Patents

Literature

219results about How to "Save packing time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

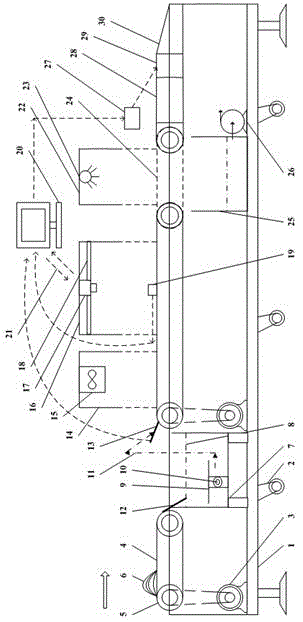

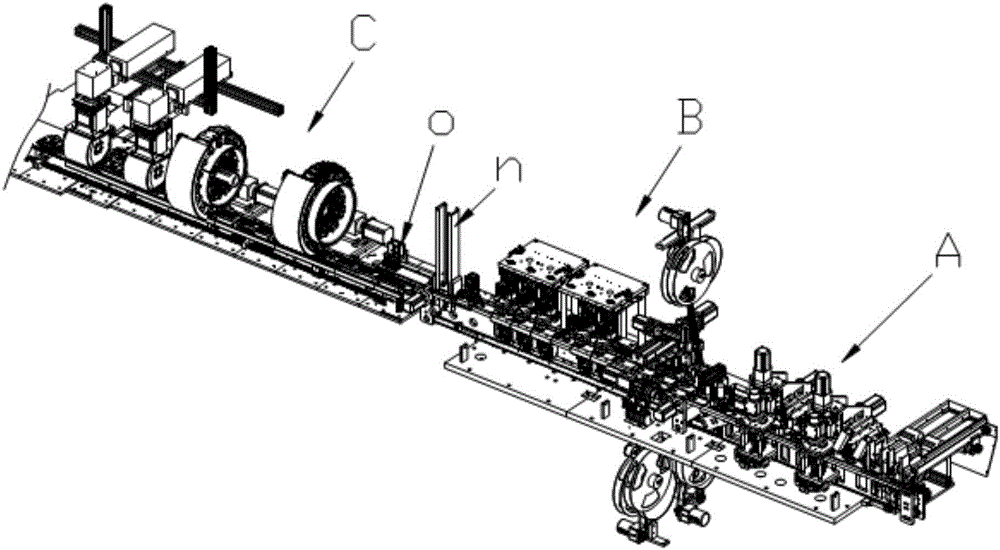

Machine-vision-based online grading and packaging production line for bananas

InactiveCN103143508ASave packing timeIncrease the level of automationPackaging protectionSortingUltravioletEngineering

The invention relates to a machine-vision-based online grading and packaging production line for bananas. The production line comprises a conveying device, a grading device, a cleaning and refreshing device and a packaging device, wherein the grading device and the cleaning and refreshing device are connected with the packaging device through the conveying device. According to the machine-vision-based online grading and packaging production line for the bananas, appearance qualities such as shapes, sizes, colors and defects of the cleaned and dried bananas can be detected by a computer vision system in the grading device; besides, the detections on conventional physical and chemical indicators such as textures, pH and soluble solids of the bananas can be realized by exchanging light sources in an illumination box (e.g., by adopting lasers, ultraviolet rays and the like); the grade, grade information and position information, acquired by a position sensor, of the bananas can be determined by an industrial personal computer (IPC) through synthesizing the appearances and the physical and chemical indicators and can be transmitted to a grading execution module; the bananas in different grades are sorted to corresponding fruit discharging chutes by the grading execution module and enter the packaging device to be contained into boxes; and the bananas can be subjected to postharvest batch detecting, grading and packaging, so that the industrial automation level of the bananas is improved.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

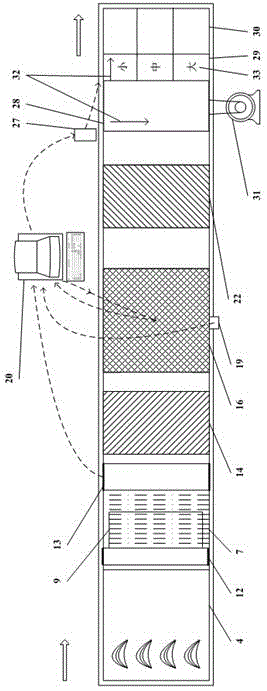

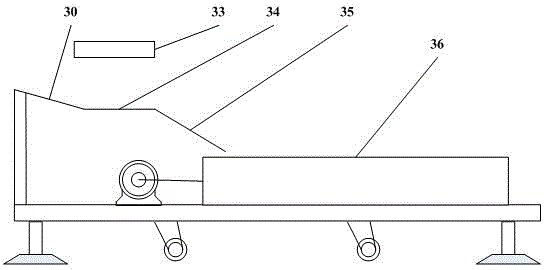

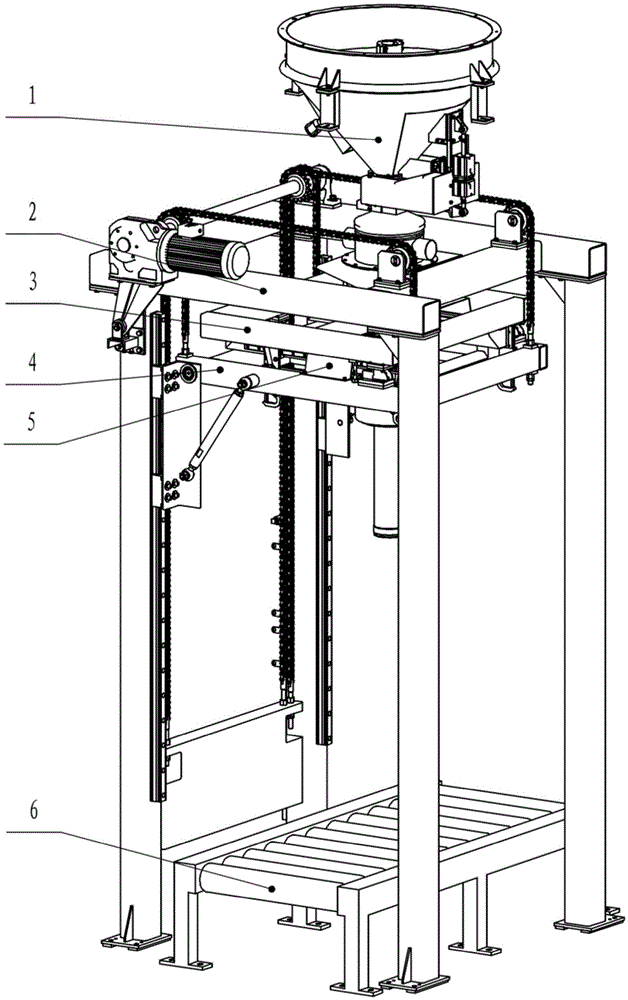

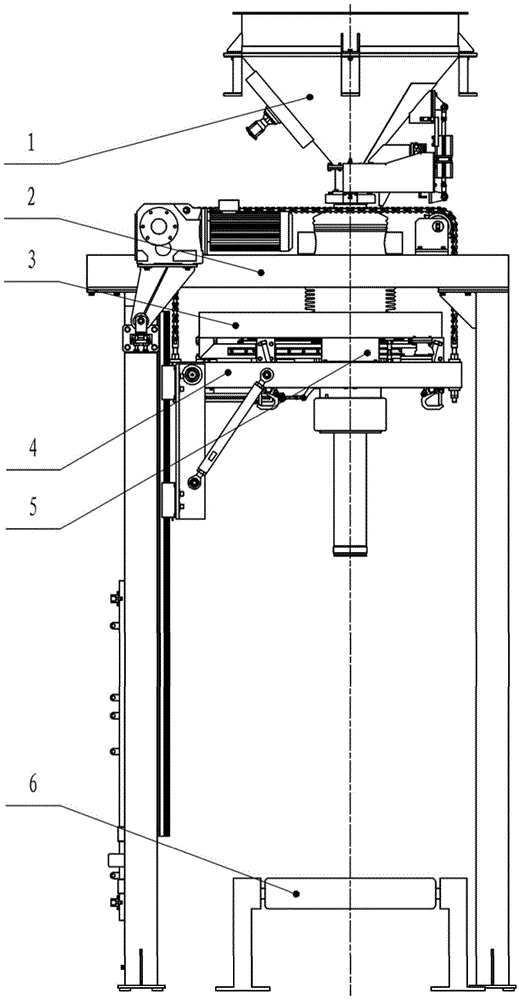

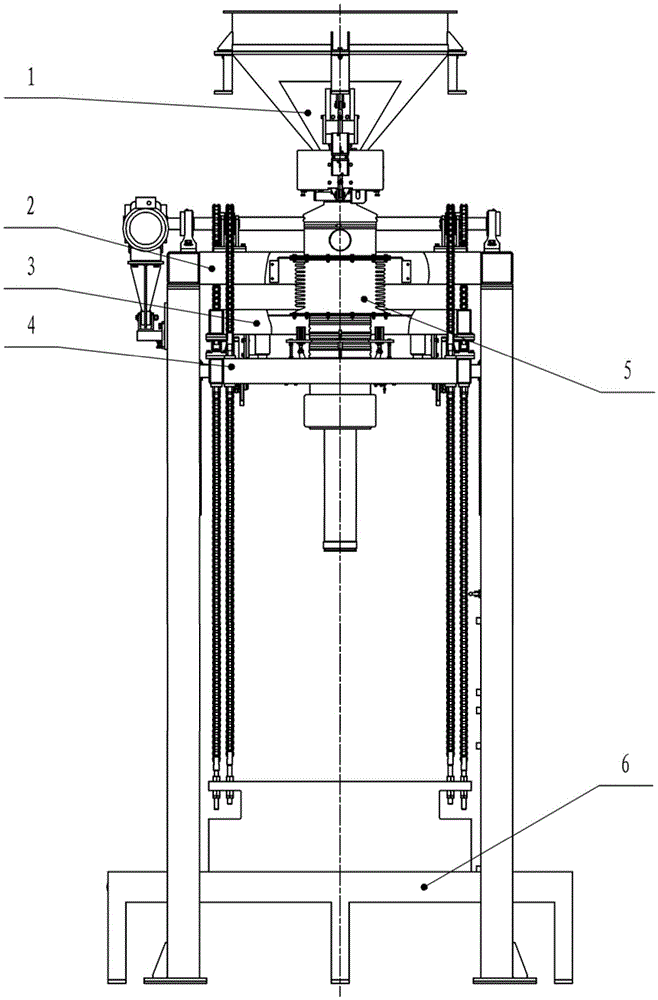

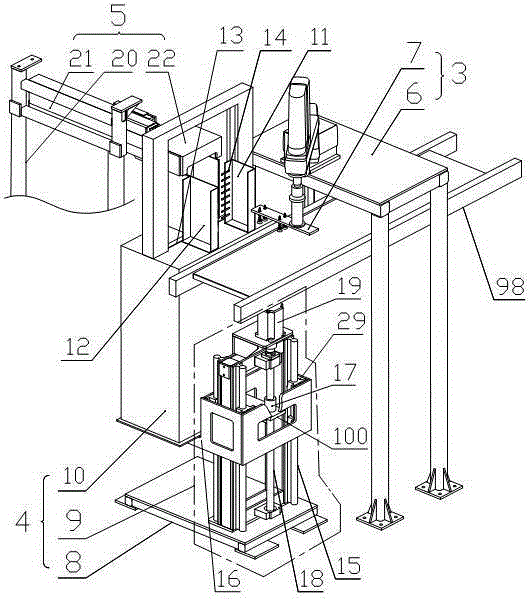

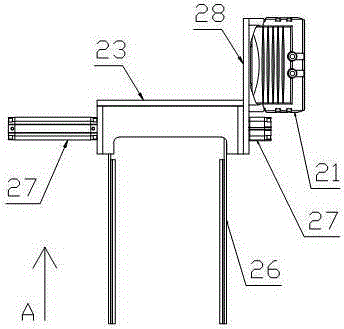

Automatic ton bag packing device suitable for fine powder

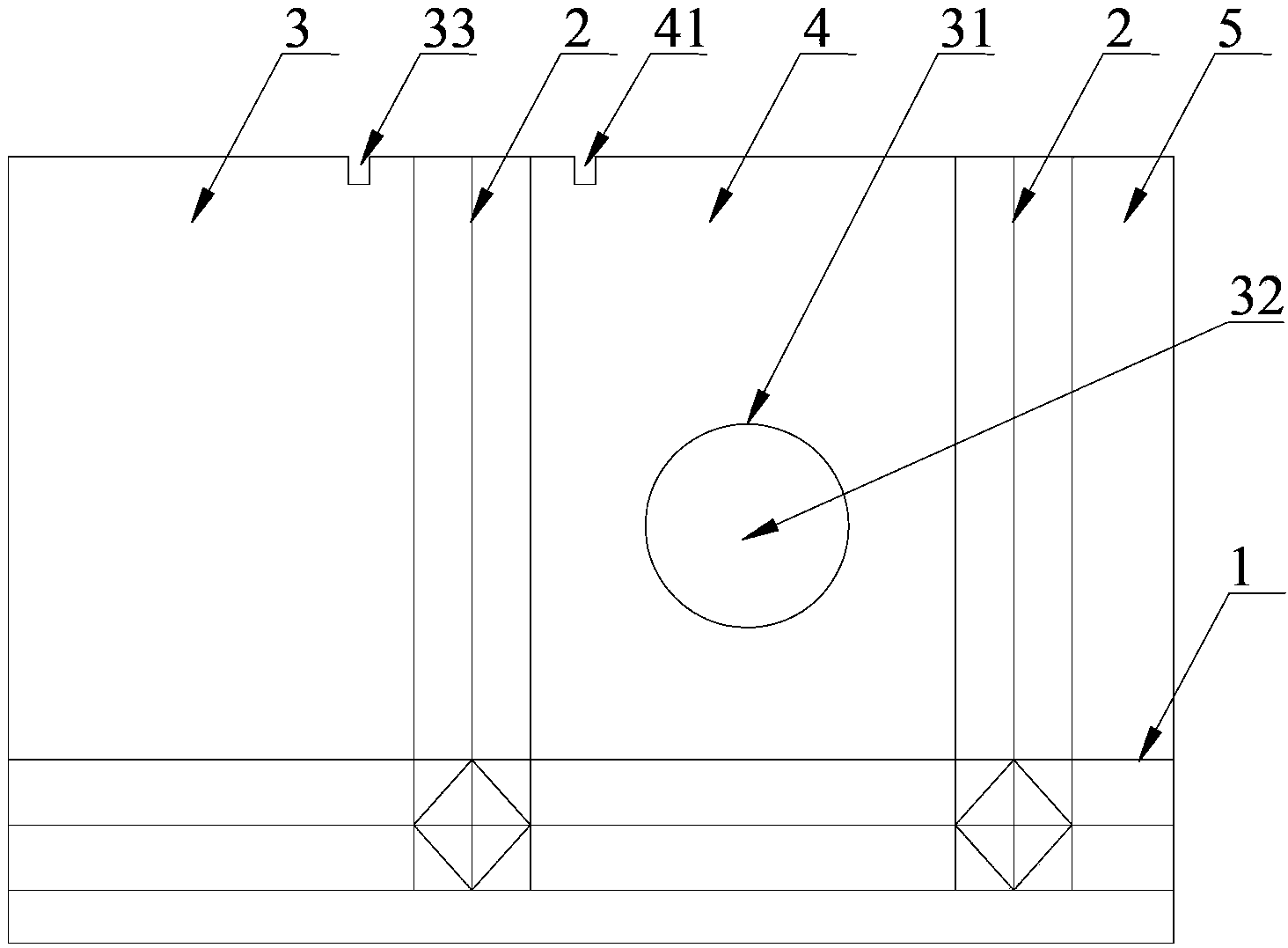

The invention discloses an automatic ton bag packing device suitable for fine powder. The device comprises a feeder 1, a frame 2, a bag clamping device 3, a lifting frame 4, an inflation dust removing pipeline 5 and a conveyor 6, wherein the feeder 1 is positioned at the upper part of the center of the frame 2; a chain lifting mechanism arranged at the upper end of the frame 2 drives the lifting frame 4 to move up and down; three weighing sensors 42 are arranged on the lifting frame 4, and are connected with the bag clamping device 3; the bag clamping device 3 is provided with a bag hanging mechanism 32, a bag opening expanding mechanism 33 and a butt joint mechanism 34; the butt joint mechanism 34 includes a butt joint soft cylinder 343; the upper end of the butt joint soft cylinder 343 is connected with a lower mounting plate 54 of the inflation dust removing pipeline 5; the lower mounting plate 54 is fixed on the lifting frame 4; the upper end of the inflation dust removing pipeline 5 is flexibly and tightly connected with an outer cylinder of the feeder 1; and the conveyor 6 is arranged at the lower part of the frame 2. The automatic ton bag packing device suitable for fine powder can satisfy the production requirements of packing the fine powder in ton bags, reduces the generation of dust, improves the operation environment, and improves the equipment productivity.

