Patents

Literature

51results about How to "Reduce auxiliary processing time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

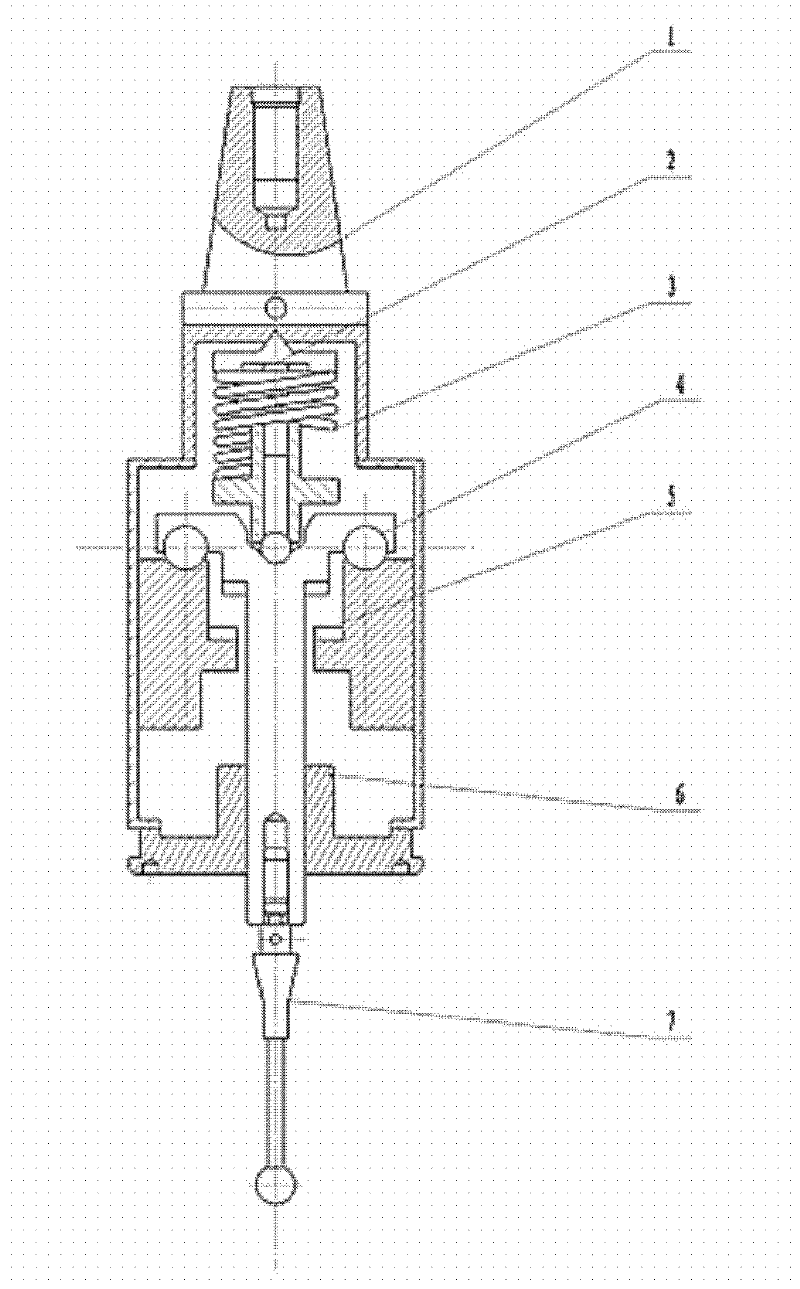

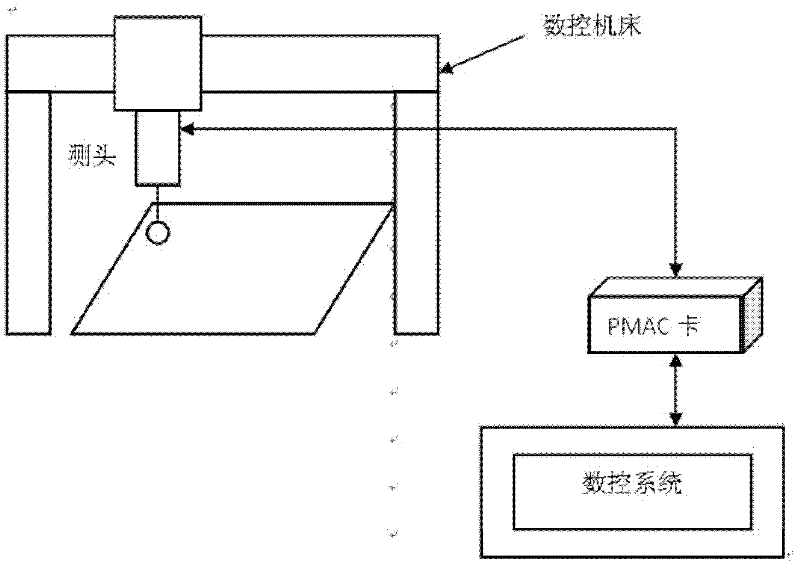

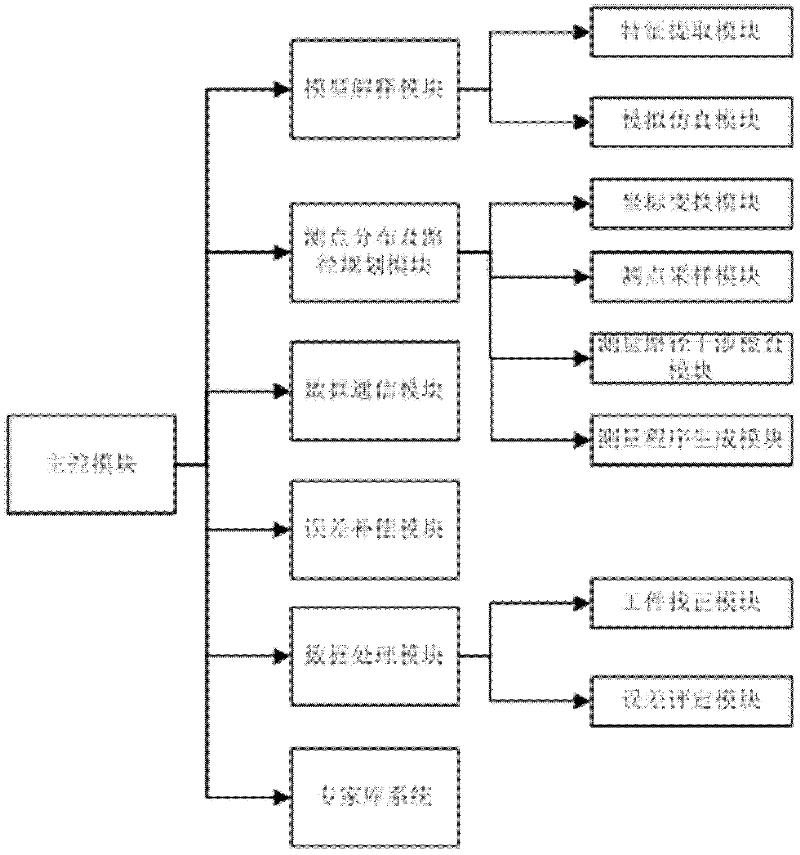

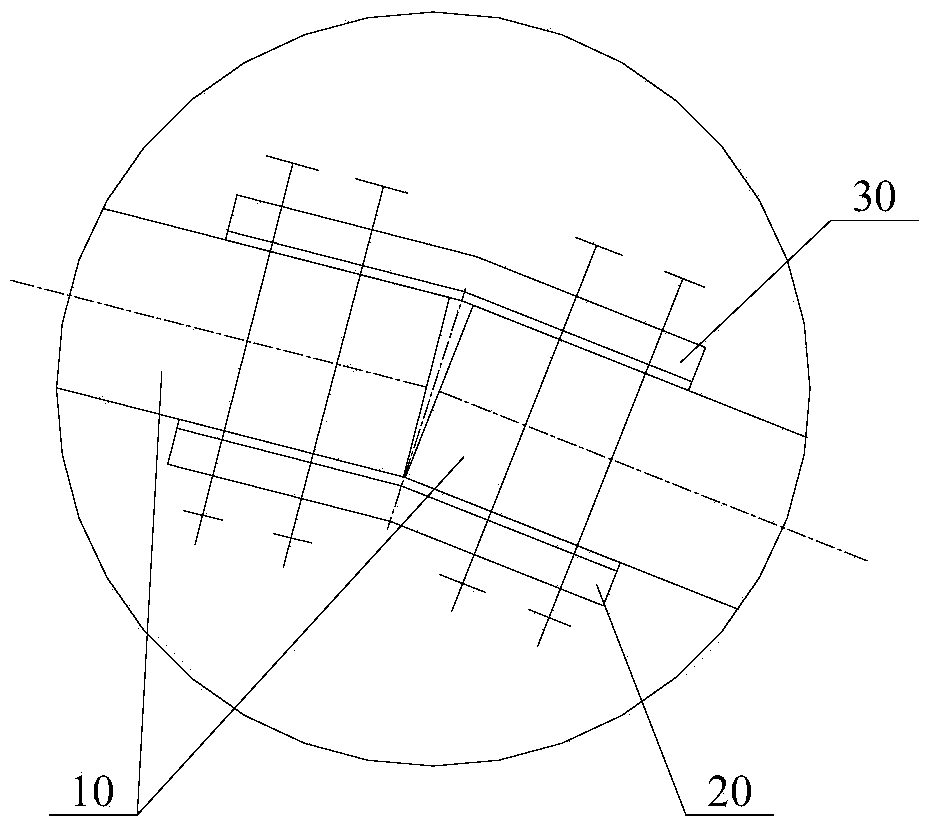

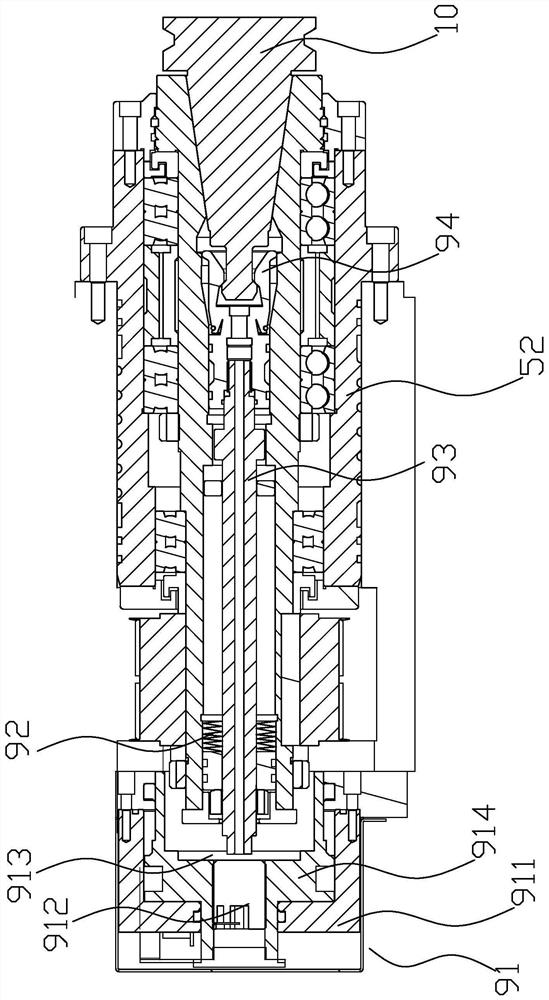

On-machine detection measuring head and detection system for numerical control machine tool

ActiveCN102501136AImprove measurement efficiencyHigh measurement accuracyProgramme controlComputer controlElectricityLinear motion

The invention discloses an on-machine detection measuring head for a numerical control machine tool. The on-machine detection measuring head comprises a measuring bar and a guide mechanism for guiding the measuring bar to make the vertical linear motion. The top of the measuring bar is provided with an elastic reset mechanism. The on-machine detection measuring head is characterized in that a linear displacement sensor is arranged at the position close to the measuring bar. The invention also discloses a detection system applying the measuring head, and the detection system comprises the measuring head, a signal acquisition circuit and a control center which are sequentially electrically connected. A numerical control system executes a measuring program to control a servo system of the machine tool to drive the measuring head to carry out measurement; coordinates of a point which is measured each time are timely transmitted back to the detection system; after the model detection is completed, the detection system carries out error compensation on measurement data; a spatial position and shape information of a measured workpiece can be calculated by carrying out corresponding operation on the corrected data; and the positioning and processing correction of the workpiece are guided by utilizing an obtained result. Auxiliary processing time can be greatly saved and the rejection rate of the workpiece is reduced.

