Method for preparing reflecting film, solar cell panel and its crystalline silicon wafer

A technology of crystalline silicon wafers and reflective films, applied in the field of solar cells, can solve problems such as reducing the solar light efficiency of crystalline silicon wafers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

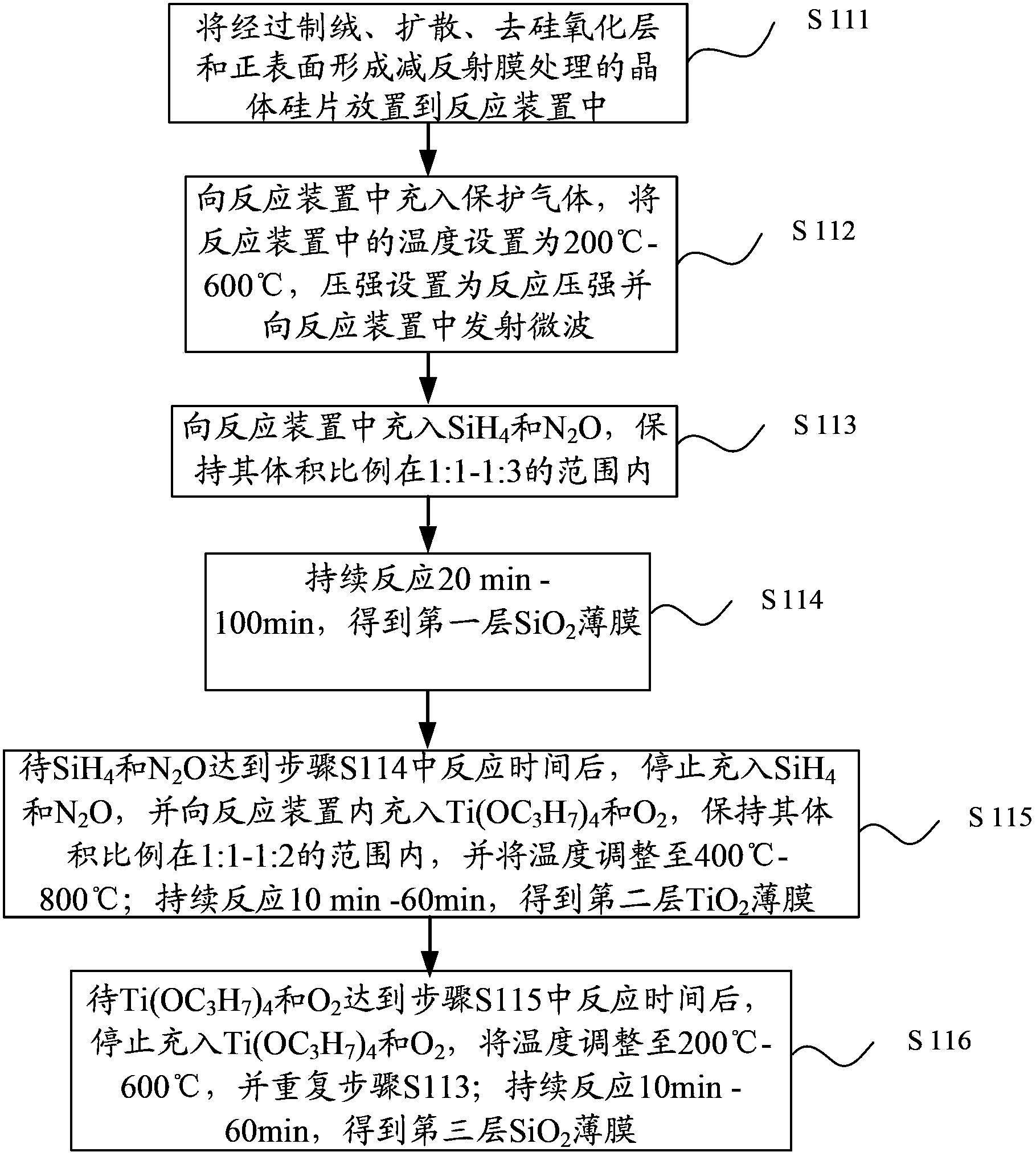

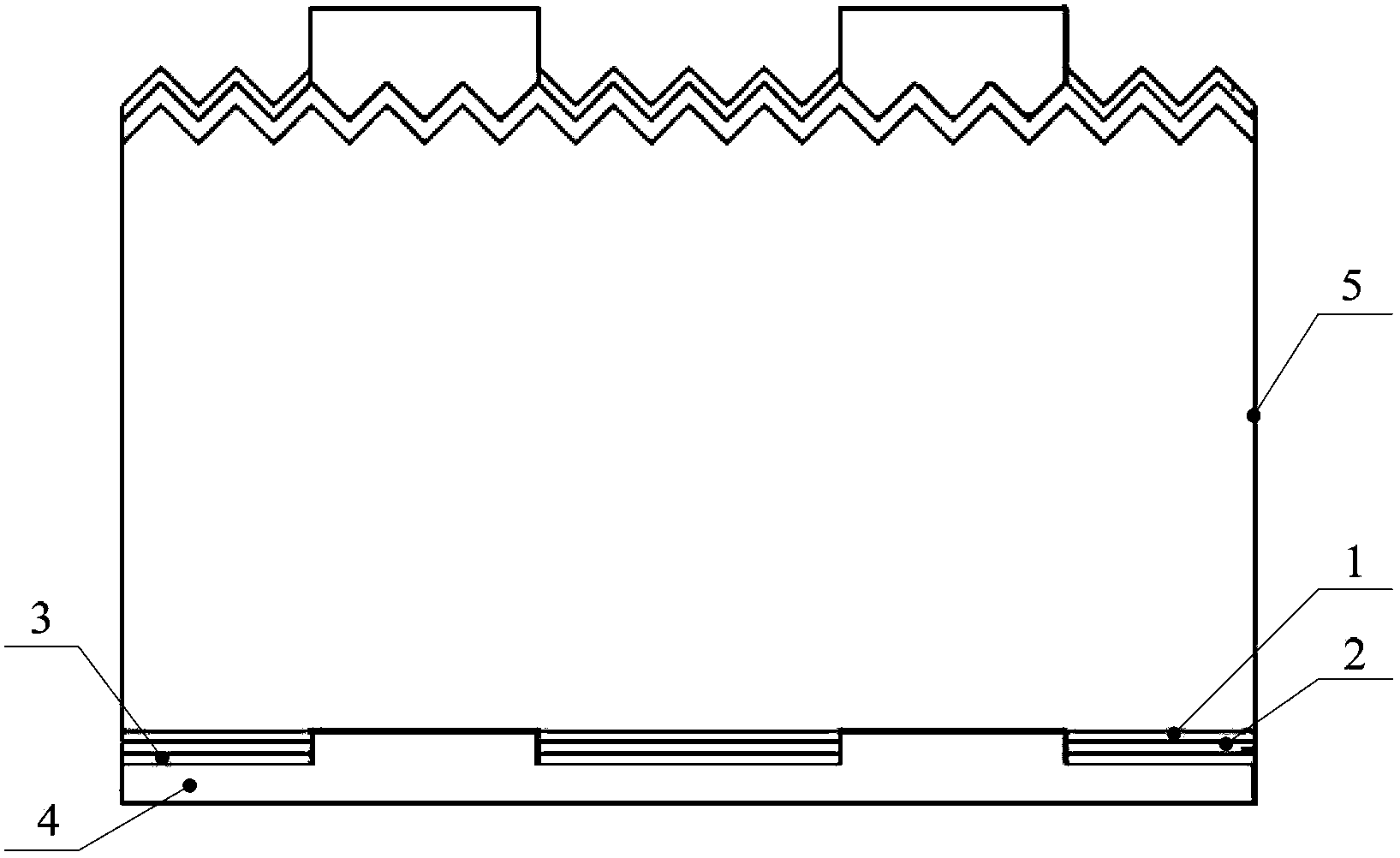

[0035] The method for preparing a reflective film provided in the embodiment of the present invention is used to prepare a reflective film on the back surface of a crystalline silicon wafer 5, comprising the following steps:

[0036] S111 placing the crystalline silicon wafer 5 treated with texturing, diffusion, silicon oxide layer removal and anti-reflection film formation on the front surface into the reaction device;

[0037] S112 filling the reaction device with protective gas, setting the temperature in the reaction device to 200°C-600°C, setting the pressure to the reaction pressure and emitting microwaves into the reaction device;

[0038] S113 Fill SiH into the reaction device 4 and N 2 O, keep its volume ratio in the scope of 1:1-1:3;

[0039] S114 continues to react for 20min-100min to obtain the first layer of SiO 2 film1;

[0040] S115 to be SiH 4 and N 2 After O reaches the reaction time in step S114, stop charging SiH 4 and N 2 O, and fill the reactor wit...

Embodiment 1

[0052] Place the crystalline silicon wafer 5 through texturing, diffusion, silicon oxide layer removal and anti-reflection film formation on the front surface in the quartz furnace tube, and fill it with N 2 As a protective gas, the temperature in the quartz furnace tube is raised to 200°C, the pressure is raised