Owner:HARBIN BOSHI AUTOMATION

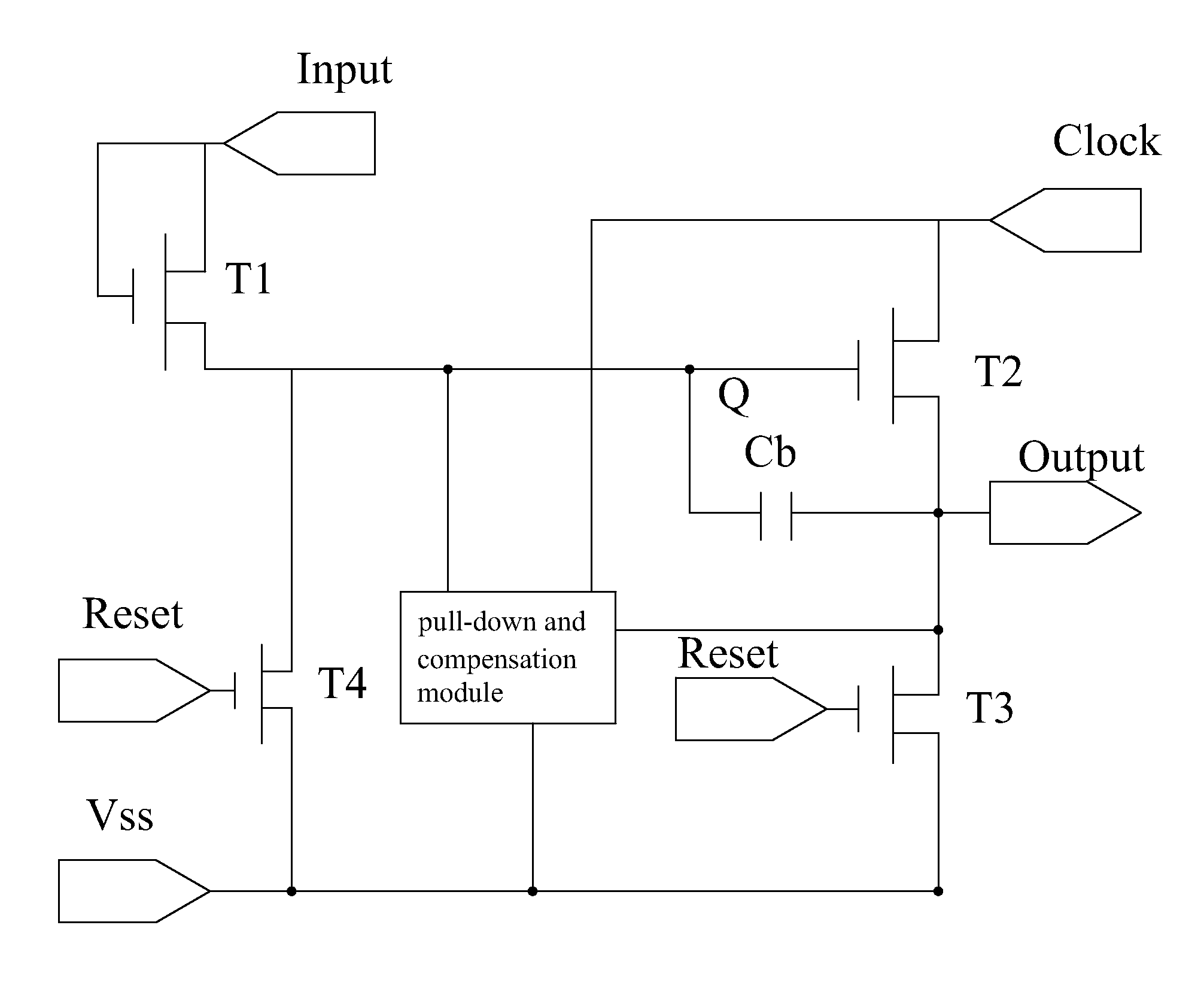

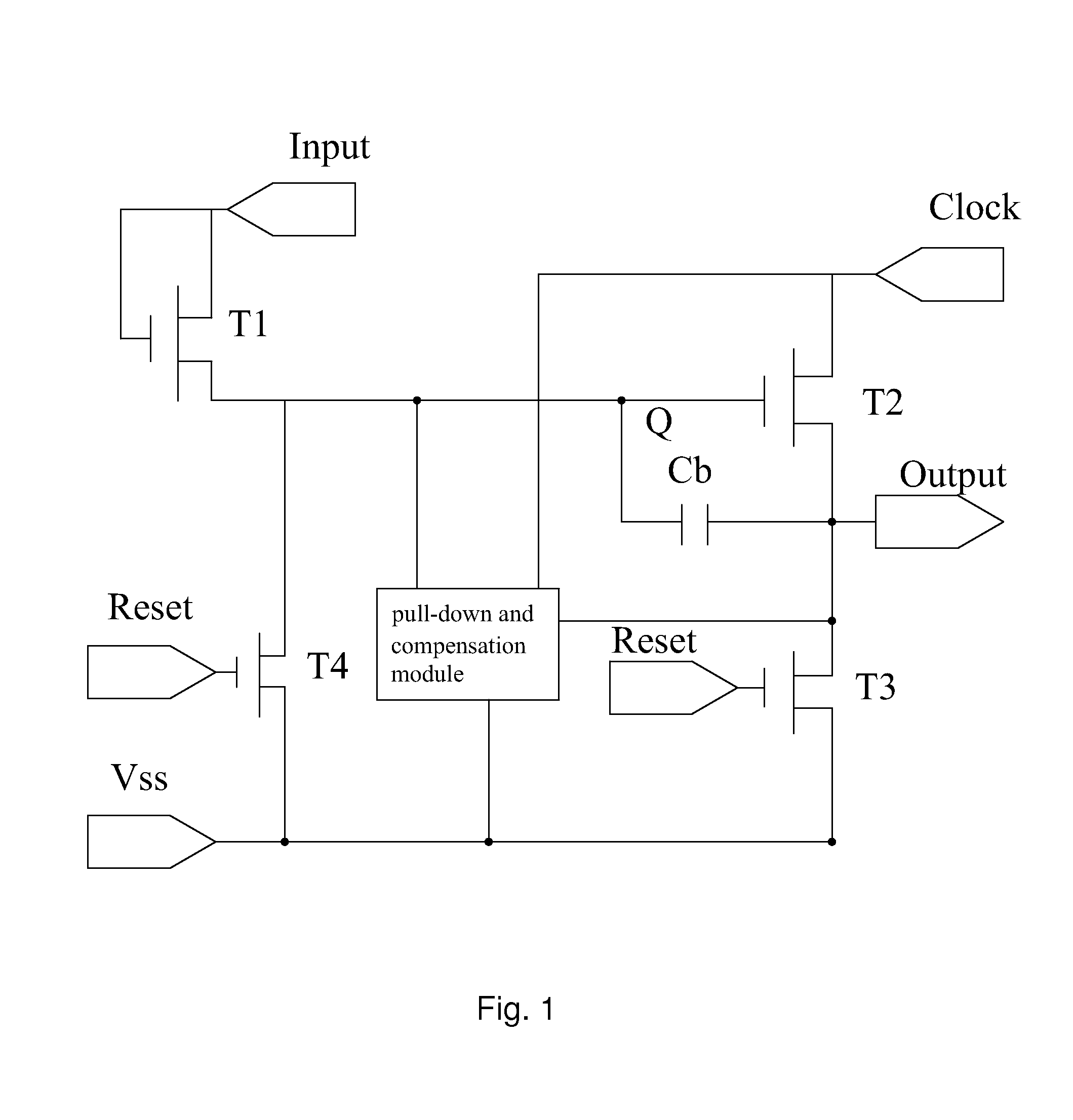

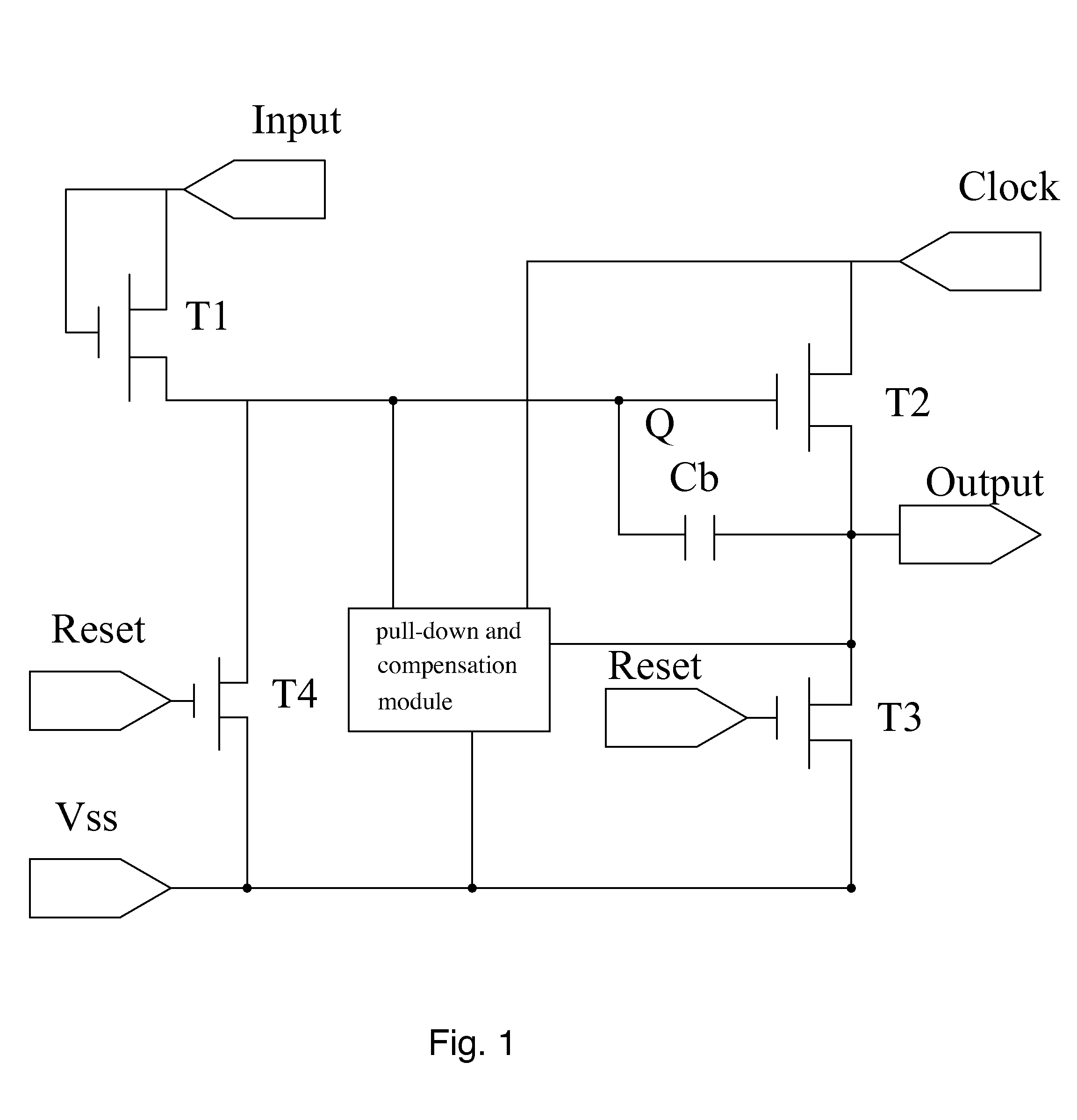

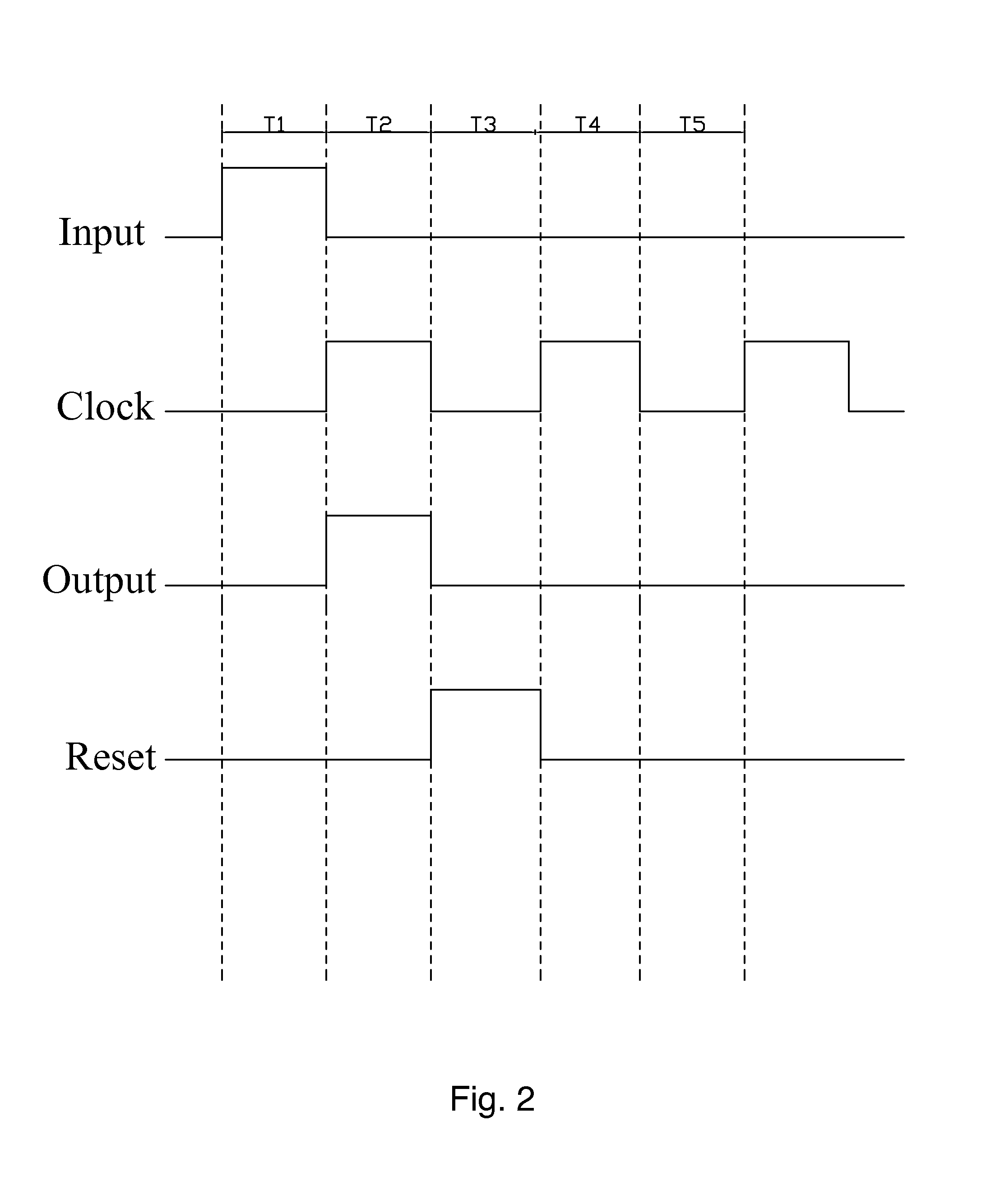

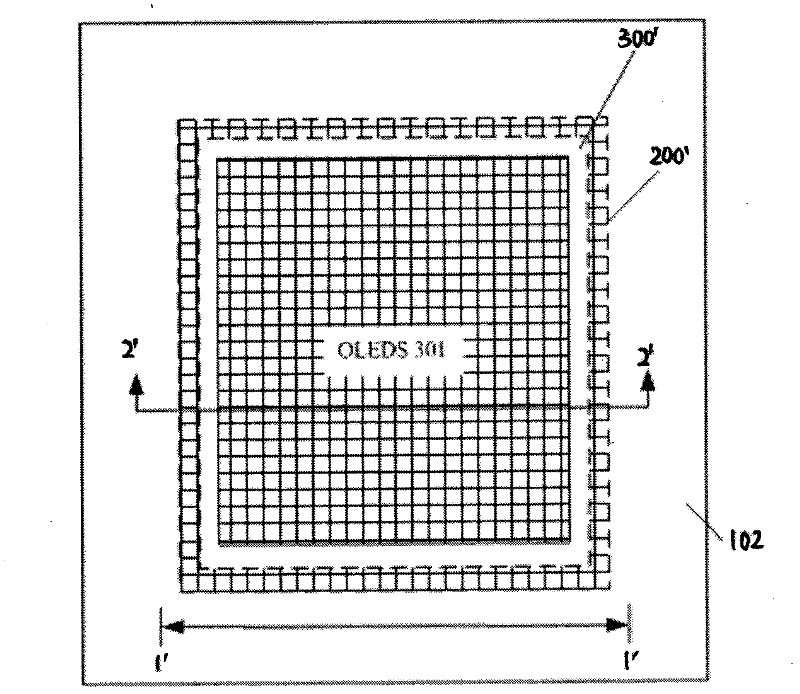

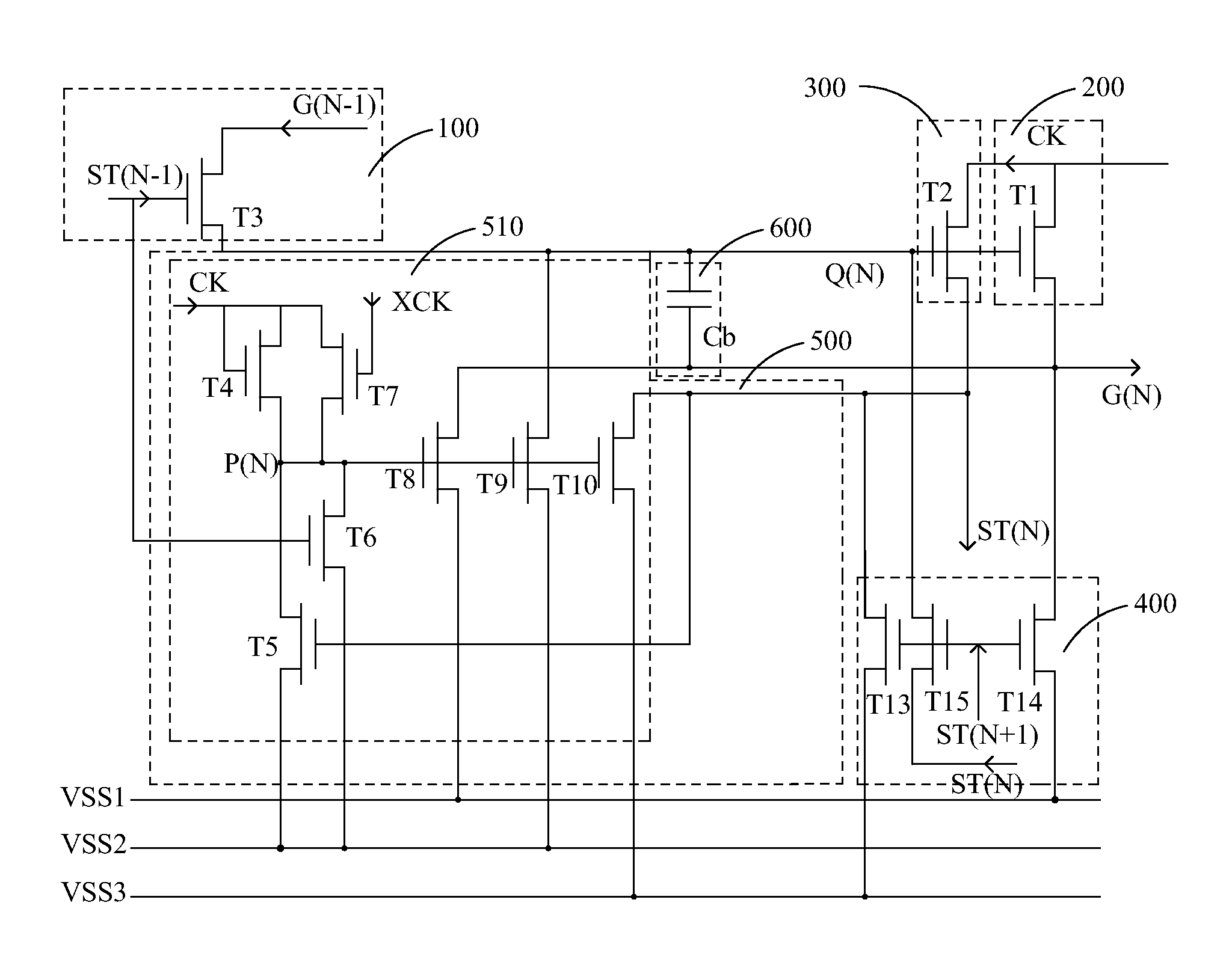

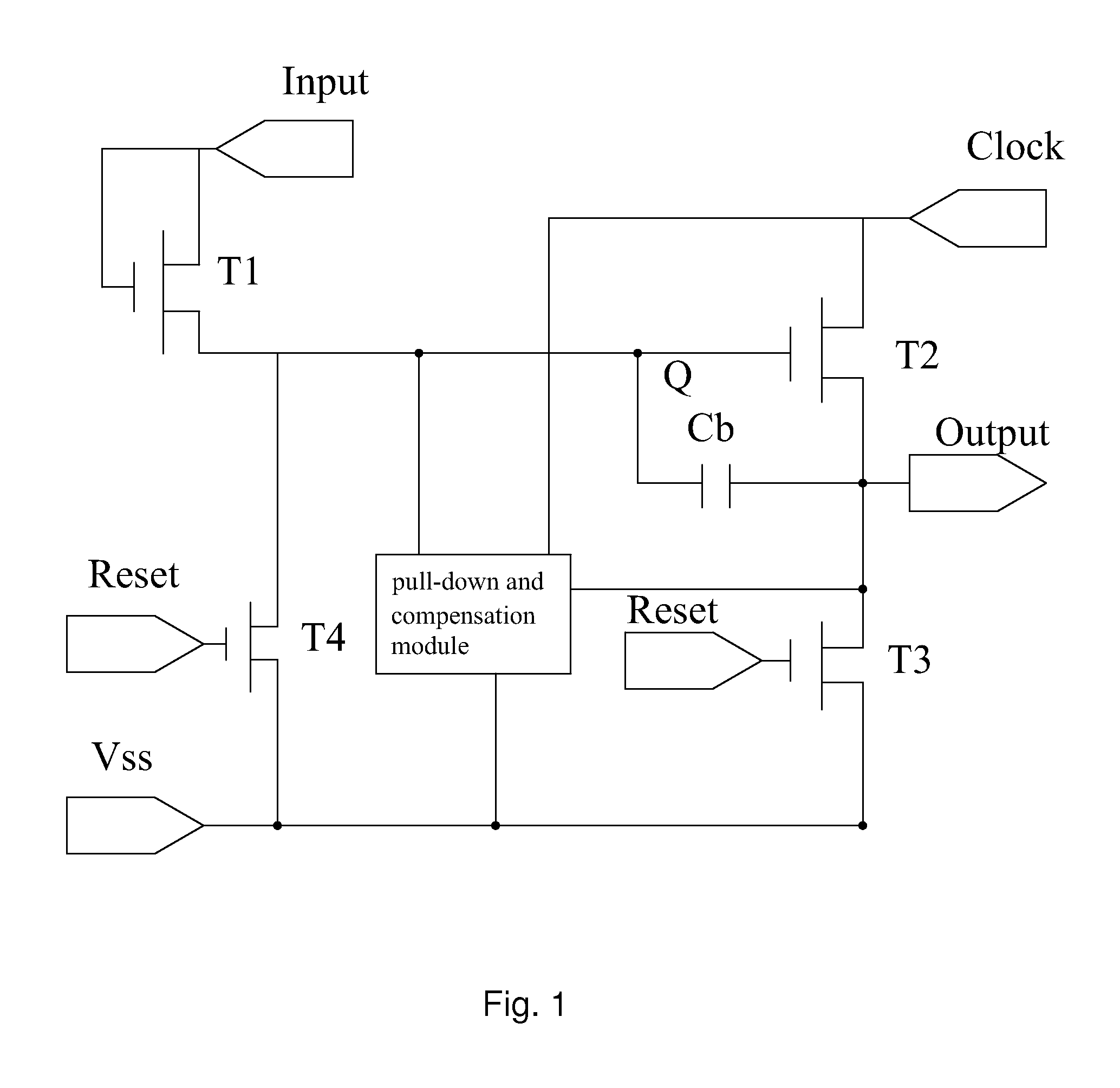

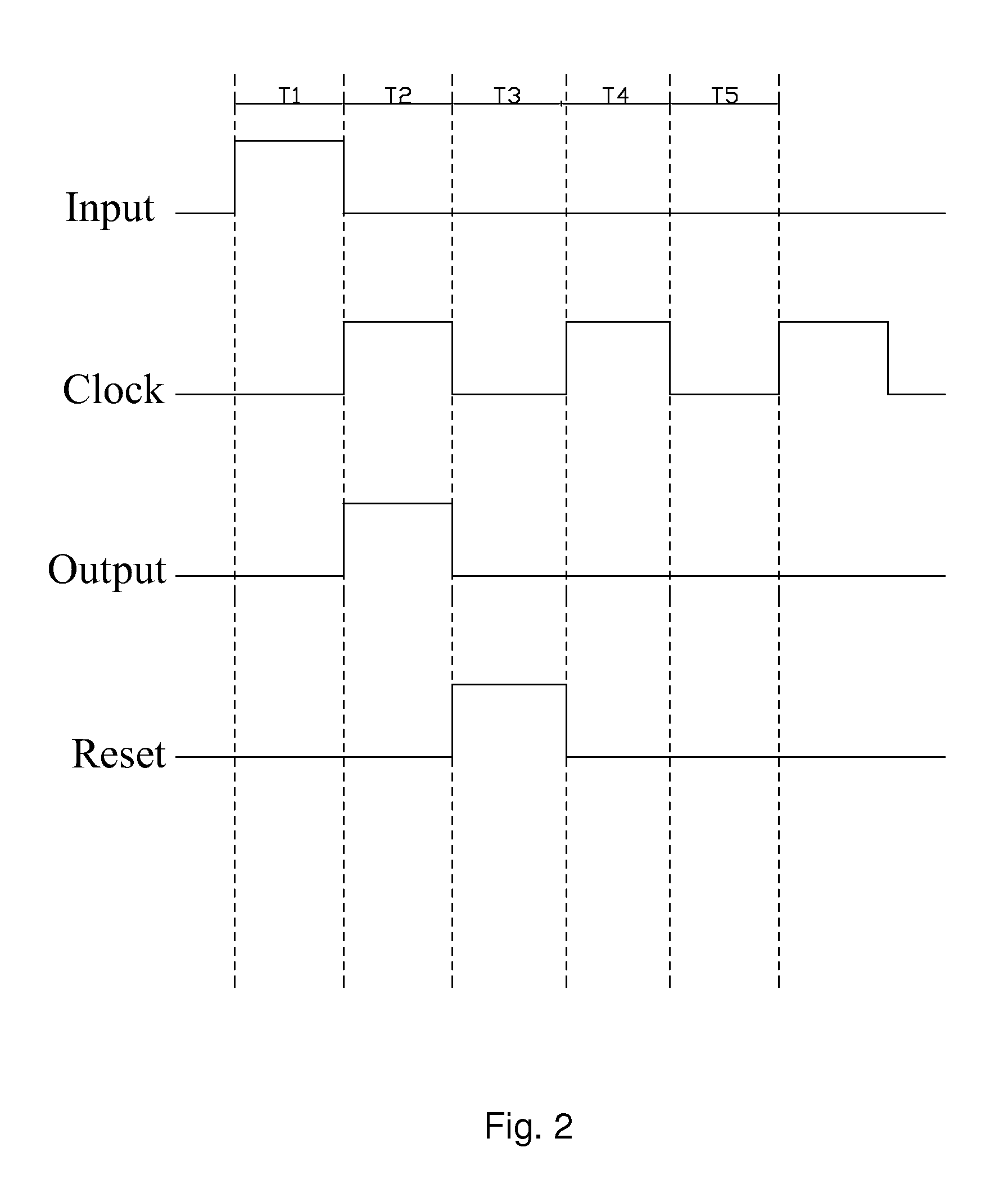

A gate driver circuit basing on igzo process

ActiveUS20160247476A1Reduce load effectImprove stabilityStatic indicating devicesDigital storageDriver circuitEngineering

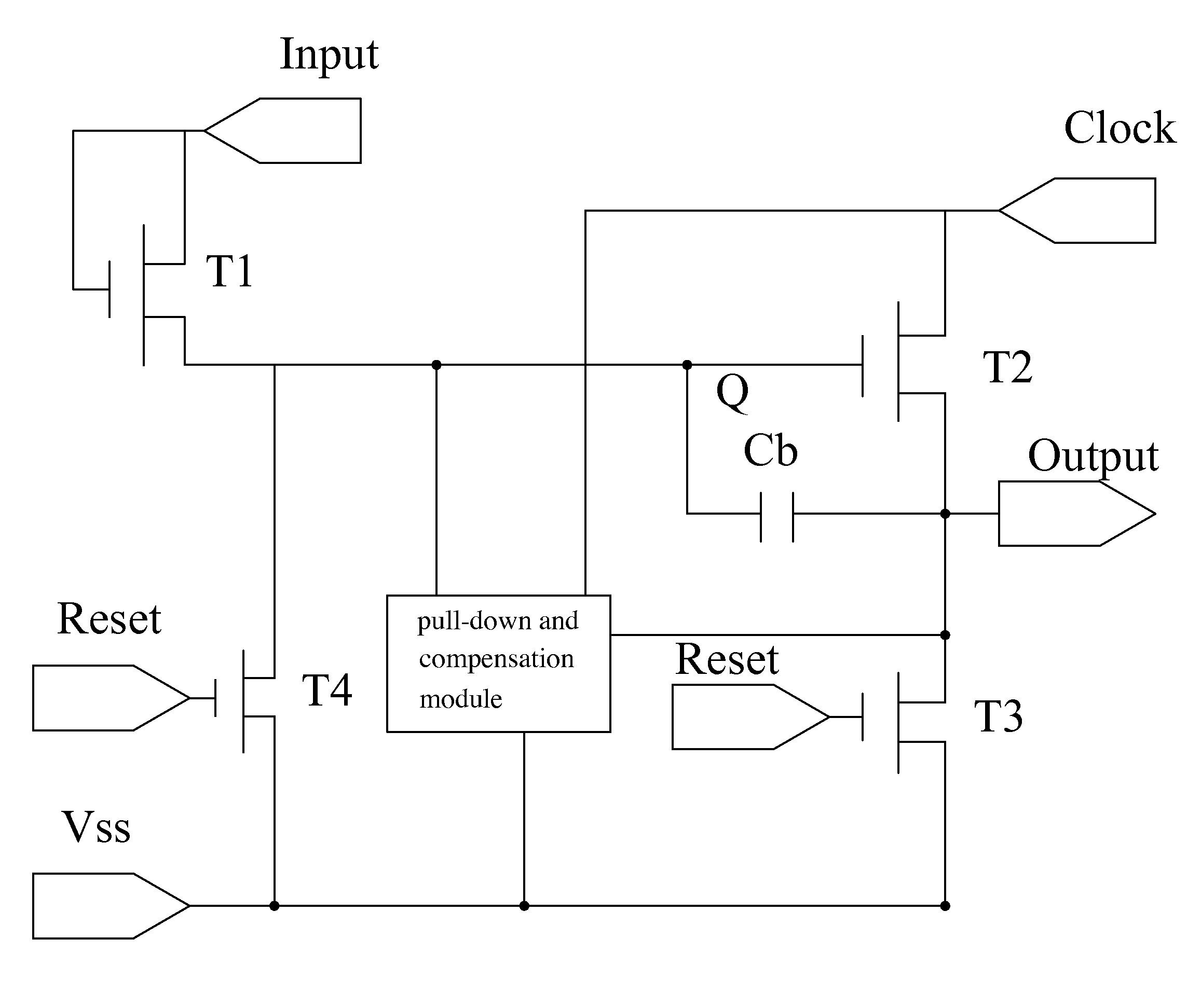

The present invention provides a gate driver basing on IGZO process, comprising: GOAs in cascade connection comprising a Nth-stage GOA, wherein the Nth-stage GOA further comprising: a pull-up control part 100, a pull-up part 200, a transfer part 300, a pull-down part 400, a pull-down holding part 500, a boost part 600, a first negative supply VSS1, a second negative supply VSS2, a third negative supply VSS3, which are three gradually decreasing negative supplies and pull down an output terminal G(N), a first node Q(N), a second node P(N), and a driving single ST(N) to prevent the electrical leakage of TFTs effectively. And channels of the TFT switches of the gate driver basing on the IGZO process are oxide semiconductor channels.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

Automatic steel roll packaging device

InactiveCN106064679ASimple structureEasy to use and maintainWrapping with article rotationElectric machineryEngineering

The invention provides an automatic steel roll packaging device which comprises a material transporting trolley, a lifting mechanism, a side pressing unit and a core penetrating pressing unit. The upper end of the material transporting trolley is rotationally connected with two material rotating rollers. Rolling shafts of the two material rotating rollers are in chain transmission. The roller shaft of one material rotating roller is in chain transmission with a motor shaft of a motor. The lifting mechanism is rotationally connected with a paper pressing roller. The two ends of the paper pressing roller are rotationally connected with paper pressing frames. The longitudinal section of each paper pressing frame is in a shape like the Arabic number '7', and the end portion of each paper pressing frame is fixedly connected to the front wall of the lifting mechanism. The side pressing unit comprises side pressing rollers which are in left-right symmetry about the center line of the lifting mechanism, and the axial direction of the side pressing rollers is the vertical direction. The core penetrating pressing unit comprises two core penetrating pressing rollers which are in left-right symmetry about the center line of the lifting mechanism, and the two core penetrating rollers reciprocate at the same time in the vertical direction. According to the automatic steel roll packaging device, it is ensured that a packaging material can be attached to the outer circular side wall, the two end portions and the inner circular side wall of a roll completely; and packaging materials are saved, the packaging time is also shortened, and the working efficiency is improved.

