Patents

Literature

510results about How to "Reduce turnaround time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

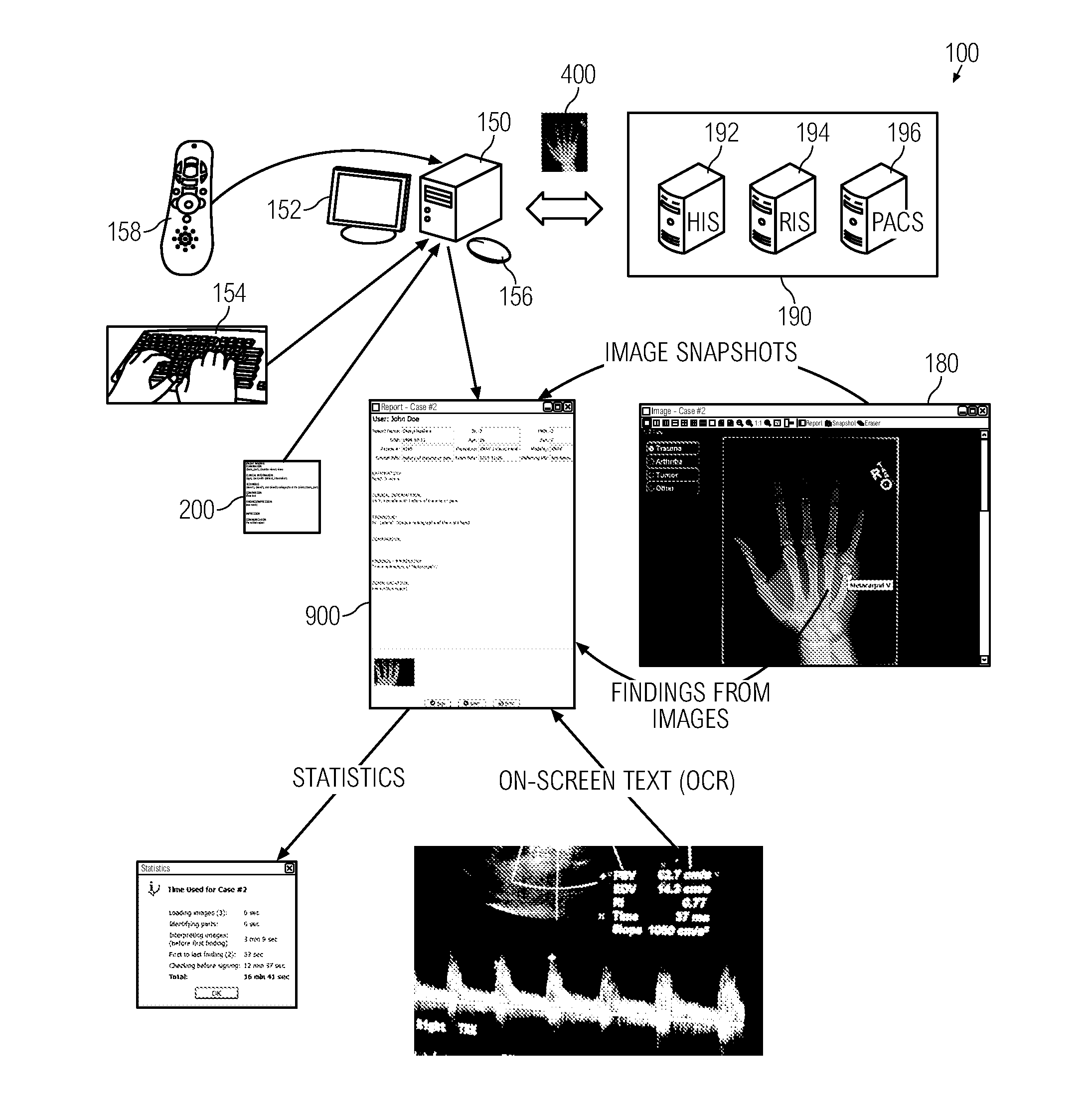

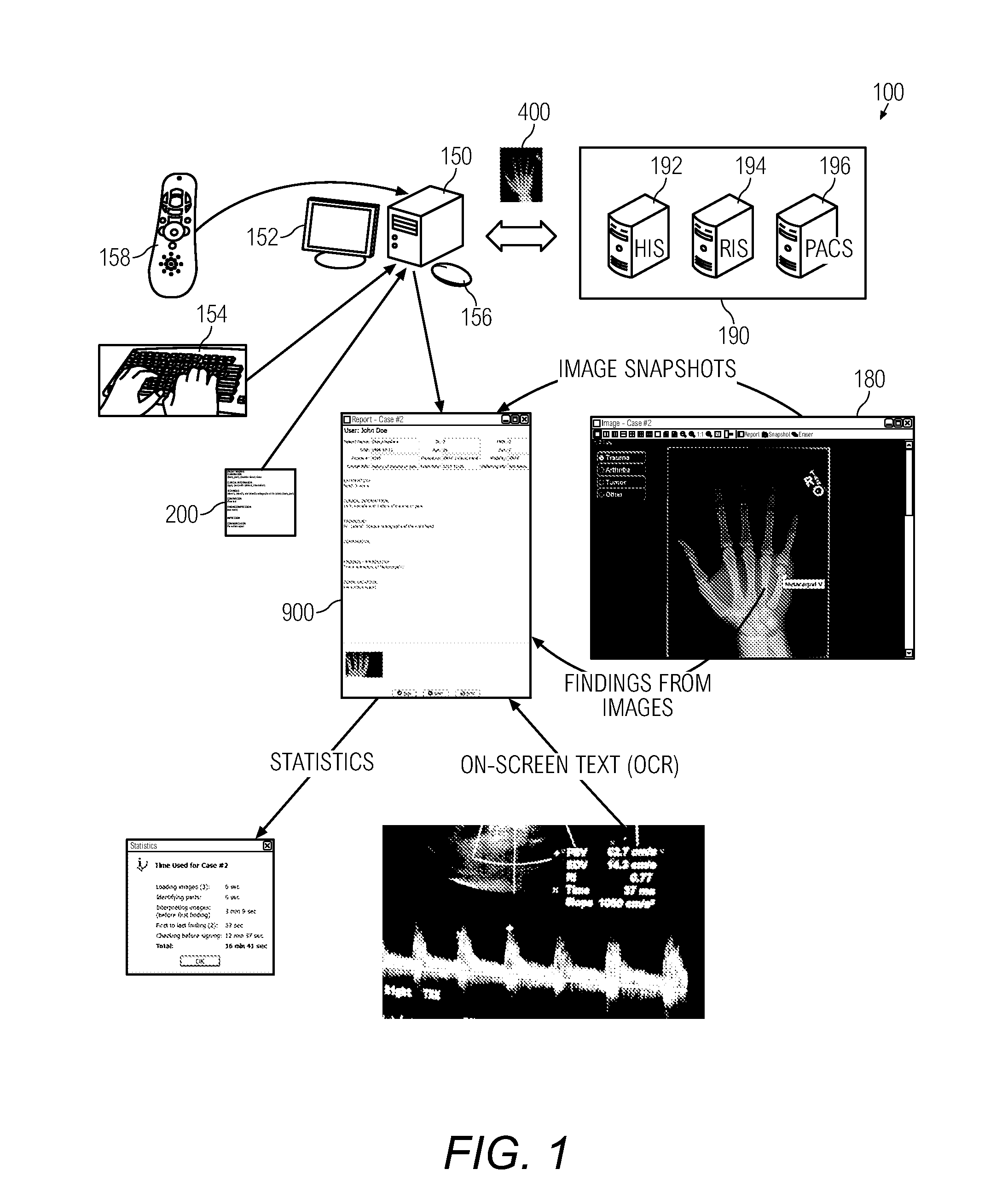

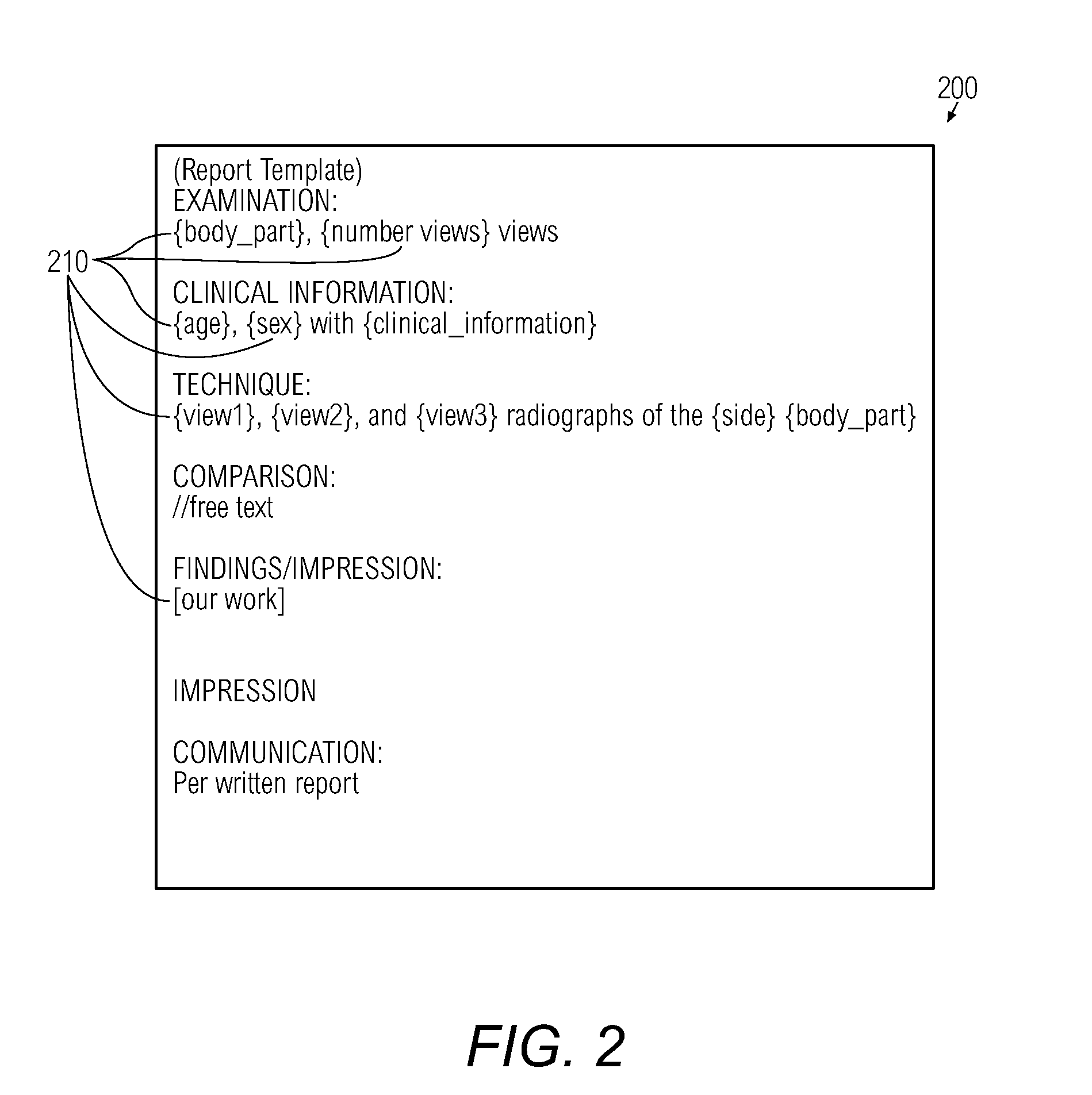

Method for creating a report from radiological images using electronic report templates

InactiveUS20130251233A1Maximize similarity scoreAccurate fitImage analysisCharacter and pattern recognitionAnatomical landmarkReference Region

Creating a report from a radiological image using an electronic report template, the radiological image being an image of an anatomic region and the report template initially having empty fields includes displaying the radiological image on a screen of a workstation; providing a structural template, the structural template being a map of a reference region that corresponds to the anatomical region, t structural template identifying a plurality of anatomical landmarks each associated with corresponding landmark data; fitting the structural template with the radiological image such that the anatomical landmarks match corresponding anatomical landmarks of the radiological image; using the fitting to generate pathological data indicative of a pathology in one or more of the anatomical landmark and using the landmark data and pathological data to populate the empty field of the report template to thereby create the report.

