Patents

Literature

87results about How to "Simplify the process flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

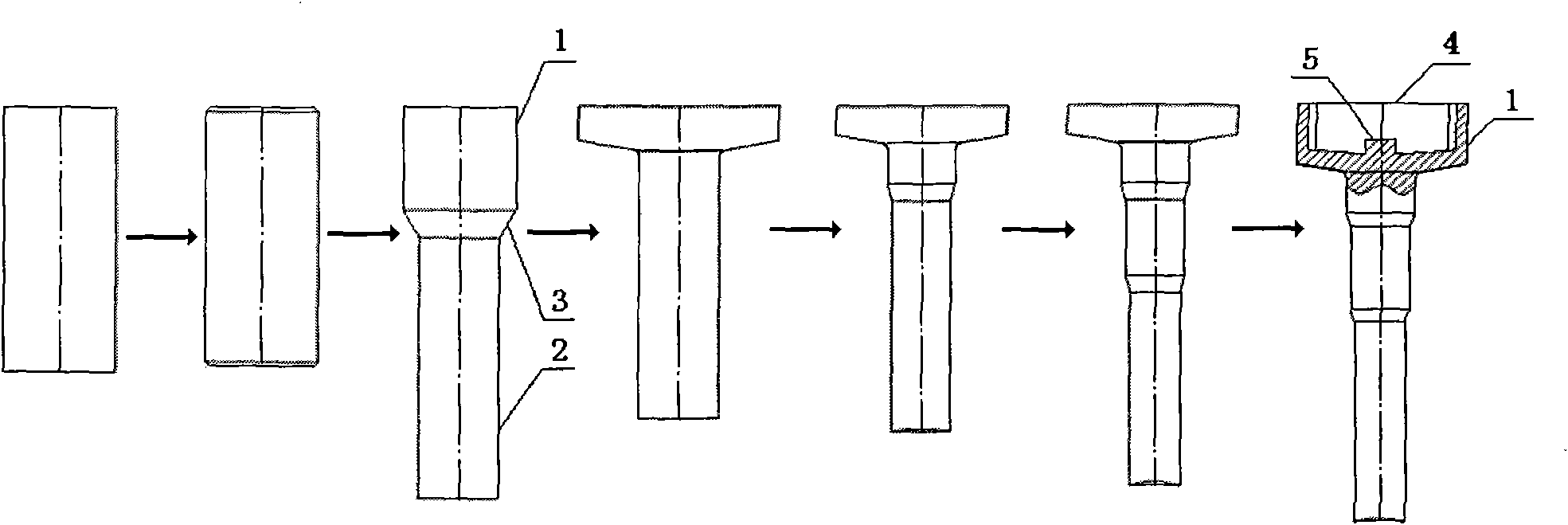

Cold forging precise forming process for mechanical transmission gear shaft

InactiveCN102463320AMeet the precision requirementsHigh strengthEngine componentsHigh volume manufacturingGear wheel

The invention discloses a cold forging precise forming process for a mechanical transmission gear shaft. The process comprises the following steps of: blanking, annealing, performing shot blasting, phosphatizing, saponifying, performing reducing extrusion, performing upsetting extrusion, performing small-end reducing extrusion, and reversely extruding an inner bore. By the process, blanks are processed by a cold forging precise forming mold and are machined to form finished products, so that the process has a simple production process flow, toothed holes in the wall of the inner bore at a large end have high intensity and high consistency, an outer wall is convenient to hob after a small end is subjected to reducing extrusion, and the process is suitable for mass production.