Owner:天津松洋金属制品有限公司

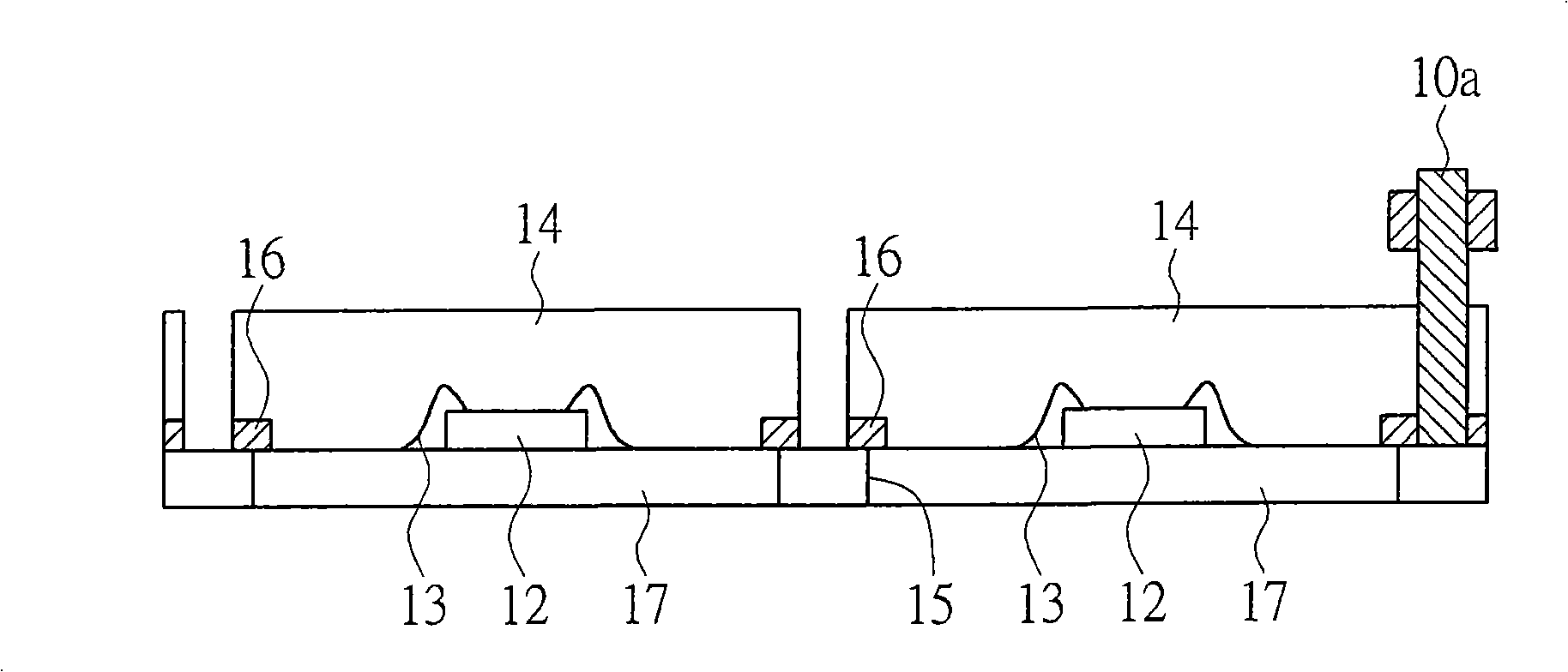

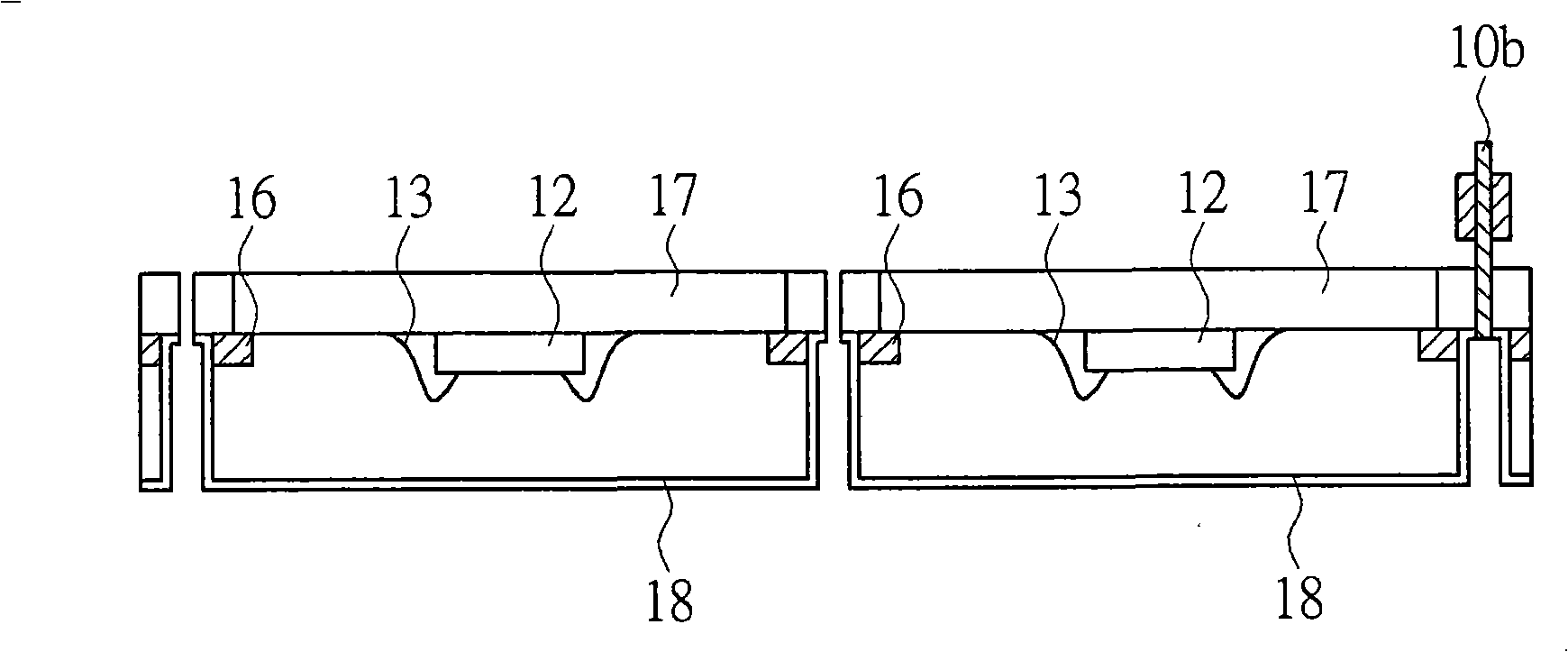

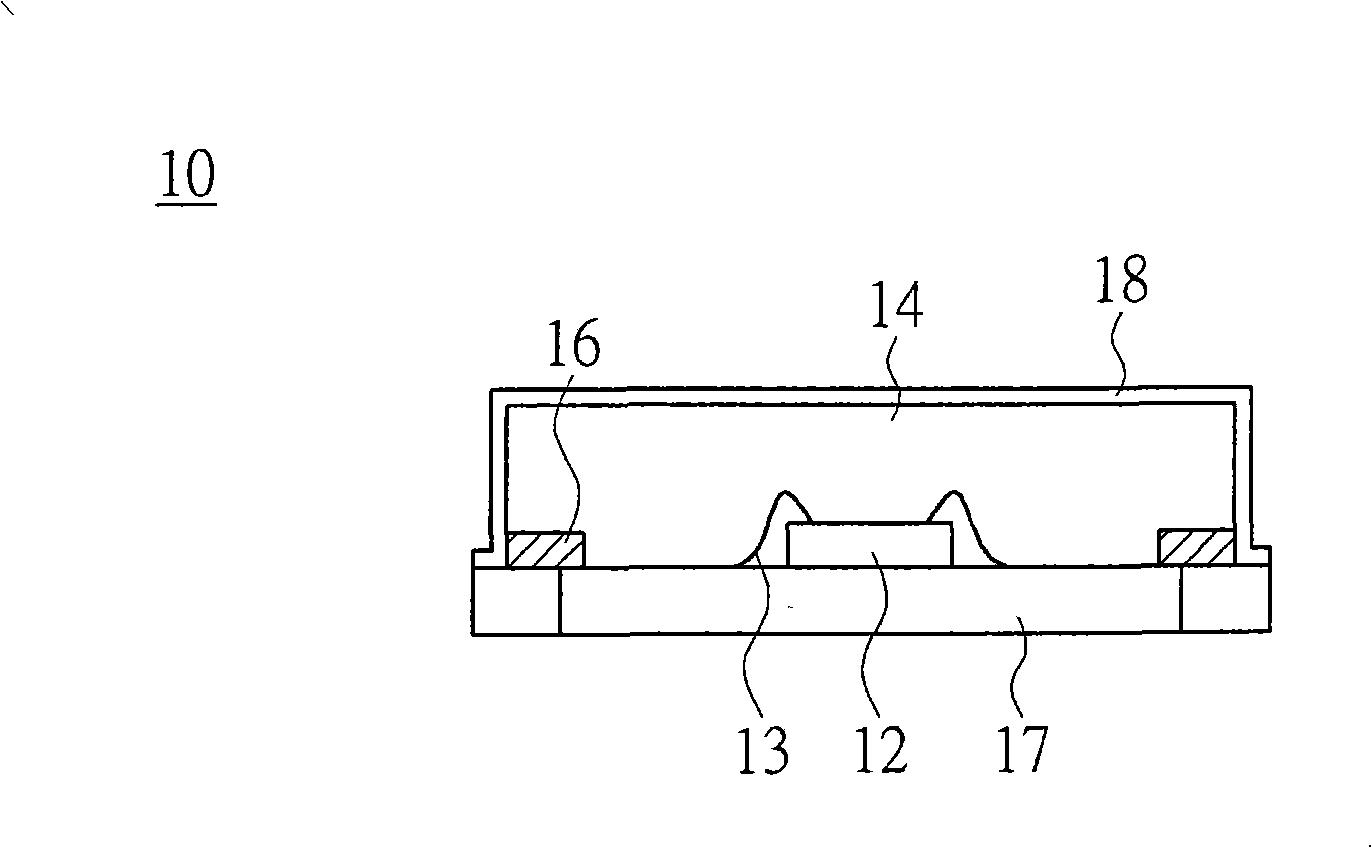

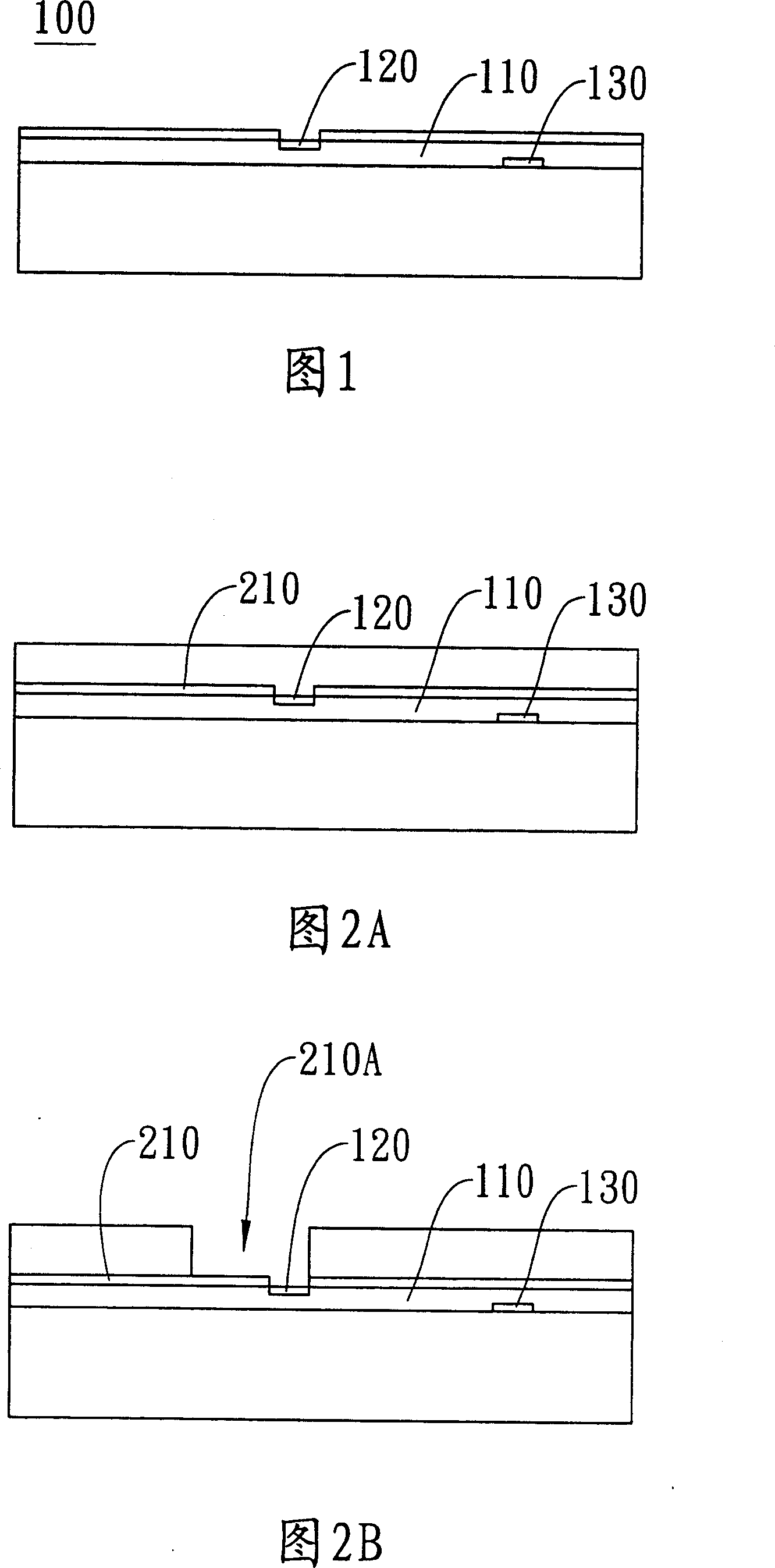

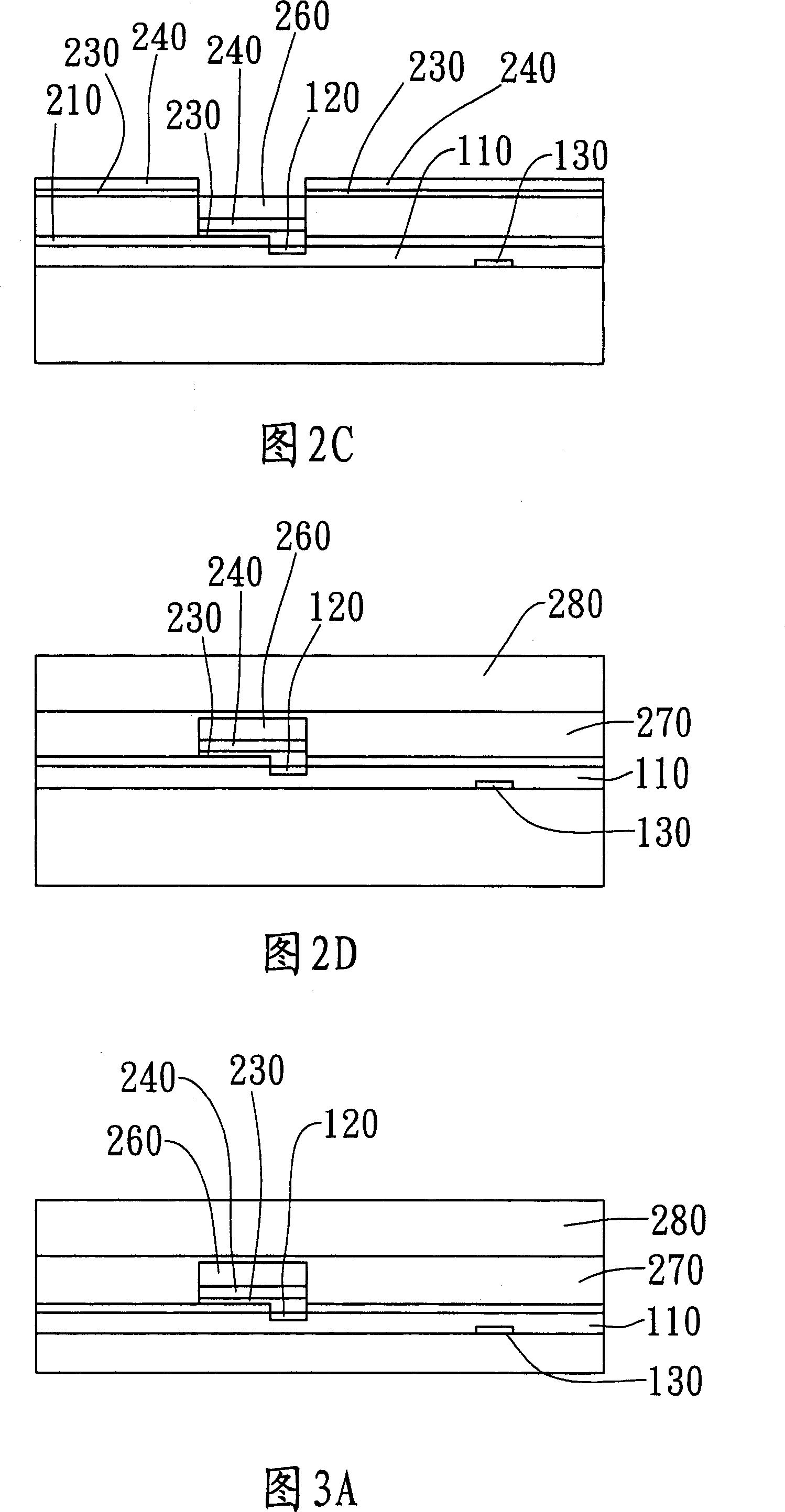

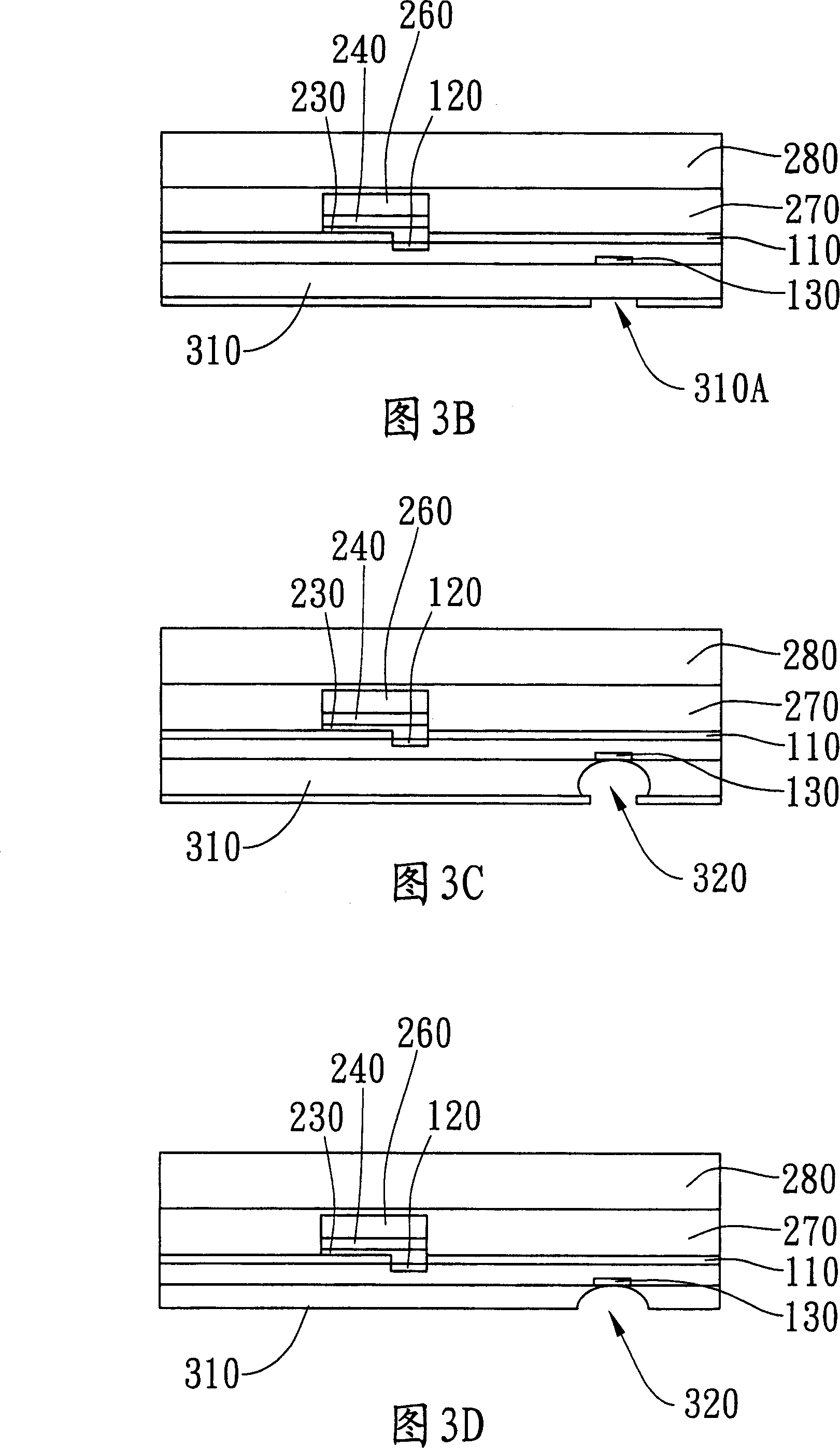

Encapsulation construction and encapsulation method

ActiveCN101339939ASave materialHigh densitySemiconductor/solid-state device detailsSolid-state devicesElectrical conductorColloid

A package structure comprises a substrate, a semiconductor assembly, a sealing glue and a conductive film. The substrate possesses a first surface, a second surface, a first side surface and an earthing assembly. The first side surface connects first surface and second surface. The earthing assembly is disposed inside of substrate and exposed at the first side surface and possesses a plane. The semiconductor assembly is disposed at the first surface and electrically connected with substrate. The sealing glue is covered on semiconductor assembly; a second side surface of sealing glue is trimming with plane. The conductive film directly forms on one external surface of sealing glue, exposed plane of earthing assembly and the first side surface of substrate; the conductive film is electrically connected with earthing assembly.