Owner:WUHAN HENGLI HUAZHEN TECH CO LTD

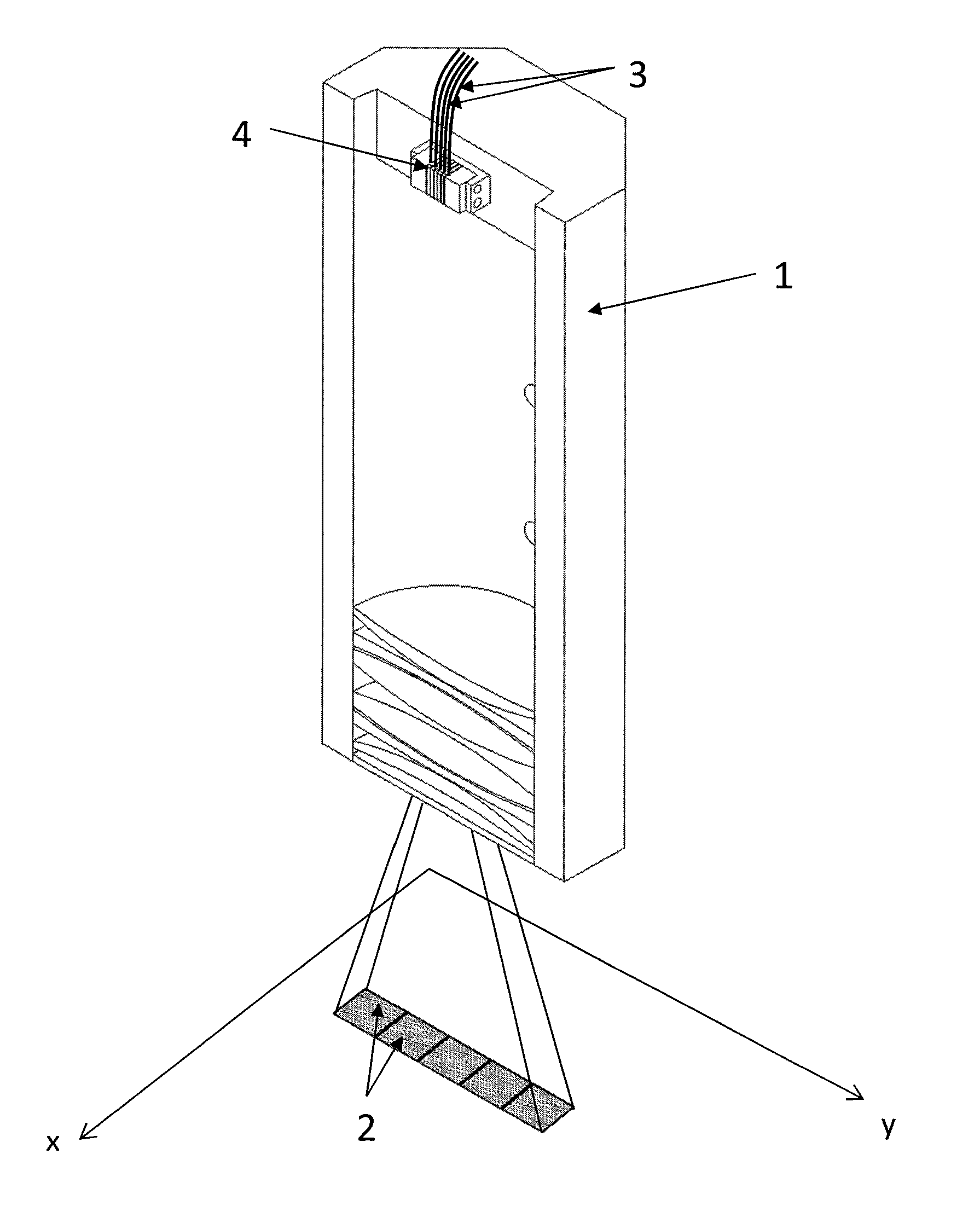

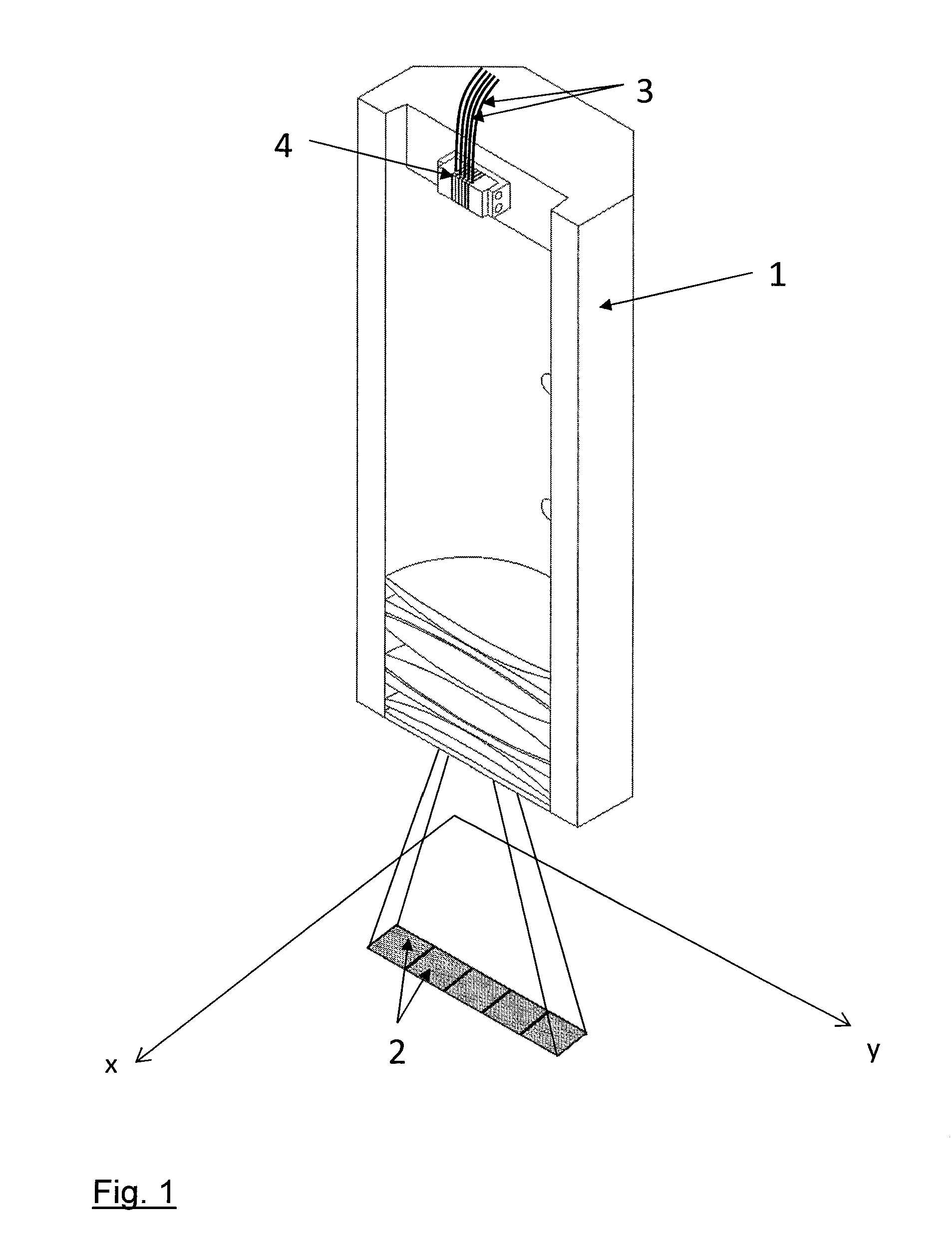

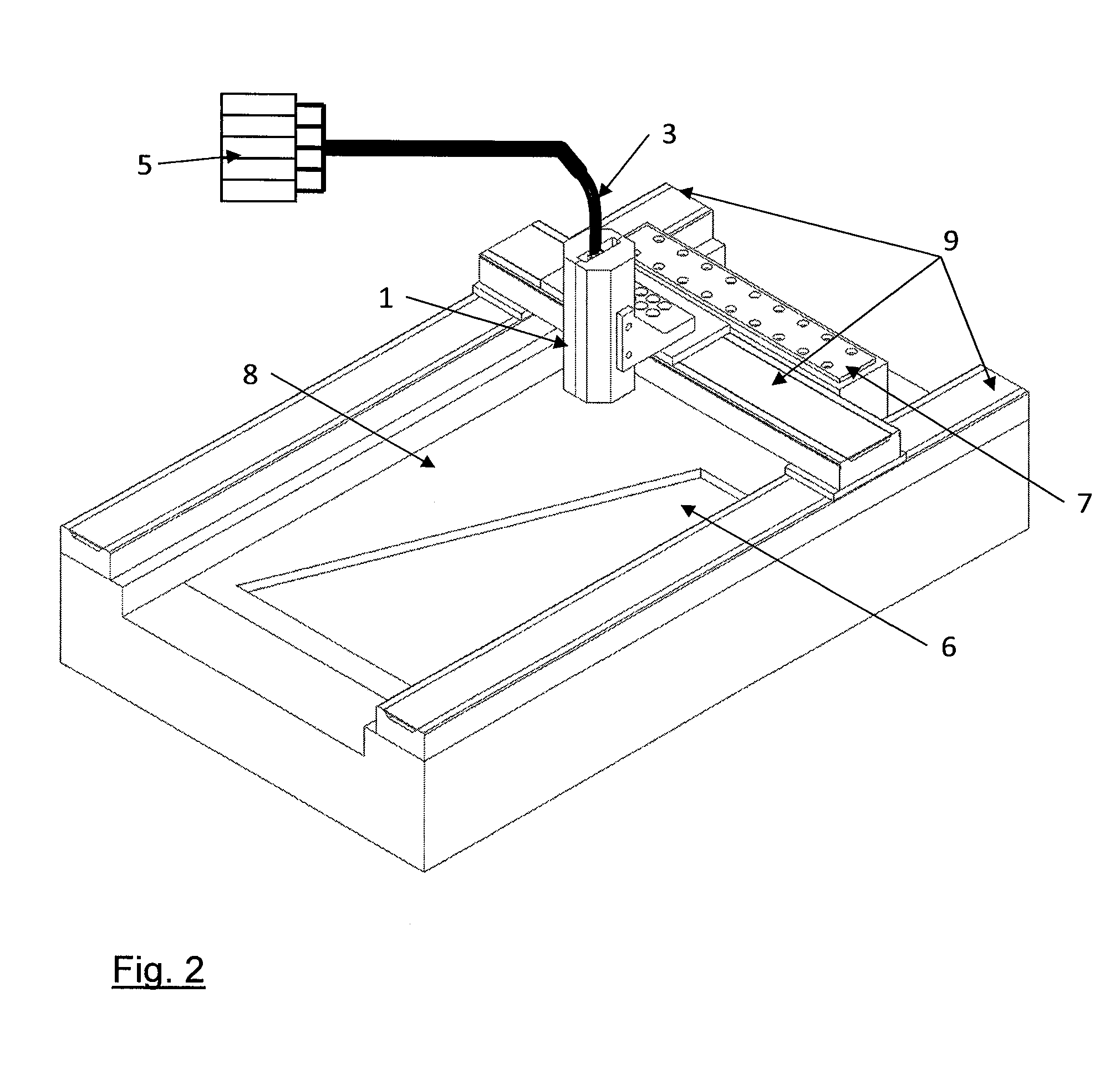

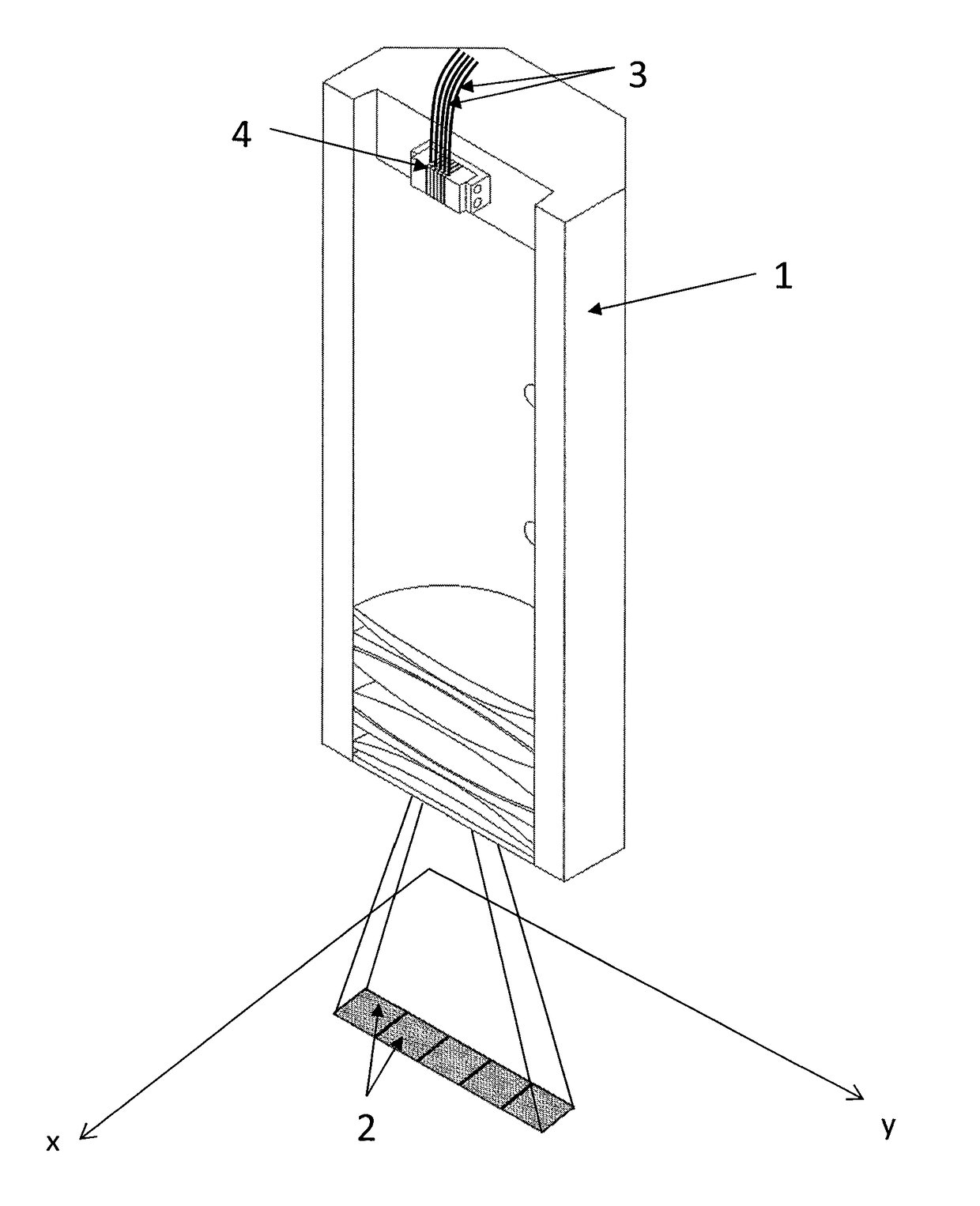

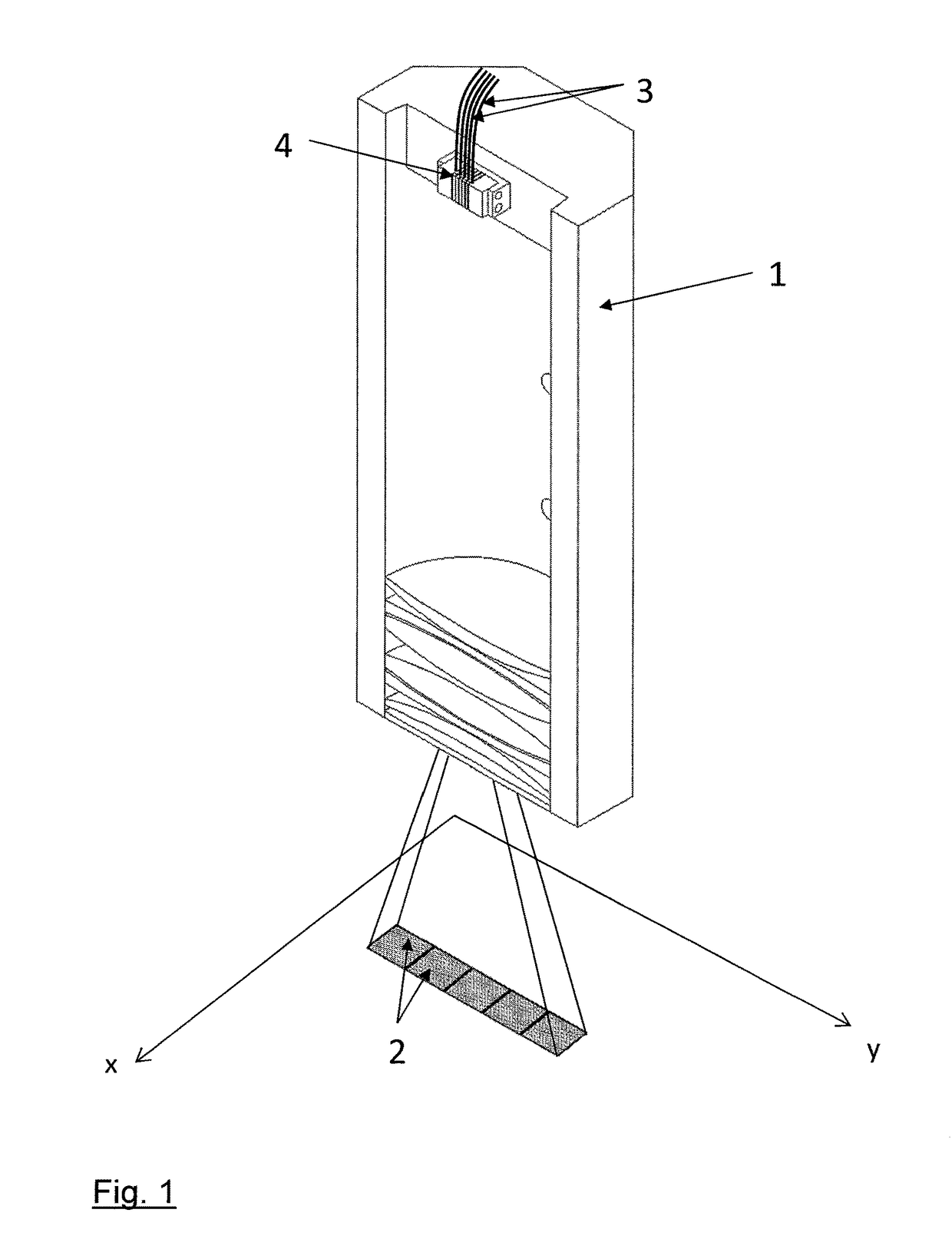

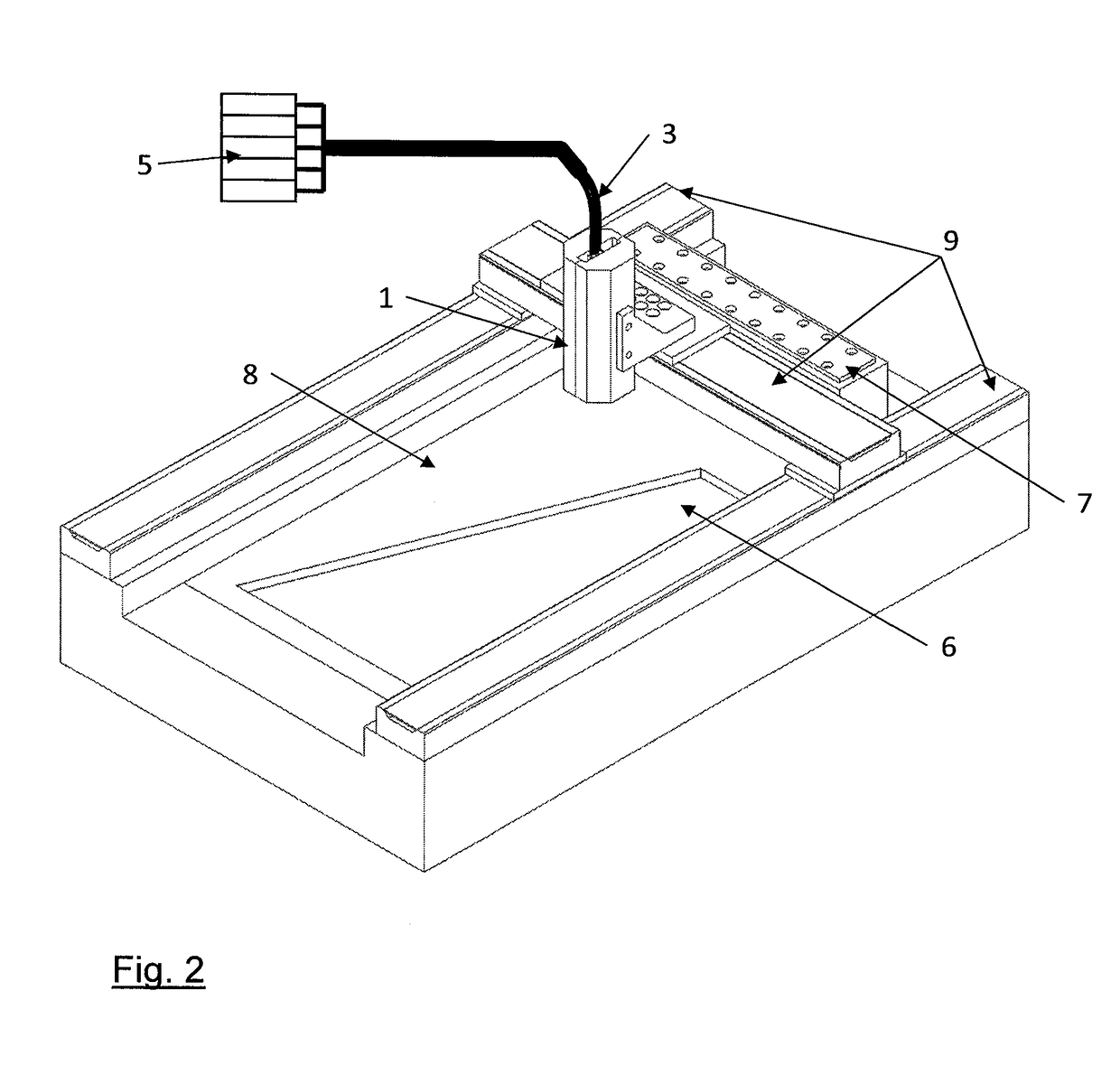

Device and method for generative component production

ActiveUS20160114427A1Reduce auxiliary processing timeEliminate timeAdditive manufacturing apparatusArc welding apparatusBiomedical engineeringEngineering

The present invention relates to a device for laser-based generative component production. The device comprises a processing head (1), using which a plurality of mutually separate laser beams are directed adjacently and / or overlapping to some extent onto the processing plane, The processing head (1) is moved across the processing plane using a movement apparatus (9), whilst the mutually separate laser beams are modulated independently of one another in terms of intensity, in order to obtain the desired exposure geometry. The laser power and the dimensional size can be scaled cost effectively during the generative production using the suggested device and the associated method.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

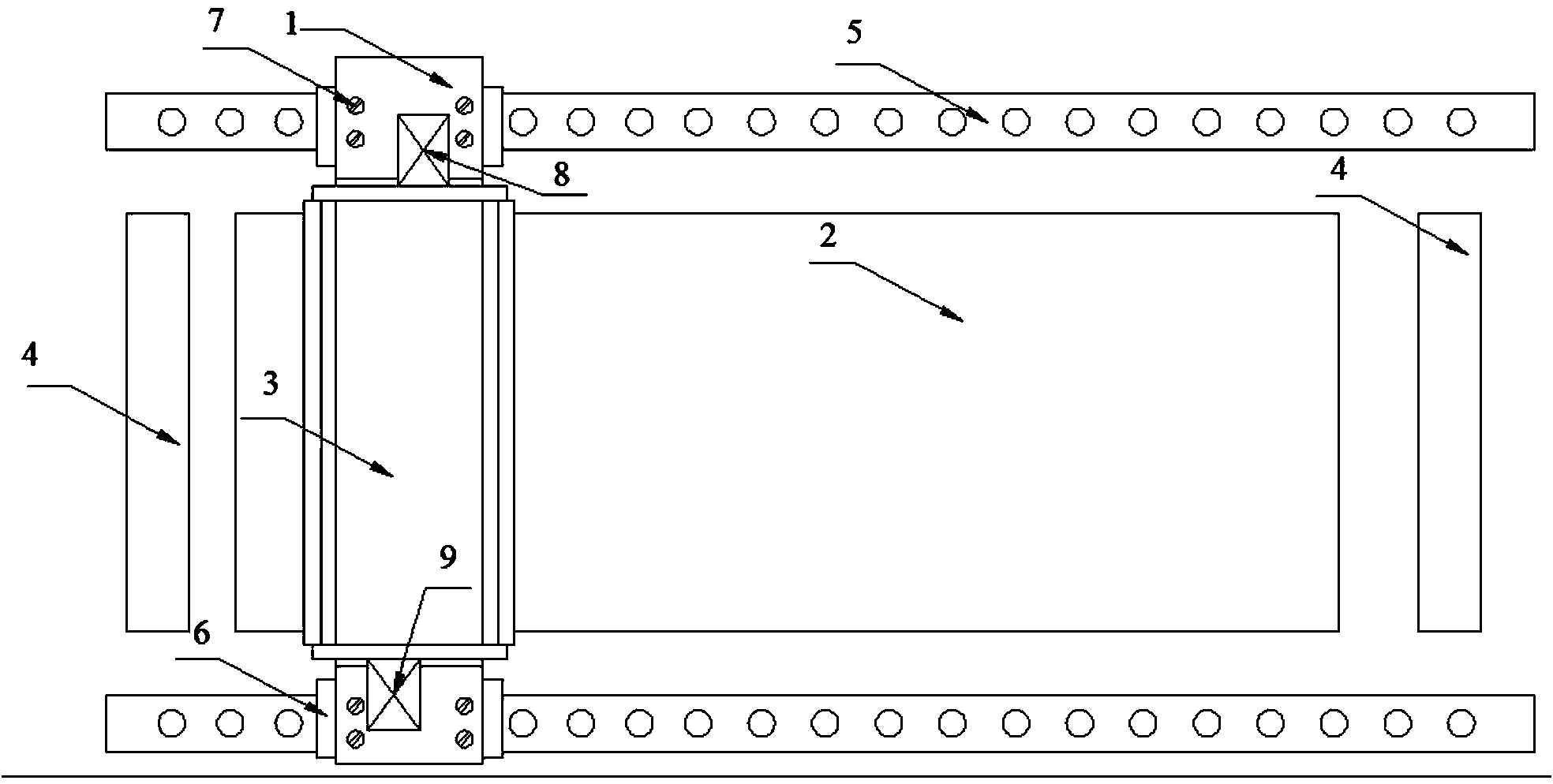

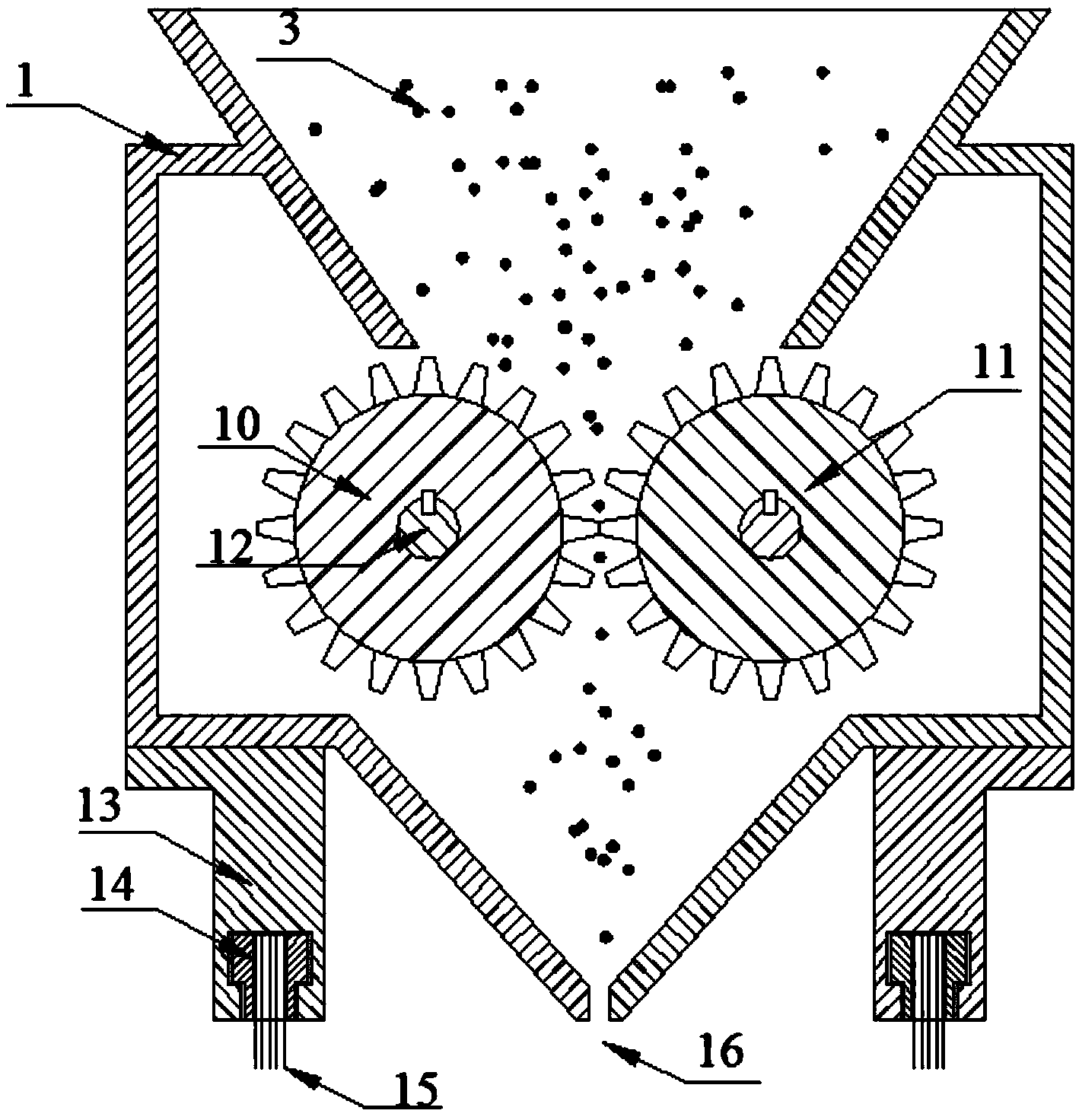

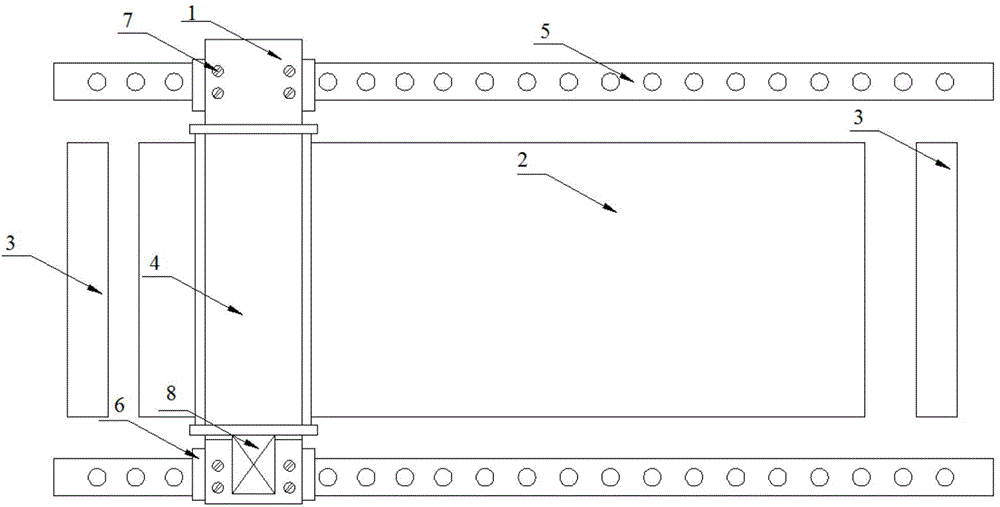

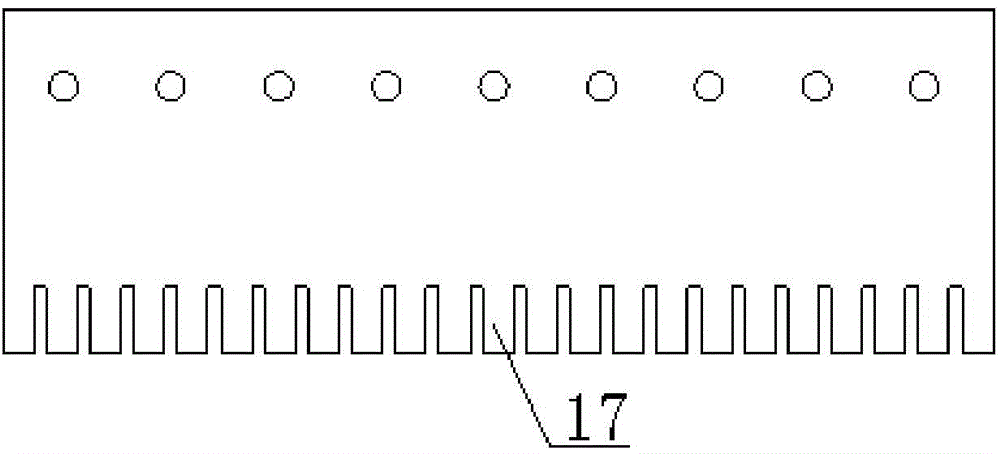

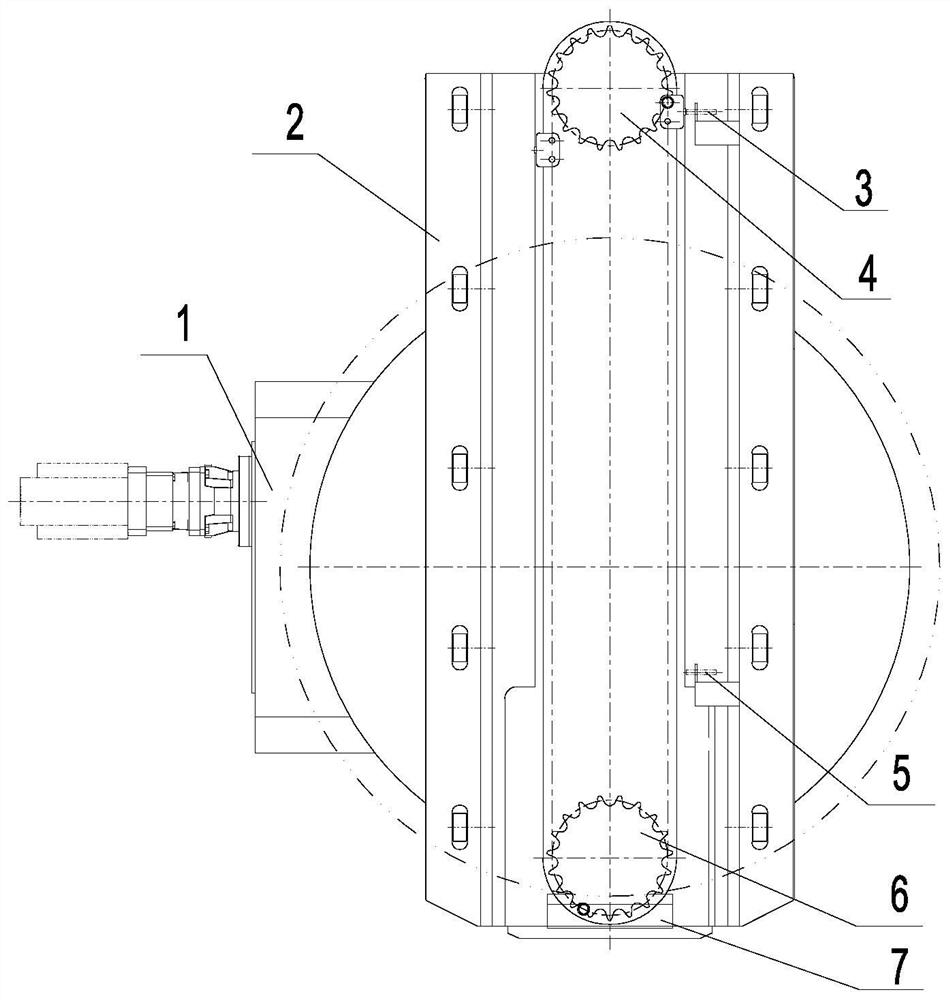

Two-way powder spreading device of SLM equipment and powder spreading method

ActiveCN103658646AGuaranteed uniformityGuaranteed flatnessIncreasing energy efficiencyDrive shaftInstability

The invention discloses a two-way powder spreading device of SLM equipment and a powder spreading method. The powder spreading device comprises a powder spreading device body, two parallel auxiliary linear motor guide rails and two parallel linear motor movable sliding blocks, wherein the linear motor movable sliding blocks are arranged on the auxiliary linear motor guide rails; the powder spreading device body is arranged on the linear motor movable sliding blocks in an erecting mode and comprises a powder carrying device and two powder supply gears arranged inside the powder carrying device; the circle center position of each powder supply gear is provided with a servo motor transmission shaft; the two powder supply gears are arranged at the equal altitude; the gear top circles of the two powder supply gears are tangent in the radial direction; flexible powder scraping brushes are arranged on the two sides of the powder carrying device. By means of the powder spreading device, the redundant steps in the powder spreading process are reduced, powder is spread in the back and forth direction, the evenness and flatness of the spread powder are ensured through the flexible powder scraping brushes on the two sides, and the good repairing function is achieved on the process instability.

