Special abrasive band polishing machine for crankshaft journals

A crankshaft journal and abrasive belt polishing technology, which is applied to abrasive belt grinders, grinding/polishing equipment, grinding/polishing safety devices, etc., can solve the problems of wasting manpower and material resources, wasting production costs, and small local areas, and achieves Improve work efficiency, increase production efficiency, and speed up the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

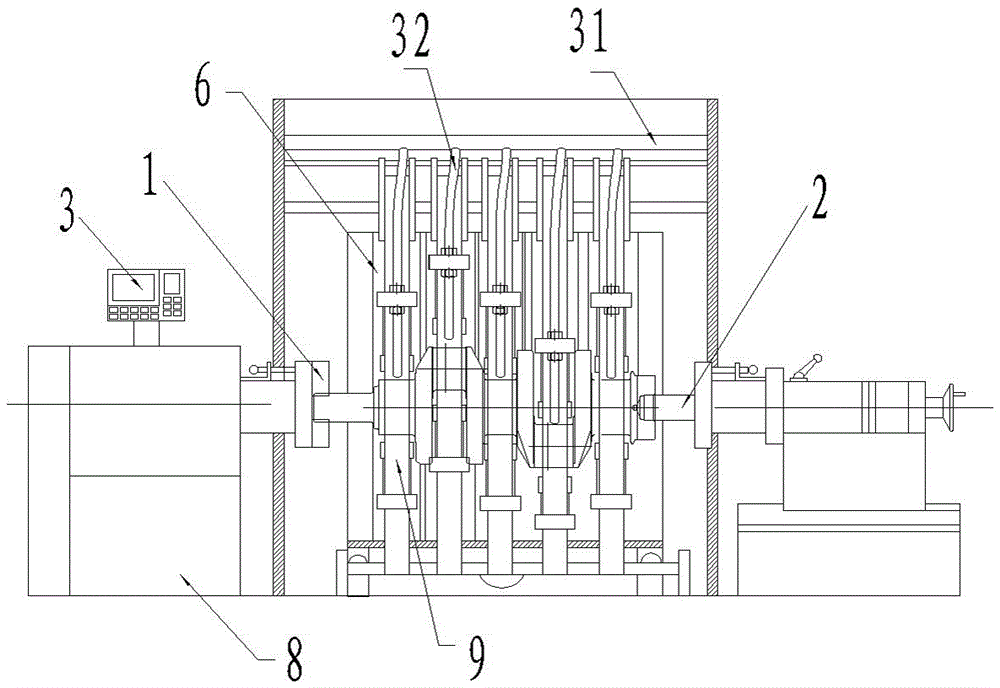

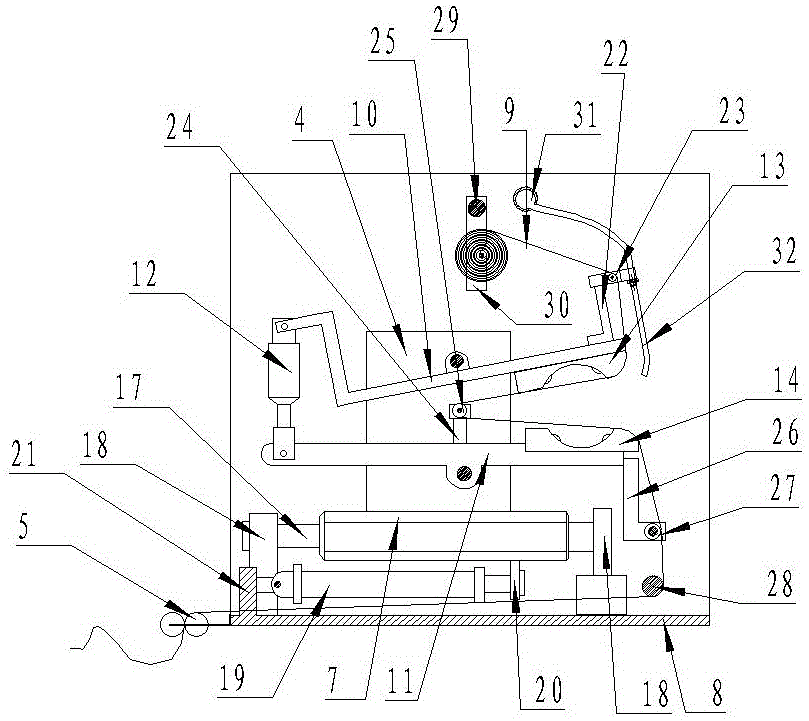

[0015] Such as figure 1 and figure 2 As shown, a special abrasive belt polishing machine for crankshaft journal polishing includes the rotating clamping part 1 of the machine tool 8, the top joint part 2 and the automatic control part 3 of the machine tool 8, and the special machine of the present invention also includes a fixed frame 4 , clamping mechanism, guiding mechanism, hydraulic drive mechanism, ribbon assembly, reversing mechanism, reel 5 and cooling mechanism, wherein, the quantity of clamping mechanism corresponds to the quantity of the axle journal of crankshaft, and set There are several grooves 6 for installing the clamping mechanism, the number of the grooves 6 is the same as the number of the clamping mechanism, the fixed frame 4 is fixed on the guide sleeve 7 of the guiding mechanism, and the guiding mechanism is connected with the machine tool 8 , the hydraulic drive mechanism is connected with the machine tool 8, the hydraulic drive mechanism is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com