Automatic processing machine for bearing inner ring screw hole

A technology of automatic processing and bearing inner ring, applied in metal processing machinery parts, metal processing, metal processing equipment and other directions, can solve the problems of high processing cost, high labor intensity of workers, low processing efficiency, etc., to reduce production costs, labor The effect of strength reduction and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

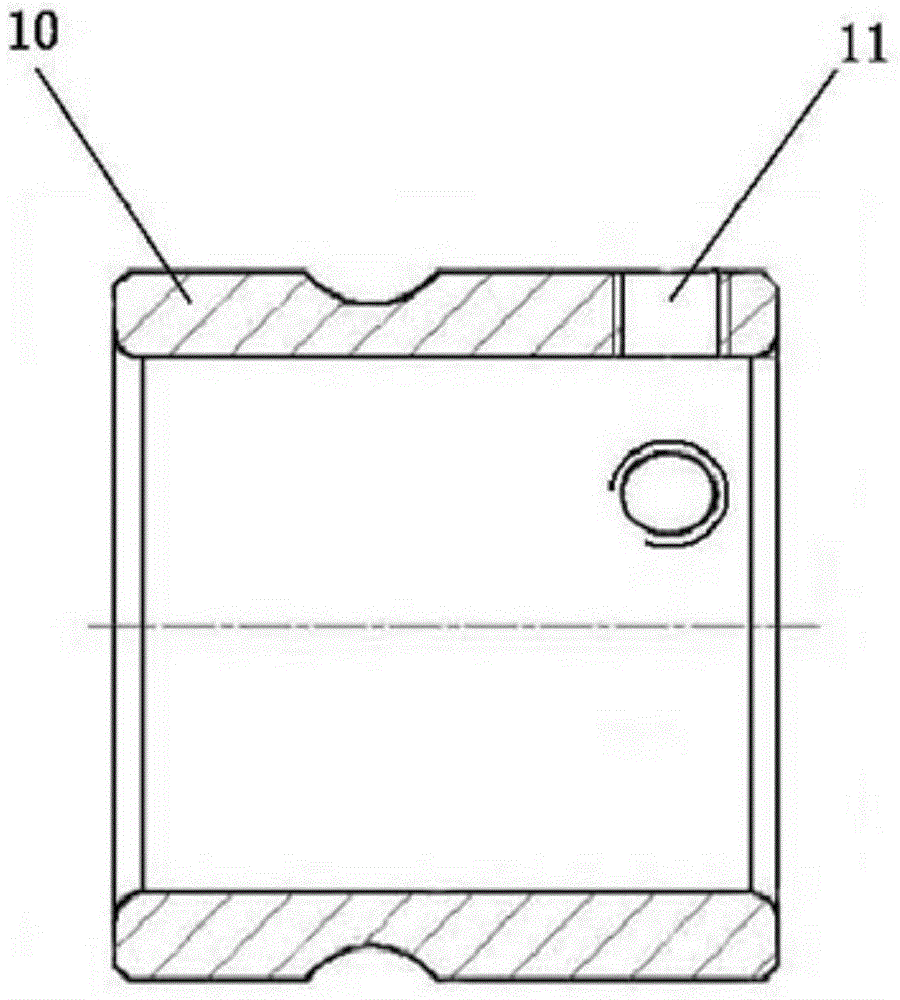

[0029] The present invention can be used for hole processing such as drilling, tapping etc. to axle class or cover class parts, in the present embodiment is to such as figure 1The shown workpiece 10, that is, the bearing inner ring, is processed with two screw holes 11. Of course, the present invention is not limited to the processing of this kind of part.