Owner:SOUTH CHINA UNIV OF TECH

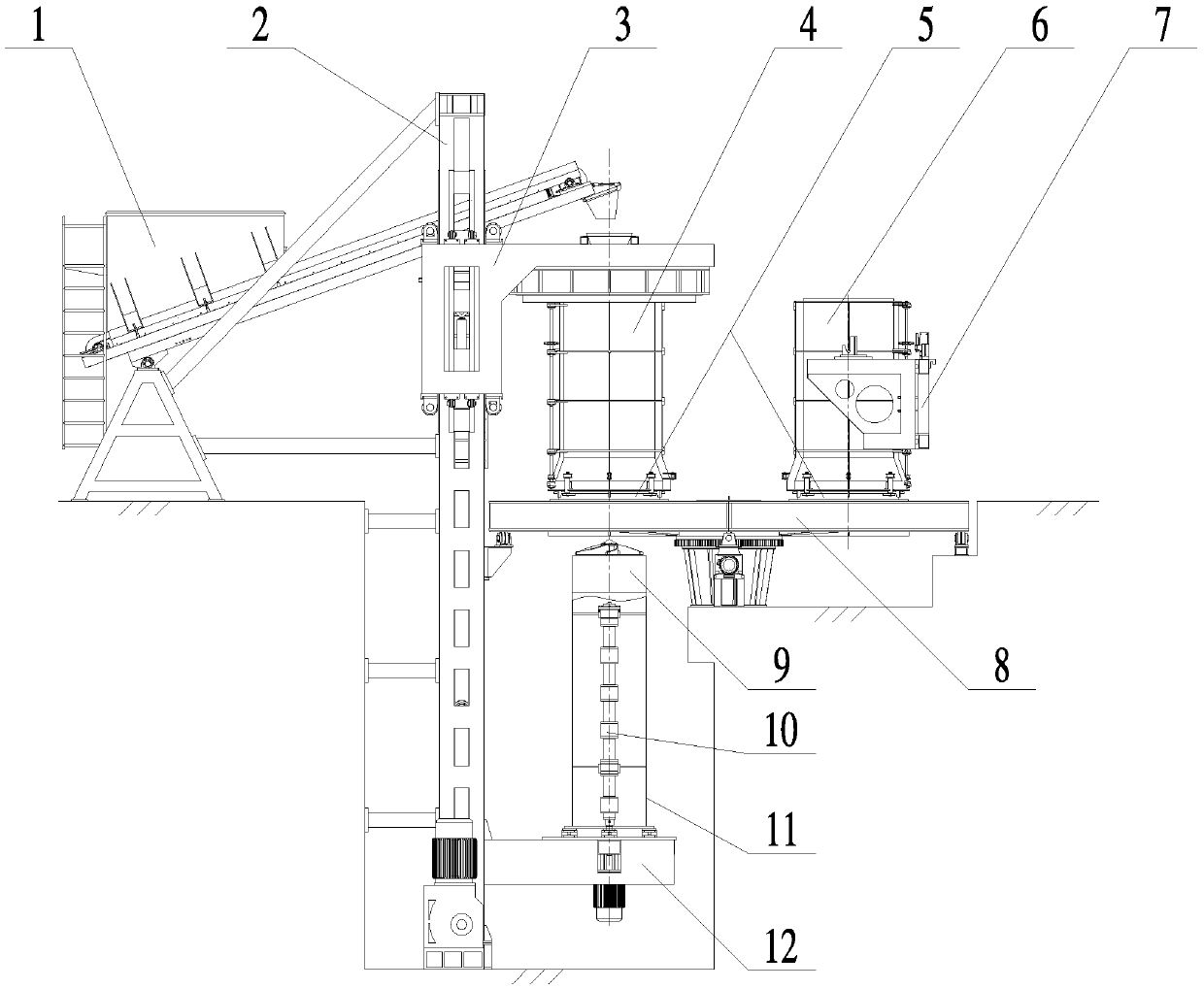

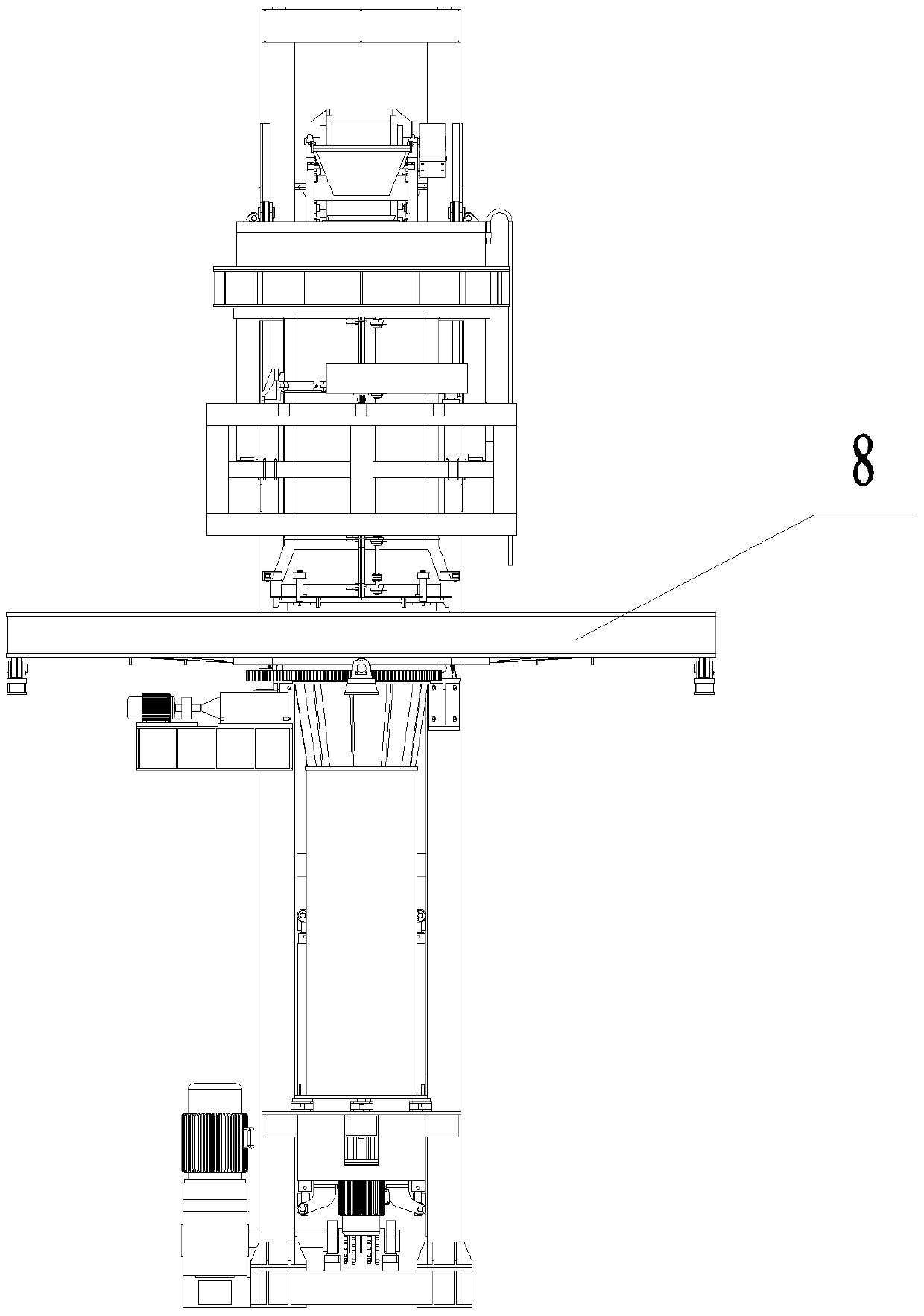

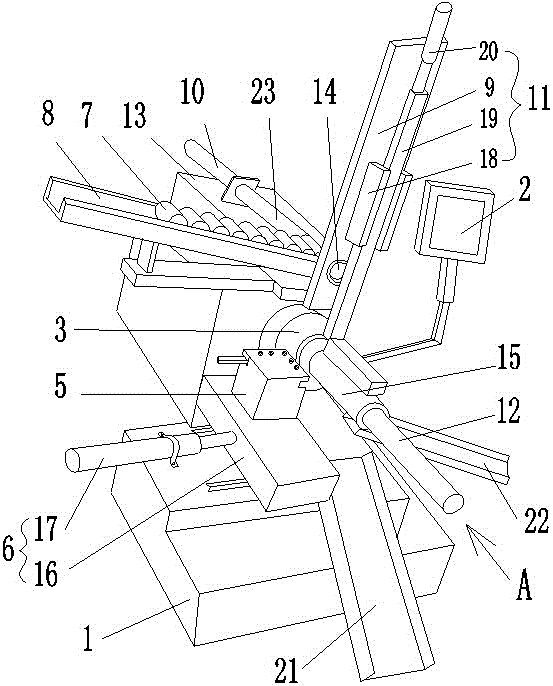

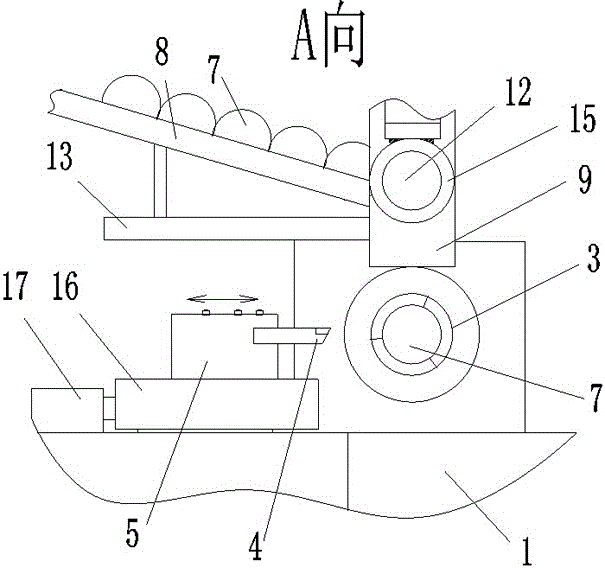

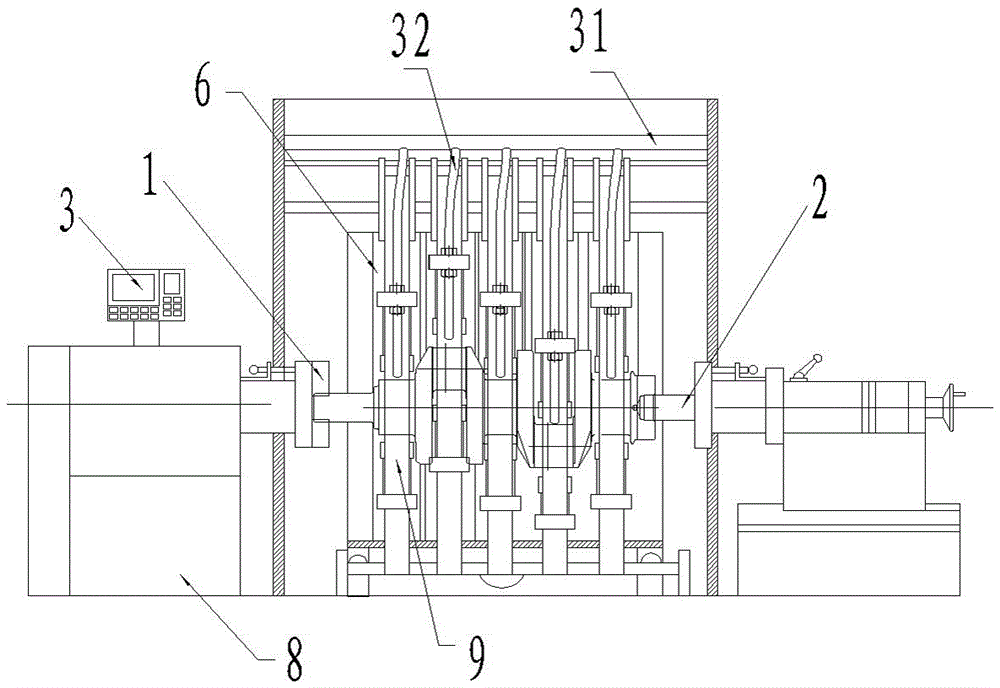

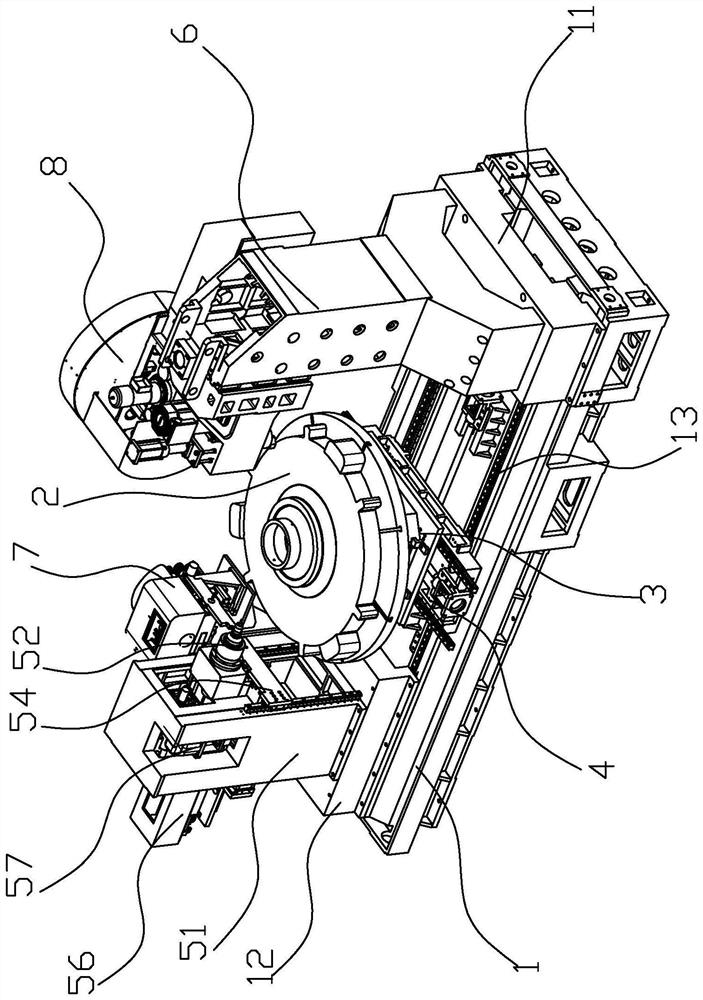

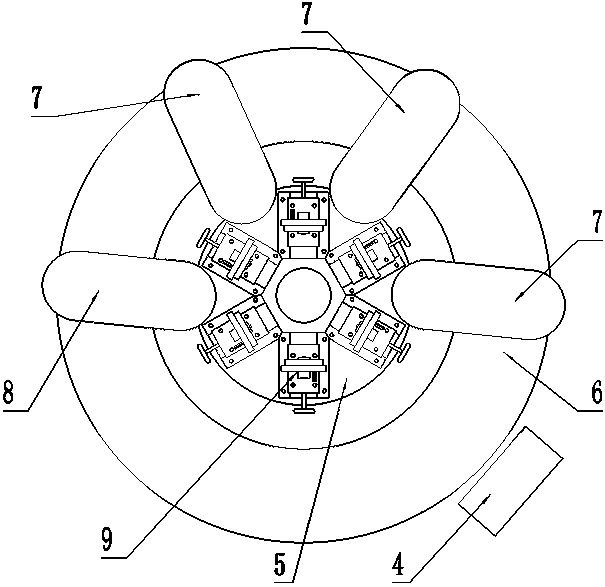

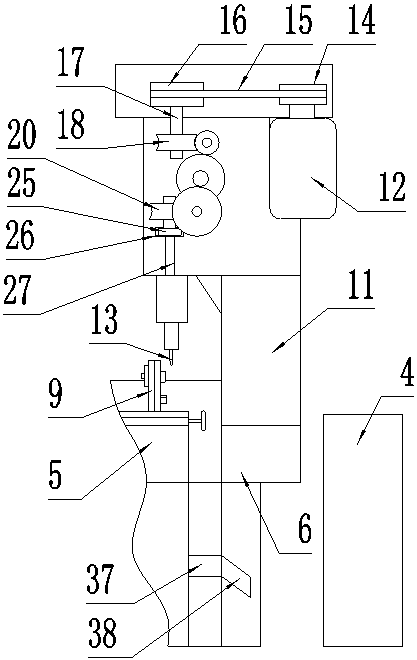

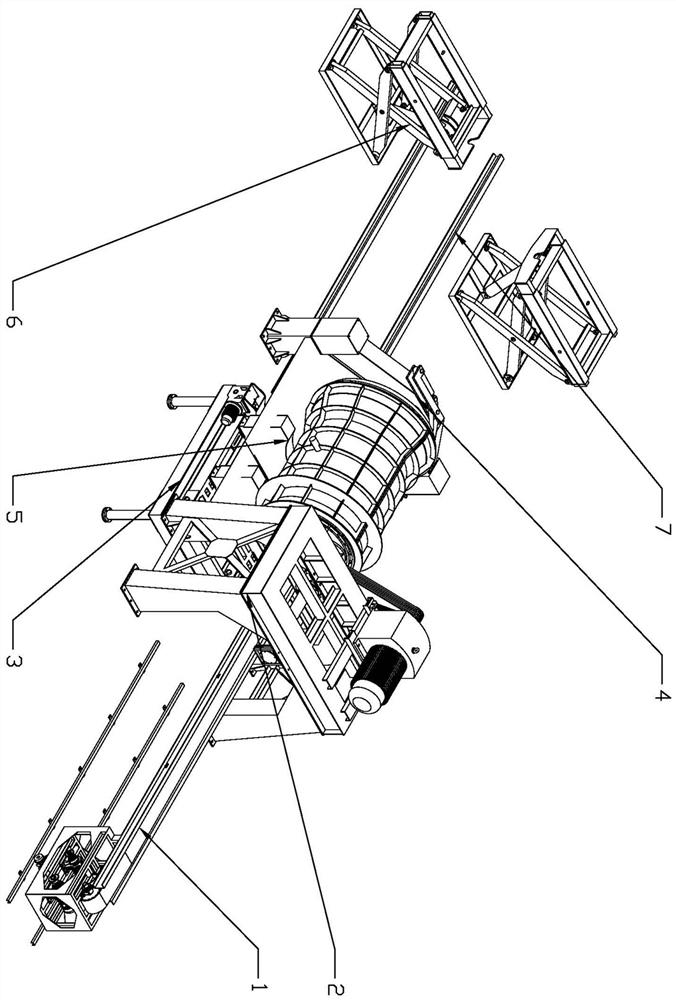

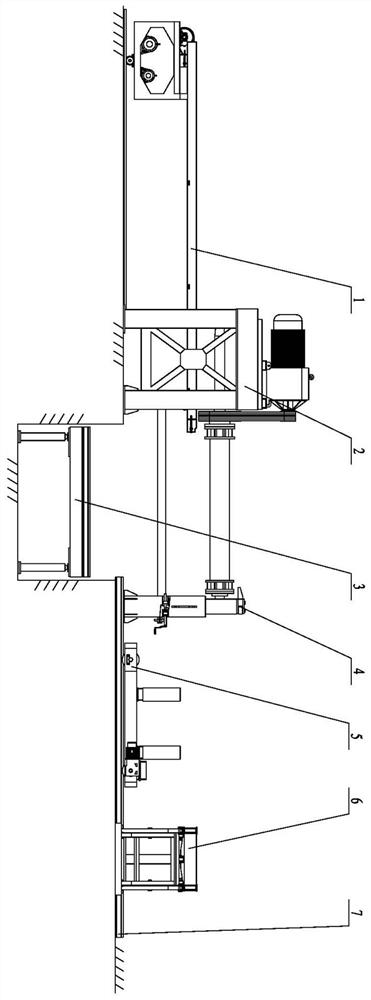

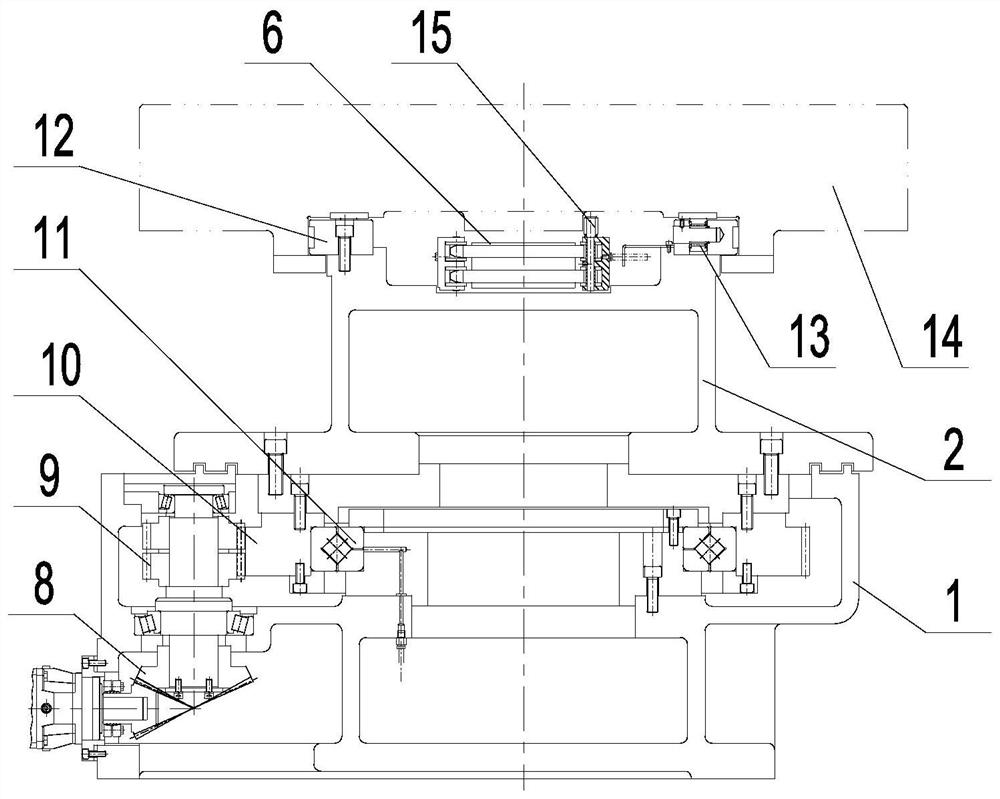

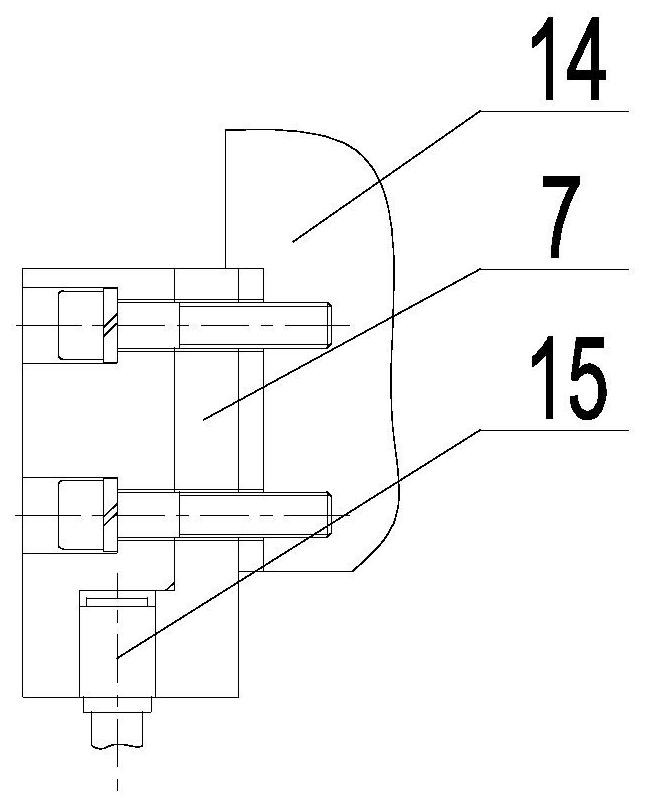

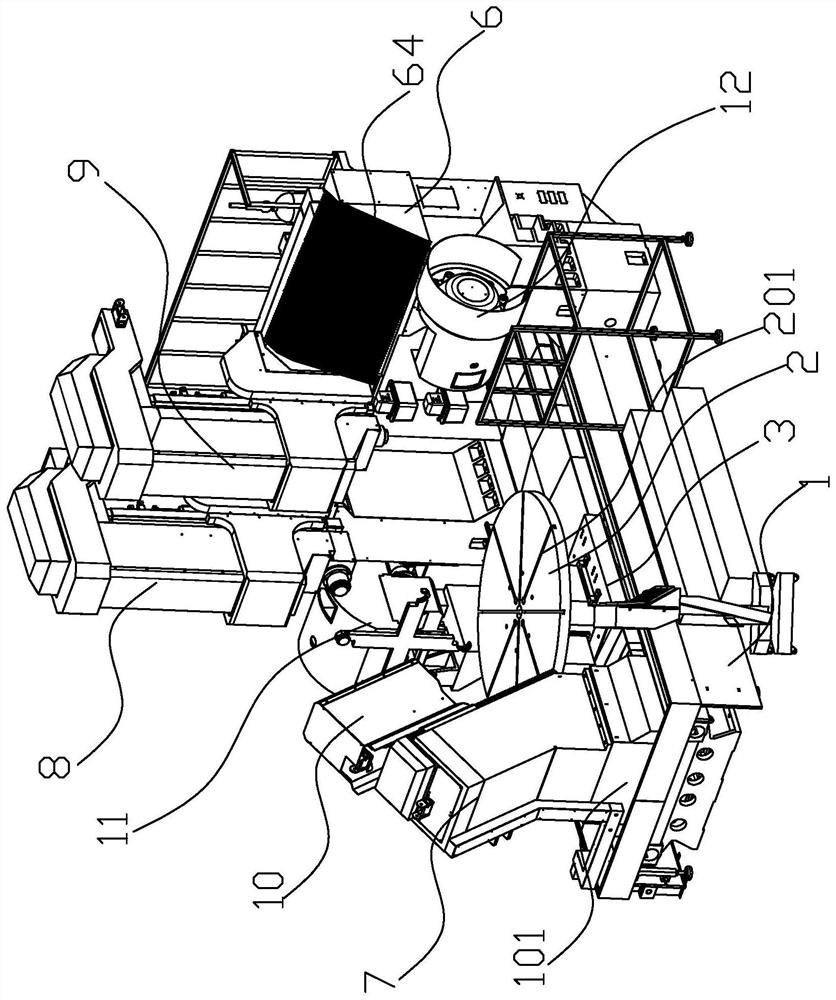

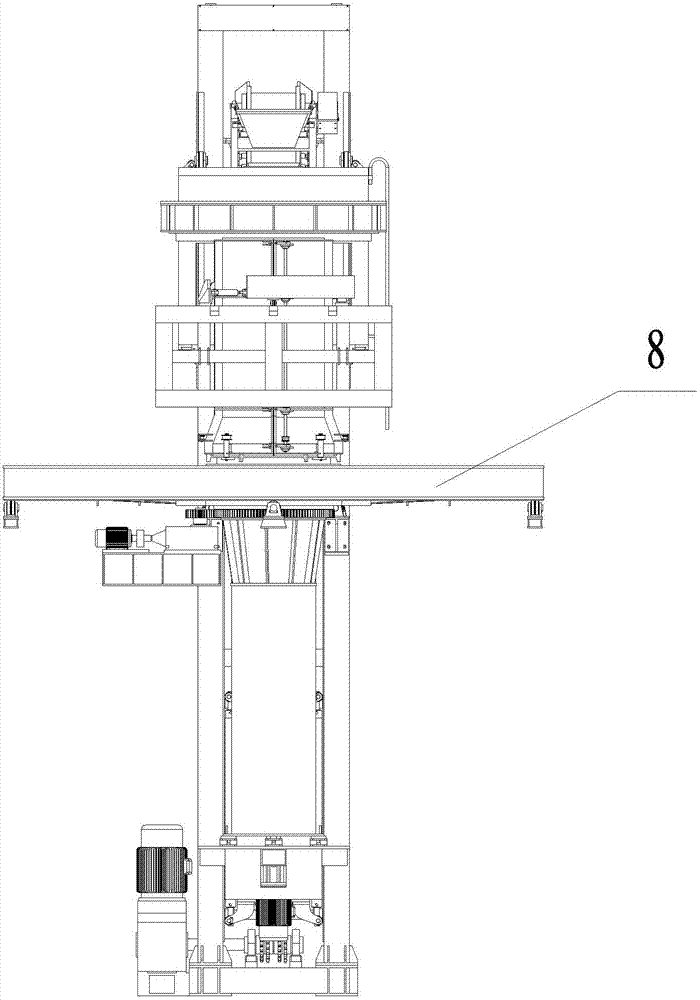

Core-lifting rotary type vibrating extrusion forming tubing machine

ActiveCN105500519AReduce auxiliary process timeImprove work efficiencyMouldsFeeding arrangmentsEngineeringMechanical engineering

The invention provides a core-lifting rotary type vibrating extrusion forming tubing machine. According to the core-lifting rotary type vibrating extrusion forming tubing machine, an automatic core lifting mode is adopted to an inner die, a special forklift demoulding mechanism is adopted to outer dies for quick die opening and die assembly, the outer dies can be quickly arranged in place through a rotary platform, and production efficiency is improved. The core-lifting rotary type vibrating extrusion forming tubing machine comprises a rack, a feeding mechanism, a rolling plate, the rotary platform, the outer dies, a rotary material uniforming mechanism, a vibrating mandrel and the inner die. The outer dies are arranged on the rotary platform which drives the outer dies to rotate, and the rotary platform is located above the inner die. The rotary material uniforming mechanism is arranged on the top of the inner die, the vibrating mandrel is arranged in the inner die, the inner die ascends and descends relative to the rack through a lifting mechanism, and the inner die enters the outer dies to form a tube cavity. The feeding mechanism is used for feeding materials to the tube cavity, the rolling plate is arranged on the rack and ascends and descends, and the rolling plate is used for rolling concrete products on the upper portion of the tube cavity. By means of the core-lifting rotary type vibrating extrusion forming tubing machine, auxiliary procedure time consumed in the production process is shortened, and work efficiency is improved.

Owner:孙祥 +1

Automatic turning machine tool

InactiveCN106141206AReduce labor intensityRealize mechanized controlAutomatic/semiautomatic turning machinesMetal working apparatusEngineeringMachine tool

The invention discloses an automatic turning machine tool, and relates to the technical field of cold machining equipment. The automatic turning machine tool comprises a machine base, a turning device connected with a control panel and a feeding device connected with the control panel; the turning device comprises a chuck driven by a motor and a knife base provided with a turning knife and connected with a radial supply device, and the feeding device is arranged above the chuck; the feeding device comprises a feeding chute, a stand column and a pushing mechanism, wherein the stand column and the pushing mechanism are arranged on the two sides of the bottom end of the chute; a material via hole is formed in the bottom of the stand column, a lifting mechanism is arranged on the other side of the stand column, and a maternal storage hole is formed in the bottom of the lifting mechanism; and a feeding mechanism connected with the maternal storage hole is arranged at the bottom of the lifting mechanism. The maternal storage hole is lifted by the lifting mechanism to be coincide with the material via hole of the stand column, workpieces at the bottom of the feeding chute are pushed by the pushing mechanism into the maternal storage hole, the lifting mechanism descends to enable the workpieces in the maternal storage hole to descend to the position of a clamping claw of the chuck, the feeding mechanism drives a stretchable rod to push the workpieces from the material storage hole into the clamping claw of the chuck, and the feeding device is matched with the turning device through the control panel so as to achieve feeding, clamping and turning of the workpieces.