Owner:UNIV OF MASSACHUSETTS +1

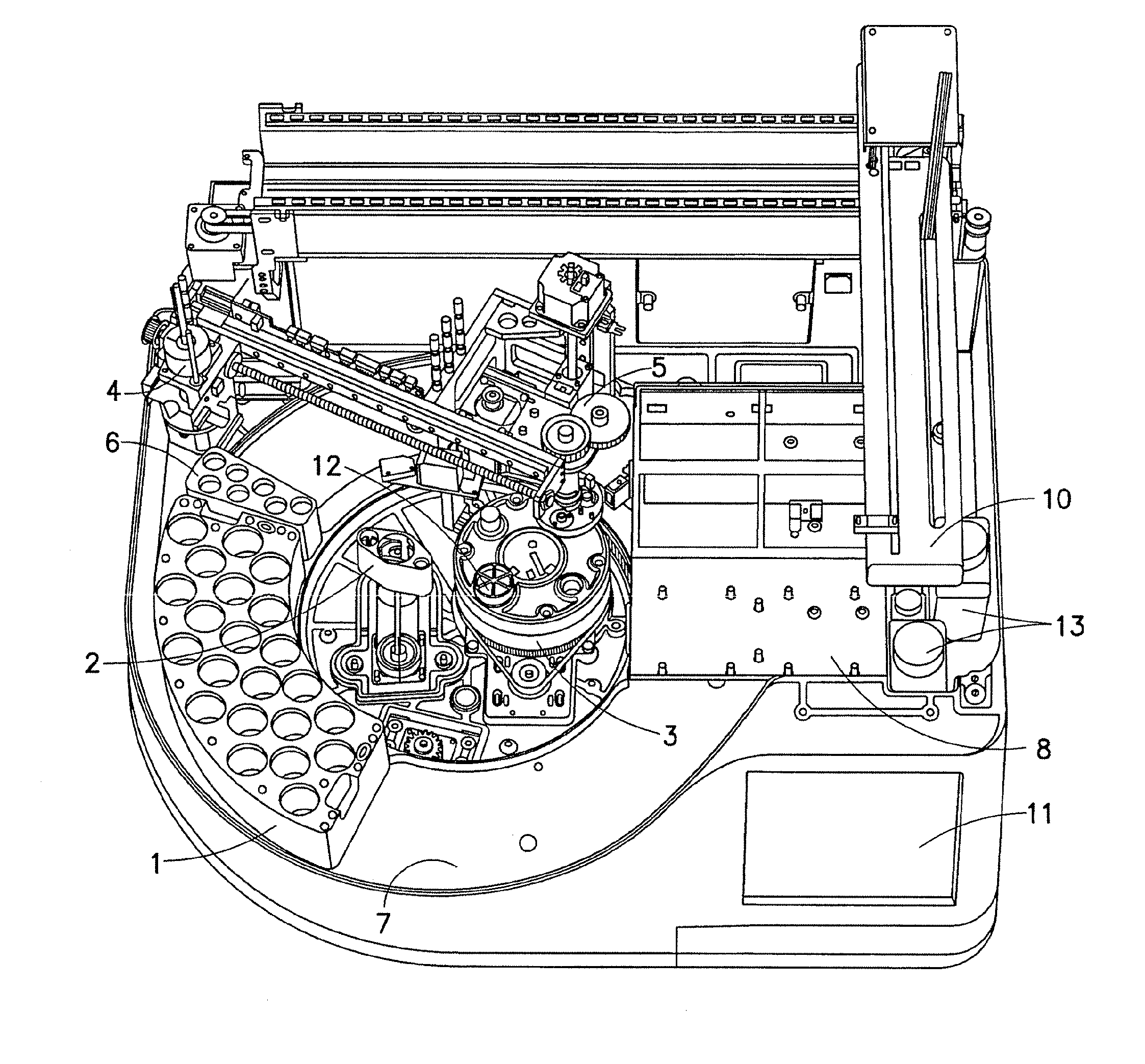

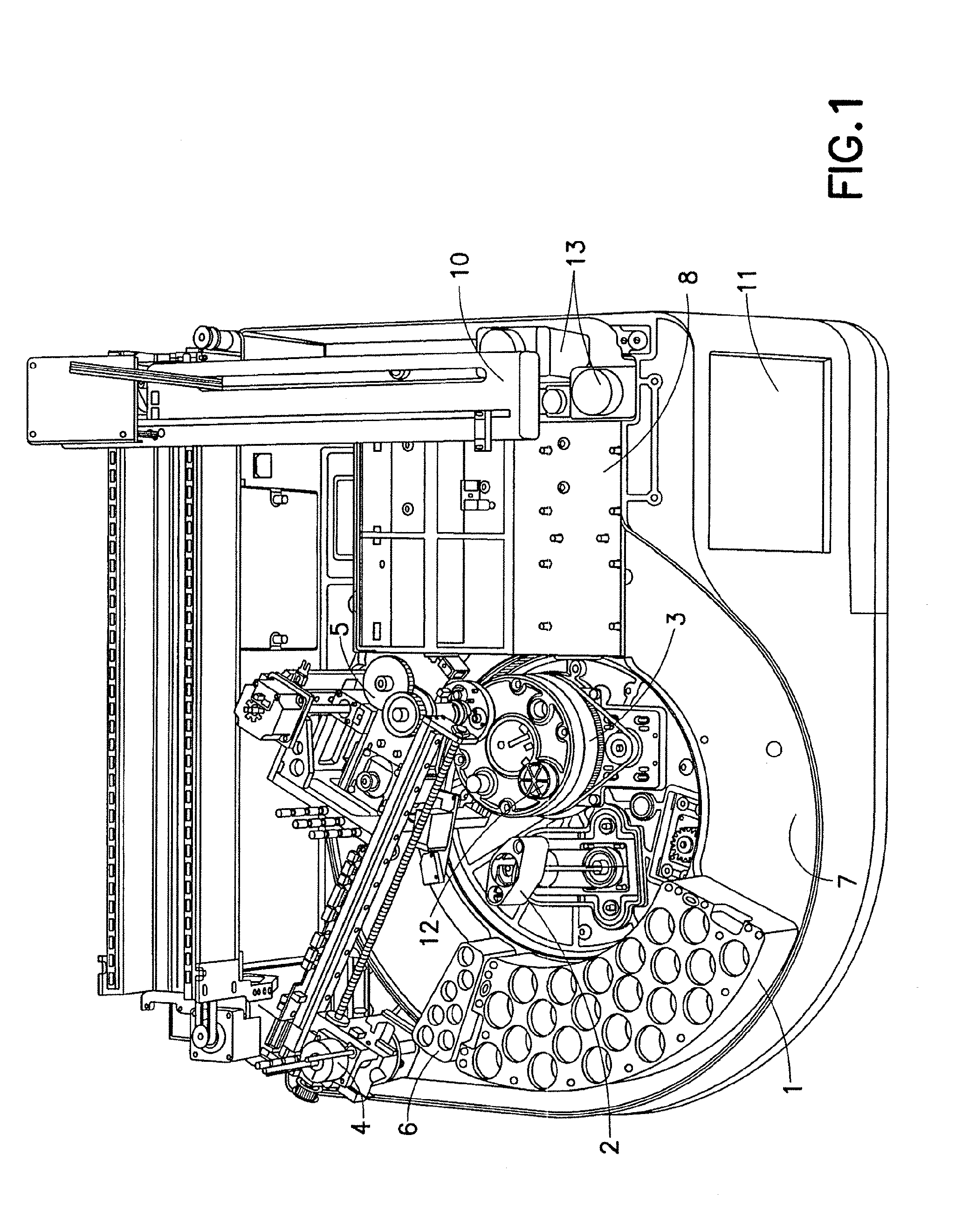

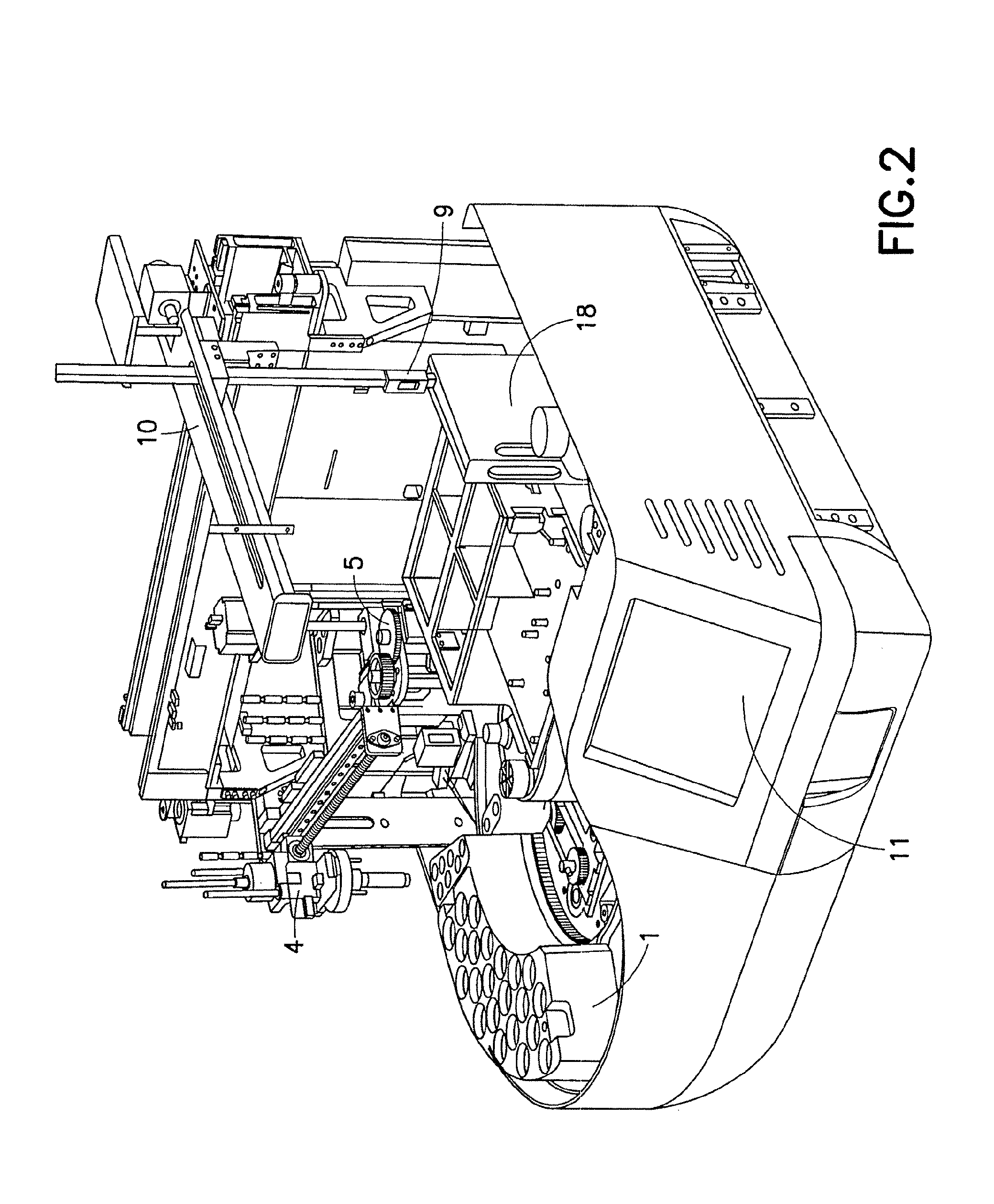

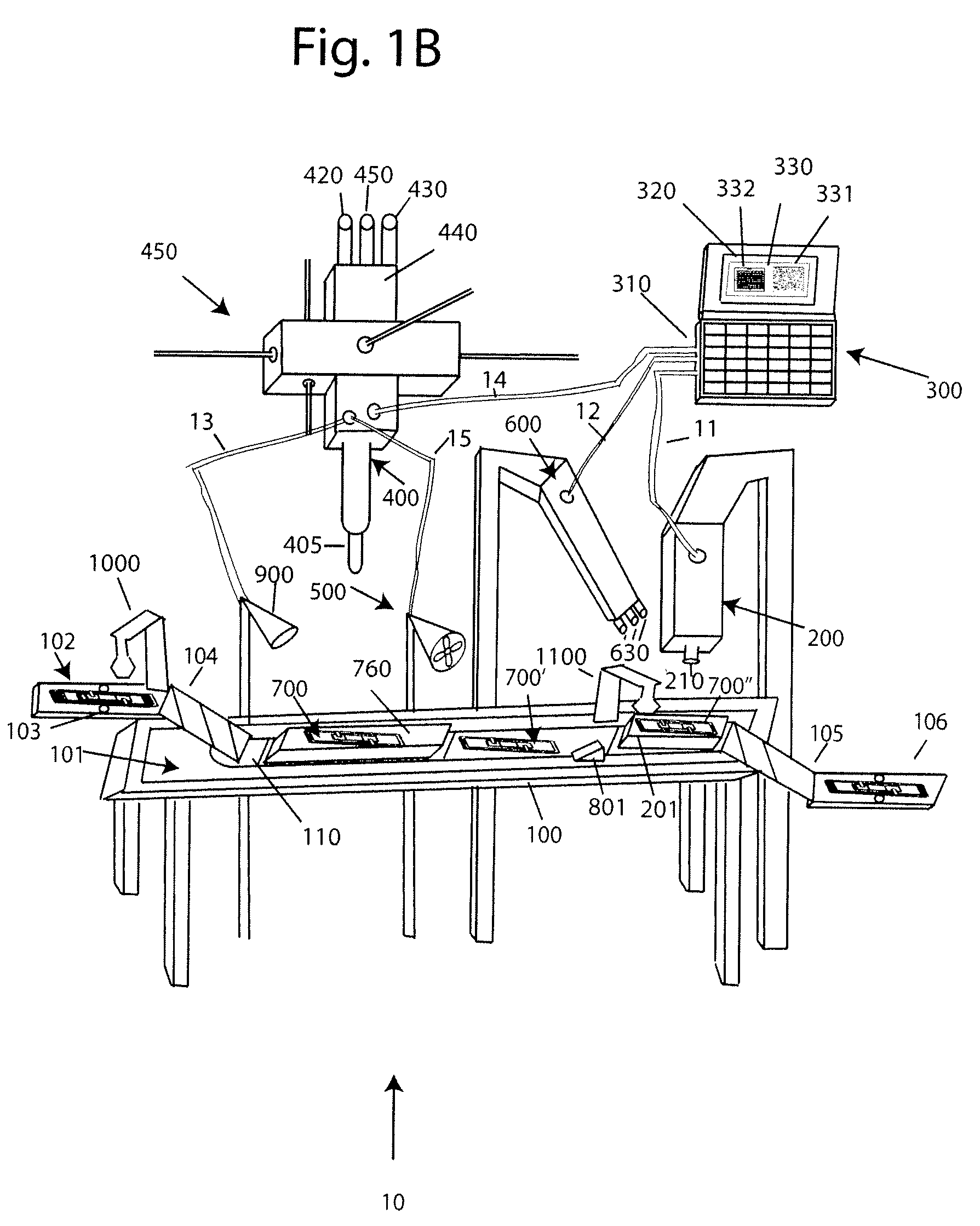

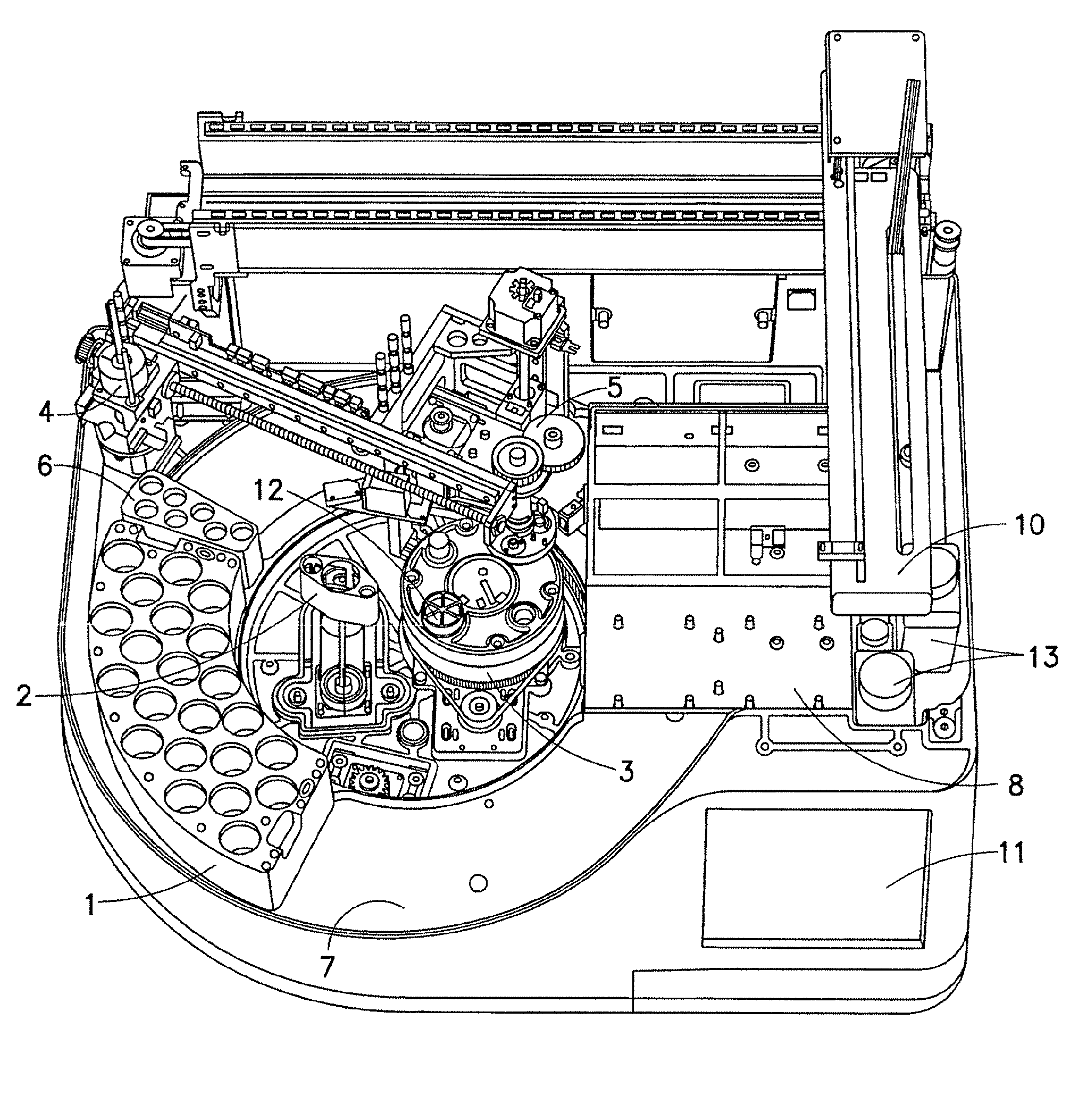

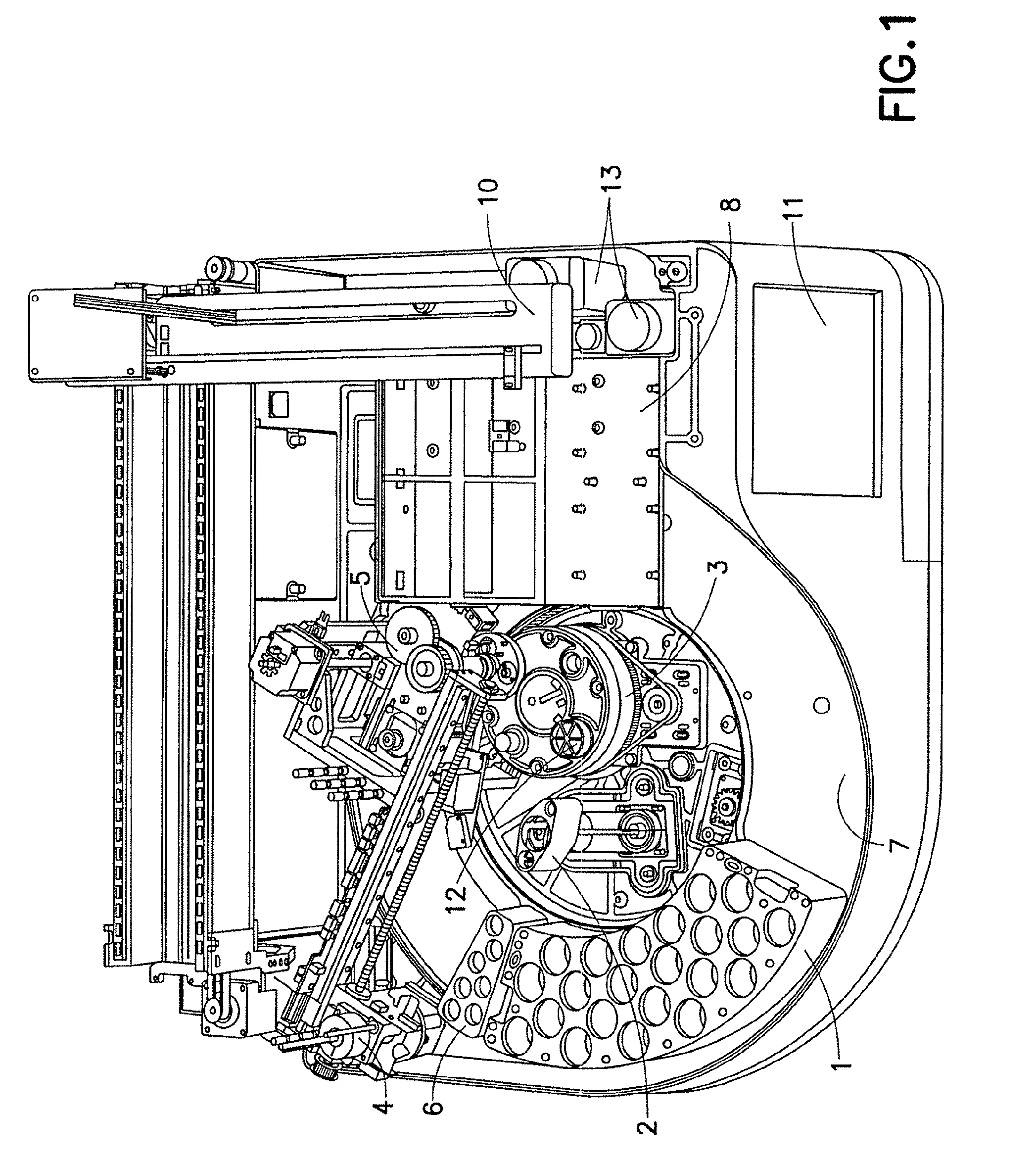

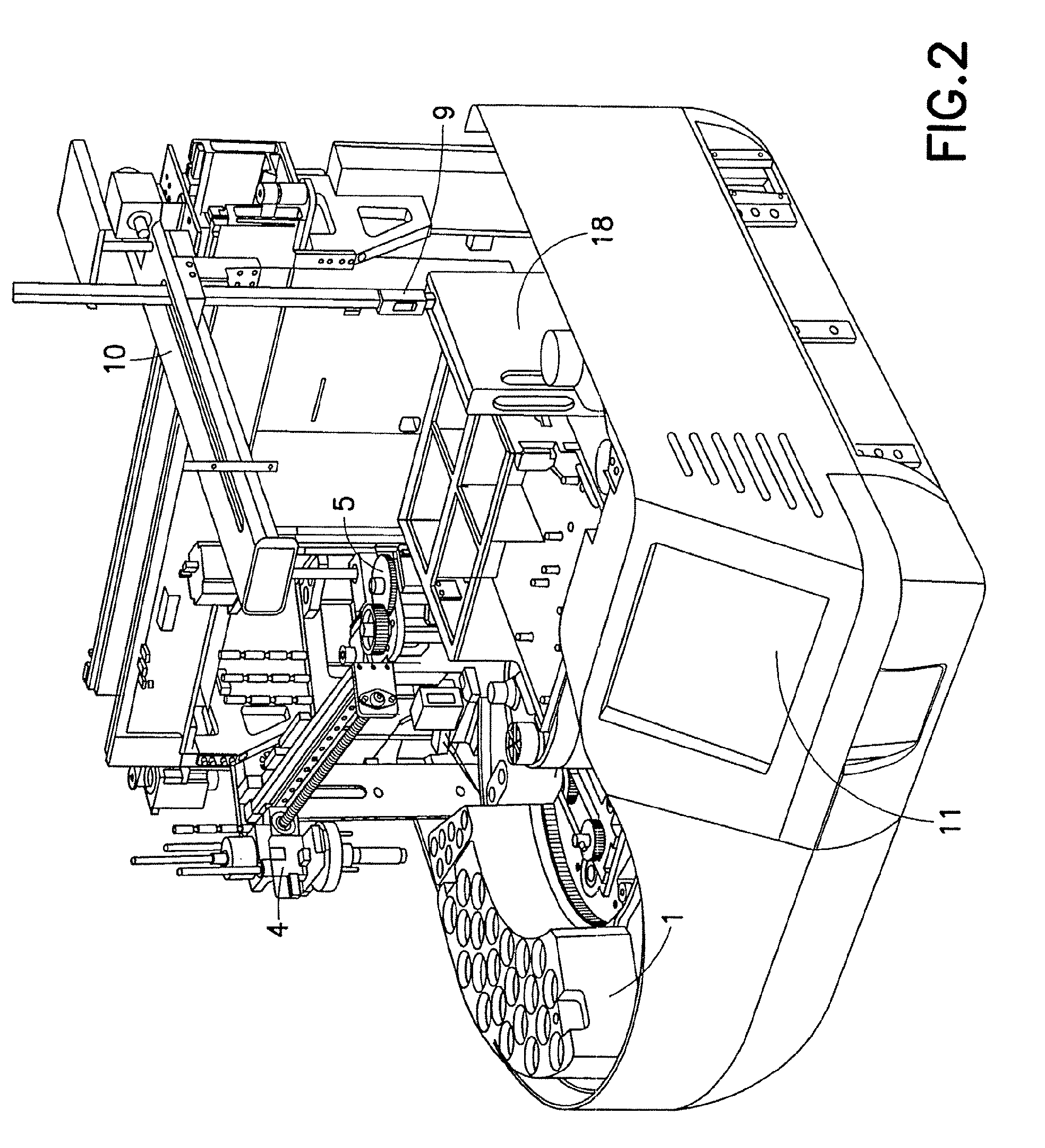

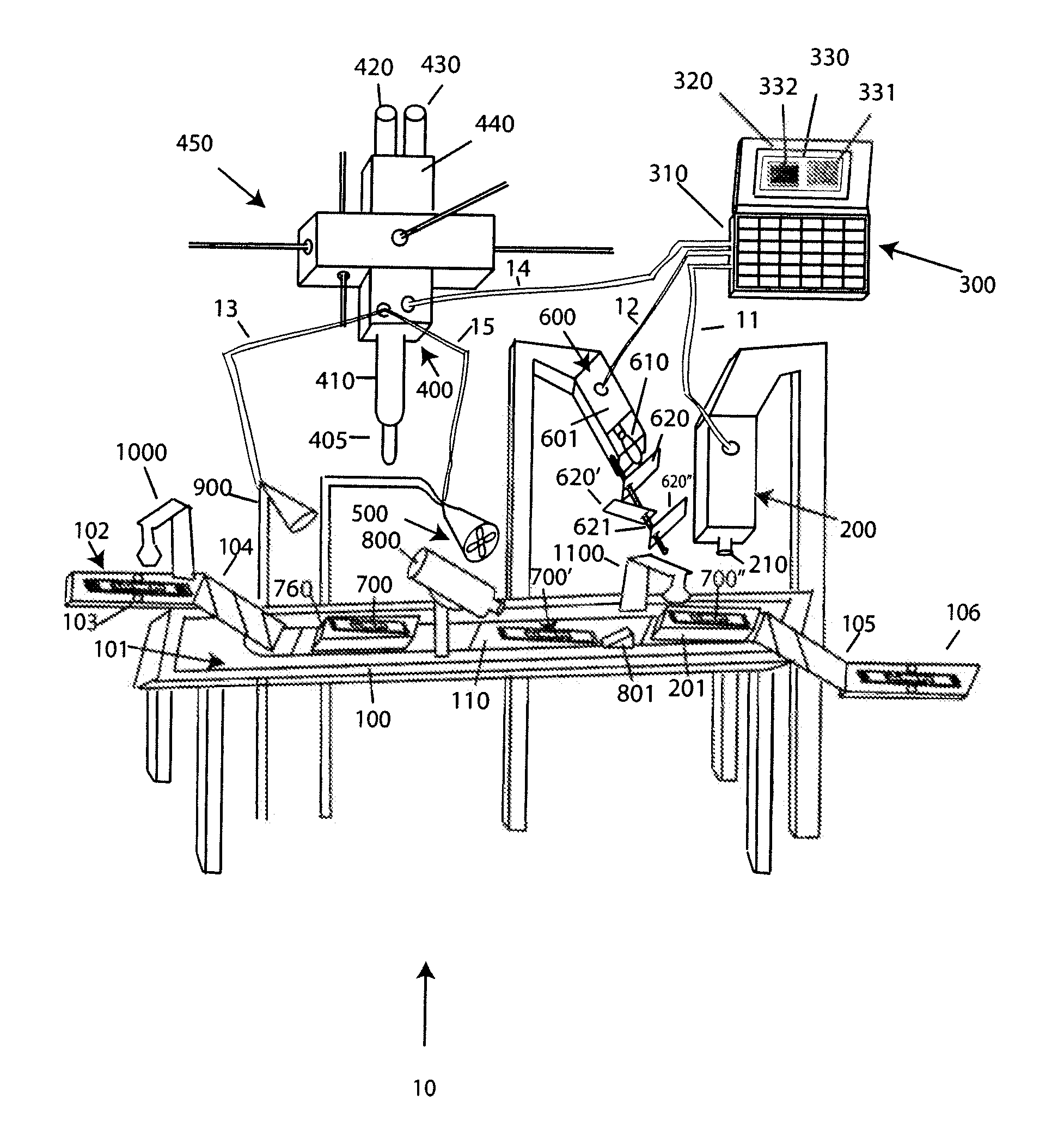

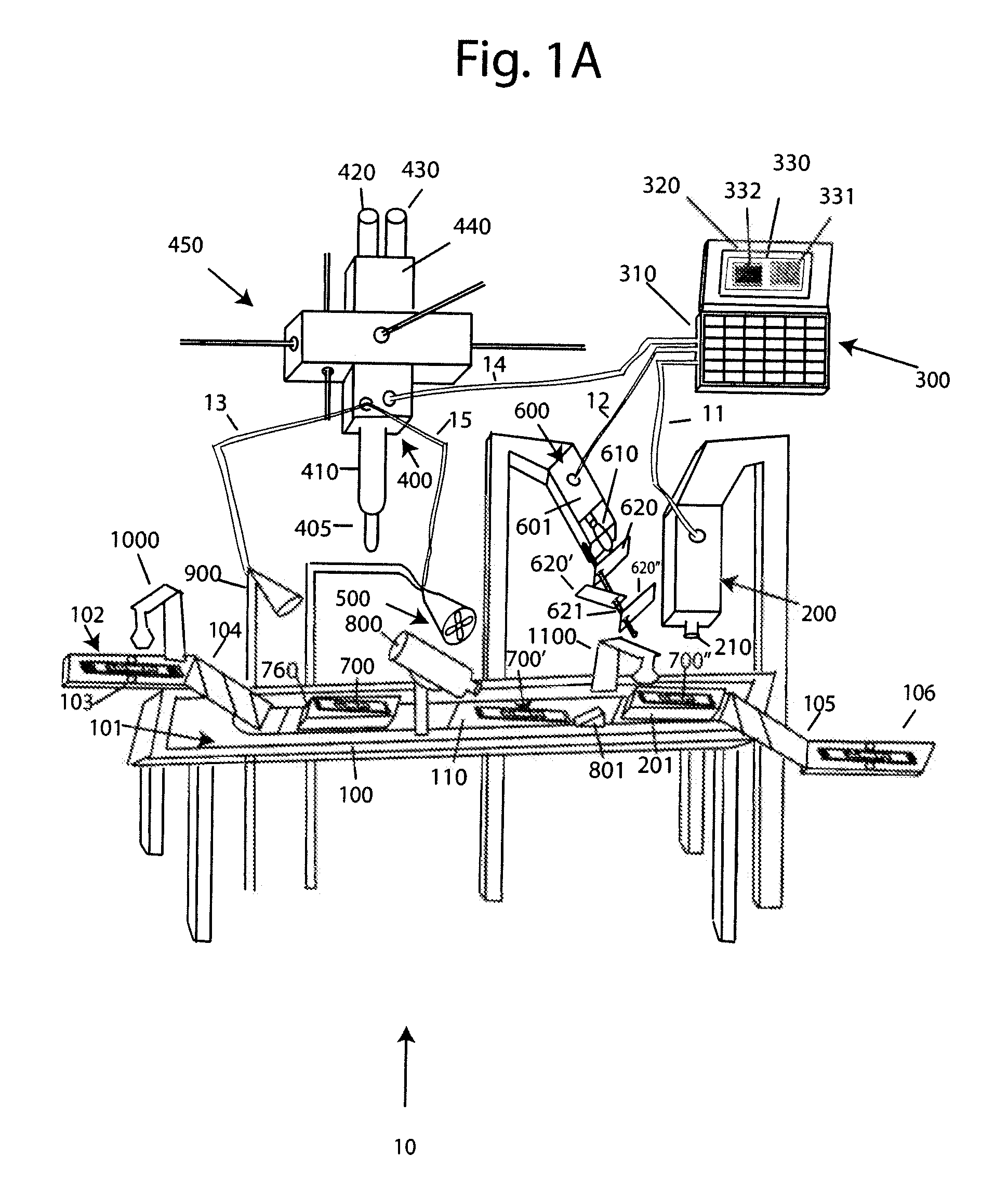

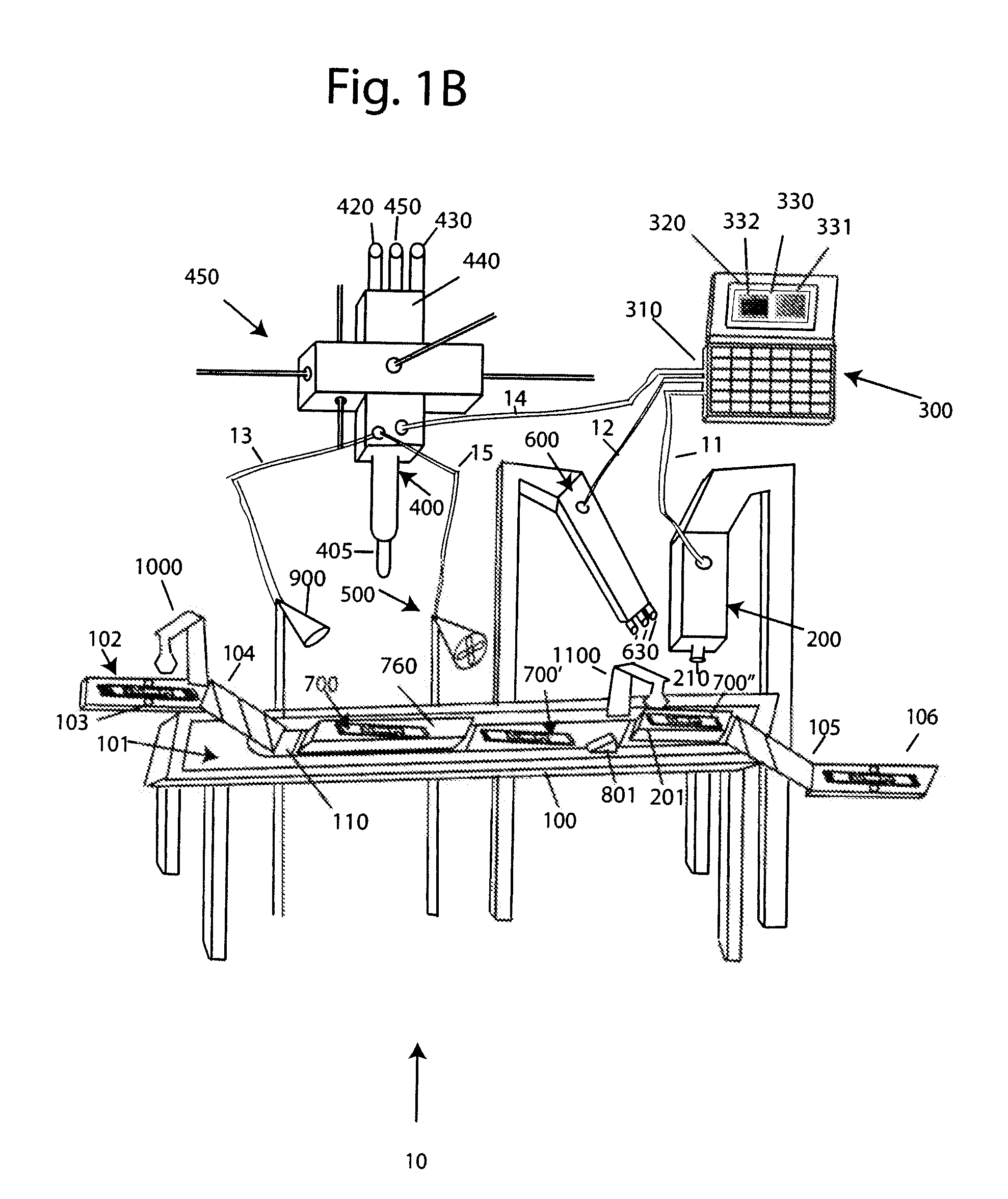

Sample Preparation System And Method for Processing Clinical Specimens

ActiveUS20080247914A1Reduce turnaround timeLow efficiencyAnalysis using chemical indicatorsMicrobiological testing/measurementRobotic systemsMolecular analysis

A system and method for automated handling of vials containing liquid medical specimens is disclosed. The robotic system processes the specimens for further downstream molecular analysis. The processing comprises automated vial cap removal, pipetting of the vial contents, transfer of the vial contents to a destination tray such as a multiwell plate, and recapping of the vial.

Owner:BECTON DICKINSON & CO

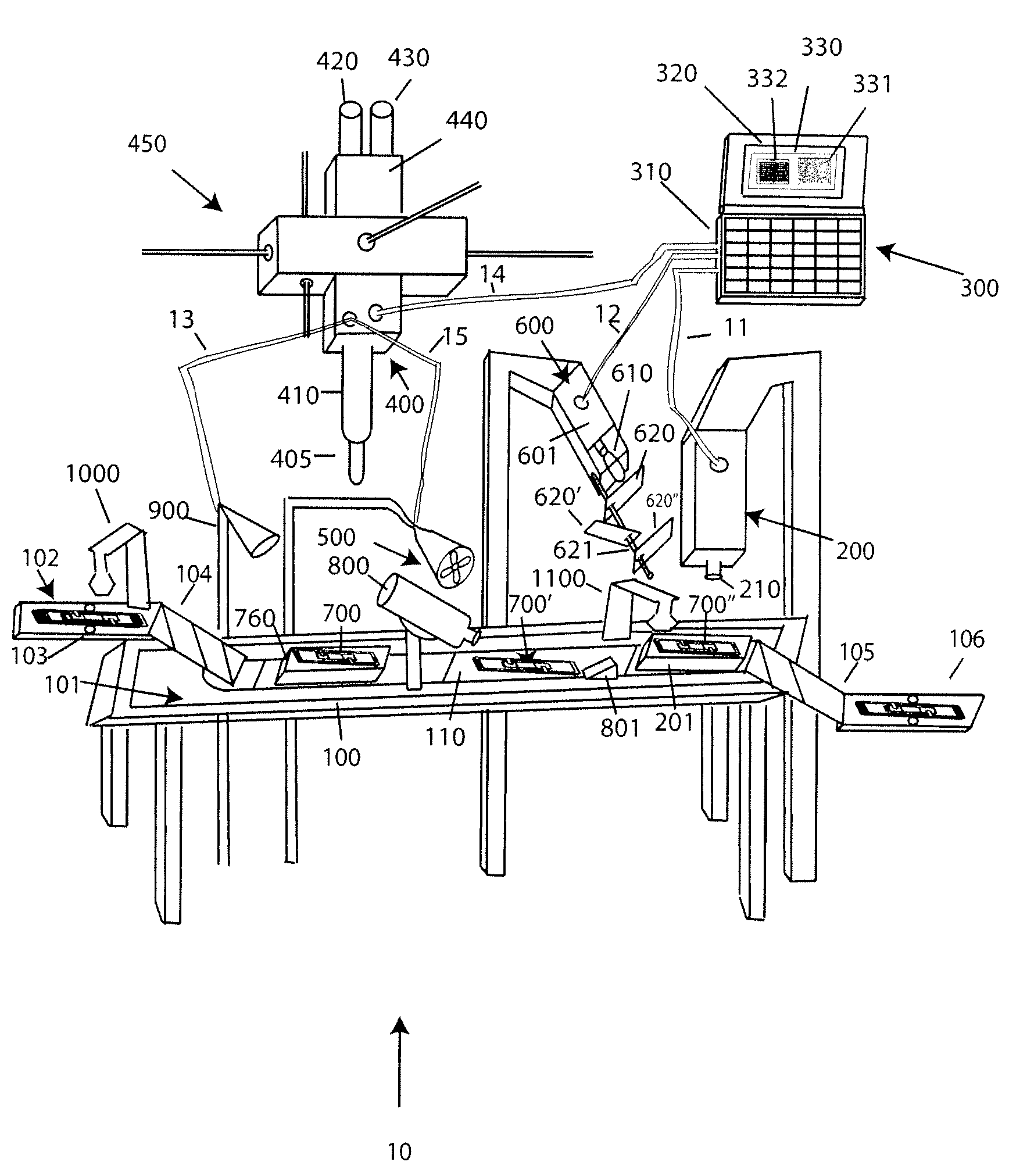

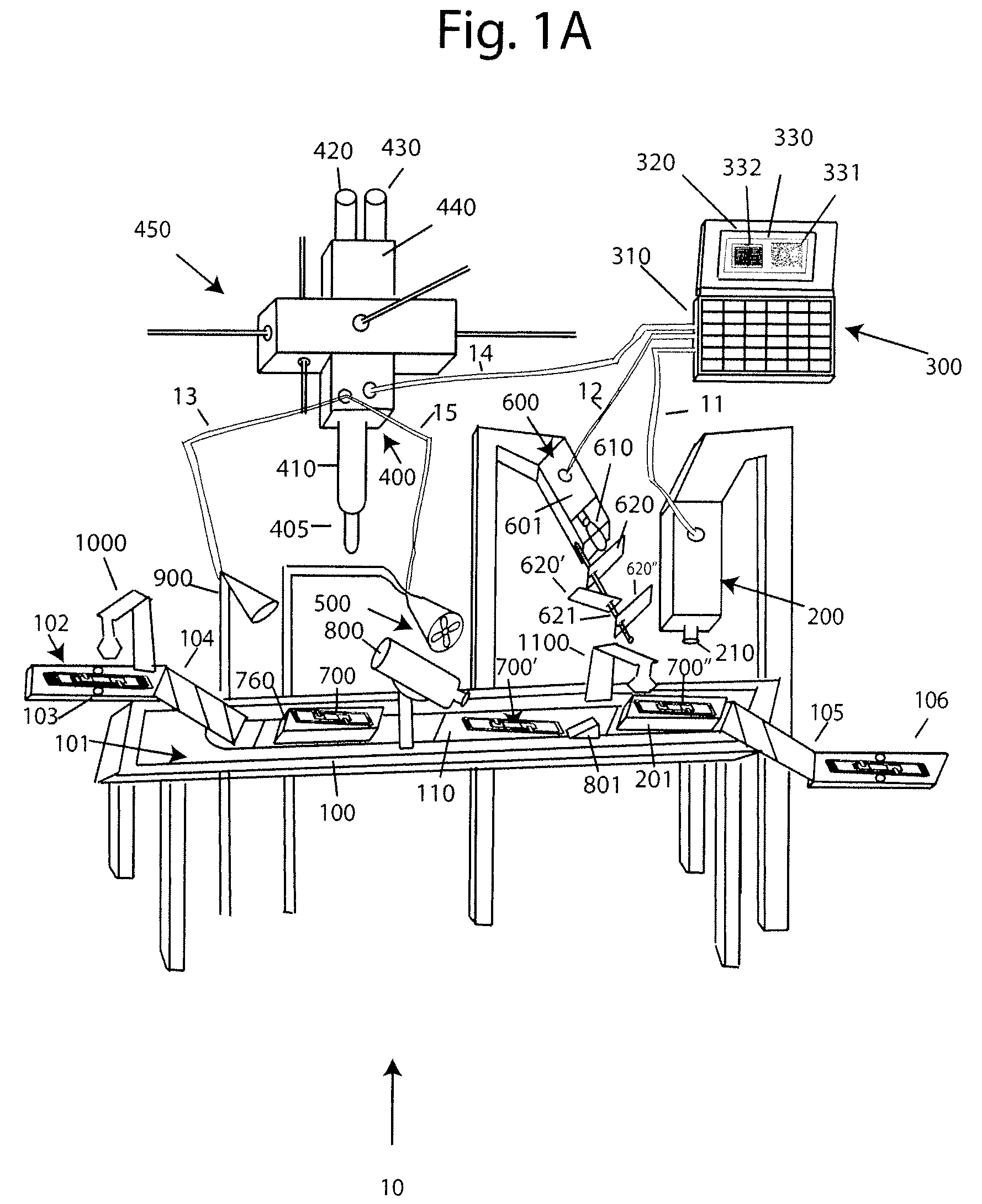

Systems and methods for analyzing body fluids

ActiveUS20110070606A1Improve accuracyLow costBioreactor/fermenter combinationsBiological substance pretreatmentsBody fluidVaginal tissue

Systems and methods analyzing body fluids contain cells including blood, bone marrow, urine, vaginal tissue, epithelial tissue, tumors, semen, and spittle are disclosed. The systems and methods utilize an improved technique for applying a monolayer of cells to a slide and generating a substantially uniform distribution of cells on the slide. Additionally aspects of the invention also relate to systems and method for utilizing multi-color microscopy for improving the quality of images captured by a light receiving device.

Owner:ROCHE DIAGNOSTICS HEMATOLOGY INC

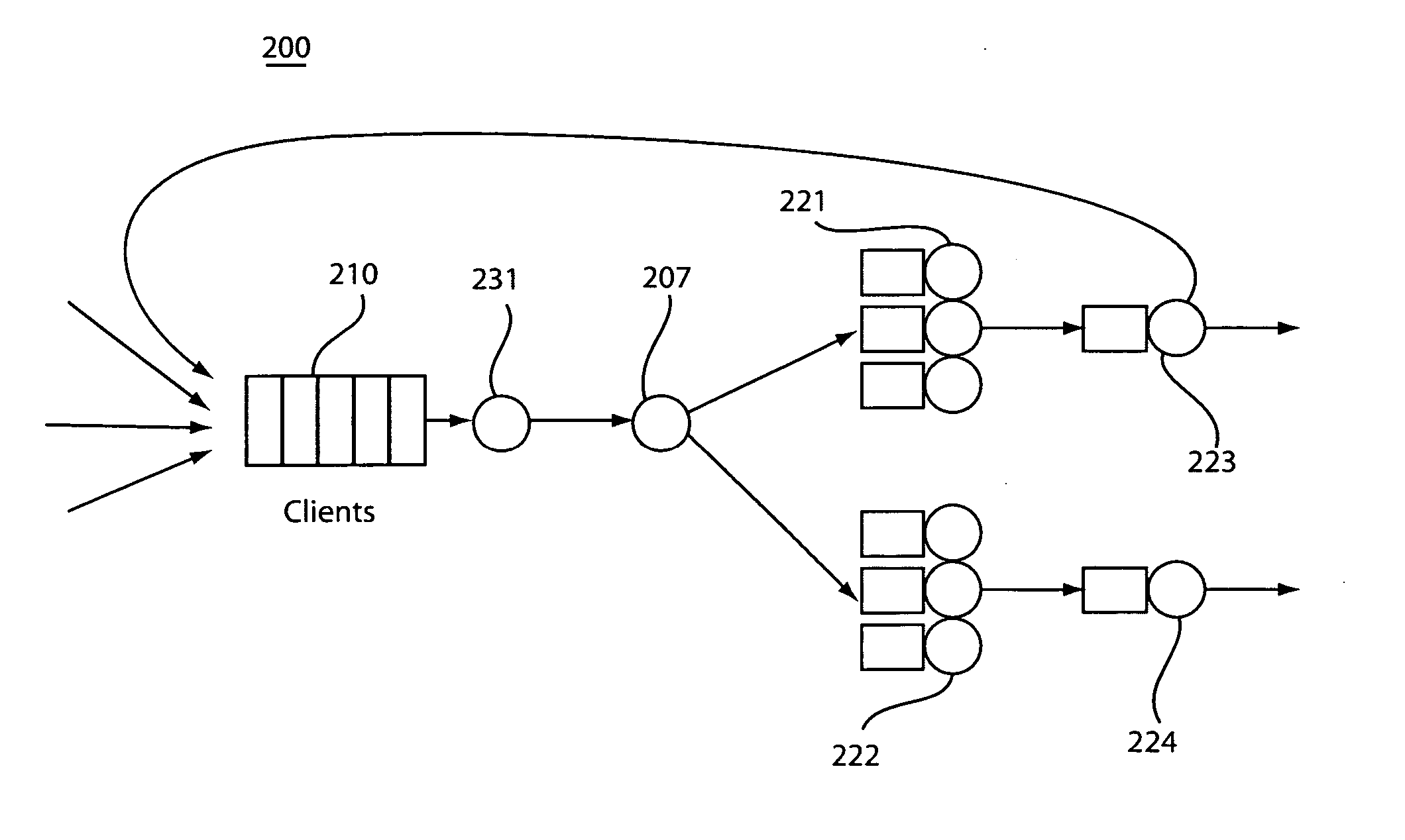

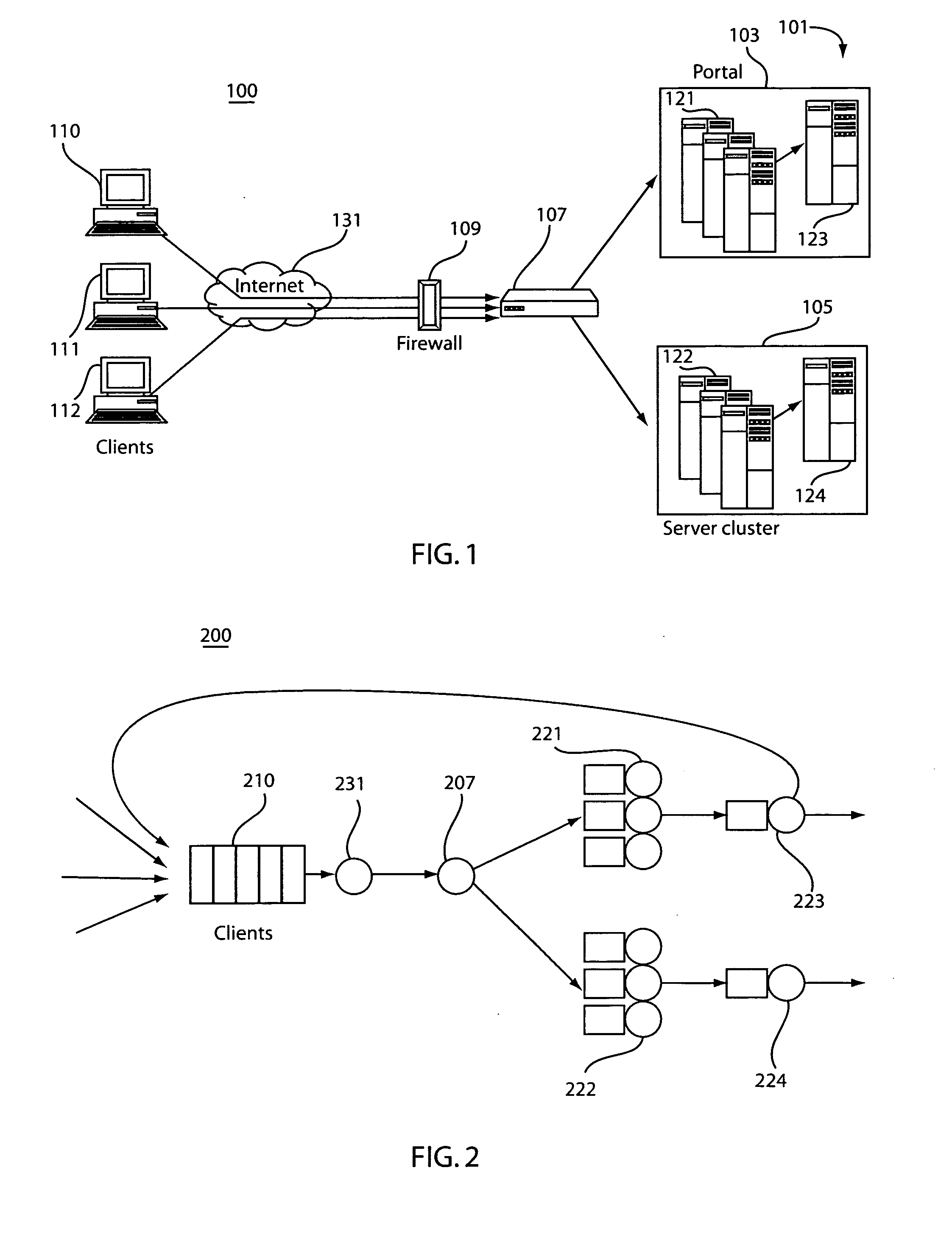

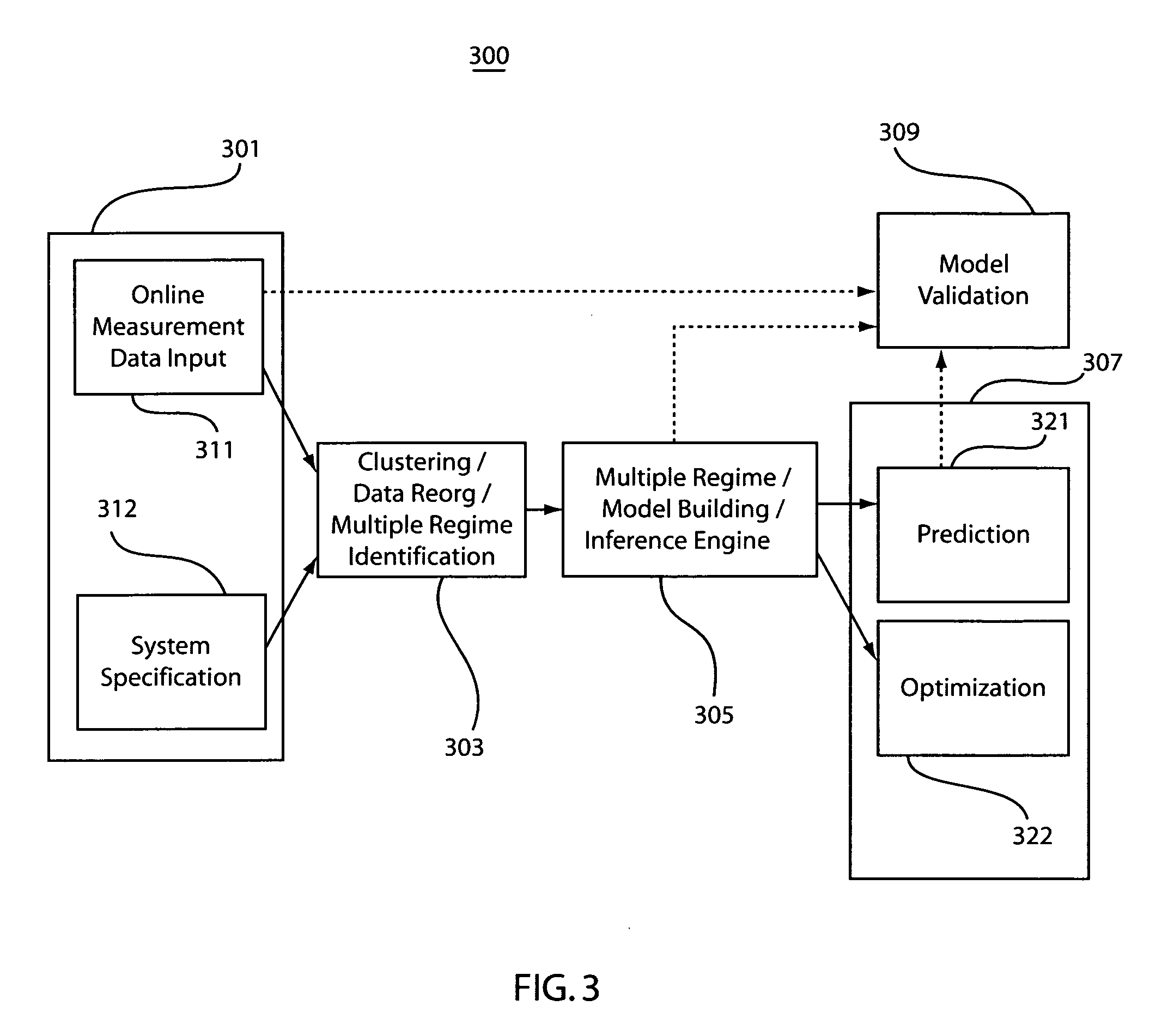

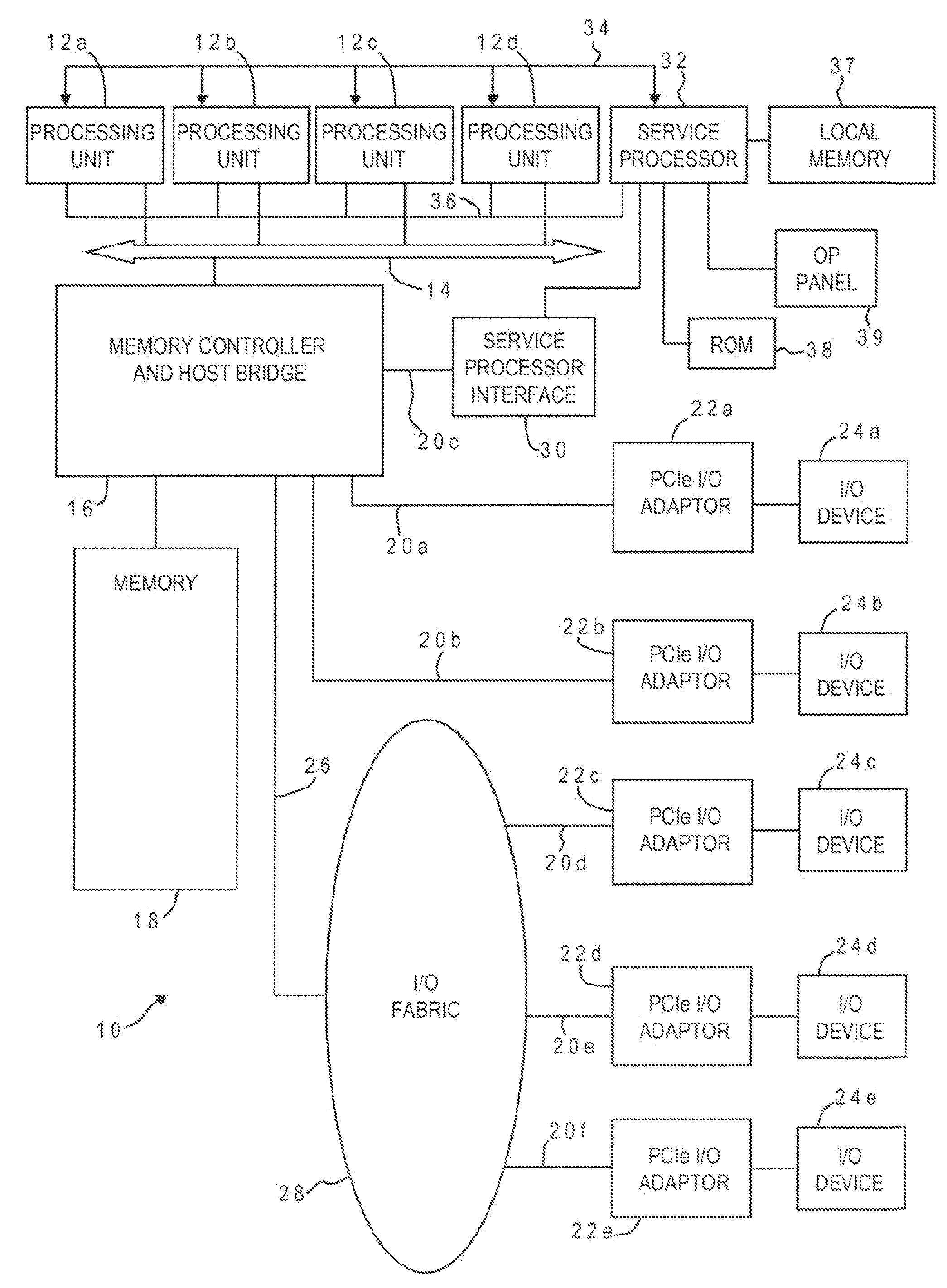

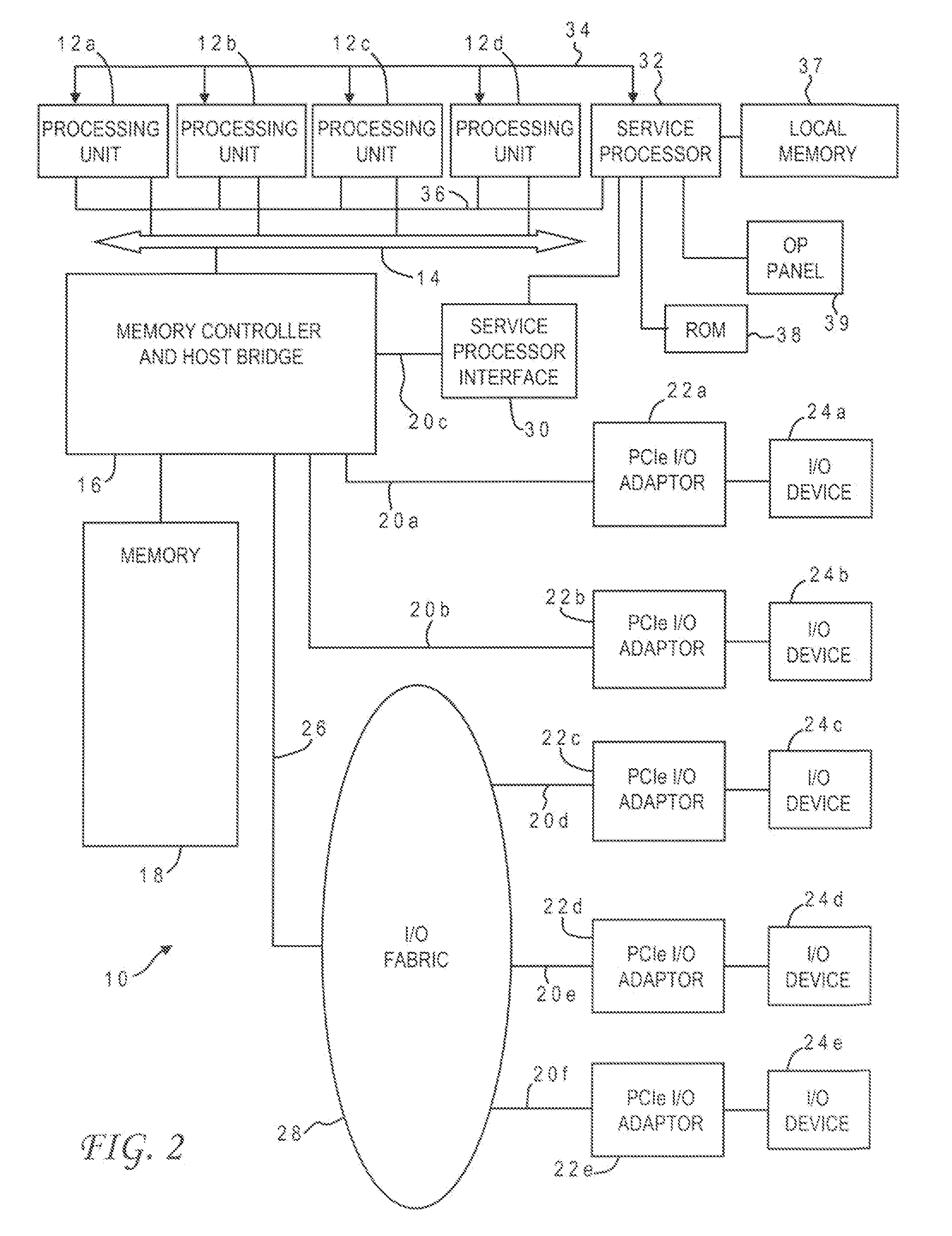

Method and system for on-line performance modeling using inference for real production it systems

ActiveUS20070168494A1Reduce equipmentReduce laborDigital computer detailsNuclear monitoringClustered dataCluster based

A system and method for performance modeling for an information technology (IT) system having a server(s) for performing a number of types of transactions includes receiving data for system topology and transaction flows and receiving performance measurement data for the IT system. The measurement data is clustered into multiple regimes based on similarities. Service demand and network delay parameters may be inferred based on clustered data.

