On-machine detection measuring head and detection system for numerical control machine tool

A technology of numerical control machine tools and detection systems, applied in general control systems, control/adjustment systems, program control, etc., can solve the problems that cannot be eliminated, difficult to compensate for measurement errors, and low feed speed, etc., and achieve the improvement of measurement efficiency and measurement accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

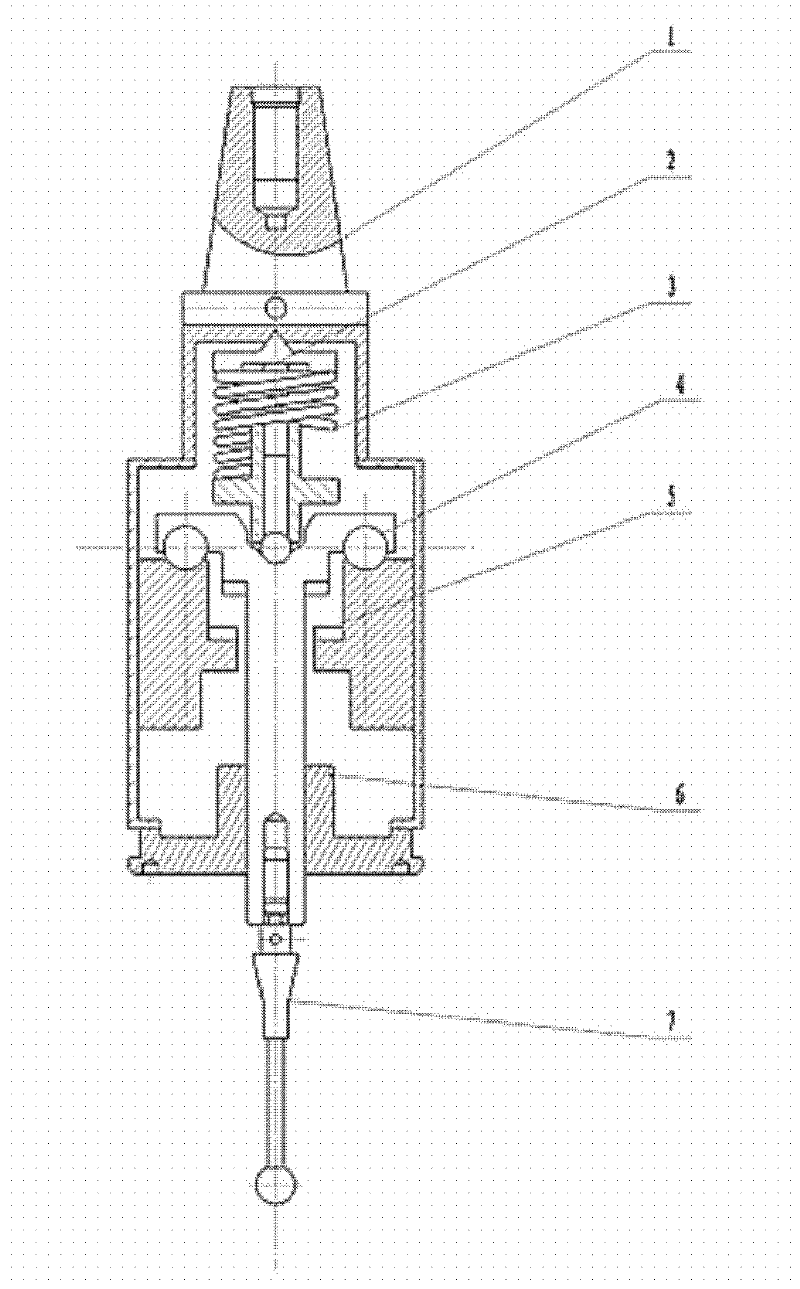

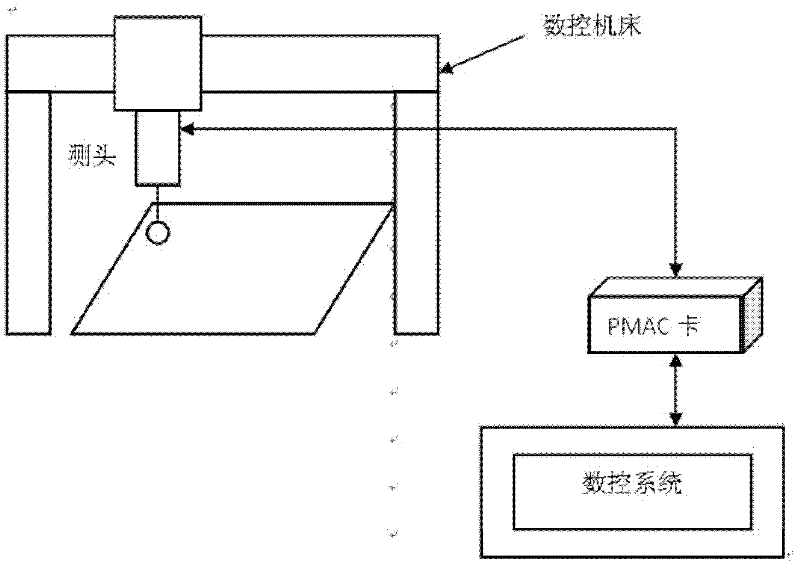

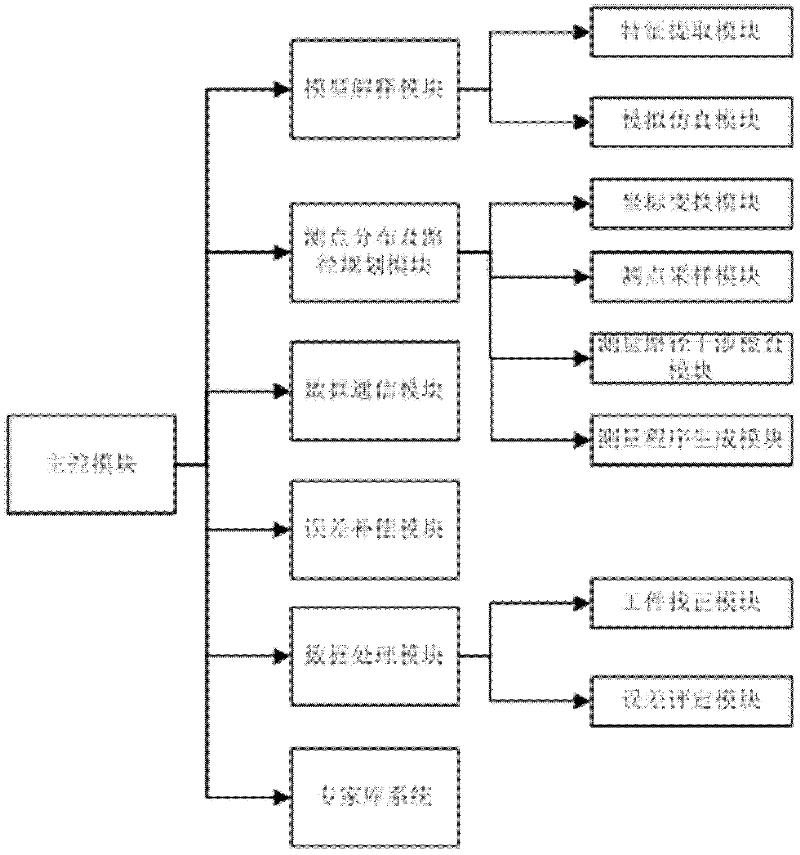

[0028] The invention first optimizes and transforms the original machine tool trigger probe, and uses multi-sensing fusion technology to solve the accuracy and efficiency problems of the machine tool probe in the actual measurement process. exist figure 1 Among them, the measuring rod 7 can do linear motion in the vertical direction under the constraint of the guide mechanism 6, and 4 is the installation bearing. 5 is a linear displacement sensor, one piece is fixed and one piece is movable during the installation process, and the installation distance between the two pieces is determined according to the measurement stroke. The spring 3 is wound on the stud 2 as an automatic reset mechanism. The probe can automatically return to its original position during the measurement process. Structure 1 is a tool handle, which is used to be installed on the spindle of the machine tool.

[0029] A linear displacement sensor is installed in the shell of the machine tool probe, which i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com