Owner:郭世怡

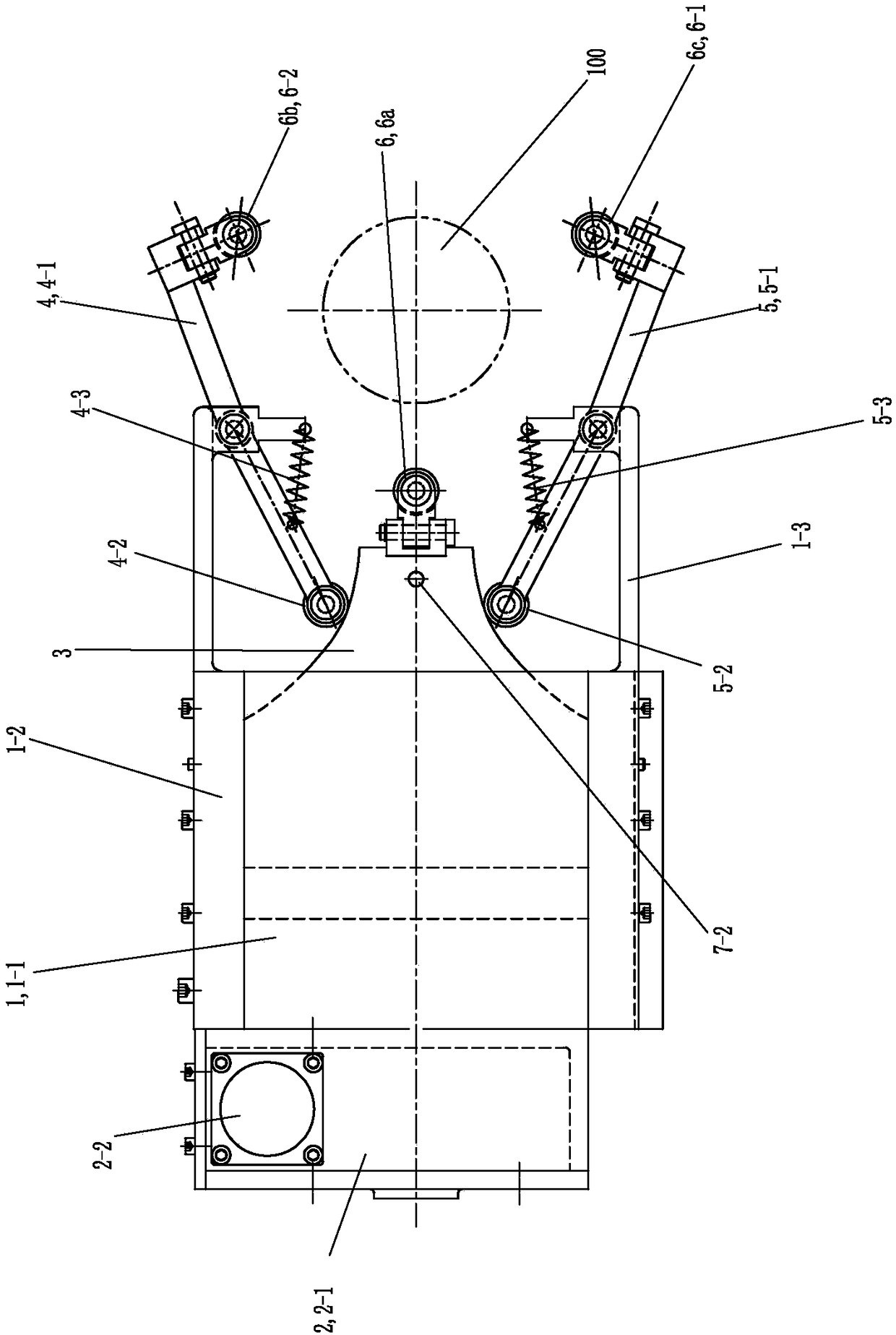

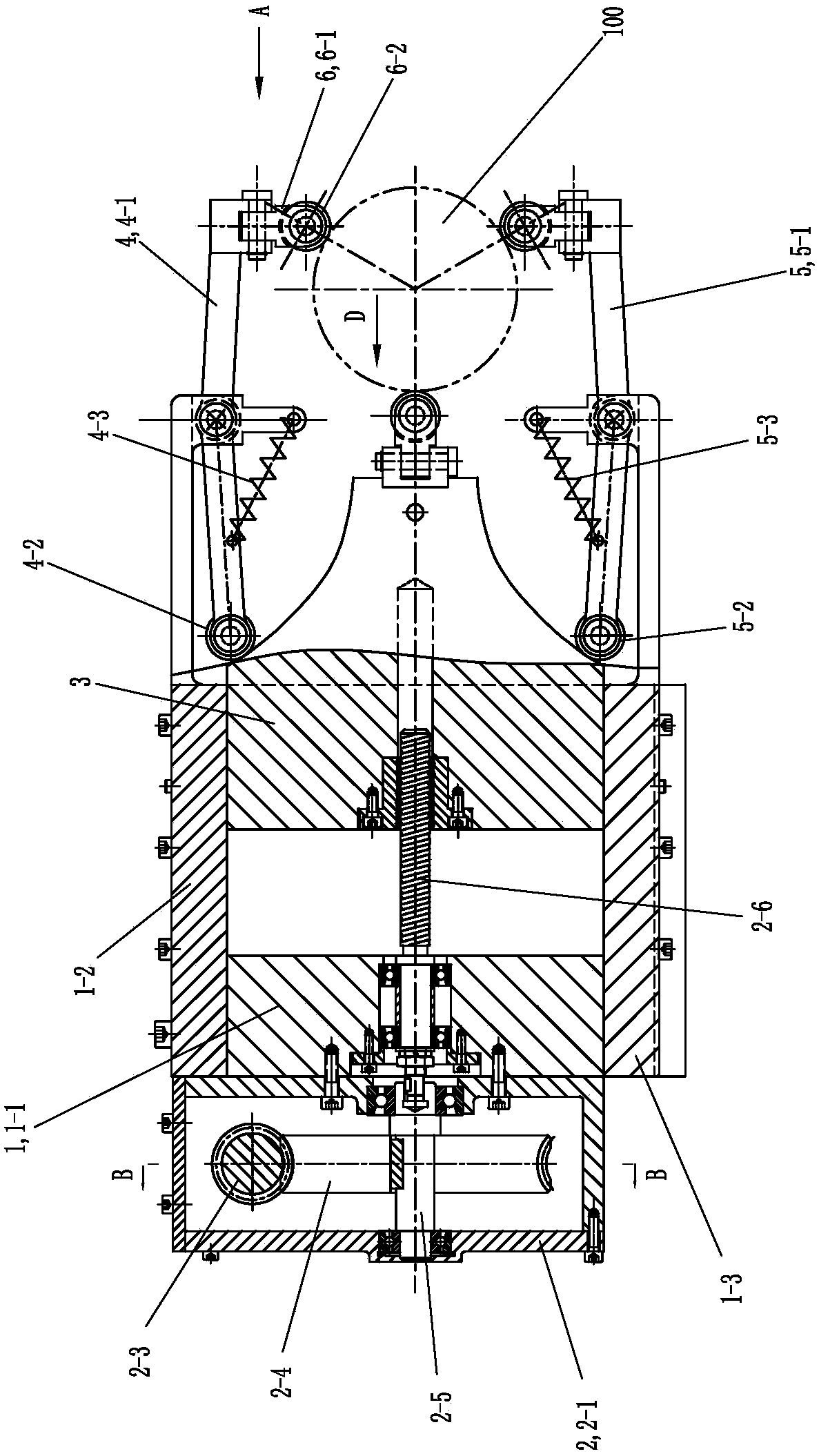

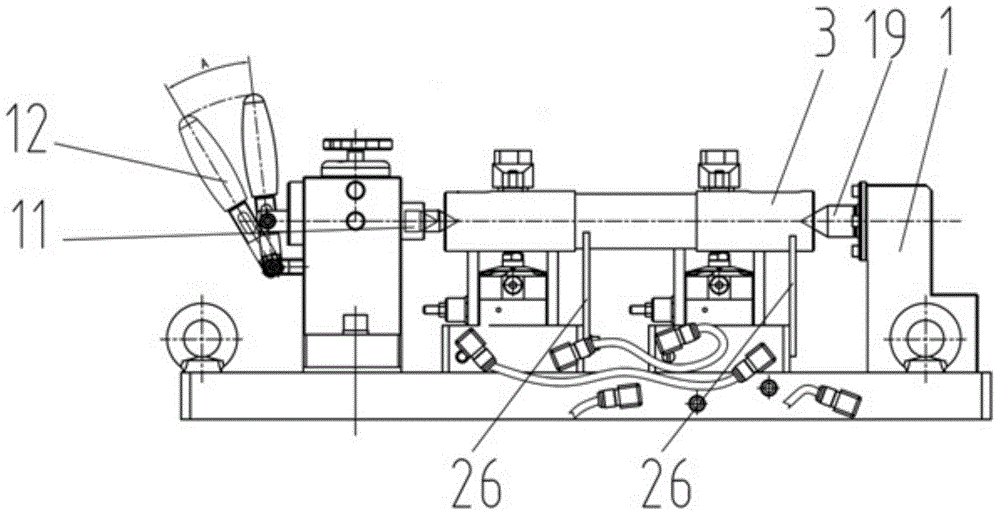

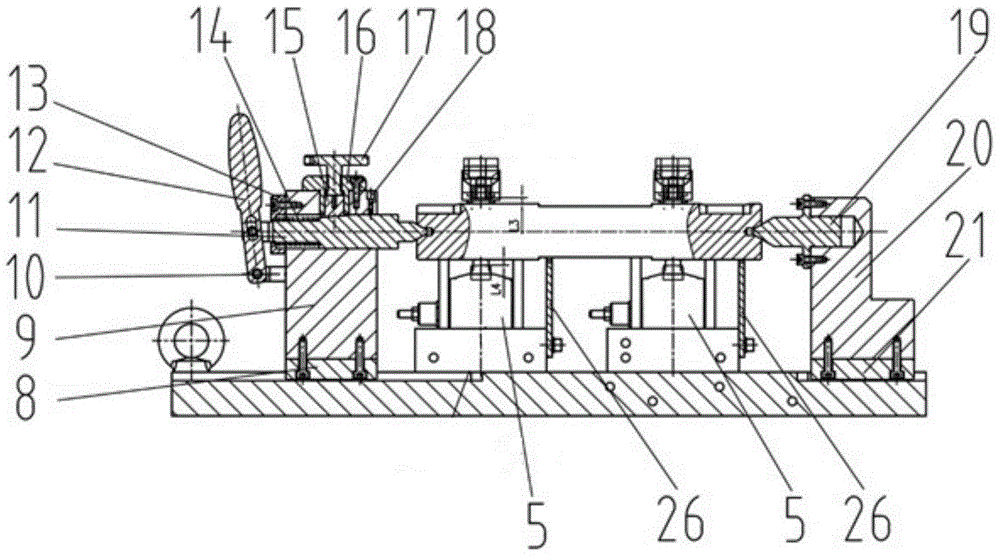

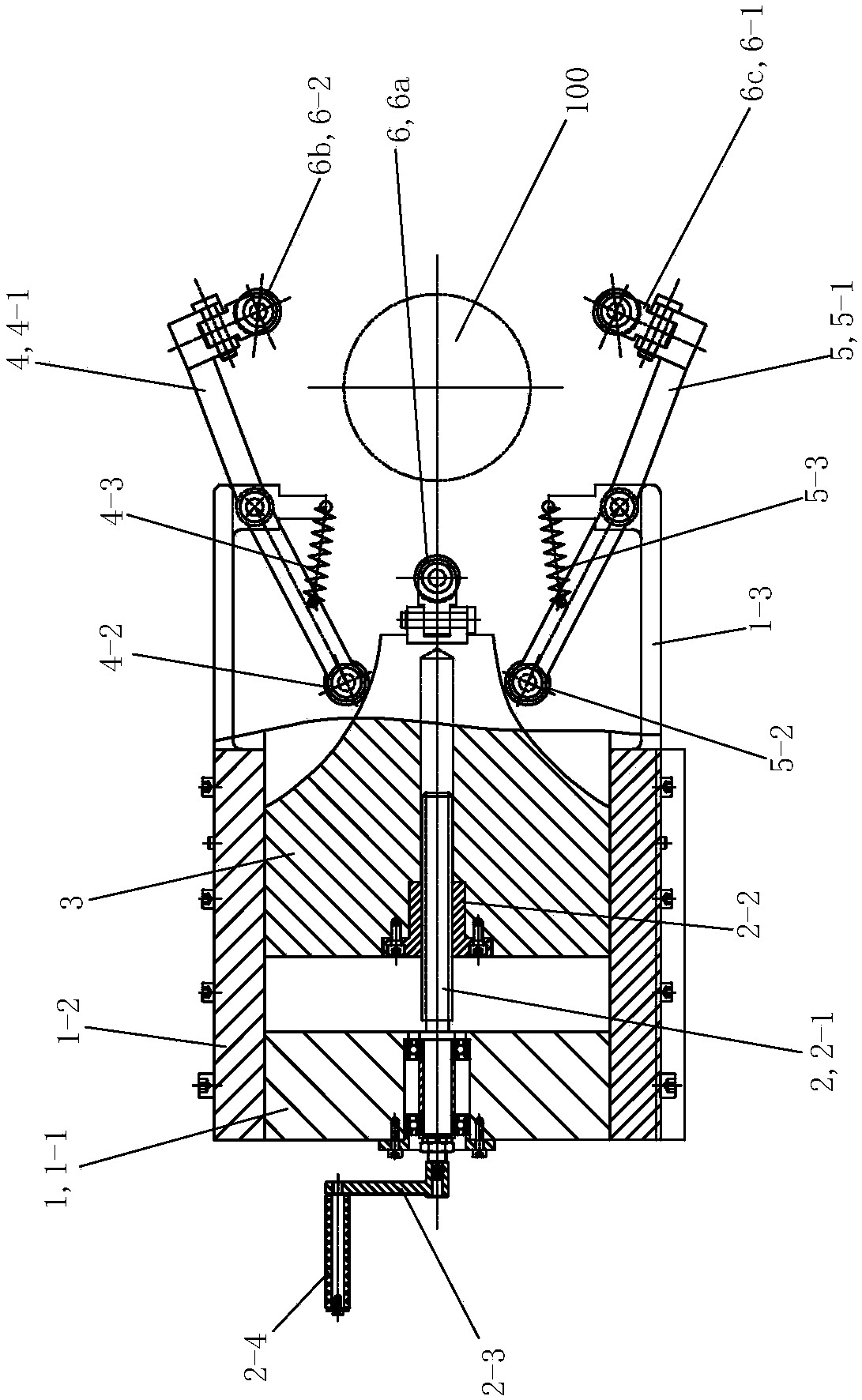

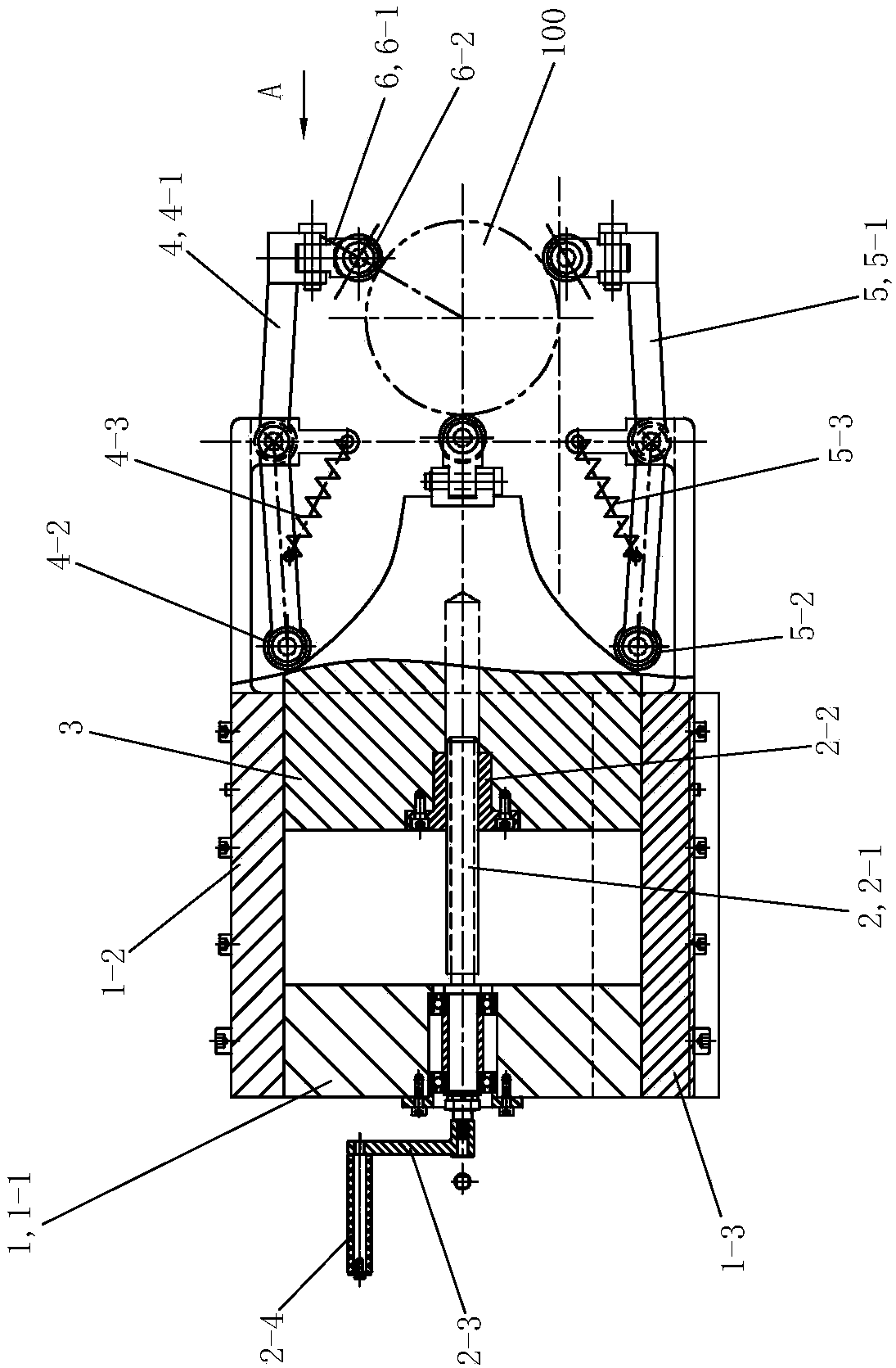

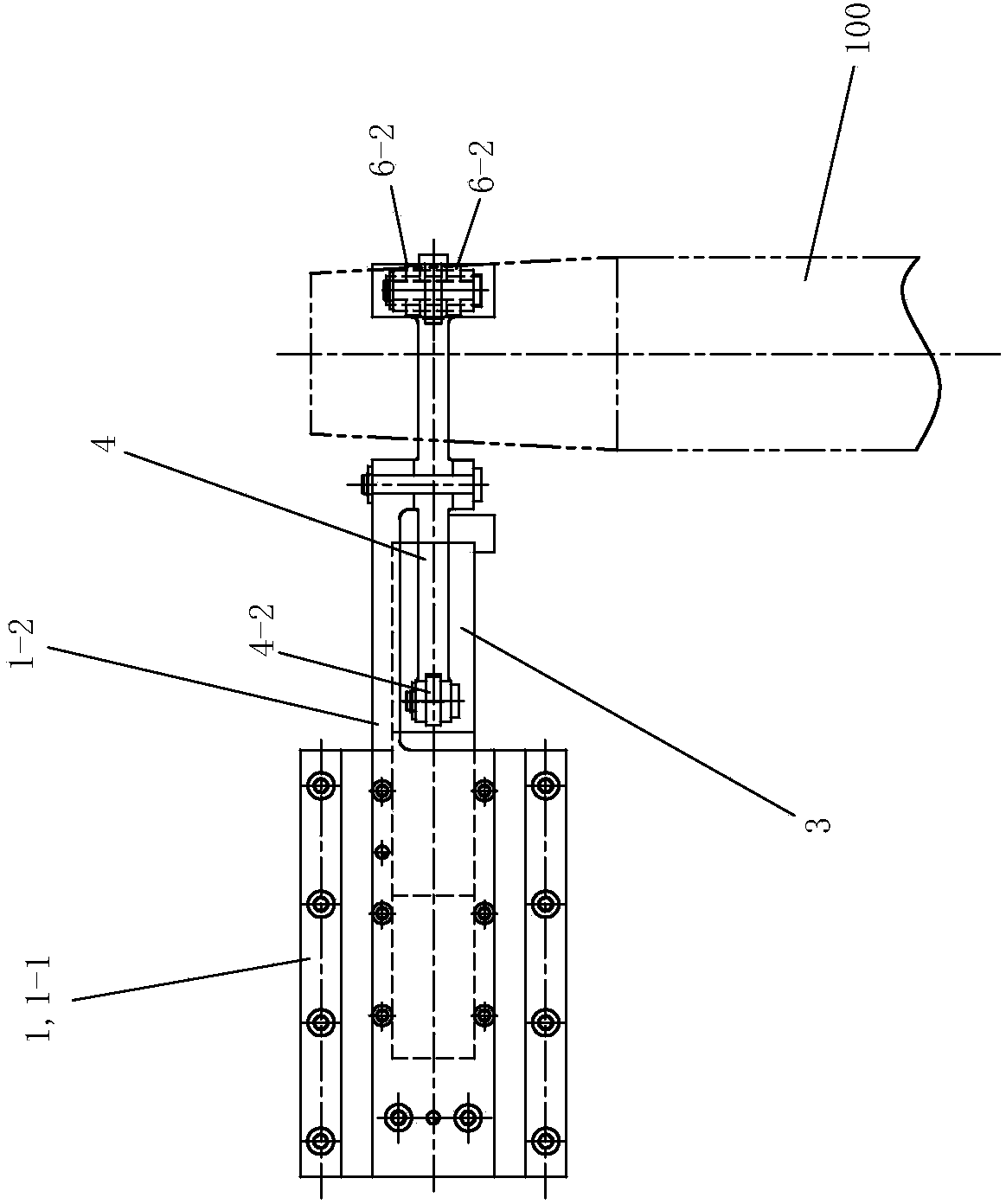

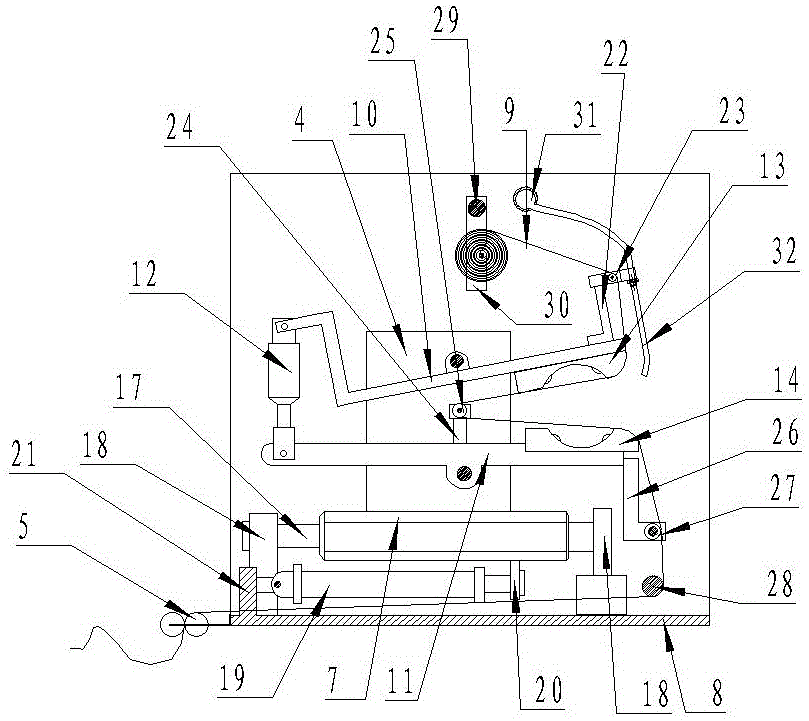

Automatic alignment center rack

InactiveCN108481018ASimple structureEasy to install and disassemble the workpieceLarge fixed membersGrinding work supportsEdge surfaceEngineering

The invention discloses an automatic alignment center rack. The automatic alignment center rack is characterized by comprising a machine box, a driving device, a translation cam, an upper pressing rodcomponent, a lower pressing rod component and pressing head components, the translation cam is arranged inside the machine box in a left and right sliding manner and is driven by the driving device to move left and right, an upper pressing rod on the upper pressing rod component and a lower pressing rod are made to swing by the translation cam to make the pressing head components located on the upper pressing rod and the lower pressing rod and the pressing head component on the translation cam be simultaneously closed to the axis of a workpiece to be machined, so that the workpiece to be machined is supported, wheel support racks of the pressing head components automatically rotate according to the shape of the outer edge surface of the workpiece to be machined, and two support wheels ofeach wheel support rack are guaranteed to be pressed tightly against the workpiece to be machined simultaneously.

Owner:CHANGZHOU COLLEGE OF INFORMATION TECH

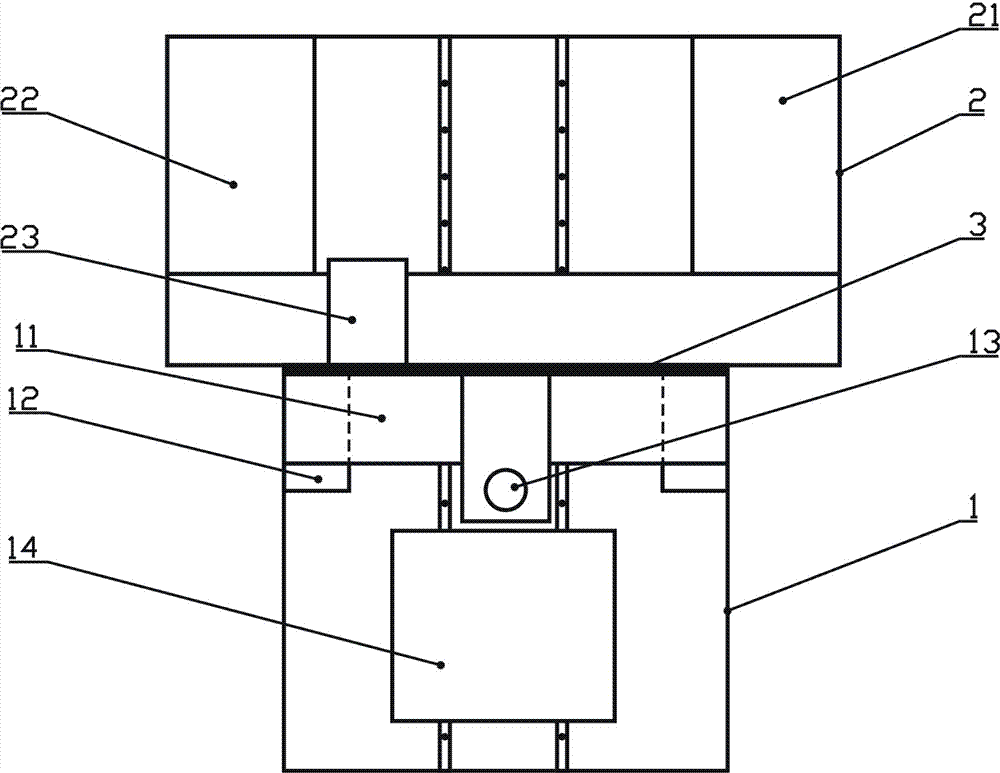

Two-spindle numerically-controlled machine tool with translation interaction worktables

InactiveCN106514303AConvenient for automatic loading and unloadingPrevent splashLarge fixed membersDriving apparatusNumerical controlMachining time

The invention belongs to the technical field of machine tool equipment, and in particular relates to a two-spindle numerically-controlled machine tool with translation interaction worktables. The two-spindle numerically-controlled machine tool with the translation interaction worktables comprises a machine tool body, a cross beam, vertical columns, a first worktable, a second worktable, a first electric spindle and a second electric spindle, wherein the cross beam and the vertical columns form a portal structure which is mounted on the machine tool body; the first worktable and the second worktable which are arranged in parallel are correspondingly slidably mounted on the machine tool body and are correspondingly driven by two Y-axis servo driving devices to be horizontally lengthways fed; the first electric spindle and the second electric spindle are mounted on the cross beam through slide assemblies and can be transversely fed along an X axis and can also be fed along a Z axis in an up-down reciprocating manner. According to the two-spindle numerically-controlled machine tool with the translation interaction worktables, the interaction worktables and the two-spindle structure are adopted to achieve synchronous two-station processing or two-process processing of replacing and processing, so that the influence of charging and discharging on the processing time can be effectively avoided, and as a result, the production efficiency can be improved.

