Steel plate package box and package method thereof

A packaging box and steel plate technology, applied in packaging, transportation and packaging, rigid containers, etc., can solve the problems of small surface friction coefficient, slippage in the horizontal direction, deformation in the longitudinal direction, etc., achieve large load bearing, simple production, and reduce packaging time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The invention is especially suitable for cold-rolled steel plates with a single package weight of 4.0-5.0 tons.

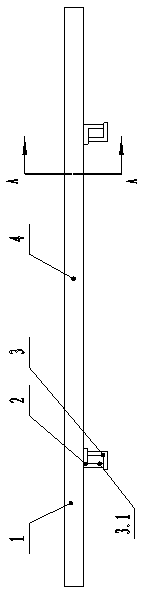

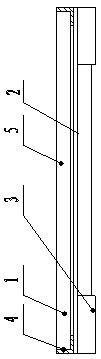

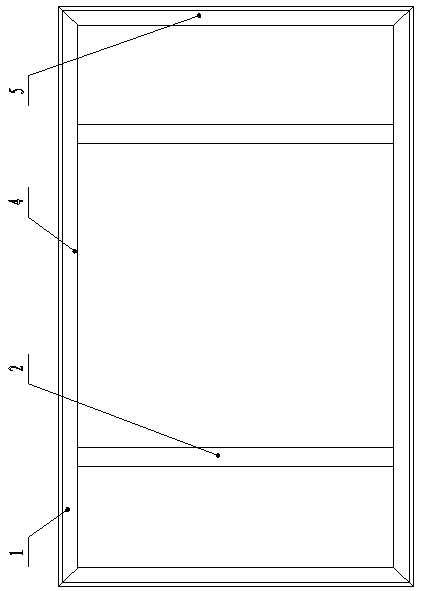

[0035] The steel plate packaging box is mainly composed of angle steel bracket 1 and galvanized iron cover 6, figure 1 , figure 2 and image 3 The described angle steel bracket 1 is rectangular, has two longitudinal angle steels 4 and two transverse angle steels 5, and has two angle steel beams 2 welded under the longitudinal angle steel 4 to support the longitudinal angle steel 4, and is characterized in that:

[0036] A section of short angle steel 3 is respectively welded below the two ends of the angle steel beam 2, and the short angle steel 3 is close to each other relative to the angle steel beam 2 in the horizontal direction, and the distance between the short angle steel 3 and the angle steel beam 2 on both sides in the horizontal direction is smaller than that in the vertical direction. The distance between the sides, the short angle steel 3 and ...

Embodiment 2

[0044] This embodiment is suitable for products with a length of 2150~3500mm, or a product with a thickness of 2.0mm or less. In order to prevent the collapse and deformation of the brackets in the length direction due to the long length or the product thickness is too thin during long-term stacking, Affect the quality of product form. The steel plate of the present embodiment is 2400mm long and 1300mm wide, and the length and width of the plastic plate 7 are the same as the steel plate.

[0045] The length of the long angle steel bracket 1.1 of the present embodiment is 2430mm, and the width is 1320mm, and the angle steel rectangular tube 14 of long 100mm is welded below the long angle steel bracket 1.1, and the angle steel rectangular tube 14 is two specifications 50 * 4 long 100mm Angle steel welded. The leftover material of angle steel can be used.

[0046] Galvanized iron cover 6.1 has a thickness of 1mm, a height of 200mm, a length of 2440mm, and a box cover of 1330mm ...

Embodiment 3

[0048] The steel plate 10 described in this embodiment is a cold-rolled steel plate, and the others are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com