Owner:IBM CORP

Sample preparation system and method for processing clinical specimens

ActiveUS7985375B2Reduce turnaround timeLow efficiencyAnalysis using chemical indicatorsMicrobiological testing/measurementRobotic systemsMolecular analysis

Owner:BECTON DICKINSON & CO

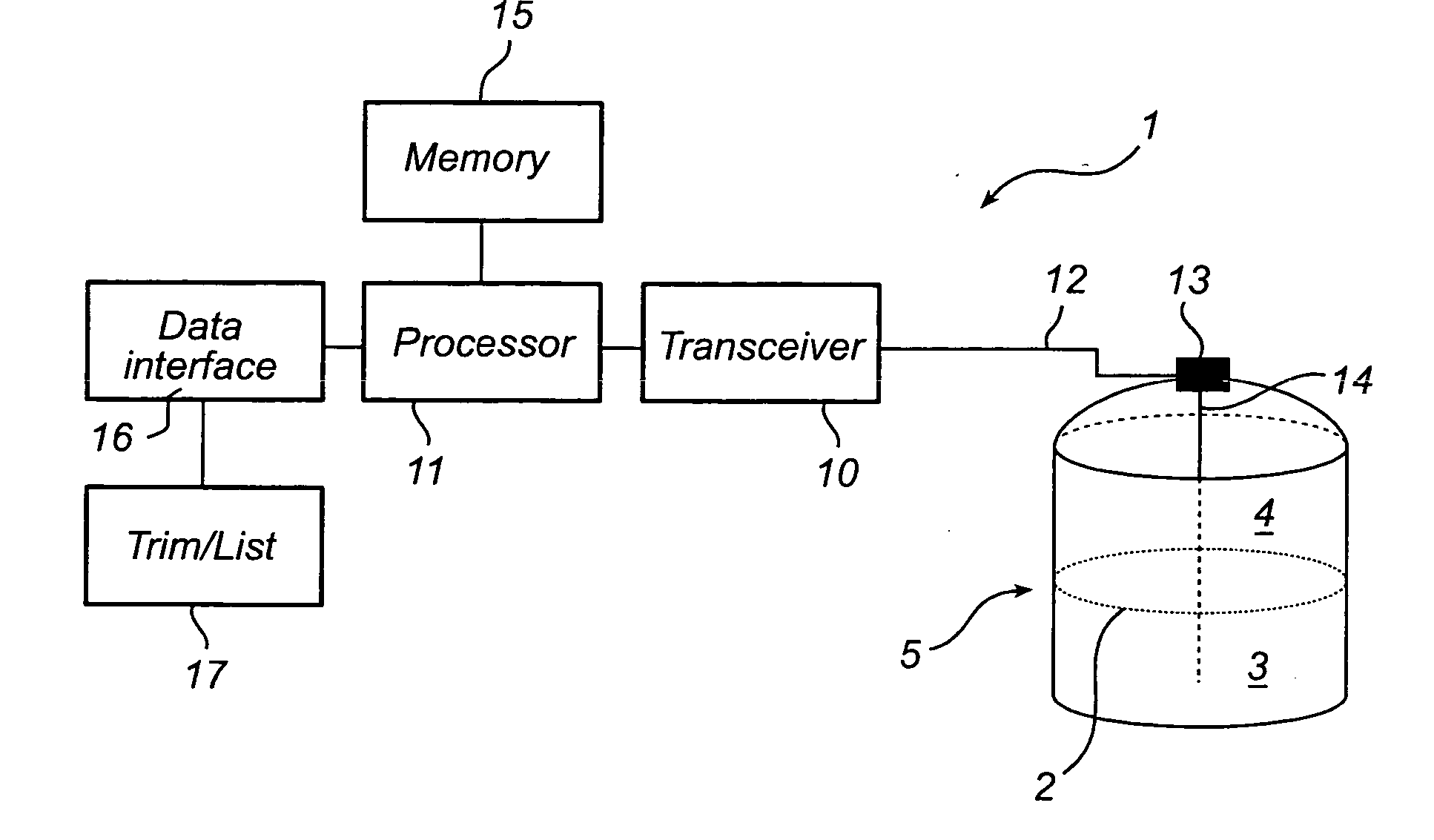

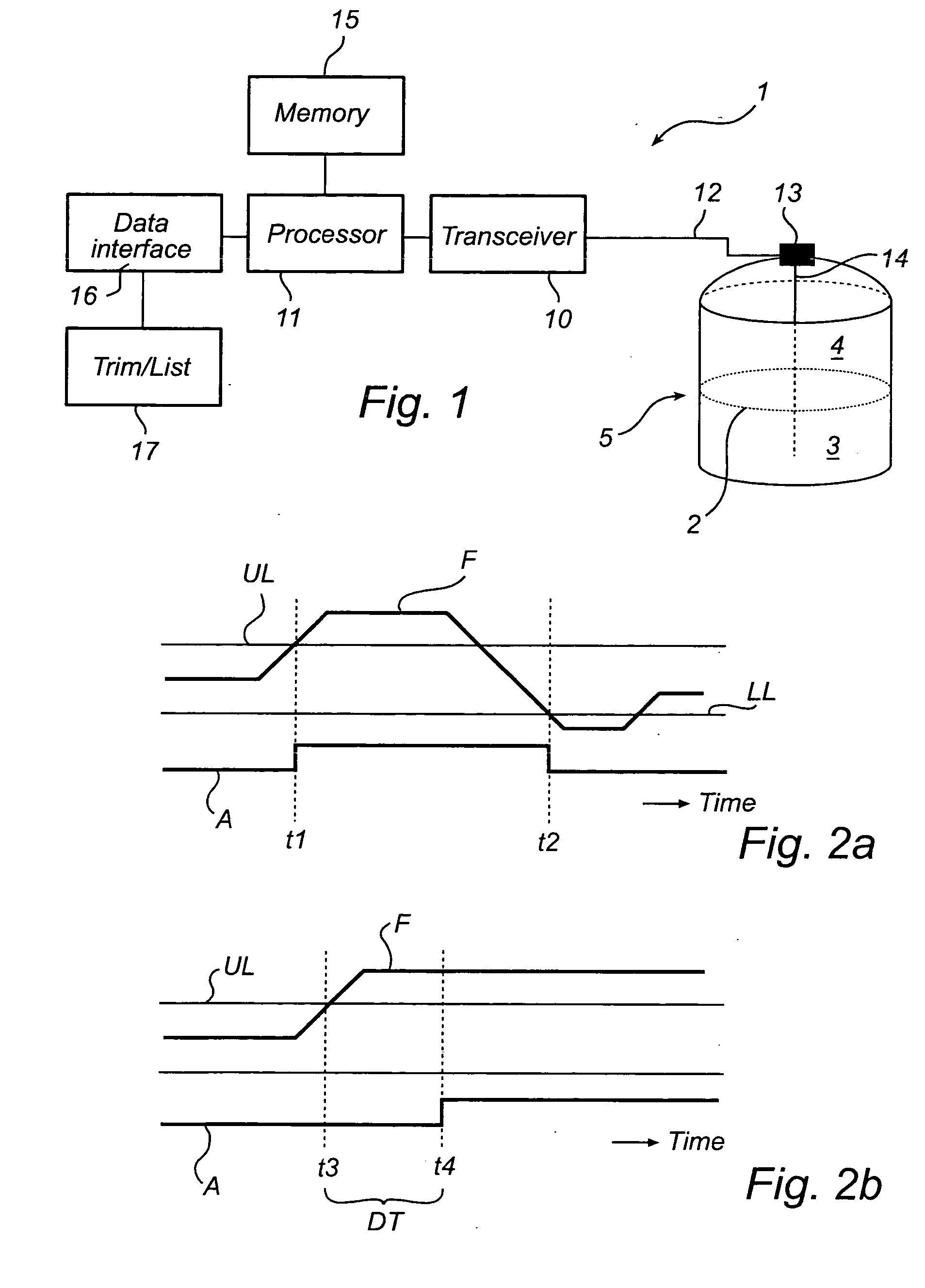

Radar level gauge system with variable alarm limits

InactiveUS20060044145A1Improve securityReduce riskAnalysing solids using sonic/ultrasonic/infrasonic wavesTesting/calibration apparatusRadarFilling materials

A radar level gauge system for determining the filling level of a filling material in a tank is disclosed. The system comprises a transmitter for transmitting measuring signals towards the surface of the filling material; a receiver for receiving echo signals from the tank; processing circuitry for determining the filling level of the tank based on said echo signal and adapted to compare said determined filling level with at least one preset threshold value and to produce an alarm signal in dependence of said threshold value; and a storage means for storing the preset threshold value, wherein said threshold value in said storage means is replaceable and / or adjustable. The alarm signal could indicate high level and / or overfill. The possibility of adjusting / replacing the threshold values enables adjustment of the alarm levels when the system is already installed. A corresponding method of operation is also disclosed

Owner:ROSEMOUNT TANK RADAR

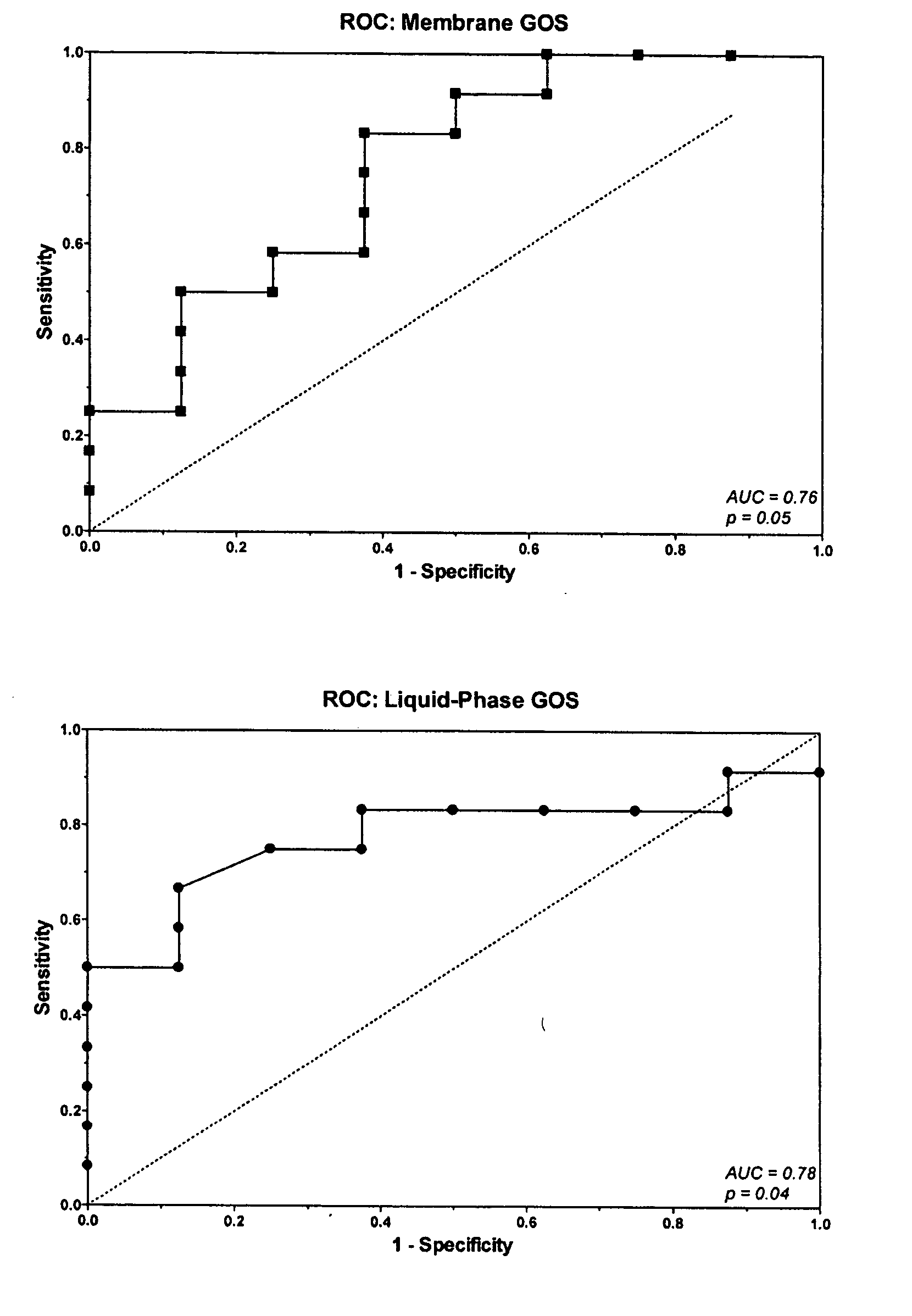

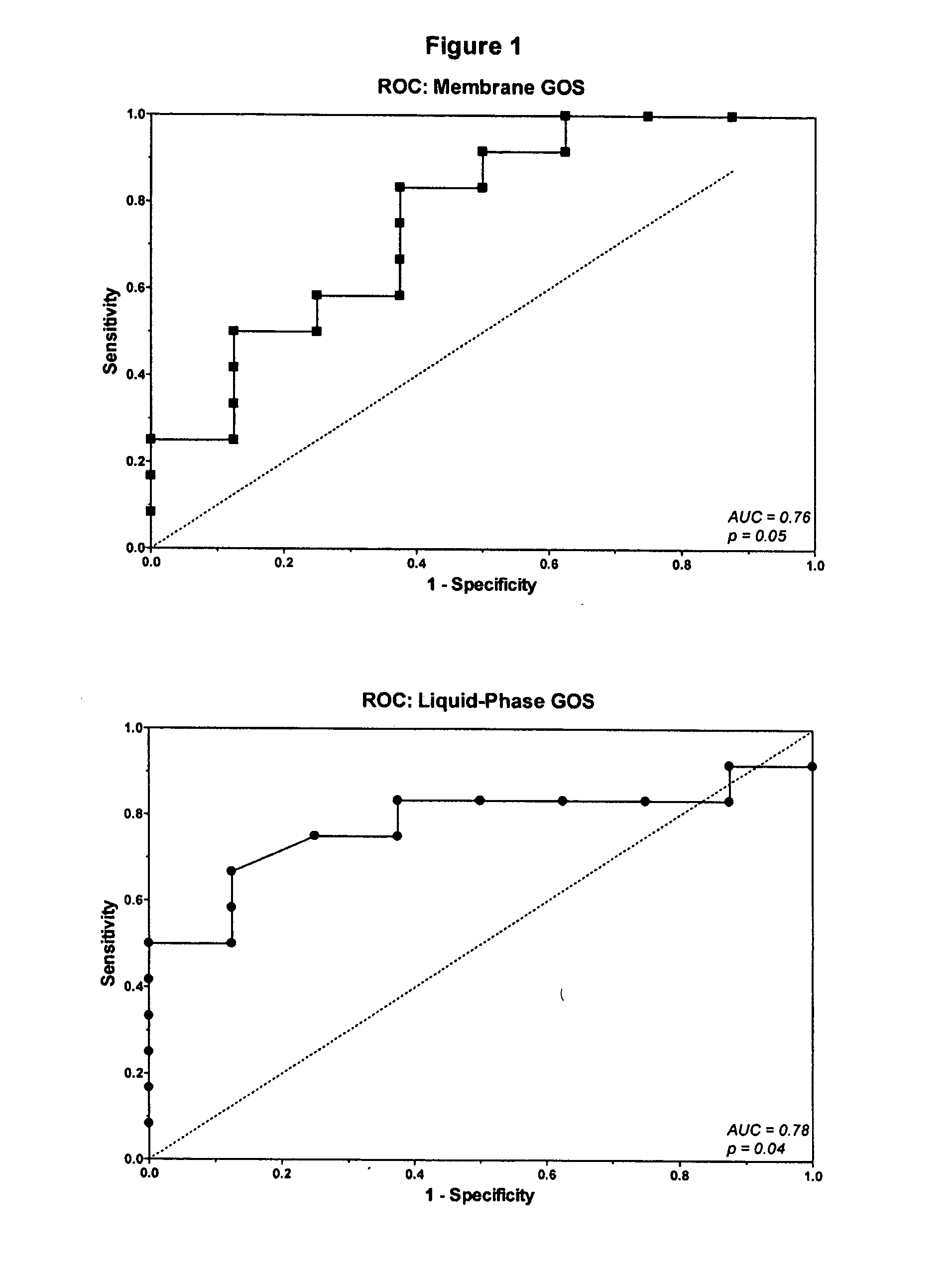

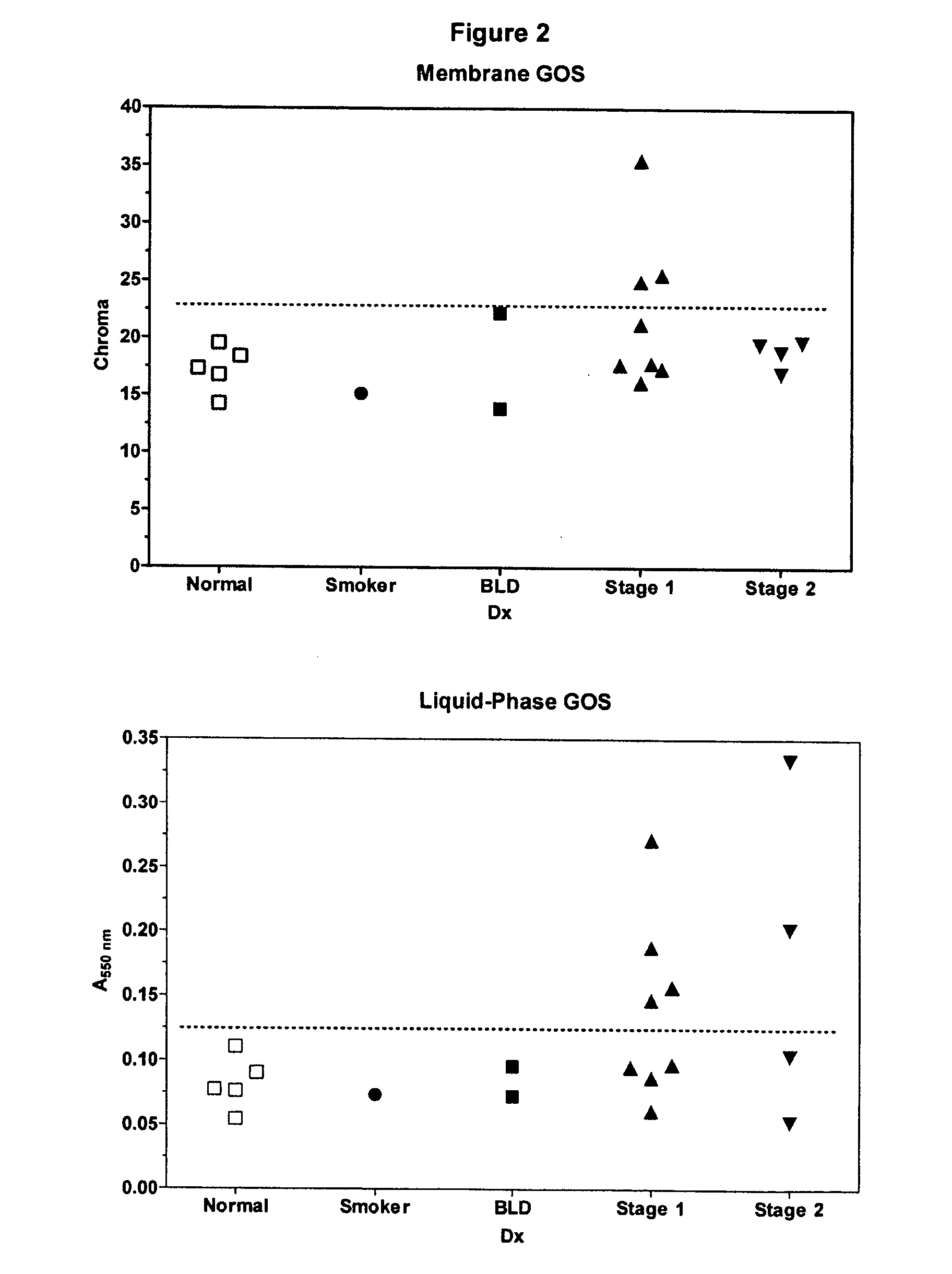

Liquid-phase galactose oxidase-schiff's assay

InactiveUS20070065893A1Less timeReduce turnaround timeMicrobiological testing/measurementBiological material analysisAldehydeLactose

The invention provides an improved method for detecting cancer or a precancerous condition in a sample using an oxidation agent, such as galactose oxidase, and an aldehyde detection agent, such as Schiff's reagent that does not require the sample to be immobilized onto a solid support. The invention also provides kits comprising the components necessary for carrying out the methods of the invention.

Owner:CARTE CAROL +2

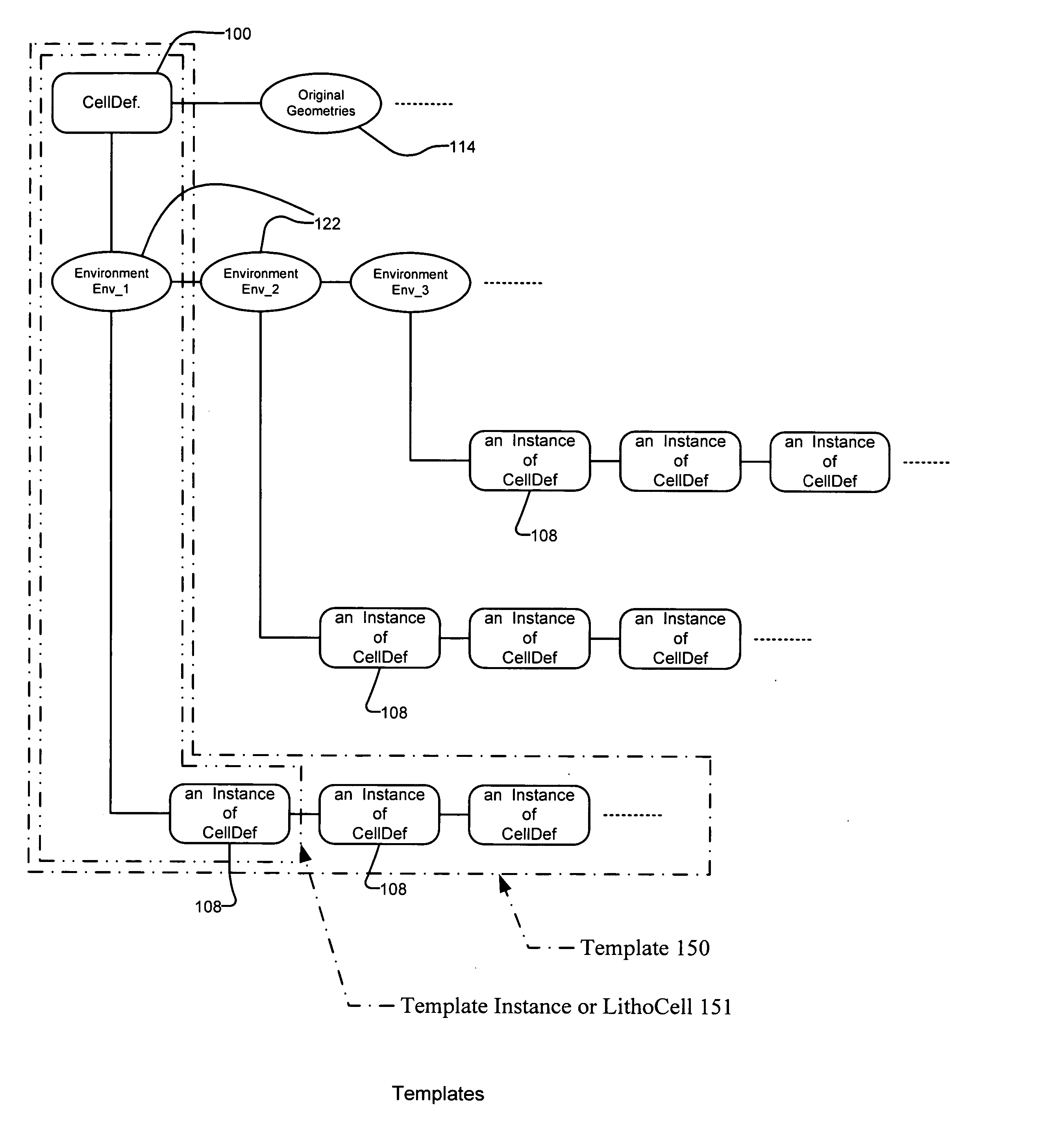

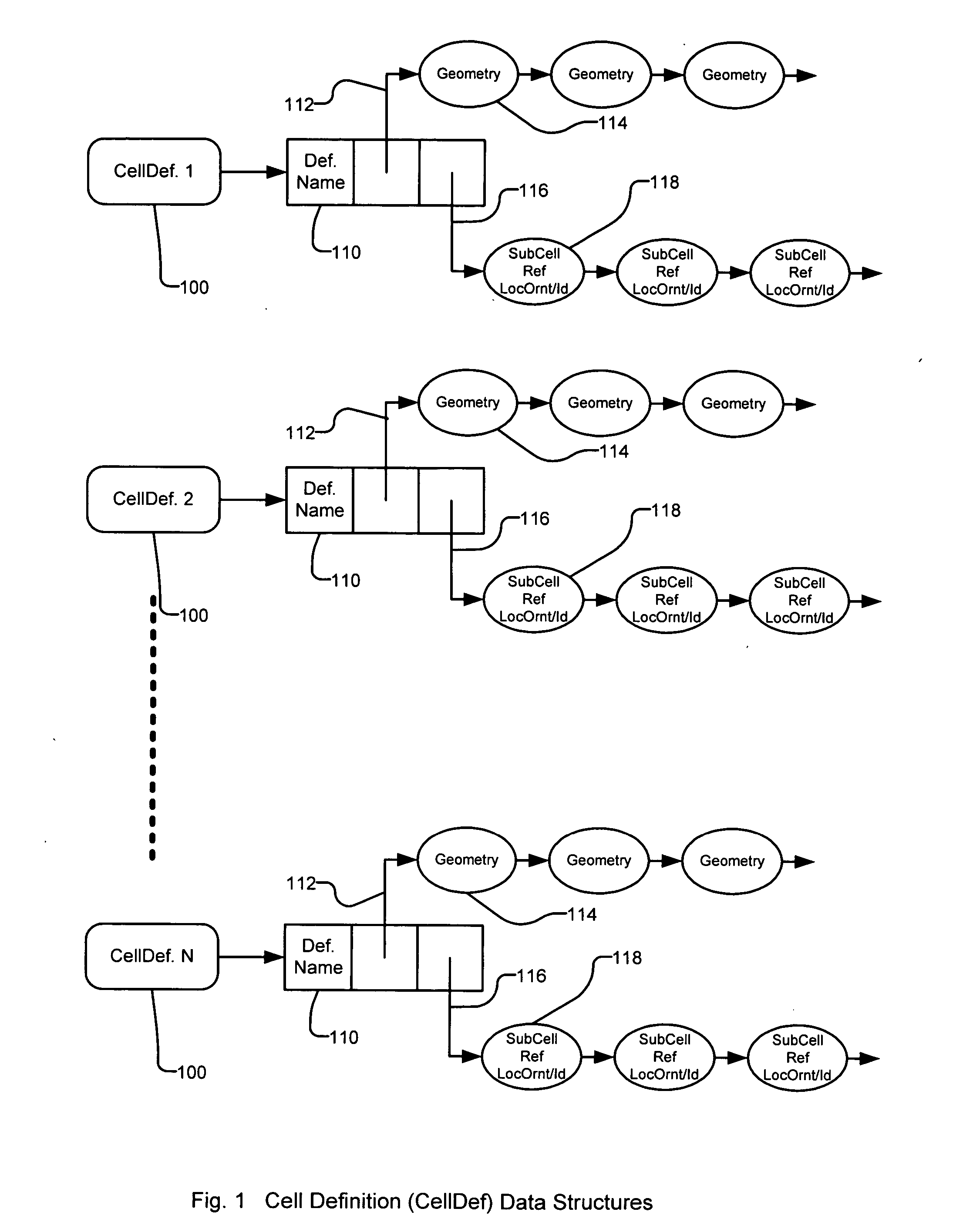

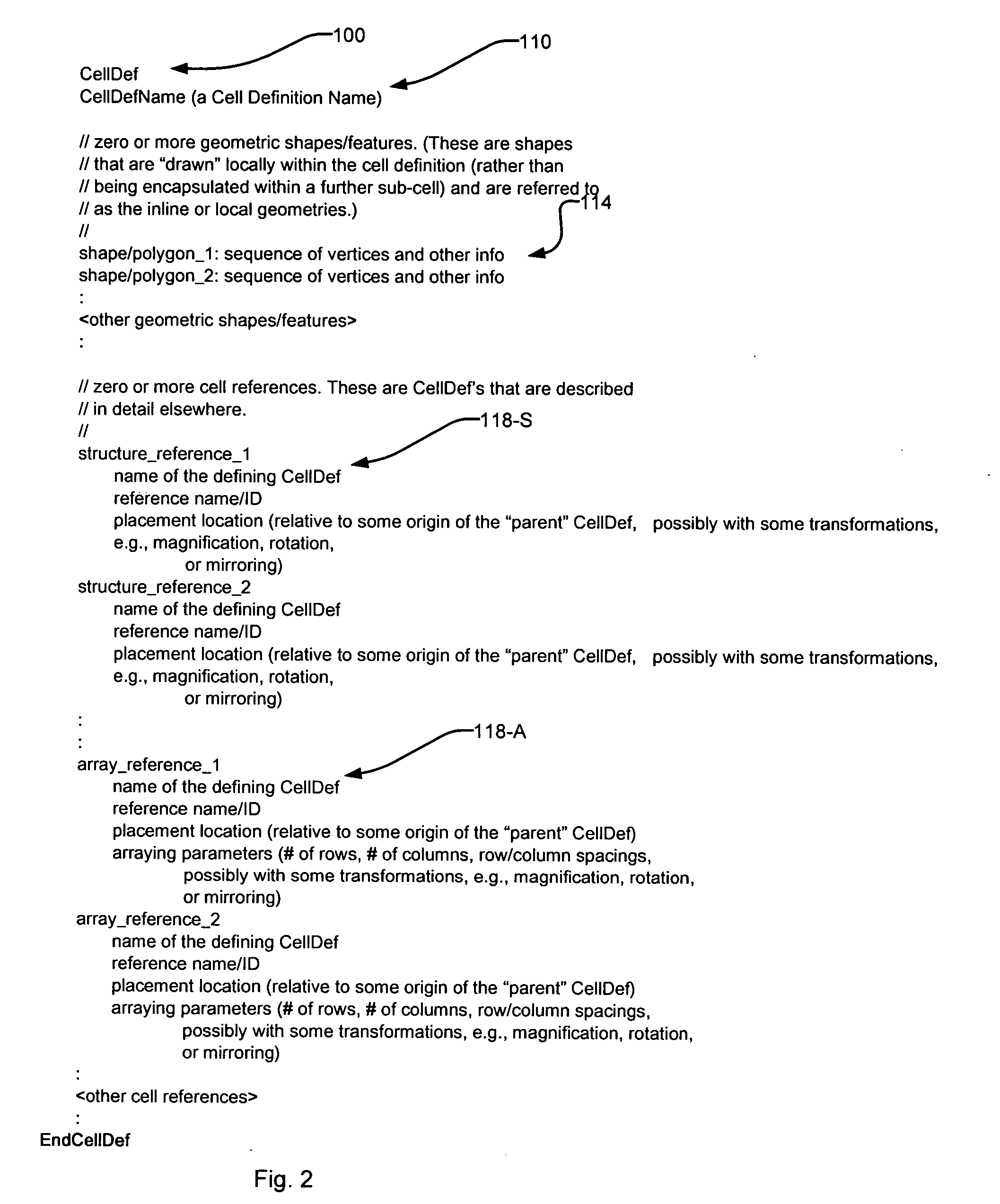

Method and system for reticle-wide hierarchy management for representational and computational reuse in integrated circuit layout design

ActiveUS20060143589A1Maximize reuseSaving in representational data volumeElectric discharge tubesOriginals for photomechanical treatmentComputation reuseComputer architecture

A hierarchical representation encapsulates the detailed internal composition of a sub-circuit using the notion of a cell definition (a CellDef). The CellDef serves as a natural unit for operational reuse. If the computation required for the analysis or manipulation (e.g. parasitic extraction, RET, design rule confirmation (DRC), or OPC) based on a CellDef or one cell instance can be applied, with no or minimal additional effort, to all or a significant subset of other instances of the cell, very substantial reduction in computational effort may be realized. Furthermore, a hierarchical representation also allows for the partitioning of the overall analysis / manipulation task into a collection of subtasks, e.g. one per CellDef. Multiple jobs may then be distributed across a large number of computational nodes on a network for concurrent execution. While this may not reduce the aggregate computational time, a major reduction in the overall turnaround time (TAT) is in itself extremely beneficial.

Owner:CADENCE DESIGN SYST INC

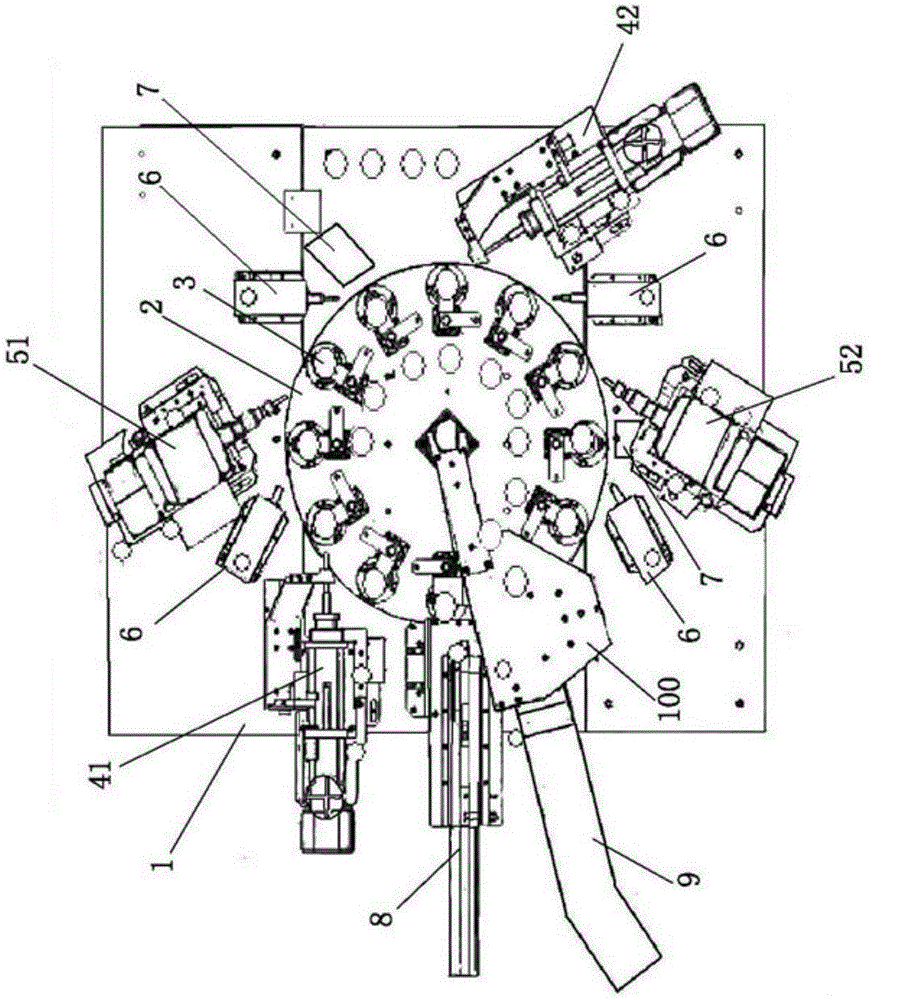

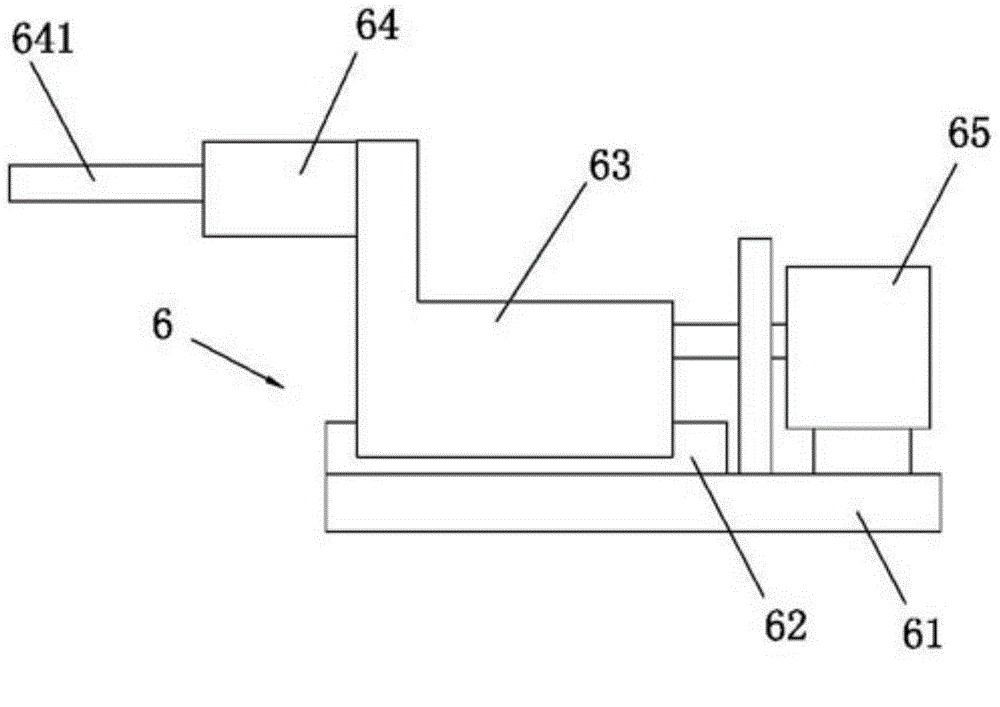

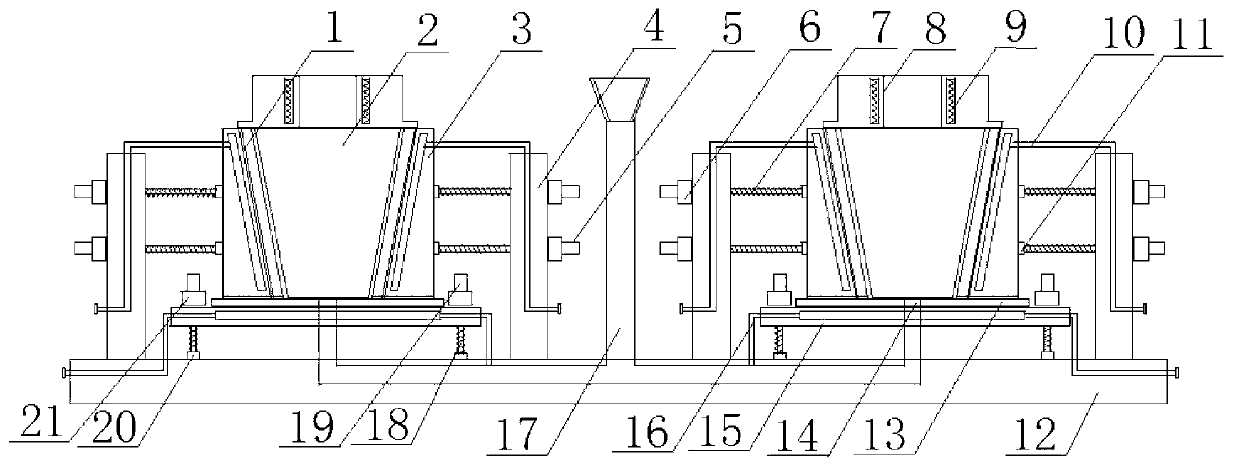

Automatic processing machine for bearing inner ring screw hole

InactiveCN104308539AReduce labor intensityReduce manufacturing costMeasurement/indication equipmentsOther manufacturing equipments/toolsProcessing costUltimate tensile strength

The invention provides an automatic processing machine for a bearing inner ring screw hole. The automatic processing machine comprises an engine base and a turntable, wherein the turntable can rotate in an indexing intermittent mode under the action of a power transmission device; the periphery of the turntable is uniformly provided with clamps for clamping workpieces; drilling devices, tapping devices, hole detection devices, burr filing devices and feeding and discharging mechanical arms are arranged around the turntable; all the devices are corresponding to positions where the clamps on the turntable stay; the hole detection devices are arranged on the downstream sides of the drilling devices and tapping devices; the burr filing devices operate after the completion of screw hole detection; the feeding and discharging mechanical arms are respectively linked with a feeding device and a discharging device. By adopting the automatic processing machine, feeding, drilling, tapping, burr removing, and discharging can be automatically realized, and only one operator is needed for carrying out management and monitoring; the labor intensity is greatly reduced, the production efficiency is high, the processing cost is low, and the product quality is stable.

