Box body drilling and tapping six-station equipment

A six-station, drilling and tapping technology, used in metal processing equipment, other manufacturing equipment/tools, positioning devices, etc., can solve the problems of manpower and material resources, not suitable for mass production, low work efficiency, etc., to achieve high production efficiency , The effect of reducing logistics turnaround time and labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

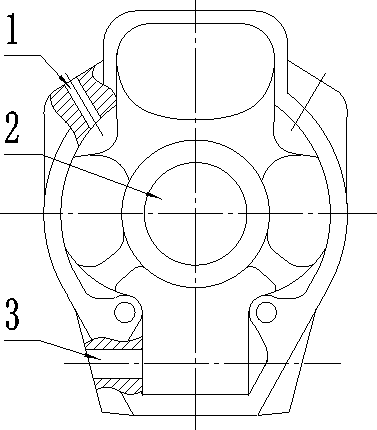

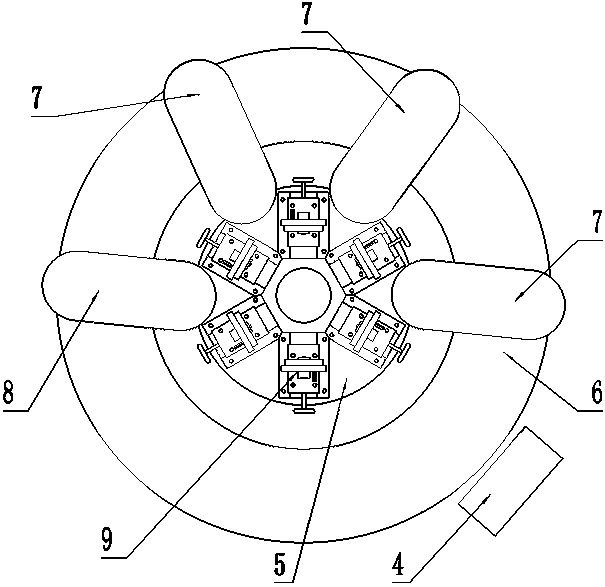

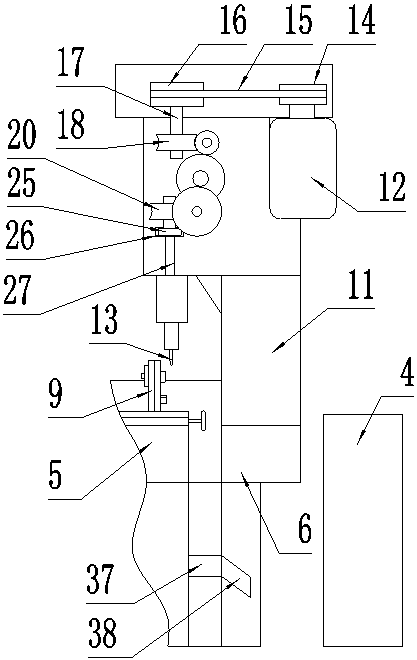

[0025] like Figure 2-8 A box drilling and tapping six-station equipment shown includes a control box 4, a rotary table 5, a frame 6, a drilling device 7 and a tapping device 8, and the rotary table 5 is provided with a rotating motor, an upper Several groups of positioning clamp bodies 9 are established, and the drilling device 7 and the tapping device 8 are arranged on the frame 6, and the rotating motor, the drilling device 7 and the tapping device 8 are all connected to the control box 4, and the machine The frame 6 is circular and is arranged on the periphery of the rotary table 5; the workpieces 10 are respectively installed on the positioning fixture body 9, and the workpiece 10 is drilled by the drilling device 7 and the tapping device 8 along with the rotation of the rotary table 5 and tapping.

[0026] The drilling device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com