Owner:江苏威鹰机械有限公司

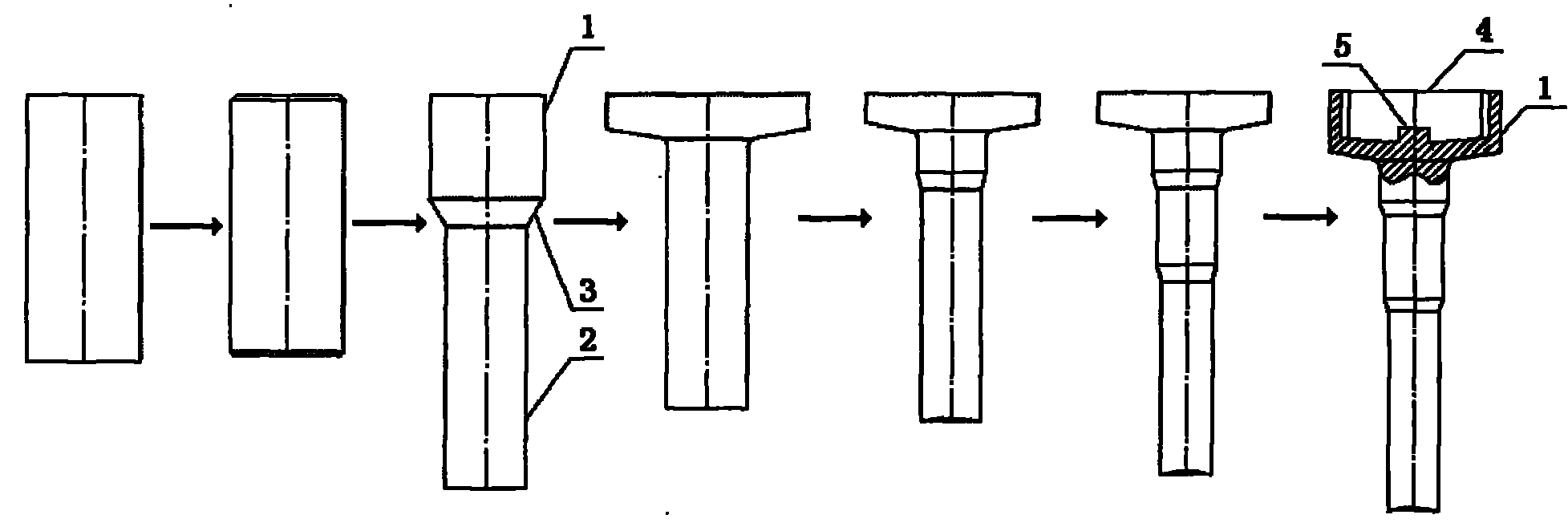

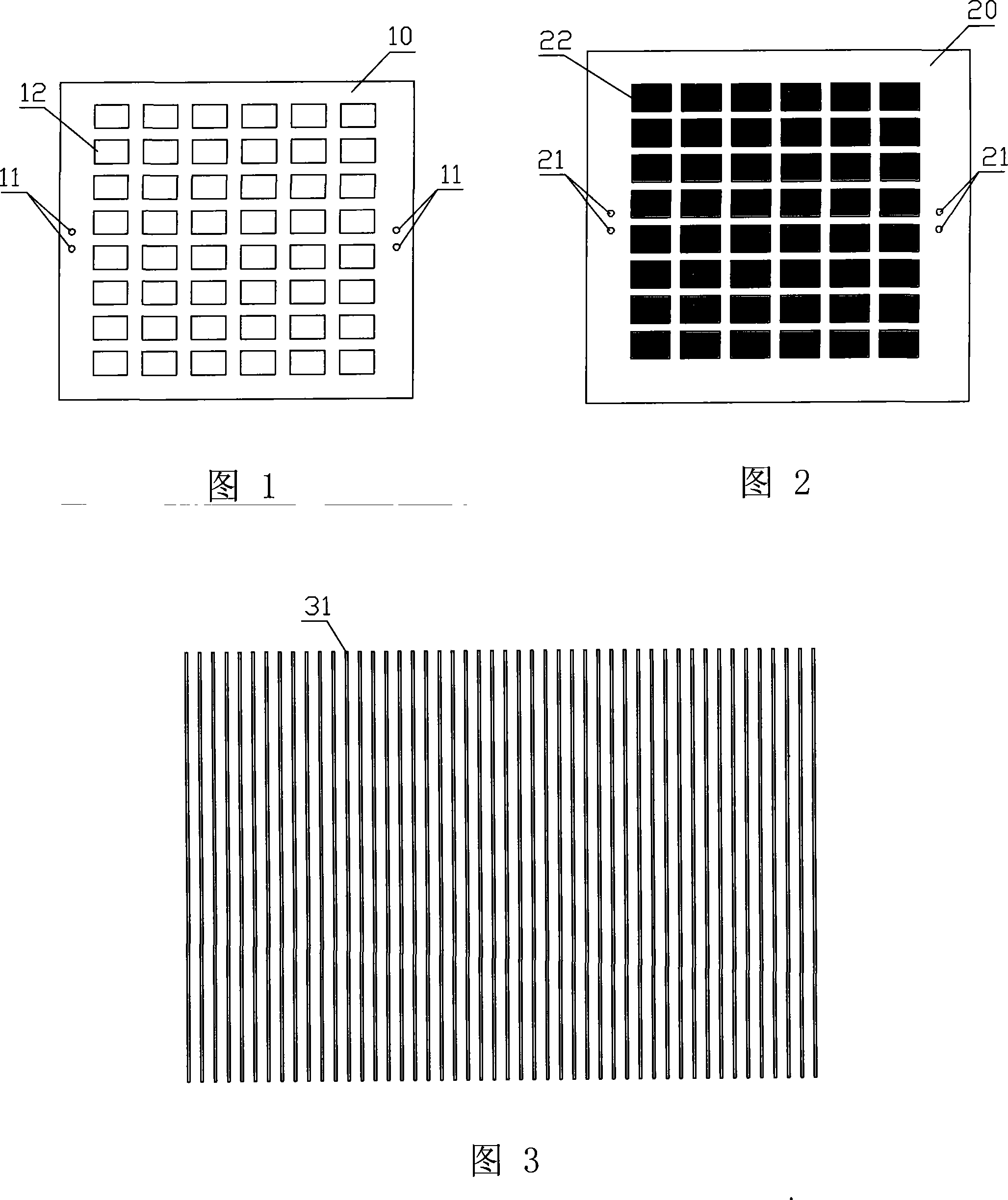

Method for preparing organic electroluminescent display mask plate

InactiveCN101250685AGuaranteed tensionReduce tensionVacuum evaporation coatingSputtering coatingWire gauzeSheet steel

The invention discloses a method for producing mask plates of organic electroluminescent displays, which comprises following steps: taking a sheet of magnetic conductive thin sheet steel, utilizing stainless steel etching or laser cutting to open holes on the thin sheet steel to form patterns, flatly spreading a silk screen on the thin sheet steel with the patterns, coating mucilage which is used to stretch the silk screen on the edge of the thin sheet steel, then, removing the silk screen on the region of thin sheet steel patterns, then, stretching the silk screen, taking a frame body, clinging the frame body on the stretched silk screen to form a net frame, tailoring along the outer margin of the net frame after bonding stably, cutting another magnetic conductive sheet steel into an outer frame of the mask plate which is needed, then, connecting the outer frame of the mask plate and the magnetic conductive thin sheet steel in the net frame, then, cutting off the silk screen, shedding the net frame, lastly, cutting off excess sheet steel along the outer margin of the outer frame of the mask plate, and finishing producing the mask plate. The method of the invention utilizes the silk screen to stretch the thin sheet steel, which lowers the production cost and simplifies the technological process, the net frame is more stably connected with the outer frame, the operation is comparatively simpler, and the precision is greatly increased.

Owner:TRULY SEMICON

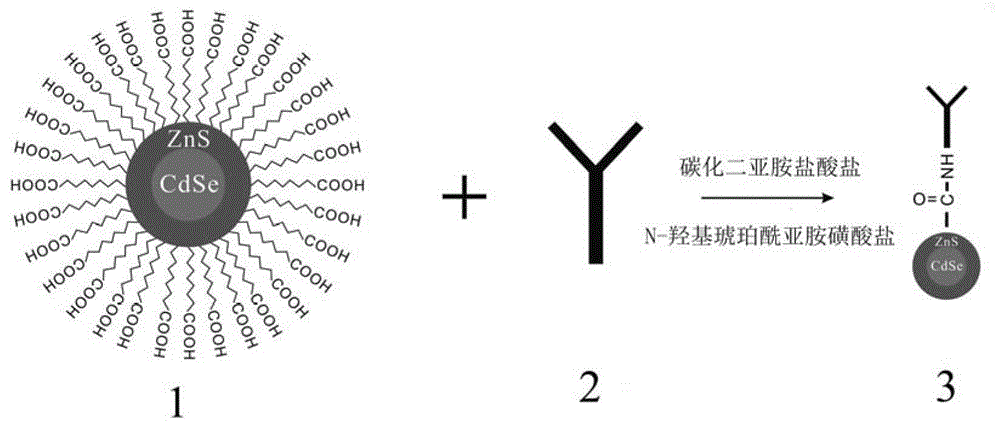

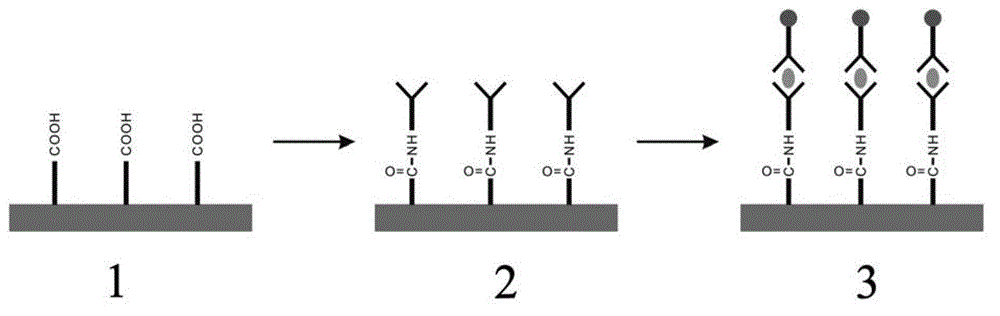

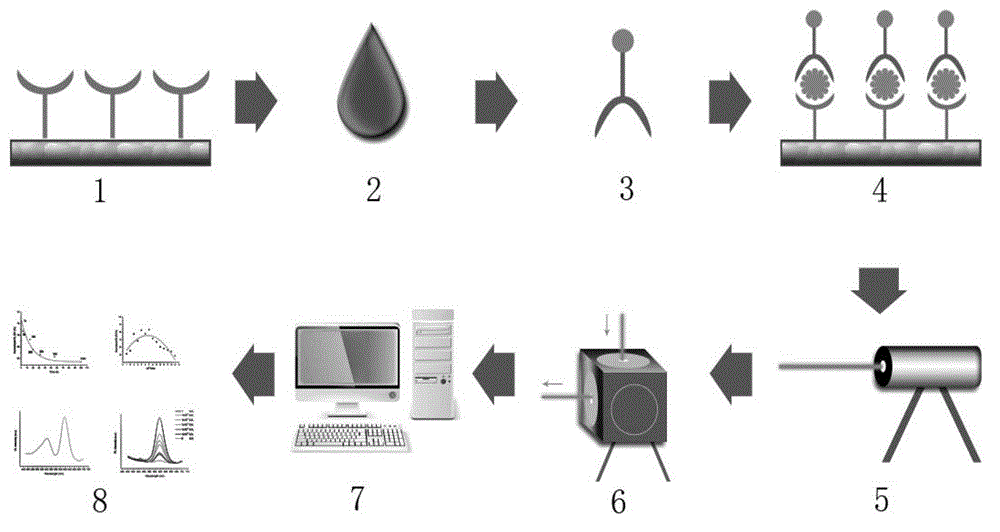

Multi-functional quick fluorescence immunoassay test method using functional substrate as media and using single color and multi-color quantum dots as mark