Owner:ADVANCED SEMICON ENG INC

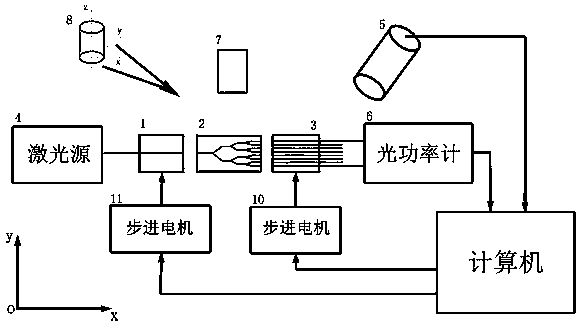

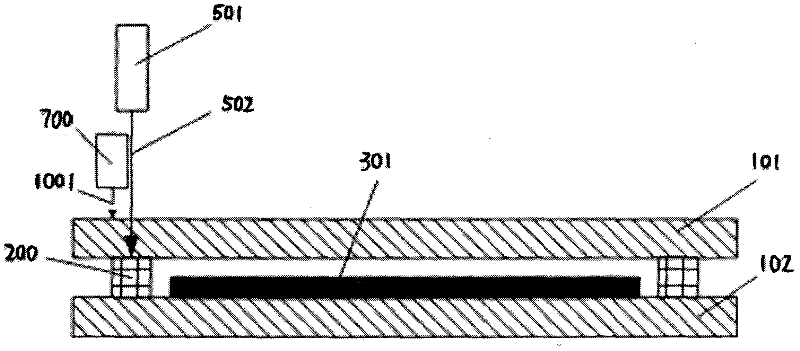

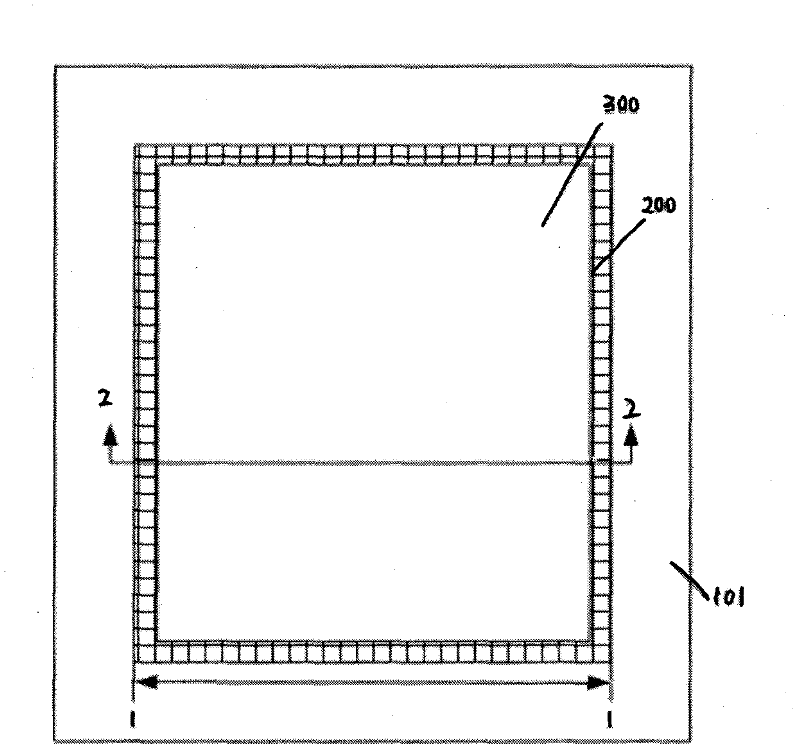

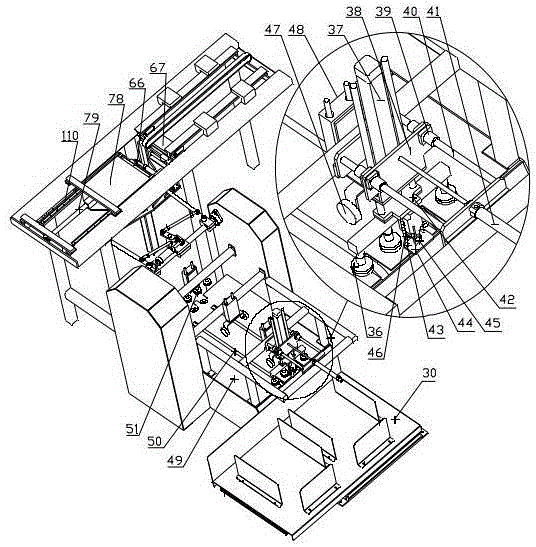

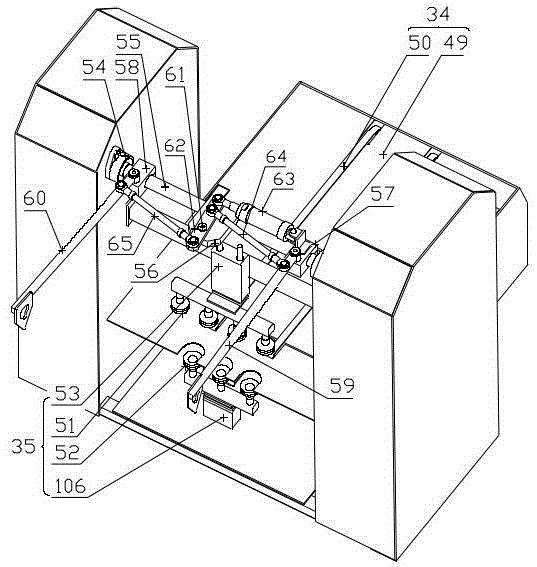

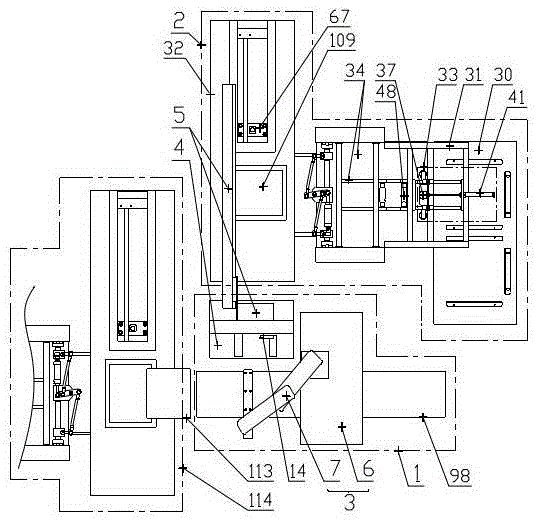

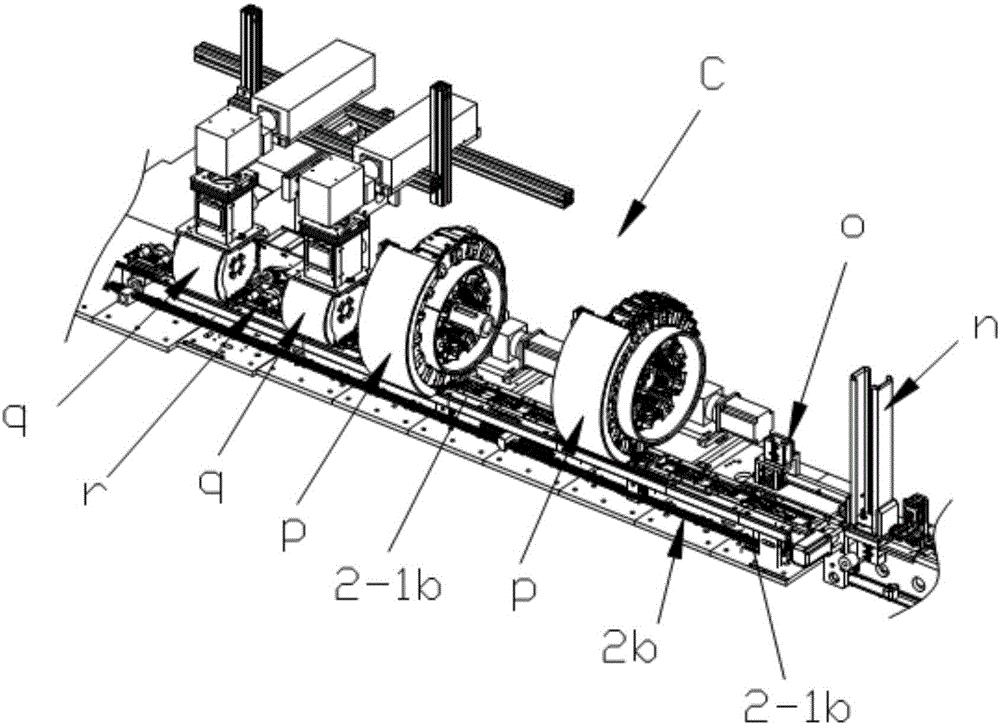

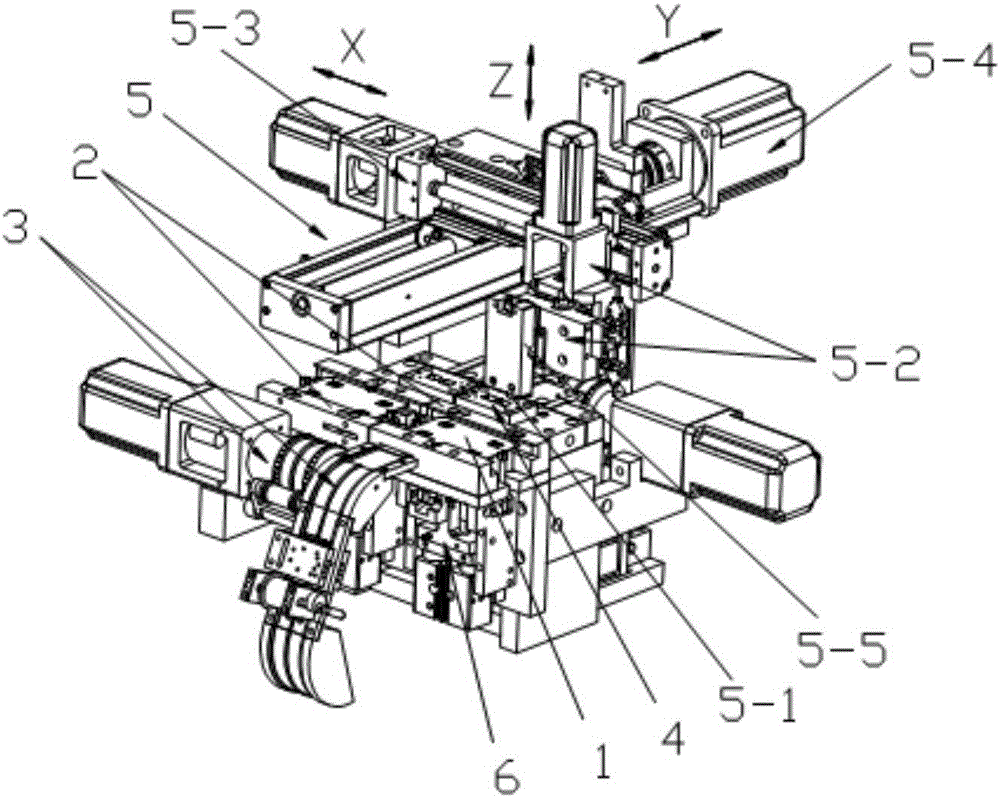

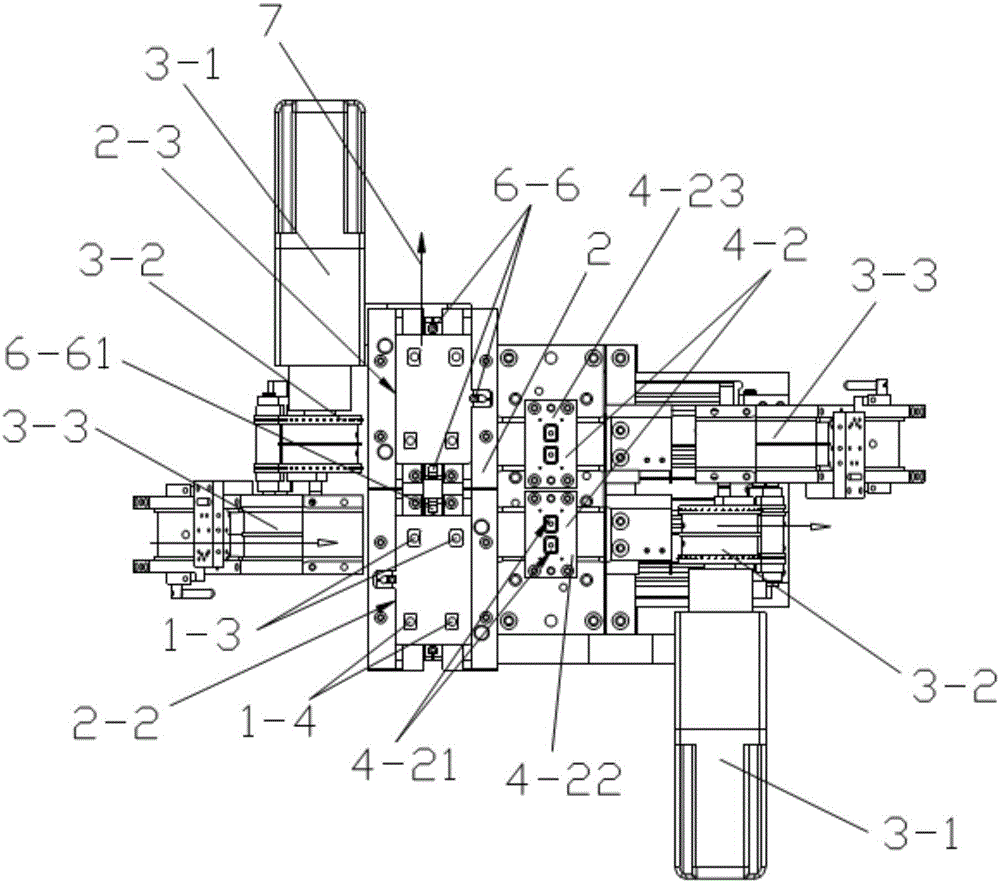

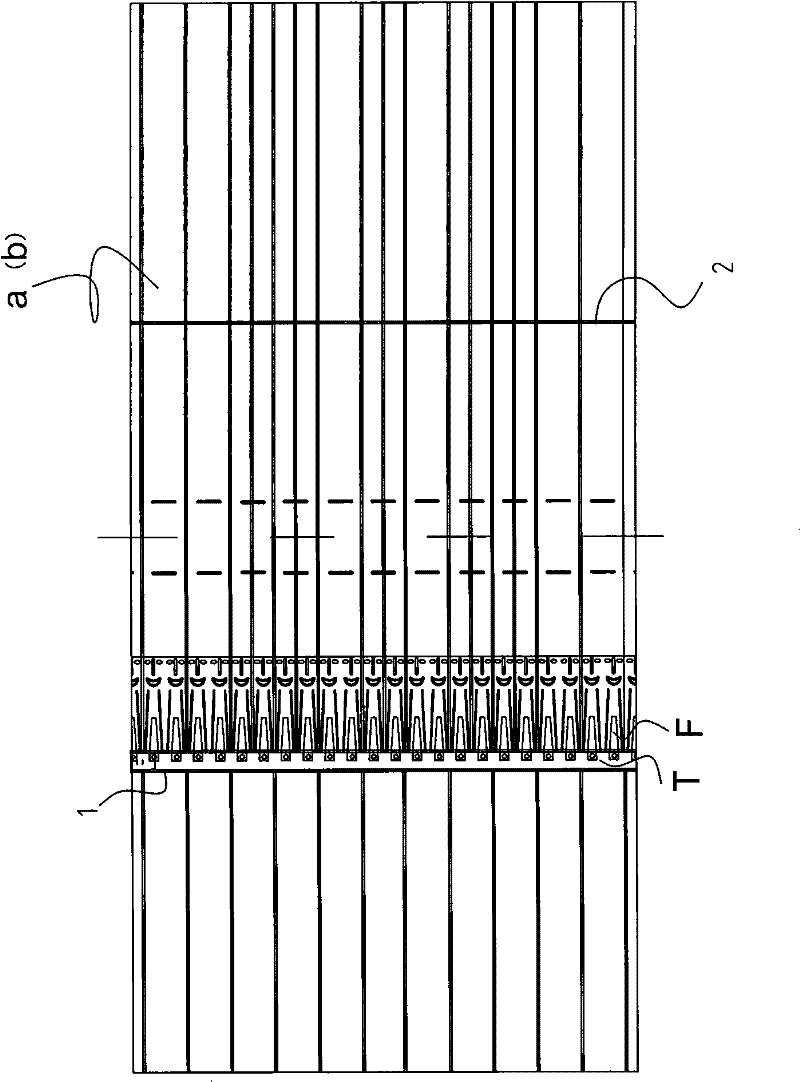

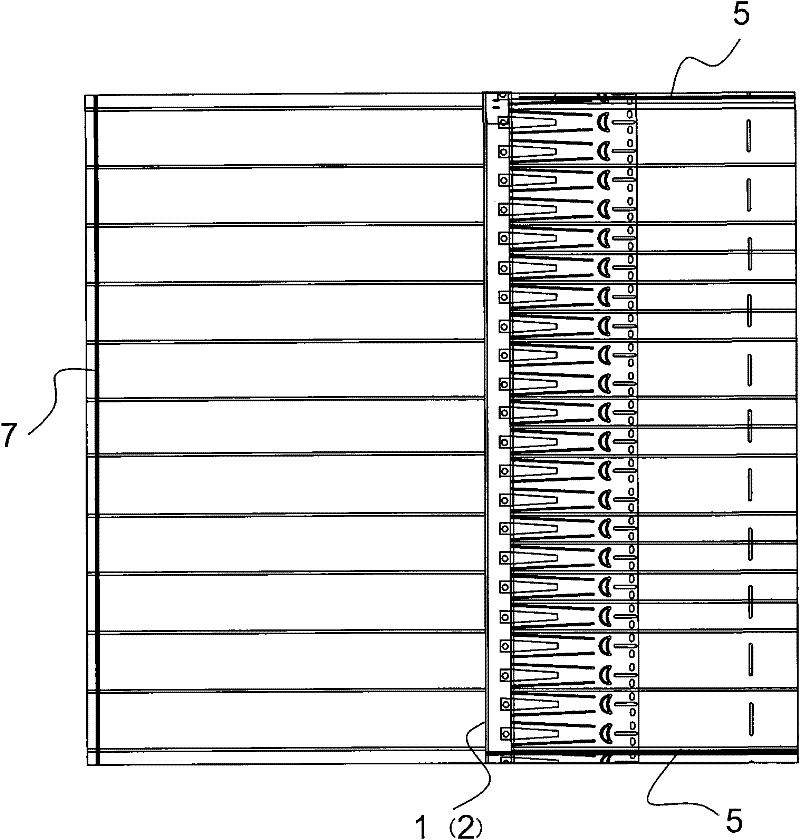

Coupling and packing system and method for full-automatic PLC subdivider

ActiveCN104007522AHigh sampling rateGood repeatabilityCoupling light guidesOptical power meterElectric machine

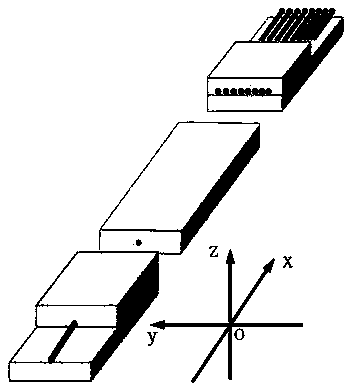

The invention relates to a coupling and packing system and method for a full-automatic PLC subdivider and belongs to the field of photo-communication. The coupling and packing system for the full-automatic PLC subdivider is composed of an input optical fiber array (1), a PLC optical divider chip (2), an output optical fiber array (3), a laser source (4), a scattered light microscopic detector (5), a bi-pass optical power meter (6), a microscopic monitoring camera (7) behind the chip, a microscopic monitoring camera (8) above the chip, a computer (9), stepping motors (10 and 11), a UV lamp motor, an optical platform and the like. According to the coupling and packing system and method for the full-automatic PLC subdivider, closed-loop control is formed by the scattered light microscopic detector and feedback of the optical power meter, automatic alignment coupling is achieved, and connecting precision and coupling efficiency are improved.

Owner:山西晋元技术有限公司

Manufacturing process for paper packaging bag

InactiveCN103407675ASave packing timeIncrease productivityBagsSacksEnvironmental resistanceBiochemical engineering

The invention relates to a manufacturing process for a paper packaging bag. The manufacturing process for the paper packaging bag comprises seven steps, namely, material selecting, printing, film attaching, mark pressing, horizontal sealing, folding and bottom sealing. The manufacturing process for the paper packaging bag has the advantages of enabling the packaging bag to stand after sealing formation, enabling the article packaging to be easy and reducing the packaging time due to the fact that three bottom folding marks are arranged at the bottom of the packaging bag; enabling glue pasting through manual work to be not needed for the whole manufacturing procedure, being convenient and rapid and improving the production efficiency due to the facts that a layer of PE (Poly Ethylene) film is attached to the reverse side of a printing surface and the sealing is directly performed through the thermal sealing technology; being environmentally friendly and saving a large quantity of resources and costs due to the fact that the packaging bag is made of paper; enabling the article packaging to be convenient due to the facts that three folding marks are arranged on one side of the packaging bag, the side has two layers of folding layers after being folded, three folding sides and a pasting edge are arranged on the other side of the packaging bag, and a three-layer folding layer which enables stretching out of the inner chamber of the packaging bag to be convenient is formed.

Owner:嘉善县欣龙服饰辅料厂(普通合伙)

Gate driver circuit basing on igzo process

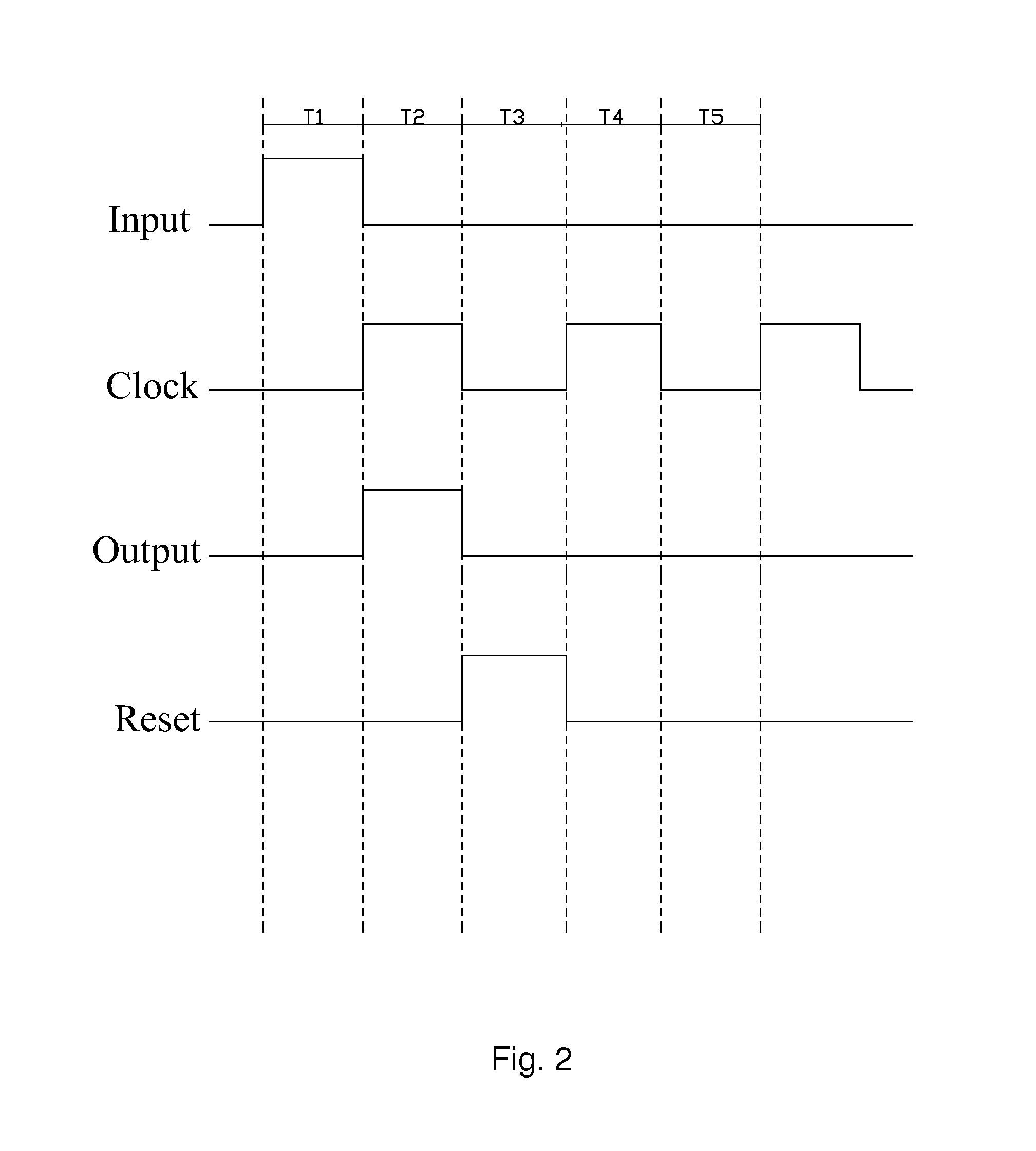

ActiveUS20160267864A1Effectively minimize amountSave packing timeStatic indicating devicesDigital storageDriver circuitEngineering

The present invention provides a gate driver circuit basing on IGZO process, comprising GOAs in cascade connection comprising a Nth-stage GOA, wherein the Nth-stage GOA further comprising a pull-up control part 100, a pull-up part 200, a transfer part 300, a pull-down part 400, a pull-down holding part 500, a boost part 600, a first negative supply VSS1, a second negative supply VSS2, a third negative supply VSS3, which are three gradually decreasing negative supplies and pull down an output terminal G(N), a first node Q(N), a second node P(N), and a driving single ST(N) to prevent the electrical leakage of TFTs effectively. And channels of the TFT switches of the gate driver circuit basing on the IGZO process are oxide semiconductor channels.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Packaging device and packaging method

InactiveCN102690045AGood technical effectAdjustable pressing forceSolid-state devicesSemiconductor/solid-state device manufacturingHermetic packagingMaterials science

The invention provides a packaging device which comprises a stage, a radiation source and a fluid source. The stage is used for bearing a packaging structure for assembly, wherein the packaging structure is provided with a first substrate, a second substrate, and a molten material which is arranged between the first substrate and the second substrate to form at least one cavity; the radiation source is used for heating the molten material so that the molten material combines with the connecting surface of the first substrate and the second substrate and the cavity forms a hermetic packaging structure; and the fluid source provides a fluid beam, wherein the fluid beam acts on the first substrate and is used for pressing the a molten material between the first substrate and the second substrate.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

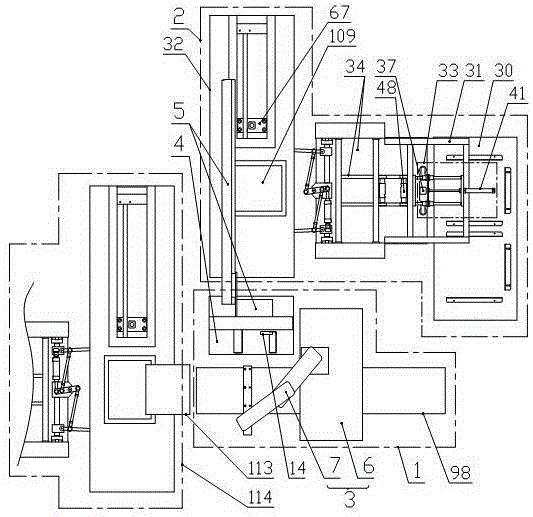

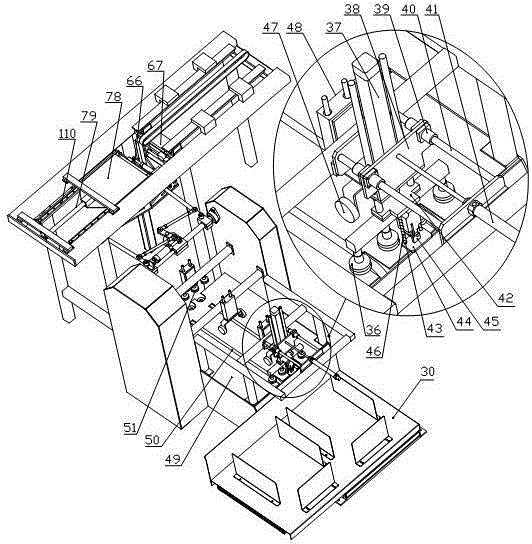

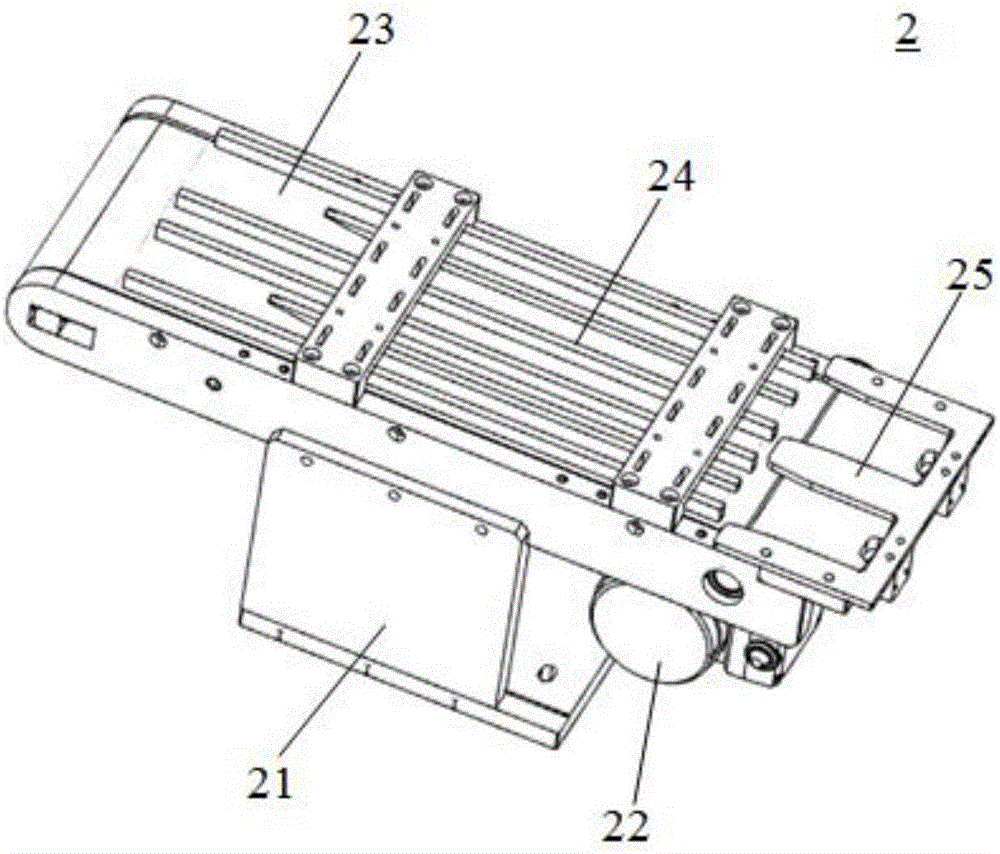

Automatic bagging and packaging device and packaging method for special-shaped cigarettes

ActiveCN105173152APrevent deviationGood effectWrapper twisting/gatheringIndividual articlesEngineeringManipulator

The invention discloses an automatic bagging and packaging device and packaging method for special-shaped cigarettes. The device comprises a bag storage device, and a bag conveying device is arranged beside the bag storage device and is connected with a bagging device; the bag conveying device comprises a bag taking mechanism, and a conveying mechanism is arranged below the bag taking mechanism; a bag expanding mechanism is arranged at the tail end of the conveying mechanism, and the bag taking mechanism comprises a bag taking mechanical arm; the bag taking mechanical arm is connected with a bag taking vertical air cylinder which is connected with an air cylinder fixing plate; longitudinal moving guide sleeves are arranged on the two sides of the air cylinder fixing plate and are connected with a longitudinal moving guide rail; and a longitudinal moving air cylinder is further arranged between the two longitudinal moving guide sleeves; a guide shaft connecting plate is further connected between the bag taking mechanical arm and the bag taking vertical air cylinder and connected with a detecting plate through a stroke guide column; and a detection sensor is arranged on the detecting plate, and a tensioning spring is further arranged on the stroke guide column. The automatic bagging and packaging device has the beneficial effects of being low in labor intensity and high in production efficiency, saving manpower and reducing the manual cost.

Owner:GUIZHOU HUILIAN TECH LIMITED

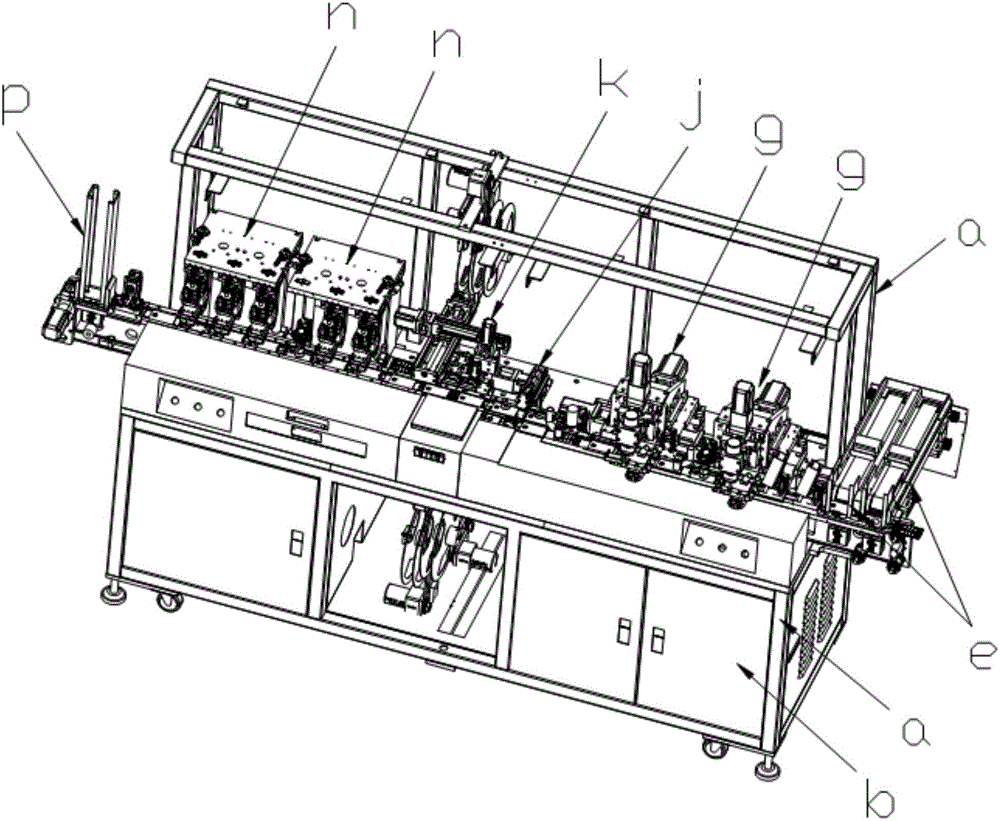

Multi-chip contact intelligent card groove milling packaging personalized production line

ActiveCN106447008AReduce transfer timeIncrease productivityCo-operative working arrangementsRecord carriers used with machinesPersonalizationProduction line

The invention discloses a multi-chip contact intelligent card groove milling packaging personalized production line. The production line comprises a groove milling device, a packaging device and a personalization device which are connected together, wherein the packaging device comprises a packaging module, the packaging module comprises two chip band supply mechanisms, a chip punching mechanism and a chip carrying packaging mechanism; two packaging work stations are arranged at positions, which are corresponding to the packaging module, in a chip carrying guide rail of the groove milling device, and each packaging work station is provided with a chip positioning mechanism; each of the two chip band supply mechanisms comprises a chip band and a chip band conveying mechanism; and the chip bands in the two chip band supply mechanisms extend in parallel along a direction vertical to a chip conveying direction, and the transmission directions of the chip bands in the two chip band supply mechanisms are opposite. The production line is applied to groove milling packaging of a single-chip card, is also applied to groove milling packaging of a multi-chip card, and has the advantages of fast packaging speed, high production efficiency, high packaging precision and the like.

