Automatic feeding and discharging device of structural steel wheel stamping equipment

A technology of automatic loading and unloading and stamping equipment, applied in the field of wheel processing, can solve the problems of unguaranteed product quality and low production efficiency, and achieve the effect of saving manual handling time, reducing product cost, and saving auxiliary processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

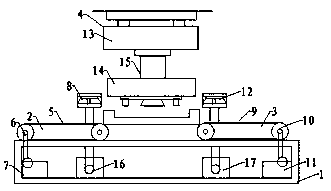

[0013] see figure 1 , the present invention provides a technical solution: an automatic loading and unloading device for steel wheel stamping equipment, including a workbench 1, a loading mechanism 2 is installed on the left end of the workbench 1, and a feeding mechanism 3 is installed on the right end, the upper A stamping host 4 is installed between the feeding mechanism 2 and the unloading mechanism 3. The feeding mechanism 2 includes a feeding conveyor belt 5 and a feeding electromagnetic chuck 8. The inside of the feeding conveyor belt 5 is sleeved with a feeding synchronous Runner 6, the axle of described feeding synchronous runner 6 is connected with feeding servo motor 7, and described feeding electromagnetic sucker 8 is installed on the end of feeding conveyor belt 5 by fixed bracket; Described unloading mechanism 3 comprises unloading Conveyor belt 9, the blanking conveyor belt 9 is sleeved with a blanking synchronous runner 10, the wheel shaft of the blanking synch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com