InactiveCN103149360AShort color development (fluorescence) timeStable storageFluorescence/phosphorescenceAntigenImmuno detection

The invention relates to a novel, quick, high-sensitivity, qualitative and quantitative clinical test method which uses a chemically modified functional polymorphic substrate as media and combines inorganic fluorescent semiconductor nano materials (quantum dots) and immunology means. The multi-functional quick fluorescence immunoassay test method using a functional substrate as media and using single color and multi-color quantum dots as a mark is suitable for a single or compound qualitative and quantitative test of various hormone, protein, nucleic acid and pathogens. Compared with traditional enzyme-linked immunoassay and colloidal gold test paper, the multi-functional quick fluorescence immunoassay test method has the advantages of being simple, quick, high in sensitivity, long in storage time and the like. The multi-functional quick fluorescence immunoassay test method can meet requirements of different testing conditions and samples, can conduct the single or compound qualitative and quantitative test on different antigens on the same substrate media at the same time, and has great potential on aspects of clinical applications.

Owner:HENAN UNIVERSITY

Preparation method of albuminous degeneration preserved egg, albuminous degeneration preserved egg prepared with method, and preserved egg sausage prepared by preserved egg

The invention discloses a preparation method of an albuminous degeneration preserved egg, the albuminous degeneration preserved egg prepared with the method, and a preserved egg sausage prepared by the preserved egg, and aims to solve problems that the production period of traditional preserved eggs is long, and the traditional preserved eggs contain heavy metal salt which can influence the health of a human body, and is adverse to later processing of the preserved egg sausage. The method comprises steps as follows: a cleaned egg is placed in a pickling container, a pickling solution is added into the pickling container, the pickling container is sealed, the egg is pickled for 5-10 days, and a product is obtained. The production period of the albuminous degeneration preserved egg is short, so that the fast industrial production requirement can be met, and the production cost of the albuminous degeneration preserved egg is obviously reduced; meanwhile, according to the albuminous degeneratio preserved egg, heavy metal salt is not required, so that the damage of the heavy metal salt to a human body is effectively reduced; and the albuminous degeneration preserved egg is used for preparing the preserved egg sausage, the albuminous degeneration preserved egg is not required to be smashed, thus, the process flow of the preserved egg sausage is effectively simplified, the production period is shortened, and the potential safety hazard of the preserved egg sausage is reduced.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

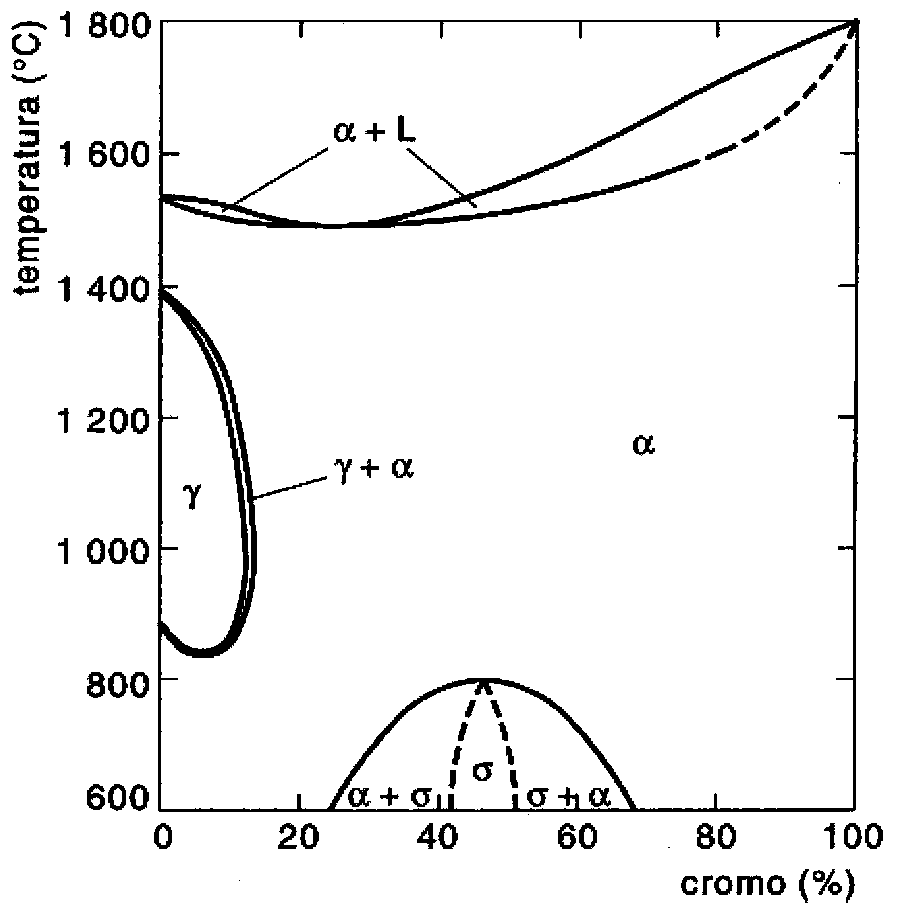

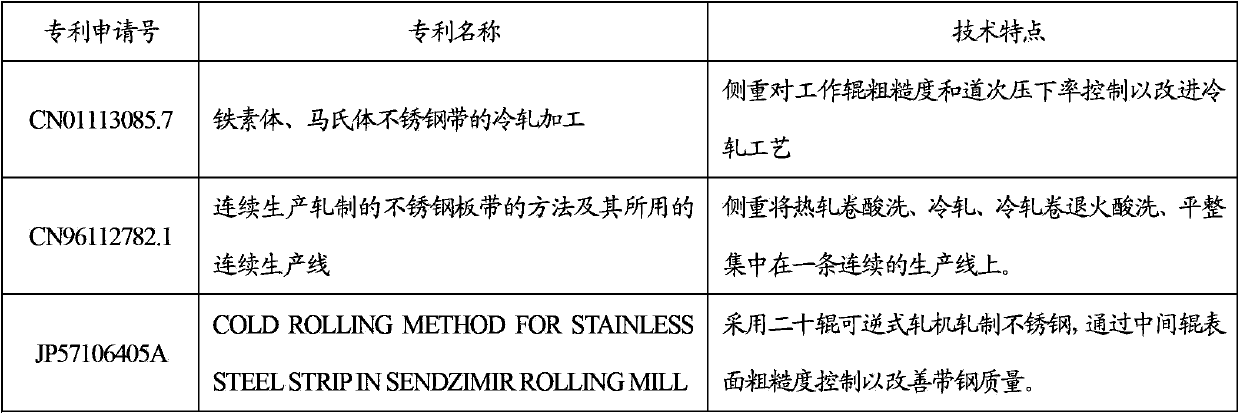

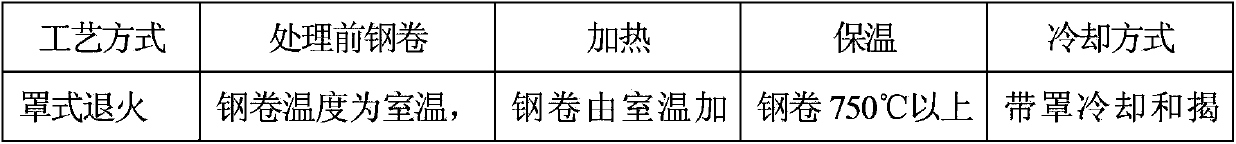

Manufacturing method for medium chrome ferrite stainless steel

InactiveCN103966409ASimplify the process flowImprove cost competitivenessRoom temperatureStrip steel