Owner:GUANGZHOU MINGSEN TECH CO LTD

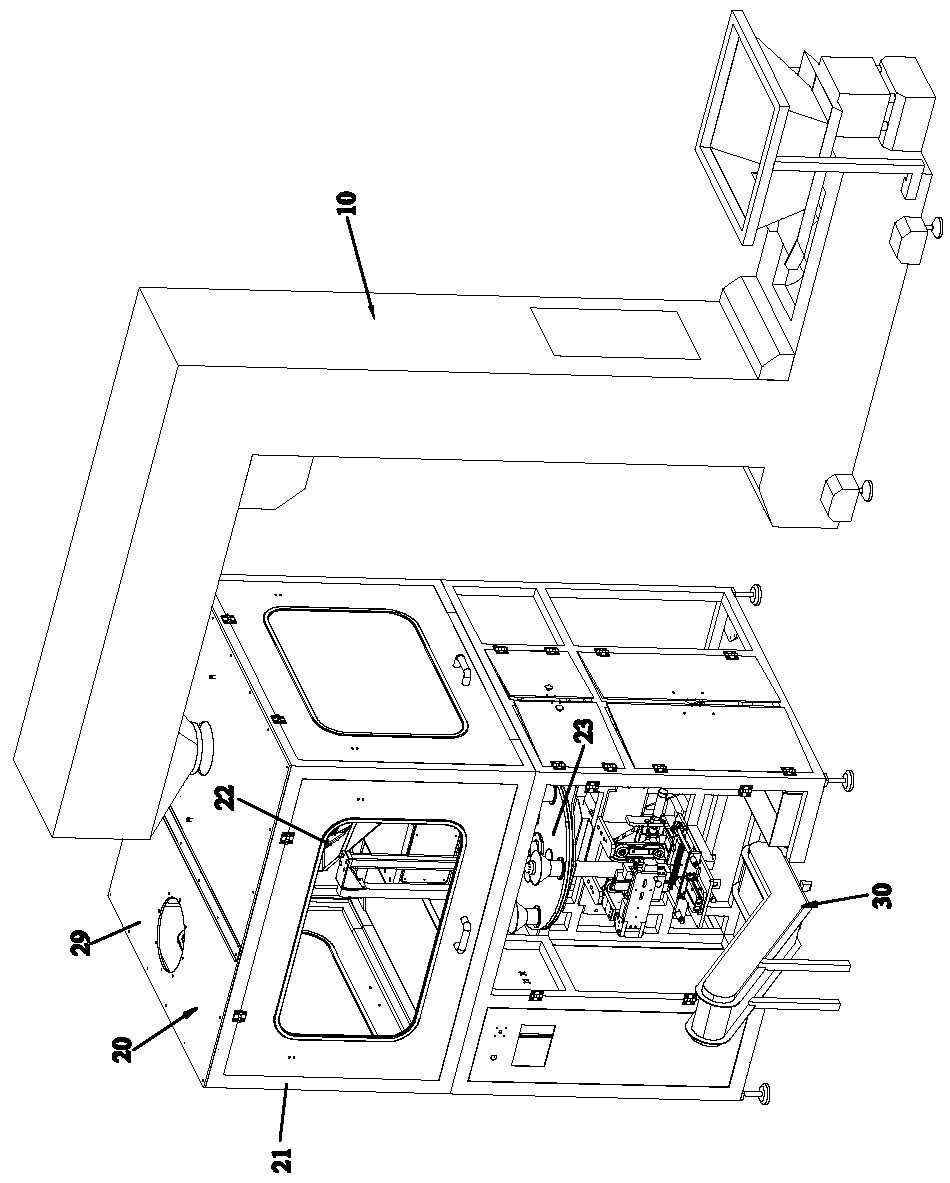

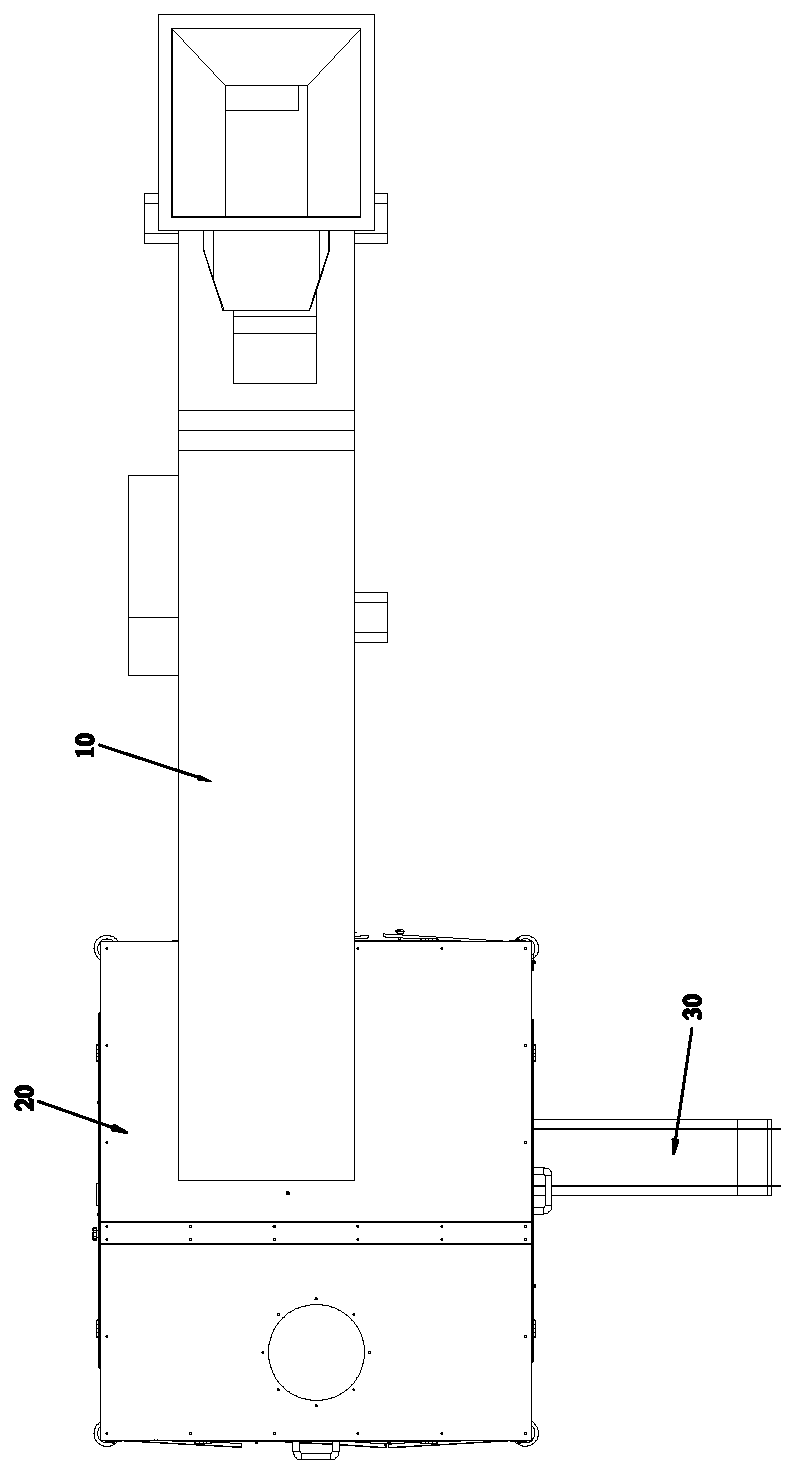

Multi-station rotating-type forage compressing and packaging machine

The invention discloses a multi-station rotating-type forage compressing and packing machine. The multi-station rotating-type forage compressing and packaging machine comprises a material hoister, a packaging machine main body and a discharging conveyor; the packaging machine main body is arranged beside the material hoister, and the packaging machine main body comprises a rack, a weighing mechanism, a compressing mechanism, a film placing mechanism, a film drawing mechanism, a bag forming mechanism, a longitudinal sealing mechanism and a transverse sealing mechanism; the compressing mechanismis arranged under the weighing mechanism, and materials are discharged to the compressing mechanism after being weighed through the weighing mechanism; and the compressing mechanism comprises a fixeddisc, a rotating disc, a motor, a plurality of hoppers, a plurality of compressing air cylinders and a blanking air cylinder. According to the multi-station rotating-type forage compressing and packing machine, the fact that multiple stations wok simultaneously and do not interfere with one another is achieved, and the production efficiency is improved; the materials are not fluffy after being compressed and occupy small space of a bag, using of a packaging film is reduced, and cost is saved; a traditional gravity blanking mode is changed through blanking by the air cylinder, and the blankingtime is shortened; and the functions of automatic bag-making, weighing, compressing and filling, sealing and the like are integrated on a whole.

Owner:GUANGZHOU V PACK IND CO LTD

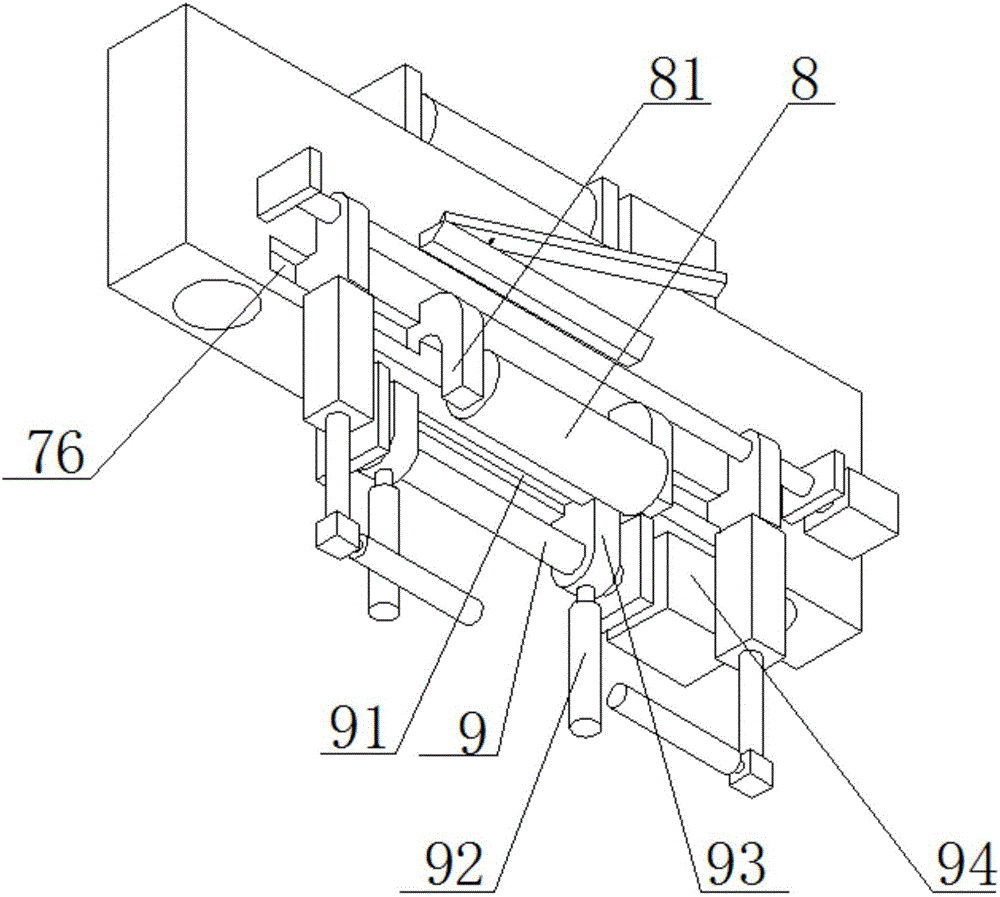

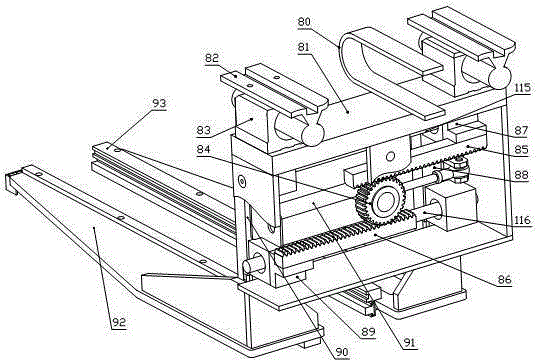

Sealing mechanism and method for special-shaped tobacco carton bundling and packaging device

The invention discloses a sealing mechanism and method for a special-shaped tobacco carton bundling and packaging device. The sealing mechanism comprises a sealing longitudinal moving belt (80) connected with a clamping mechanism fixing base (81); the clamping mechanism fixing base (81) is internally provided with a clamping gear (84); the upper portion of the clamping gear (84) is connected with an upper rack (85); the lower portion of the clamping gear (84) is connected with a lower rack (86); the upper rack (85) is connected with a first clamping base board (88) through a first clamping sliding block (87); the lower rack (86) is connected with a second clamping base board (90) through a second clamping sliding block (89); the second clamping base board (90) is connected with the first clamping base board (88) through a clamping air cylinder (91); the first clamping base board (88) and the second clamping base board (90) are provided with bag fetching clamping arms (92); an automatic sealing machine heat-sealing component (93) is arranged above the bag fetching clamping arms (92). The sealing mechanism and method have the characteristics of being high in production efficiency and low in labor intensity.

Owner:GUIZHOU HUILIAN TECH LIMITED

Efficient pad printing machine with automatic material collecting function

ActiveCN106183389AWith automatic receiving functionThe beneficial effect of the high-efficiency pad printing machine with automatic feeding function is that it can realize automatic feedingCylinder pressesPlaten pressesPad printingEngineering

The invention discloses an efficient pad printing machine with the automatic material collecting function. The machine comprises a ma unit chine table, a feeding conveying unit fixed to the machine table, a feeding adsorption unit in abut joint with the feeding conveying unit, a material dispensing unit located below the feeding adsorption unit, two pad printing components symmetrically arranged on the two sides of the feeding adsorption unit, a rubber head removing component located beside the pad printing components, a material conveying unit in abut joint with the feeding adsorption unit, a detecting unit located above the material conveying unit, a discharging adsorption unit in abut joint with the material conveying unit and a material collecting device in abut joint with the discharging adsorption unit. A series of full-automatic actions of automatic feeding, automatic pad printing, automatic detecting, automatic discharging, automatic glue head removing and the like can be achieved, automatic material collecting can be achieved, the products are stacked, packaging is convenient, and production efficiency is greatly improved.

Owner:KUNSHAN YITIAN AUTOMATION

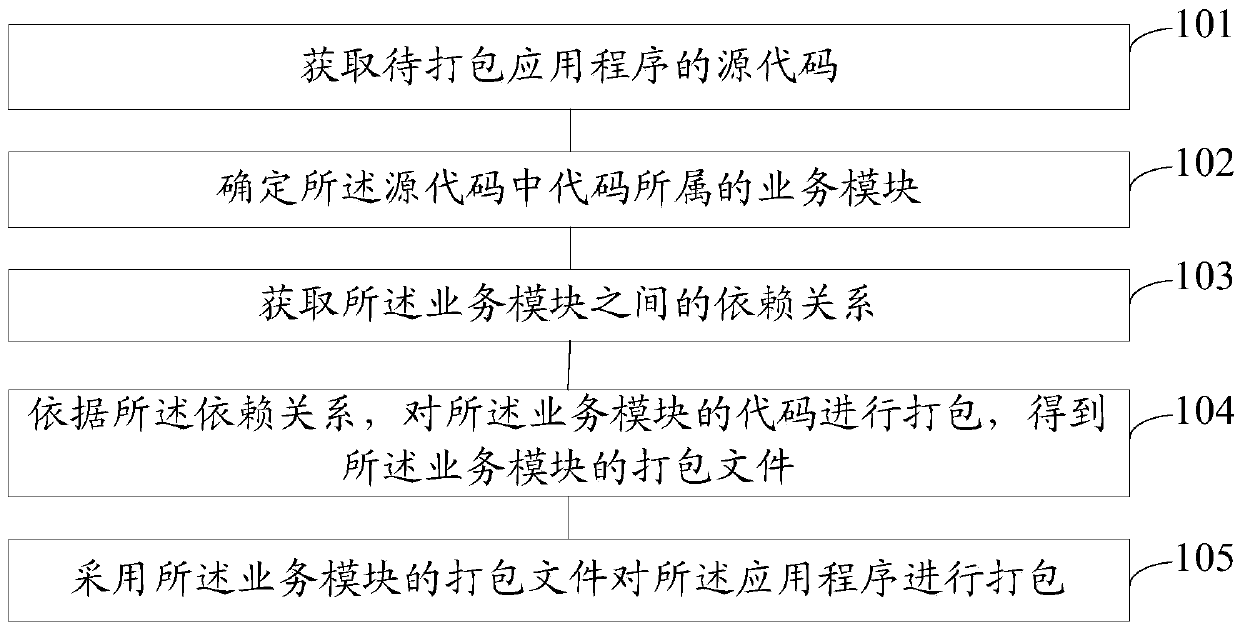

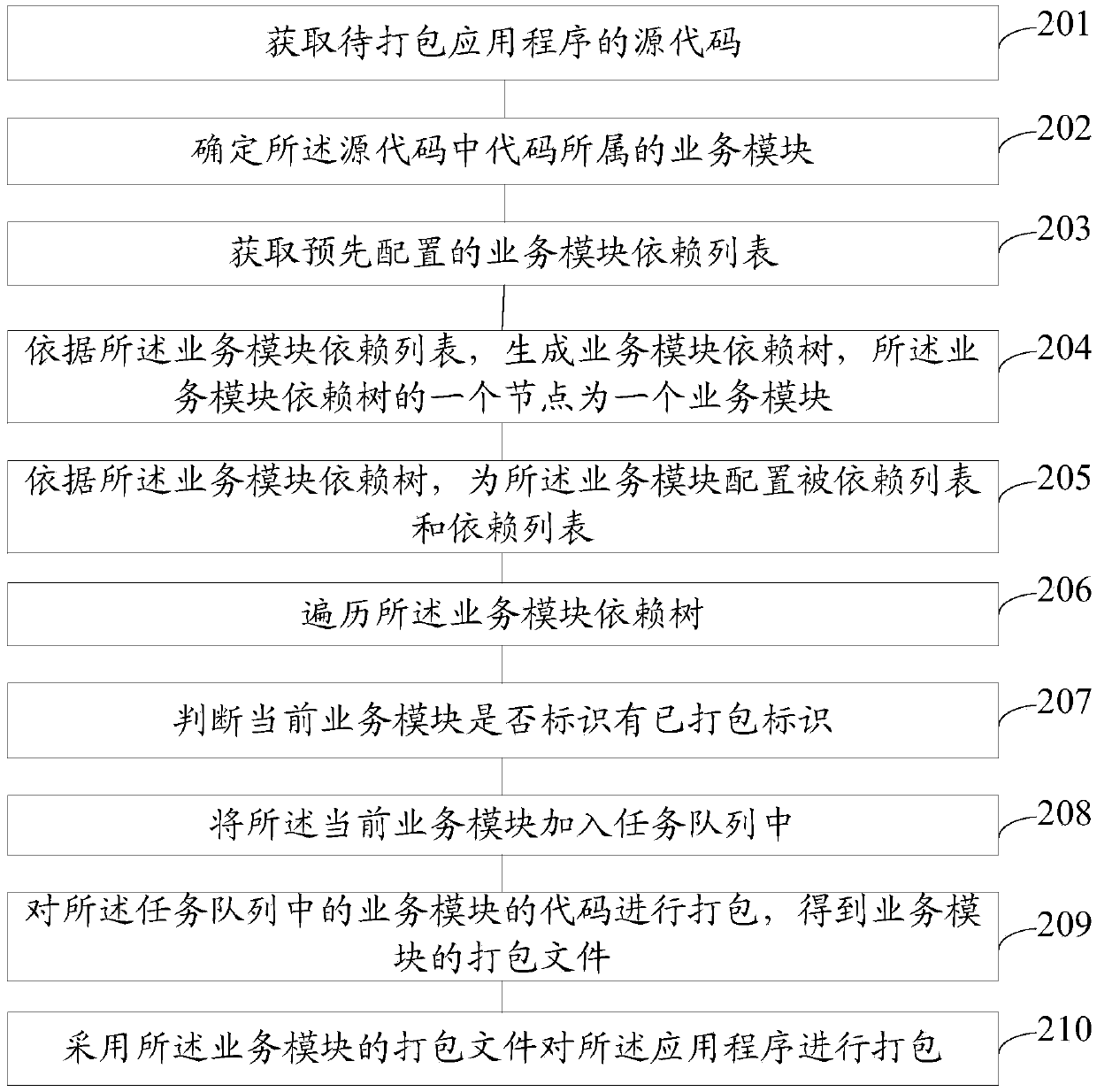

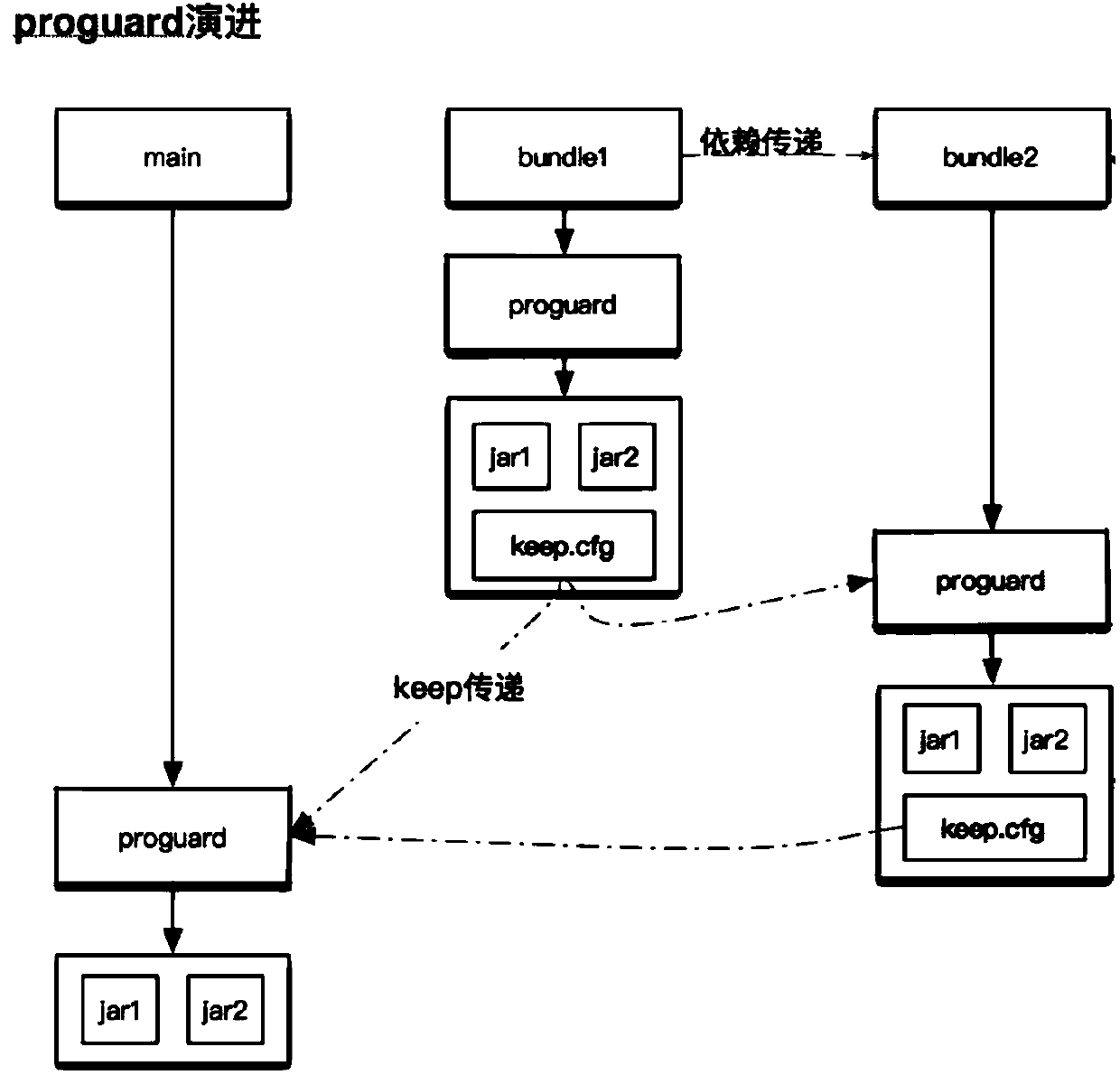

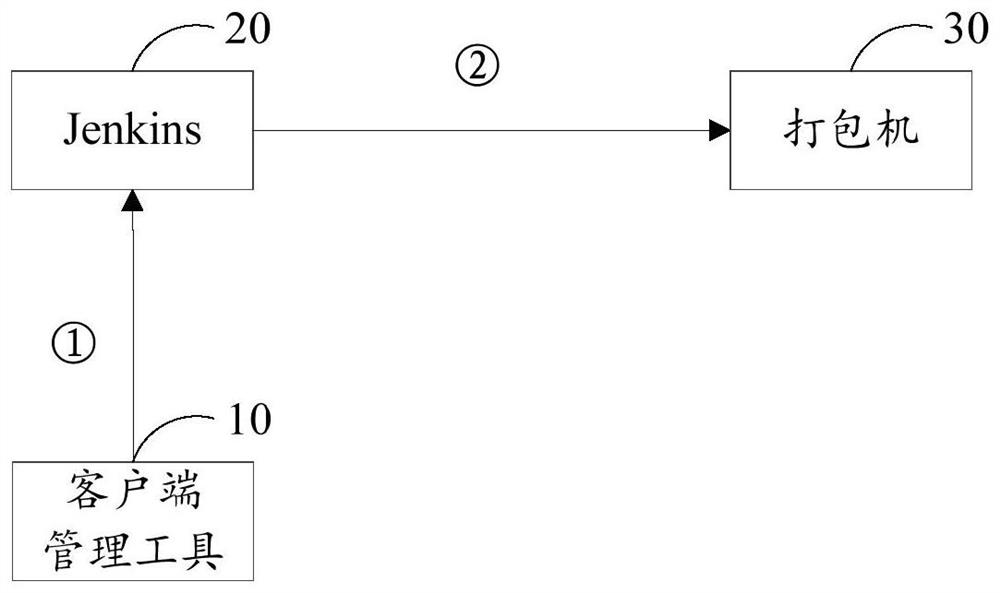

Application packaging method and device

PendingCN110347398ASave packing timeImprove packaging efficiencyDecompilation/disassemblyCode compilationApplication softwareSource code

Embodiments of the invention provide an application packaging method and an application packaging device. The application packaging method comprises the steps of obtaining a source code of a to-be-packaged application; determining a service module to which a code in the source code belongs; obtaining a dependency relationship between the service modules; according to the dependency relationship, packaging the codes of the service module to obtain a packaged file of the service module; and packaging the application program by adopting the packaging file of the service module. The source code isdivided into different service modules, and the dependency relationship between the service modules is analyzed; according to the embodiment of the invention, concurrent packaging processing can be carried out on a plurality of service modules by adopting multiple threads according to the dependency relationship, so that the problem of long time consumption for carrying out one-time packaging processing on source codes of the application program is avoided, the packaging time of the application program is shortened, and the packaging efficiency and the publishing efficiency of the applicationprogram are improved.