Owner:LANGFANG JINGDIAO MACHINE TOOL MFG +1

Die peeling device with safety push-up pin

ActiveCN102254792AReduce shockEasy to observeSemiconductor/solid-state device manufacturingIntegrated circuitEngineering

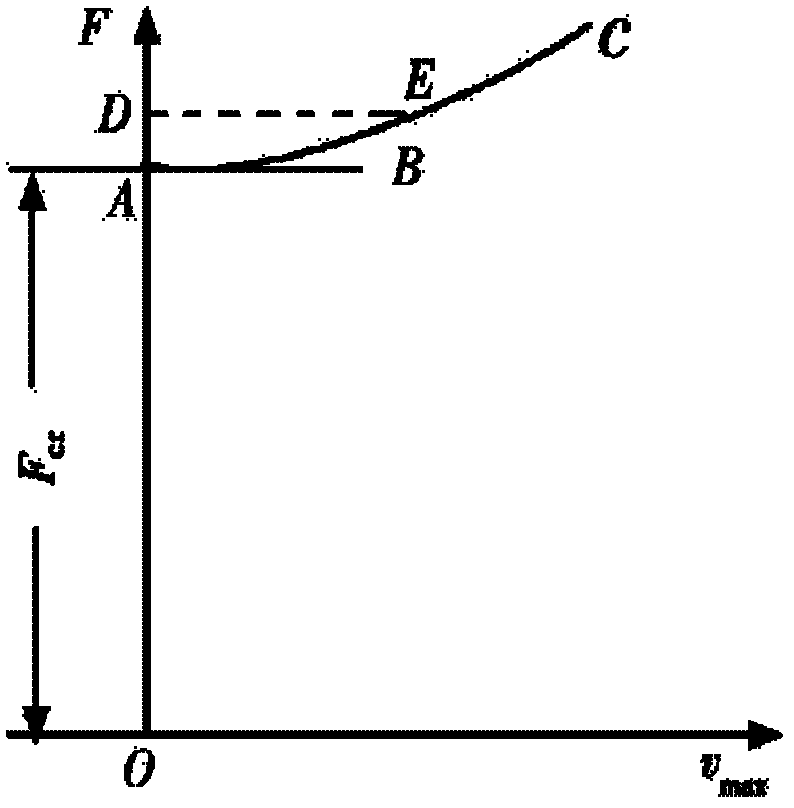

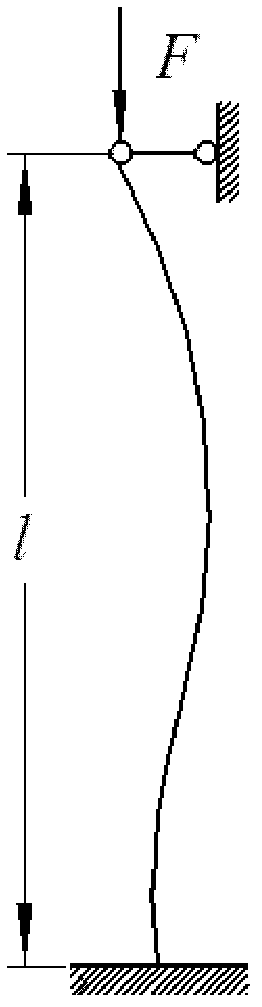

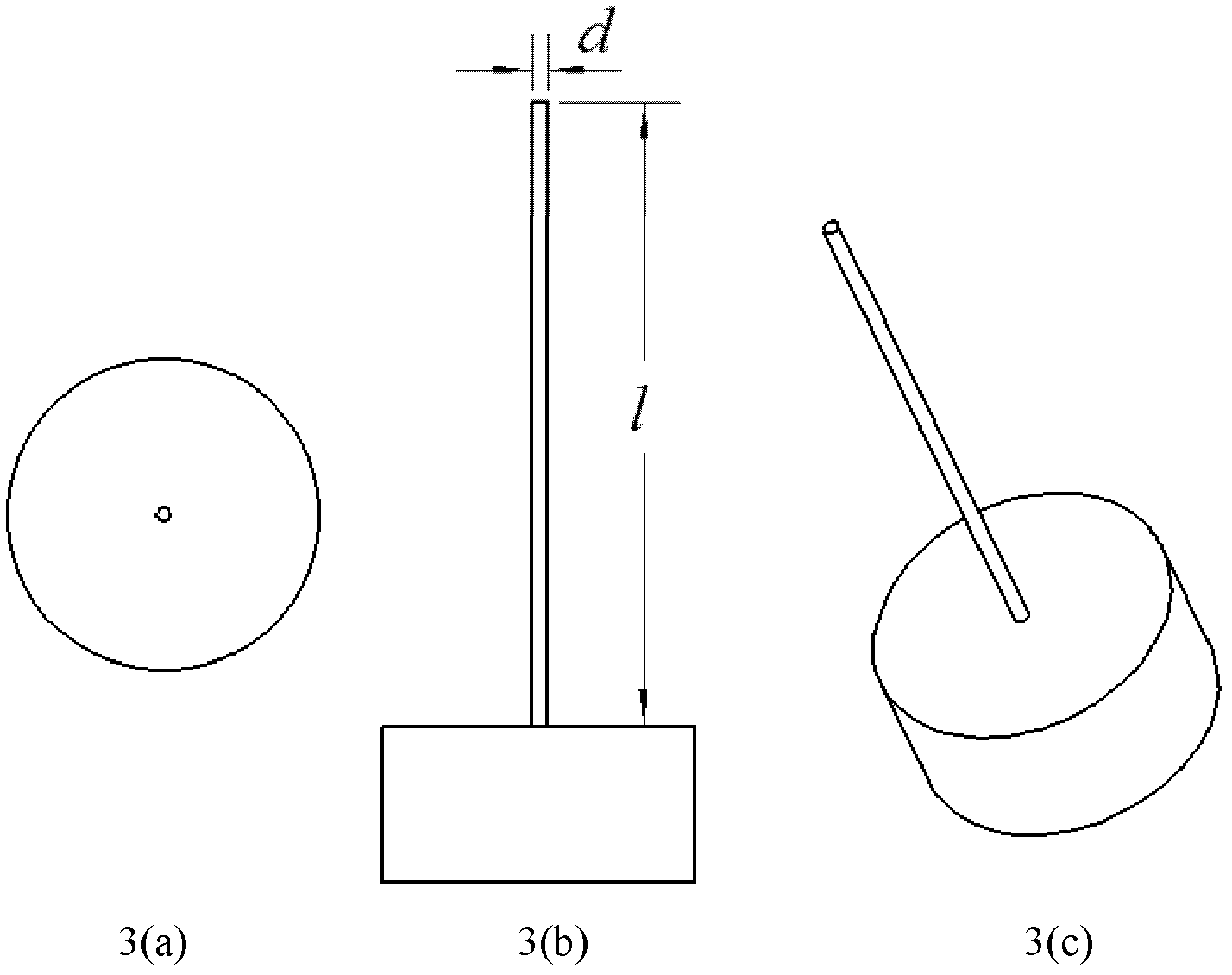

The invention discloses a die peeling device with a safety push-up pin, which can be applied to peeling a die from a bond pad in the FlipChip IC (integrated circuit) package process. The bond pad is arranged on one end surface of a sleeve, and the die to be peeled is bonded on the bond pad. The device comprises a push-up pin which is arranged inside the sleeve and used for being driven by a driving device to push up the die apart from the bond pad; and a regulating mechanism which is arranged inside the sleeve and used for holding the push-up pin and regulating the effective stress length of the push-up pin to control the Euler critical load of the push-up pin. The device is characterized in that the push-up pin is a safety push-up pin which can protect the semiconductor die from being damaged and has a preset bending feature, namely, the push-up pin bends when reaching a preset rated push-up force; and the value of the preset rated push-up force is between a die peeling force and a die damage force. The die peeling device disclosed by the invention is compatible to the conventional die peeling and pickup processes and has the characteristics of safety, high efficiency and high peeling reliability.

Owner:HUAZHONG UNIV OF SCI & TECH

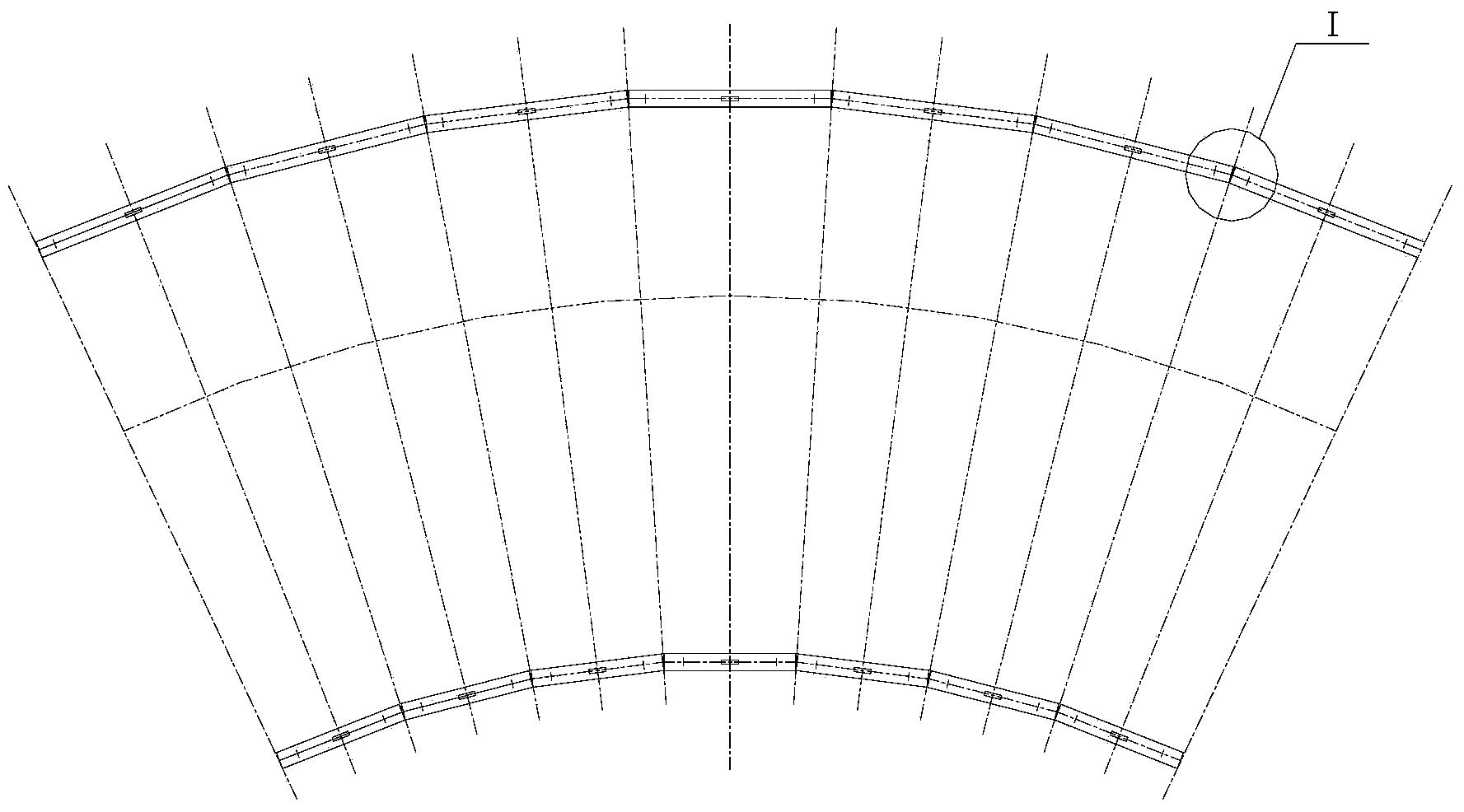

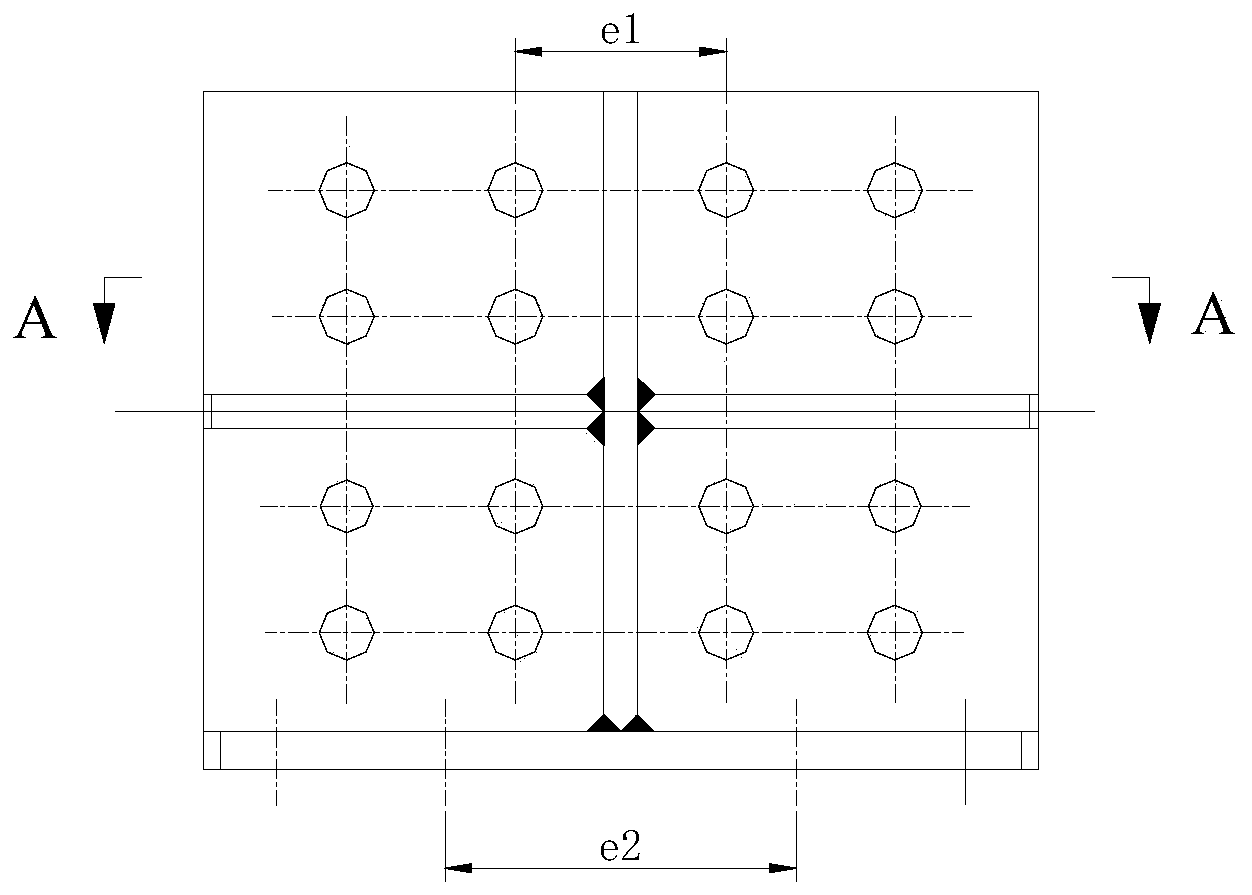

Drilling jig for machining connecting gusset of rotating frame of annular cooler and using method

The invention relates to the technical field of machining of annular coolers, and provides a drilling jig for machining a connecting gusset of a rotating frame of an annular cooler. The drilling jig comprises two hinged drilling jig bodies and a regulation mechanism, wherein a plurality of jig holes corresponding to working holes of the connecting gusset to be machined are formed in each drilling jig body; the same sides of the two drilling jig bodies are used for supporting and pressing the connecting gusset to be machined; the regulation mechanism is arranged between the two hinged drilling jig bodies to regulate a working angle between the two drilling jig bodies. The drilling jig can be adapted to changes in included angles of connecting gussets of annular coolers in different specifications, and is multipurpose and higher in universality, so that the manufacturing cost of a product is greatly lowered; in addition, the drilling jig has higher operability on a machining site, and a working angle of the drilling jig can be ensured to be adapted to and consistent with the included angle of the connecting gusset to be machined, so that accurate and reliable positioning is ensured. Compared with the prior art, the drilling jig has the advantages that the time of auxiliary procedures in a machining process is greatly shortened, and the production operation efficiency is greatly improved.

Owner:HUNAN ZHONGZHI CHANGTIAN HEAVY IND TECH

Device and method for generative component production

ActiveUS9827632B2Reduce auxiliary processing timeEliminate timeAdditive manufacturing apparatusIncreasing energy efficiencyUltimate tensile strengthLaser beams

The present invention relates to a device for laser-based generative component production. The device comprises a processing head (1), using which a plurality of mutually separate laser beams are directed adjacently and / or overlapping to some extent onto the processing plane, The processing head (1) is moved across the processing plane using a movement apparatus (9), while the mutually separate laser beams are modulated independently of one another in terms of intensity, in order to obtain the desired exposure geometry. The laser power and the dimensional size can be scaled cost effectively during the generative production using the suggested device and the associated method.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

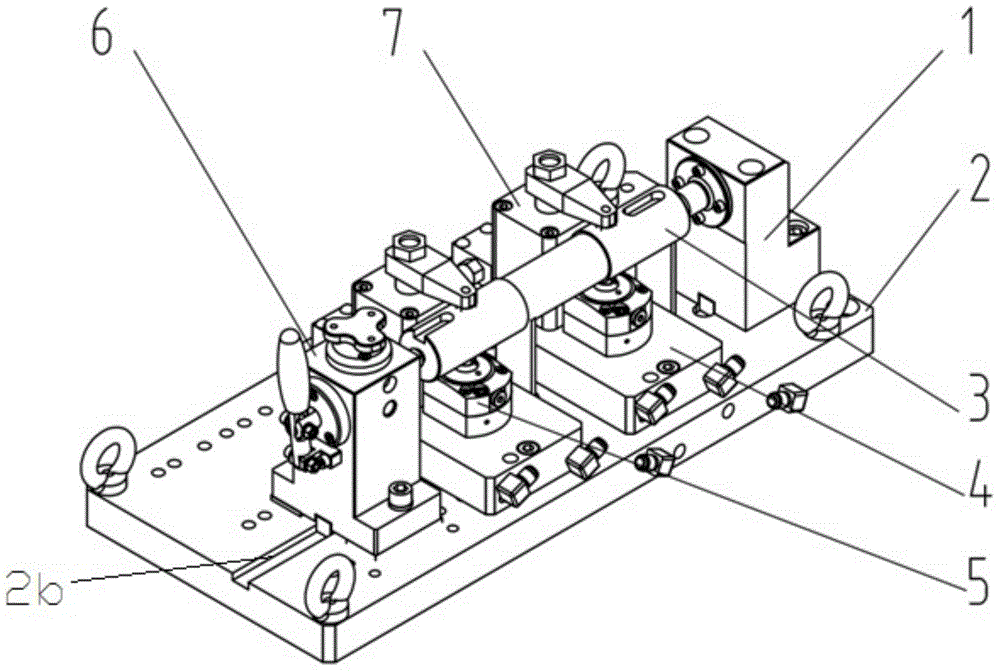

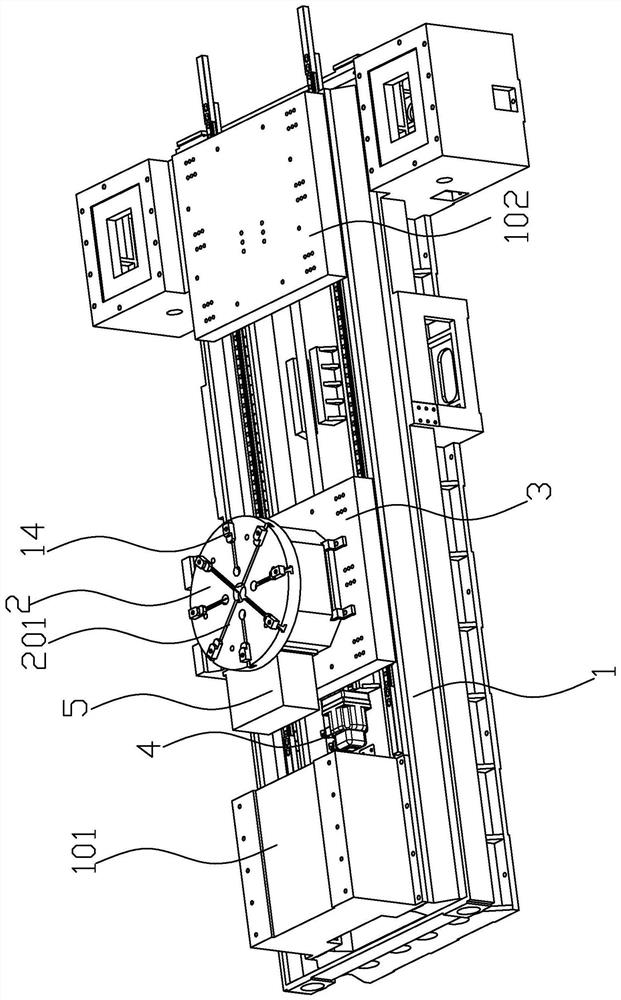

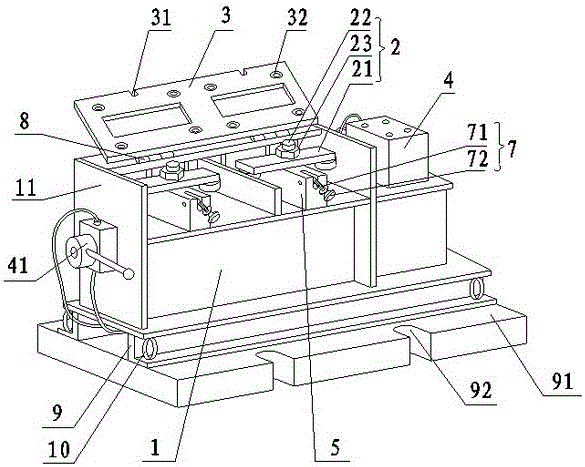

Industrial robot transmission shaft key groove machining fixture

InactiveCN104942615AReduce auxiliary processing timeQuick clampingWork clamping meansPositioning apparatusDrive shaftMachining time

The invention discloses an industrial robot transmission shaft key groove machining fixture. The industrial robot transmission shaft key groove machining fixture comprises a fixture base plate, the upper right end of the fixture base plate is provided with a fixed tailstock, the middle portion of the upper end of the fixture base plate is provided with two oil cylinder base plates, the upper ends of the oil cylinder base plates are provided with top-tight cylinders, the rear portions of the upper ends of the oil cylinder base plates are provided with compressing cylinders, the left portion of the upper end of the fixture base plate is provided with a top-tight tailstock, four corners of the fixture base plate are provided with hanging rings, and the right sides of the oil cylinder base plates are provided with V-shaped supports. The industrial robot transmission shaft key groove machining fixture has the advantages that the structural design is reasonable, the production and manufacture cost are low, and the clamping and positioning accuracy are high; quick clamping of a transmission shaft of an industrial robot can be achieved, the auxiliary machining time of clamping is shortened, the production efficiency is improved, and the machining cost is lowered.