The invention provides a manufacturing method for medium chrome ferrite stainless steel. The method consists of the processes of: smelting, continuous casting, hot rolling, coiling, acid pickling, cold rolling, cold coiling annealing and pickling. In the hot rolling process, subjecting a hot rolled black coil to hot rolling at a finishing rolling temperature of 860-1000DEG C, and conducting coiling at 750-850DEG C; after coiling, subjecting the hot coil to heat preservation in a heat preservation pit directly, controlling the temperature of the hot coil sent into the heat preservation pit greater than 750DEG C, slowly cooling a steel coil at a cooling speed of less than 20DEG C / h, taking the steel coil out of the pit when the temperature of the steel coil is lower than 200DEG C, and performing air cooling to room temperature; subjecting the hot rolled black coil to acid pickling directly on a continuous acid pickling line, and removing the surface oxide scale; after acid pickling, conducting cold rolling on the steel coil; carrying out recrystallization and continuous annealing on cold-rolled strip steel; and performing acid pickling to remove the surface oxide scale, and at the same time conducting passivation treatment on the strip steel. The method provided by the invention omits the process of hot coil bell-type furnace annealing, simplifies the process flow, and strengthens the cost competitiveness. Compared with single-stand reversible rolling, cold continuous rolling has the advantages of high production efficiency and low cost.

Owner:BAOSTEEL STAINLESS STEEL

Bicolor product injection mould

The invention discloses a bicolor product injection mould which comprises a male template and a female template and is characterized by further comprising a male die, two female dies and a rotary device, wherein the male die is arranged on the male template; the two female dies are arranged on the same side of the female template; a glue inlet runner is arranged on the two female dies respectively; one female die is provided with a positioning mechanism for placing a film into a cavity of the female die; and the rotary device can drive the male template to rotate for at least 180 degrees. Through the invention, the problems that the bicolor injection product has relatively single appearance effect, the pattern is located on the appearance surface of the bicolor injection product and easily drops and fades along with the increase of the service time and the product has short service life and relatively bad using effect in the prior art are solved; and the invention provides a bicolor product injection mould, wherein the structure is simple, the pattern is located in the bicolor injection product and does not drop or fade, and the using effect is better.