Owner:ALIBABA GRP HLDG LTD

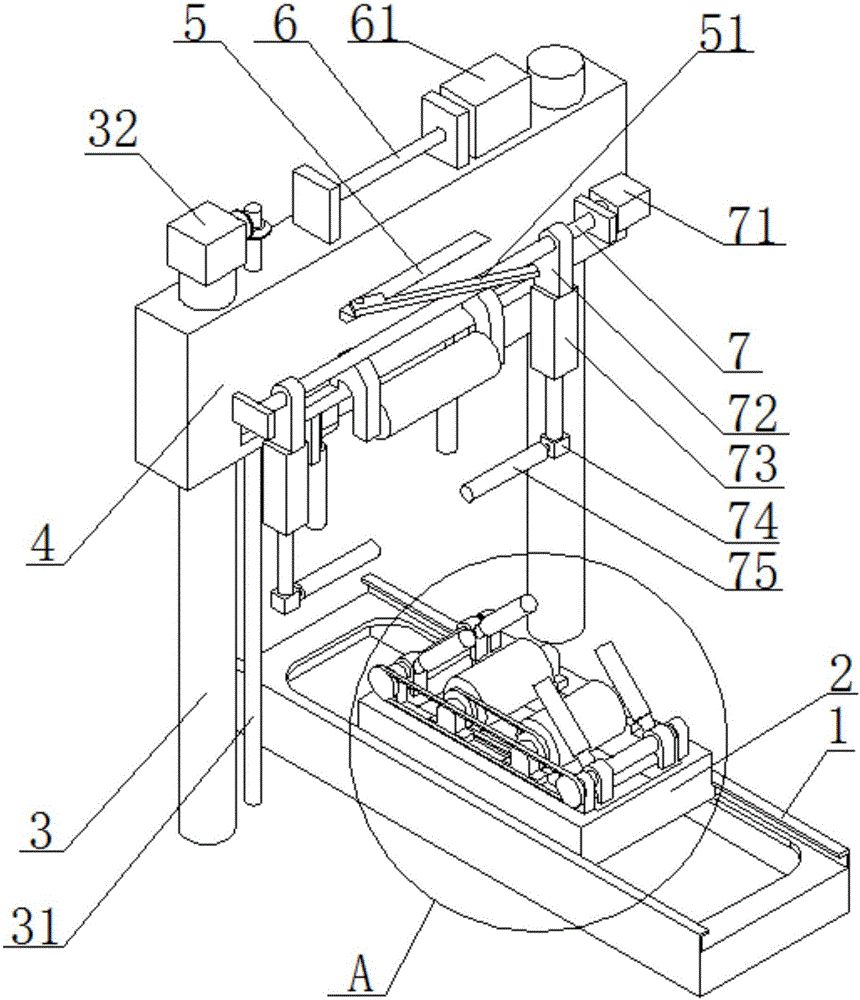

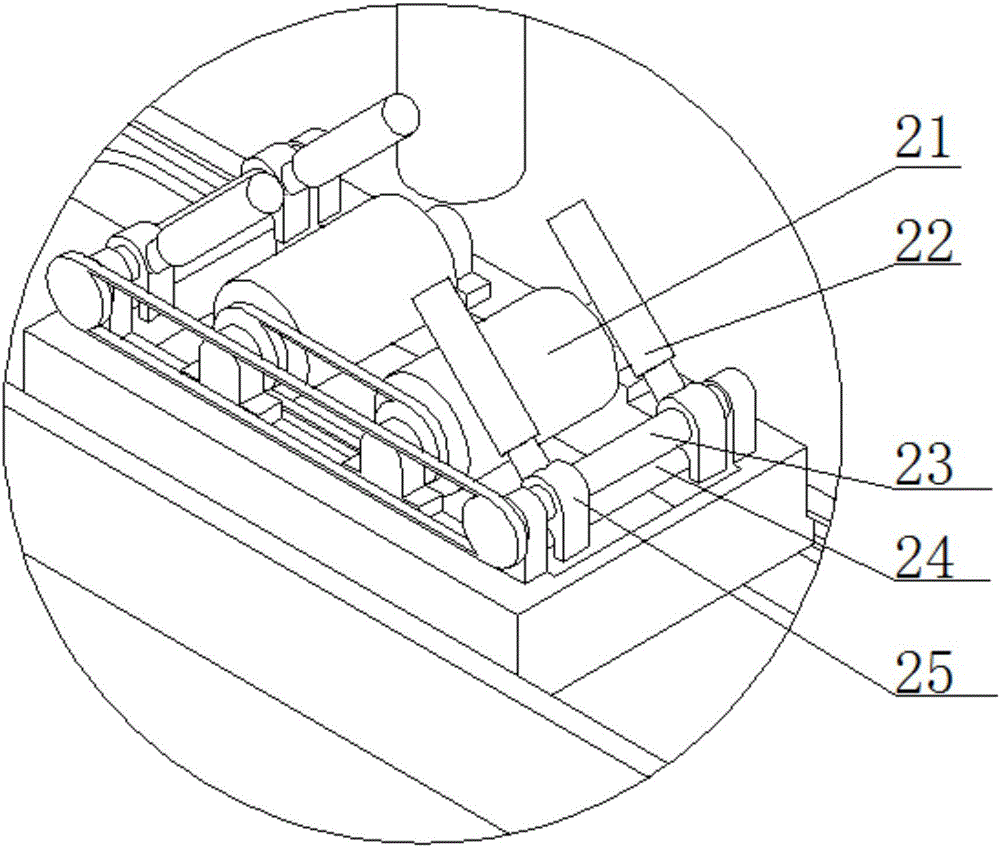

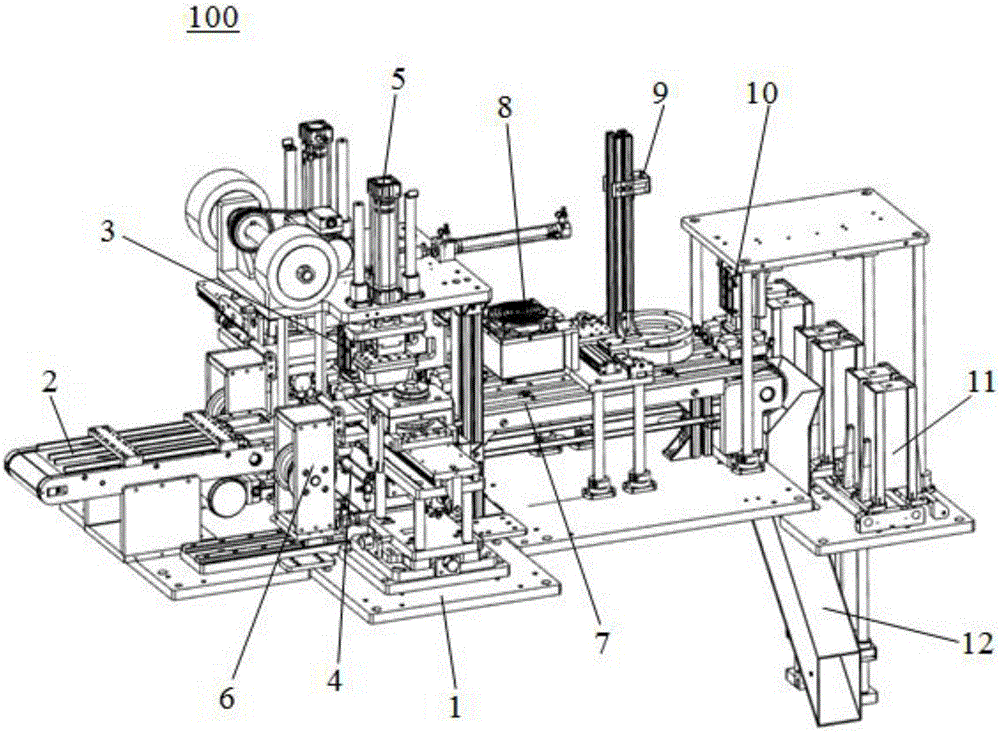

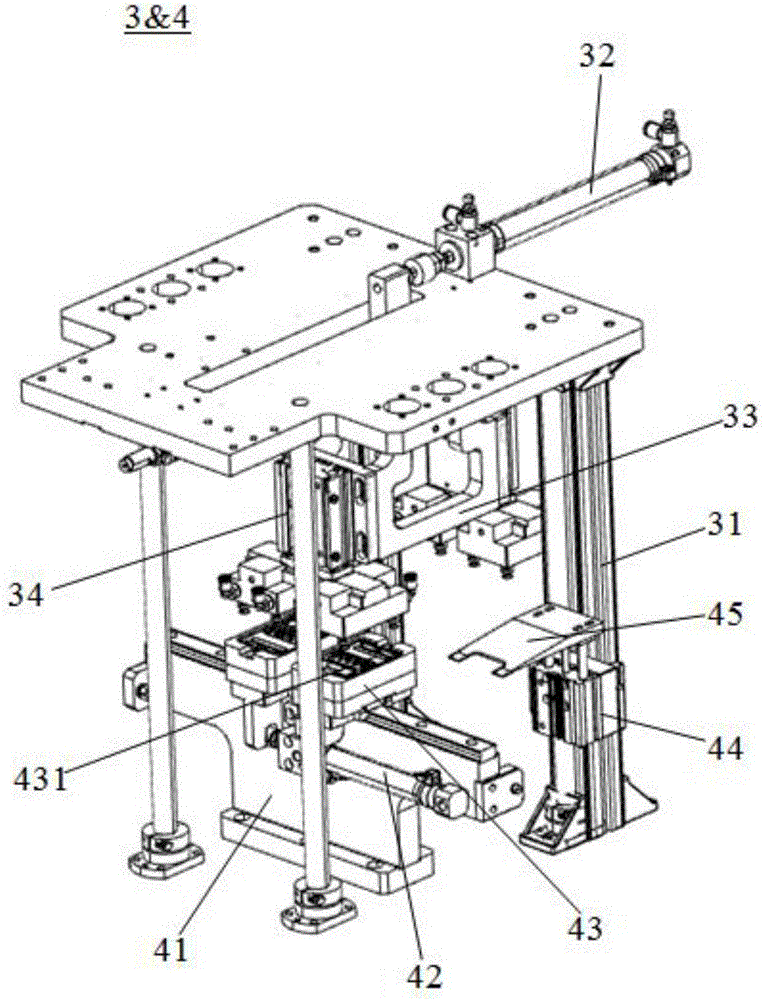

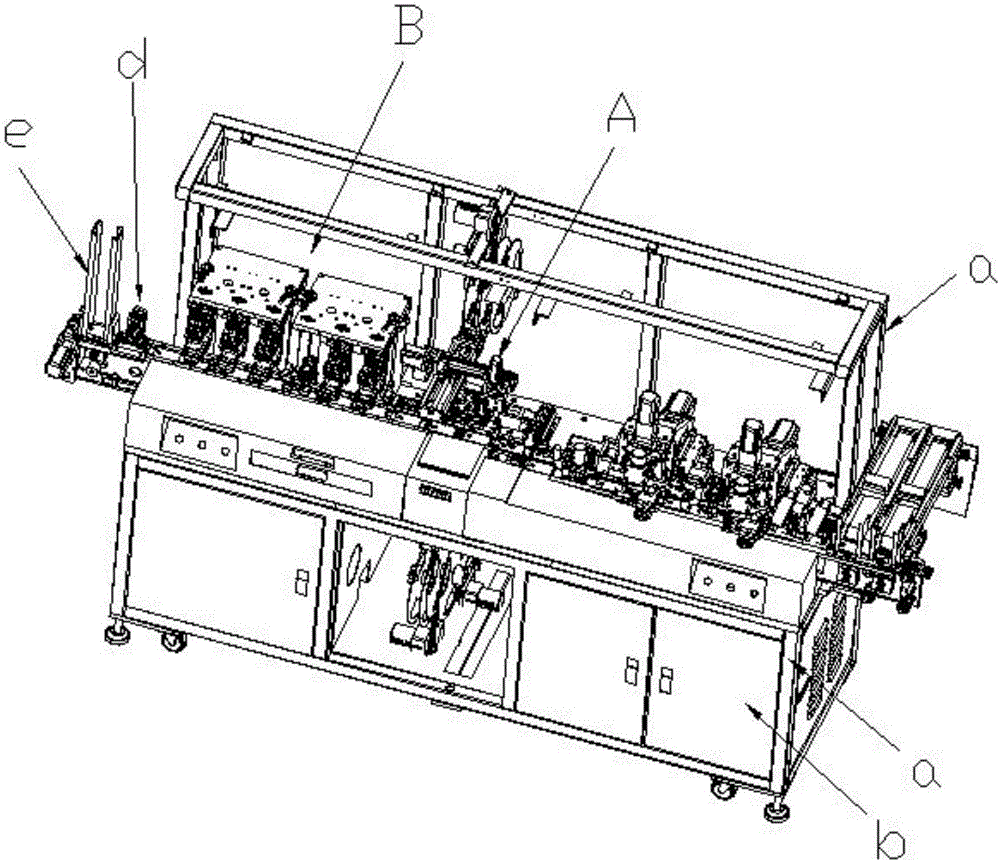

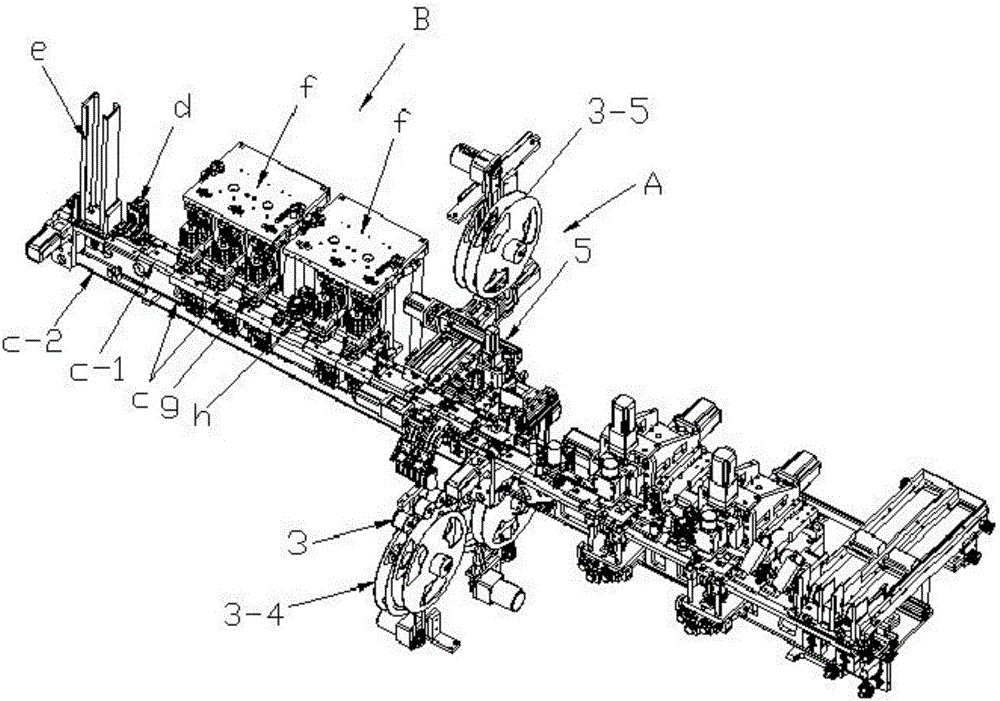

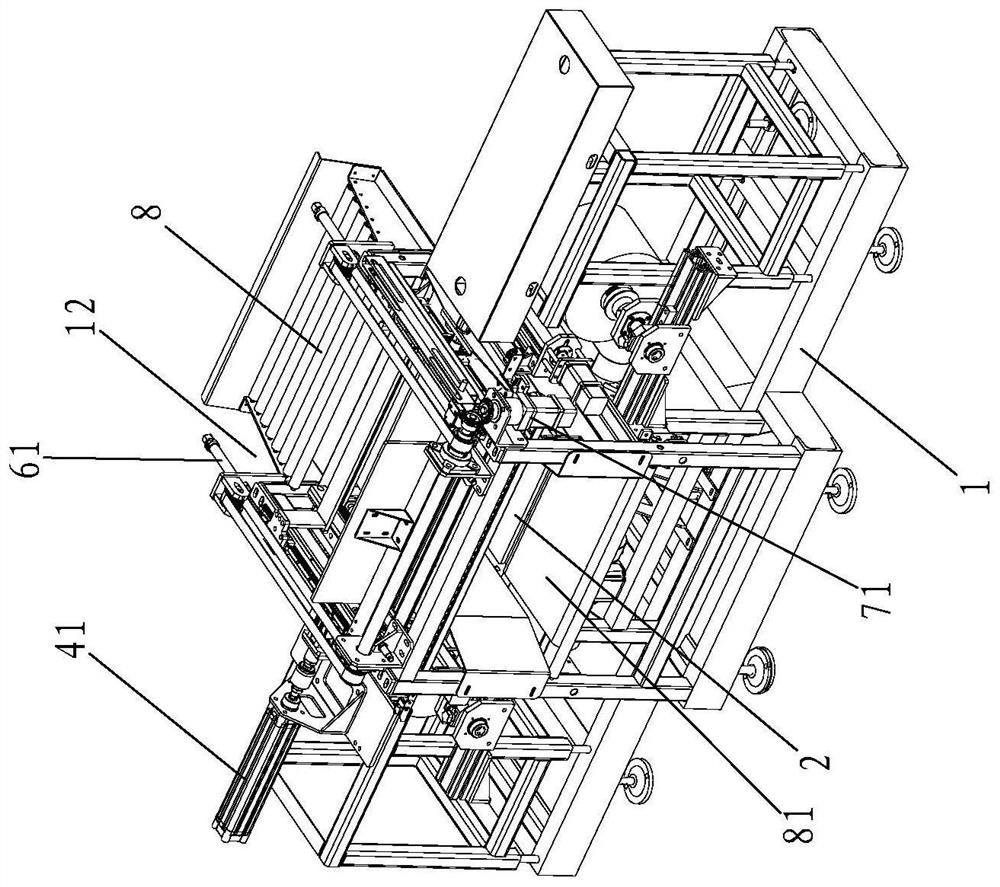

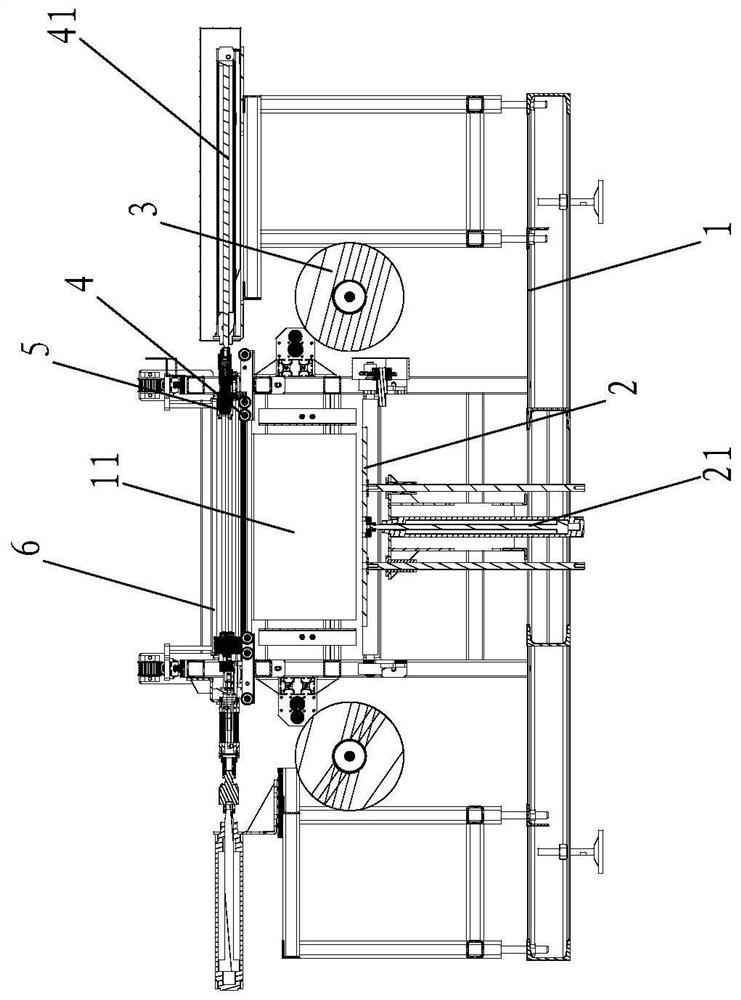

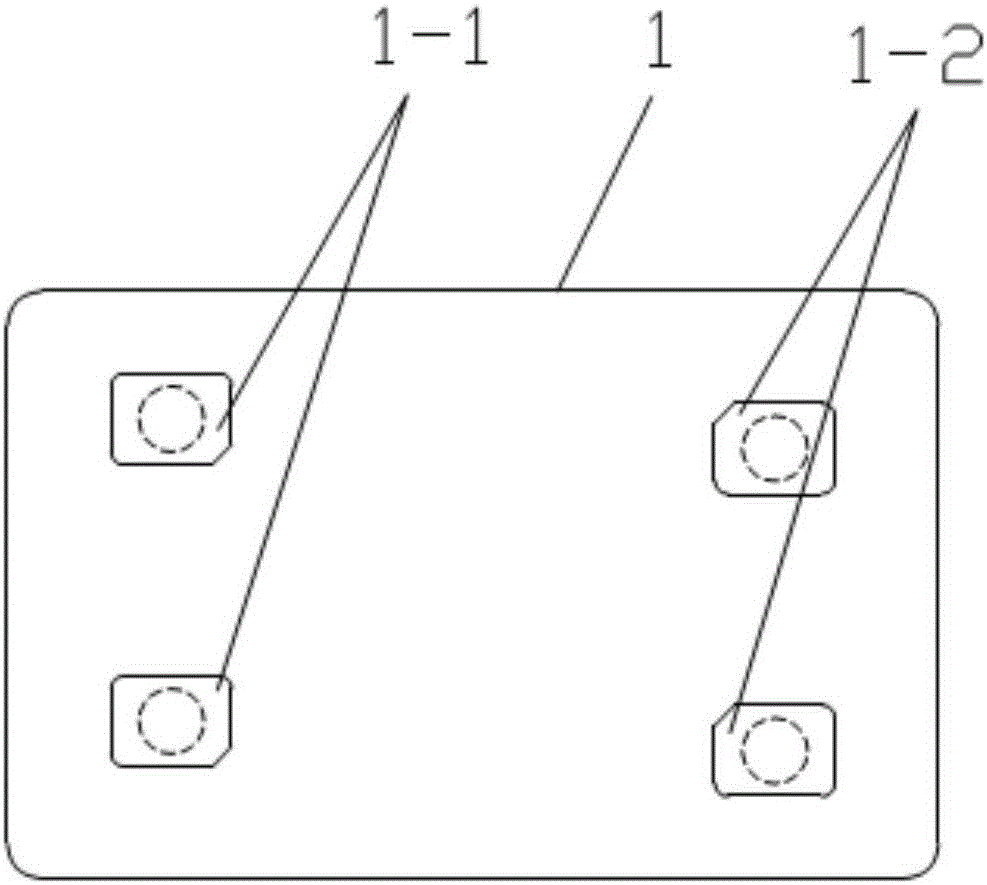

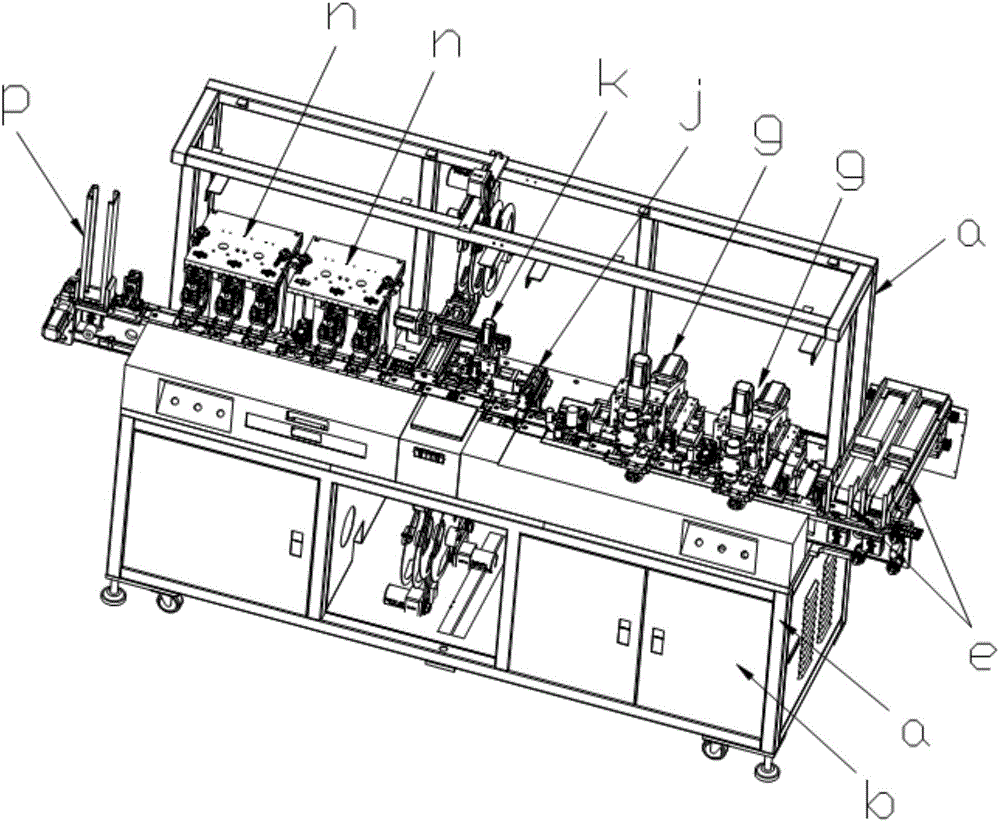

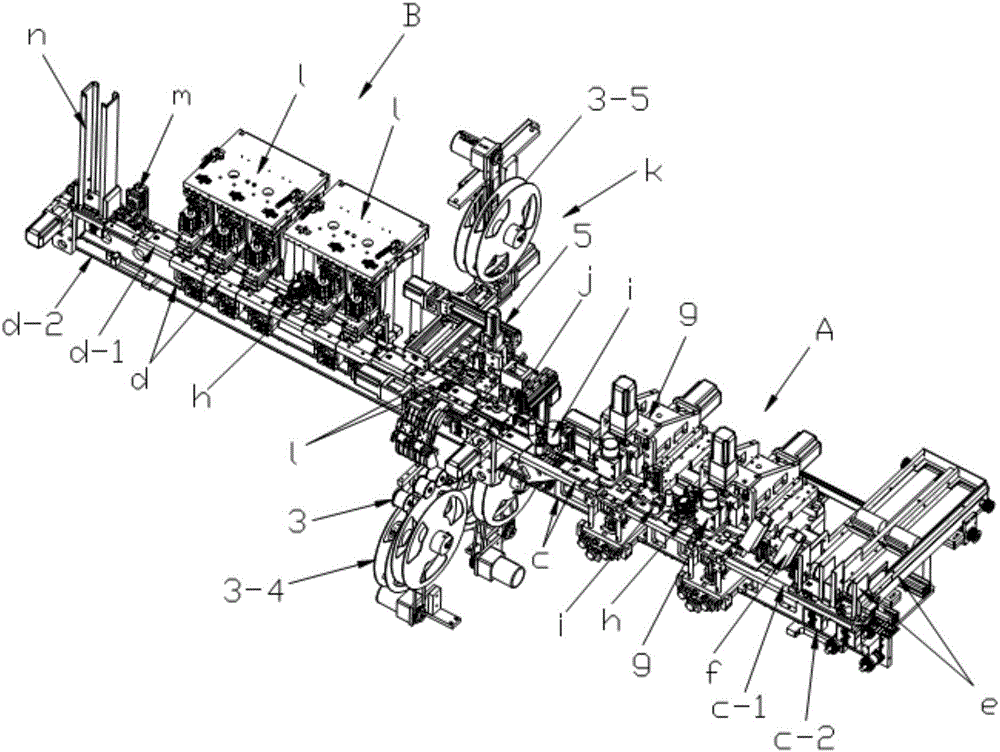

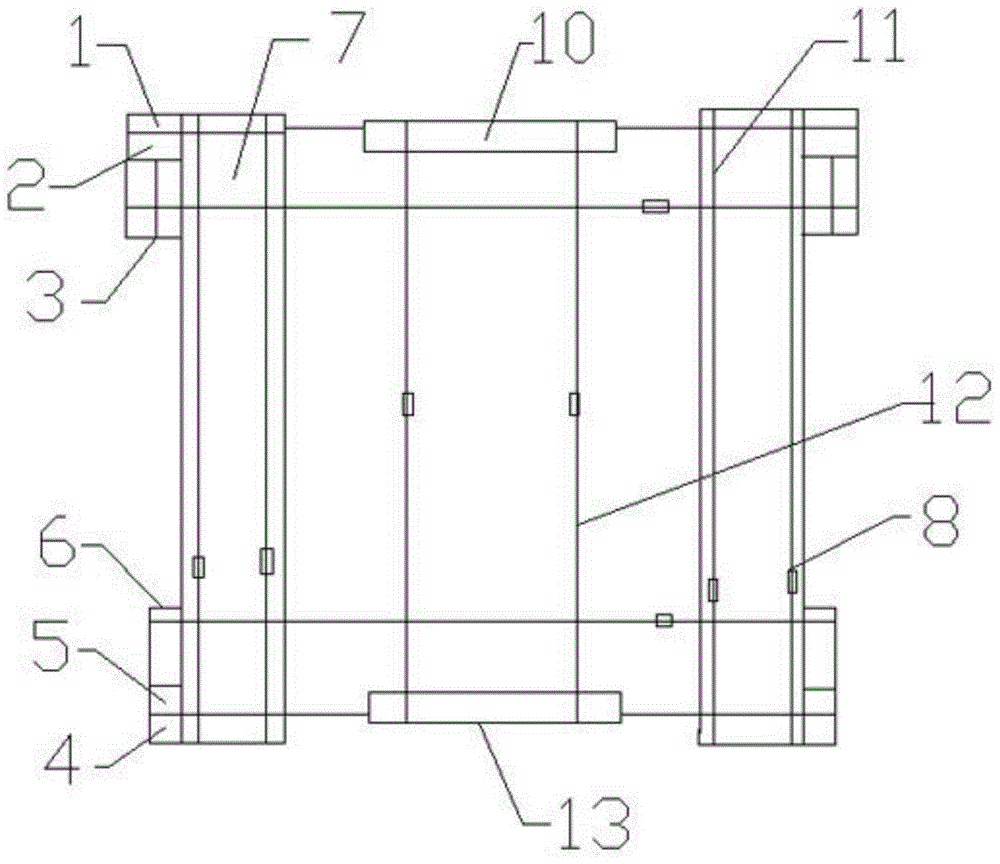

Automatic stacking, bundling, bagging and packaging device for special-shaped cigarettes and packaging method

ActiveCN105173167AReduce labor intensityVertical stroke reductionBinding material applicationBundling machine detailsManipulatorEngineering

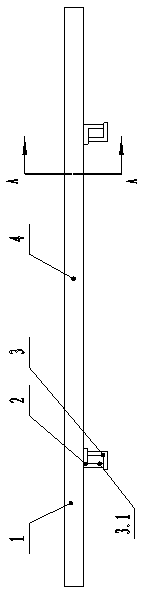

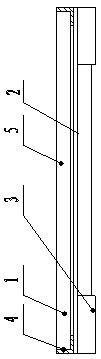

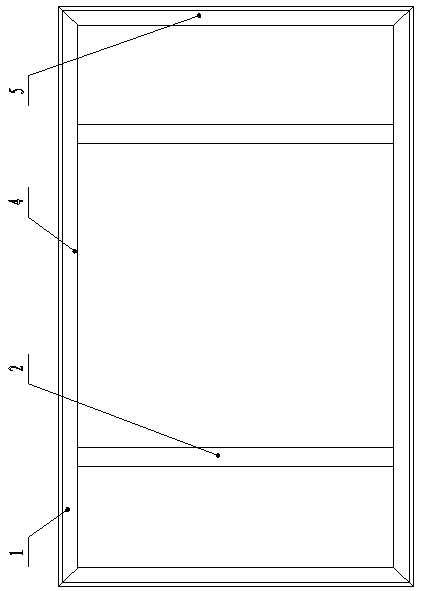

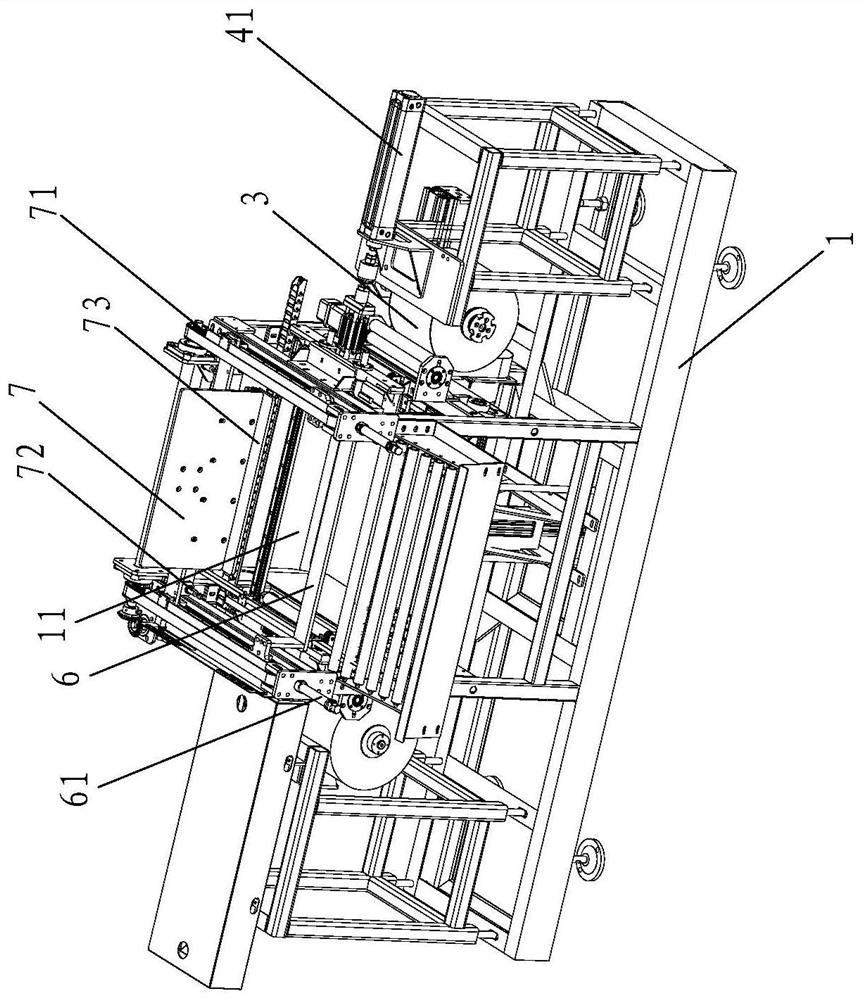

The invention discloses an automatic stacking, bundling, bagging and packaging device for special-shaped cigarettes and a packaging method. The device comprises an automatic bundling device (1), and the automatic bundling device (1) is connected with a bagging and packaging device (2); the automatic bundling device (1) comprises a tobacco taking mechanism (3), and a bundling mechanism (4) is arranged beside the tobacco taking mechanism (3); the bundling mechanism (4) is connected with a tobacco conveying mechanism (5), and the tobacco taking mechanism (3) comprises a mechanical arm supporting table (6); a joint mechanical arm (7) is arranged on the mechanical arm supporting table (6), and the bundling mechanism (4) comprises a base (8); the base (8) is provided with a lifting unit (9) which is connected with an automatic bundling machine (10); a first fixing plate (11) is arranged on the automatic bundling machine (10), and a second fixing plate (12) is arranged opposite to the first fixing plate (11); bundling openings (13) are formed in the same sides of the first fixing plate (11) and the second fixing plate (12); and an anti-collapsing brush (14) is arranged on the first fixing plate (11). The automatic stacking, bundling, bagging and packaging device has the beneficial effects of being low in labor intensity and high in production efficiency, saving manpower and reducing the labor cost.