Owner:FK BEARING GRP

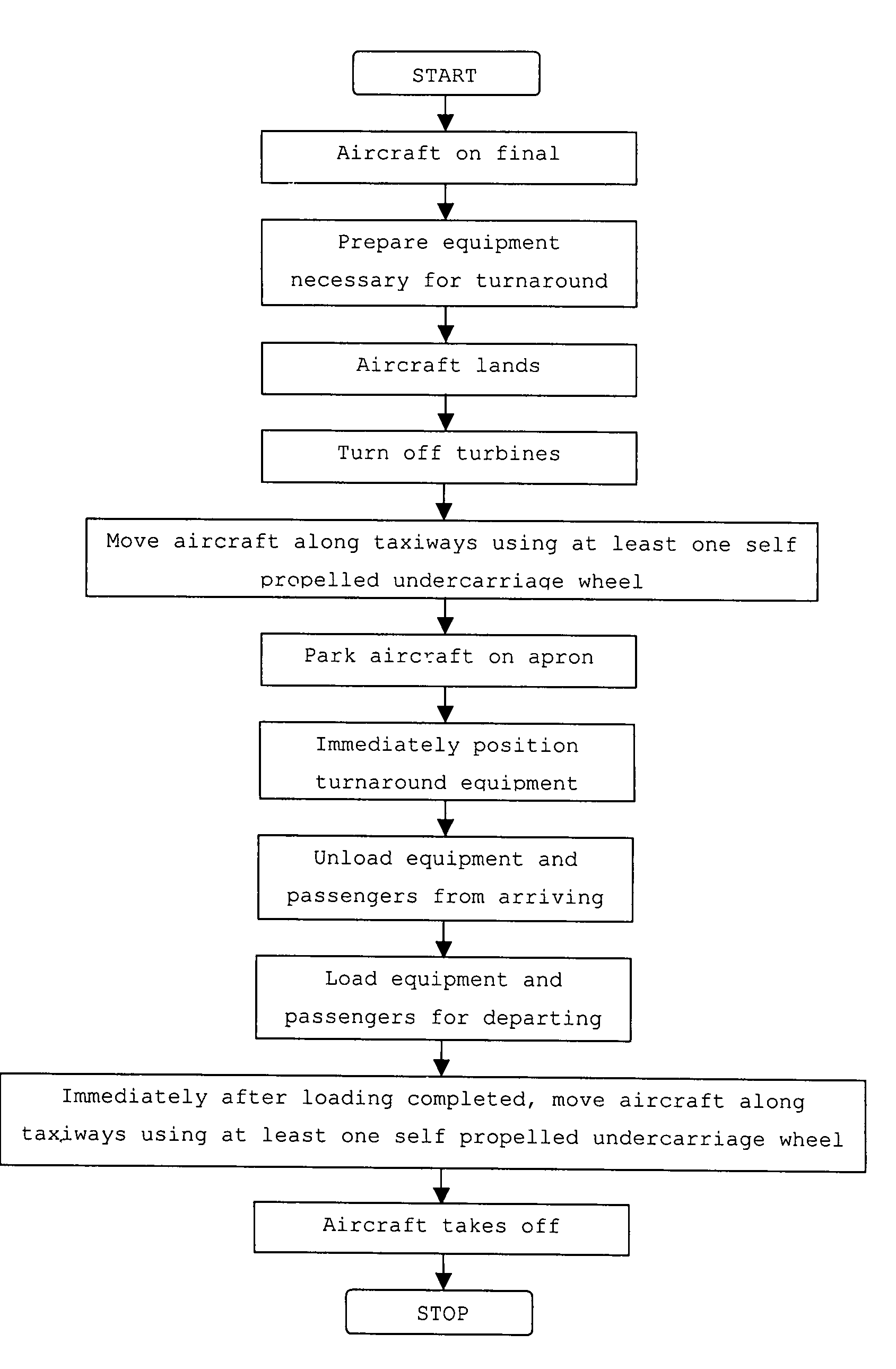

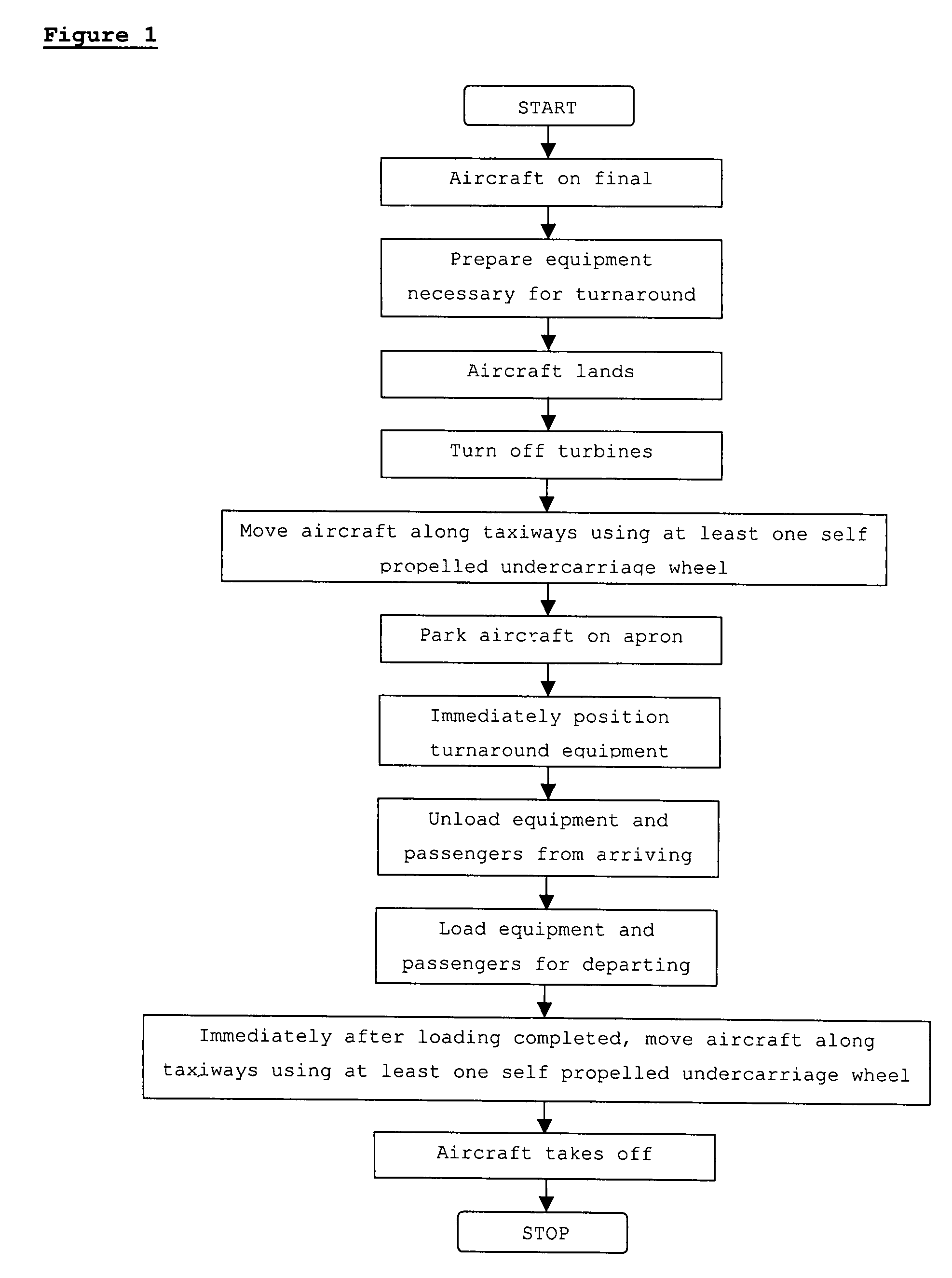

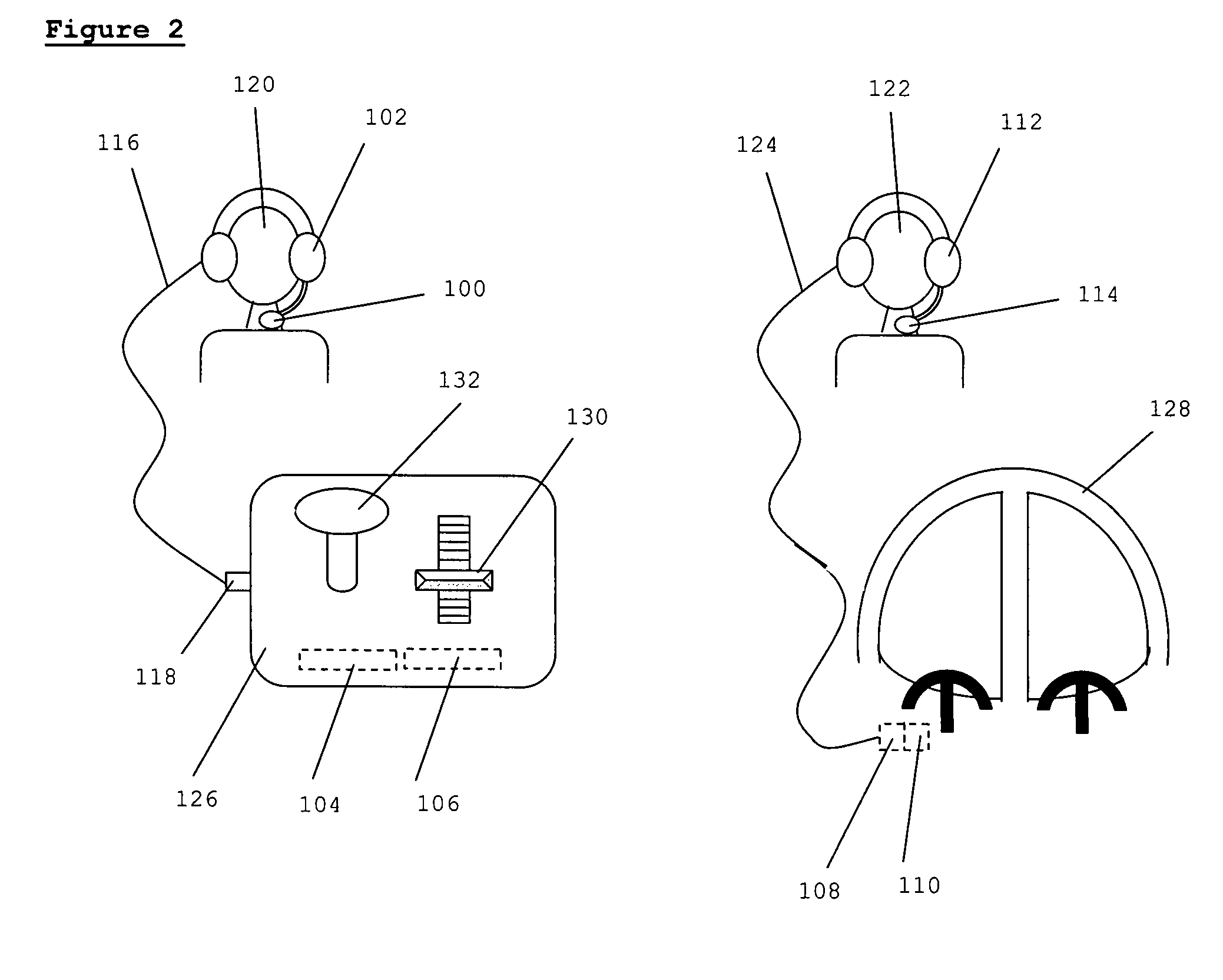

Turnaround methods

ActiveUS7891609B2Reduce turnaround timeImprove efficiencyAnalogue computers for vehiclesEnergy efficient operational measuresVoice communicationFlight vehicle

A method for reducing the turnaround time of an aircraft having at least one self-propelled undercarriage wheel comprising the step of: moving the aircraft to a required location using at least one self-propelled undercarriage wheel; wherein thrust equipment, (e.g. turbines) are turned on only when needed for takeoff or prior to landing, and are turned off until takeoff or after landing; whereby departing equipment, arriving equipment, and turnaround equipment are not at risk from operating thrust equipment, (e.g. turbines). An apparatus for reducing the turnaround time of an aircraft is disclosed comprising a control unit for facilitating voice communication between a pilot and ground staff. Said control unit may further comprise a control arm for inputting the required direction of movement of said nosewheel; means for transmitting direction information to said self-propelled nosewheel; means for receiving direction information at said self-propelled nosewheel; and means for controlling the direction of said nosewheel. The control unit may also comprise means for turning on and off an APU, parking brakes, and other aircraft features.

Owner:BOREALIS TECH LTD

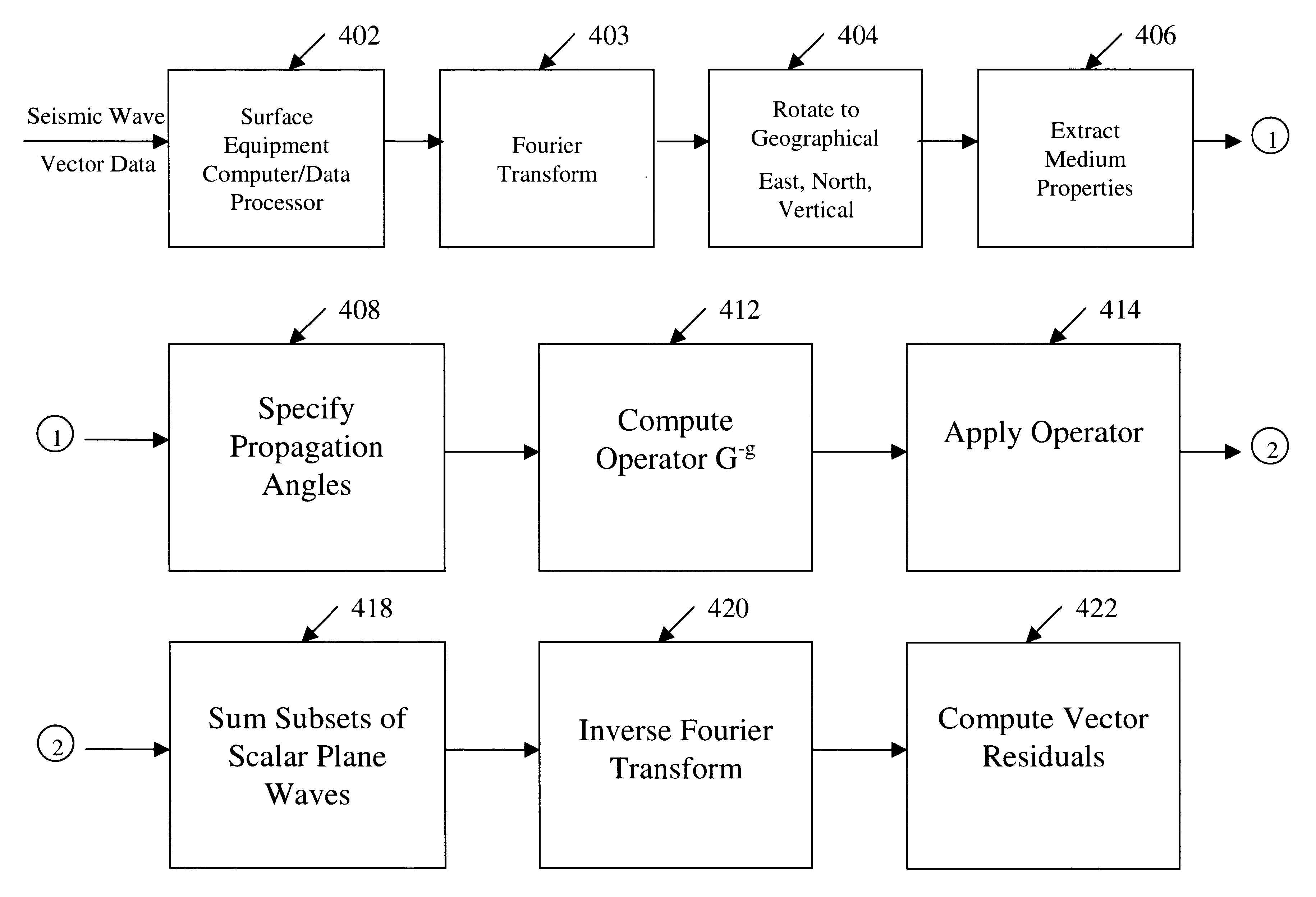

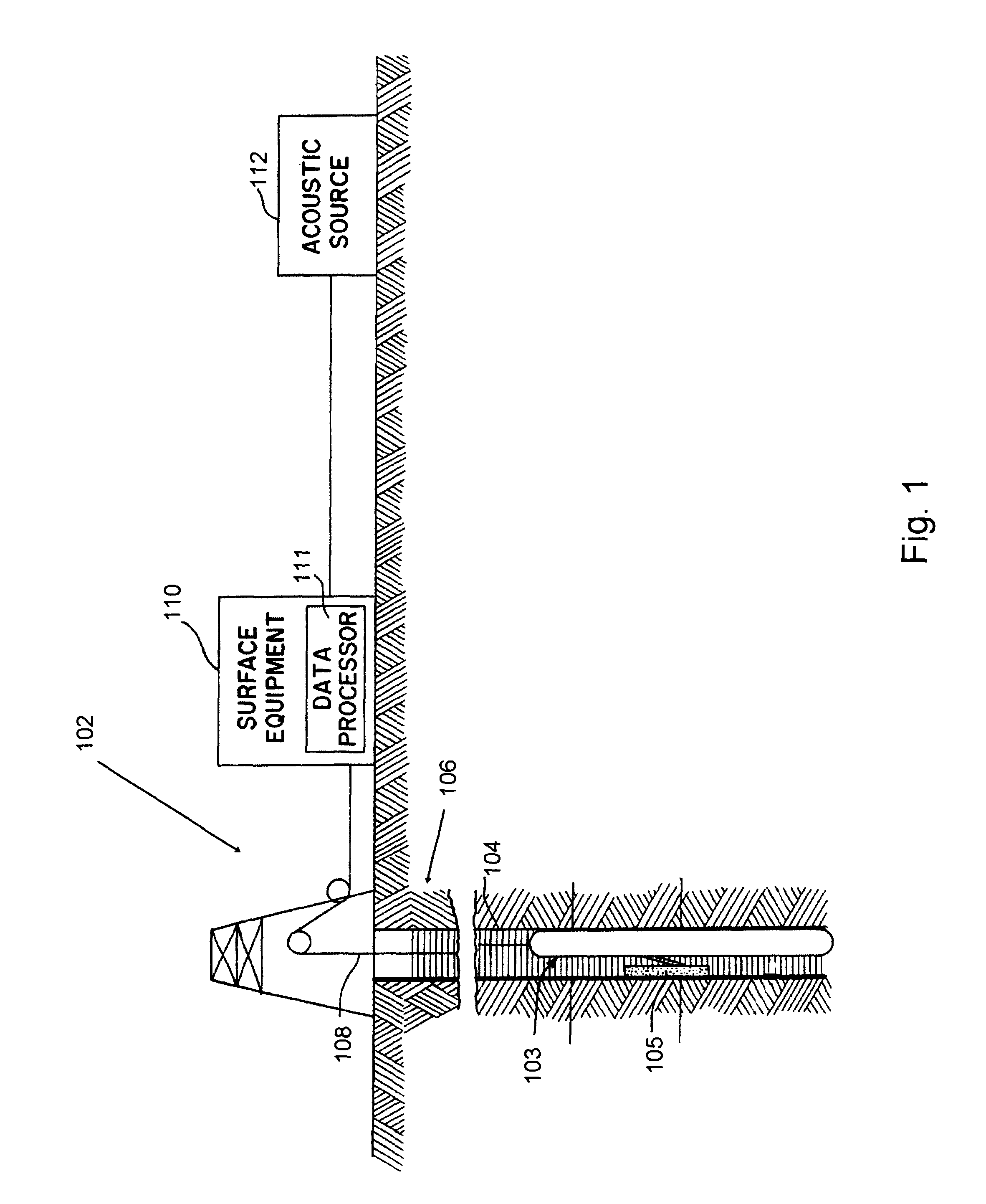

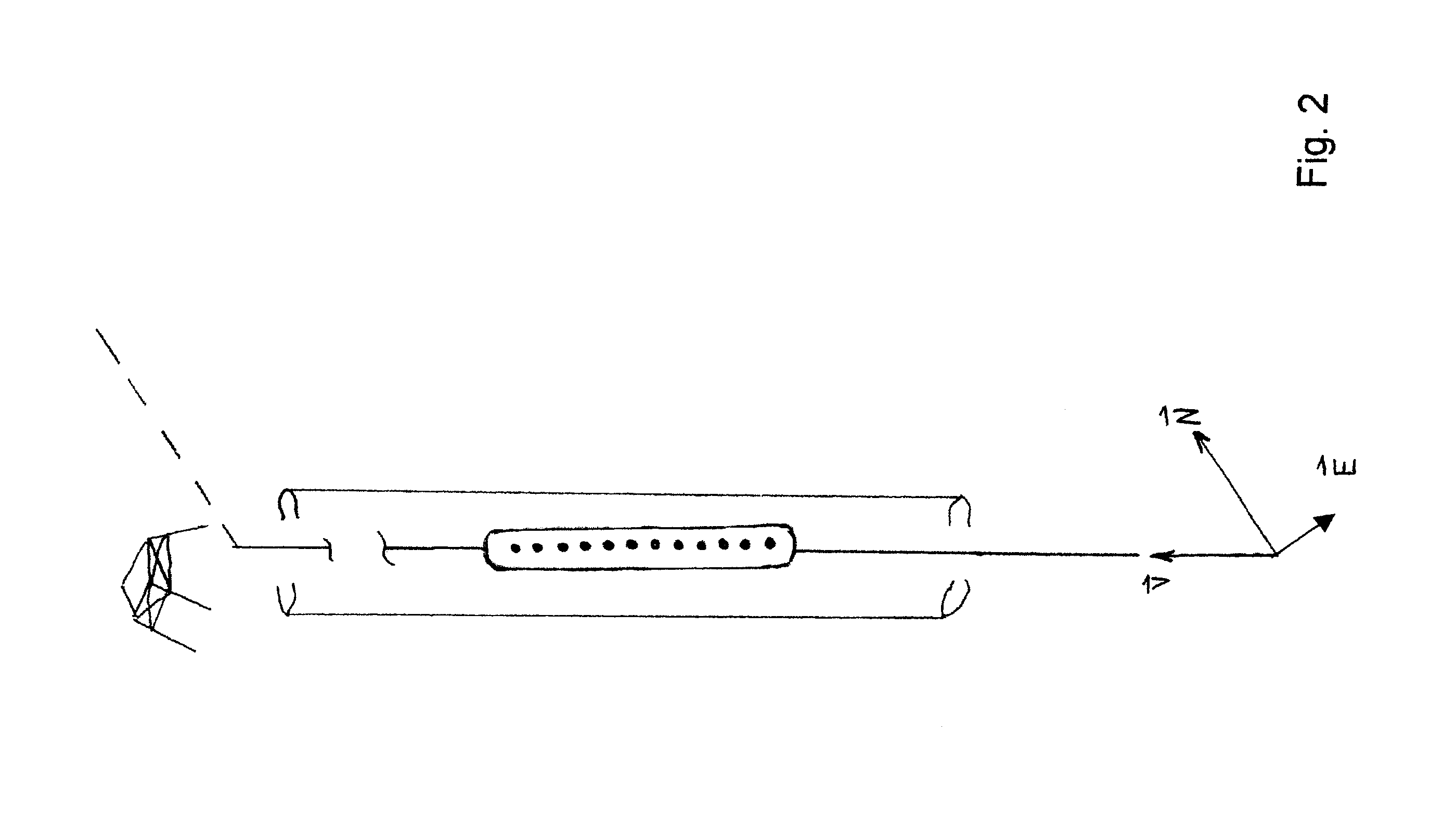

Method and apparatus for anisotropic vector plane wave decomposition for 3D vertical seismic profile data

InactiveUS6748330B2Simplify workEasy to separateSeismic signal processingSeismology for water-loggingEigen analysisVertical seismic profile

A wavefield separation method and apparatus for 3D VSP data, which handles arbitrary 3D source and receiver geometries, and common shot 3C data oriented to North, East and Vertical geographical coordinates and makes use of anisotropic medium properties at the downhole receivers. When given a range of propagation angles, slowness and polarization vectors are computed for each plane wave and a linear system is solved at each frequency to yield the scalar plane-wave amplitudes. A novel regularization scheme is used that obviates the need for eigen analysis of the steering matrix. Sums within subsets of these scalar plane waves are constructed to provide up and down qP (P), qS (Sv) and Sh wavefields. Vector residuals can be computed for parameter testing, quality control and imaging purposes.

Owner:SCHLUMBERGER TECH CORP

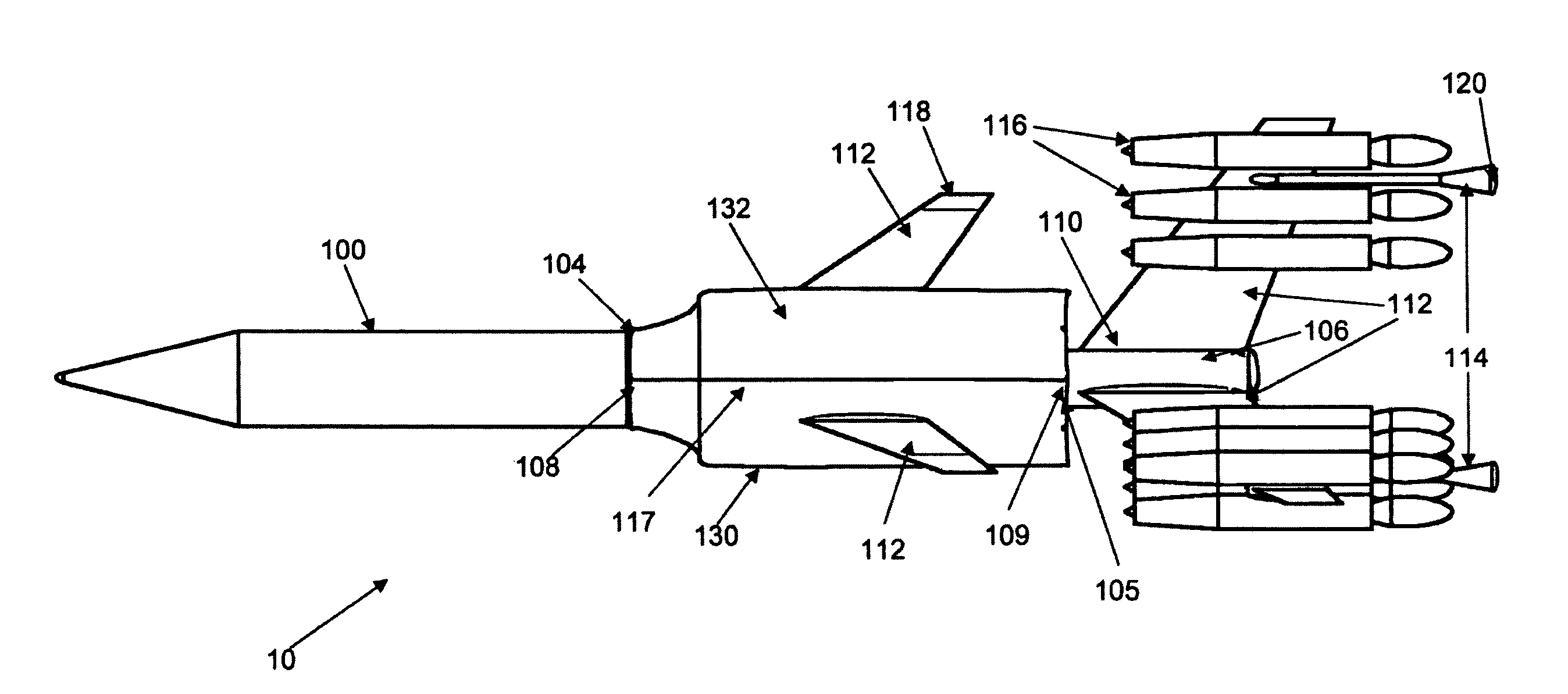

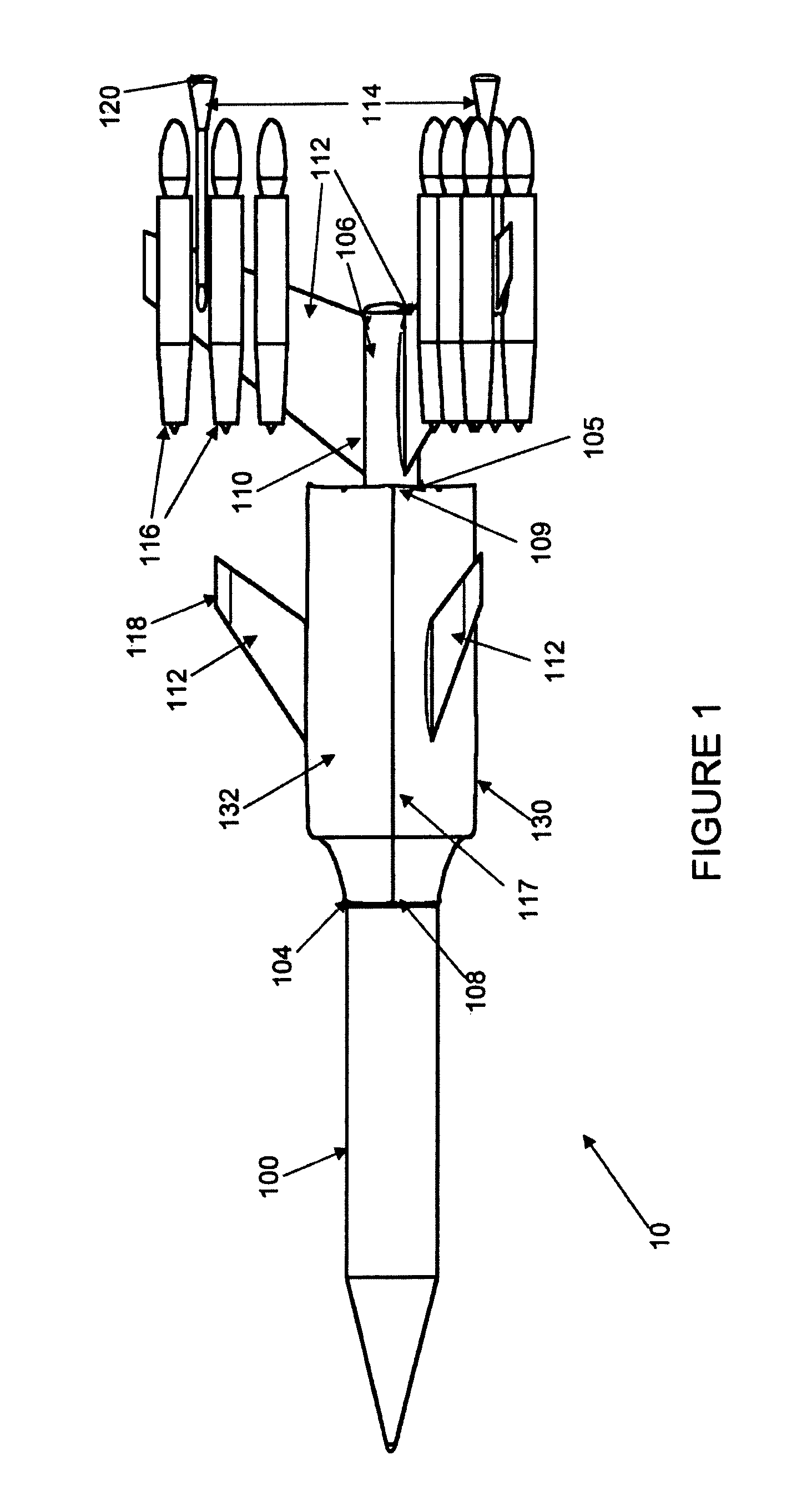

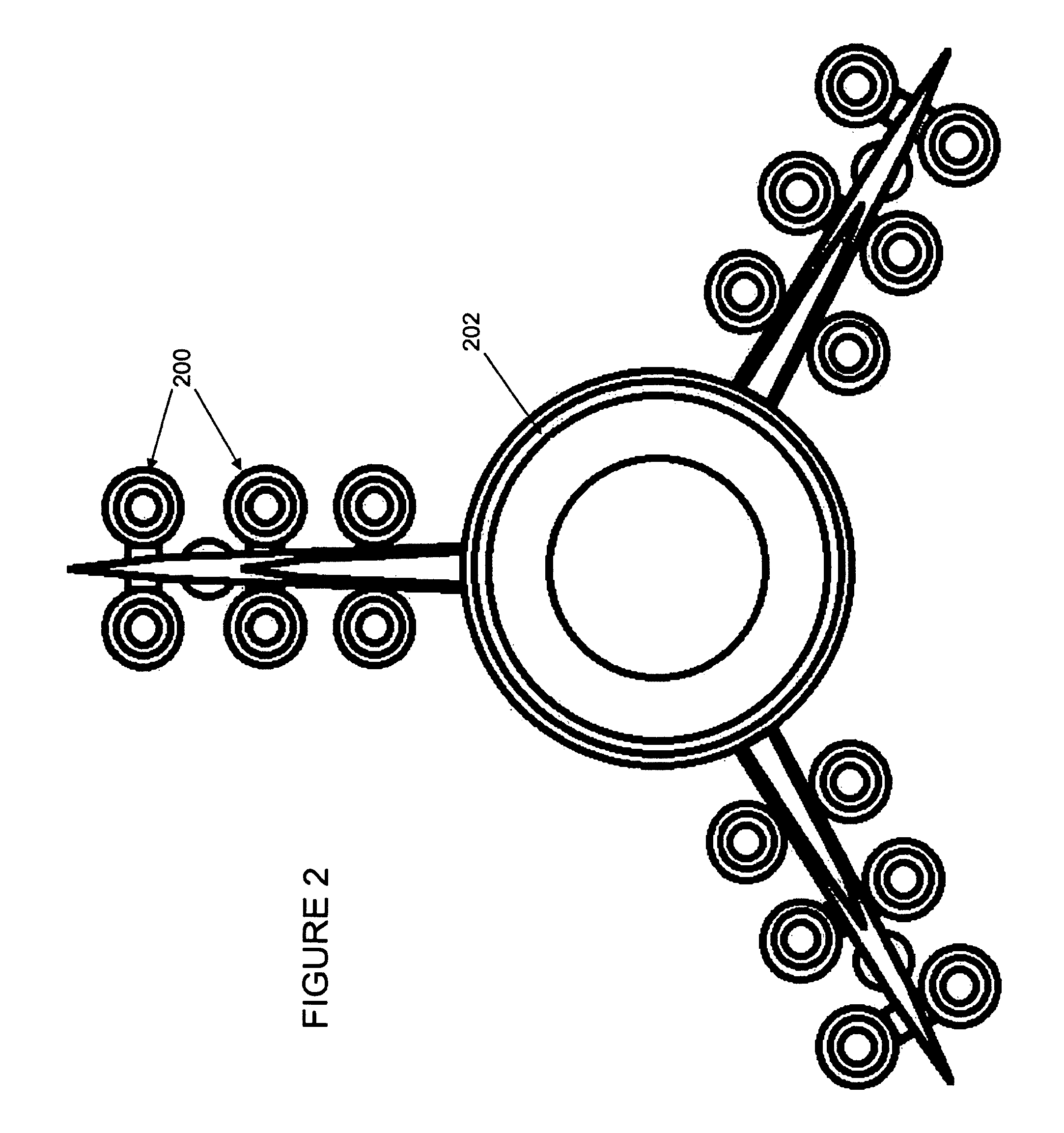

Ram booster

InactiveUS8047472B1Low costIncreased user lifeLaunch systemsCosmonautic propulsion system apparatusThree stageOrbit

The present invention is a space launch system and method to propel a payload bearing craft into earth orbit. The invention has two, or preferably, three stages. The upper stage has rocket engines capable of carrying a payload to orbit and provides the capability of releasably attaching to the lower, or preferably, middle stage. Similar to the lower stage, the middle stage is a reusable booster stage that employs all air breathing engines, is recoverable, and can be turned-around in a short time between missions.

Owner:NAT AERONAUTICS & SPACE ADMINISTATION UNITED STATES OF AMERICA AS REPRESENTED BY THE DIRECTOR OF THE

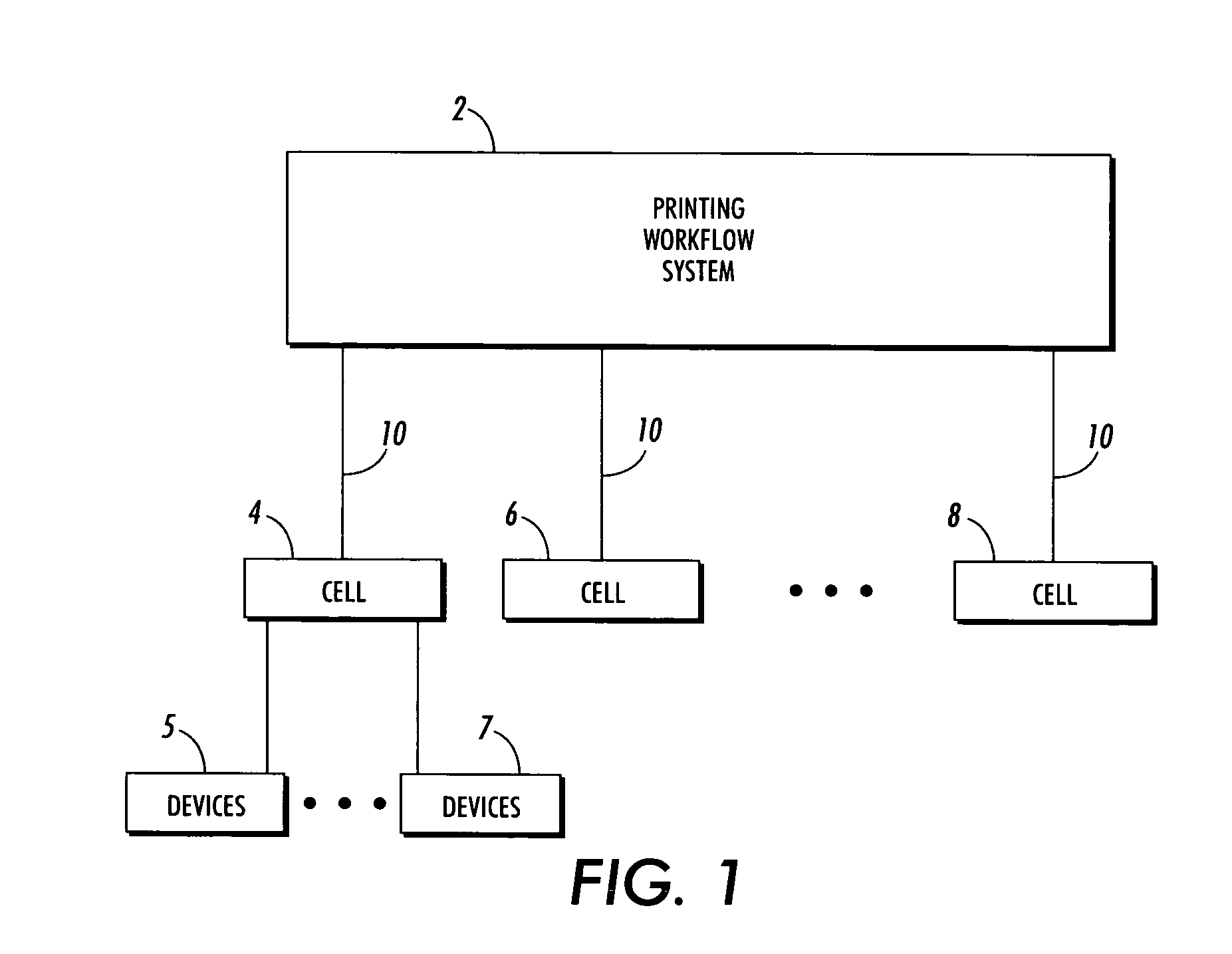

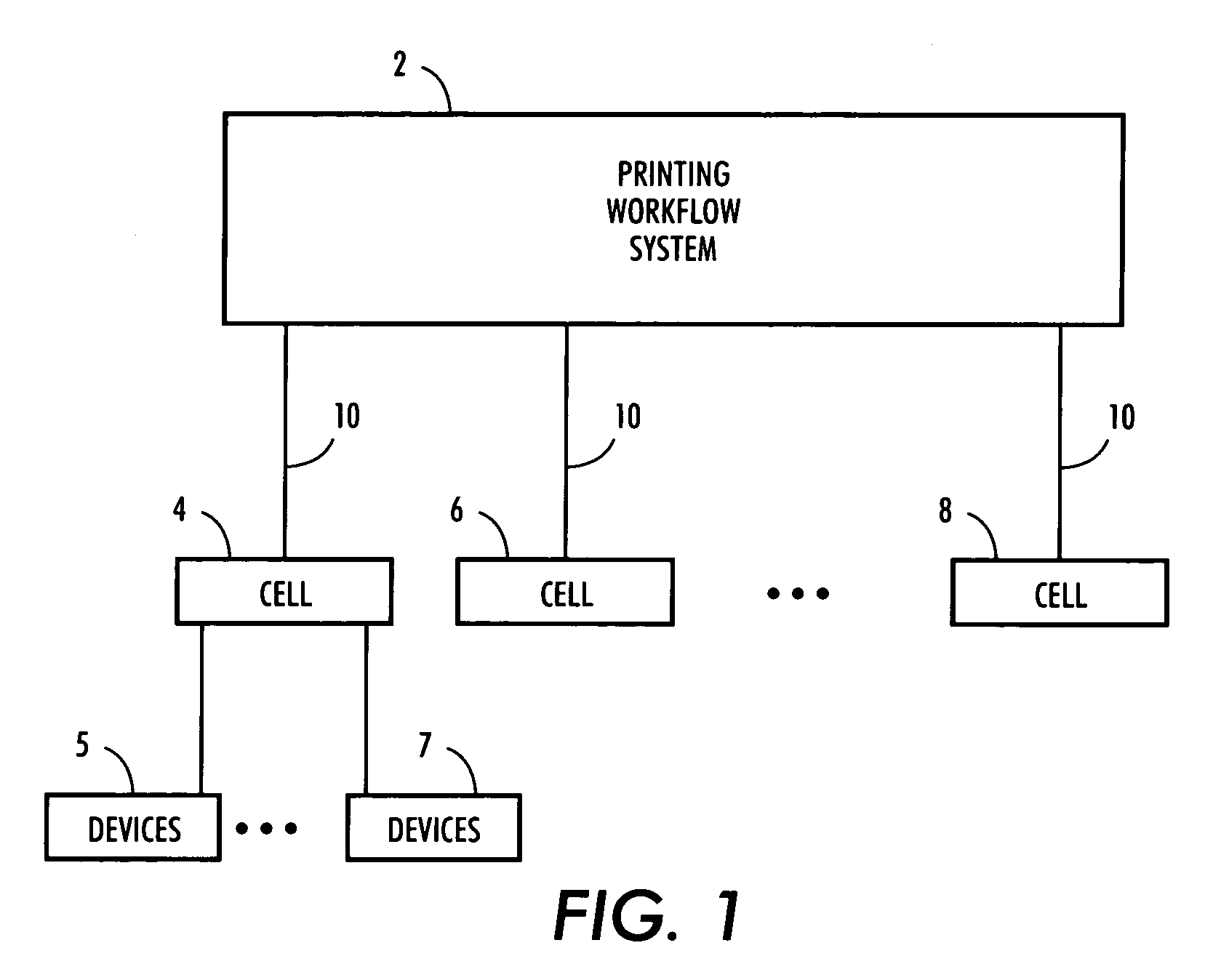

Print job management system

InactiveUS20070247659A1Significant time delayReduce turnaround timeDigitally marking record carriersFinanceComputer scienceManagement system

A method is provided for managing the scheduling of a plurality of print jobs for a print shop. The method includes obtaining a print job input stream including the plurality of print jobs. Each of the plurality of print jobs is scheduled for processing unless at least one of the plurality of print jobs is determined to be a disturbance job, the disturbance job causing delays in processing of other print jobs in the plurality of print jobs that would not occur but for the existence of the disturbance job in the print job input stream. The disturbance job is then assigned a processing related value that increases over time, and scheduling of the disturbance job is delayed until the processing related value exceeds a selected threshold value.