Owner:JINLI TRADE MARK KUSN

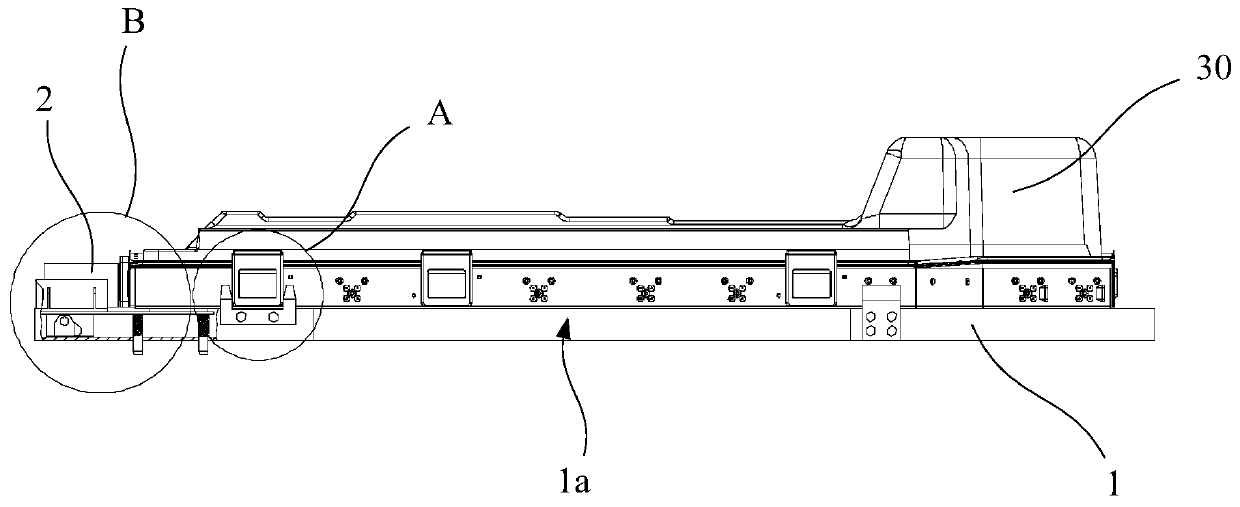

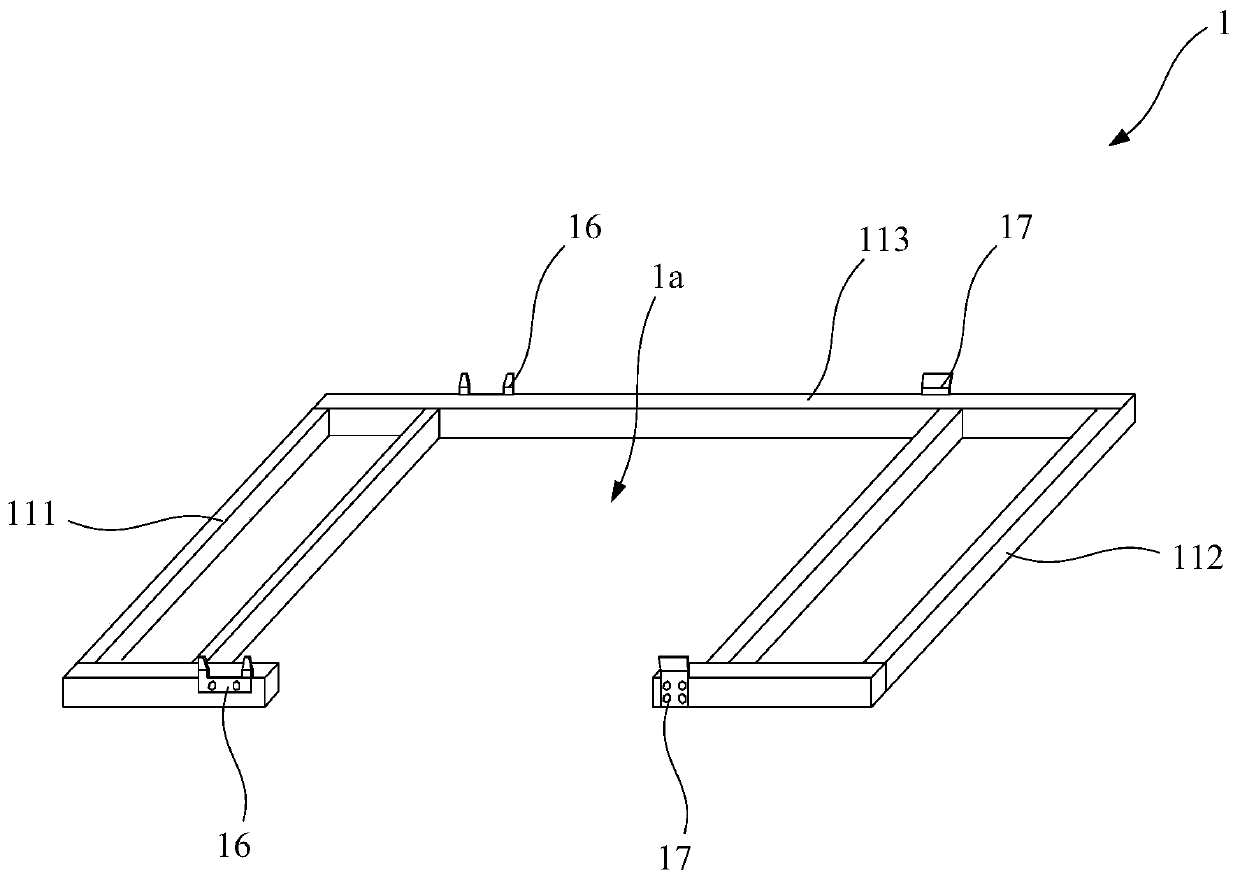

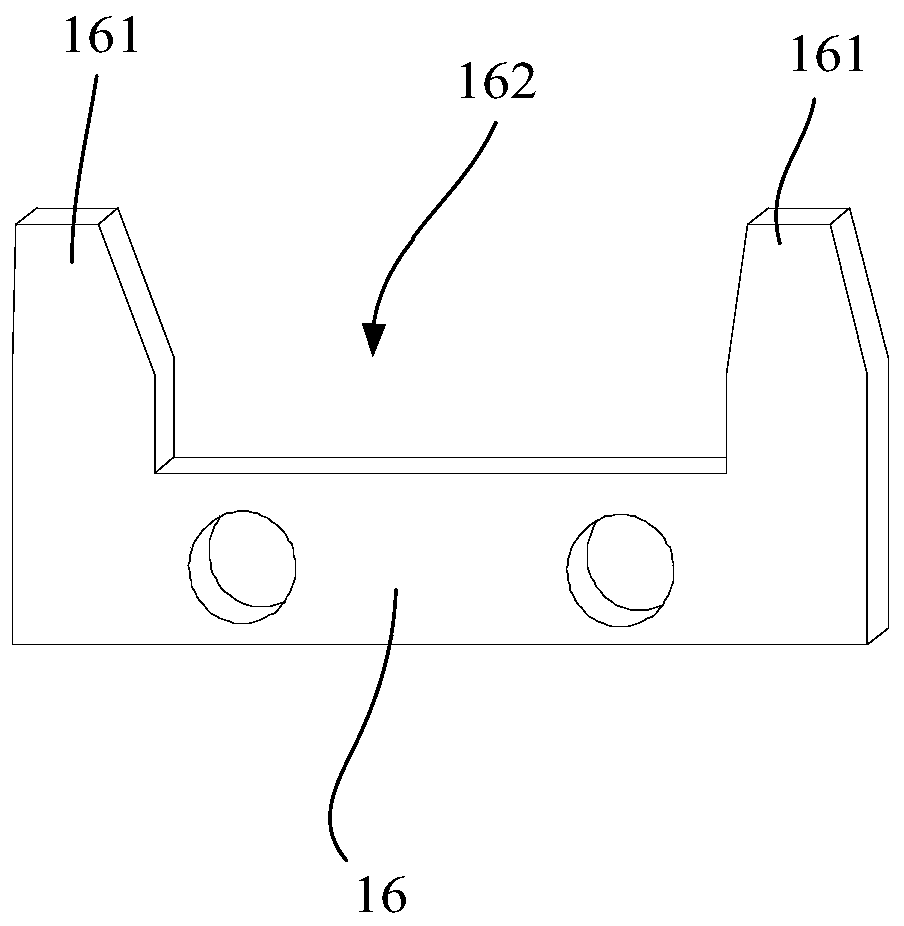

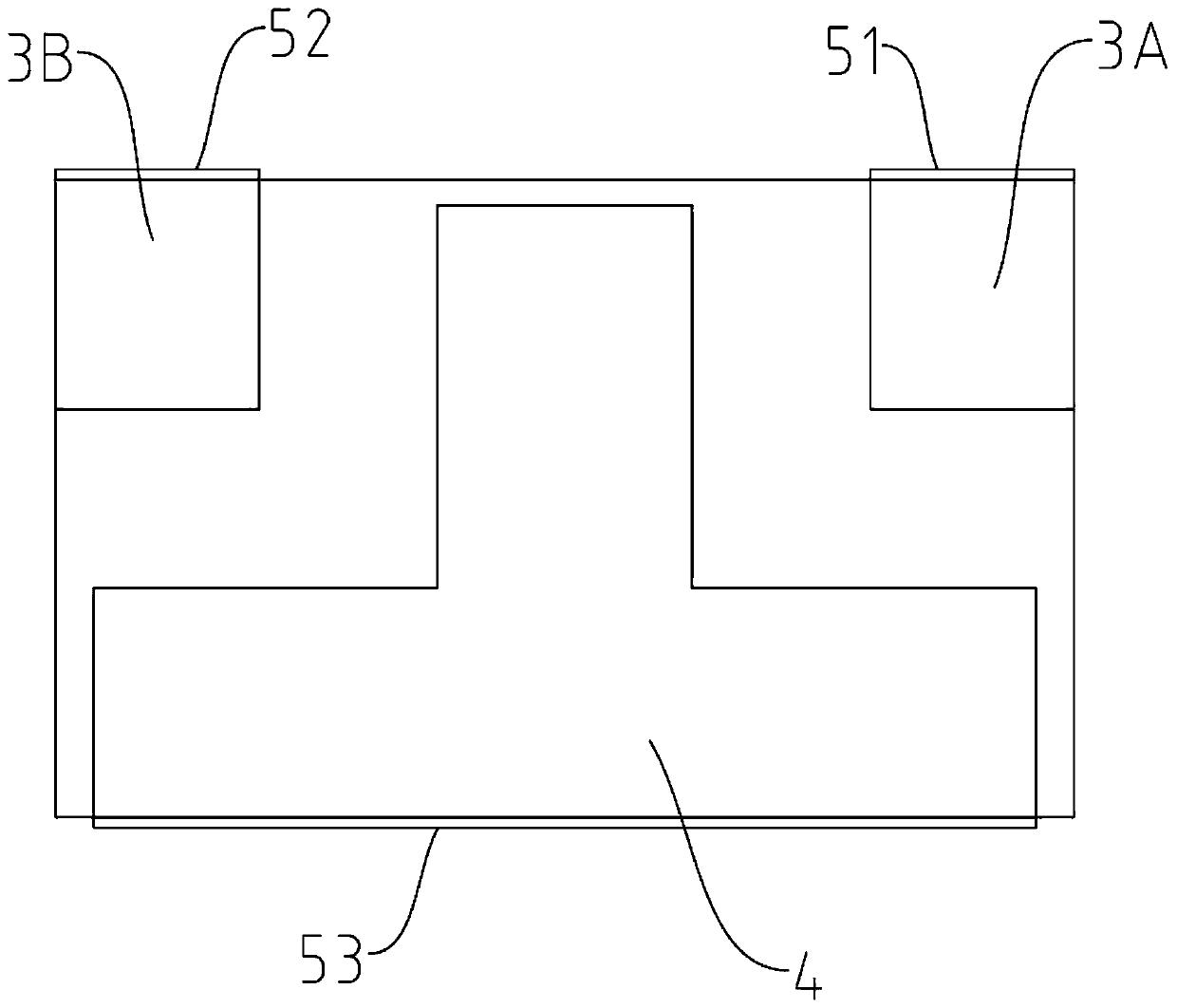

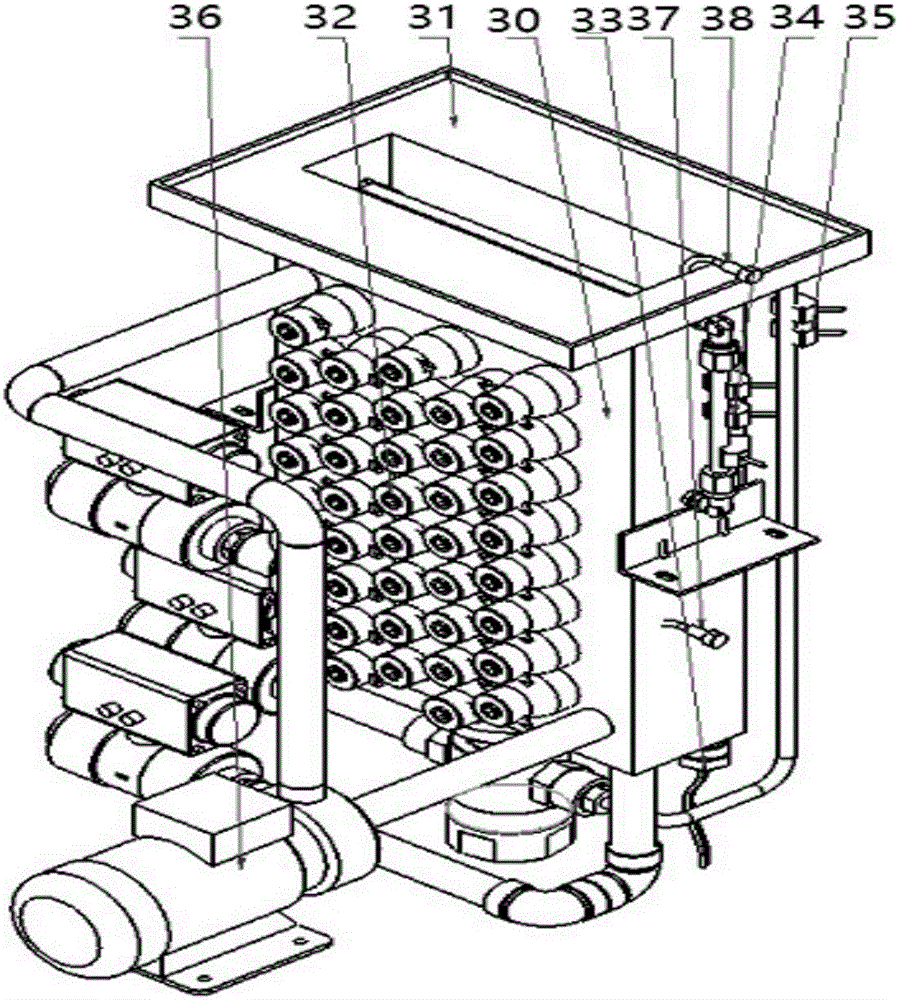

Charging bin, charging rack comprising charging bin, battery swap station and energy storage station

PendingCN111251918AGuaranteed structural strengthWill not affect the ability of the battery packBatteries circuit arrangementsCharging stationsElectrical batteryControl theory

The invention discloses a charging bin, a charging rack comprising the charging bin, a battery swap station and an energy storage station. The charging bin is used for placing a battery pack by a battery pack transfer device. The charging bin comprises: a bearing mechanism, which bears a battery pack through a frame structure, and is provided with a frameless space allowing an extending mechanismof the battery pack transfer device to enter when the battery pack transfer device places the battery pack to the bearing mechanism; and an electric connection mechanism, which is arranged on the bearing mechanism, and is used for being electrically connected to the battery pack after the battery pack is placed on the bearing mechanism. According to the charging bin, the frameless space allowing the extending mechanism of the battery pack transfer device to enter is formed on the bearing mechanism, the battery pack transfer device can be prevented from interfering with the bearing mechanism when the battery pack is placed or taken out relative to the bearing mechanism, and meanwhile the structure of the charging bin and the battery pack taking and placing process flow of the battery pack transfer device can be simplified.

Owner:AULTON NEW ENERGY AUTOMOTIVE TECHNOLOGY GROUP

Preparation method of high-toughness magnesium alloy bar

ActiveCN103388115AImprove mechanical propertiesResolve inhomogeneity of deformationSolution treatmentSolid solution

The invention relates to a preparation method of a high-toughness magnesium alloy bar. The method comprises the following steps: 1, carrying out a solid solution treatment on a magnesium alloy casting blank with diameter of 300-400 mm, so as to completely dissolve a second phase Mg17Al12 formed in a non-equilibrium solidification process into a Mg matrix; 2, employing a routine horizontal extruder according to specifications of bars to be prepared with different diameters, wherein the horizontal extruder is assorted