Owner:GUIZHOU HUILIAN TECH LIMITED

Packaging process of light emitting diodes

InactiveCN103325918AAvoid yellowingSimple processSemiconductor devicesUltraviolet lightsRefractive index

The invention discloses a packaging process of light emitting diodes. Packaging glue is made of epoxy resin, positive ion photoinitiator, sensitizer, chain transfer agent, epoxy reactive diluent, solvent and addition agent; primary radiation solidification is conducted on the packaging glue through an ultraviolet light source; then, secondary radiation solidification is conducted on the packaging glue through a far-infrared heating system. By the adoption of the preparation method of the packaging process, packaging time can be shortened greatly, and production efficiency is improved by dozens of times. By the adoption of the ultraviolet-infrared double solidification mode, relative strength of two types of radiation is regulated so that glue yellowing caused by excessive ultraviolet radiation can be avoided and the solidification degree can be guaranteed. In addition, residual stress caused by ultraviolet solidification can be released through infrared secondary solidification. The hardness, the refractive index, the transmittance, the temperature resistance and the like of the solidified packaging glue can be regulated through packaging glue formulas, thereby being suitable for requirements of different LED products, beneficial to protecting luminous chips better, and suitable for new development of electronic and lighting products.

Owner:HANGZHOU HANGKE OPTOELECTRONICS

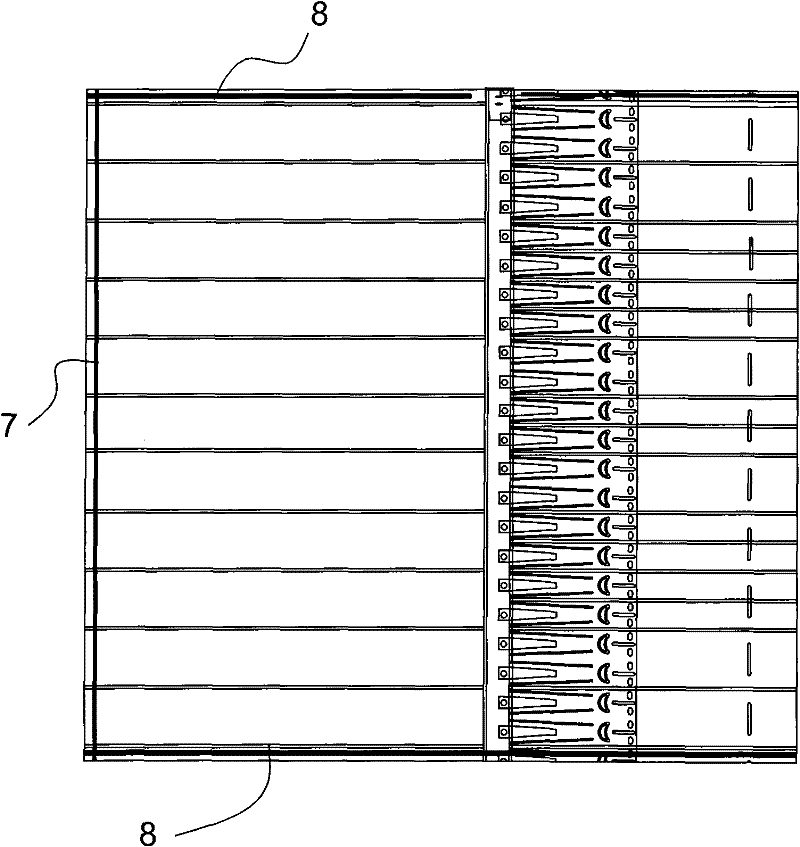

Chip package production line of multichip intelligent card

ActiveCN106328566AHigh packaging precisionSave packing timeSemiconductor/solid-state device manufacturingProduction lineThermal compression

The invention discloses a chip package production line of a multichip intelligent card, comprising a card conveying mechanism, a packaging module, a thermal compression module, a chip detection module and a card receiving module, wherein the modules are in sequence arranged along a card conveying direction; the packaging module comprises two chip belt supply mechanisms, a chip blanking mechanism and a chip carry packaging mechanism; two packaging stations are configured for the packaging module; a chip positioning mechanism is respectively arranged at each packaging station; chip belt supply mechanisms comprise chip belts and chip belt transmission mechanism; chip belts in two chip belt supply mechanisms in parallel extend along a direction perpendicular to the card conveying direction, and the transmission directions thereof are opposite. The equipment is applicable to package and fixation of the single-chip card and the multichip card and has the advantages of quick package and thermal compression fixation speed, high production efficiency and precision.

Owner:GUANGZHOU MINGSEN TECH CO LTD

Wafer level packaging method and its structure

InactiveCN101071781AImprove yieldShorten the timeSemiconductor/solid-state device detailsSolid-state devicesInterface layerEngineering

The invention is an integrated wafer packaging structure, comprising a chip, at least a passive component, an interface layer, an insulating layer, at least a connection, an internal connecting pad and a protection layer, where the chip comprises a surface connecting pad, an internal connecting pad and a circuit component, the passive component is formed on one side of the chip, the interface layer increases the bond between the passive component and the chip, the insulating layer covers part of the surface on the other side of the chip, the connection covers part of the surface of the insulating layer and the internal connecting pad and is used to connect with the internal connecting pad, and the protection layer is used to protect the chip.

Owner:中国台湾格雷蒙股份有限公司

Steel plate package box and package method thereof

The invention relates to a steel plate package box and a package method thereof. The steel plate package box comprises an angle steel bracket and an upper cover, the angle steel bracket is provided with longitudinal angle steel, transverse angle steel and two angle steel cross beams, and the upper cover covers the angle steel bracket. The steel plate package box is characterized in that short angle steel is welded to the two ends of the angle steel cross beams separately, the short angle steel and the angle steel cross beams constitute a rectangular pipe, and the upper cover is a galvanized sheet iron cover. The package method comprises the steps of 1, making the two ends of each of two longitudinal inward steel belts penetrate through the lower portion of the transverse angle steel from the upper portions of the angle steel cross beams; 2, putting a plastic plate on the angle steel bracket; 3, laying plastic coating woven fabric on the plastic plate, stacking a cold-roll steel sheet on the plastic coating woven fabric and using the plastic coating woven fabric to package the cold-roll steel sheet into a steel sheet package; 4, using two longitudinal inward steel belts and three transverse inward steel belts to bind the steel sheet package and the angle steel bracket together; 5, using the galvanized sheet iron cover to lid the steel sheet package, covering the angle steel bracket and using three transverse outward steel belts to bind the galvanized sheet iron cover and the angle steel bracket together. The steel plate package box is large in loading, and the package methodsaves package time.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Tobacco carton three-dimensional packaging machine and tobacco carton three-dimensional packaging method

PendingCN113148308AImprove work efficiencyRealize the footprintWrapping material feeding apparatusWrappingStructural engineeringPacking method

The invention relates to the field of tobacco carton packaging, in particular to a tobacco carton three-dimensional packaging machine. The machine comprises a machine frame, an input conveying belt and an output conveying belt, a lifting platform used for lifting tobacco cartons is arranged at the position, located between the input conveying belt and the output conveying belt, of the machine frame, and a lifting driving mechanism used for driving the lifting platform to ascend and descend is arranged on the machine frame. A lifting channel is formed at the position, located at the lifting area of the lifting platform, of the machine frame, a packaging mechanism used for transversely and / or longitudinally packaging objects on the lifting platform is arranged at the position, located at the top end of the lifting channel, of the machine frame, and a conveying receding opening is formed at the position, located at the side, close to the output conveying belt, of the lifting platform, of the lifting channel. The machine frame or the lifting platform is provided with an output mechanism used for inputting the objects on the lifting platform to the output conveying belt from the conveying receding opening. The technical problem that the working efficiency is lower when existing tobacco cartons are subjected to film sleeving packaging is solved. The invention further provides a tobacco carton three-dimensional packaging method.

Owner:福建科盛智能物流装备有限公司

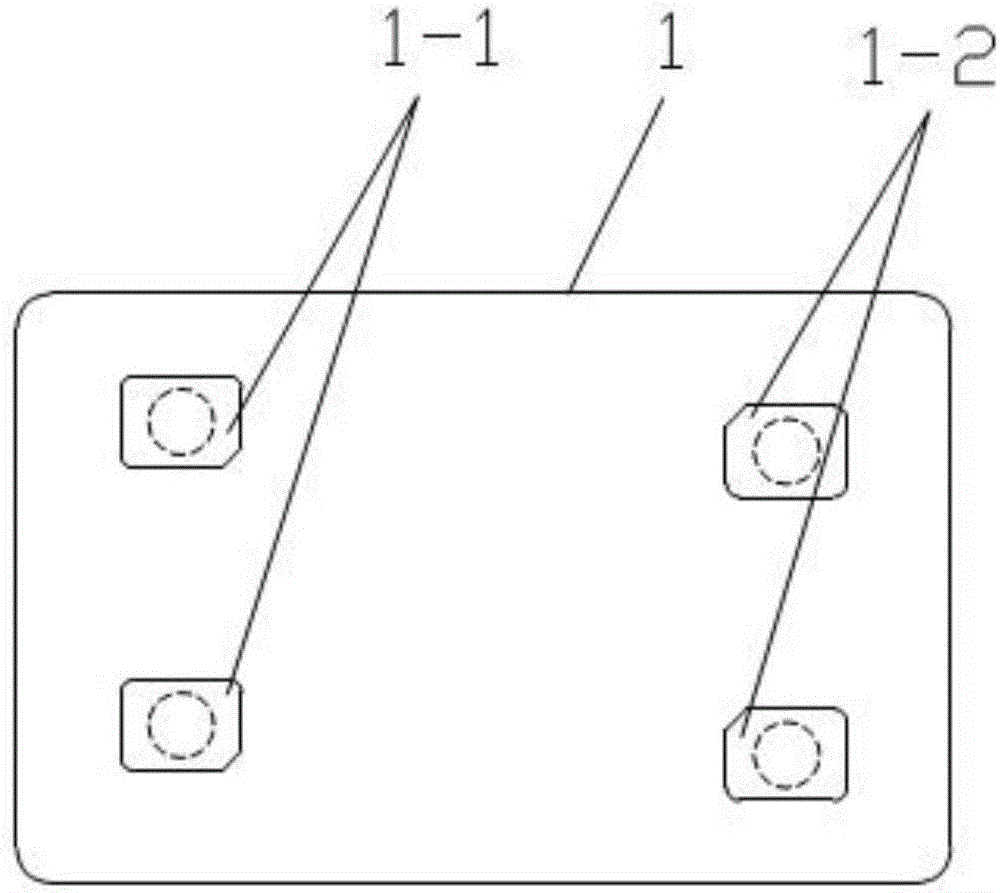

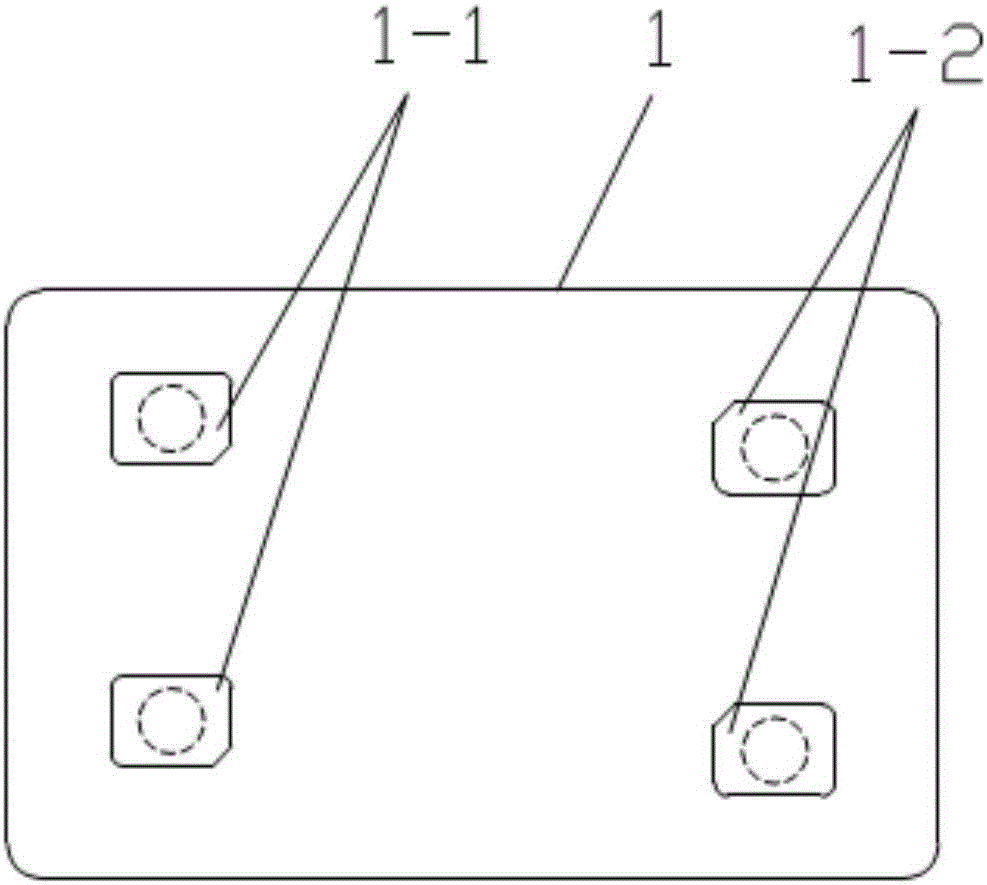

Chip packaging device of multi-chip intelligent card

ActiveCN106295766AHigh packaging precisionSave packing timeRecord carriers used with machinesPunchingEngineering

The invention discloses a chip packaging device of a multi-chip intelligent card. The chip packaging device of the multi-chip intelligent card comprises a card conveying guide track, two chip belt supply mechanisms, chip punching mechanisms and a chip carrying and packaging mechanism, wherein two packaging stations are arranged on the card conveying guide track; each chip belt supply mechanism comprises a chip belt and a chip belt conveying mechanism; the chip belts in the two chip belt supply mechanisms extend in parallel in the direction perpendicular to the card conveying direction; the conveying directions of the chip belts in the two chip belt supply mechanisms are opposite; each chip punching mechanism comprises a punching die and a punching actuating mechanism arranged below the punching die; two punching holes are formed in each punching die; and the two chip belts in the two chip belt supply mechanisms respectively pass through places below the punching die of one of the chip punching mechanisms. The chip packaging device has the advantages of high packaging speed, high production efficiency, high packaging precision and the like.

Owner:GUANGZHOU MINGSEN TECH CO LTD

Multi-chip contact type intelligent card slot milling packaging device

ActiveCN106601651AReduce transfer timeIncrease productivitySemiconductor/solid-state device manufacturingMilling equipment detailsEngineeringContact type

The invention discloses a multi-chip contact type intelligent card slot milling packaging device comprising a slot milling device and a packaging device, which are connected together. The packaging device comprises packaging modules, which comprises chip belt supply mechanisms, chip blanking mechanisms, and chip conveying packaging mechanisms. The card conveying guide rail of the slot milling device is provided with two packaging stations corresponding to the packaging modules, and each packaging station is provided with a card positioning mechanism. The two chi belt feeding mechanisms are provided, and each chip belt supply mechanism comprises a chip belt and a chip belt conveying mechanism. The chip belts of the two chip belt supply mechanisms are extended parallely along a direction vertical to the card conveying direction, and the conveying directions of the conveying belts of the two chip belt supply mechanisms are opposite to each other. The multi-chip contact type intelligent card slot milling packaging device is suitable for slot milling packaging of single-chip cards, and is suitable for slot milling packaging of multi-chip cards. When the multi-chip contact type intelligent card slot milling packaging device is used for the slot milling packaging of the multi-chip cards, the multi-chip contact type intelligent card slot milling packaging device has advantages of fast packaging speed, high production efficiency, and high packaging precision.

Owner:GUANGZHOU MINGSEN TECH CO LTD

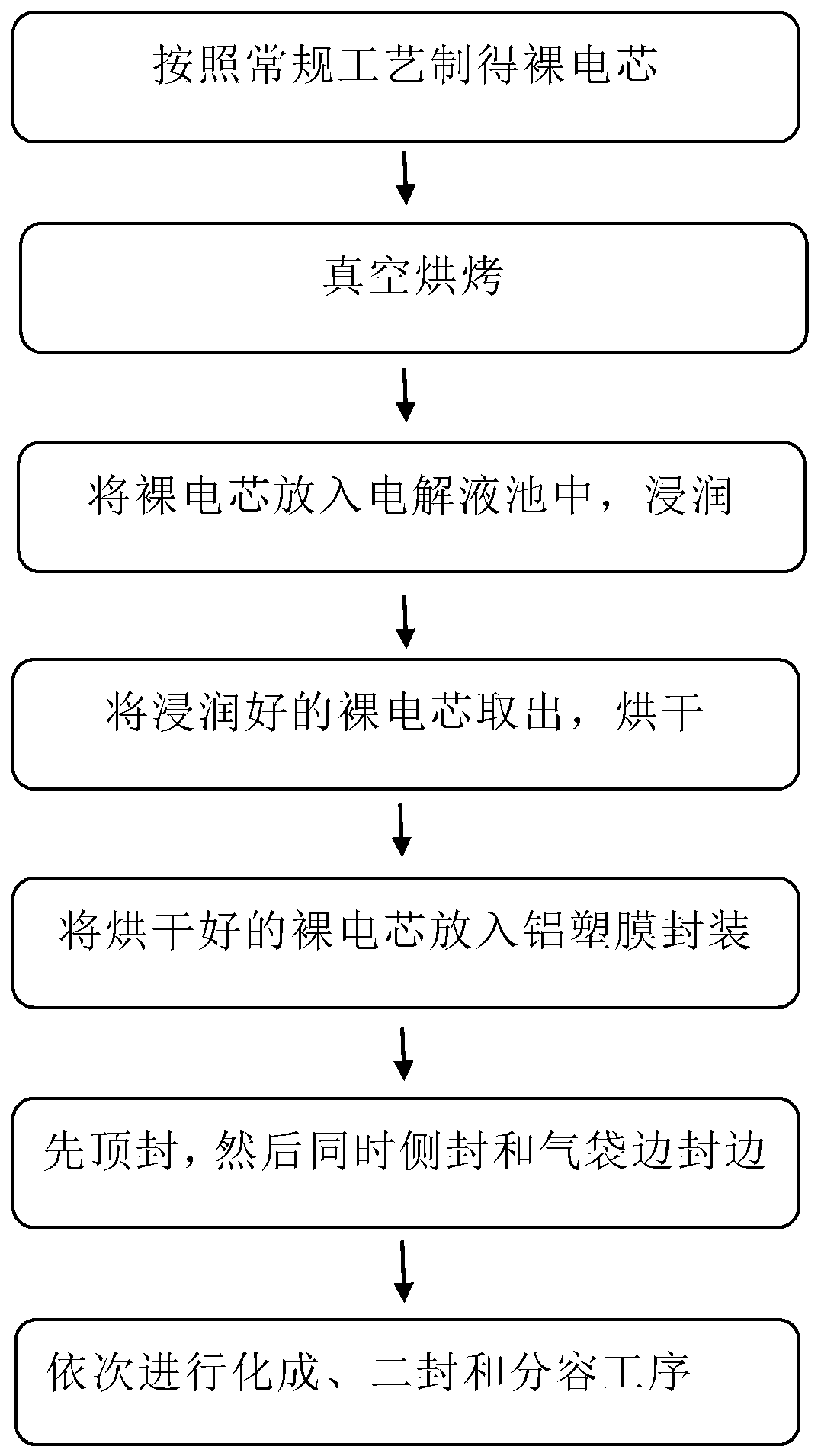

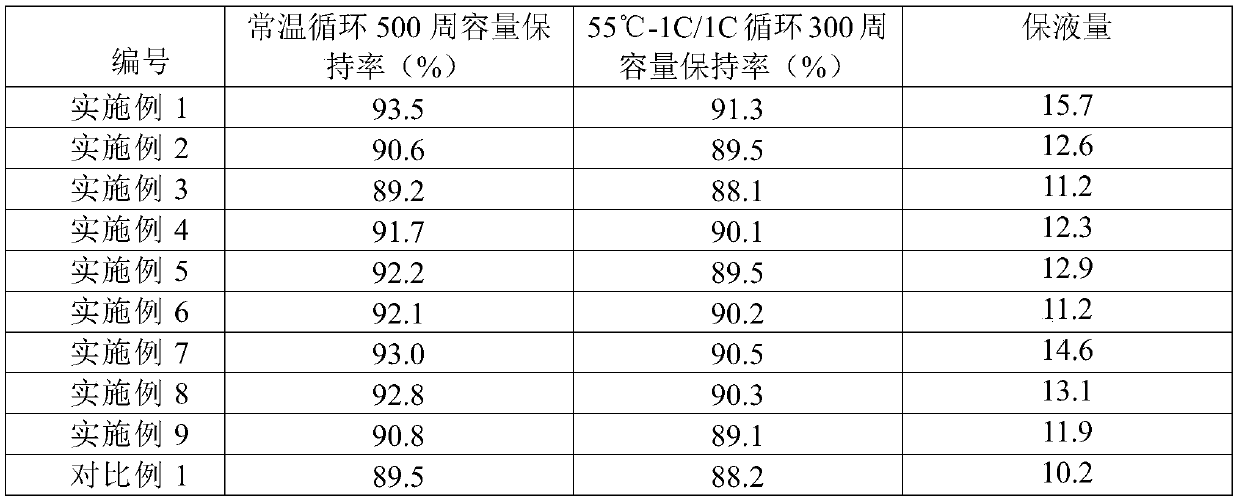

Soft-packed lithium ion battery manufacturing process

InactiveCN110718669APromote reabsorptionShorten production timeFinal product manufactureCell component detailsElectrolytic agentPhysical chemistry

The invention provides a soft-packed lithium ion battery manufacturing process which comprises the following steps: S1, after a bare cell is wound, the bare cell is put into an electrolyte tank in a dry and oxygen-free environment until the electrolyte level reaches the tab glue position of the bare cell, the bare cell is soaked for 10 seconds to 2 hours, and the temperature of electrolyte is maintained at 20 to 150 DEG C; S2, the soaked bare cell is taken out, and the bare cell is dried at 20-150 DEG C until the bare cell does not drop electrolyte anymore and the content of the electrolyte meets a preset value; and S3, the bare cell is put into an aluminum-plastic film after being dried, top sealing is carried out first, and then, side sealing and air bag edge sealing are carried out at the same time, and thus, packaging is completed. Compared with the prior art, the bare cell is directly placed and soaked in the electrolyte tank and dried, side sealing and air bag edge sealing are carried out at the same time, and by improving the existing process, the standing time is greatly shortened, the process flow is simplified, and the production efficiency is improved.

Owner:HUIZHOU LIWINON NEW ENERGY TECH CO LTD

Return plug type air packaging device and manufacturing method thereof

The invention relates to a return plug type air packaging device. Two thermoplastic film layers are subjected to thermal plastic packaging twice to form a three-dimensional packaging body which is provided with an opening and can seal the air, the three-dimensional packaging body comprises a plurality of independent sealing air chambers and a main channel, the main channel is provided with an air inlet, each sealing air chamber is communicated with the main channel by virtue of a check valve composed of a check valve film, the three-dimensional packaging body is also internally provided with an inner bag which can not be aerated, and the inner bag is formed by plastically packaging an outward extending section at one side of an opening of the packaging body and the other side of the opening or the outward extending section at the other side and is suspended in the inflated three-dimensional packaging body. The invention provides an air packaging device applicable to packaging of materials which are about to be packaged and provided with edges on the surface. By applying the packaging device, the packaging film for the materials to be packaged is saved; and meanwhile, a packaging film packaging process is eliminated, the packaging time is greatly reduced, and the accident probably existing in the packing process is further reduced, thus the cost is saved.