Owner:EFORT INTELLIGENT EQUIP CO LTD

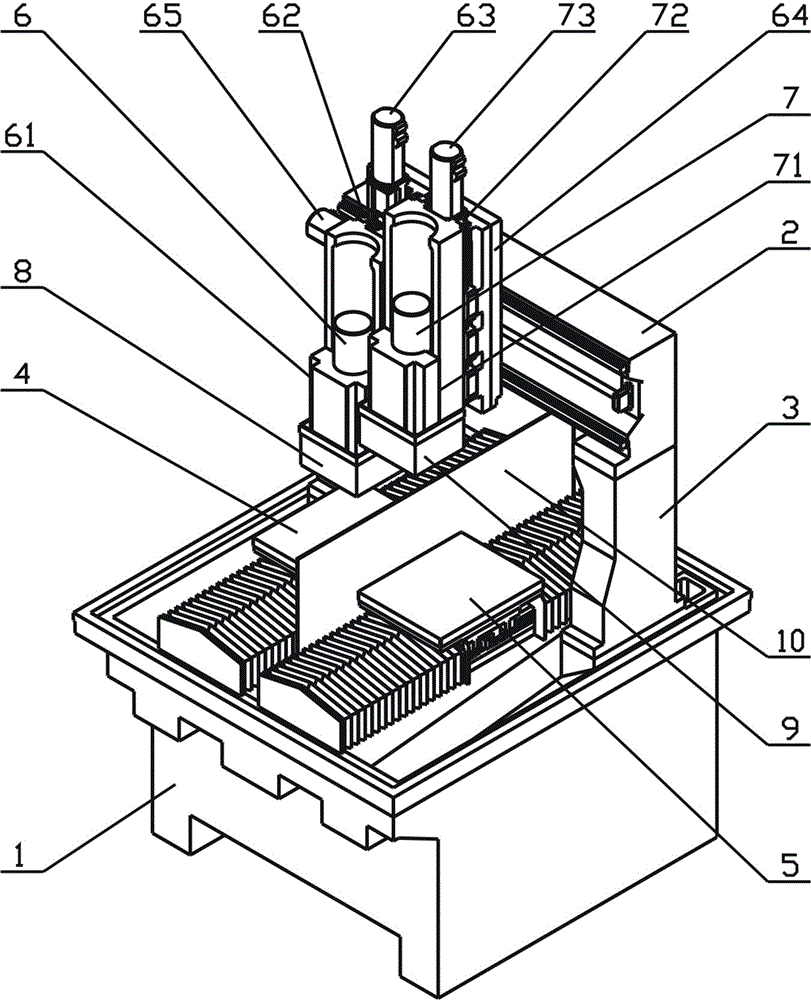

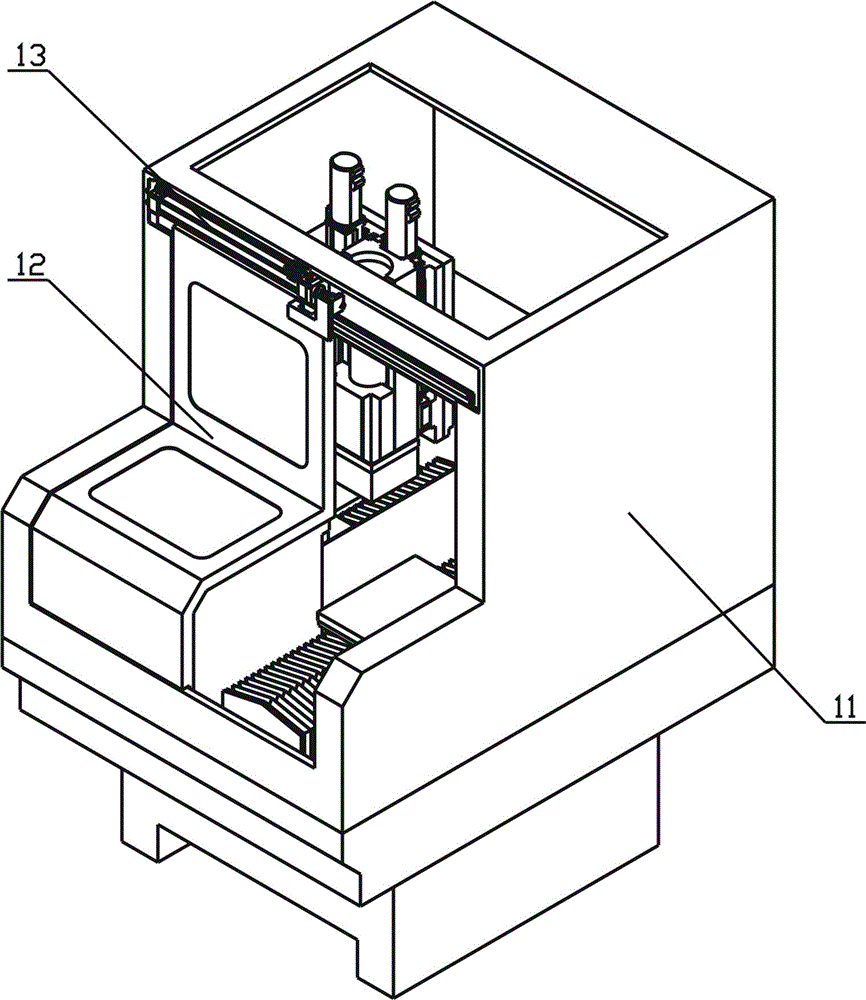

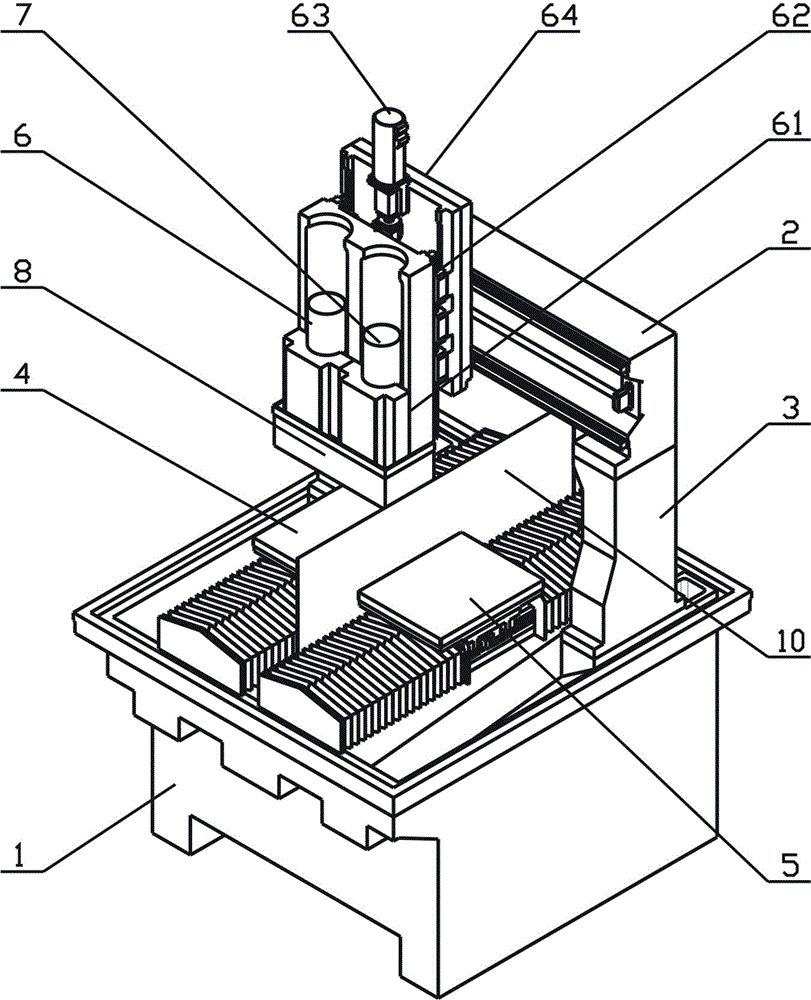

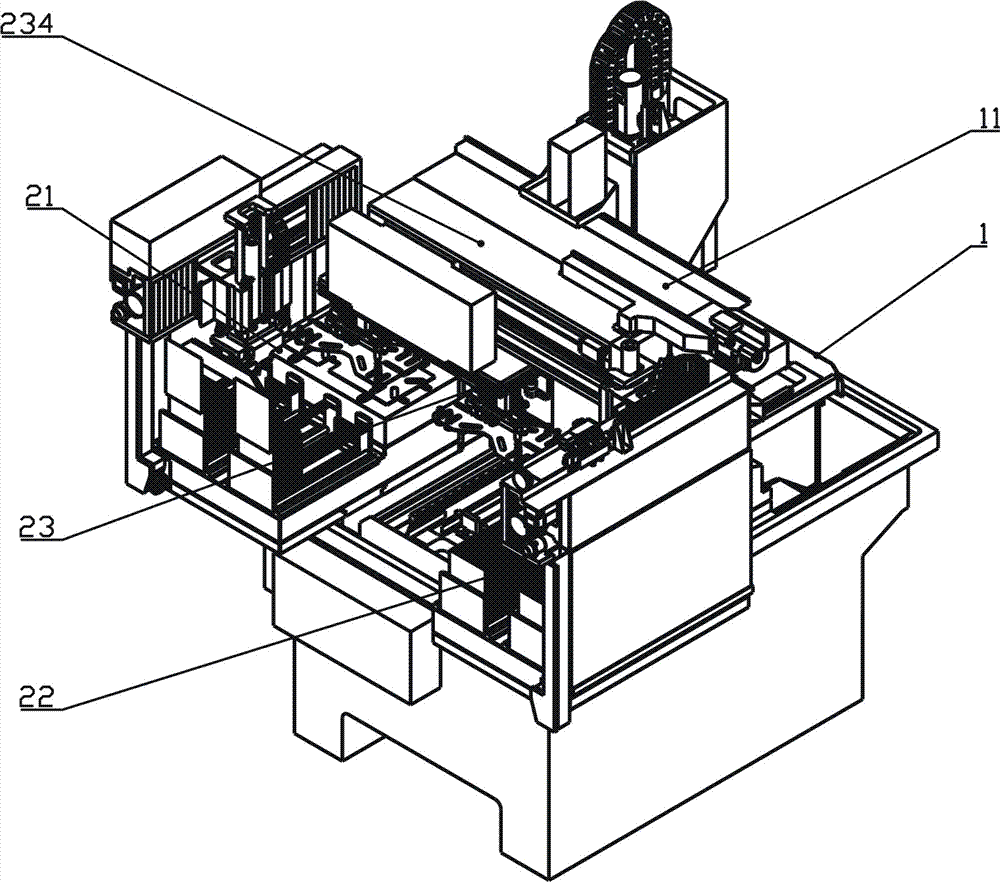

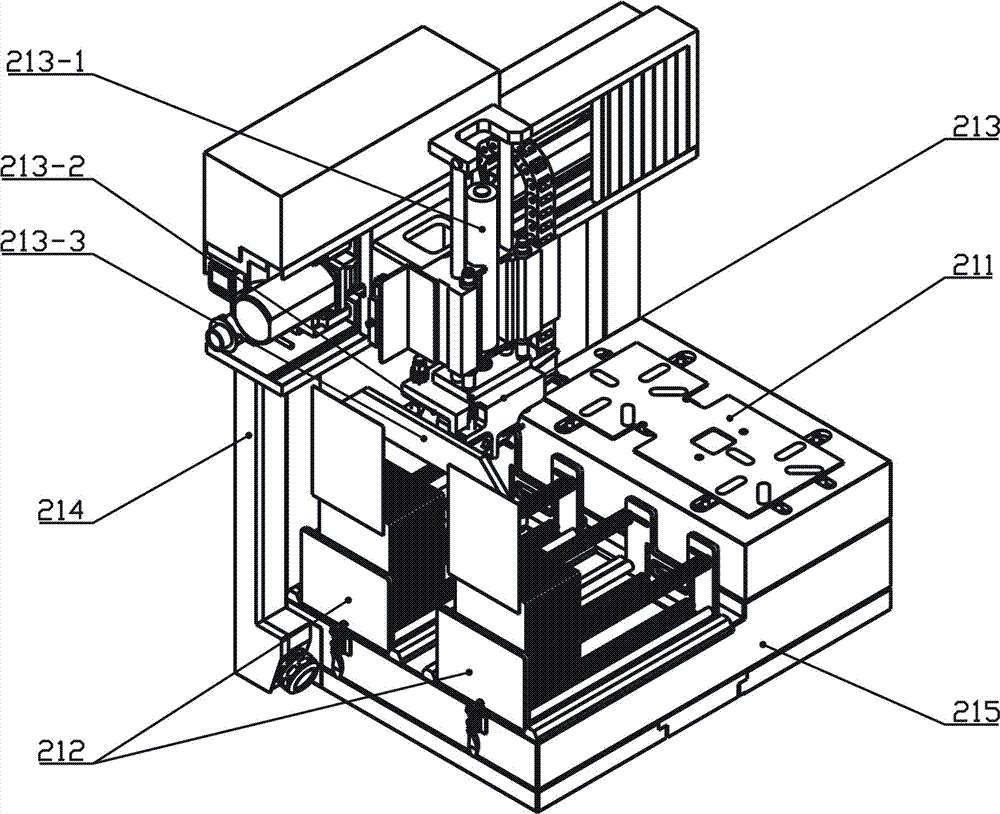

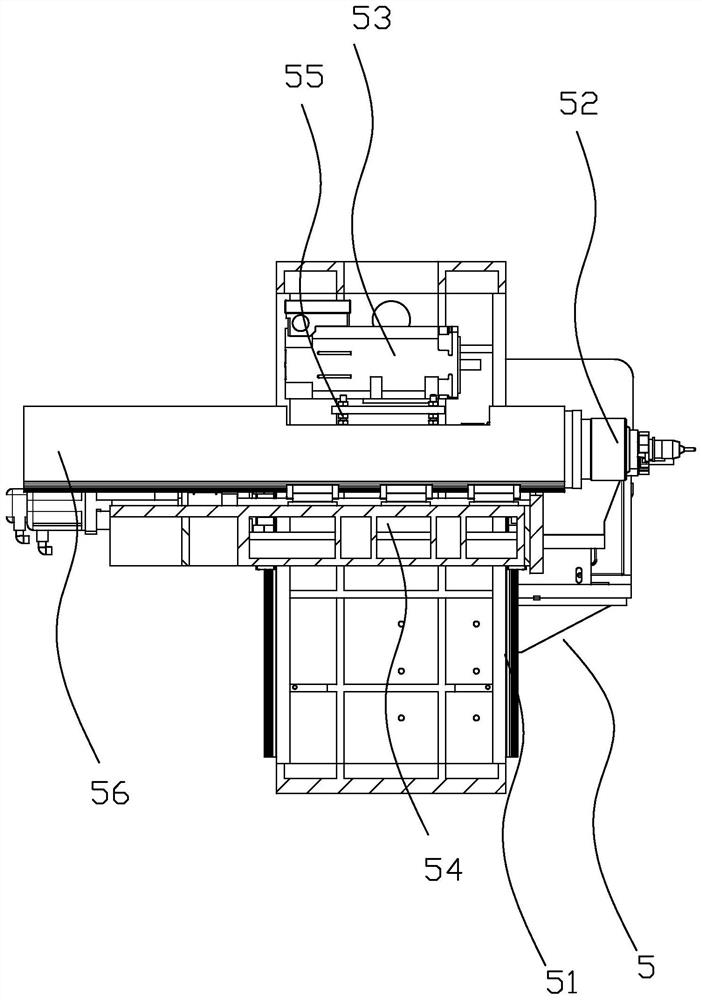

Machine tool with rear off-machine positioning and automatic loading-unloading functions

PendingCN107127627ASimple and spacious spaceAvoid damageMetal working apparatusMaterials preparationMachine parts

The invention belongs to the technical field of numerical-control automatic machining, and particularly relates to machine tool with rear off-machine positioning and automatic loading-unloading functions. The machine tool comprises a machine tool machining part and an automatic loading-unloading part, wherein both the machine tool machining part and the automatic loading-unloading part are mounted on a machine tool body; the automatic loading-unloading part is positioned at the rear of the machine tool machining part, and is isolated and protected through an automatic door; the machining tool machining part comprises a cross beam, a vertical column, an electric spindle and a workbench; the workbench can move between the machine tool machining part and the automatic loading-unloading part; the automatic loading-unloading part comprises a loading zone, an unloading zone and a handling manipulator; the loading zone and the unloading zone are mounted in a left-right symmetric manner; the loading zone comprises a loading positioning table; the unloading zone comprises an unloading transfer table; and the handling manipulator is arranged between the loading zone and the unloading zone, and can move between the loading positioning table and the unloading transfer table. The machine tool provided by the invention is simple in structure; the loading-unloading operation, the material preparation operation and the positioning operation are all performed in an off-machine manner; the automatic loading-unloading part and the machine tool machining part, namely a machining zone, are prevented from influencing each other; the auxiliary machining time is effectively shortened; and the production efficiency is improved.

Owner:BEIJING JINGDIAO GRP CO LTD

Automatic feeding and discharging device of structural steel wheel stamping equipment

InactiveCN109290470ARealize streamlined operationReduce manual handling timeMetal-working feeding devicesPositioning devicesEngineeringMechanical engineering

The invention discloses an automatic feeding and discharging device of structural steel wheel stamping equipment. The automatic feeding and discharging device of the structural steel wheel stamping equipment comprises a workbench. A feeding mechanism is mounted at the left end of the workbench. A discharging mechanism is mounted at the right end of the workbench. A stamping body is mounted betweenthe feeding mechanism and the discharging mechanism. The feeding mechanism comprises a feeding conveying belt and a feeding electromagnetic chuck. A feeding synchronous wheel is connected into the feeding conveying belt in a sleeved mode. A feeding servo motor is connected to an axle of the feeding synchronous wheel. The feeding electromagnetic chuck is mounted at the tail end of the feeding conveying belt through a fixing support. The discharging mechanism comprises a discharging conveying belt. A discharging synchronous wheel is connected into the discharging conveying belt in a sleeved mode. A discharging servo motor is connected to an axle of the discharging synchronous belt. A discharging electromagnetic chuck is mounted at the head end of the discharging conveying belt. By adoptionof the automatic feeding and discharging device of the structural steel wheel stamping equipment, the labor productivity and product quality are improved, the auxiliary machining time is shortened, and the product cost is reduced.

Owner:赵斌

Center frame

InactiveCN108500652ASimple structureEasy to install and disassemble the workpieceLarge fixed membersGrinding work supportsEngineeringCam

The invention discloses an automatic-centering center frame. The automatic-centering center frame is characterized by comprising a machine box, a driving device, a translation cam, an upper pressing rod assembly, a lower pressing rod assembly and pressing head assemblies. The translation cam is arranged in the machine box in a left-right sliding mode and driven by the driving device to move left and right. An upper pressing rod of the upper pressing rod assembly and a lower pressing rod are made to swing through the translation cam, so that the pressing head assemblies located on the upper pressing rod and the lower pressing rod and the pressing head assembly on the translation cam are gathered towards the axis of a workpiece to be machined at the same time, the workpiece to be machined issupported, a supporting wheel frame of each pressing head assembly can be automatically rotated according to the shape of the outer edge face of the workpiece to be machined, and it is ensured that two supporting wheels located on each supporting wheel frame are pressed on the workpiece to be machined at the same time.

Owner:CHANGZHOU COLLEGE OF INFORMATION TECH

Special abrasive band polishing machine for crankshaft journals

InactiveCN106112751AIncrease productivityImprove work efficiencyBelt grinding machinesGrinding work supportsAutomatic controlMachine tool

The invention relates to a special abrasive band polishing machine for crankshaft journals. The number of clamping mechanisms corresponds to the number of the crankshaft journals; a plurality of grooves used for assembling the clamping mechanisms are formed in a fixed rack; the number of the grooves is equal to the number of the clamping mechanisms; the fixed rack is fixed on a guide sleeve of a guiding mechanism; the guiding mechanism is connected with a machine tool; a hydraulic driving mechanism is connected with the machine tool; the hydraulic driving mechanism is connected with the guiding mechanism and is used for pushing the guiding mechanism to slide front and back; the clamping mechanism are rotatably arranged in the grooves of the fixed rack; an abrasive band in an abrasive band component passes by a reversing mechanism, passes by parts for clamping crankshafts on the clamping mechanisms and then is clamped by reels; a cooling mechanism is fixed above the clamping mechanisms; and after the crankshafts are arranged on the machine tool and are fixed through a rotary clamping part of the machine tool and an ejection connection part of the machine tool, the clamping mechanisms clamp the journals of the crankshafts through control of an automatic control part. The special abrasive band polishing machine is reasonable in structure, simple for manufacture and convenient for operation, and is applicable to crankshaft journal polishing devices of similar crankshafts.

Owner:侯马市威创动力机械有限公司

Numerical control vertical and horizontal compound machine

PendingCN112589539AThe overall space occupied is smallReduce auxiliary processing timeMetal working apparatusNumerical controlVertical plane

The invention relates to a numerical control machine tool, and provides a numerical control vertical and horizontal compound machine. The numerical control vertical and horizontal compound machine comprises a machine frame, a work table, a fixing seat, a cross slide table, a first driving unit, a horizontal main shaft box, a vertical main shaft box, a horizontal tool magazine and a vertical tool magazine, wherein the the horizontal main shaft box comprises a stand column, a power head, a main shaft motor, a sliding table, a supporting base, a transverse rod, a second driving unit and a third driving unit, the stand column is an n-shaped stand column provided with a hollow groove, the sliding table is arranged on the hollow groove of the stand column in an up-down sliding mode through the second driving unit, the transverse rod is arranged on the upper surface of the sliding table in a horizontal sliding mode through the third driving unit, the upper surface of the transverse rod perpendicularly intersects with the vertical plane of the hollow groove of the stand column, the main shaft motor is arranged on the supporting base, and an output shaft of the main shaft motor is connectedwith and drives a main shaft of the power head to rotate to machine a to-be-machined workpiece on the work table. The numerical control vertical and horizontal compound machine solves the problems that an existing vertical and horizontal combined machining center is large in occupied space and high in manufacturing cost.

Owner:泉州市创佳自动化设备有限公司

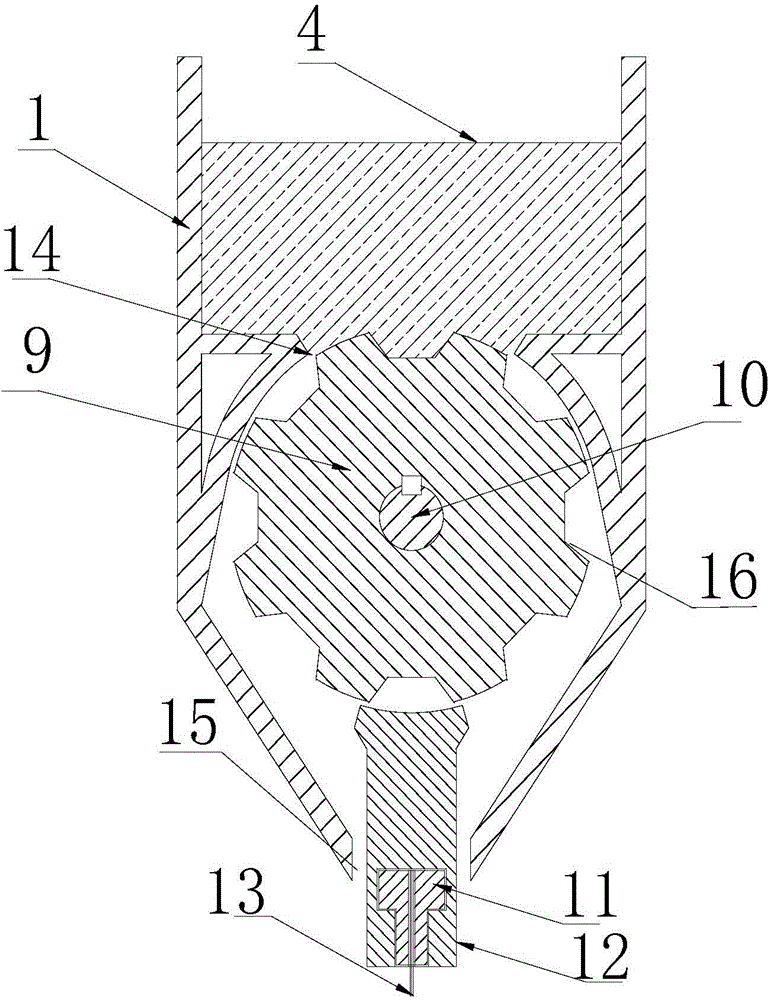

A powder spreading device and powder spreading method for laser selective melting SLM equipment

ActiveCN103691947BReduce wasteRealize quantitative powder supplyIncreasing energy efficiencySelective laser meltingDusting powders

The invention discloses a powder spreading device and a powder spreading method for selective laser melting (SLM) equipment. The device comprises a powder spreading main body, an auxiliary guide rail linear motor and an auxiliary powder spreading guide motor, wherein the auxiliary guide rail linear motor is used for driving the powder spreading main body to slide on an auxiliary powder spreading guide rail; the inside of the powder spreading main body is partitioned into three segments, namely, a cylindrical segment, a circular arc segment and a conical segment from top to bottom respectively; the cylindrical segment is a powder carrying area; a powder feeding hole is formed between the cylindrical segment and the circular arc segment; the circular arc segment is provided with a powder supply roller; a plurality of dovetail grooves are uniformly formed on the powder supply roller; the excircle of the powder supply roller is tangential to a circular arc on the upper part of the circular arc segment; the powder supply roller is driven to rotate by a servo driving motor; the conical segment is provided with a powder scraping device; the bottom of the conical segment is provided with a powder outlet; the upper end of the powder scraping device is tangential to the excircle of the powder supply roller, and the lower end of the powder scraping device extends out of the powder outlet; gaps are reserved between the lower end of the powder scraping device and the two ends of the powder outlet; the powder scraping device comprises a flexible powder scraping brush. By adopting the powder spreading device and the powder spreading method, quantitative powder supply can be realized, waste of powder is reduced, bidirectional powder spreading can be performed, the SLM molding auxiliary process time is shortened, and the SLM molding efficiency is increased.

Owner:SOUTH CHINA UNIV OF TECH

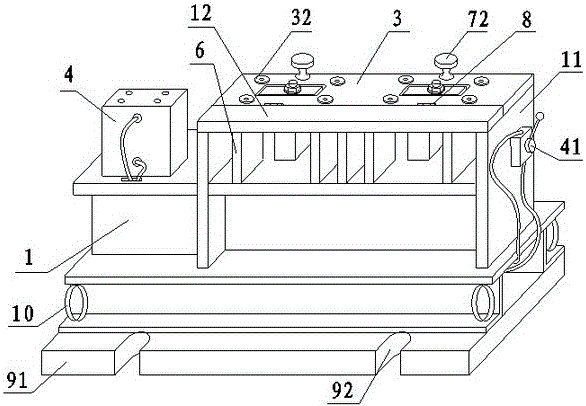

Box body drilling and tapping six-station equipment

InactiveCN108526893AReduce labor intensityReduce turnaround timeOther manufacturing equipments/toolsLarge fixed membersHigh volume manufacturingMachining time

The invention discloses box body drilling and tapping six-station equipment and relates to the technical field of mechanical cold machining equipment. The box body drilling and tapping six-station equipment comprises a control box, a rotary workbench, a rack, drilling devices and a tapping device. A rotary motor is arranged below the rotary workbench, and a plurality of sets of positioning fixturebodies are arranged on the rotary workbench. The drilling devices and the tapping device are arranged on the rack, the rotary motor, the drilling devices and the tapping device are all connected withthe control box, and the rack is round and is arranged on the periphery of the rotary workbench. Workpieces are installed on the positioning fixture bodies, the rotary workbench, the drilling devicesand the tapping device are started through the control box, through rotation of the rotary workbench, the workpieces can pass through the drilling devices and the tapping device on the rack in sequence, machining of a box body inclined hole can be realized through one-time clamping, the aided machining time is greatly reduced, and labor intensity of the operation staff is greatly lowered. The boxbody drilling and tapping six-station equipment has the advantages of being compact in structure, convenient to operate and high in production efficiency, the automation degree is improved, the logistics turnaround time for workpiece machining is reduced, and the box drilling and tapping six-station equipment is particularly suitable for large-batch production.

Owner:孙丽君

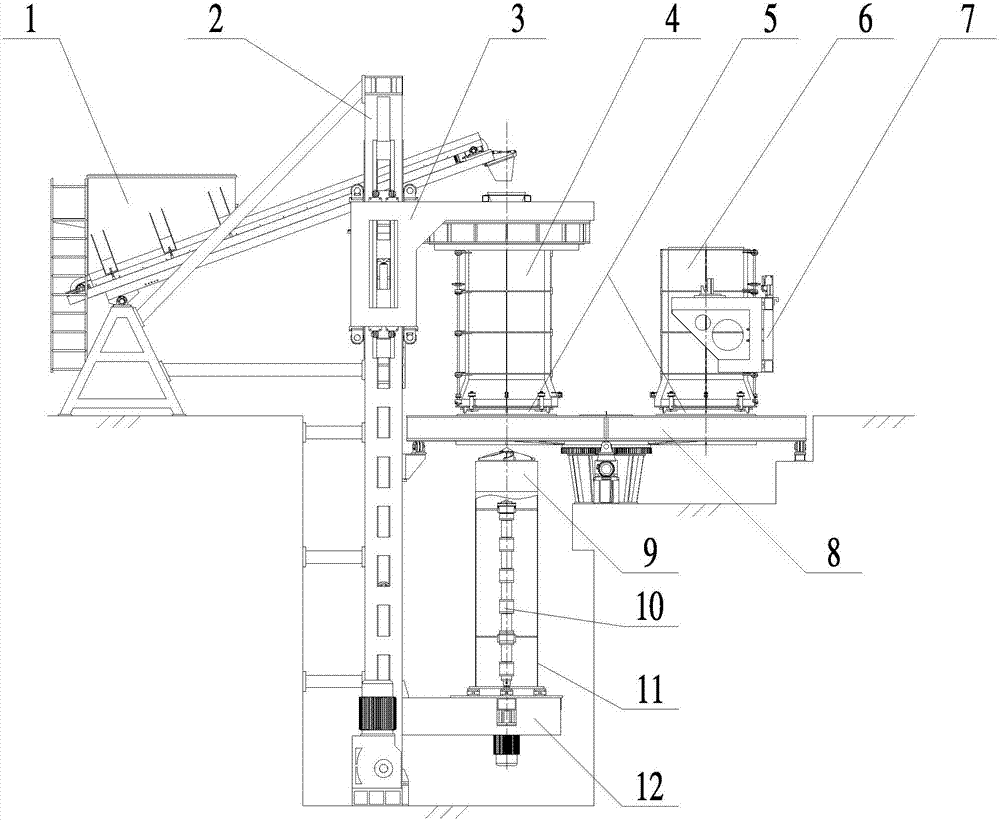

Overhang roll overturning vertical demolding pipe manufacturing equipment

ActiveCN112917668AReduce in quantityAchieve mass productionFeeding arrangmentsStructural engineeringMachine

The invention relates to overhang roll overturning vertical demolding pipe manufacturing equipment in the field of cement machinery. A pit is further arranged on the ground where the equipment is mounted in a cooperation manner and is used for mounting of a lifting platform, and an equipment body sequentially comprises a feeding machine, an overhang roll machine used in cooperation with the feeding machine and the lifting platform arranged in cooperation with the overhang roll machine and mounted in the pit. A positioning shifting fork is arranged at an outlet of the overhang roll machine in a cooperation manner, a ground guide rail is mounted on the ground at the rear end of the positioning shifting fork, a conveying trolley is correspondingly arranged on the ground guide rail, and lifting overturning machines are mounted on the two sides of the ground guide rail in a cooperation manner. The equipment body is further provided with overhang roll molds in a cooperation manner, and each overhang roll mold is correspondingly provided with a bottom tray. According to the equipment, the number of the overhang roll molds can be reduced, the auxiliary process time in the production process can be reduced, so that the production process becomes smooth, meanwhile, a vertical demolding process is adopted, immediate demolding is achieved after production of products is completed, the products can be naturally cured, the molds can be recycled, the production efficiency is improved, batch production of concrete pipelines is realized, and meanwhile the product quality is improved.