to 0.02mbar, microwaves with a power of 2500W are emitted into the quartz furnace tube, and the SiH 4 and N 2 O is continuously filled into the quartz furnace tube at a volume ratio of 1:1, so that SiH 4 and N 2 O takes place chemical reaction, and reaction time continues 20min, to deposit the first layer SiO on the back surface of crystalline silicon wafer 5 2 Film 1; after the above process is completed, the temperature in the quartz furnace tube is raised to 400°C, the pressure and microwave power are still 0.02mbar and 2500W respectively, and the quartz furnace tube is filled with Ti(OC 3 h 7 ) 4 and O 2 , the reaction time is maintained for 20min, and then ...

Embodiment 2

[0055] Place the crystalline silicon chip 5 with thick anti-reflection film formed on the front surface through texturing, diffusion, silicon oxide layer removal and anti-reflection film thickness into the quartz furnace tube, and fill it with N 2 As a protective gas, the temperature in the quartz furnace tube is raised to 300°C, the pressure is raised to 0.065mbar, microwaves with a power of 2750W are emitted into the quartz furnace tube, and the SiH 4 and N 2 O is continuously filled into the quartz furnace tube at a volume ratio of 1:1.5, so that SiH 4 and N 2 A chemical reaction occurs in O, and the reaction time lasts for 40 minutes to deposit the first layer of SiO on the back surface of the crystalline silicon wafer 5 2 Film 1; after the above process is completed, the temperature in the quartz furnace tube is raised to 500°C, the pressure and microwave power are still 0.065mbar and 2750W respectively, and Ti(OC 3 h 7 ) 4 and O 2 , the reaction time is maintained ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com