Soft-packed lithium ion battery manufacturing process

A lithium-ion battery and manufacturing process technology, which is applied in the manufacture of electrolyte batteries, secondary batteries, battery pack components, etc., can solve problems affecting battery performance and service life, insufficient electrolyte absorption, and low battery production efficiency. Achieve the effect of shortening the time of standing at room temperature, shortening the standing time, and shortening the production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

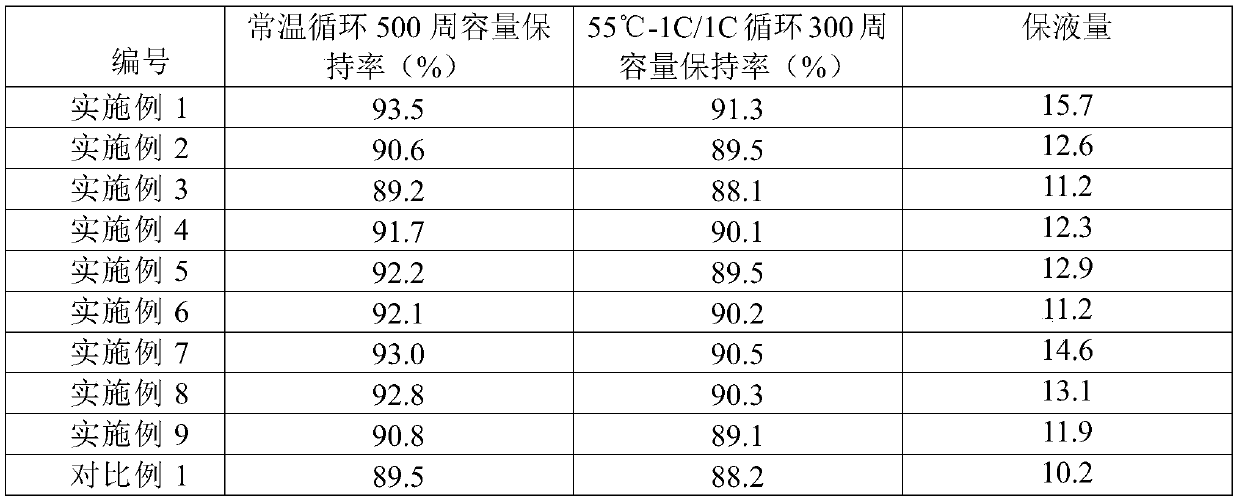

Examples

Embodiment 1

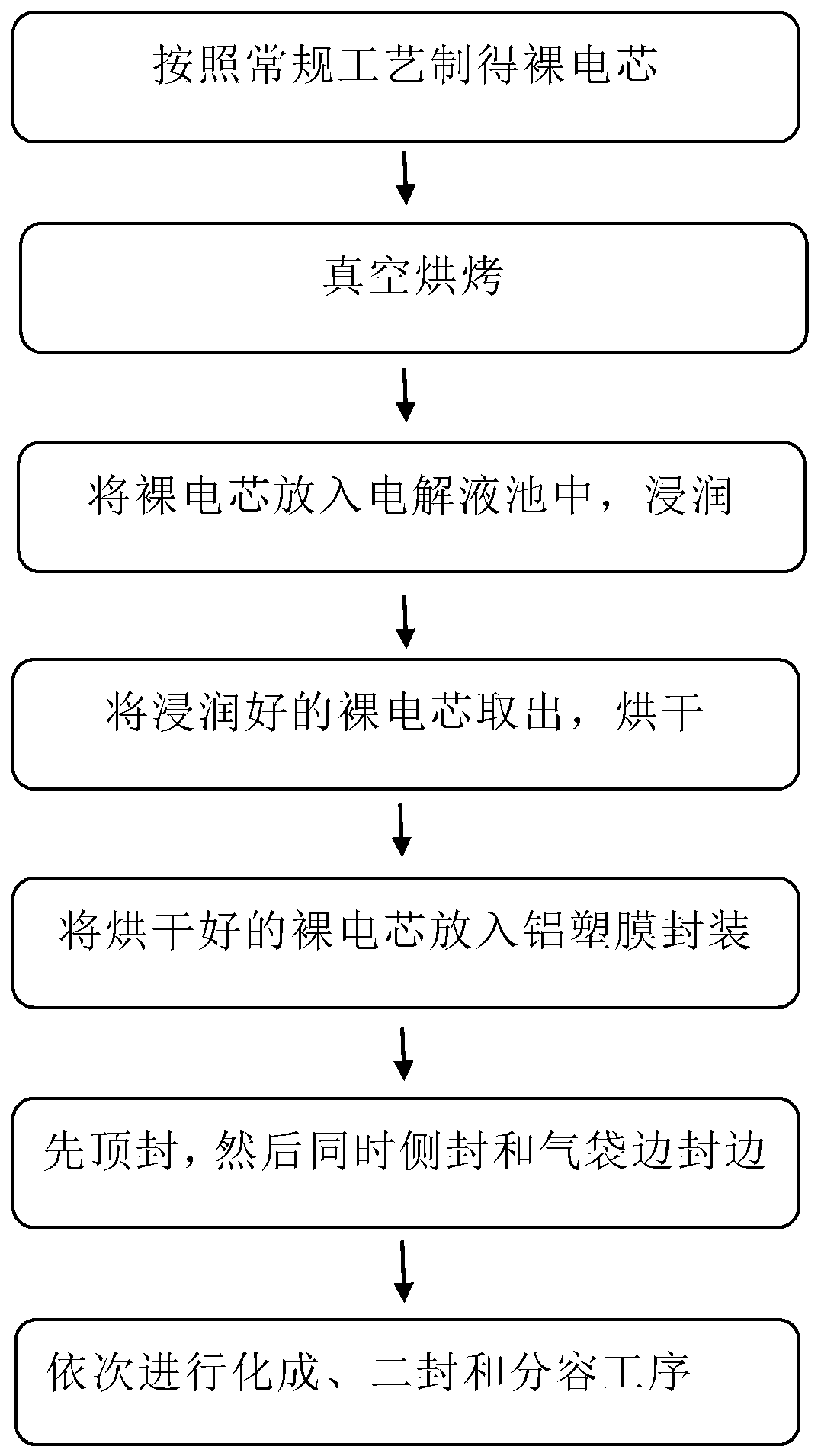

[0025] Such as figure 1 Shown, a kind of soft package lithium-ion battery manufacturing process comprises the following steps:

[0026] ①According to the conventional lithium-ion battery manufacturing process, the positive electrode sheet with lithium cobalt oxide as the positive electrode material and the negative electrode sheet with graphite as the negative electrode material are prepared, and the positive electrode, negative electrode and separator are wound into a bare cell;

[0027] ② After the bare cell is wound, it is first vacuum baked. The vacuum degree of the vacuum bake is -80kPa, and then in a dry and oxygen-free environment with a dew point temperature of ≤ -35°C, the bare cell is slowly placed by a manipulator. Into the electrolyte pool until the electrolyte liquid level reaches the position of the tab glue of the bare cell, the soaking time is 20min, wherein, the speed of the bare cell immersion is 3cm / s, and the temperature of the electrolyte is maintained at ...

Embodiment 2

[0032] The difference from Example 1 is the speed at which the bare cell is immersed in the electrolyte pool. Among them, the speed at which the bare cell is immersed is 8cm / s.

[0033] The rest are the same as in Embodiment 1, and will not be repeated here.

Embodiment 3

[0035] The difference from Example 1 is the speed at which the bare cell is immersed in the electrolyte pool. Among them, the speed at which the bare cell is immersed is 16cm / s.

[0036] The rest are the same as in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com