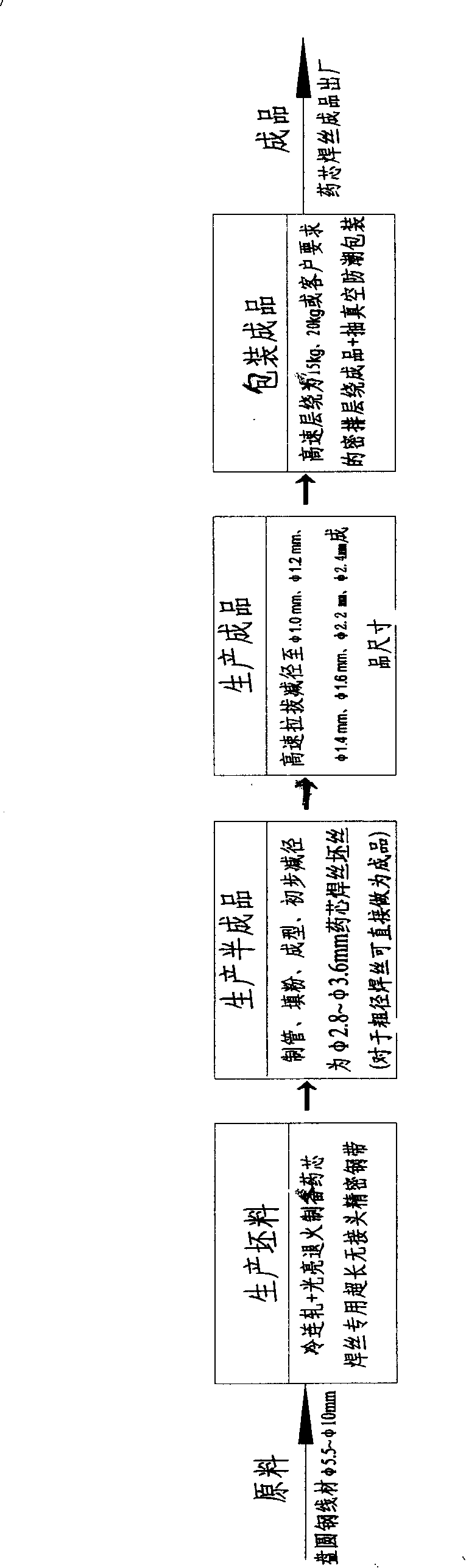

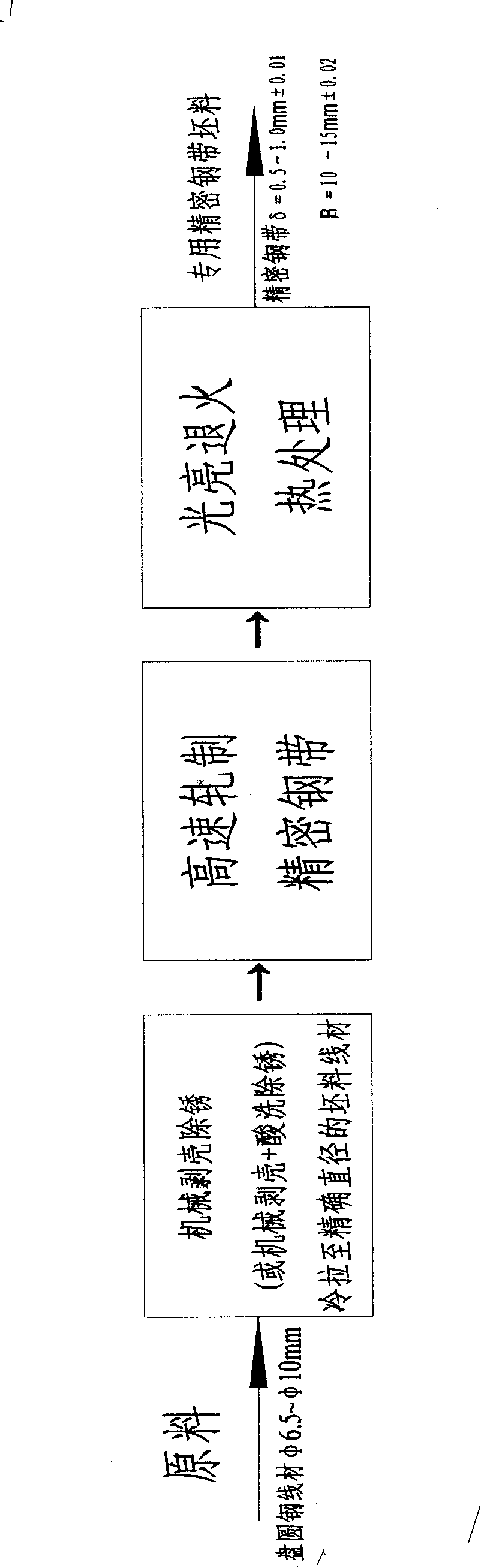

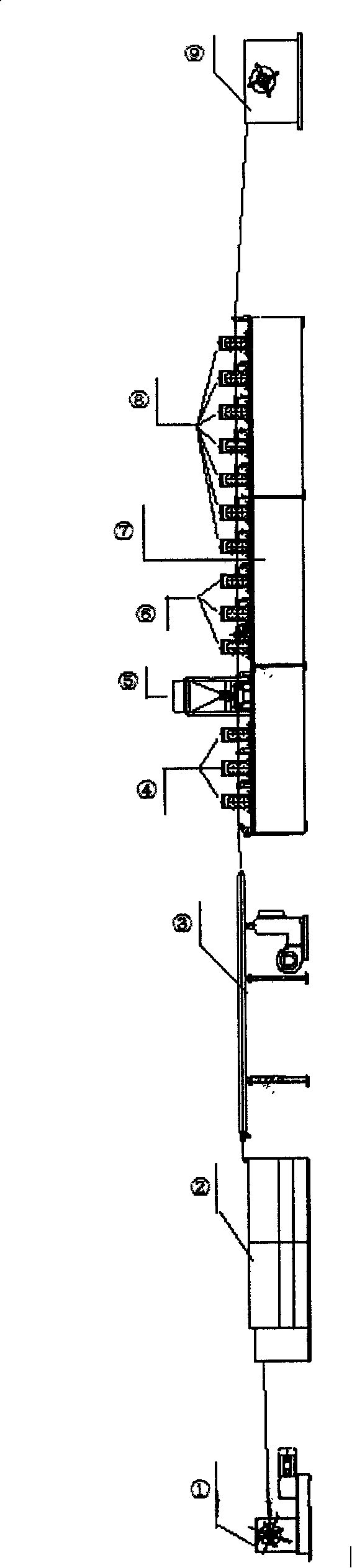

Method used

Image

Examples

Embodiment

[0040] Example: take The H08A high-speed hot-rolled round steel is cold-drawn and sized after peeling and derusting The round steel wire is placed on the pay-off machine of the high-speed precision tandem cold rolling mill, and is formed into a billet steel strip by one-time cold rolling of the six-tandem rolling mill. Belt winding, line speed 480m / min. The bright annealed blank steel strip is placed on the unwinding machine of the flux-cored wire forming unit, rolled into a U-shaped open tube, filled with powder, rolled and closed, rolled and rolled, and rolled to reduce the diameter. Flux-cored wire semi-finished products, the filling rate is 16%, and the absolute error of the filling rate is ≤±0.2%. The maximum linear speed of the steel strip at the powder feeding place is 120m / min. Put the semi-finished welding wire on the pay-off machine of 10 high-speed straight wire drawing machines, and the diameter of the wire after drawing is The maximum linear speed of weldi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com