Owner:江苏江桥机械制造有限公司

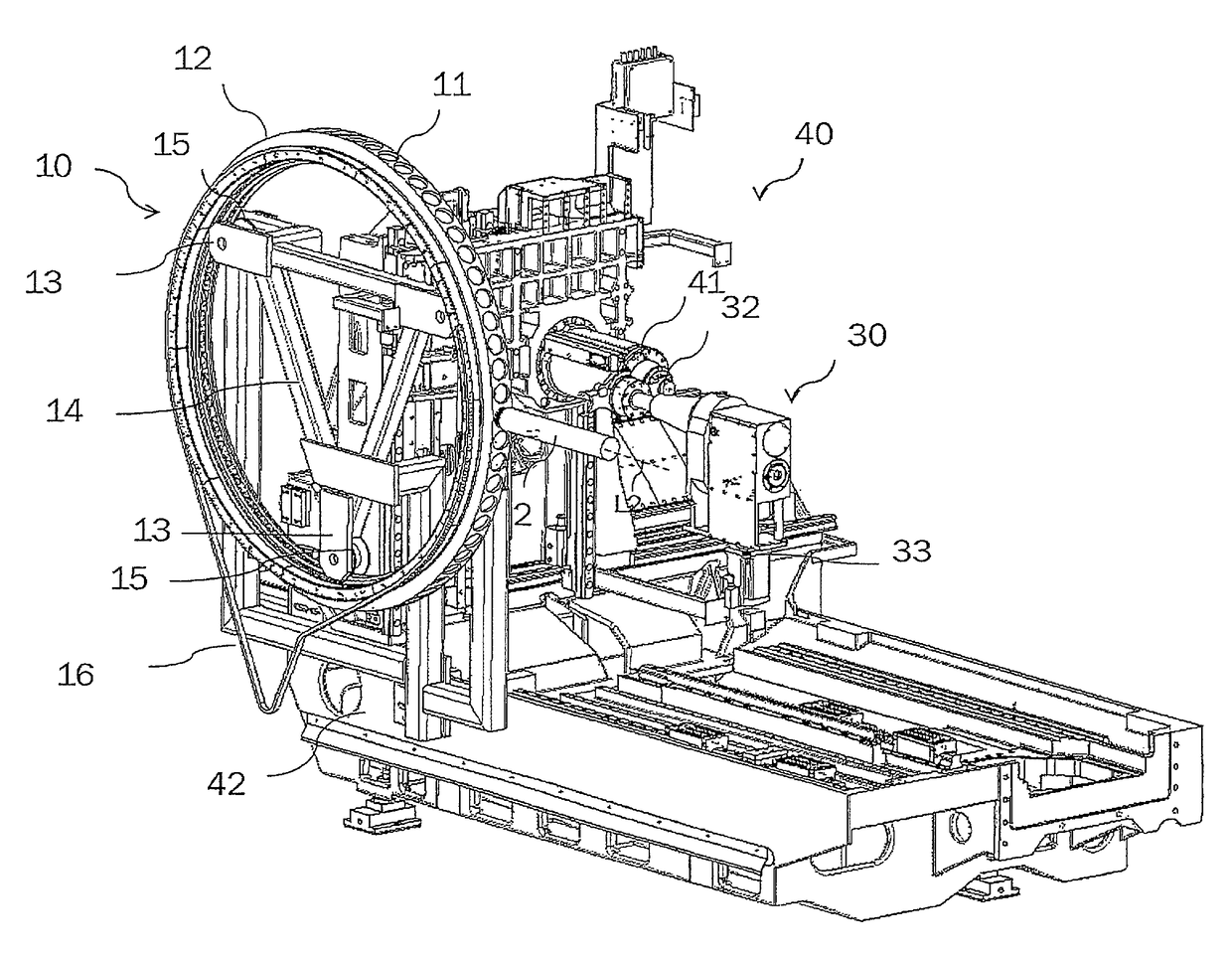

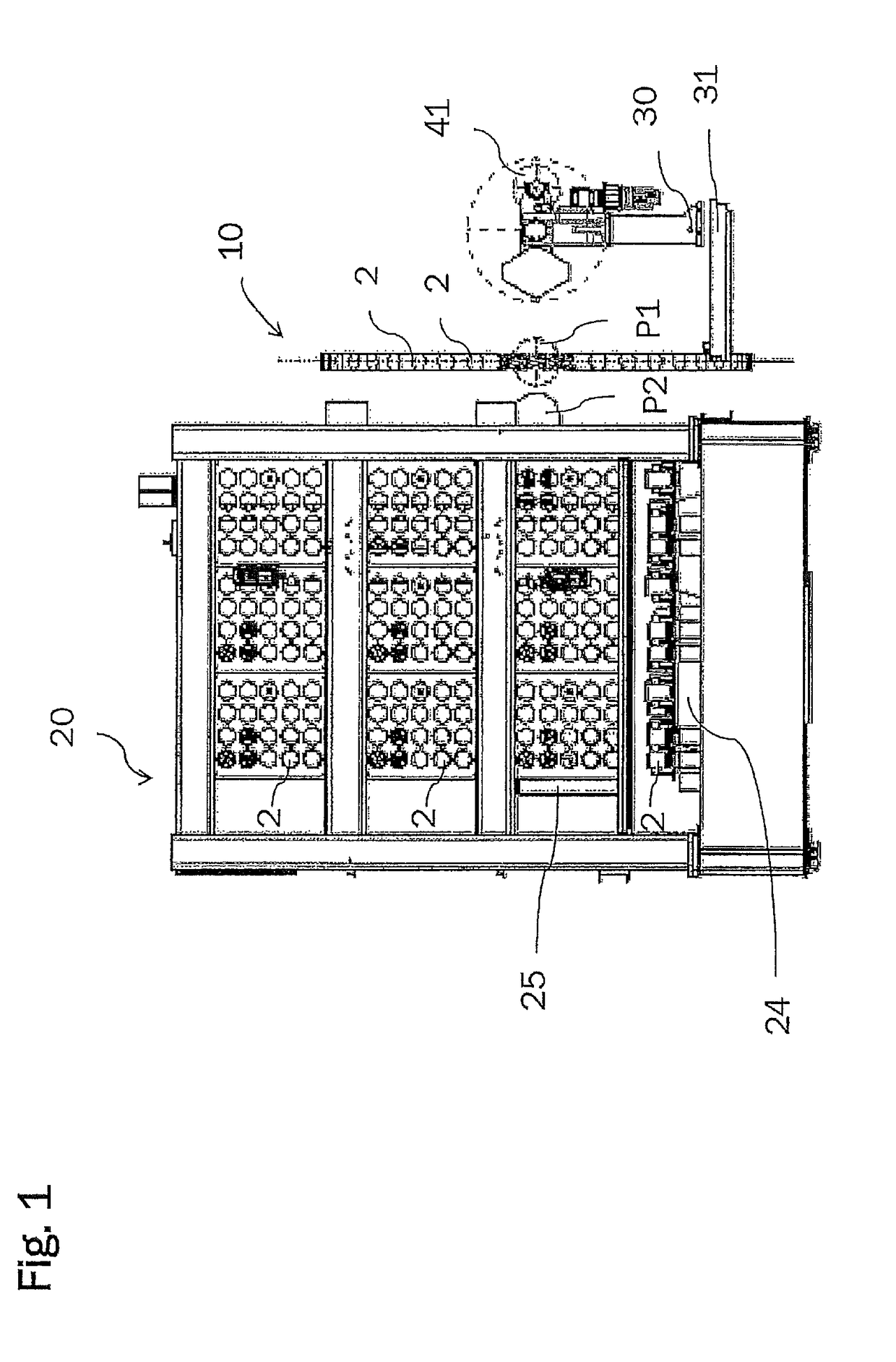

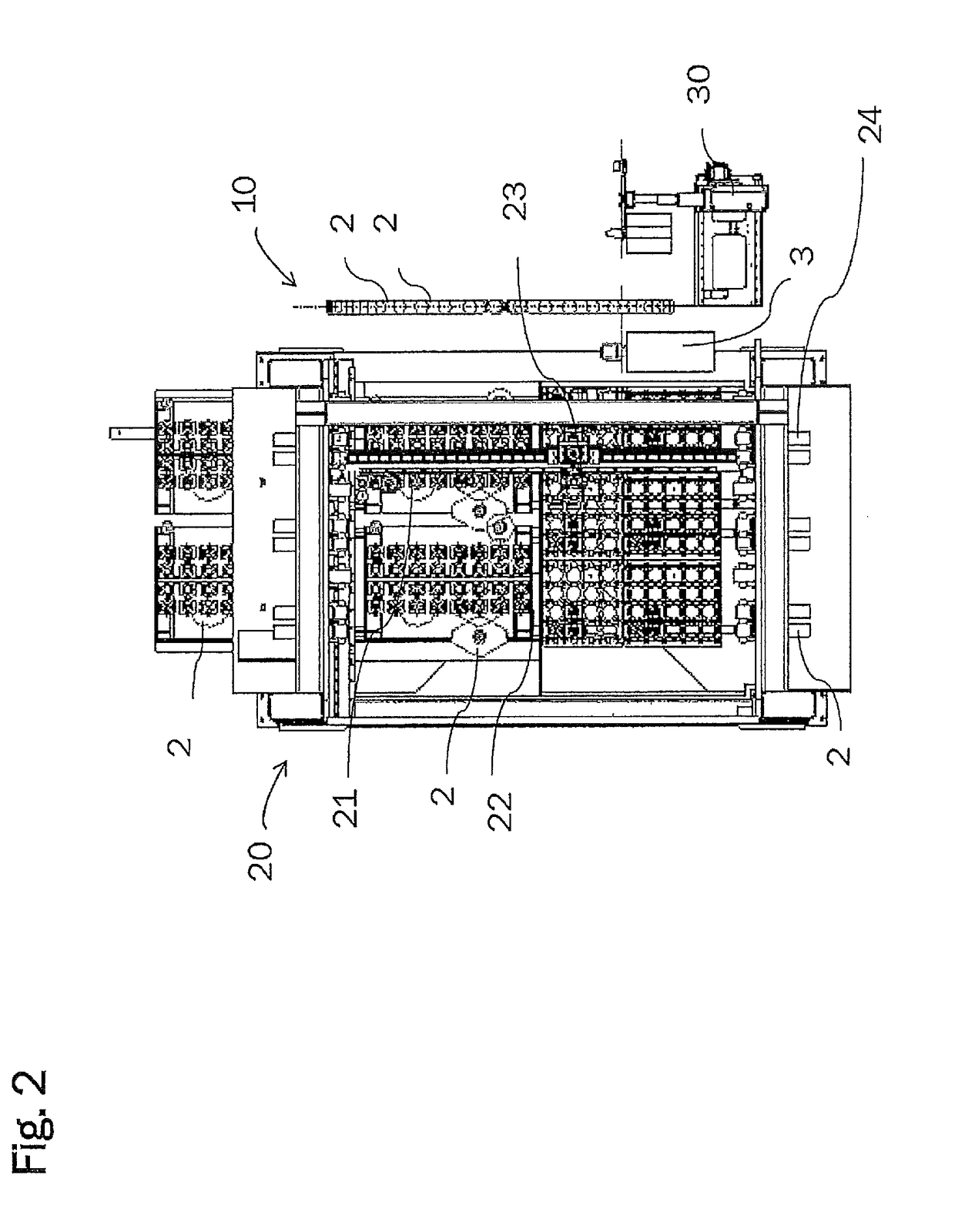

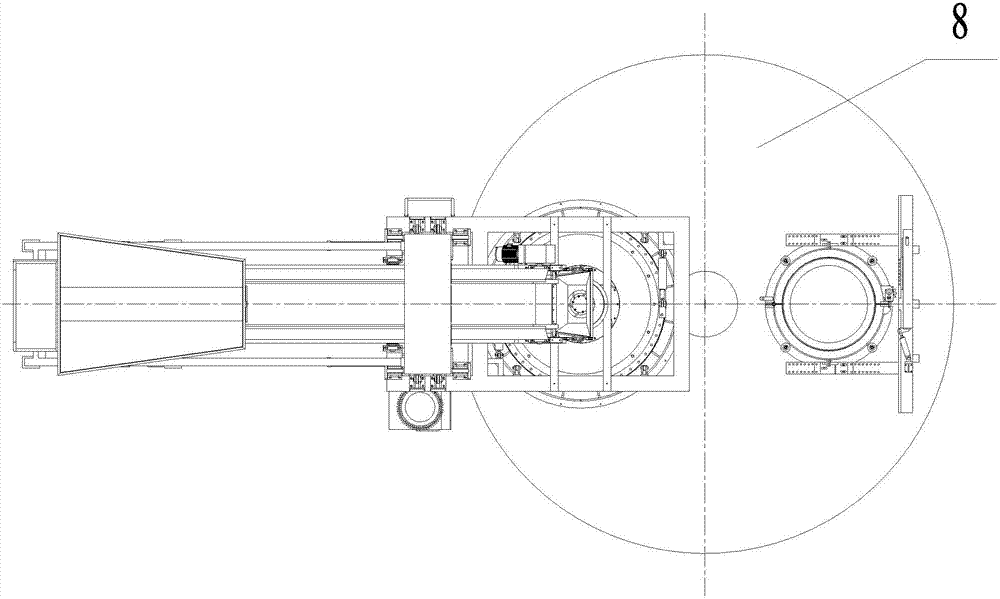

System and method for providing tools on a machine tool and machine tool having a tool change system

InactiveUS10099330B2Reduce auxiliary processing timeConducive to loadTool changing apparatusPositioning apparatusProcess engineeringComputer science

The present invention relates to a system, an apparatus and a method for providing tools on a machine tool. The system includes a first tool magazine for accommodating a plurality of tools; a first feeding device which is adapted to remove tools from the first tool magazine and feed them to the spindle; at least one second tool magazine for accommodating a plurality of tools; a second feeding device which is adapted to remove tools from the second tool magazine and provide them at a predetermined transfer position; and a transfer apparatus which is adapted to feed tools removed from the second tool magazine to the first tool magazine, with the result that the second tool magazine serves as a supply magazine for the first tool magazine.

Owner:DECKEL MAHO PFRONTEN GMBH

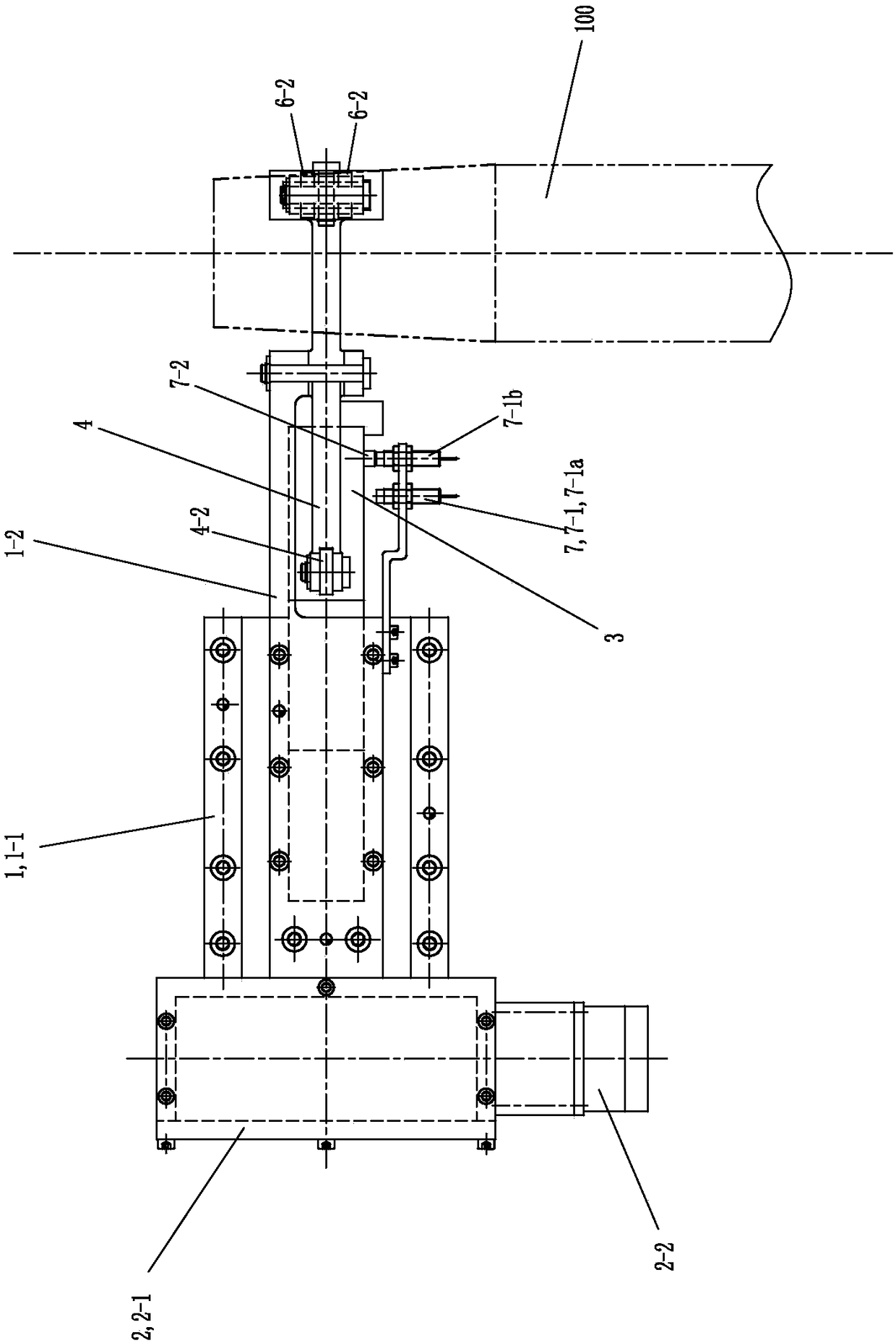

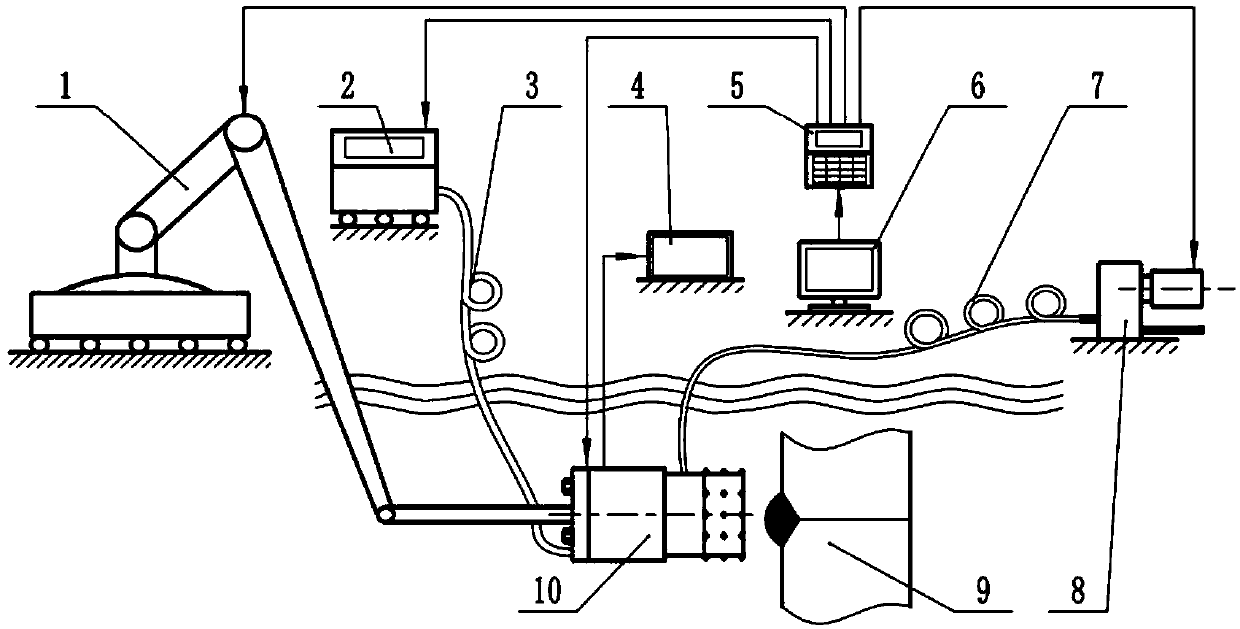

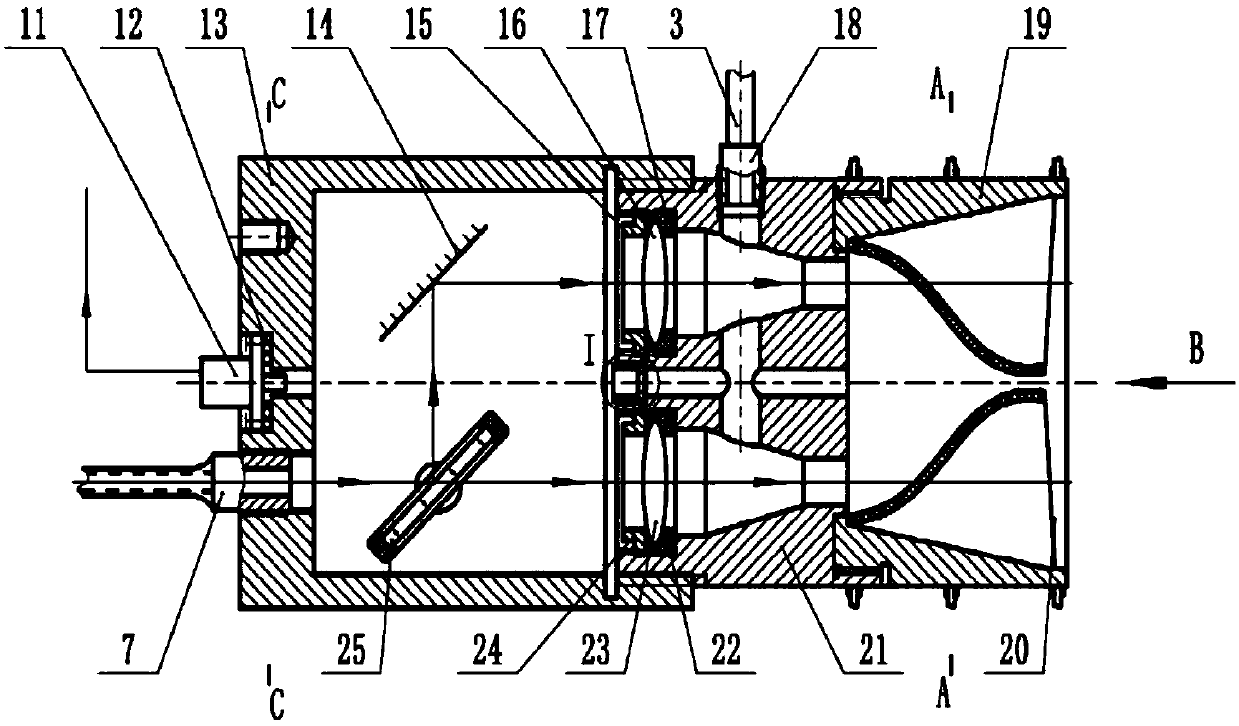

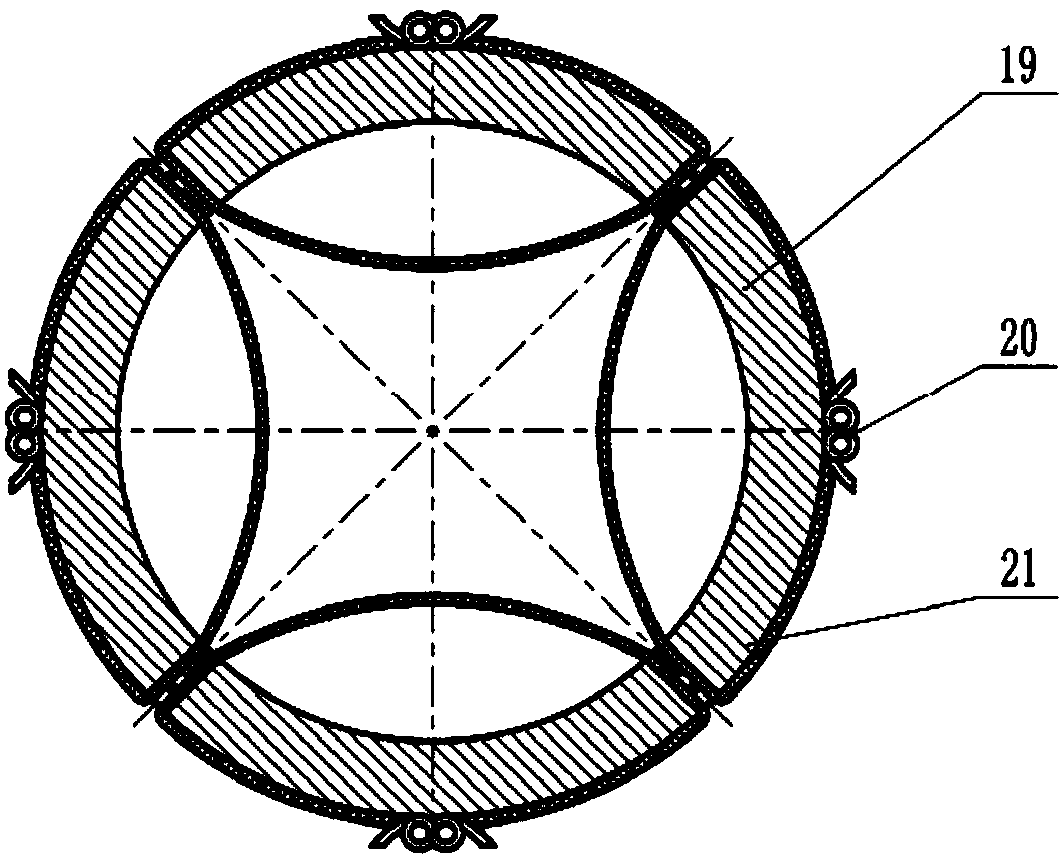

Method and device for reinforcing underwater welding seam based on laser impact wave technology

ActiveCN107739812APrecisely controlled pressurePrecise energy controlHeat treatment process controlFailure rateManufacturing technology

The invention discloses a method and device for reinforcing an underwater welding seam based on the laser impact wave technology and belongs to the technical field of manufacturing of ship and marineengineering equipment. According to the method, impact waves induced by double low-energy light spots simultaneously are utilized for impacting, and thus the welding seam of an underwater member is reinforced. The strength of the welding seam can be improved, and the fatigue resistant performance and corrosion resistant performance of the welding seam of the member are improved; the cracking failure rate of a welding piece is decreased greatly, and the service life of the workpiece is prolonged; and meanwhile, the service life of the reinforcing device is also prolonged, the production efficiency is improved, and the production cost is reduced greatly.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

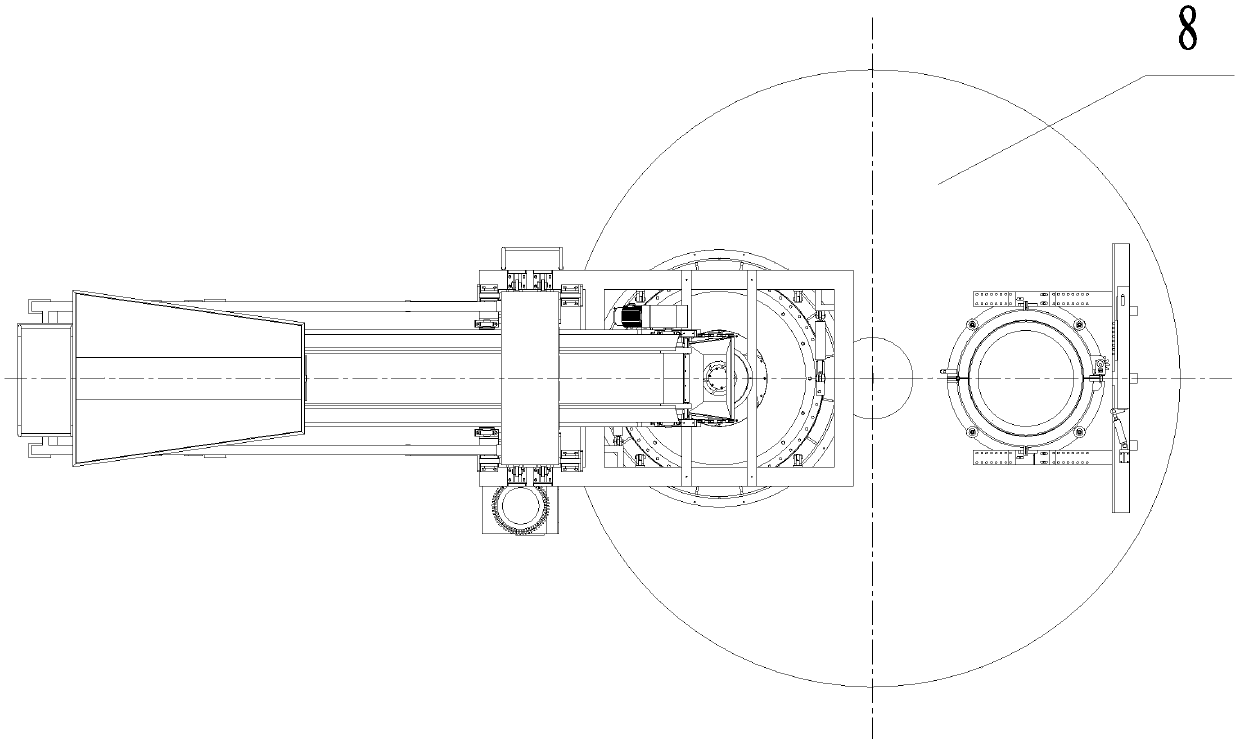

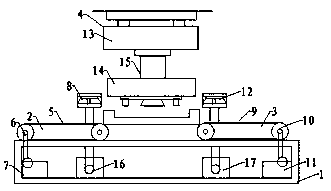

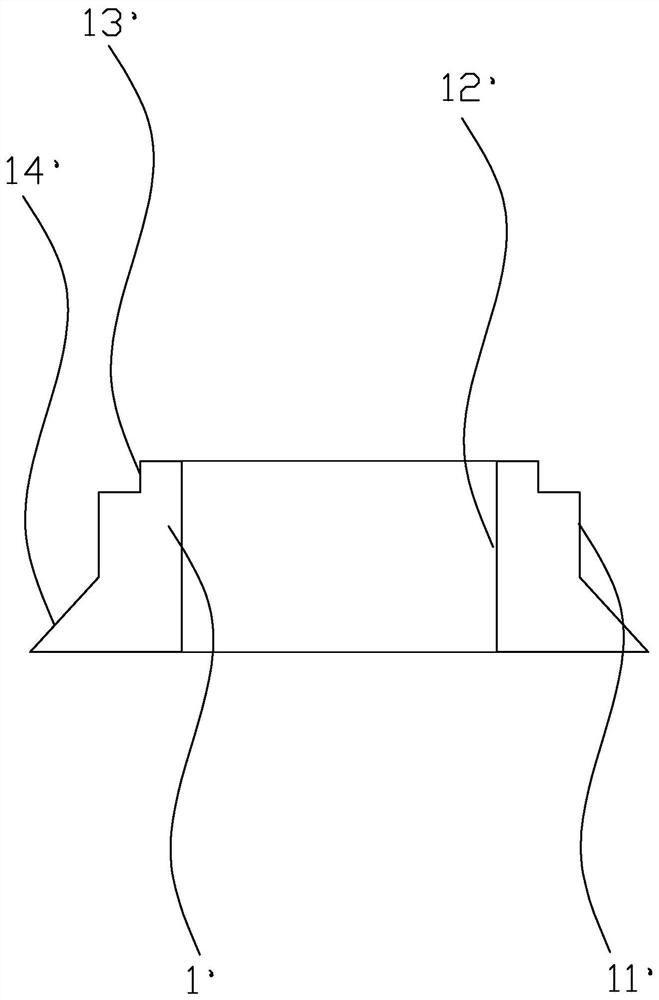

Workpiece tray exchange device of vertical type lathe exchange workbench

PendingCN111673489AReduce auxiliary processing timeImprove processing efficiencyLarge fixed membersPhysicsEngineering

The invention discloses a workpiece tray exchange device of a vertical type lathe exchange workbench. The device mainly solves the problem that an existing vertical type lathe loading and unloading workpiece needs to be stopped and the time is wasted. The device is characterized in that a tray guide rail (12) is connected to a rotary seat (2), a support roller (13) is connected to the tray guide rail (12), and a workpiece tray (14) is arranged on the support roller (13); a first chain wheel (4) and a second chain wheel (6) are connected to the rotary seat (2), a roller chain is connected between the first chain wheel (4) and the second chain wheel (6), a roller wheel (15) is connected to the upper part of the roller chain, and the roller wheel (15) is matched with a groove plate (7) on theworkpiece tray (14); and a first switch (3) and a second switch (5) are fixed on one side of the roller chain on the rotary seat (2), and a shaking sheet corresponding to the switch is fixed on one side of the roller chain. The exchange device is used for loading, unloading and centering workpieces, does not need to stop, shortens auxiliary processing time and improves machine tool processing efficiency.

