Automatic stacking, bundling, bagging and packaging device for special-shaped cigarettes and packaging method

A technology of automatic strapping and bagging device, which is applied to strapping materials, parts of strapping machinery, etc., can solve the problems of high labor intensity of workers, increase labor costs, improve production efficiency, etc. Time, vertical stroke reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

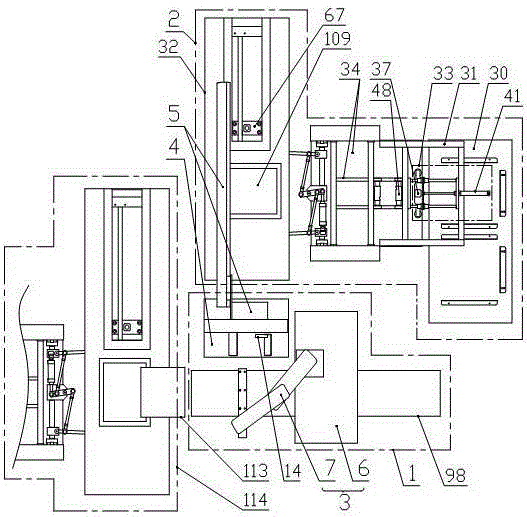

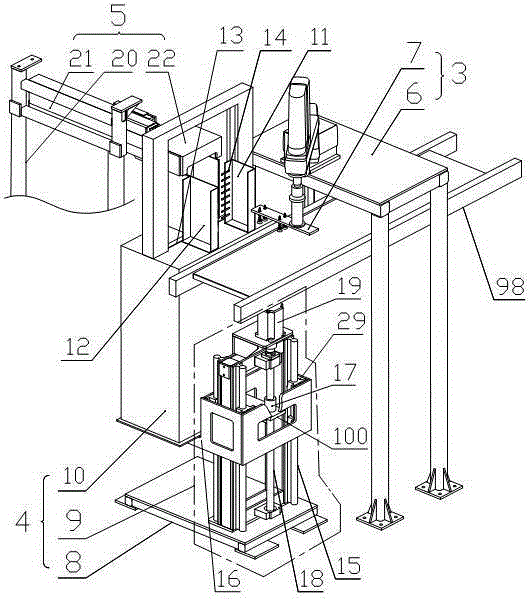

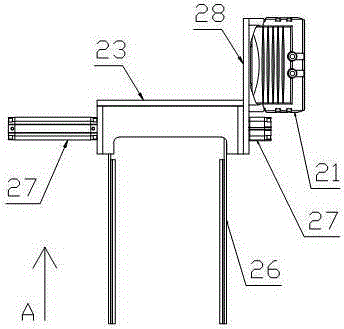

[0027] Example 1. An automatic stacking, bundling, bagging and packaging device for special-shaped cigarettes, which is composed of Figure 1-10 Shown, comprise automatic binding device 1, automatic binding device 1 is connected with upper bag packing device 2; Described automatic binding device 1 comprises cigarette taking mechanism 3, is provided with binding mechanism 4 beside cigarette taking mechanism 3, and binding mechanism 4 is connected with sending The smoke mechanism 5 is connected; the smoke taking mechanism 3 includes a manipulator support platform 6, and a joint manipulator 7 is arranged on the manipulator support platform 6; the binding mechanism 4 includes a base 8, and a lifting unit 9 is provided on the base 8, The lifting unit 9 is connected with the automatic binding machine 10; the automatic binding machine 10 is provided with a first fixed plate 11, and the opposite side of the first fixed plate 11 is provided with a second fixed plate 12, and the first f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com