with a corresponding extruding sleeve, has a tonnage of 3600 t, and smearing a lubricant on a casting blank and a surface of the extruding sleeve, and carrying out isothermal extrusion molding. According to the invention, researches on influences of technological parameters including extrusion ratio, extruding temperature and extruding rate on crystal size and mechanical properties of magnesium alloy are conducted, and a two-step extrusion deformation process is employed to prepare the high-performance magnesium alloy material, so as to substantially improve integrated mechanical properties of the magnesium alloy material.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

Method for forming zinc alloy product through selective laser melting technology

ActiveCN109365811AQuality improvementImprove mechanical propertiesAdditive manufacturing apparatusTransportation and packagingSelective laser meltingSurface finish

The invention relates to the field of material preparation, and provides a method for forming a zinc alloy product through the selective laser melting technology. The method comprises the following steps that a three-dimensional structural model of the product needing to be formed is firstly constructed, and is treated and guided into printing forming equipment computer through 3D printing editingsoftware to carry out a printing task; processing technological parameters of a zinc alloy powder laser melting system are set; printing preparation work is done, wherein powder pre-paving, airflow circulating system checking, check parameter setting and the like are carried out; and powder is fast melted and solidified under protection of inert atmosphere, and is stacked layer by layer to form the product. According to the method, specific zinc alloy ingredients and specification parameters thereof are selected, the processing technological parameters are optimized, and the zinc alloy product stable in quality and excellent in mechanical property and surface smoothness can be obtained. According to the method, the processing procedure flow is optimized, and the method has unparalleled advantages for preparing high-precision complex-structure zinc alloy through the selective laser melting technology, especially forming small-batch personalized zinc alloy parts.

Owner:北京科技大学广州新材料研究院

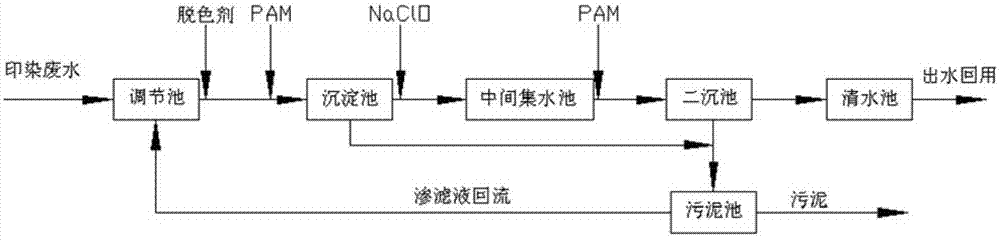

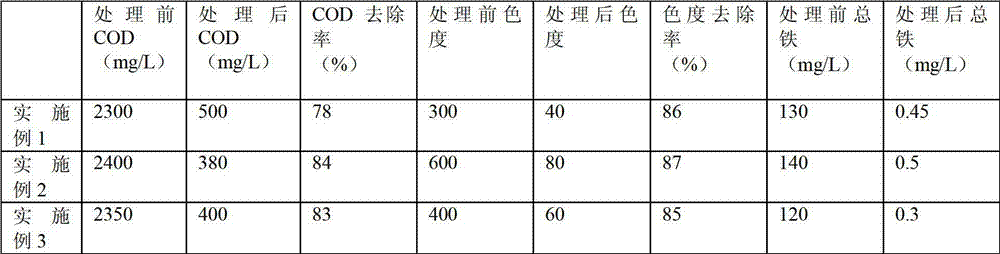

Method for treating alkaline printing and dyeing wastewater by utilizing waste acid