Owner:XEROX CORP

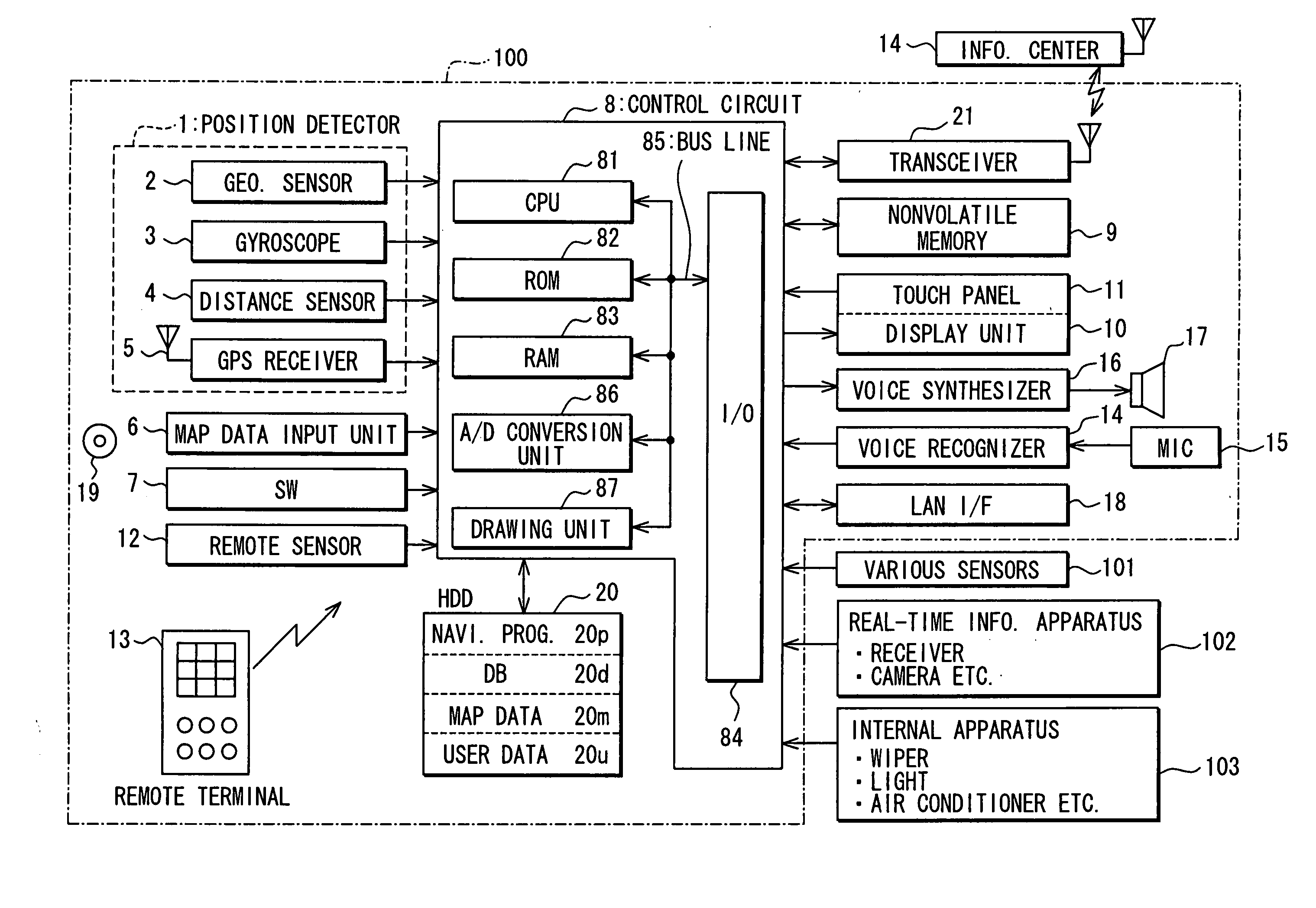

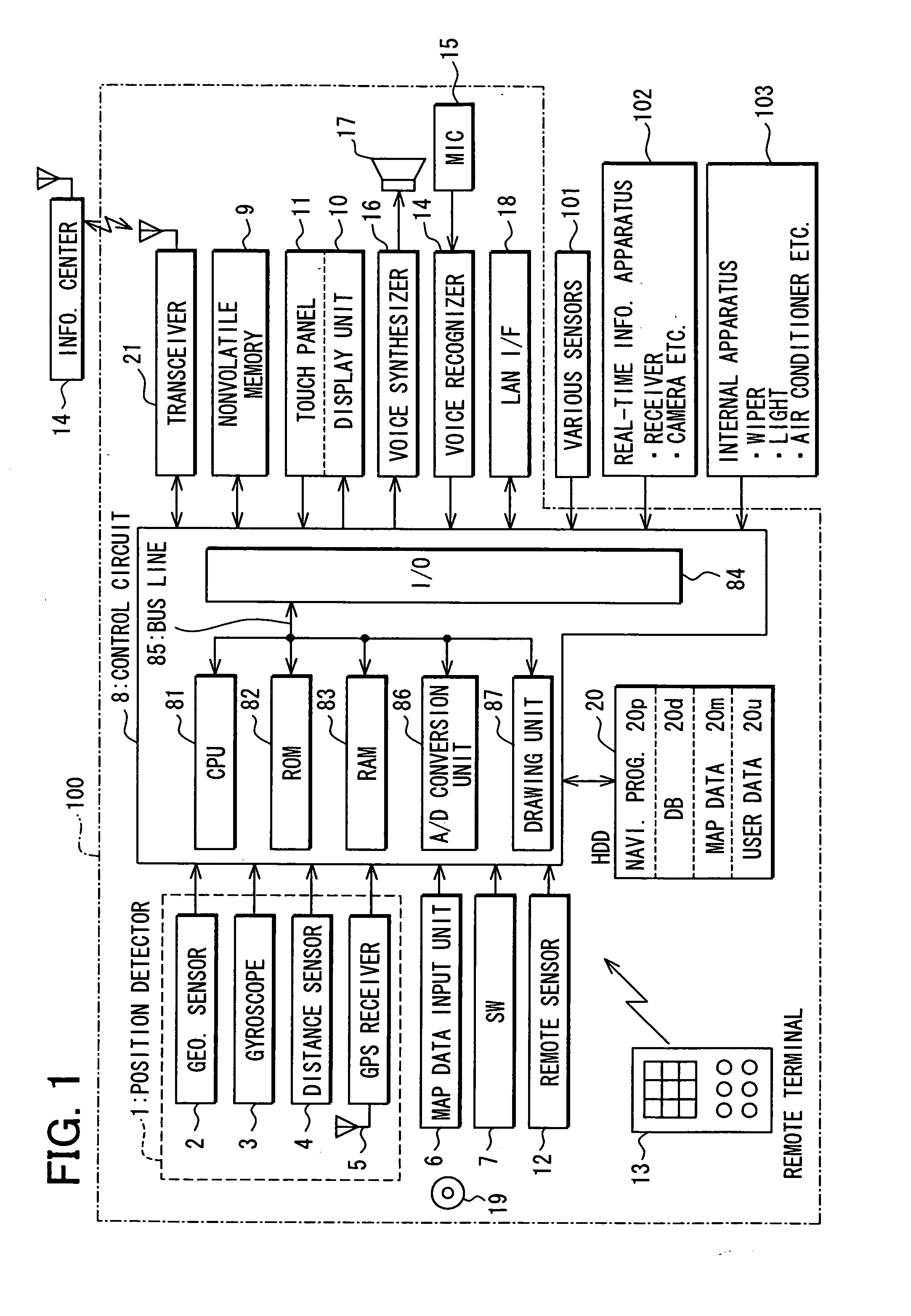

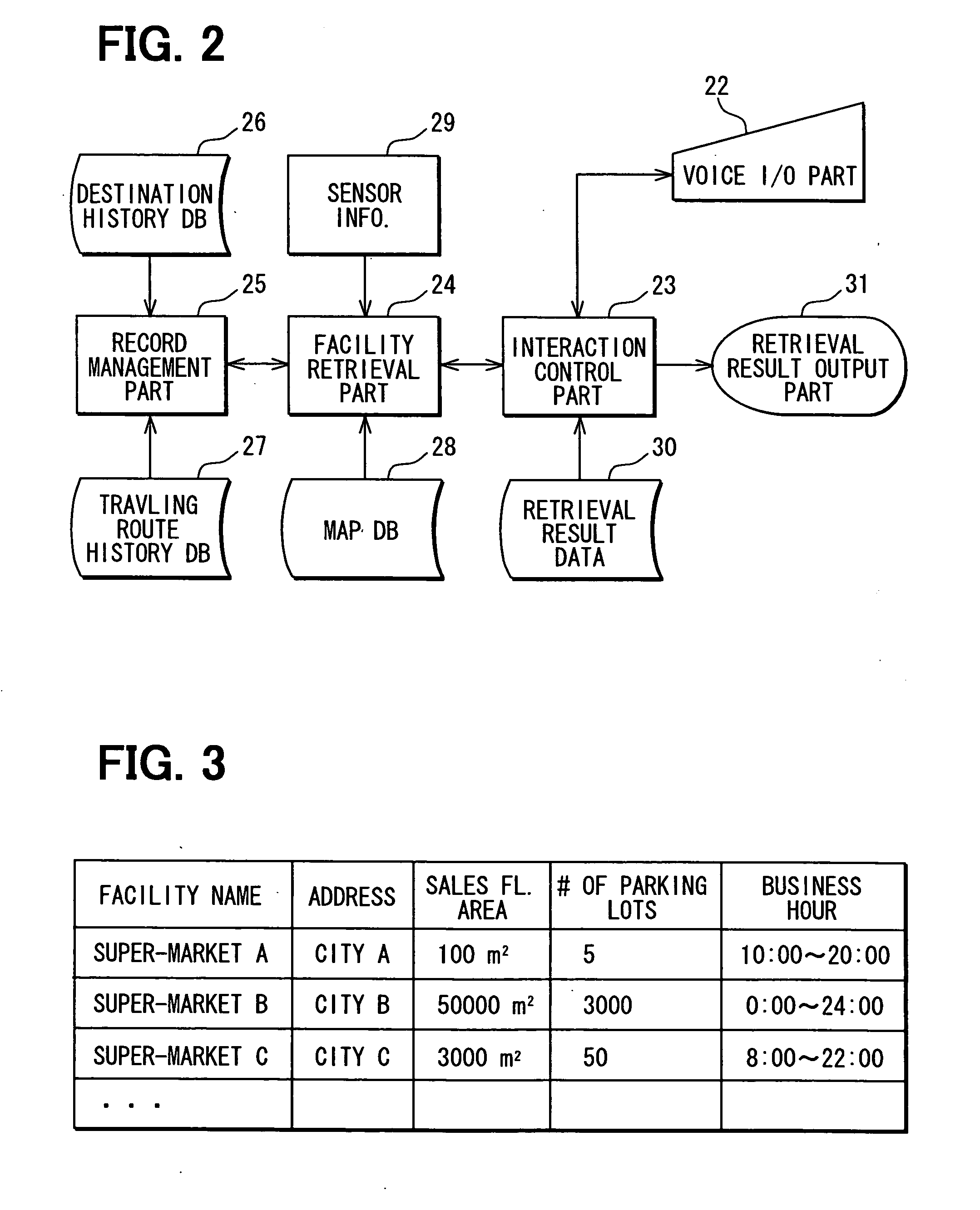

System and method for facility search

InactiveUS20070118279A1Narrow downImprove search speedRoad vehicles traffic controlNavigation instrumentsEngineeringNavigation system

A navigation system for use in a vehicle precludes a certain search area from a scope of a facility search based on a vehicle condition, sensor data, a vehicle travel history or the like for better serving a user by reducing a turnaround time.

Owner:DENSO CORP

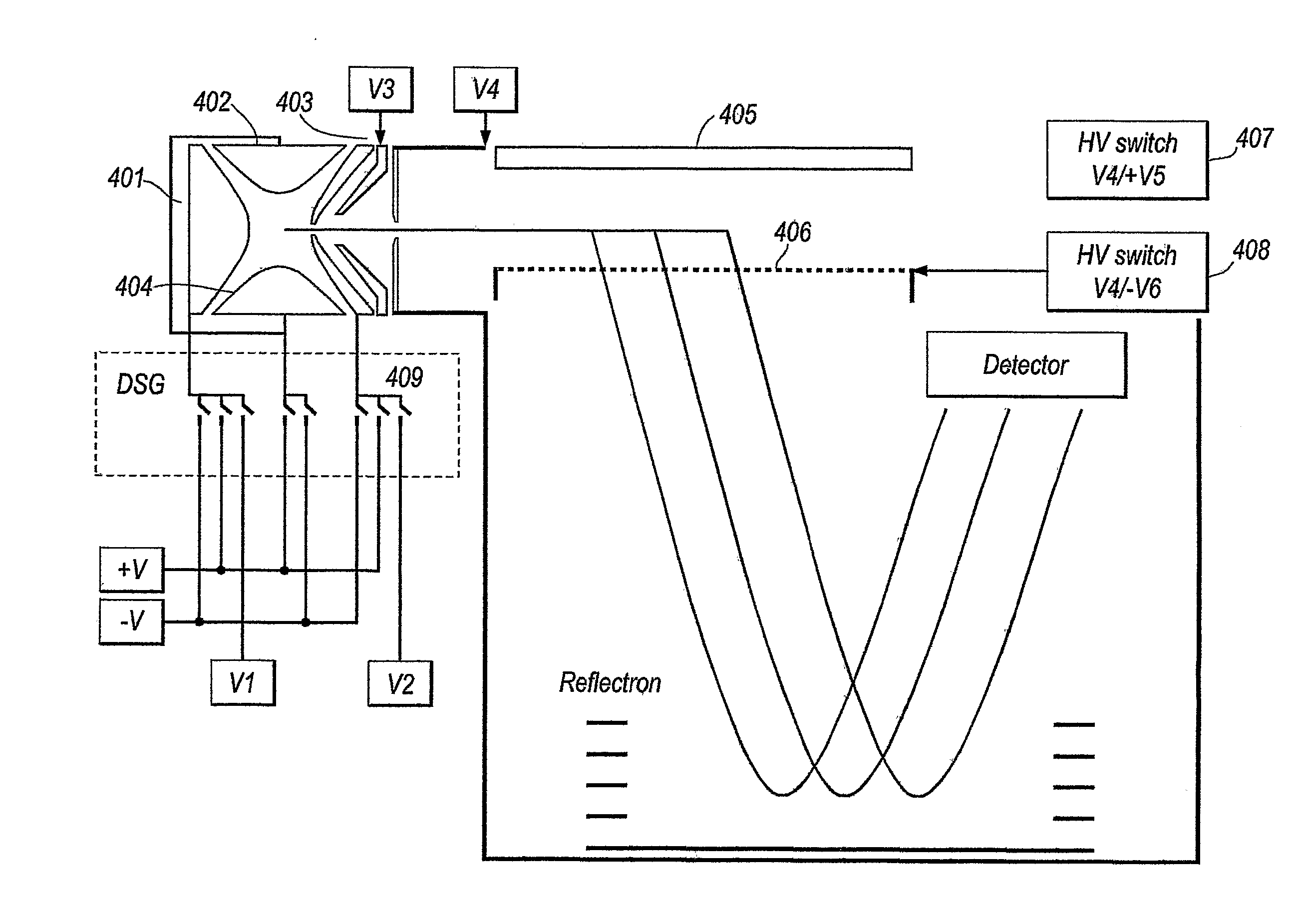

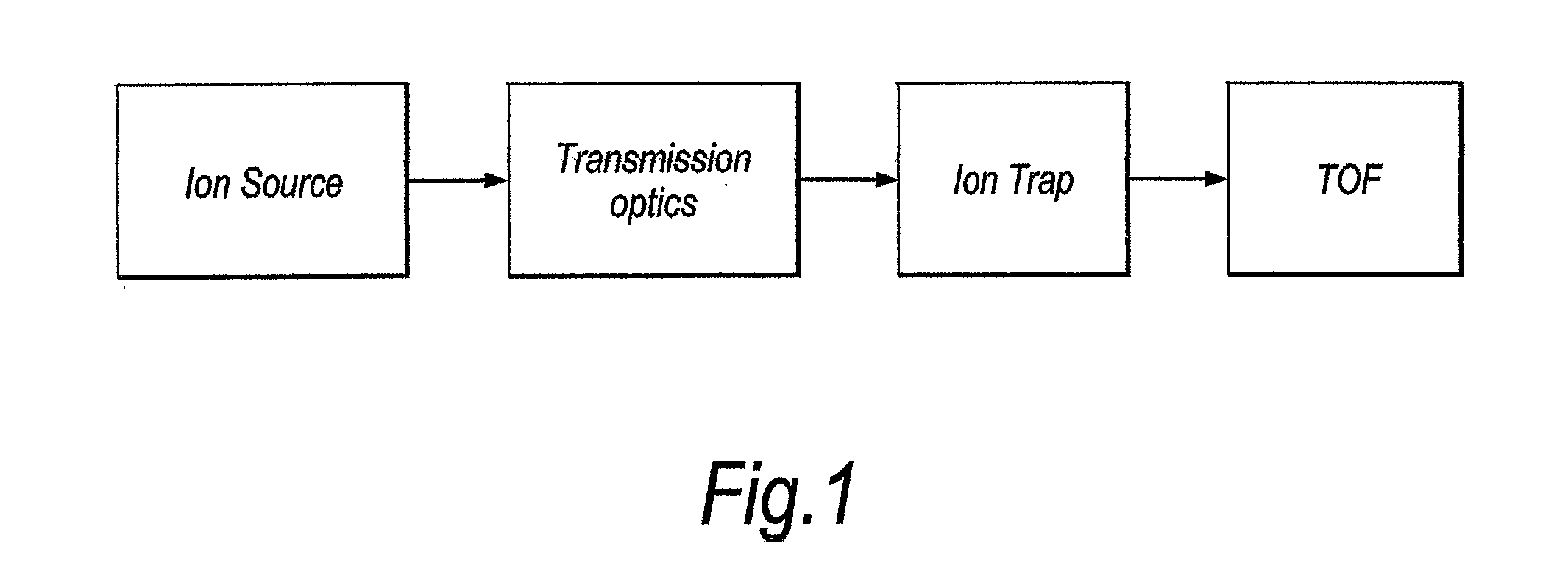

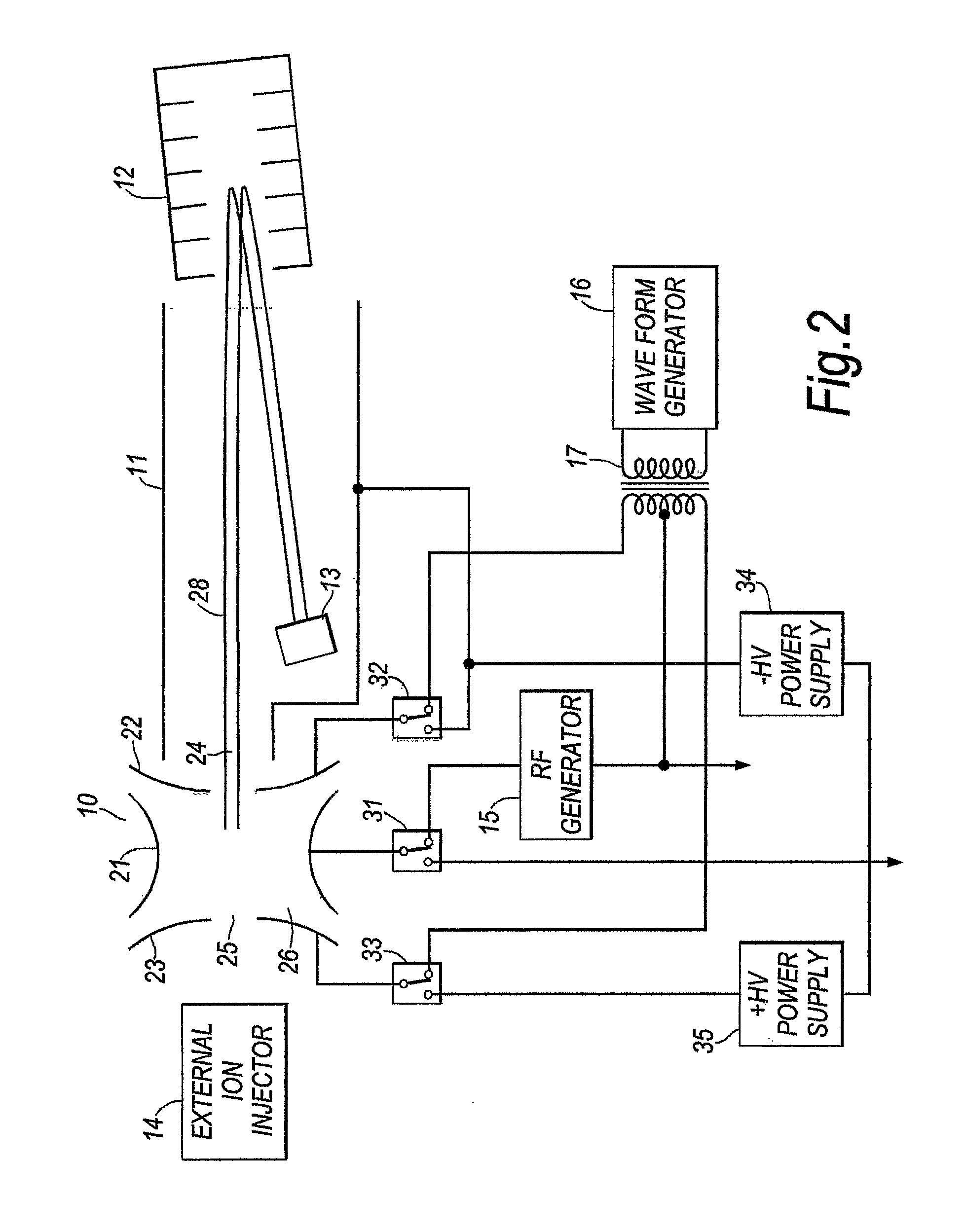

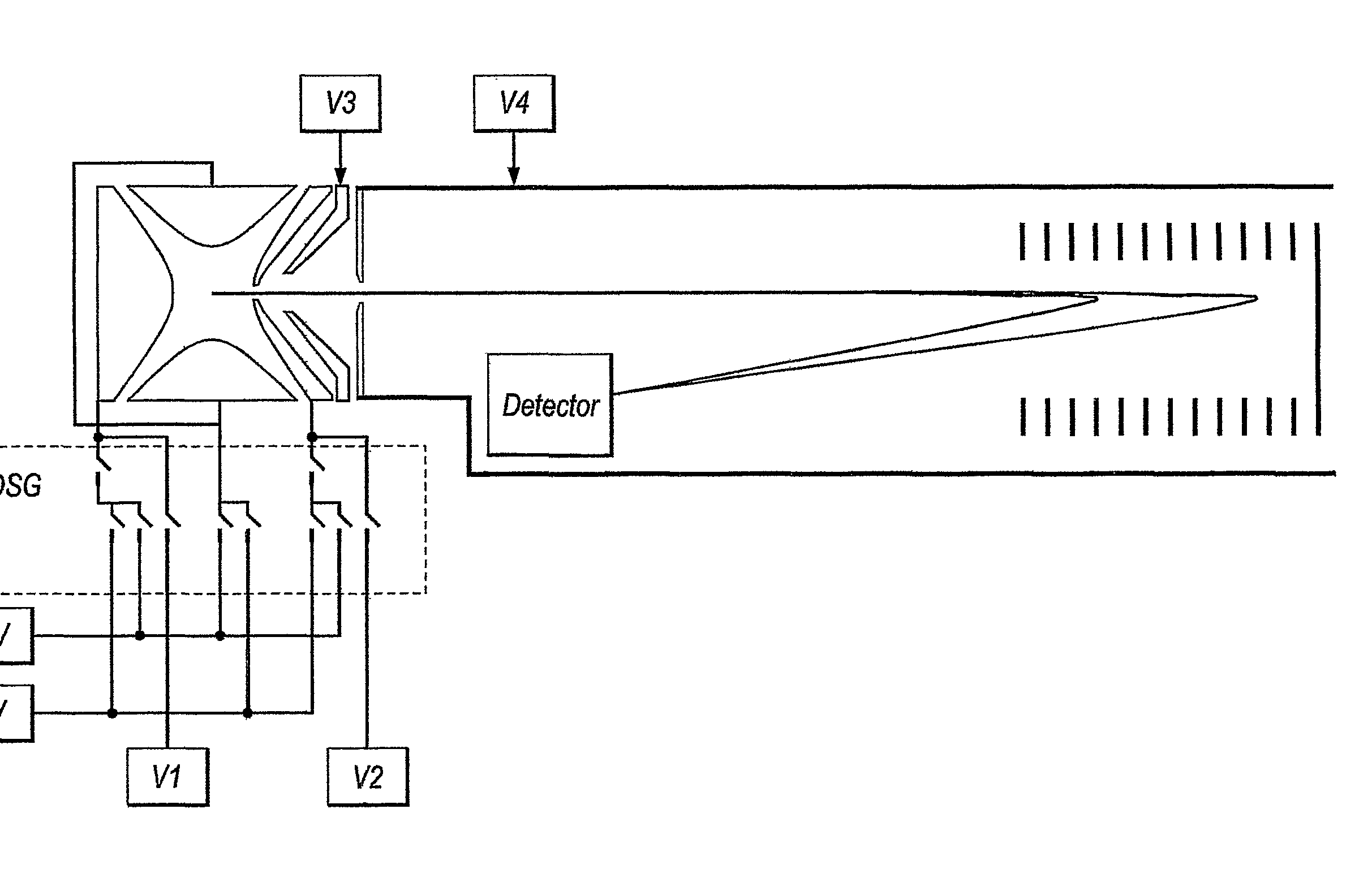

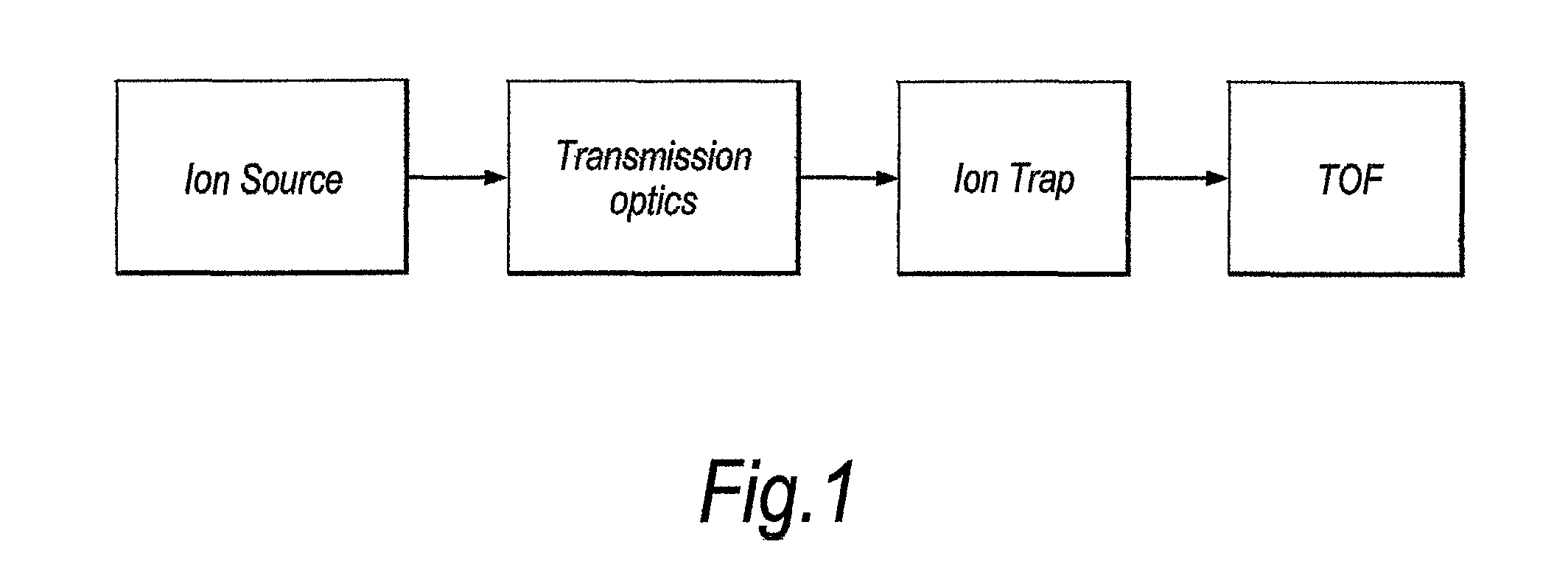

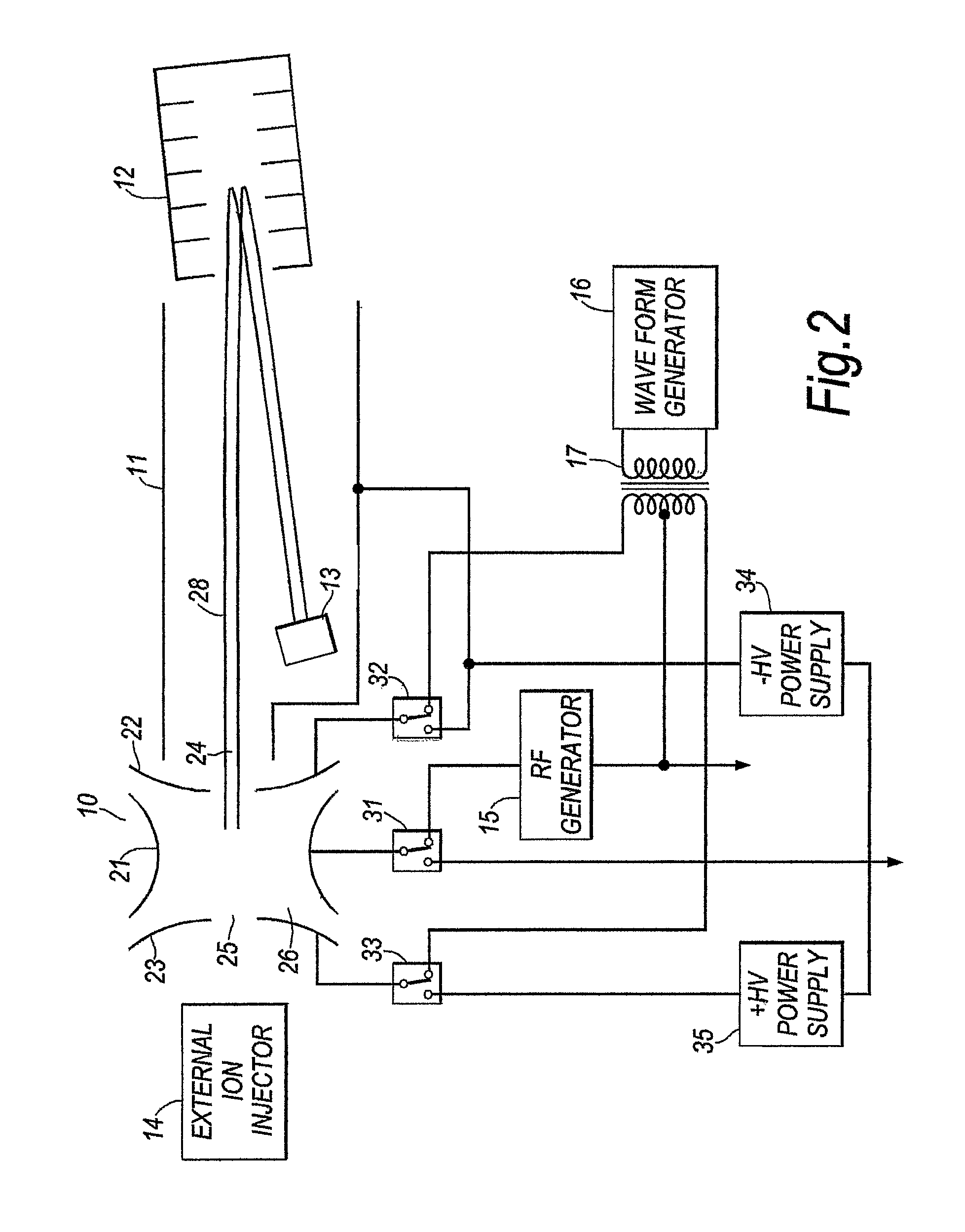

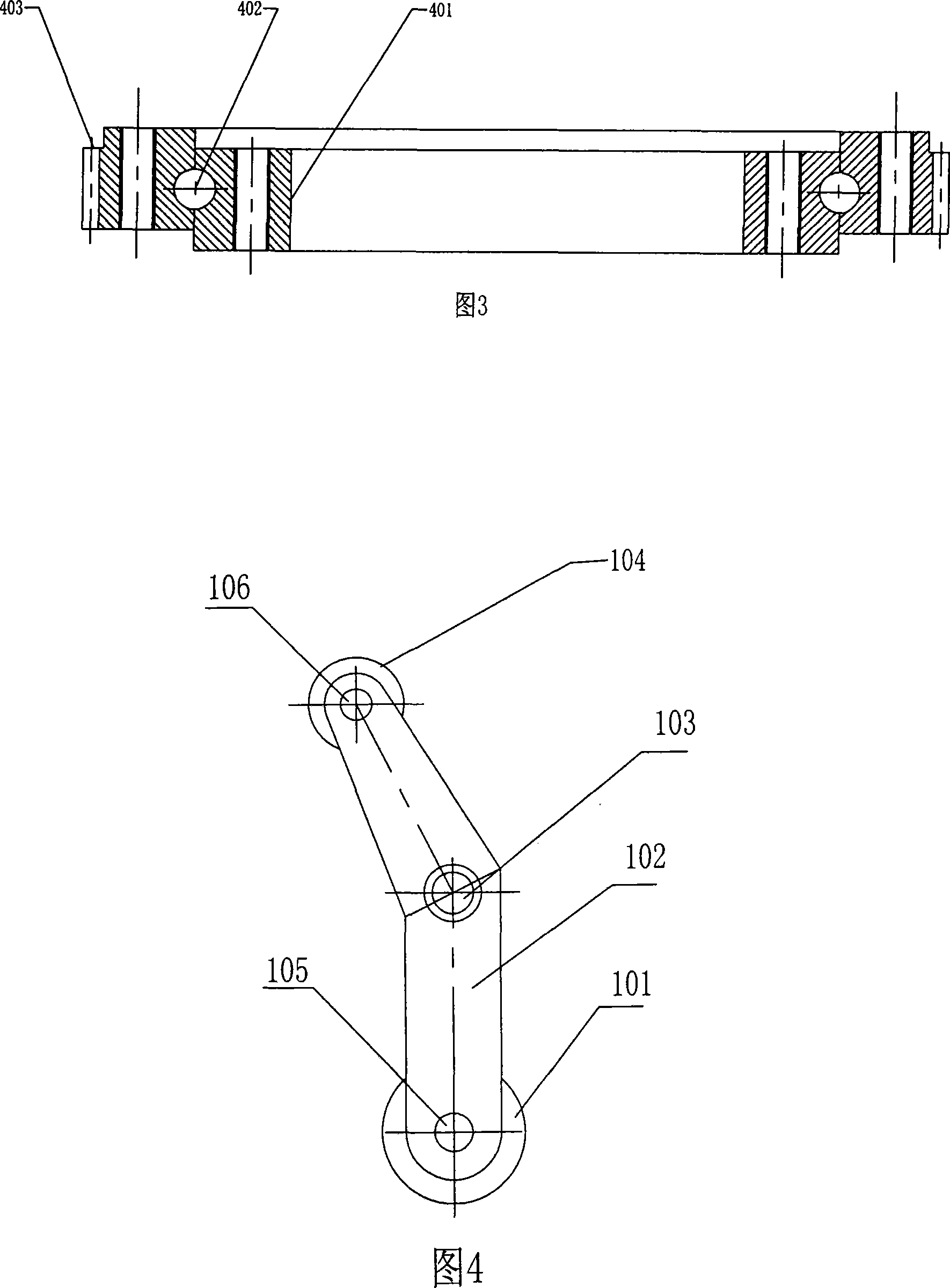

Tandem Ion-Trap Time-Of-Flight Mass Spectrometer

InactiveUS20080035842A1Electronics SimplifiedLow costStability-of-path spectrometersTime-of-flight spectrometersIon trap mass spectrometryElectronic switch

A tandem linear ion trap and time-of-flight mass spectrometer, where the ion trap has a straight central axis orthogonal to the flight path of the mass spectrometer. The ion trap comprises a set of electrodes, (401, 403, 402, 404) at least one of the electrodes has a slit for ejecting ions towards the mass spectrometer; a set of DC voltage supplies (+V, −V, V1, V2) to provide discrete DC levels and a number of fast electronic switches (409) for connecting / disconnecting the DC supplies to at least two of the electrodes; a neutral gas filling the ion trap and a digital controller to provide a switching procedure of ion trapping, manipulation with ions, cooling and including a state at which all ions are ejected from the ion trap towards the mass spectrometer.