Owner:通用技术齐齐哈尔二机床有限责任公司

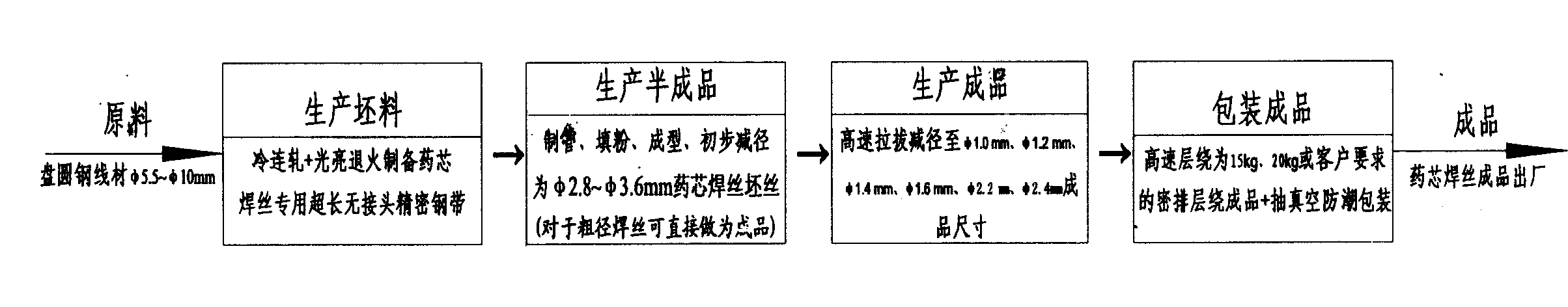

Technique for manufacturing flux-cored wire from disk round steel wire bar

A technique for producing flux-cored wires by using disc round steel wire bars is characterized by comprising following steps: using disc round steel wire bars as raw materials; producing accurate steel bands used for flux-cored wires exclusively; producing semi-finished products which are flux-cored wire blank tubes by using accurate steel bands; producing termination products by drafting to reduce the diameter thereof with a high speed; packaging the termination products by winding with a high speed. The advantages of the invention are: the invented technique uses high-speed hot-rolling disc round steel wire bars to replace broad cold-rolled steel strip, so that the raw material cost is reduced greatly; the continuous overlong endless accurate steel bands are used to save assistant procedure time for welding steel band joints, reduce end breakage rate during rolling and drafting procedures, improve continuous operation rate, and further reduce production cost; the invented techniqueuses high-speed accurate cold tandem rolling machine group to solve the problem that the sheet iron rolling precision is difficult to be controlled when rolling flux-cored wires by using disc round steel wire bars directly, and the filling precision is improved greatly since size accuracy of the flux-cored wire exclusive use accurate steel bands is high.

Owner:TIANJIN SAINTEAGLE WELDING CO LTD

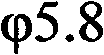

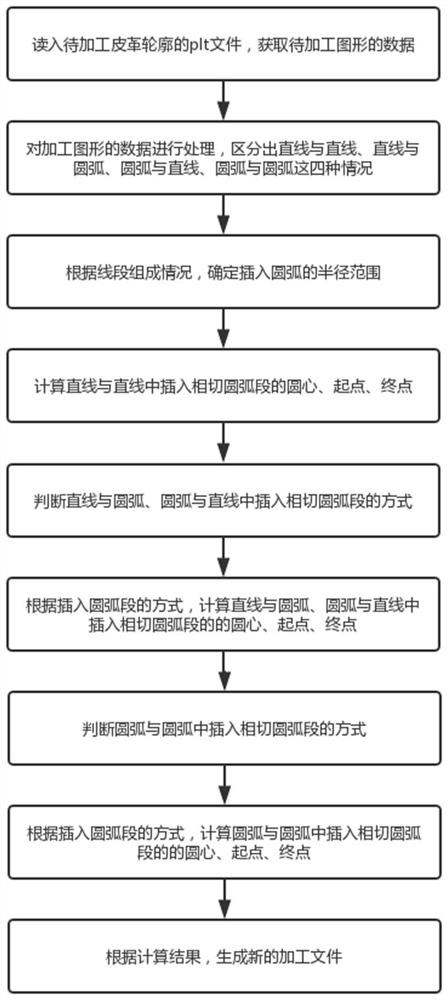

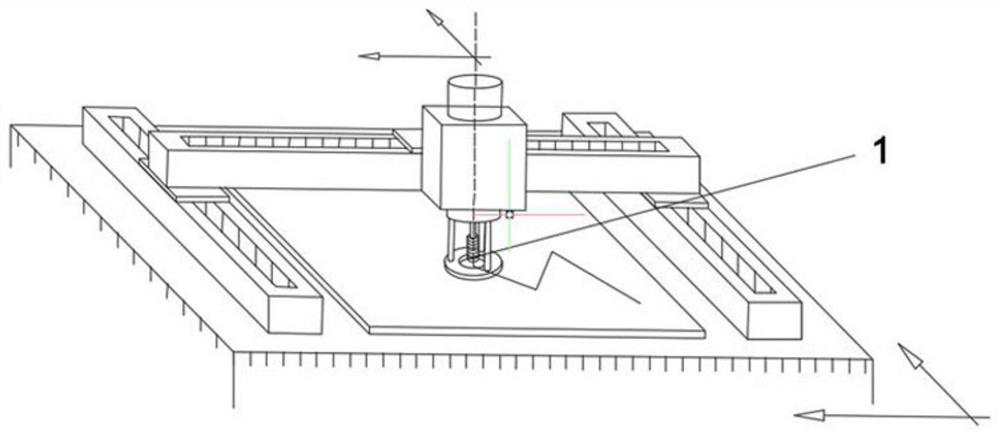

Track optimization method for improving processing speed of leather cutting machine

PendingCN112835328AReduce auxiliary processing timeImprove processing efficiencyNumerical controlStructural engineeringMechanical engineering

The invention discloses a track optimization method for improving the processing speed of a leather cutting machine, and the method comprises the following steps: S1, reading a PLT file of to-be-processed leather, and obtaining the data of a to-be-processed circle; S2, processing the data of the processing graph, and distinguishing four conditions of straight lines and straight lines, straight lines and arcs, arcs and straight lines, and arcs and arcs; s3, determining the radius range of the inserted arc; S4, calculating the circle center, the starting point and the ending point of the straight line and the straight line inserted with the tangent arc section; s5, judging modes of inserting tangent arc sections between the straight line and the arc and between the arc and the straight line; s6, calculating circle centers, starting points and ending points of straight lines and arcs and inserting tangent arc sections between the arcs and the straight lines; S7, judging the arc and the mode of inserting a tangent arc section into the arc; s8, calculating the circle center, the starting point and the ending point of the arc and the tangent arc section inserted in the arc; and S9, producing a new processing file. According to the track optimization method, the leather cutting auxiliary processing time is effectively shortened, and the leather cutting processing efficiency is improved.

Owner:FOSHAN ZHIANG TECH CO LTD

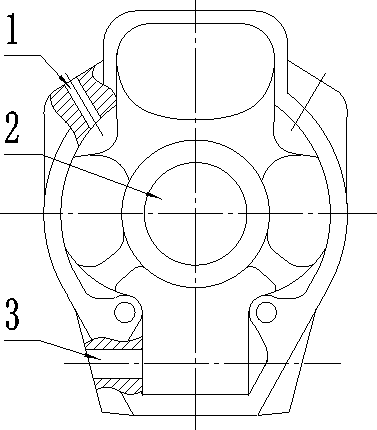

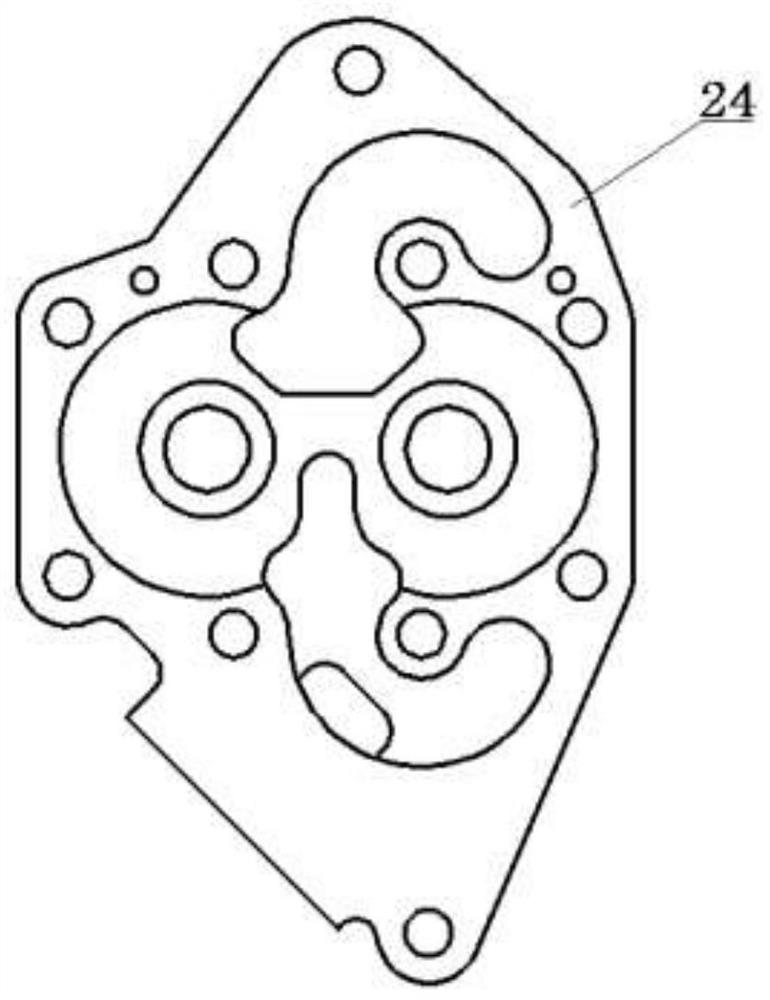

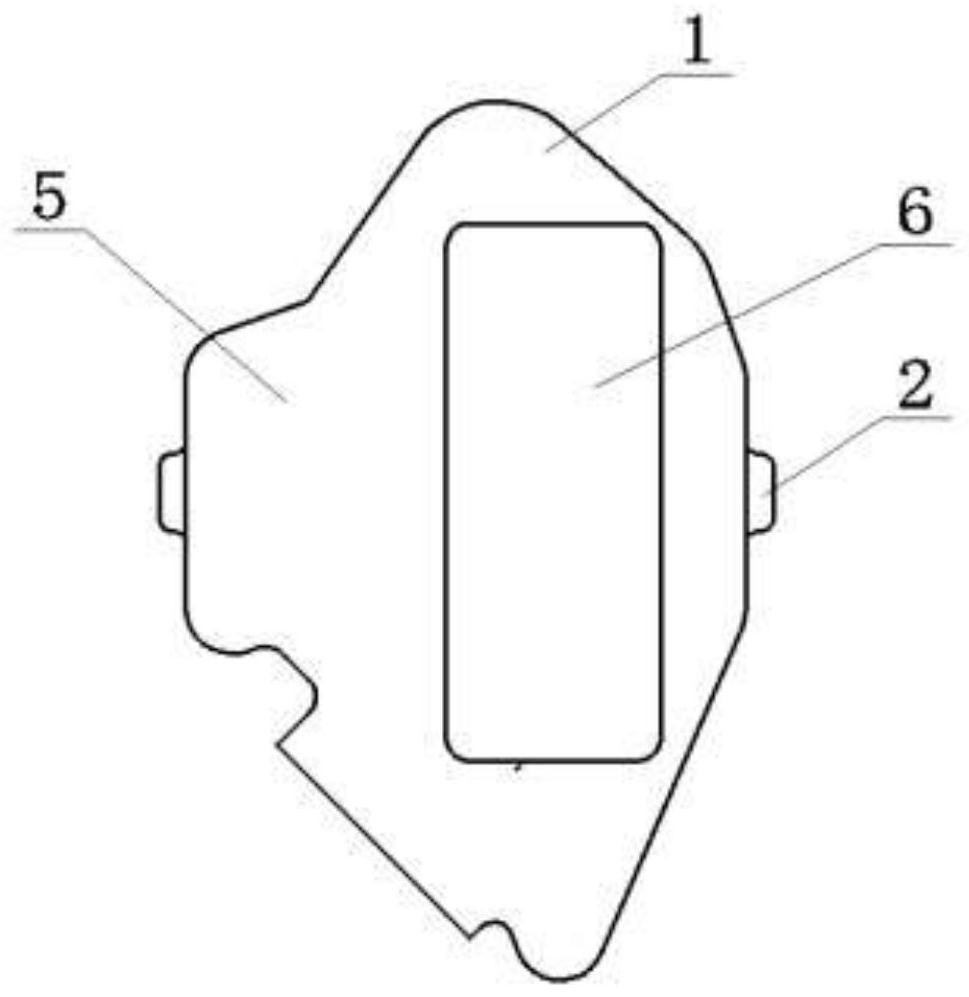

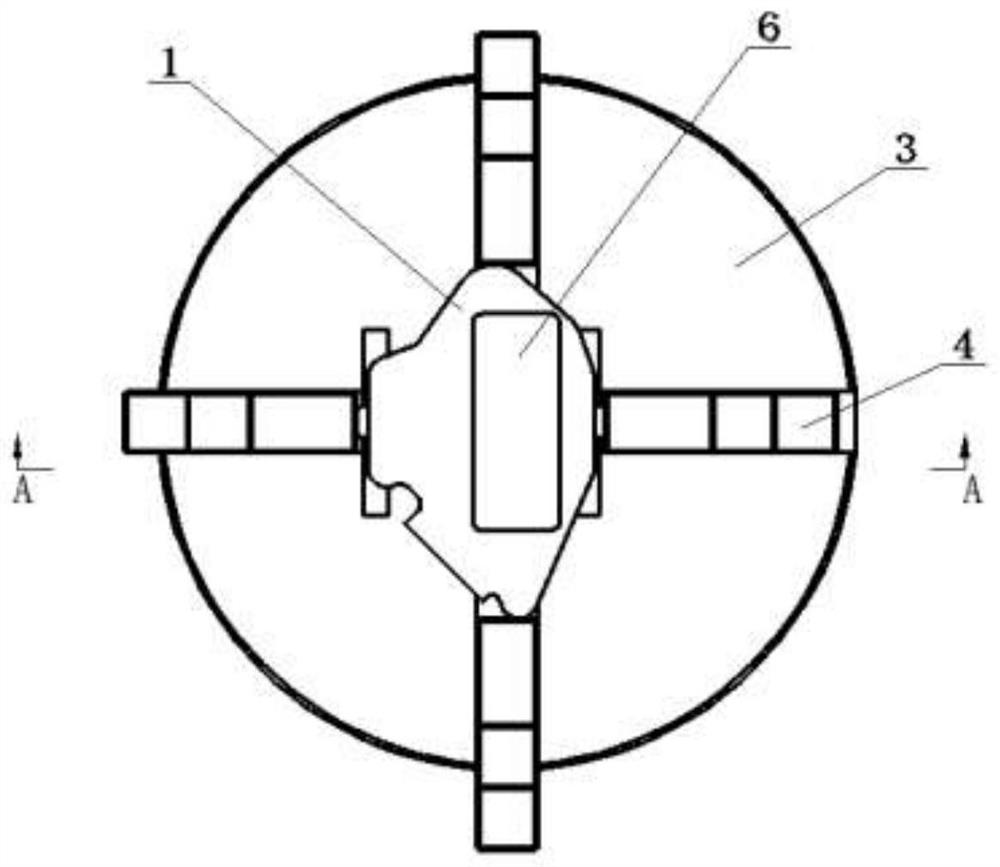

Oil pump shell machining method

The invention provides an oil pump shell machining method. The oil pump shell machining method comprises the following steps that a blank is prepared through a casting method, and at least one pair of technological convex towers are arranged on the periphery of the blank; a machine tool is provided; a chuck is provided and installed on a machine tool workbench, the blank is clamped through the chuck, and the datum plane and the datum hole are milled; a drilling and milling clamp is provided, the blank is clamped through the drilling and milling clamp, and all shape element characteristics are cut and machined; and a supporting clamp is provided, the blank is clamped through the supporting clamp, and milling is performed to remove the technological convex towers. With adoption of the technical scheme, through the procedures of sequentially arranging the technological convex towers, machining the datum plane and the datum hole and the like, the workpiece can be conveniently and stably clamped through a jaw on the chuck in the rough milling procedure, stable clamping and workpiece alignment are facilitated through the datum hole and the datum plane in the other procedures, the overall machining precision and machining quality of the workpiece are improved, the auxiliary process time is shortened, and the production efficiency is improved.

Owner:贵州凯星液力传动机械有限公司

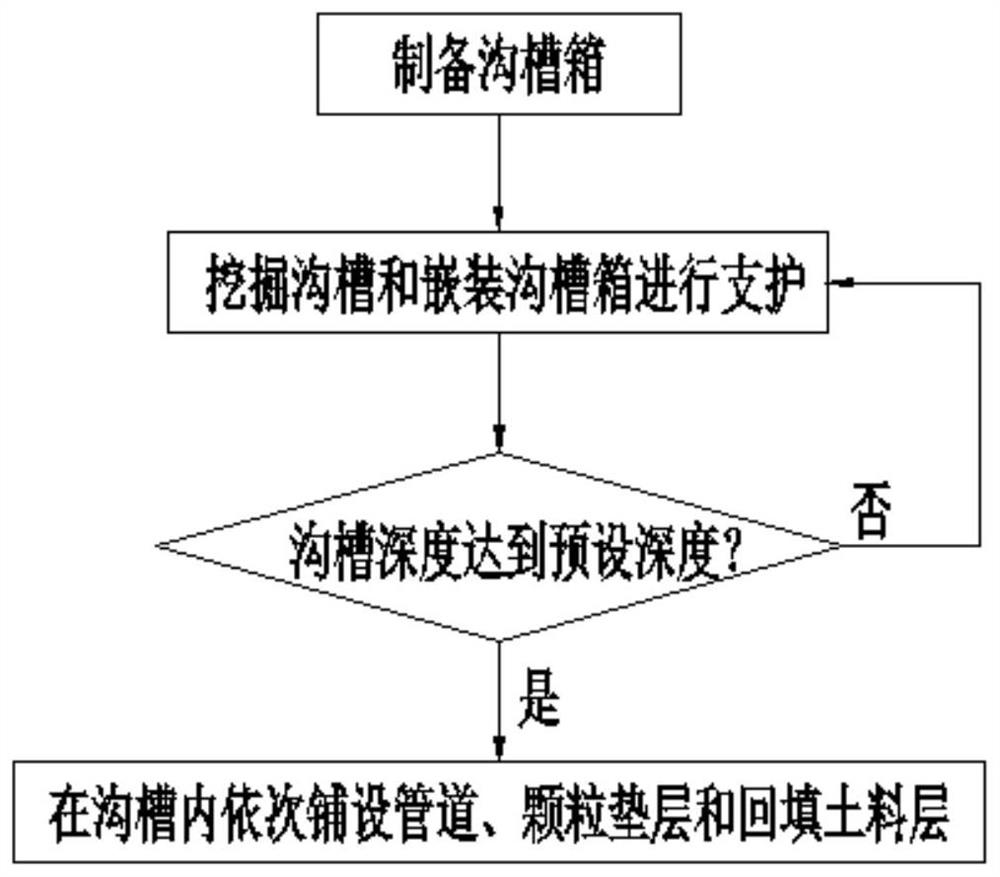

Deep groove excavation construction technology

InactiveCN113324097AEasy to installPlay a supporting rolePipe laying and repairCorrosion preventionArchitectural engineeringStructural engineering

The invention provides a deep groove excavation construction technology. The deep groove excavation construction technology comprises the following steps that a plurality of groove boxes are prepared, the upper portions and the lower portions of the groove boxes are hollow, each groove box comprises a pair of supporting plates parallel to each other, a plurality of supporting rods are fixedly connected between the supporting plates, and the supporting rods are arranged in a linear array at equal intervals in a length direction of the supporting plates; the groove box is used for supporting a groove while the groove is excavated; and the steps are repeated for multiple times until the depth of the groove reaches a preset depth. By the adoption of the technical scheme, the groove box is convenient to install, the inner wall of the groove can be rapidly supported, collapse is prevented, preparation materials of the groove box are easy to obtain, structure is simple, shortening of an auxiliary process time is facilitated, construction period is shortened, and construction efficiency is improved; organic substances in a soil material are isolated from the pipeline material by laying a granular cusgion first and then a backfill material when laying a pipeline, so that the pipeline can be prevented from being corroded by the organic substances in the soil, and service life of the pipeline can be prolonged.

Owner:SINOHYDRO BUREAU 9

Compound numerically-controlled gantry machine

PendingCN112318145AImprove processing qualityIncrease production profitLarge fixed membersPositioning apparatusNumerical controlEngineering

The invention relates to a numerically-controlled machine tool, and provides a compound numerically-controlled gantry machine. The compound numerically-controlled gantry machine comprises a rack, a workbench, a fixing base, a horizontal moving mechanism, a driving unit, a gantry frame, an oblique stand column, a horizontal spindle box, a first vertical spindle box, a second vertical spindle box, ahorizontal tool changer, a first vertical tool changer and a second vertical tool changer, wherein both the horizontal spindle box and the first vertical spindle box are slidingly arranged on a beamof the gantry frame, an outer circumferential side and an inner ring inner circumferential side of a to-be-machined circular knitting machine saddle on the workbench are machined by the horizontal spindle box, an upper end surface of the to-be-machined circular knitting machine saddle on the workbench is machined by the first vertical spindle box, and the second vertical spindle box which can vertically slide on an oblique surface of the oblique stand column is arranged on the oblique stand column to machine a lower oblique ring surface, at the outer circumferential side, of the to-be-machinedcircular knitting machine saddle on the workbench. By means of the compound numerically-controlled gantry machine, the problems of low machining efficiency and high production costs of circular knitting machine saddle workpieces, with multidimensional and multistation requirements, according to existing compound machining centers are solved.

Owner:泉州市创佳自动化设备有限公司

A method of polishing magnetic cores of different sizes

ActiveCN106737112BReduce breakage rateGuaranteed polishing effectEdge grinding machinesPolishing machinesCooking & bakingEngineering

The invention relates to the field of magnetic core processing, in particular to a method for polishing magnetic cores with different sizes, and aims to provide a magnetic core polishing method which selects different polishing materials according to the magnetic cores of different sizes, ensures polishing effect and decreases breakage ratio of the magnetic cores. The method includes the steps: determining a set value for distinguishing large magnetic cores and small magnetic cores, and comparing the lengths of long edges of the magnetic cores with the set value; adding the magnetic cores into a roller of a polishing machine; adding polishing materials into the roller; adjusting polishing time and frequency, and starting the polishing machine to polish the magnetic cores; cleaning the polished magnetic cores by the aid of diluting agents, and drying the magnetic cores by the aid of a baking oven. When the larger magnetic cores are added into the roller of the polishing machine, the added polishing materials are emery, when the small magnetic cores are added into the roller of the polishing machine, and the added polishing materials are water. The method solves the problem that the breakage ratio of the magnetic cores is high when the magnetic cores are polished by the aid of a mechanical device in the prior art.

Owner:江苏引拓电力科技有限公司

Pneumatic clamping drilling tool

ActiveCN103611969BEasy to adjustEasy to operatePositioning apparatusDrill jigsLocking mechanismMachining time

The invention discloses a pneumatic clamping type drilling tool and relates to the technical field of auxiliary drilling equipment. The pneumatic clamping type drilling tool comprises a lower housing, two sets of clamping and positioning mechanisms, a drill plate, an air cylinder and a lower driving lever. The rear of the drill plate is hinged to a connecting piece of a supporting plate while the front of the same is provided with two openings. Front ends of two supporting seats are hinged to two opening locking mechanisms. The drill plate is provided with drill bushings, two rectangular through holes are formed in positions, corresponding to two pressing pieces, of the middle of the drill plate, and lower end faces of the rectangular through holes are higher than or equal to those of the pressing pieces. Vertical positioning plates are arranged in the rear of the supporting seats and above the housing. The hinged drill plate is convenient to clean and replace, the positioning plates are accurate in positioning, and the drill plate provided with the rectangular through holes is fastened through the locking mechanisms after being covered, so that the drill plate is enabled to be closer to the surface of a work piece, and drilling accuracy can be guaranteed. The pneumatic clamping type drilling tool has the advantages of being compact in structure, accurate in positioning, high in processing accuracy and applicable to processing of products of different specifications.

Owner:CRRC SHIJIAZHUANG CO LTD

A kind of rising core rotary vibration extrusion forming pipe making machine

ActiveCN105500519BReduce auxiliary processing timeImprove work efficiencyMouldsFeeding arrangmentsEngineeringMechanical engineering

The invention provides a core-lifting rotary type vibrating extrusion forming tubing machine. According to the core-lifting rotary type vibrating extrusion forming tubing machine, an automatic core lifting mode is adopted to an inner die, a special forklift demoulding mechanism is adopted to outer dies for quick die opening and die assembly, the outer dies can be quickly arranged in place through a rotary platform, and production efficiency is improved. The core-lifting rotary type vibrating extrusion forming tubing machine comprises a rack, a feeding mechanism, a rolling plate, the rotary platform, the outer dies, a rotary material uniforming mechanism, a vibrating mandrel and the inner die. The outer dies are arranged on the rotary platform which drives the outer dies to rotate, and the rotary platform is located above the inner die. The rotary material uniforming mechanism is arranged on the top of the inner die, the vibrating mandrel is arranged in the inner die, the inner die ascends and descends relative to the rack through a lifting mechanism, and the inner die enters the outer dies to form a tube cavity. The feeding mechanism is used for feeding materials to the tube cavity, the rolling plate is arranged on the rack and ascends and descends, and the rolling plate is used for rolling concrete products on the upper portion of the tube cavity. By means of the core-lifting rotary type vibrating extrusion forming tubing machine, auxiliary procedure time consumed in the production process is shortened, and work efficiency is improved.

Owner:孙祥 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com