InactiveCN102951756AIncrease costIncrease drug costMultistage water/sewage treatmentWaste water treatment from textile industryProduction lineSodium hypochlorite solution

The invention relates to a treatment process of industrial wastewater, in particular to a method for treating alkaline printing and dyeing wastewater by utilizing waste acid. The method comprises the following steps of: 1), measuring the pH value of the alkaline printing and dyeing wastewater, and ensuring that the pH value is between 11 and 13; 2), adding a waste acid decoloring agent to carry out decoloring treatment; 3), adding a flocculating agent, standing and precipitating to obtain supernatant fluid and sludge; 4), adding an industrial sodium hypochlorite solution and the flocculating agent to the supernatant fluid to further treat the obtained supernatant fluid; and 5), discharging and dewatering the sludge to obtain dewatered sludge and clear water, discharging the sludge, returning the clear water to the first step, mixing the clear water with the alkaline printing and dyeing wastewater to treat again. The method provided by the invention is simple in treatment procedure, and is easy to operate; the pH value of the treated clear water is in the range of 6-9; the pH value does not need to be further adjusted, so that the clear water can be recycled again in a printing and dyeing washing production line for utilization; and the dosage of the acid is saved.

Owner:青岛海安生物环保有限公司

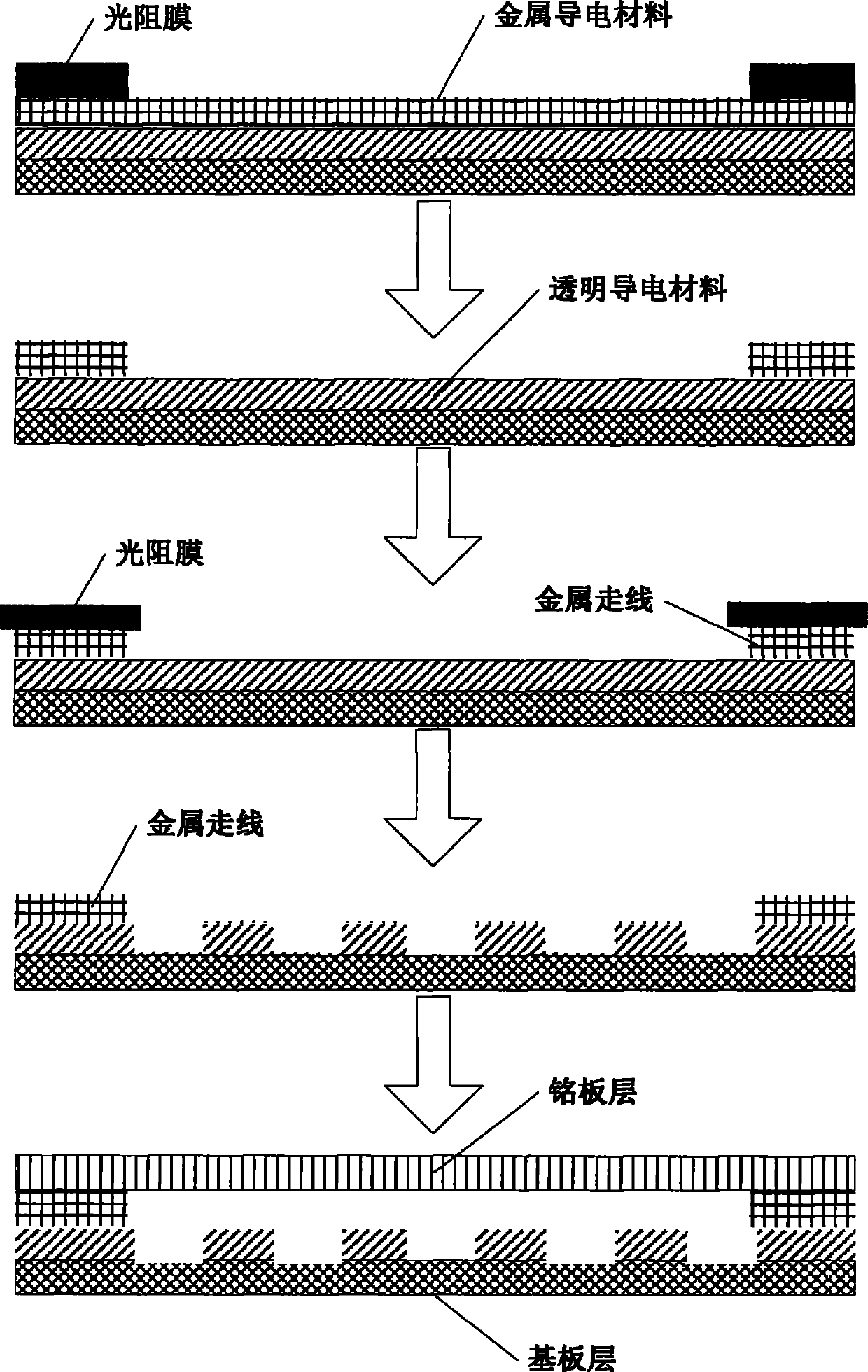

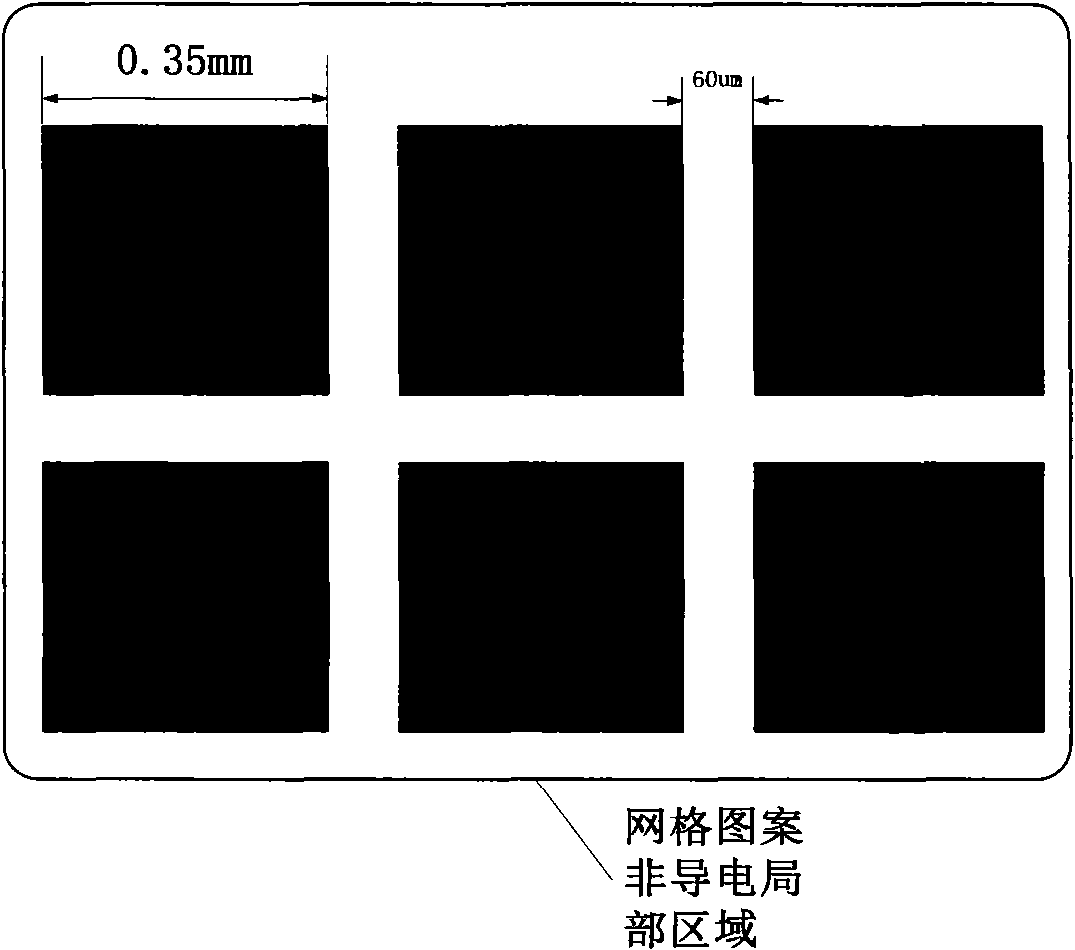

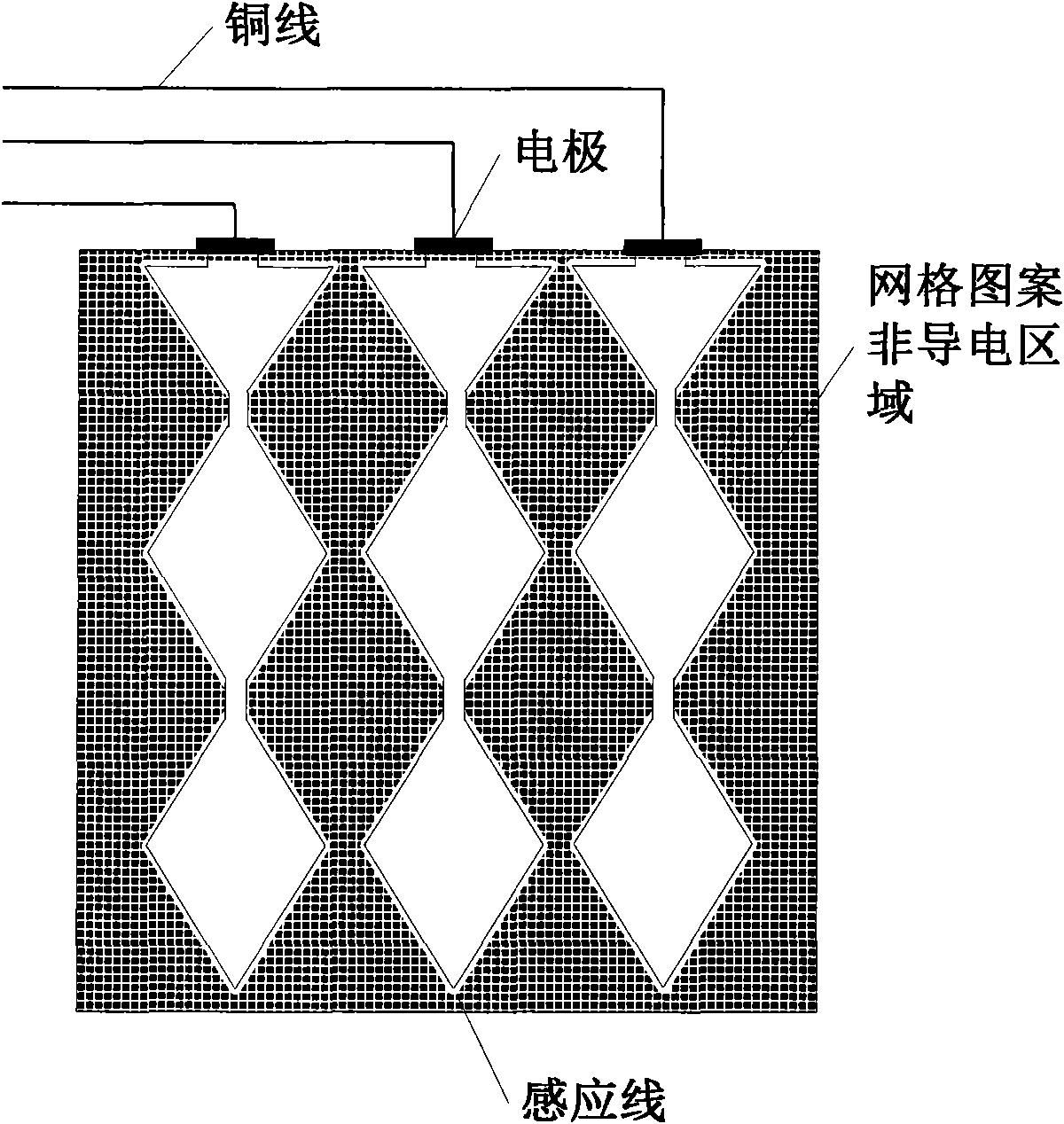

Method for externally expanding single edge of circuit of touch panel

InactiveCN101907946AAvoid the phenomenon that the electrode deviates from the end of the conductive areaReduce etch marksConductive material chemical/electrolytical removalInput/output processes for data processingManufacturing cost reductionConductive materials