Owner:SHIMADZU RES LAB EURO

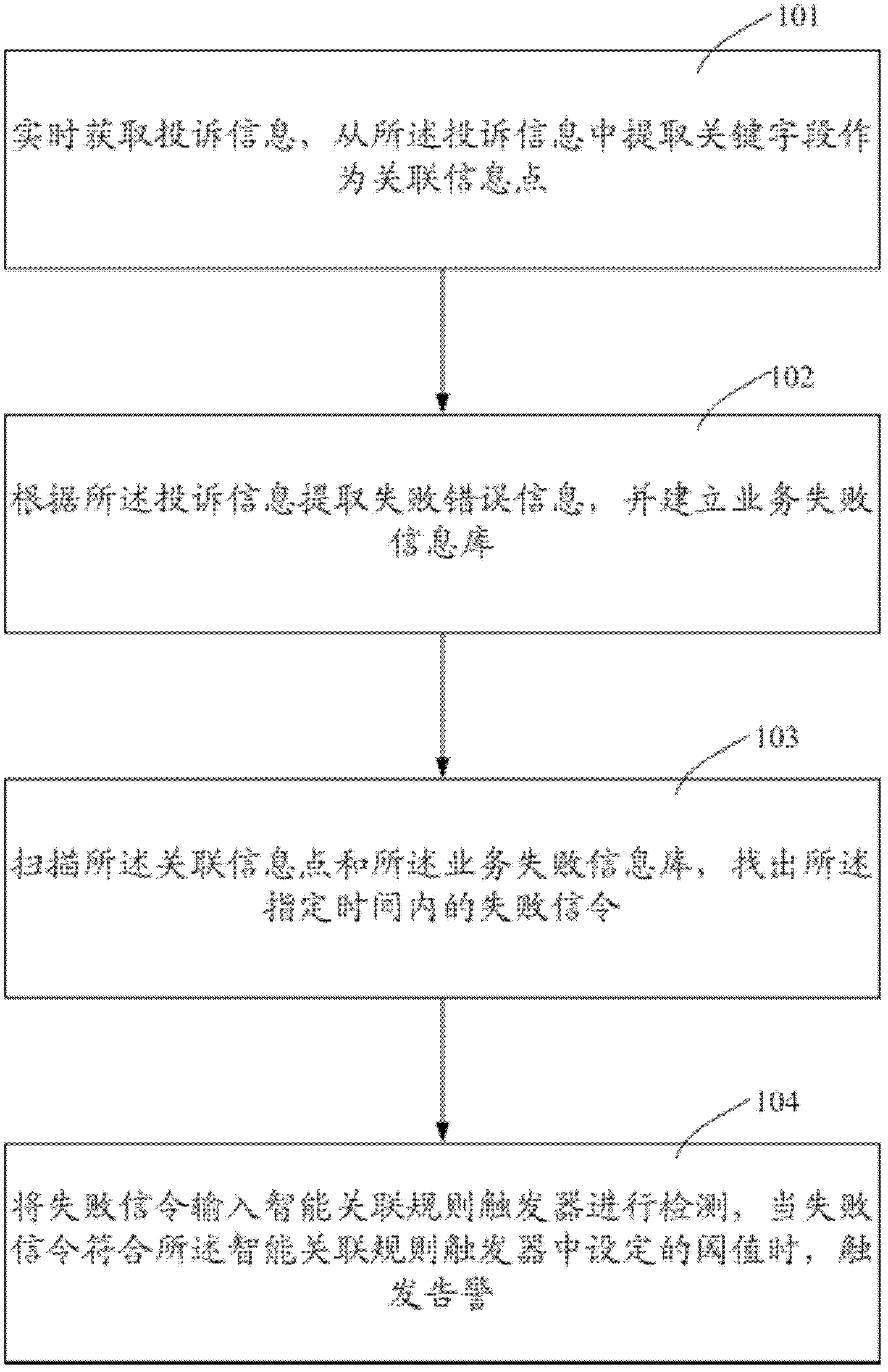

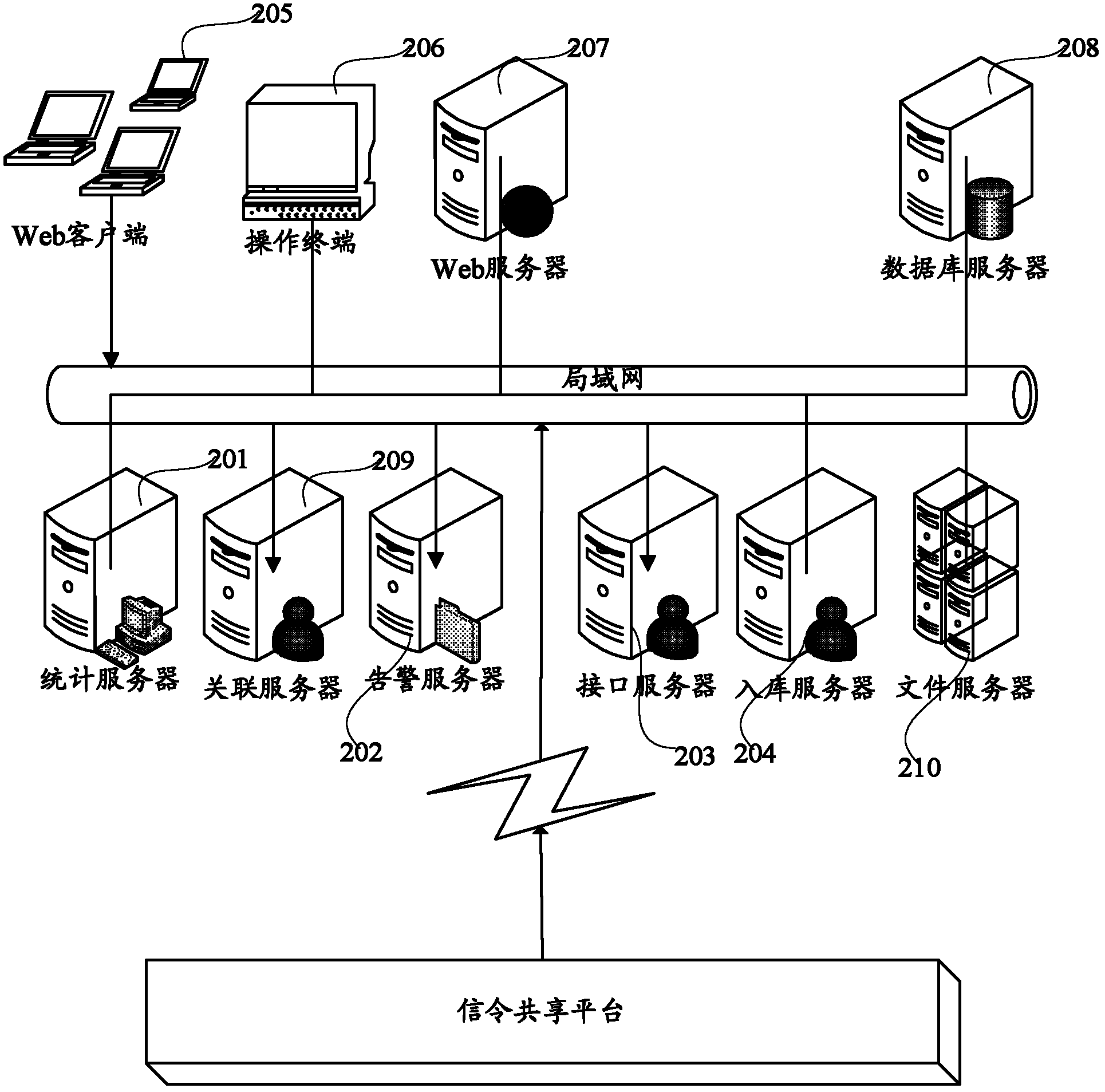

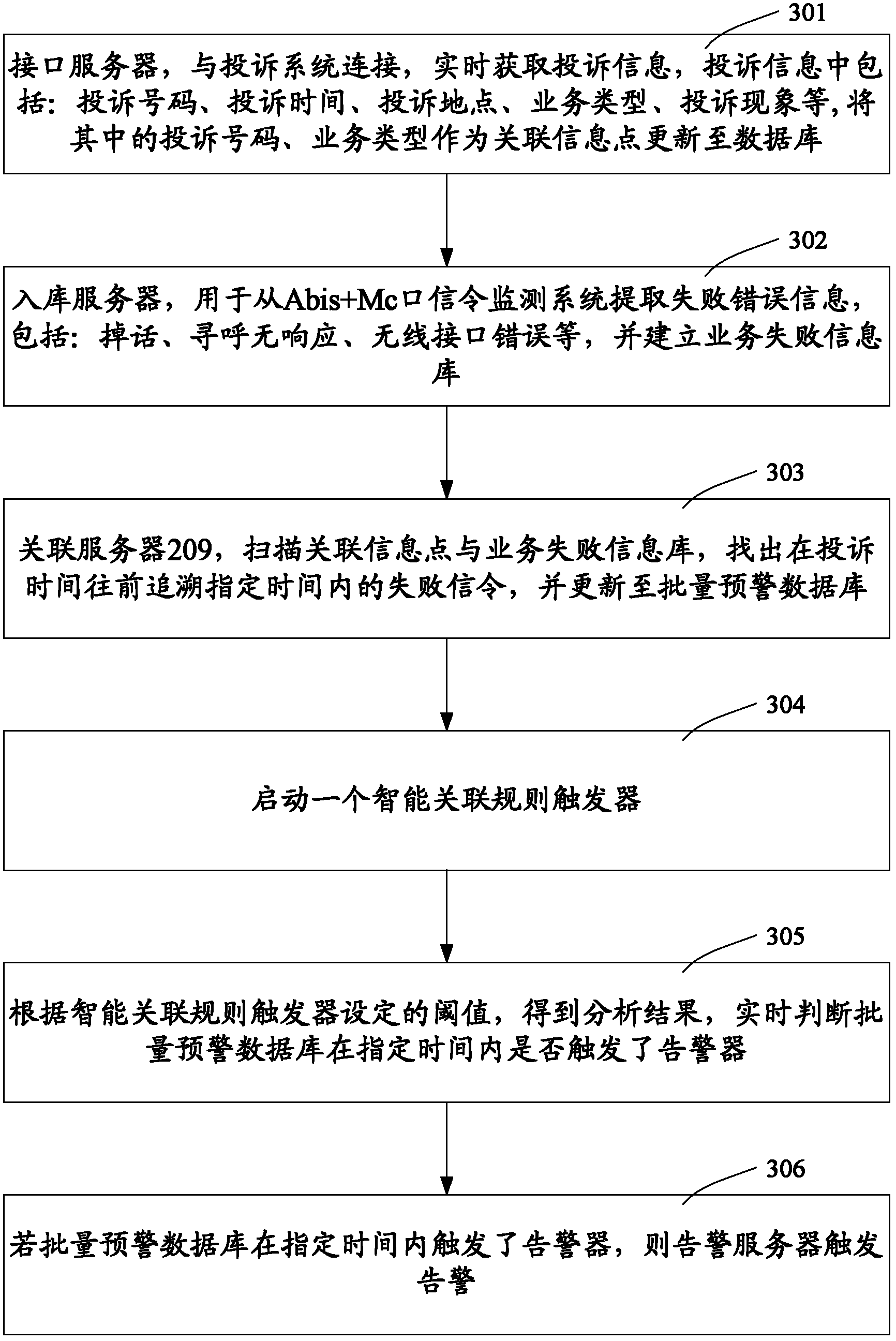

Method for performing alarm locating on batch complains and alarm locating device

ActiveCN103188705AReduce manual judgmentReduce distortion problemsWireless communicationMonitoring systemFlow time

An embodiment of the invention provides a method for performing alarm locating on batch complains and an alarm locating device. The method comprises the steps of acquiring complain information in real time, abstracting key fields from the complain information to serve as relative information points; abstracting signaling failure information from a signaling monitoring system according to the complain information and establishing a service failure information base; scanning the relative information points and the service failure information base and finding failure signaling in specified time; and inputting the failure signaling into an intelligent relative rule trigger for detection, and when the failure signaling accords with a threshold set in the intelligent relative rule trigger, generating alarm information and triggering alarm. The method for performing alarm locating on batch complains and the alarm locating device improve timeliness ratio and locating accuracy of great batch complains, reduce manual judgment links of customer service and network maintenance personnel when faults occur, and reduces information distortion and flow time.

Owner:CHINA MOBILE GRP GUANGDONG CO LTD

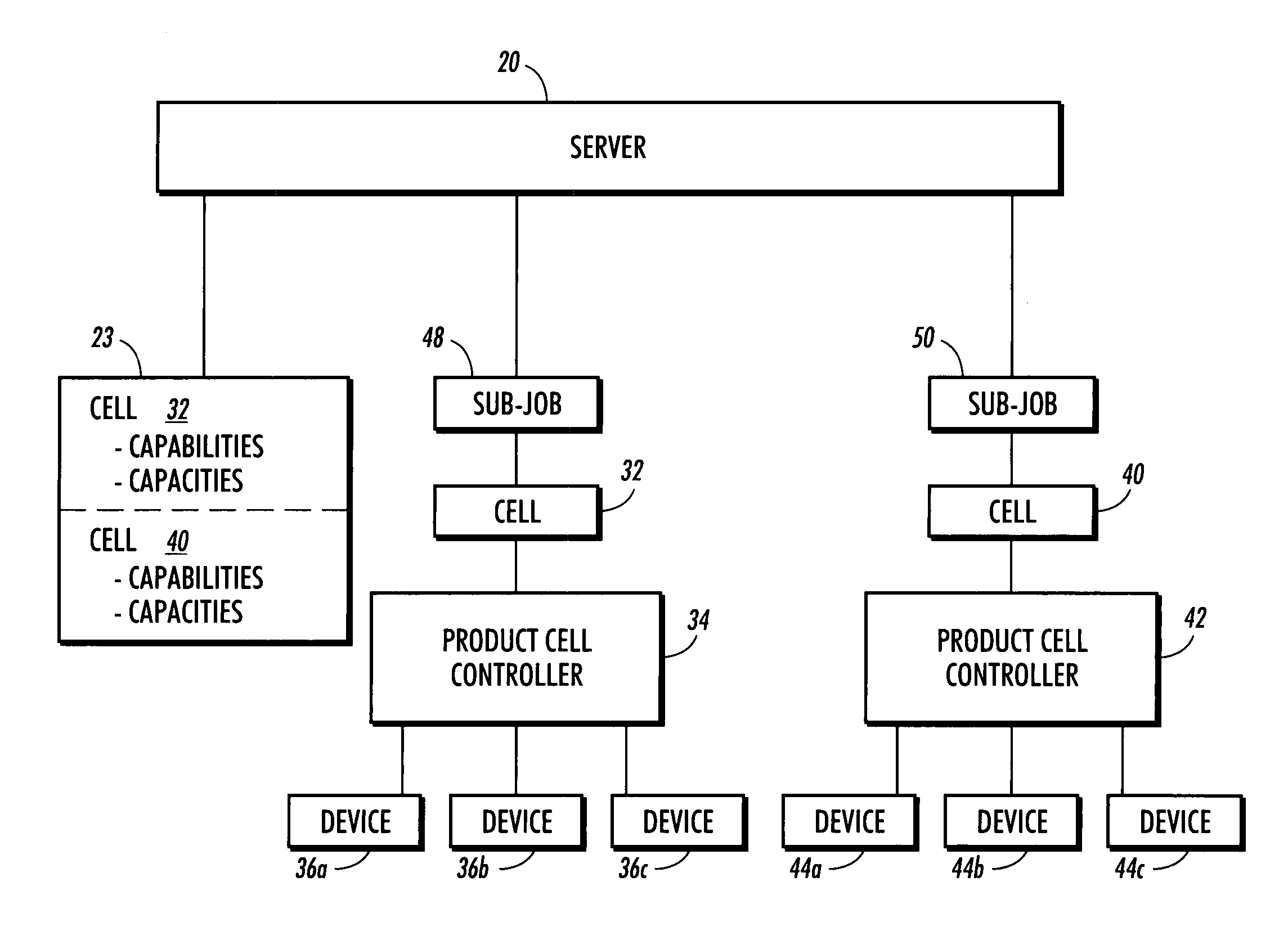

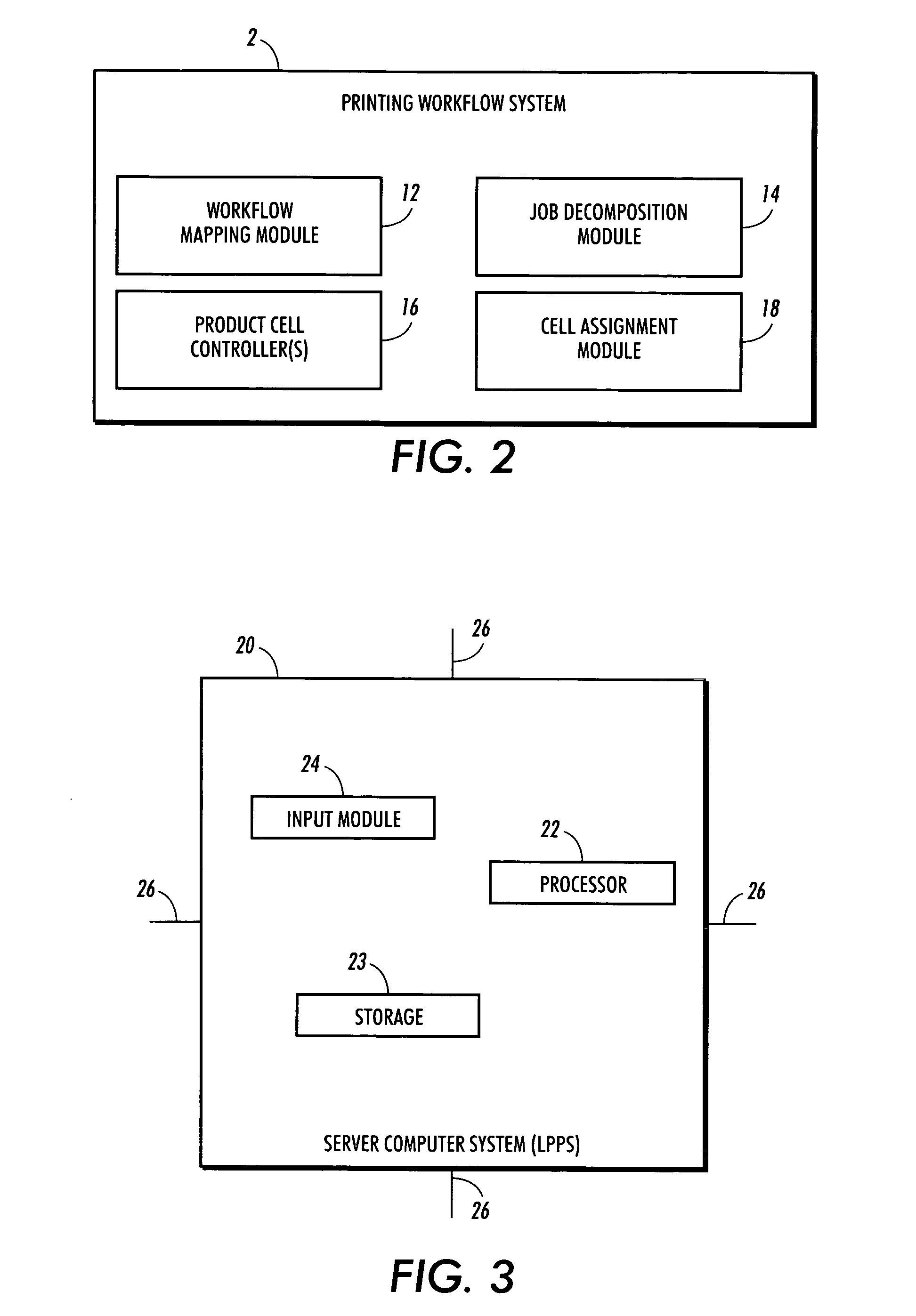

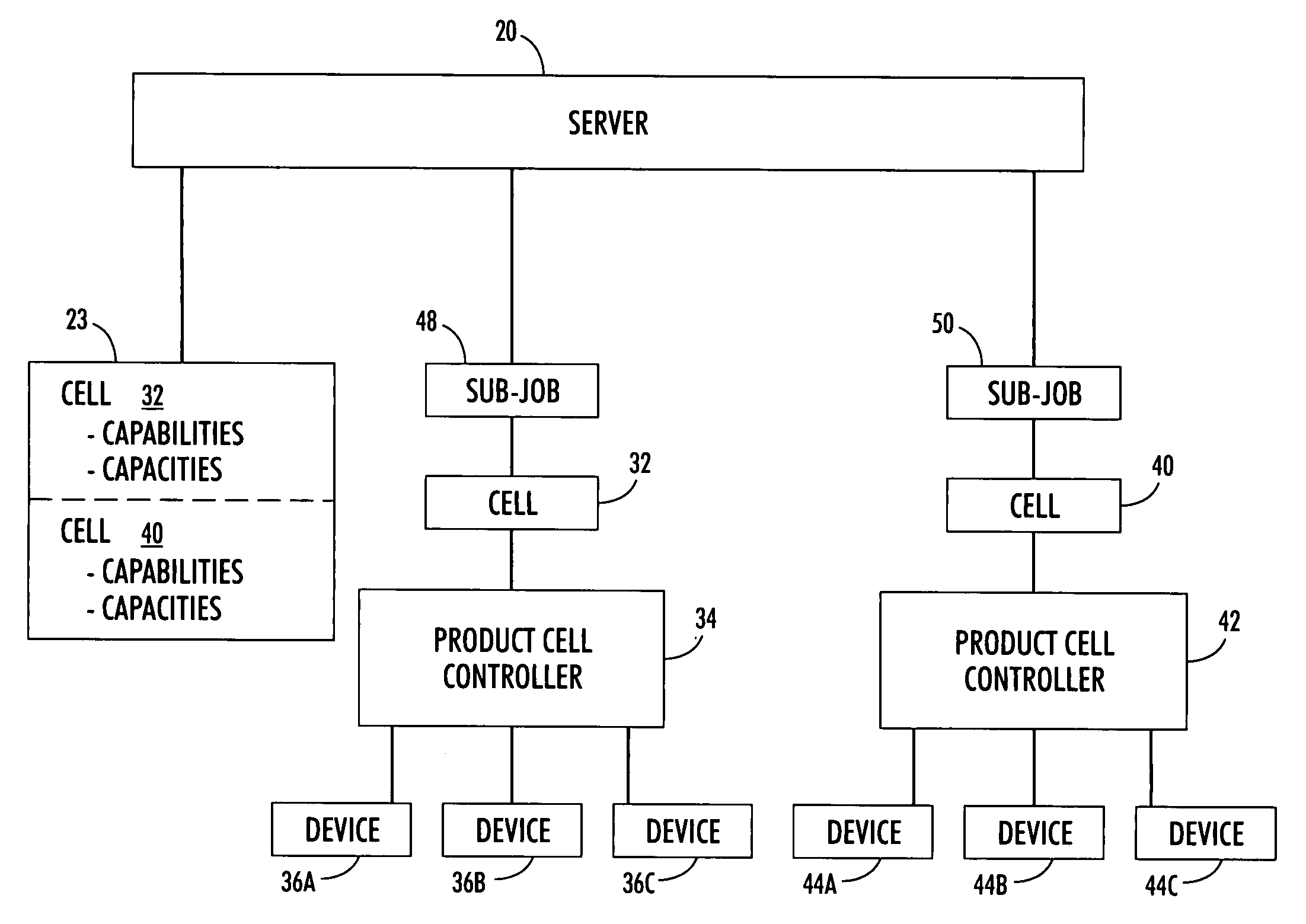

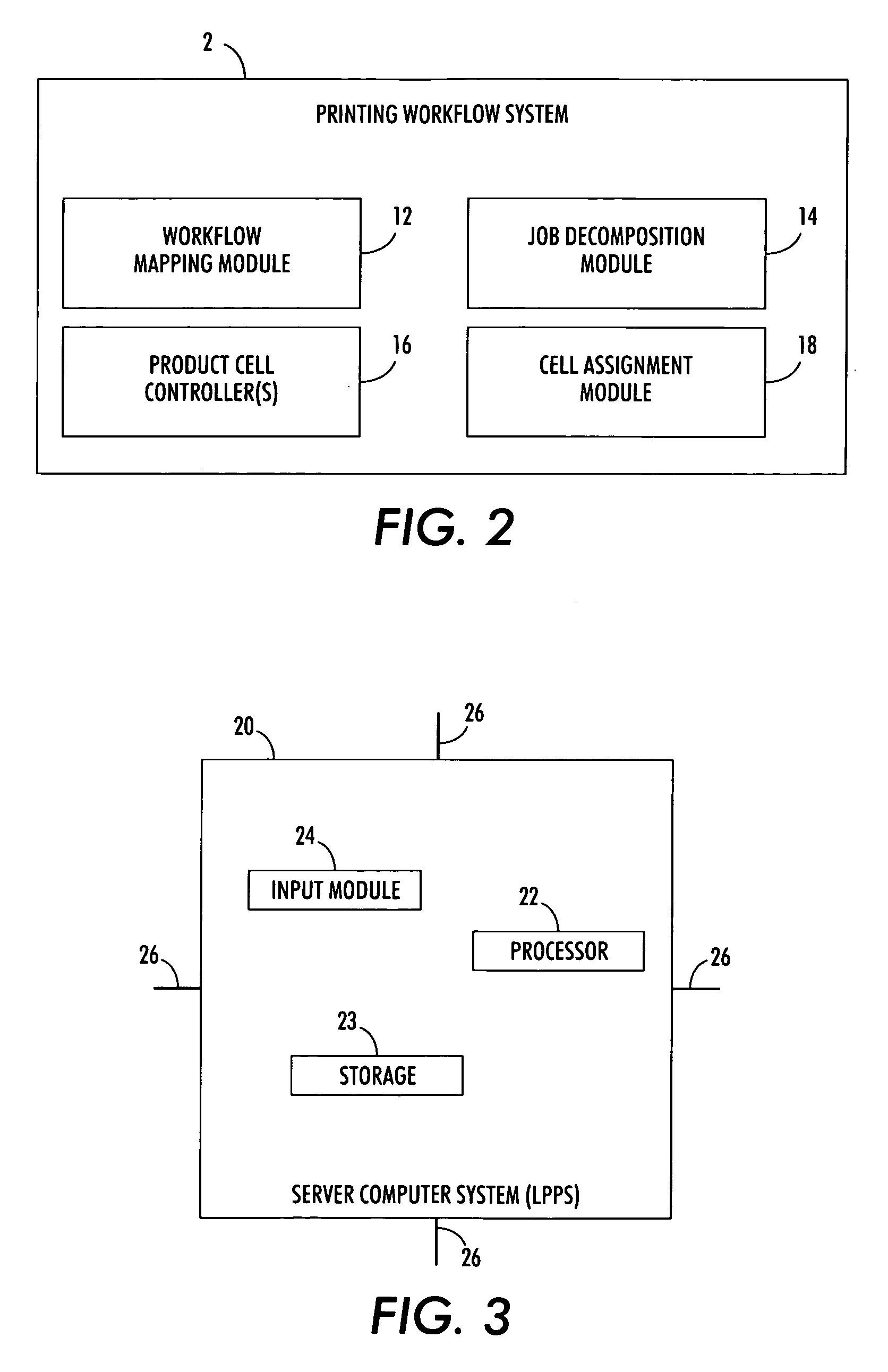

Print job management system

InactiveUS20070236724A1Significant time delayReduce turnaround timeDigitally marking record carriersDigital computer detailsControl limitsComputer science

A system for managing the size of a print job to be processed in a print shop is provided. The print shop includes a plurality of autonomous cells and the job size management system includes a scheduling tool for generating a list including a plurality of jobs. A processor is used to (a) assign a job size related value to each one of the plurality of jobs so that the plurality of jobs are corresponded respectively with a set of job size related values, (b) use the set of job size related values to calculate a control limit, and (c) for each job size related value exceeding the control limit, splitting the job corresponding with the job size related value exceeding the control limit into n number of sub-jobs for processing at the plurality of autonomous cells.

Owner:XEROX CORP

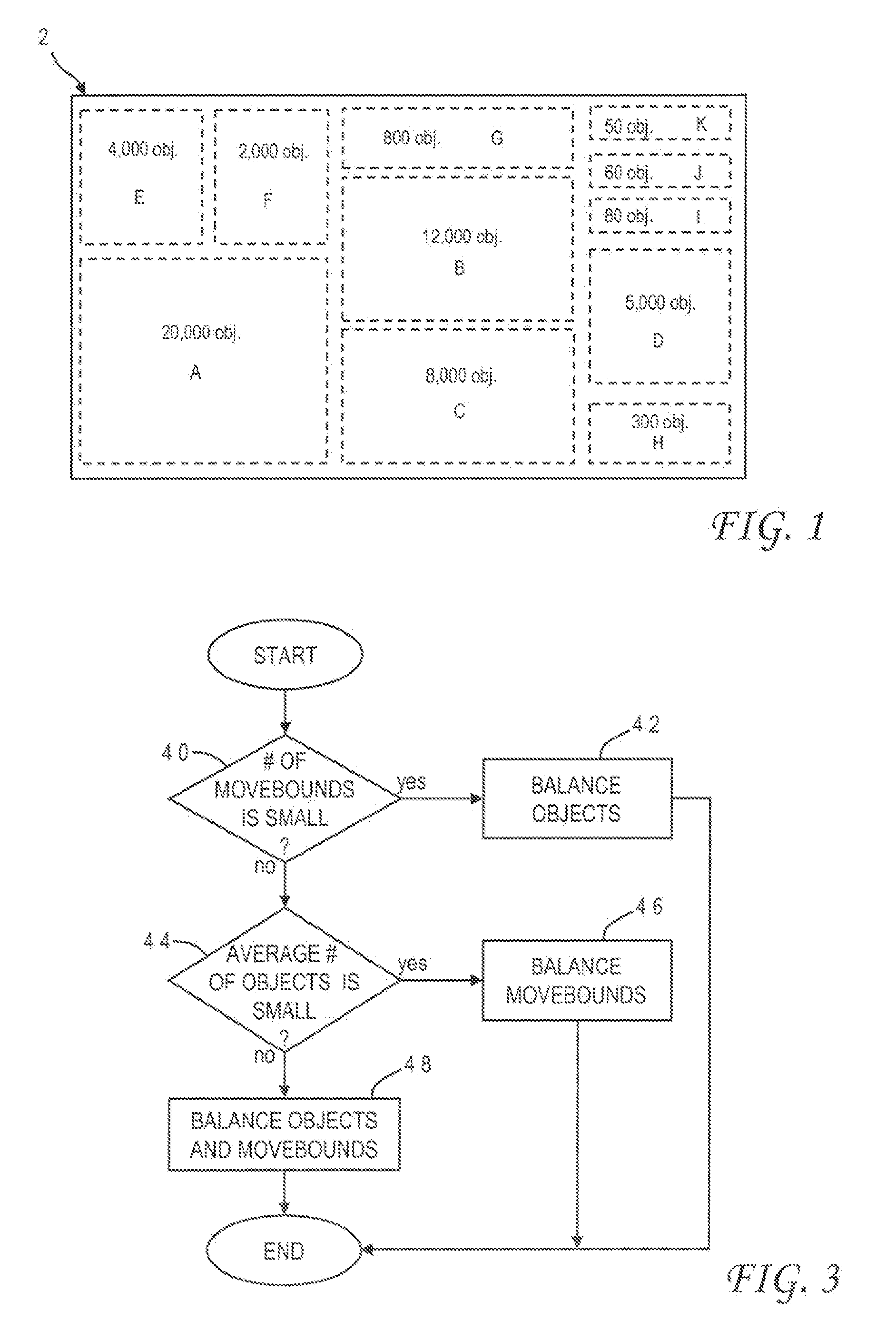

Scheduling for parallel processing of regionally-constrained placement problem

ActiveUS20100192155A1Simple methodReduce turnaround timeResource allocationComputer aided designIdeal numberParallel processing

Scheduling of parallel processing for regionally-constrained object placement selects between different balancing schemes. For a small number of movebounds, computations are assigned by balancing the placeable objects. For a small number of objects per movebound, computations are assigned by balancing the movebounds. If there are large numbers of movebounds and objects per movebound, both objects and movebounds are balanced amongst the processors. For object balancing, movebounds are assigned to a processor until an amortized number of objects for the processor exceeds a first limit above an ideal number, or the next movebound would raise the amortized number of objects above a second, greater limit. For object and movebound balancing, movebounds are sorted into descending order, then assigned in the descending order to host processors in successive rounds while reversing the processor order after each round. The invention provides a schedule in polynomial-time while retaining high quality of results.

Owner:GLOBALFOUNDRIES US INC

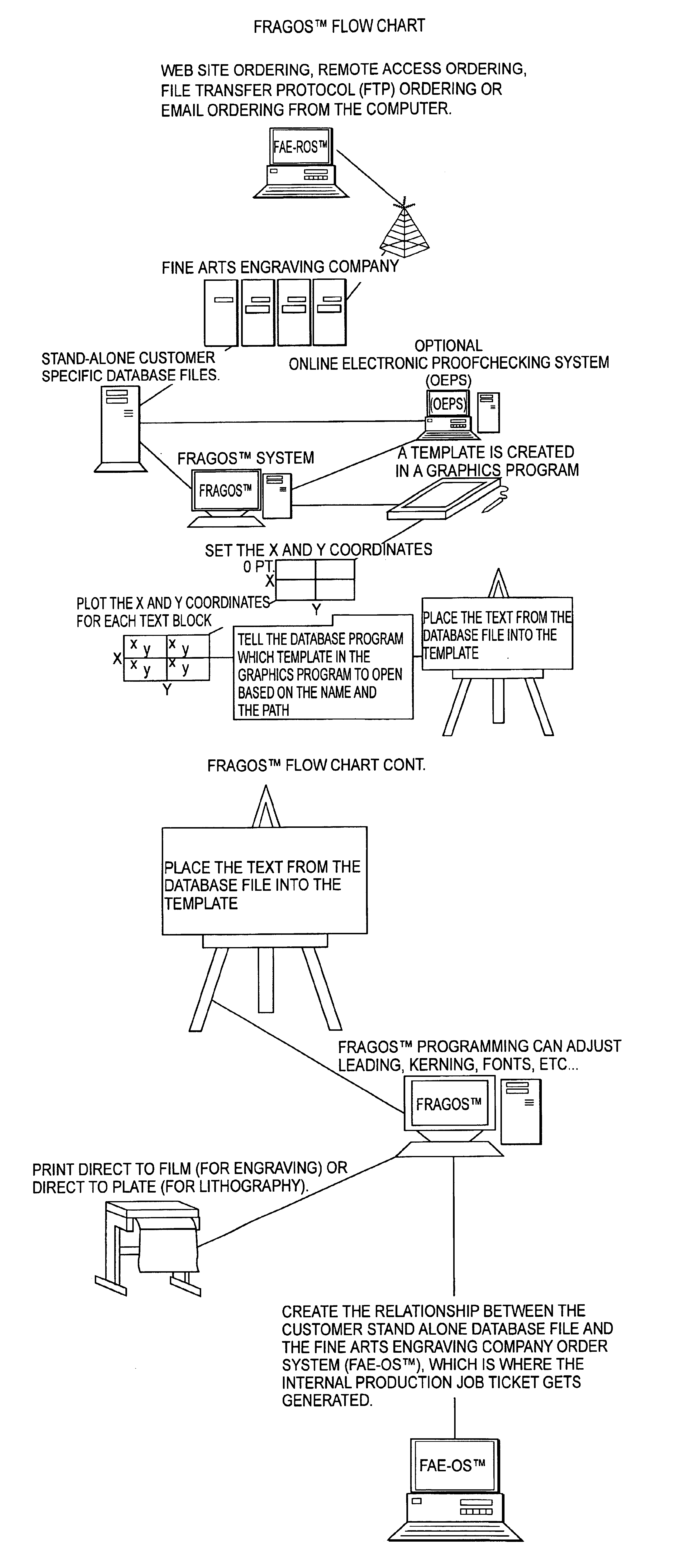

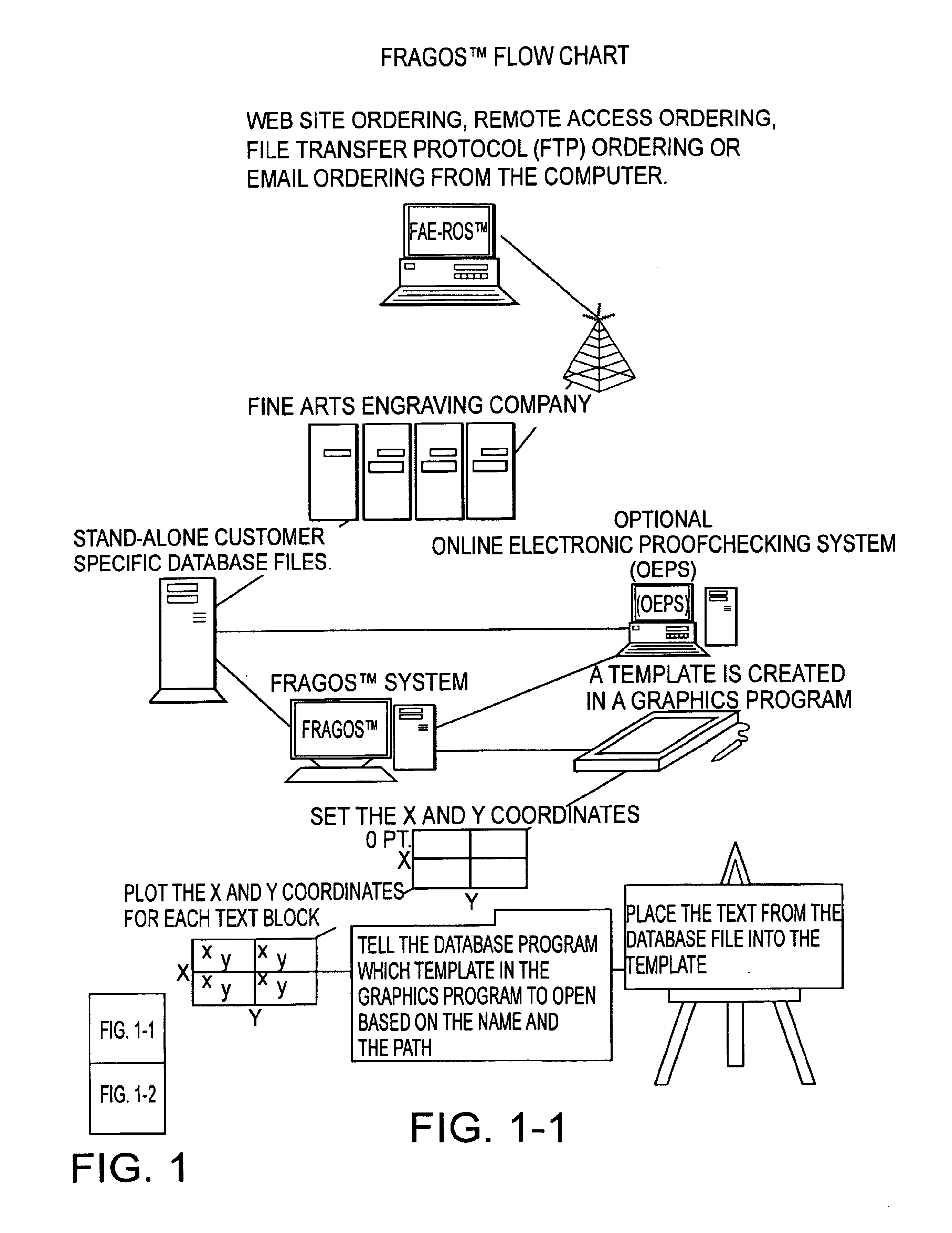

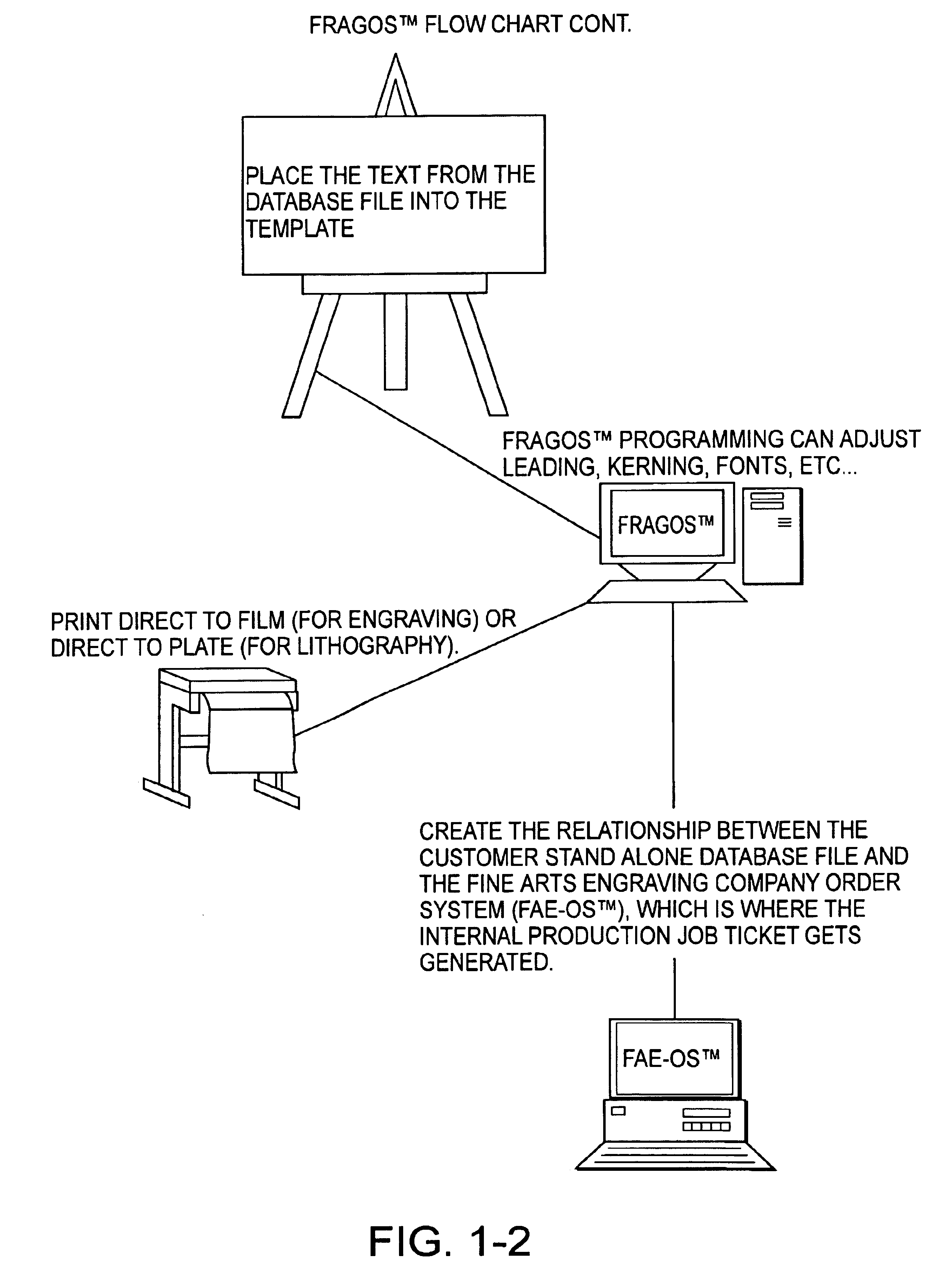

Automated typesetting system

InactiveUS6882441B1Reduce turnaround timeImprove order processing efficiencyData processing applicationsDigital computer detailsGraphicsBusiness card

An automated typesetting system is disclosed for use in the production of commercially-printed products, such as engraved, embossed, or lithographed letterhead, envelopes, business cards, and the like. The automated typesetting system is a computerized system for accurately and efficiently typesetting copy and includes a graphic template containing text and object blocks and a database containing information to be populated into the template blocks as well as instructions on how to format each of the blocks. Information from the database is optionally electronically proofchecked, populated into the template fields, formatted and typeset according to design specifications, arranged in maximally-efficient production format, and sent to print. The system may be interactively coupled with an order tracking, billing, shipping, and inventory control system.