Owner:SHANGHAI AIR PAQ COMPOSITE MATERIAL

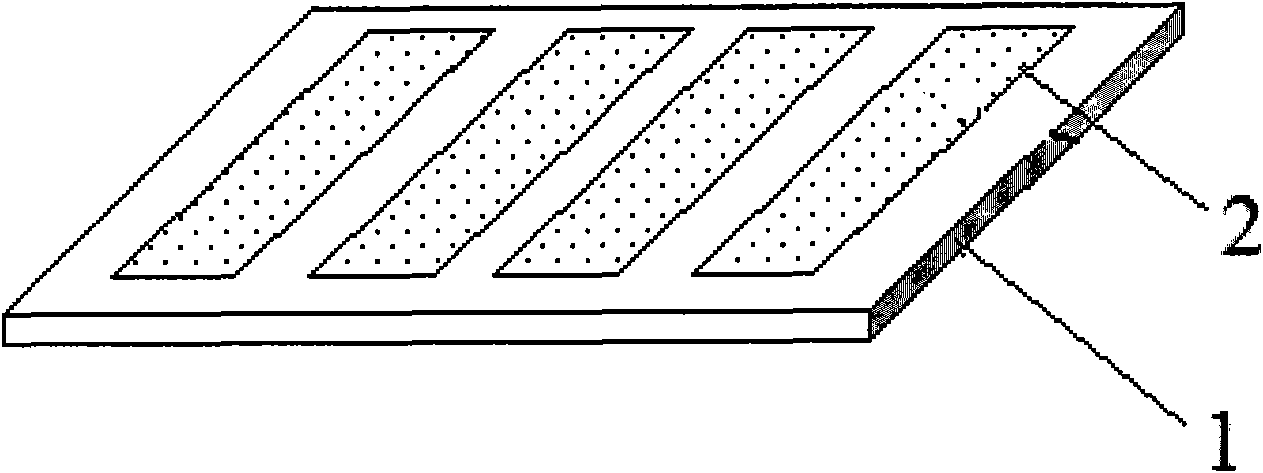

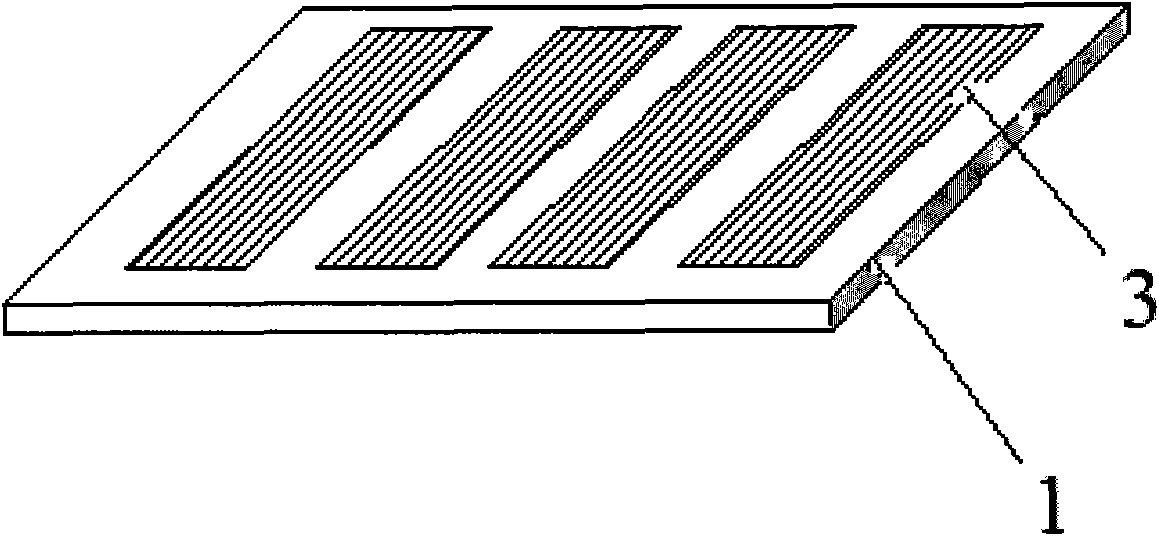

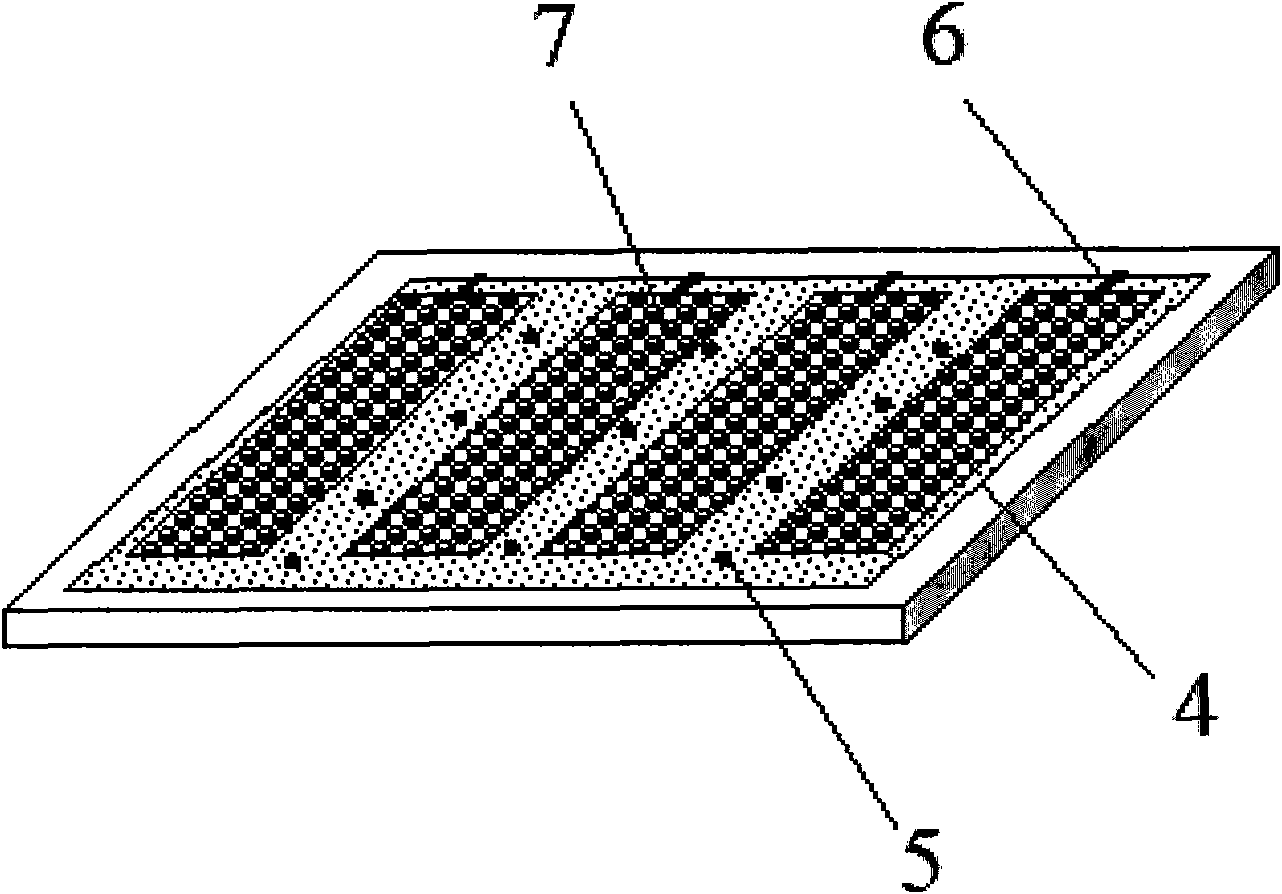

Method for packaging dye-sensitized solar cell

InactiveCN101777436AImprove performanceGood repeatabilityLight-sensitive devicesSolid-state devicesScreen printingAdhesive

The invention discloses a method for packaging a dye-sensitized solar cell, which comprises the following steps of: adopting a screen printing technique to print a TiO2 nano-particle sizing material on a piece of FTO conductive glass for manufacturing a working electrode so as to form a plurality of isolated rectangular flaky TiO2 films; sintering the TiO2 films printed in the first step (S1) and soaking the TiO2 films in a dye; doping a certain proportion of spacing agent into a liquid packaging adhesive to serve as a packaging material, and uniformly coating the packaging material in gaps of the TiO2 films; covering a counter electrode on the working electrode and applying a uniform pressure to the counter electrode; and injecting an electrolyte into spaces limited by the packaging material, sealing the spaces, and finishing the solidification of the packaging material. The scheme can improve the performance and the service life of the dye-sensitized solar cell, and is helpful for efficient and large-area production and processing of batteries.

Owner:PEKING UNIV

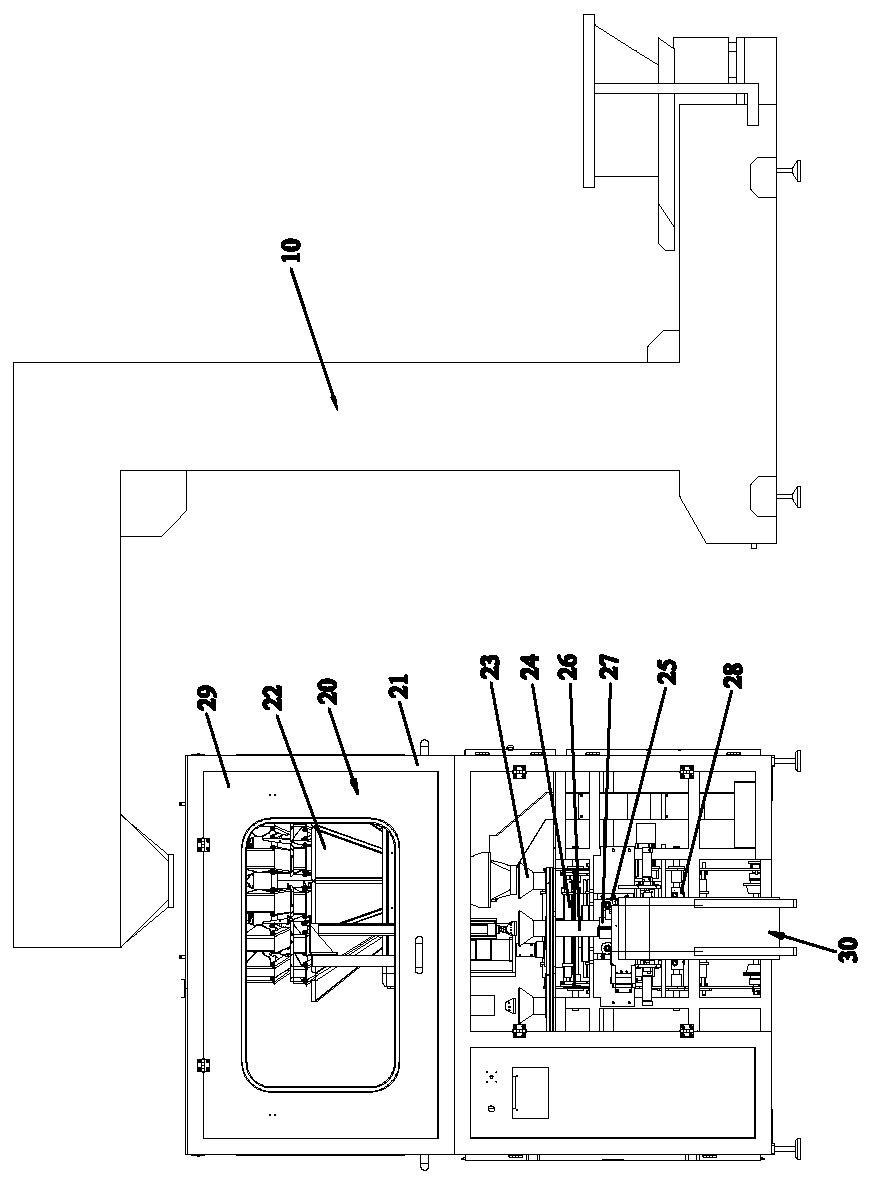

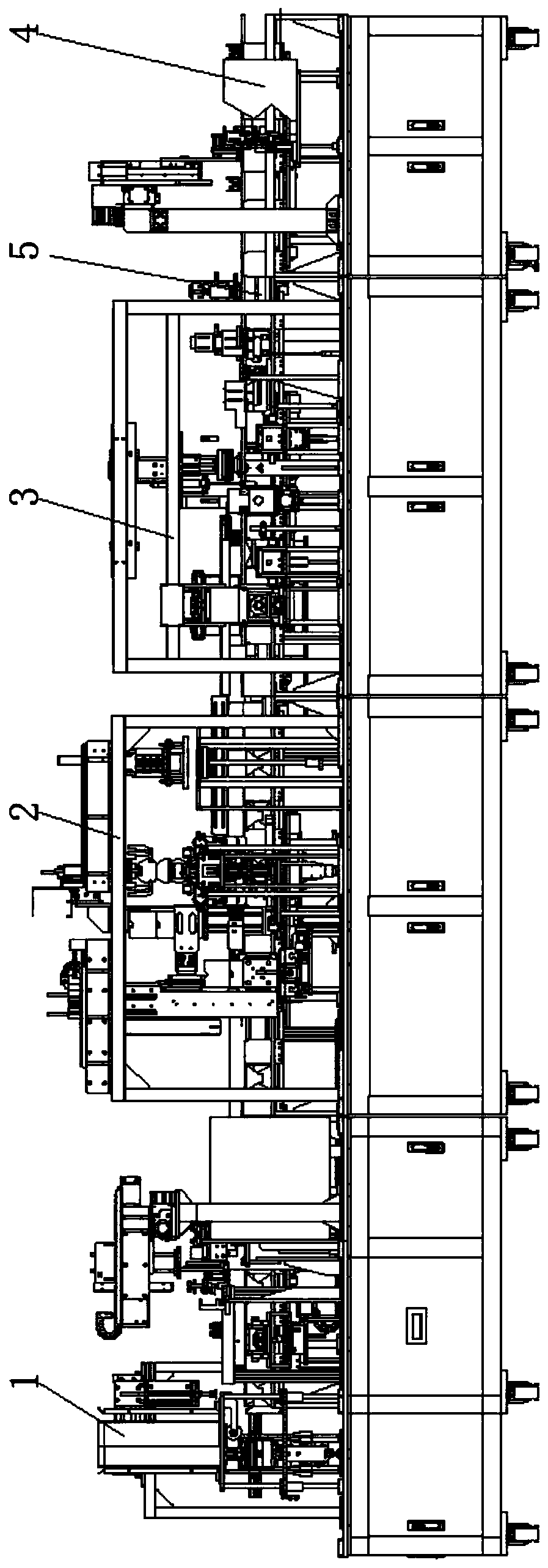

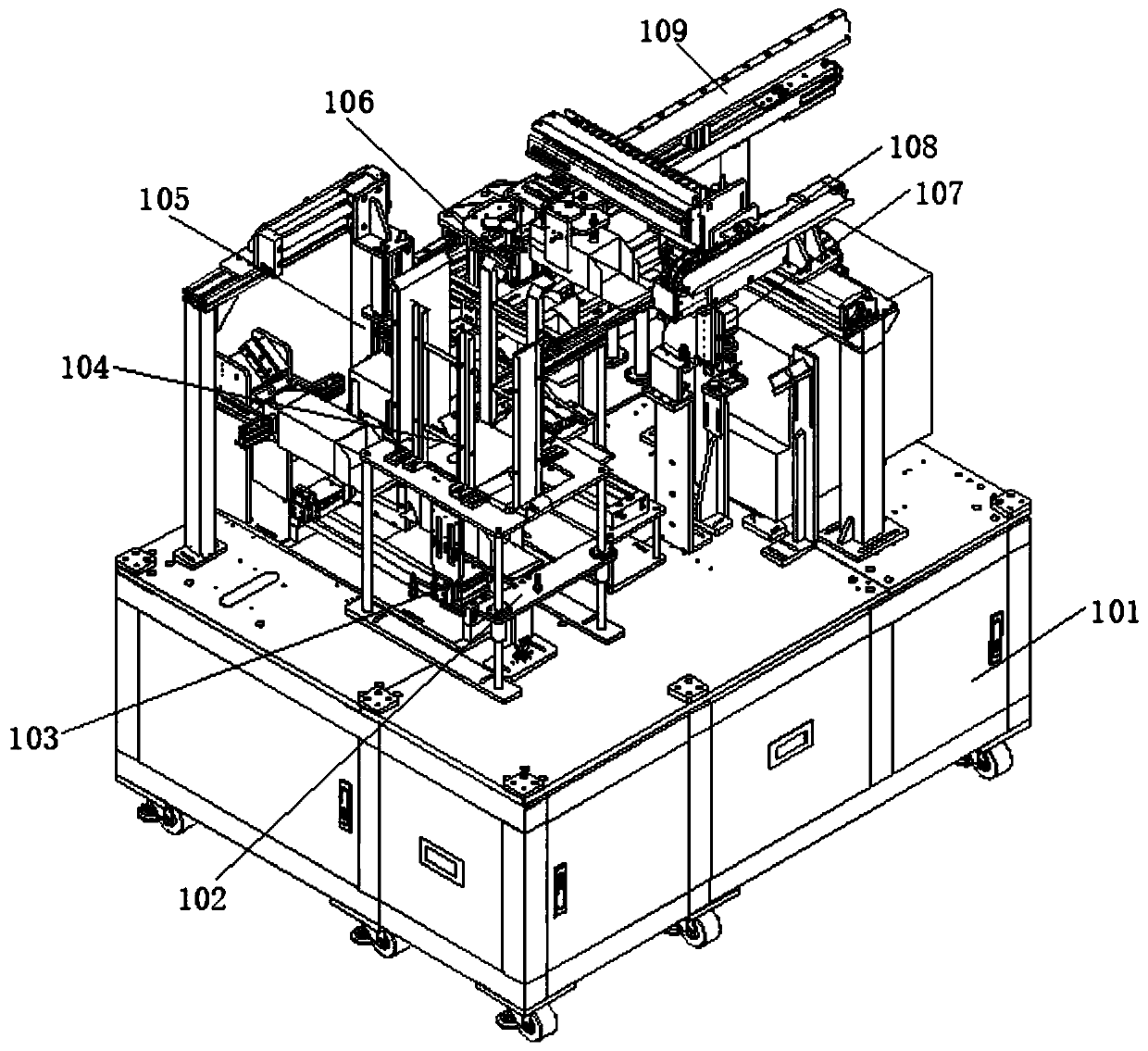

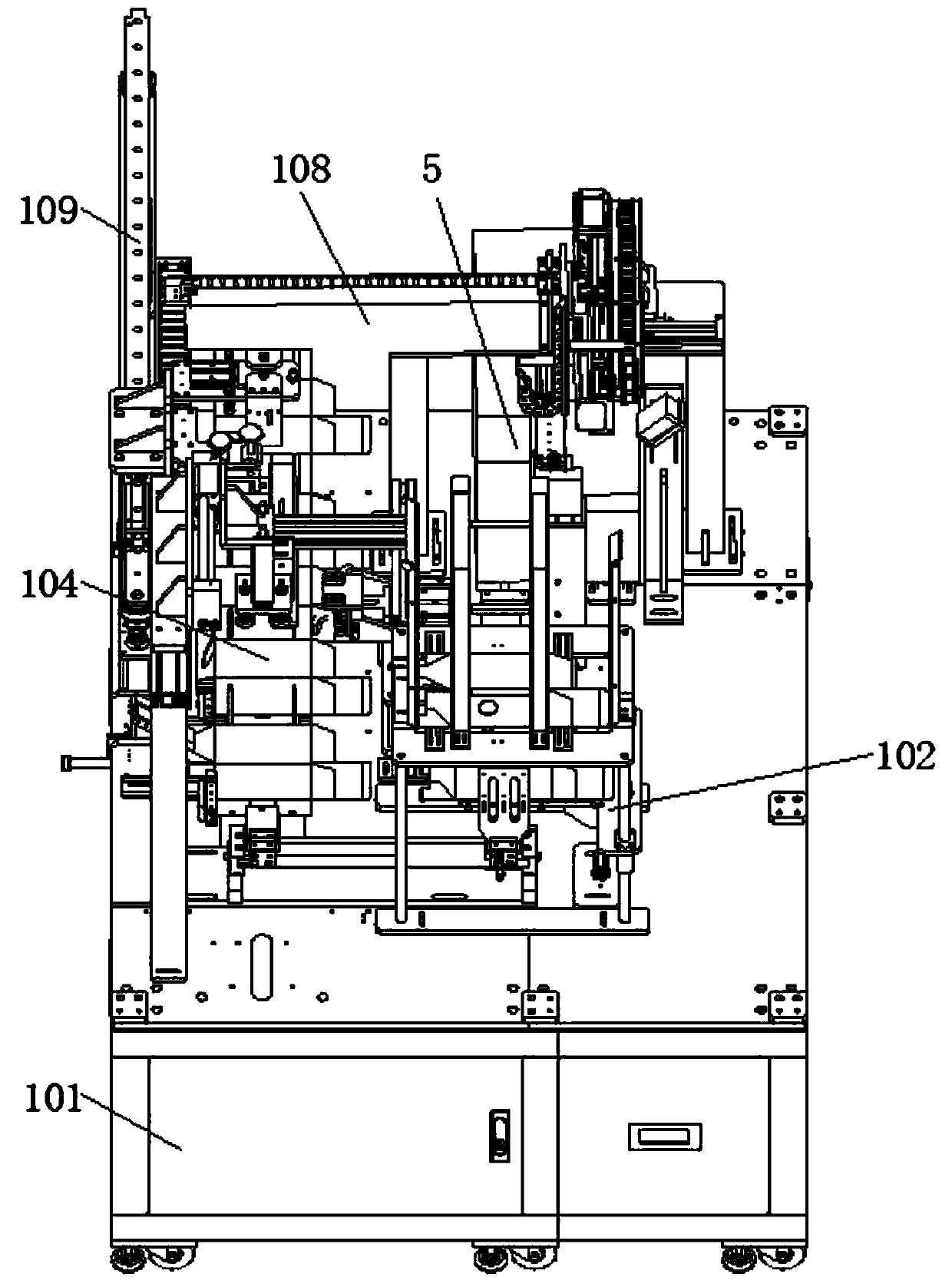

Automatic packaging production line for camera production

ActiveCN110481918AAutomate the packaging processSave packing timeLabelling flat rigid surfacesPackaging machinesProduction lineIndustrial engineering

The invention relates to the technical field of camera production, in particular to an automatic packaging production line for camera production. The automatic packaging production line comprises a first machine table device, a second machine table device, a third machine table device, a fourth machine table device and a conveying device, wherein the head end of the second machine table device isfixedly connected with the tail end of the first machine table device; the head end of the third machine table device is fixedly connected with the tail end of the second machine table device; and thehead end of the fourth machine table device is fixedly connected with the tail end of the third machine table device. According to the conveying device, a color box can be transplanted from left to right along with a line body, the forming labeling of the color box, the box entering of a product and an inner card, the box entering and packaging of accessories and the attaching of a sealing labelcan be completed in sequence, and the fully automated unmanned operation is achieved, so that the automatic packaging of a camera is achieved, the packaging time of the camera is greatly shortened, and the equipment utilization rate is improved; and the streamlined operation is achieved with a front-and-back working procedure, so that the labor intensity of operators is reduced.

Owner:广州功骏自动化科技有限公司

Rapid glass packaging and unpackaging box and packaging method

ActiveCN104944001ASave packing timeImprove packaging efficiencyContainers to prevent mechanical damageDamagable goods packagingSteel beltEngineering

The invention relates to a packaging box and a packaging method, in particular to a glass packaging box and a packaging method. The packaging method specifically comprises the steps that 1, plugs for glass packaging buckle boxes are manufactured according to the thickness of glass to be packaged; 2, the glass packaging buckle boxes are manufactured; 3, two steel belts are packaged to outer box bodies of the glass packaging buckle boxes through a steel belt die; 4, groove boxes shorter than the glass to be packaged are manufactured; 5, the glass to be packaged is packaged on a packaging workbench; 6, the suspended packaged glass is directly hoisted to a storage area to be contained into a cabinet. The glass packaging box and the packaging method have the advantages that the upper and lower groove boxes are manufactured, so that the problem that naked packaged glass cannot be directly placed into the lower groove box by a hoisting belt for years is solved, and the packaging time is greatly shortened; the left and right buckle boxes are utilized for load bearing, so that glass hoisting and prepackaging are achieved; the formed outer package is neat, attractive, elegant, solid and convenient to store, convey and use.

Owner:大连埃玛玻璃配套服务有限公司

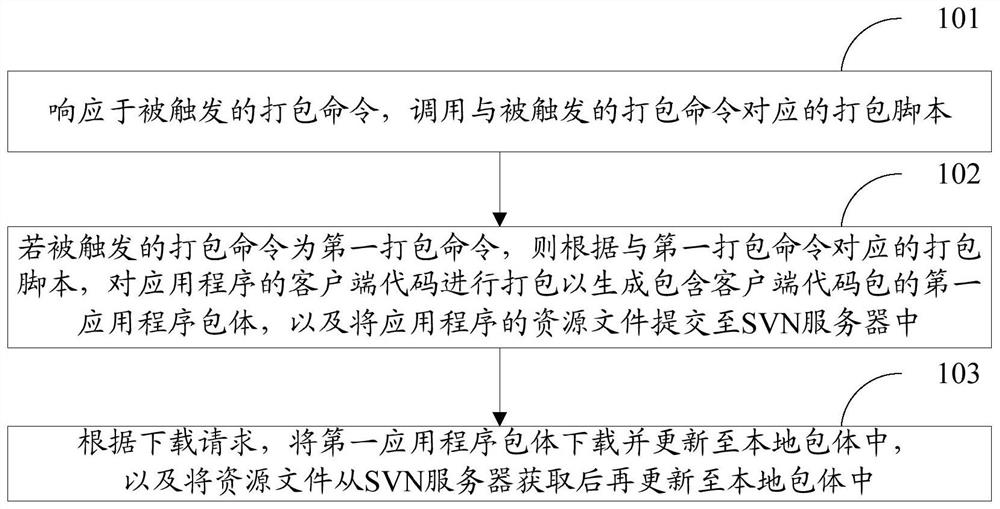

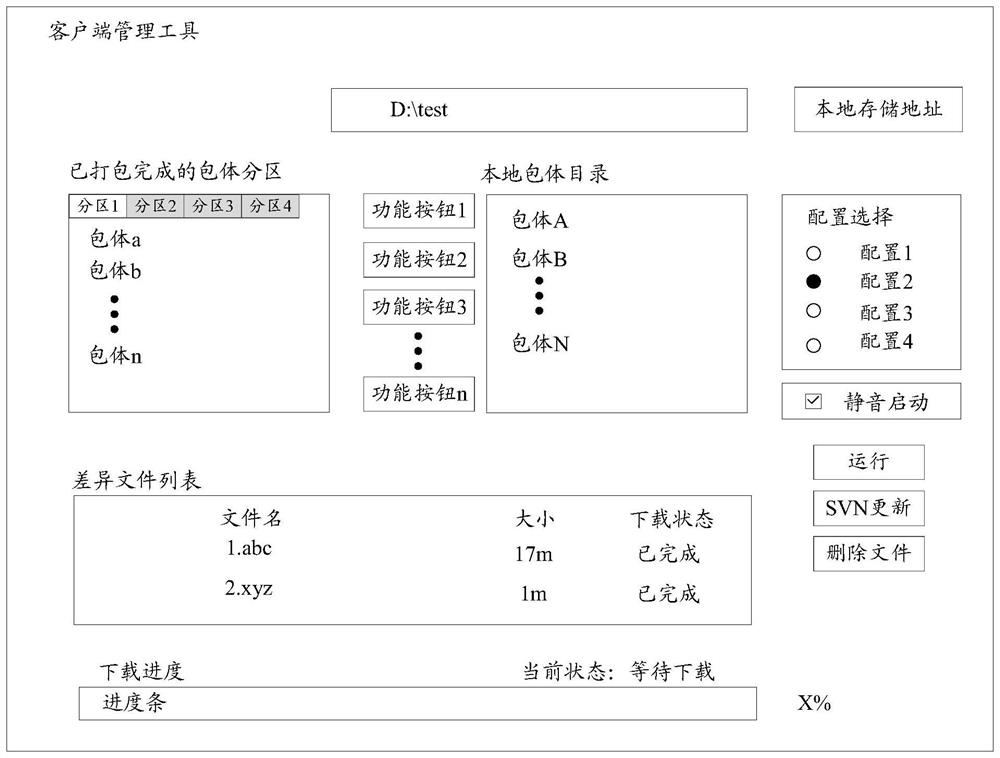

Application program management method and device, storage medium and computer equipment

PendingCN112052036AFast packSave packing timeVersion controlSoftware testing/debuggingSoftware engineeringApplication procedure

The embodiment of the invention discloses an application program management method and device, a storage medium and computer equipment. The method comprises the steps: in response to a triggered packaging command, calling a packaging script corresponding to the triggered packaging command; if the triggered packaging command is a first packaging command, according to the packaging script corresponding to the first packaging command, packaging the client codes of the application program to generate a first application program package containing the client code package and submitting the resourcefile of the application program to an SVN server; and downloading and updating the first application program package to a local package according to a downloading request, and obtaining the resourcefile from the SVN server and then updating the resource file to the local package. According to the embodiment of the invention, the updating structure of the package is reconstructed, and the clientcodes and the resource file of the application program are quickly packaged by being updated, so that the packaging time can be shortened, and the working efficiency is improved.

Owner:NETEASE (HANGZHOU) NETWORK CO LTD

Gate driver circuit basing on IGZO process

ActiveUS9472155B2Effectively minimize amountSave packing timeStatic indicating devicesElectronic switchingSemiconductorGate driver

The present invention provides a gate driver basing on IGZO process, comprising: GOAs in cascade connection comprising a Nth-stage GOA, wherein the Nth-stage GOA further comprising: a pull-up control part 100, a pull-up part 200, a transfer part 300, a pull-down part 400, a pull-down holding part 500, a boost part 600, a first negative supply VSS1, a second negative supply VSS2, a third negative supply VSS3, which are three gradually decreasing negative supplies and pull down an output terminal G(N), a first node Q(N), a second node P(N), and a driving single ST(N) to prevent the electrical leakage of TFTs effectively. And channels of the TFT switches of the gate driver basing on the IGZO process are oxide semiconductor channels.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com