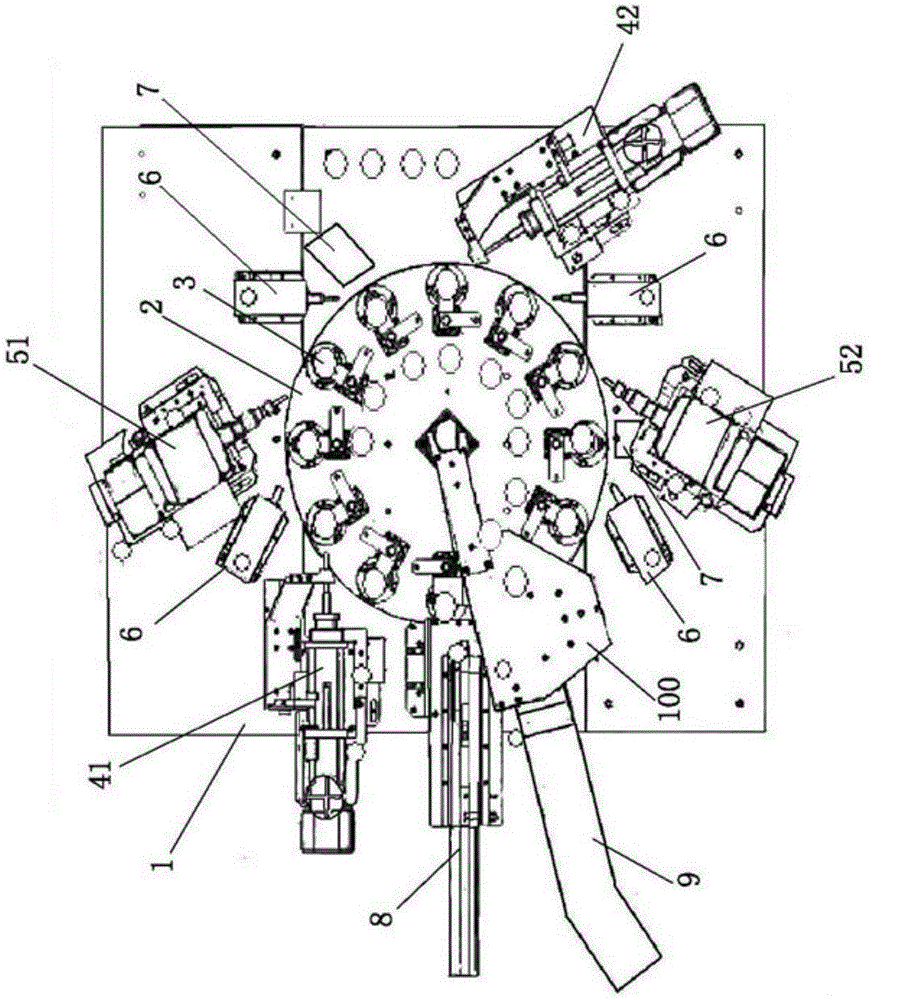

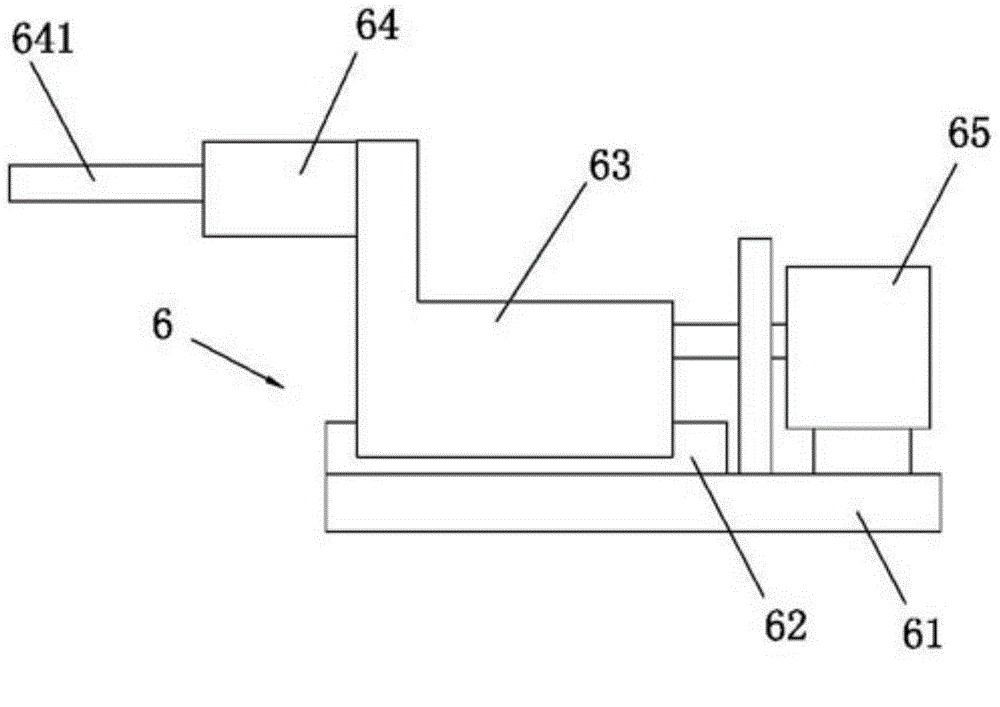

[0030] like Figure 2 to Figure 4 As shown in the figure, an automatic processing machine for bearing inner ring screw holes includes a machine base 1, a turntable 2 and a control unit. The control unit is linked with a touch control screen for human-computer interaction, and the touch control screen is used to send instructions to the control unit by finger pointing. The machine base 1 is used to install the turntable 2 and various processing devices. The power transmission device is ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com