Owner:ON LINE PRINT SERVICES

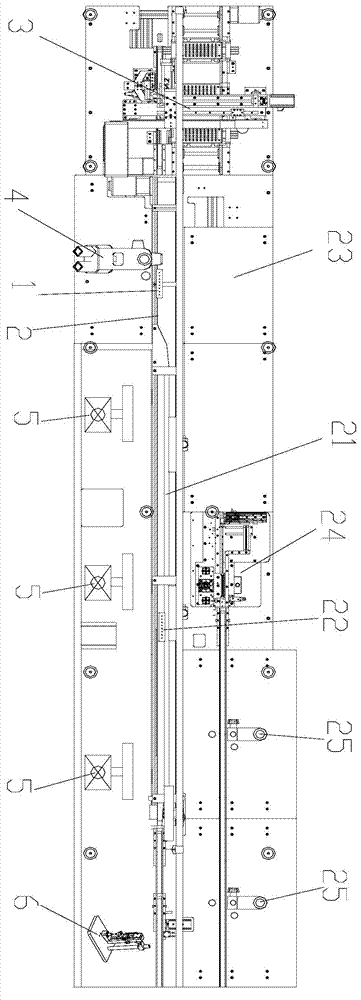

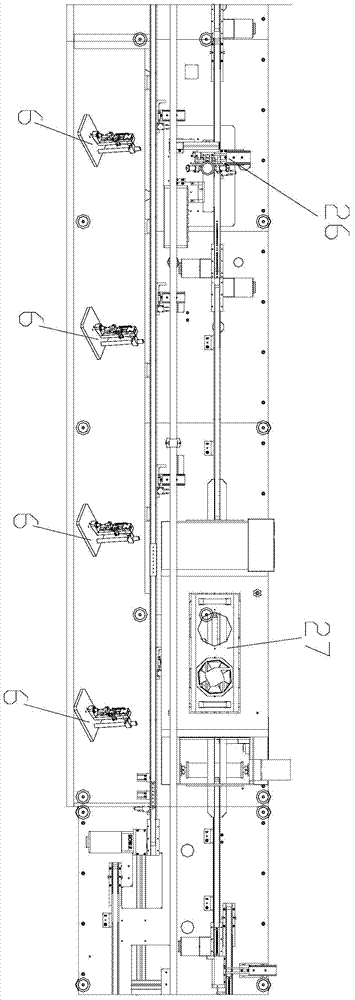

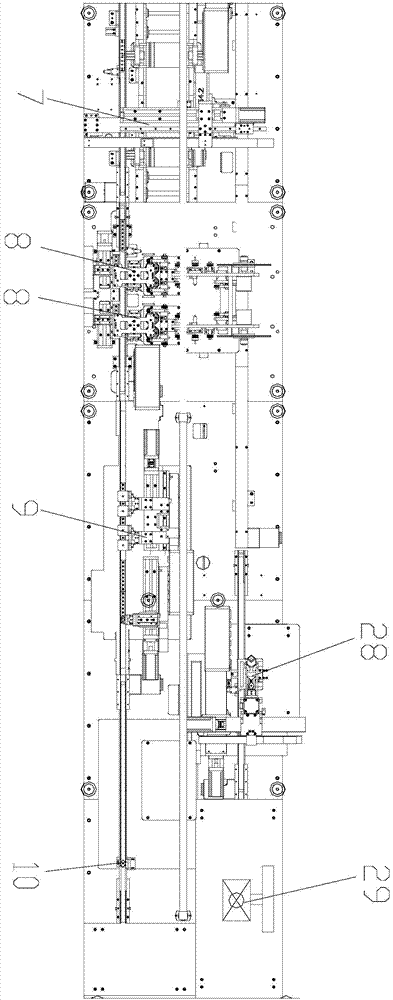

Mobile phone motor automatic assembly production line

ActiveCN103501085ARealize automatic assemblySave human effortManufacturing dynamo-electric machinesMobile phoneManufacturing line

The invention discloses a mobile phone motor automatic assembly production line which comprises a rotor assembly production line, an end cover assembly production line and a motor assembly production line which are arranged on one production line. The rotor assembly production line and the end cover assembly production line are arranged side by side; and the motor assembly production line is arranged at the tail ends of the rotor assembly production line and the end cover assembly production line. According to the mobile phone motor automatic assembly production line disclosed by the invention, the rotor assembly production line and the end cover assembly production line are arranged side by side, a stator housing assembly is combined at the position where assembly of a rotor assembly and an end cover assembly is completed, two production lines which are arranged side by side are converged into one motor assembly production line and all production processes are completed on the same production line, and thus, automatic assembly of the rotor assembly, the end cover assembly and a motor assembly can be implemented, labor can be saved, turnaround time is reduced and production efficiency is improved.

Owner:CHONGQING LINGLONG AUTOMATION EQUIP CO LTD

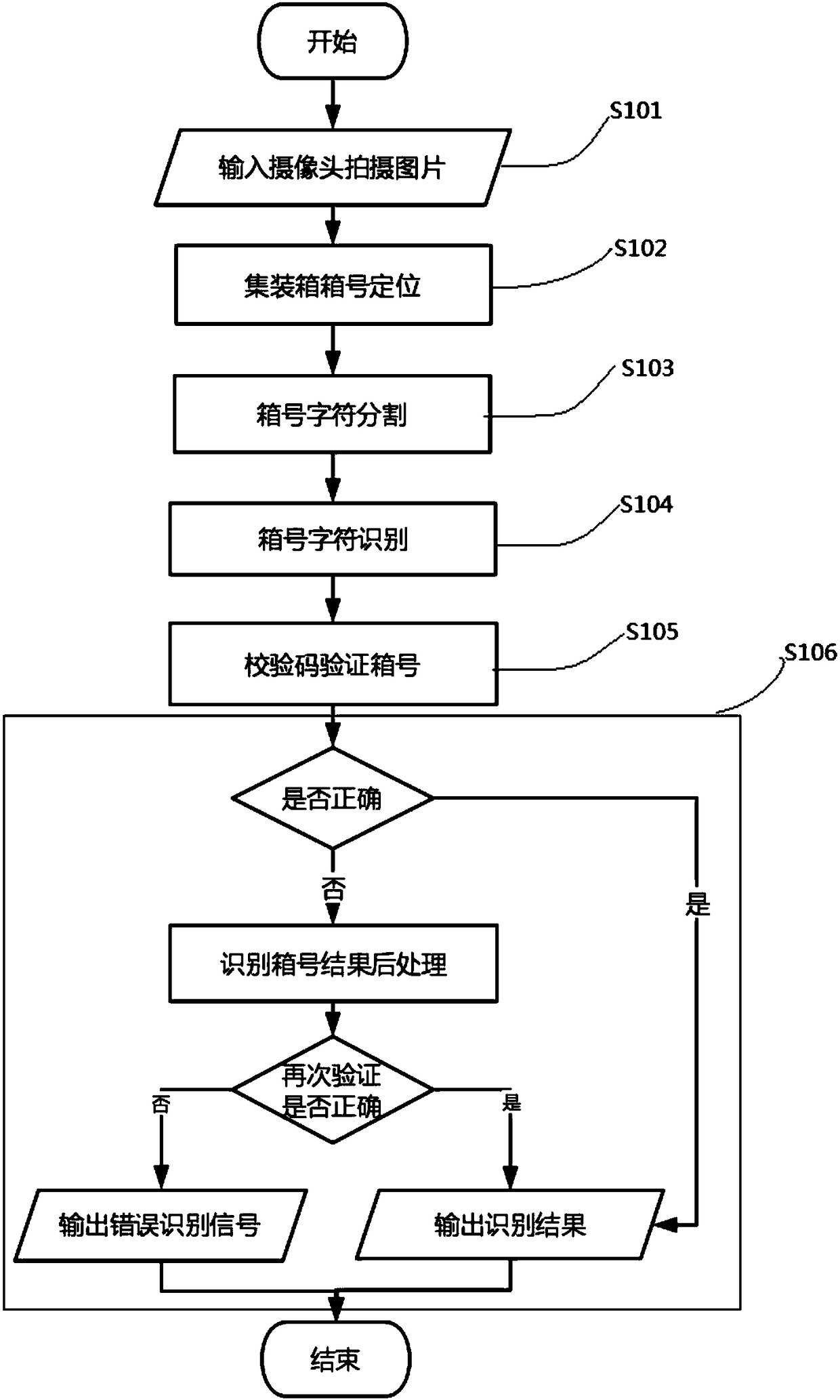

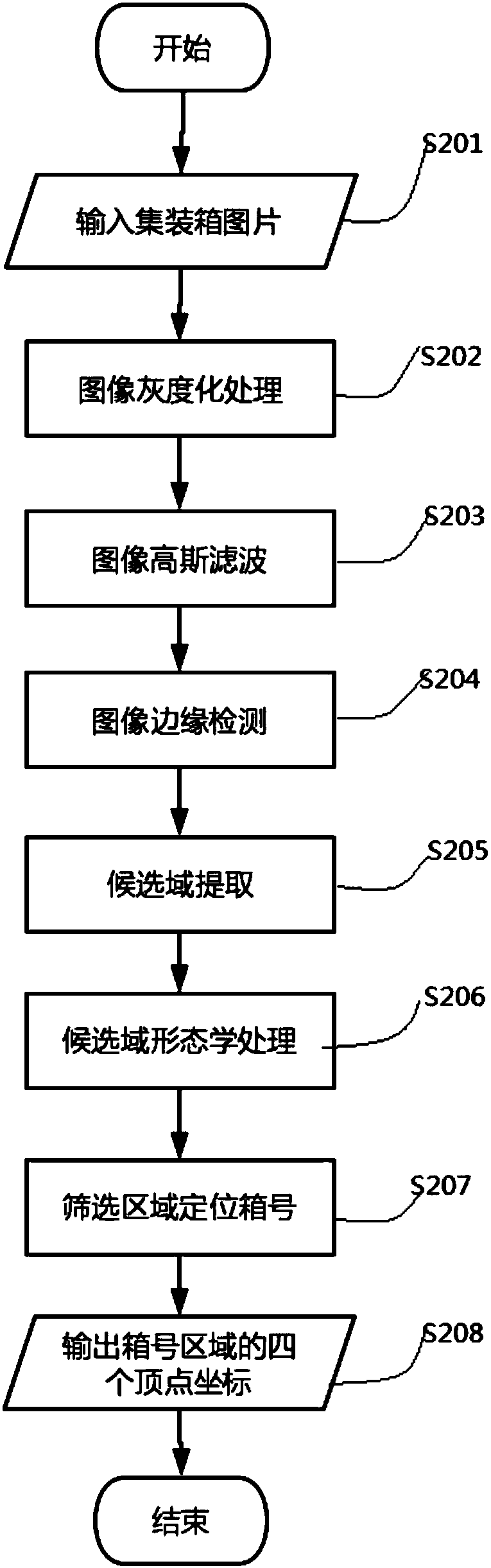

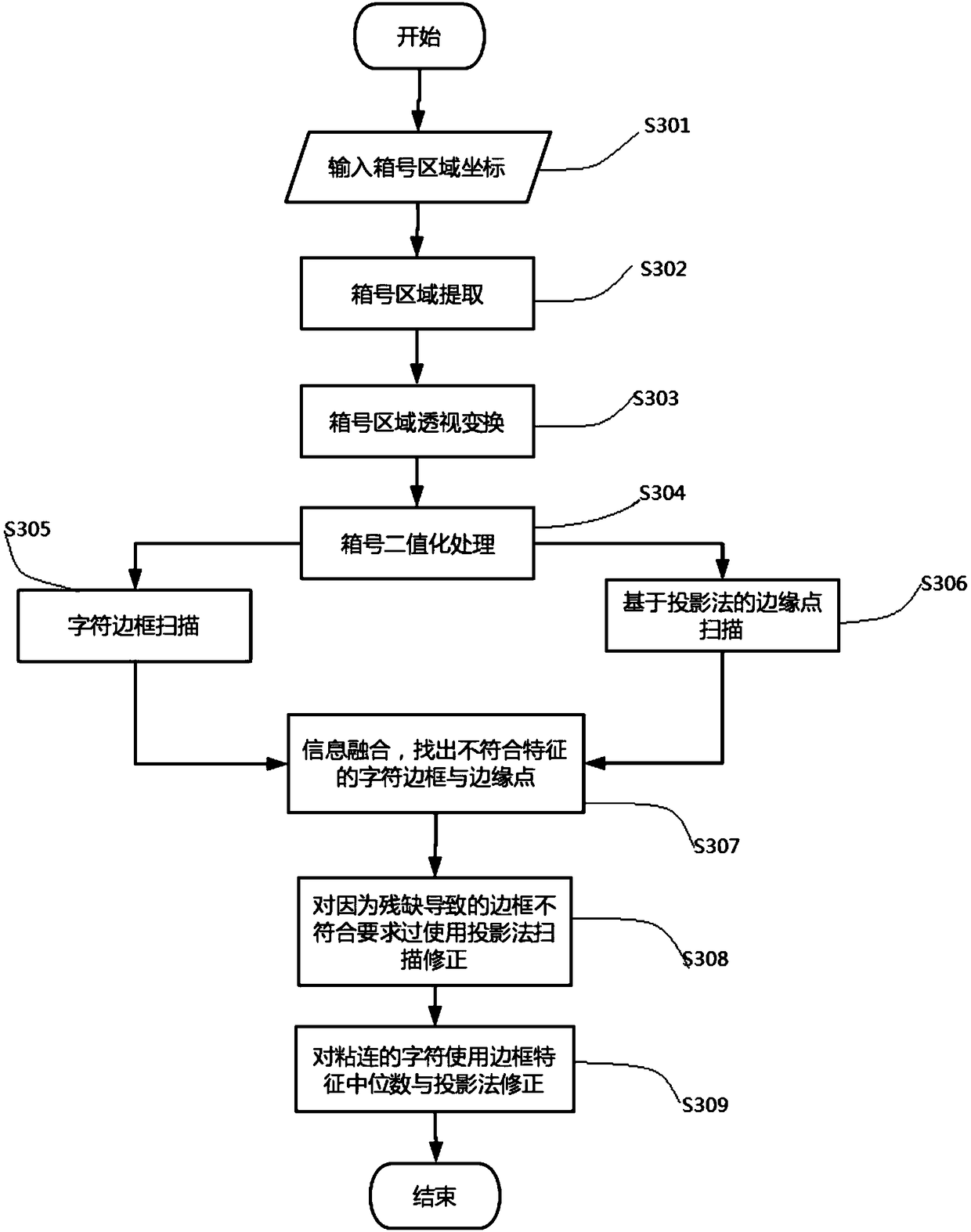

Convolutional neural network classification-based container number recognition method

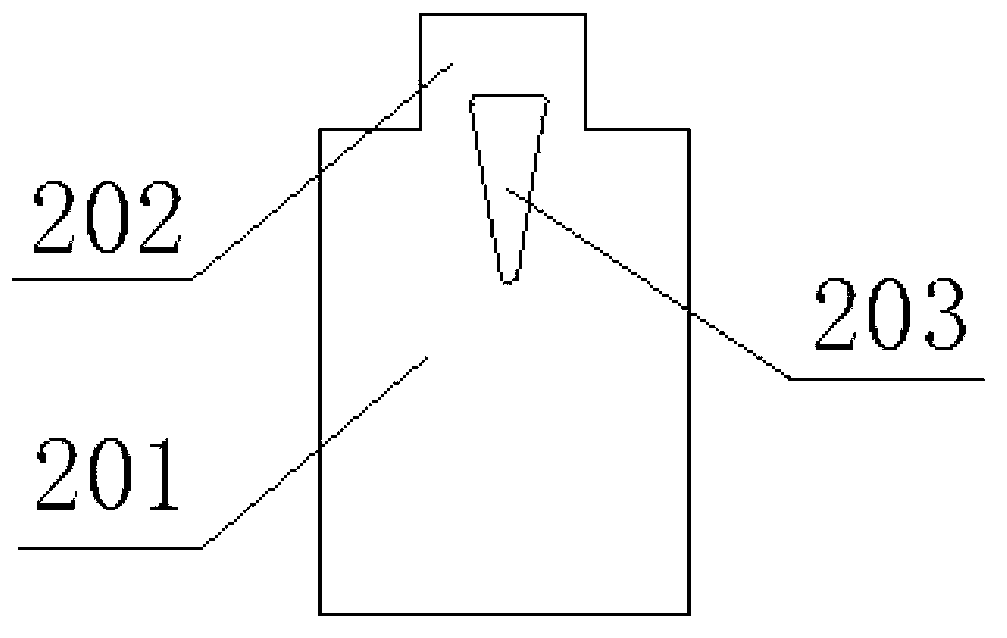

ActiveCN108596166AAccurate response to deformationAccurately respond to imperfectionsImage enhancementImage analysisRgb imagePerspective transformation

The invention discloses a convolutional neural network classification-based container number recognition method. The method comprises the following steps of: S1, obtaining RGB images of a container indifferent directions, carrying out a series of preprocessing on the RGB images so as to locate container number areas in the images; S2, carrying out perspective transformation and binarization on the located container number areas in the step S1, and correctly segmenting various container number characters through a character border and projection method combined processing method; and S3, inputting the segmented container number characters in the step S2 into a preset five-layer convolutional neural network model according to a sequence of positions of the container number characters in thecontainer number, combining recognition results, and carrying out post-processing to obtain a correct container number. The method is capable of correctly solving various problems such as character deformation, incompletion and adhesion, and realizing higher recognition correctness and speed.

Owner:SOUTH CHINA NORMAL UNIVERSITY

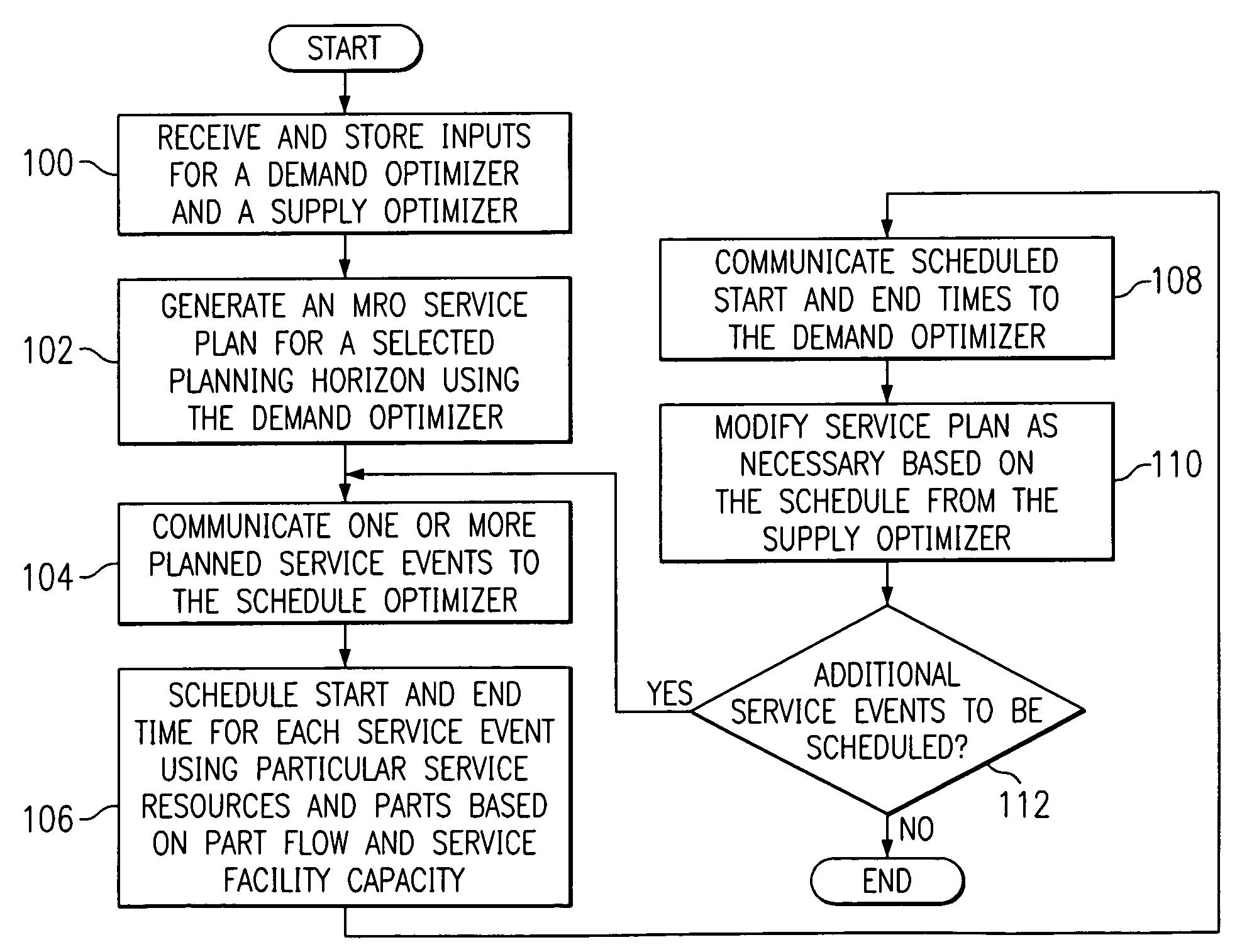

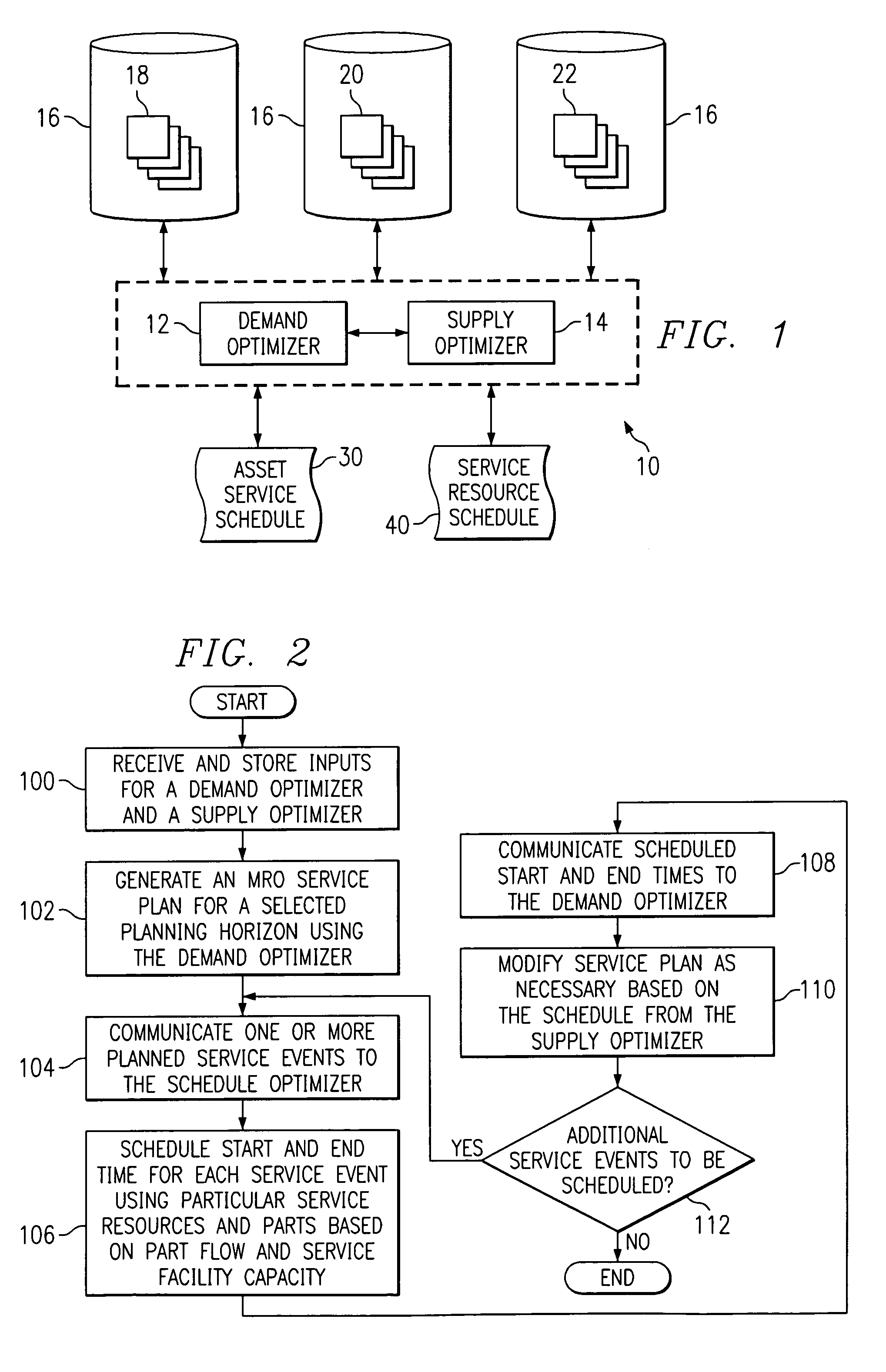

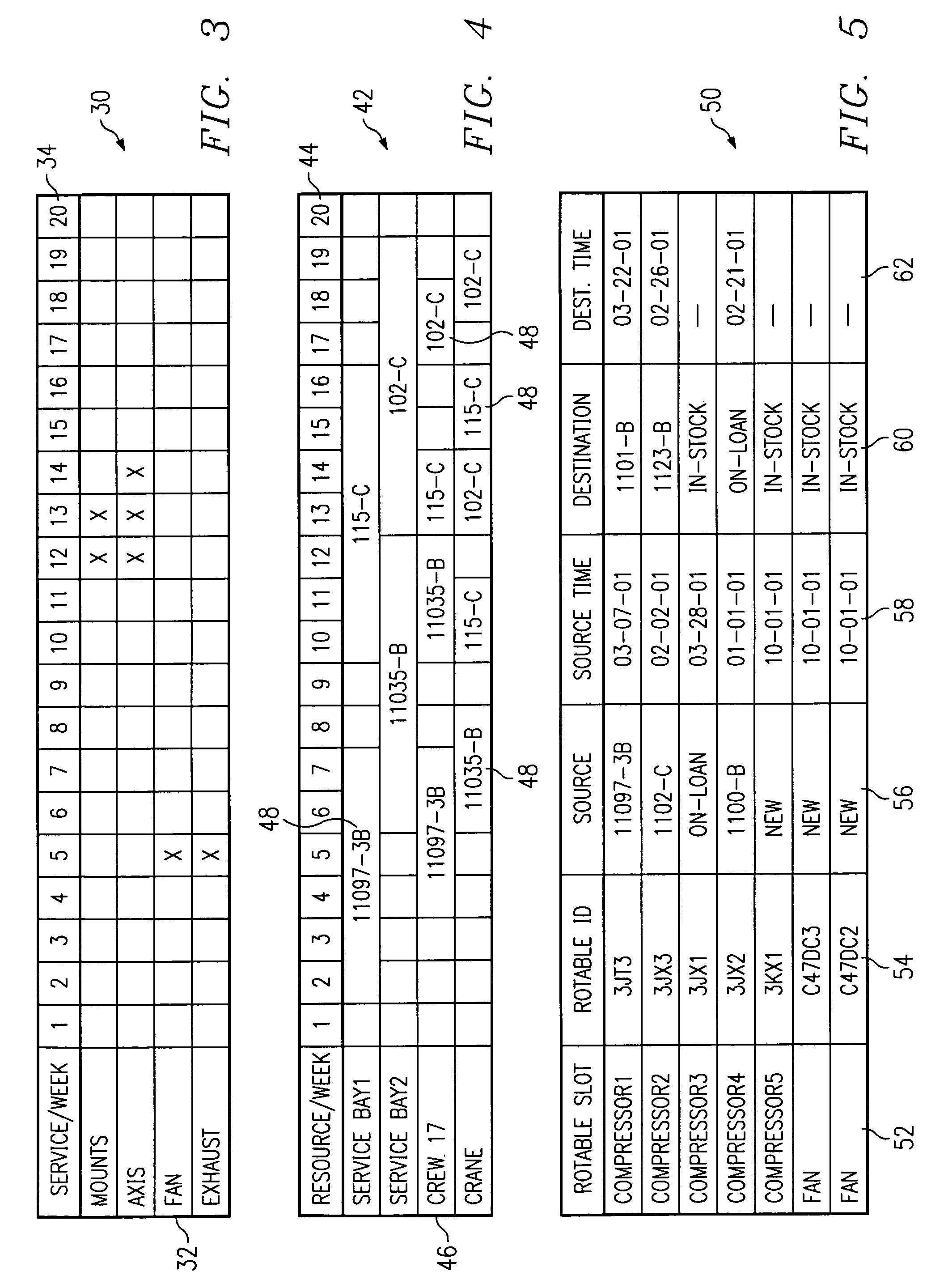

Planning and scheduling of maintenance, repair, and overhaul services

A system (10) for planning and scheduling service events for one or more assets includes a demand optimizer engine (12) that receives information regarding future service requirements for an asset and operating characteristics of the asset. The demand optimizer engine (12) also generates a service plan identifying one or more planned service events during which one or more services are to be performed on the asset and identifying a planned start time and a planned end time for each service event so as to minimize the amount of time the asset is non-operational and the costs associated with each service event. The system (10) also includes a supply optimizer engine (14) that receives the service plan from the demand optimizer engine (12) and generates a service schedule for one or more of the planned service events based on information regarding the flow of one or more parts used in conjunction with the services of each planned service event. The service schedule includes a scheduled start time and a scheduled end time for the one or more planned service events. The supply optimizer engine (14) communicates the service schedule to the demand optimizer engine (12) and the demand optimizer engine (12) modifies the service plan according to the service schedule received from the supply optimizer engine (14).

Owner:BLUE YONDER GRP INC

Method for determining a complete blood count on a white blood cell differential count

ActiveUS20100284602A1Improve accuracyLow costTelevision system detailsImage analysisWhite blood cellBody fluid

Systems and methods analyzing body fluids such as blood and bone marrow are disclosed. The systems and methods may utilize an improved technique for applying a monolayer of cells to a slide to generate a substantially uniform distribution of cells on the slide. Additionally aspects of the invention also relate to systems and methods for utilizing multi color microscopy for improving the quality of images captured by a light receiving device.

Owner:ROCHE DIAGNOSTICS HEMATOLOGY INC

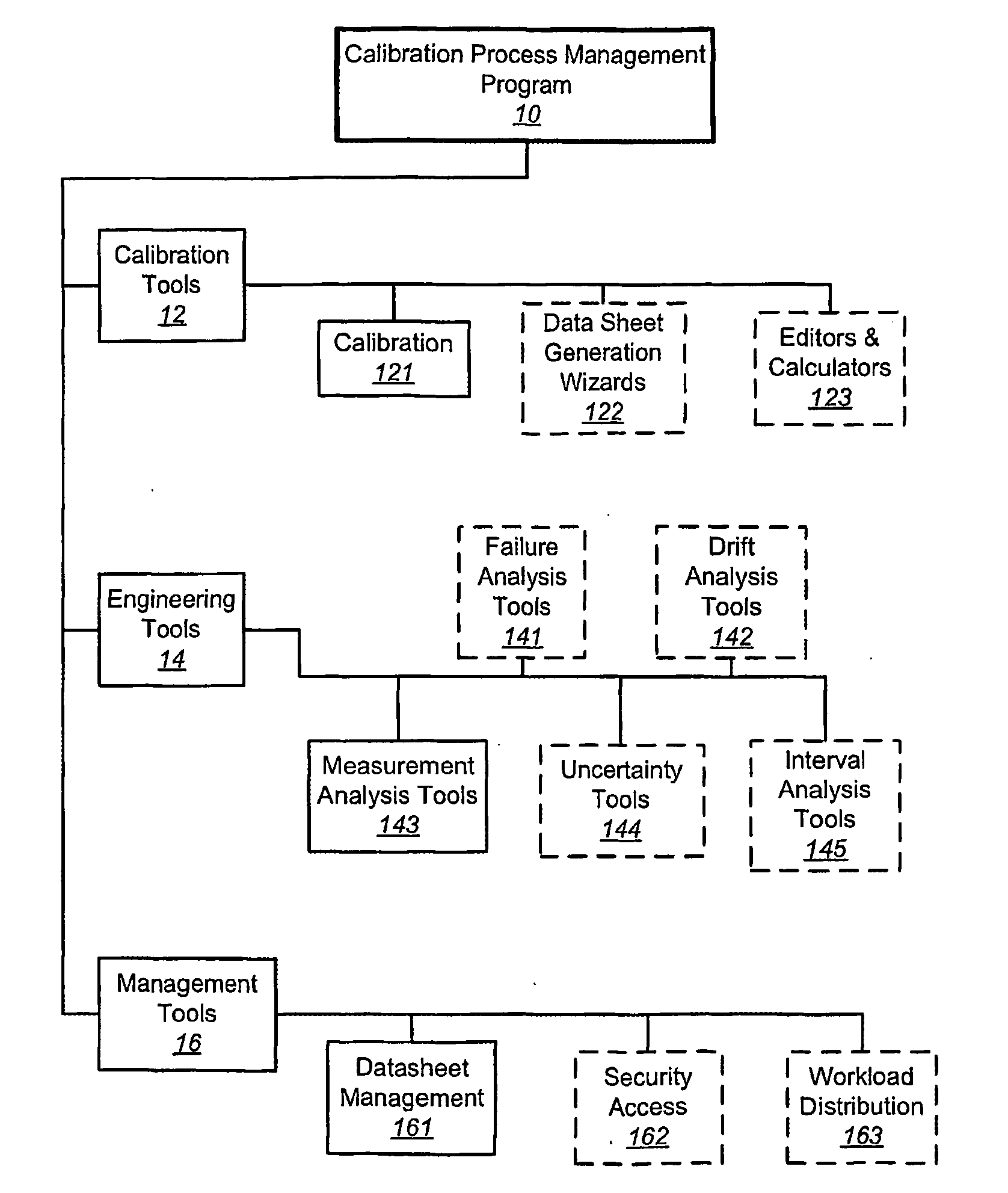

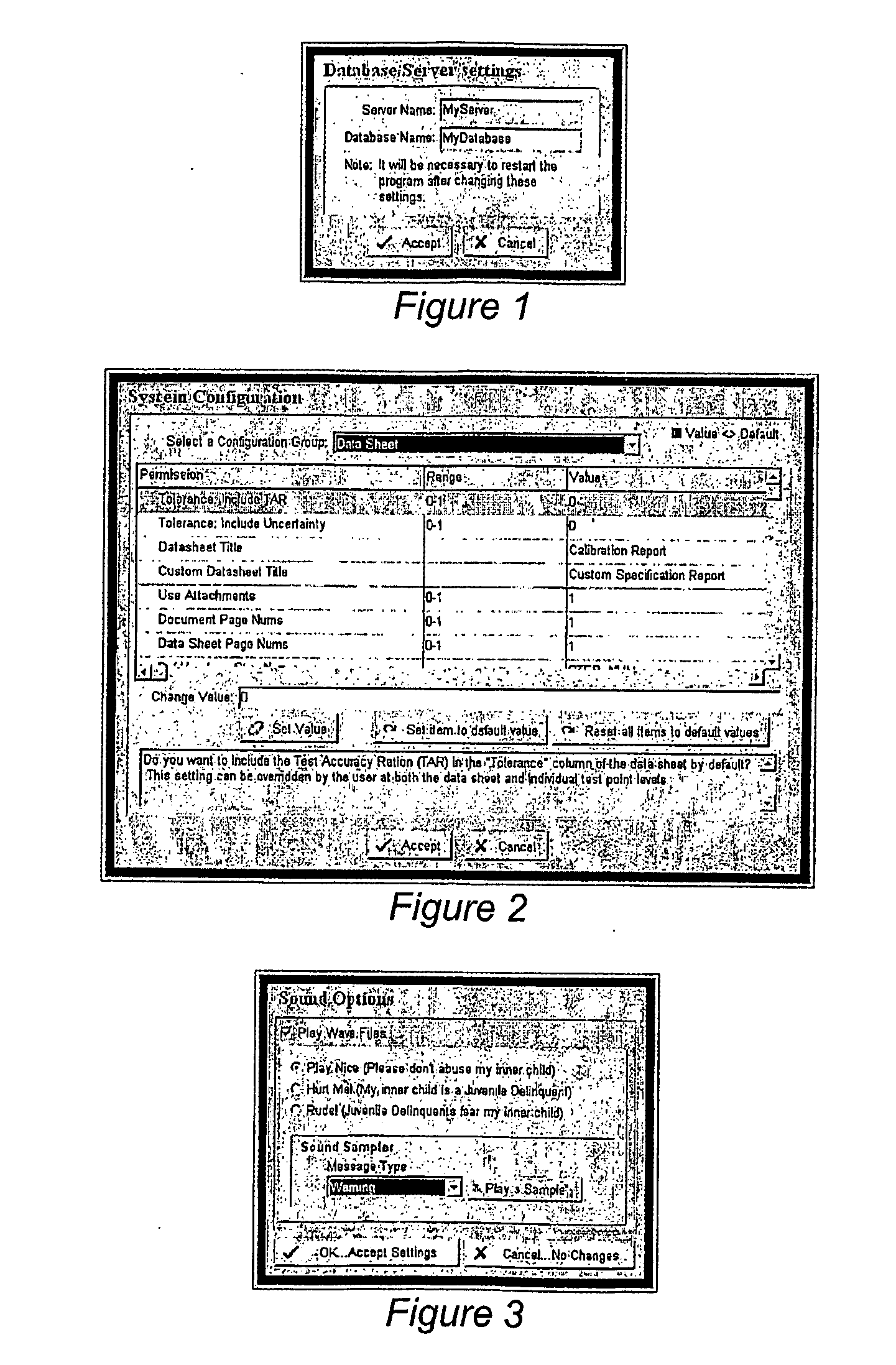

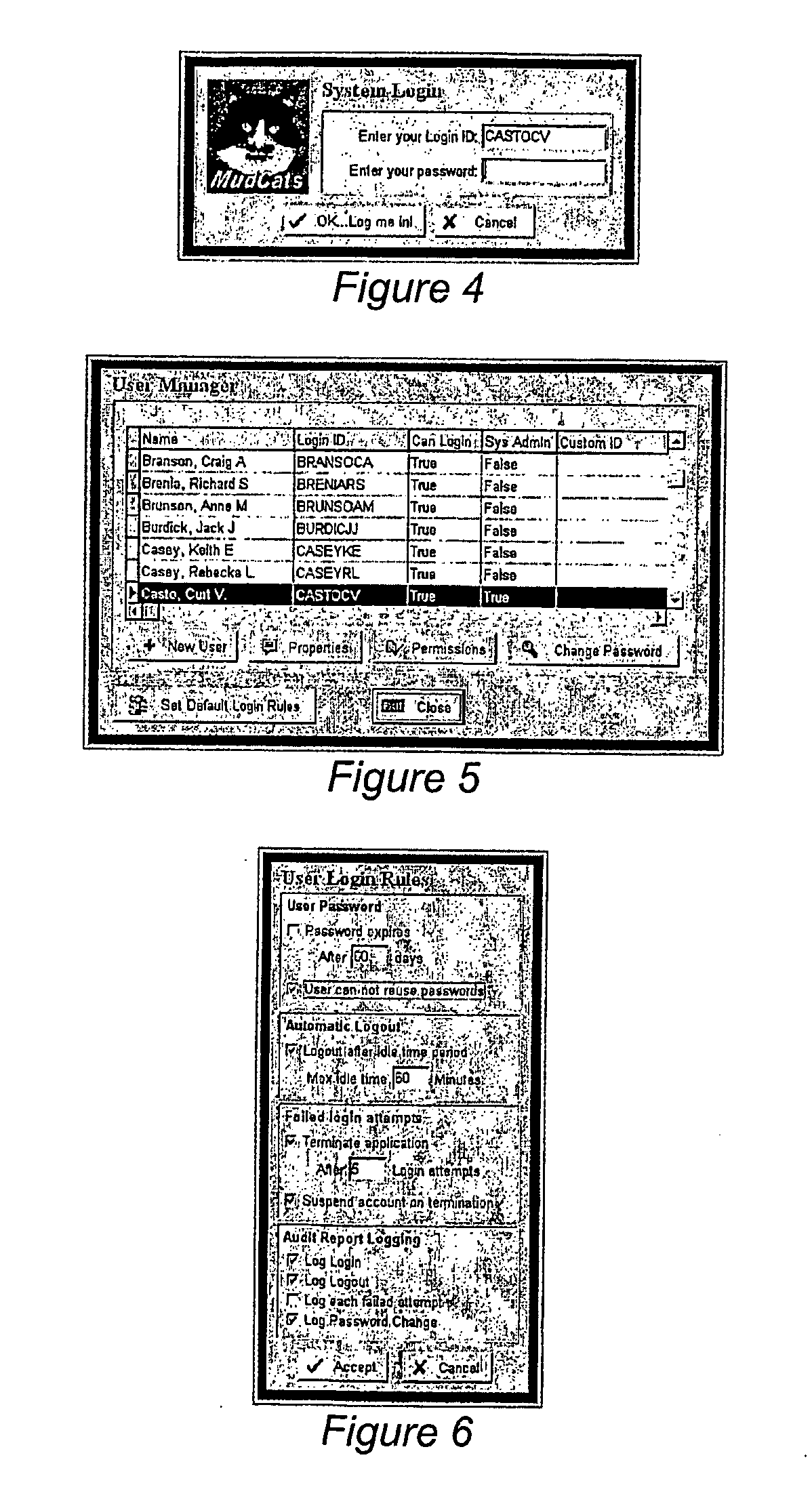

Calibration process management system and data structure

InactiveUS20060167643A1Reduce timeSpeed processElectrical measurement instrument detailsMarginal checkingTelecommunications linkUnique identifier

A method for calibration process management of a calibration testing unit and a plurality of units under test, comprising configuring a user interface in communication with a calibration process management software system, configuring a communications link in communication with the software system, the software system capable of communicating with the calibration testing unit and the plurality of units under test, wherein the software system manages the user interface and the communications link in a manner permitting an operator to calibrate the plurality of units under test. Tracking of the calibrated units under test uses a permanent unique identifier and a dynamic unique identifier.

Owner:SOUTHERN CALIFORNIA EDISON

Tandem ion-trap time-of-flight mass spectrometer

InactiveUS7897916B2Improve performanceAdd additional massStability-of-path spectrometersTime-of-flight spectrometersTime-of-flight mass spectrometryElectronic switch

A tandem linear ion trap and time-of-flight mass spectrometer, where the ion trap has a straight central axis orthogonal to the flight path of the mass spectrometer. The ion trap comprises a set of electrodes, (401, 403, 402, 404) at least one of the electrodes has a slit for ejecting ions towards the mass spectrometer; a set of DC voltage supplies (+V, −V, V1, V2) to provide discrete DC levels and a number of fast electronic switches (409) for connecting / disconnecting the DC supplies to at least two of the electrodes; a neutral gas filling the ion trap and a digital controller to provide a switching procedure of ion trapping, manipulation with ions, cooling and including a state at which all ions are ejected from the ion trap towards the mass spectrometer.

Owner:SHIMADZU RES LAB EURO

Steel plate ingot casting device and method for producing ultra-thick steel plate cast ingot with same

The invention discloses a steel plate ingot casting device, which comprises a pedestal, a fixed framework and an ingot mold, wherein the fixed framework is fixedly connected with the pedestal; the ingot mold is positioned in the fixed framework and consists of two pairs of side templates, i.e., front, rear, left and right side templates, and a bottom template; the outer sides of the side templates and the bottom template are respectively provided with a cooling water box; the side templates are provided with squeezing mechanisms; the bottom template is provided with a lifting mechanism; the side templates and the bottom template are all copper plate products; and the bottom template is provided with a runner port. According to the steel plate ingot casting device, deformation under cold and hot intensity stress can be avoided, and a shrinkage hole is avoided; since the solidification time is greatly shortened, the segregation in a steel ingot can be obviously relieved, thereby greatly improving the internal quality and the performance of a produced ultra-thick plate; and meanwhile, the steel plate ingot casting device has the advantages of freely adjustable ingot mold size, long service life of the ingot mold and the like.

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

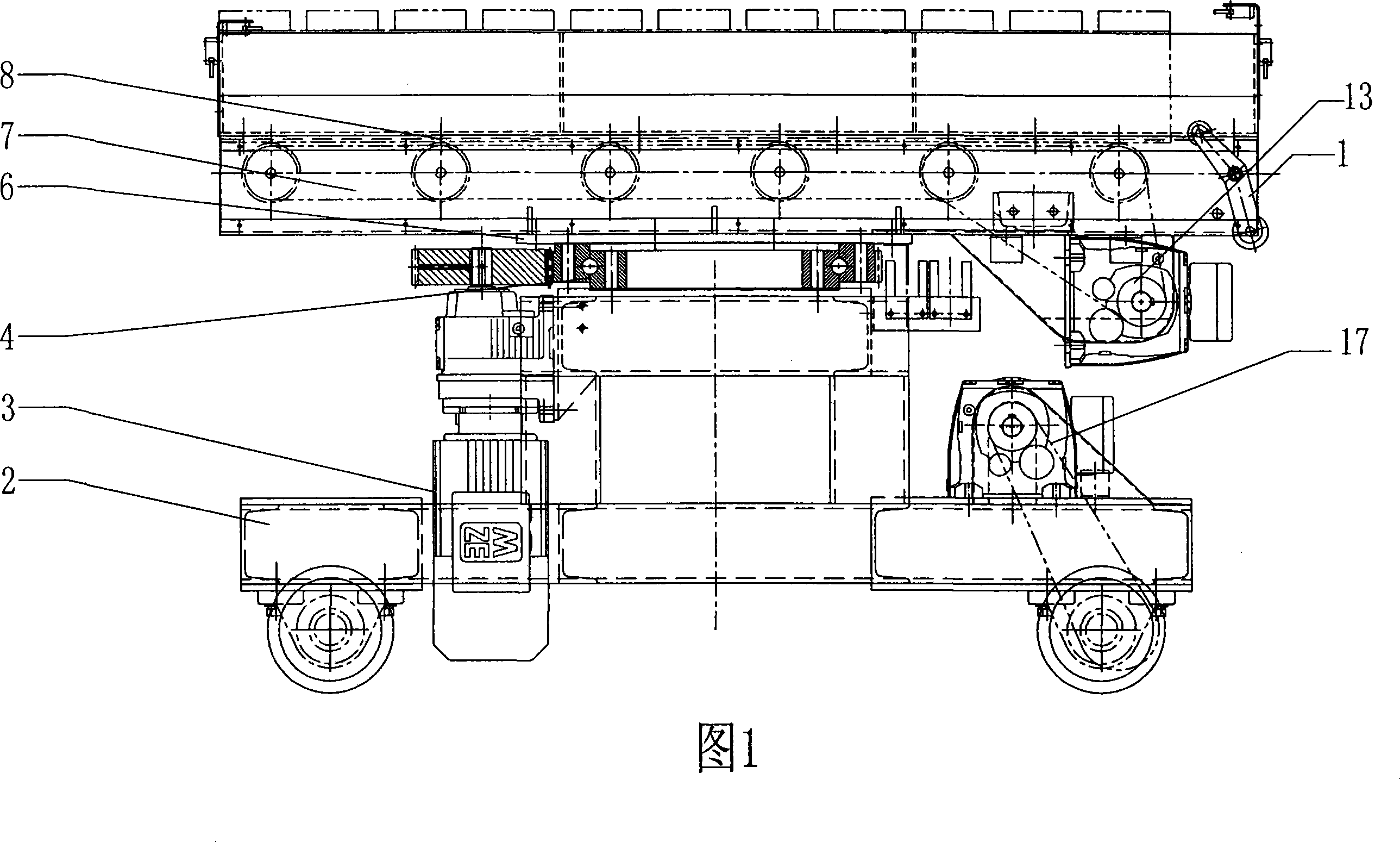

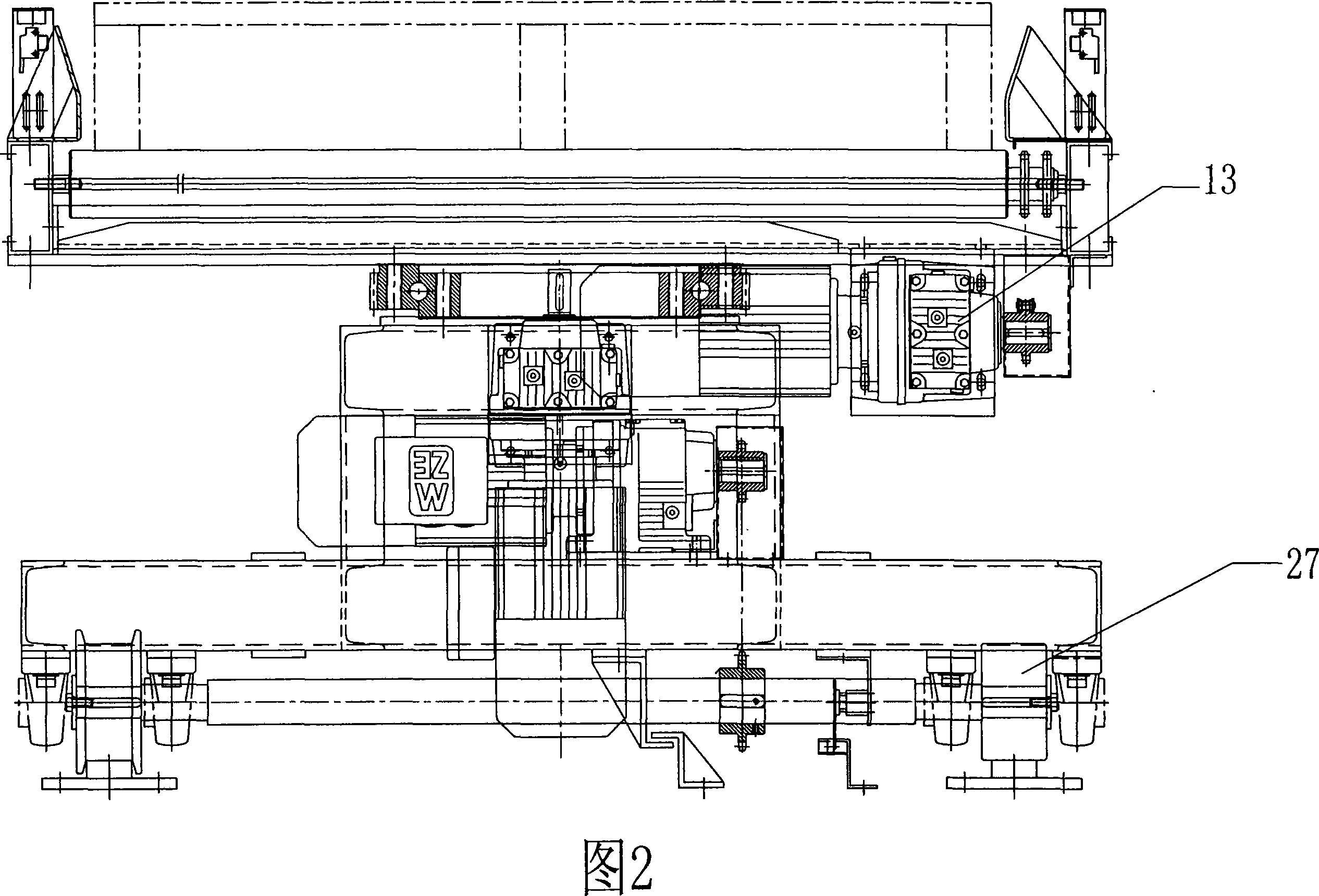

Rotary drum delivering platform vehicle

ActiveCN101024443ASimple structureReduce utilizationElectric locomotivesSupporting framesDrive wheelDrive motor

Owner:JIANGSU LIUWEI LOGISTIC EQUIP INDAL

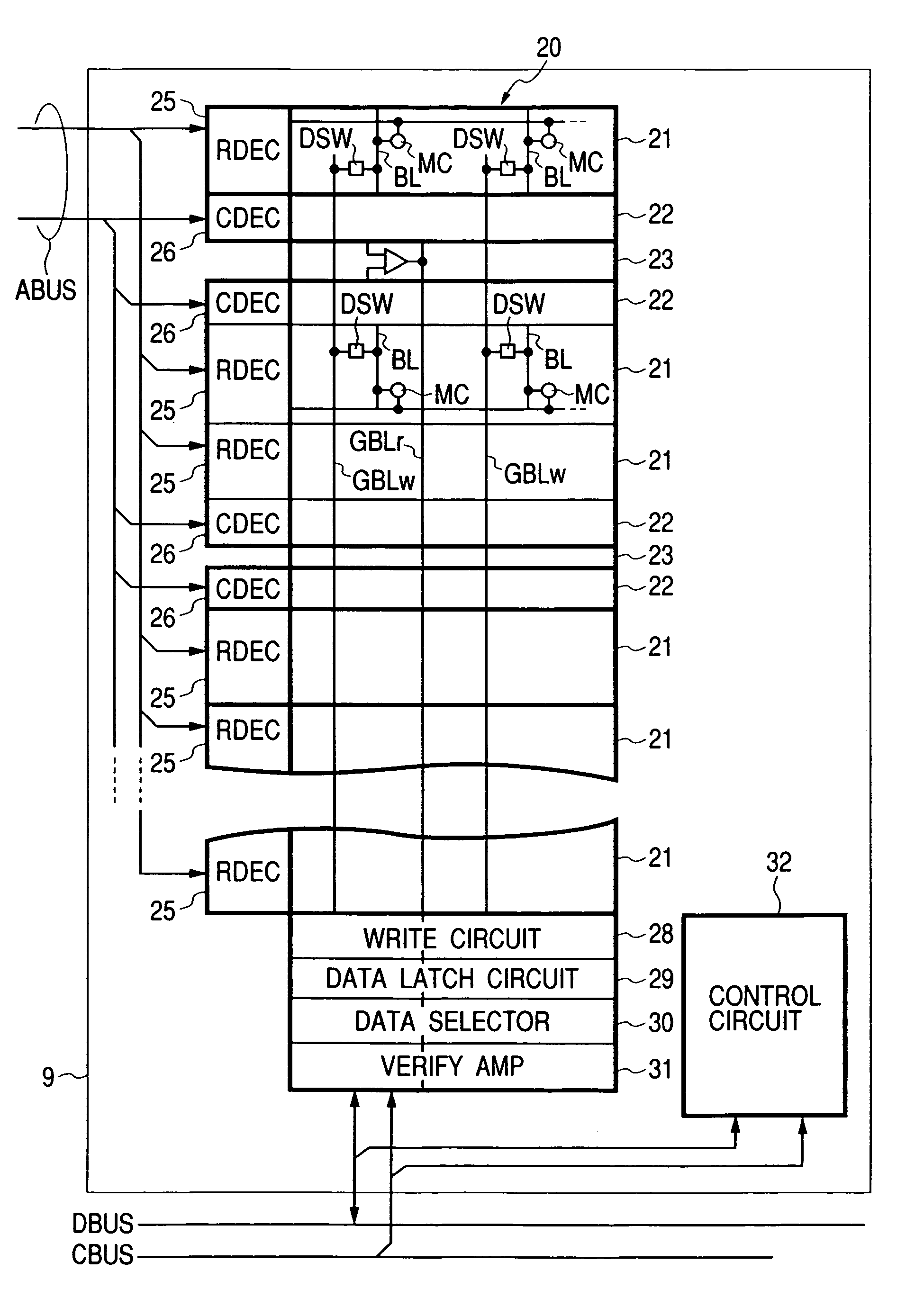

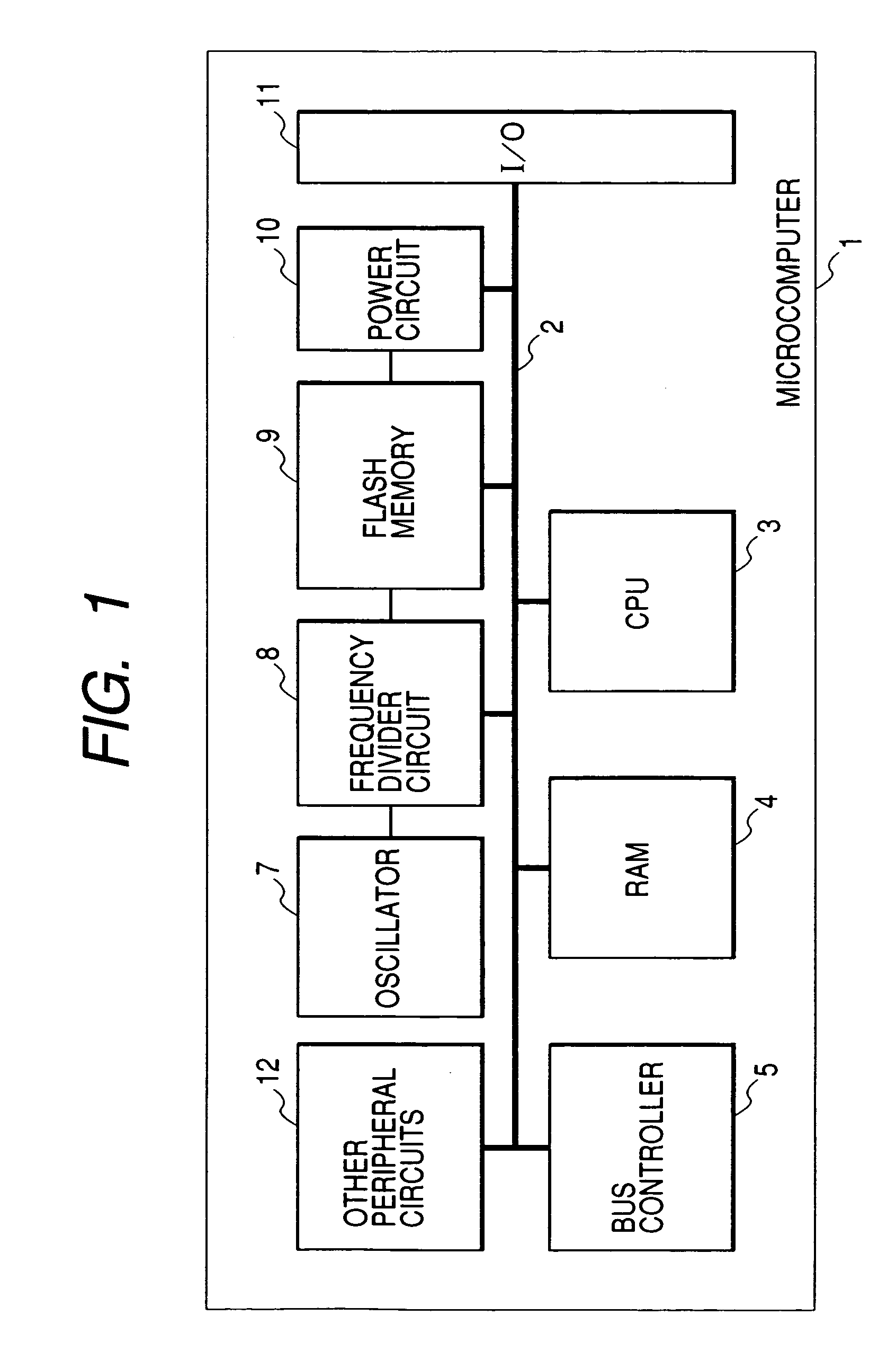

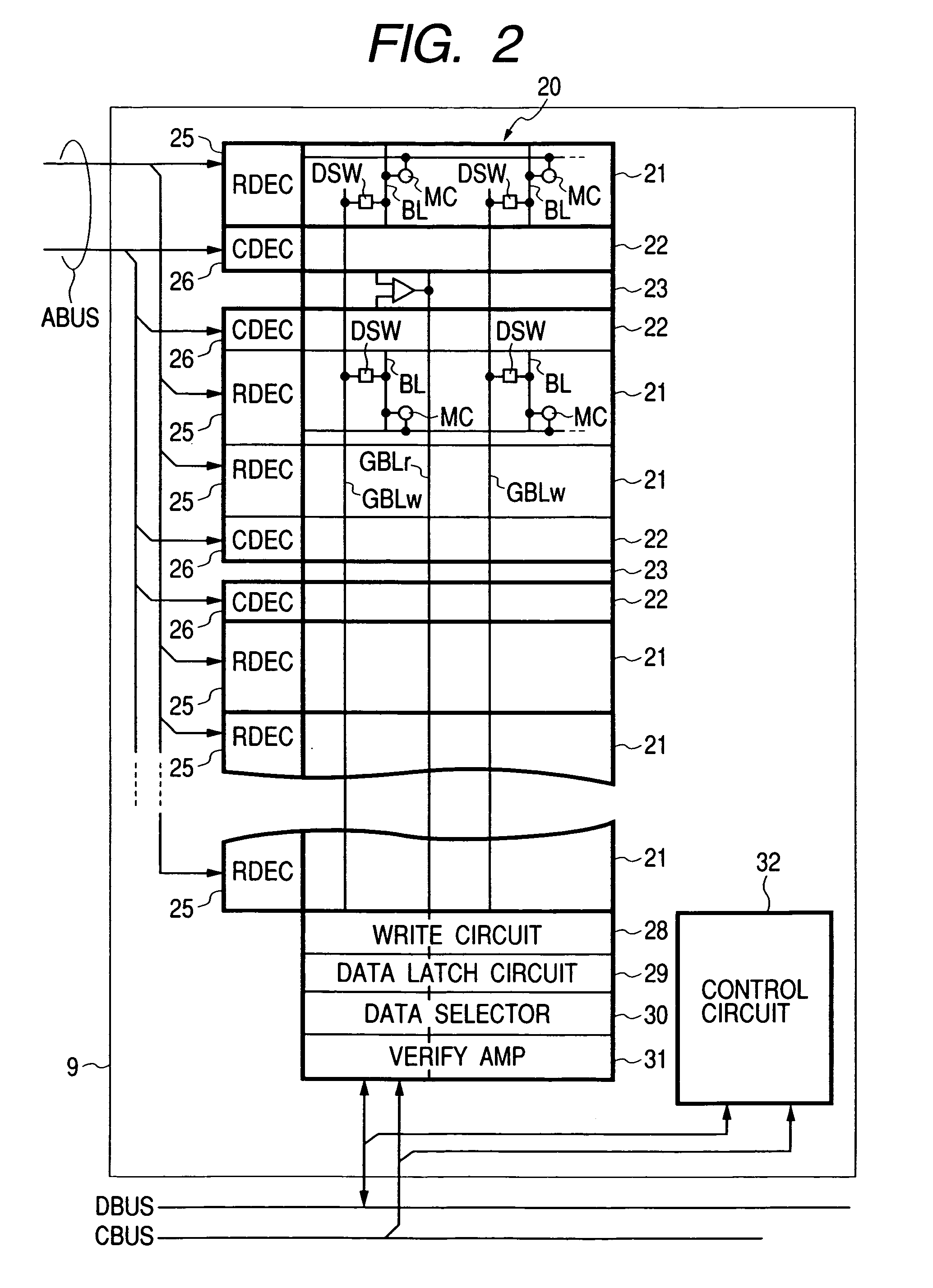

Semiconductor device

ActiveUS7190615B2Reduce turnaround timeHigh currentRead-only memoriesDigital storageSense amplifierLoad capacity

The read speed of an on-chip nonvolatile memory enabling electric rewrite is increased. The nonvolatile memory has a hierarchal bit line structure having first bit lines specific to each of a plurality of memory arrays, a second bit line shared between the plurality of memory arrays, a first selector circuit selecting the first bit line for each of the memory arrays to connect the selected first bit line to the second bit line, and a sense amp arranged between the output of the first selector circuit and the second bit line. The hierarchal bit line structure having the divided memory arrays can reduce the input load capacity of the sense amp.

Owner:RENESAS ELECTRONICS CORP

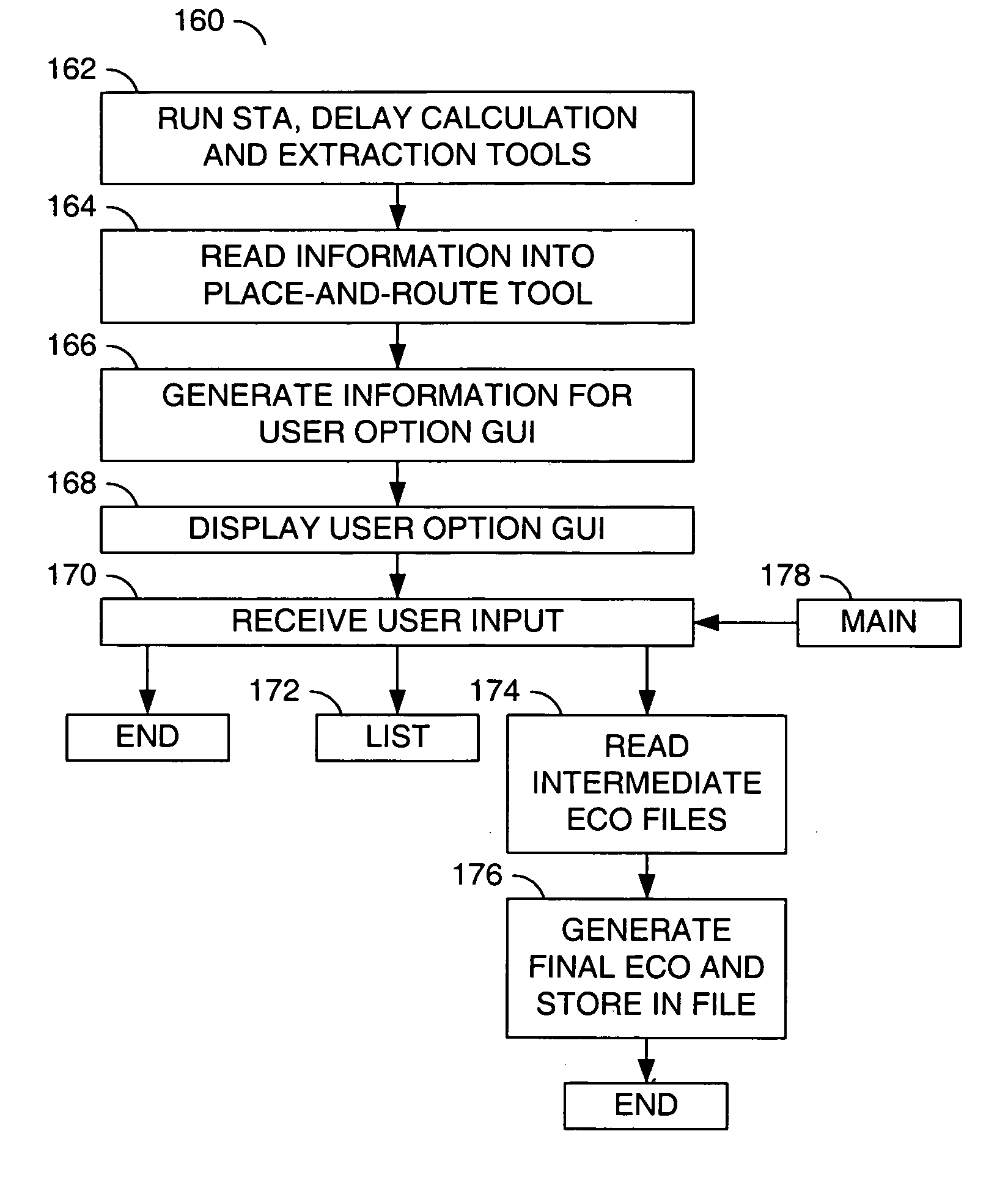

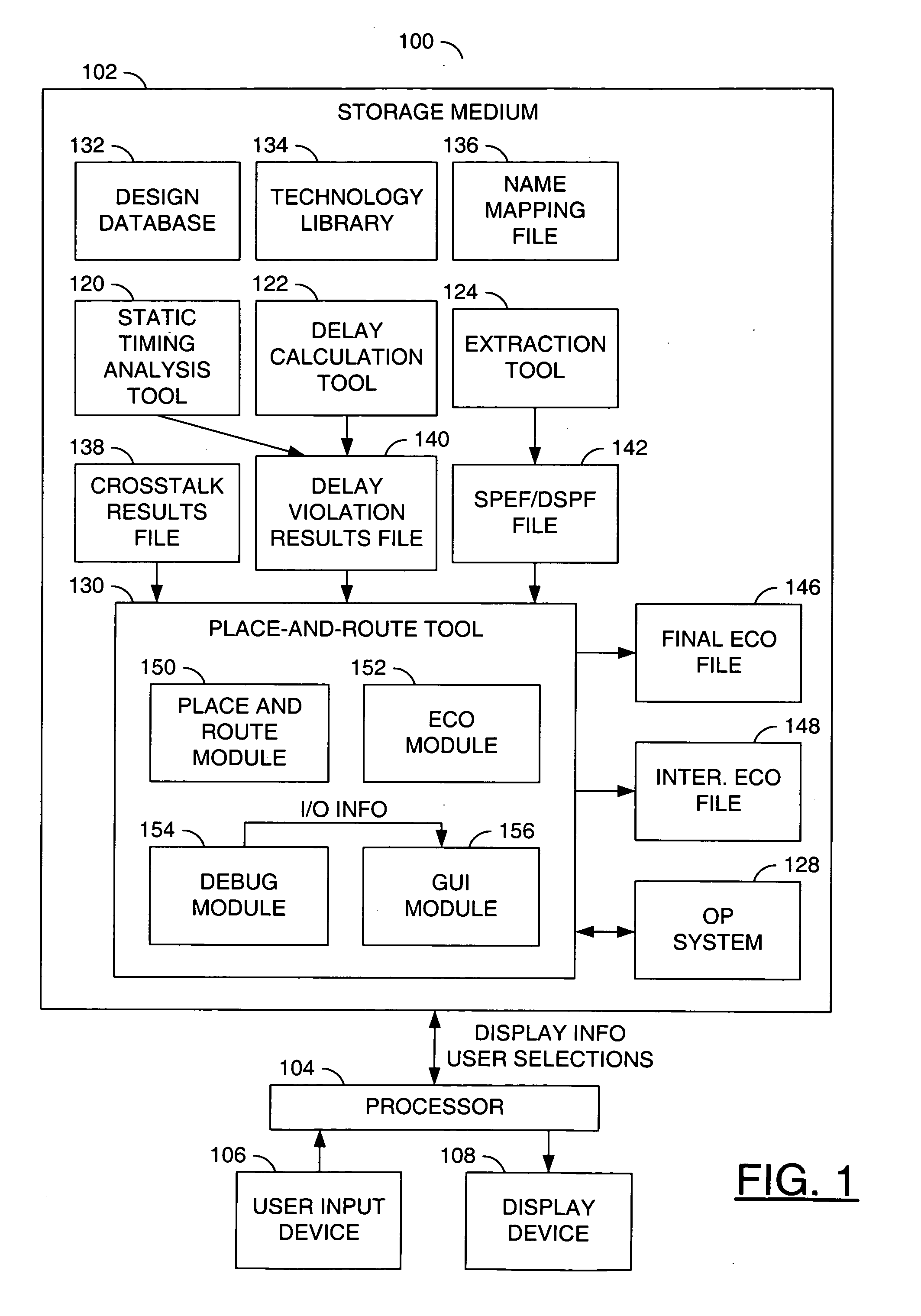

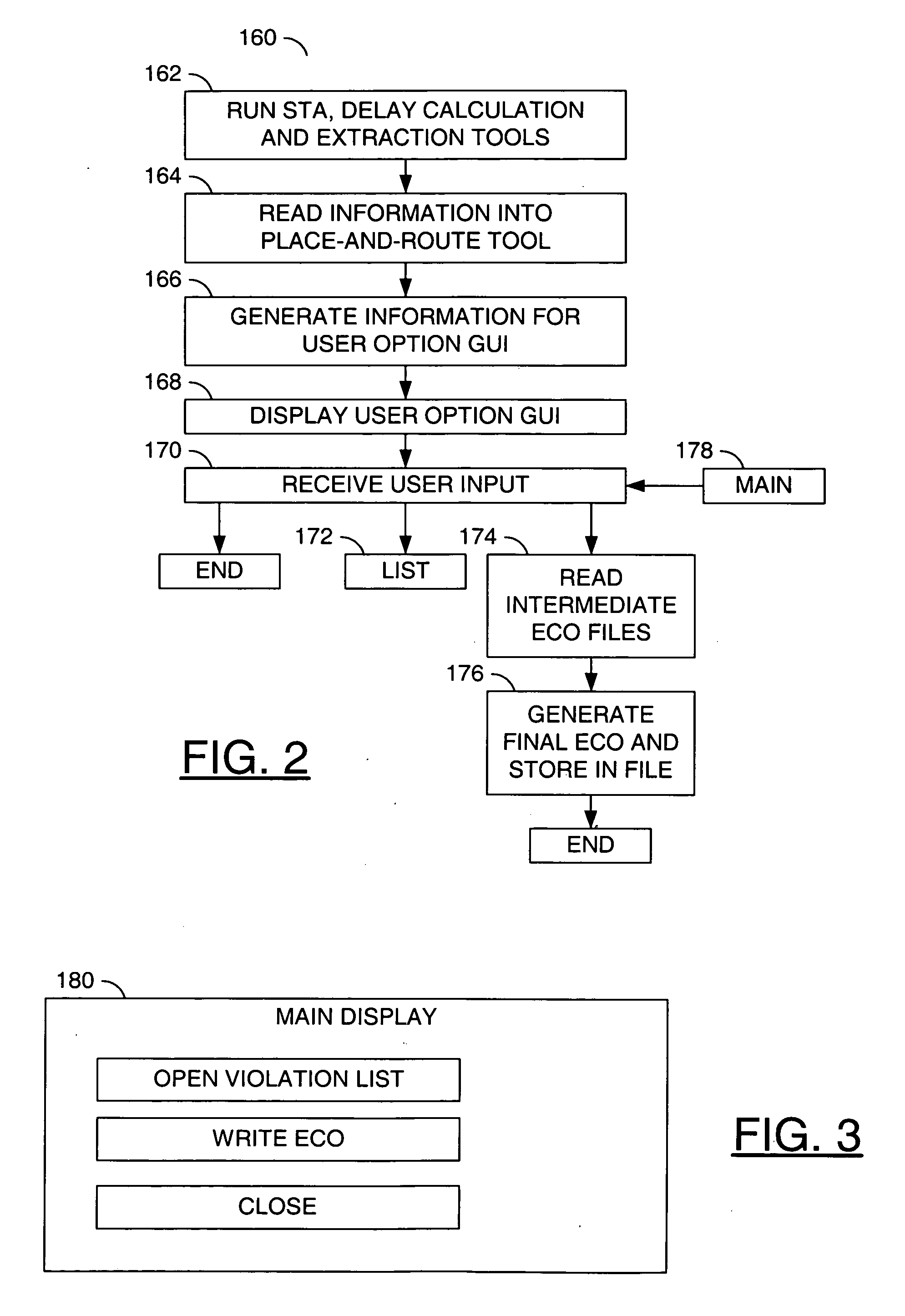

Timing violation debugging inside place and route tool

InactiveUS20070050745A1Reduce turnaround timeComputer programmed simultaneously with data introductionComputer aided designEngineeringCircuit design

A method for developing a circuit design is disclosed. The method generally include the steps of (A) generating a violation display based on violation information provided from a place-and-route tool and (B) generating a layout display based on layout information provided from the place-and-route tool. The violation display may include (i) a plurality of performance violations for the circuit design and (ii) a plurality of user inputs each associated with one of the performance violations. The layout display may include a layout view of the circuit design. The layout view may highlight at least one of (i) a plurality of cells and (ii) a plurality of networks each along a path related to a particular one of the performance violations identified by a user through the user inputs.

Owner:BELL SEMICON LLC

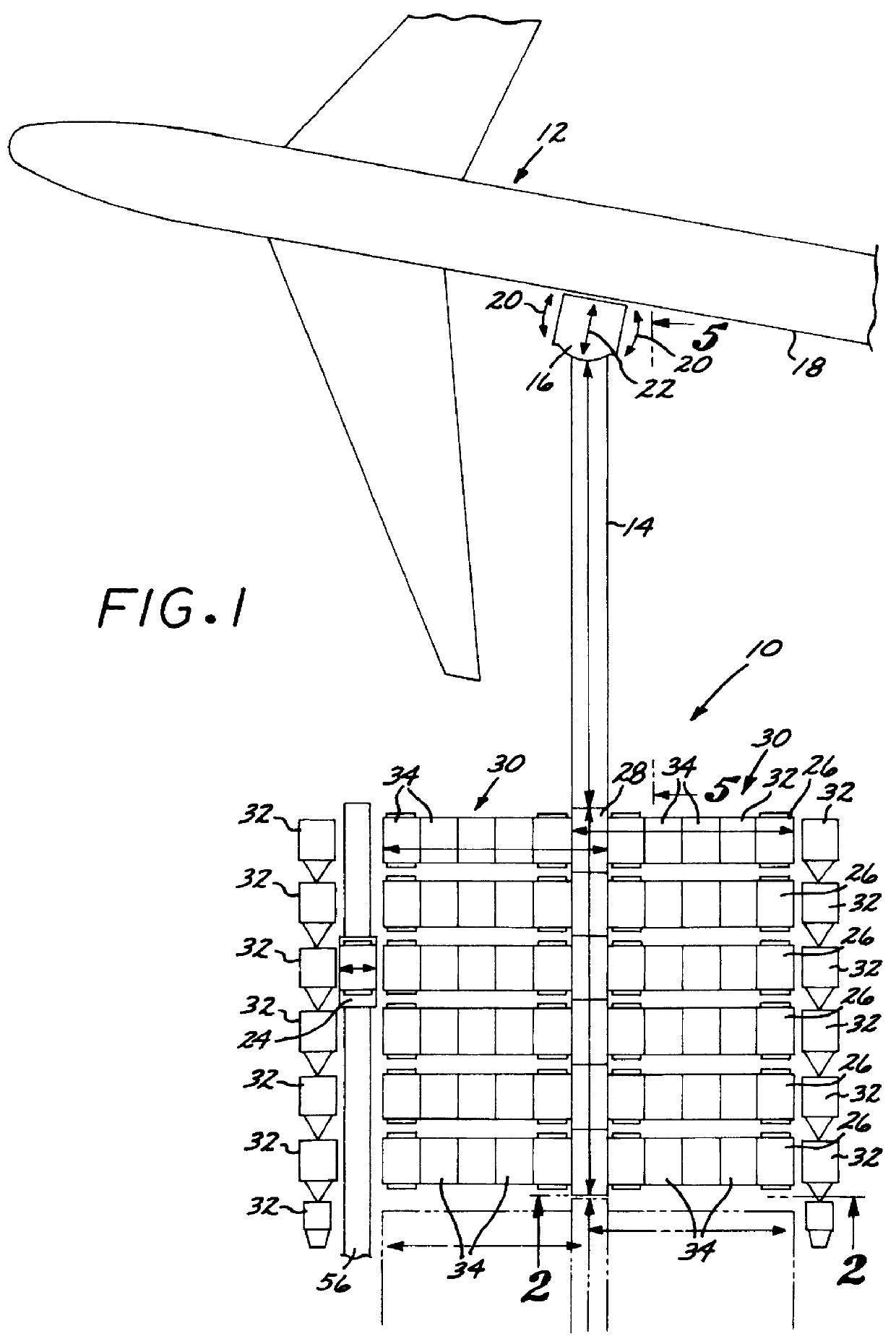

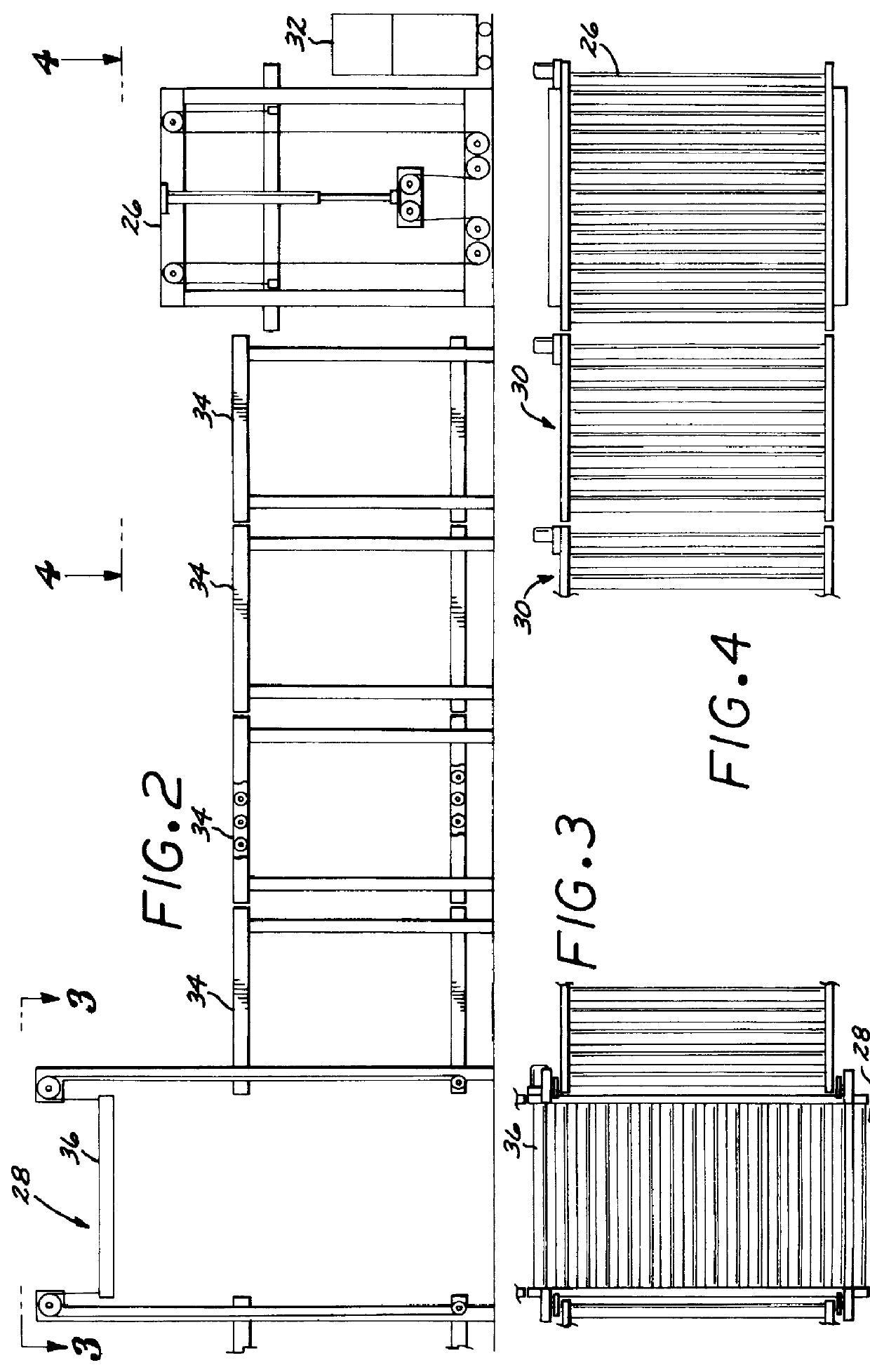

Freight loading system

InactiveUS6164892AReduces aircraft turn around timeShorten the timeFreight handling installationsFreight handlingAirplanePallet

An airport loading system which utilizes various conveyor and elevated configurations to load aircraft rapidly while requiring significantly less processing area. The aircraft loading / unloading turn around time is significantly reduced because the pallets in which the freight is loaded are not lowered to the freight ramp but instead transferred to the system platform.

Owner:MEGA LOADING SYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com