The invention relates to a method for externally expanding a single edge of a circuit of a touch panel, belonging to the technical field of manufacture of touch panels. The method comprises the following steps of: directly electroplating a metal conducting material on a transparent conducting material, adhering a photoresist film on the metal conducting material, exposing, developing and etching to form metal routings. The operating method has strong controllability and simple process flows. The manufacturing cost can be decreased. The width of the photoresist film is externally expanded with respect to the width of the metal routings, which effectively protects the corrosion of the metal routings and is beneficial to the signal transmission.

Owner:牧东光电科技有限公司

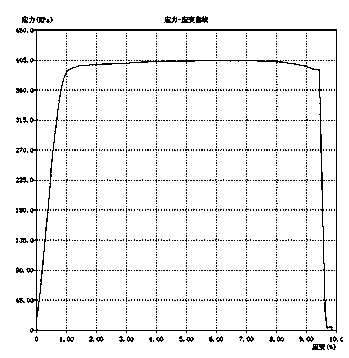

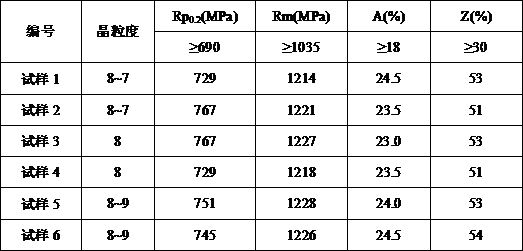

High-quality GH2132 alloy bar for fasteners and production method of high-quality GH2132 alloy bar

PendingCN113042565AStable tensile yield strength at room temperatureIncreased tensile yield strength at room temperatureFurnace typesHeat treatment furnacesIngotUltimate tensile strength

The invention relates to a high-quality GH2132 alloy bar for a fastener and a production method of the high-quality GH2132 alloy bar. The grain size of the high-quality GH2132 alloy bar for the fastener is smaller than the fifth grade, the grade difference is the second grade or within, and strip grains do not exist, meanwhile, the room-temperature tensile yield strength of a bar is larger than 720 MPa, the production method is simple in process flow and easy to control, the structure stability of the bar can be effectively improved by conducting diffusion annealing treatment on a consumable steel ingot and controlling the deformation amount during follow-up hot rolling, and the grain size of the obtained bar is generally 7-9 grade, by adopting multi-pass and small-deformation cold drawing processing, the room-temperature tensile yield strength of the material can be effectively improved, the room-temperature tensile yield strength of the bar of the same batch is 729-770 MPa, and the performance is stabler.

Owner:JIANGSU TOLAND ALLOY

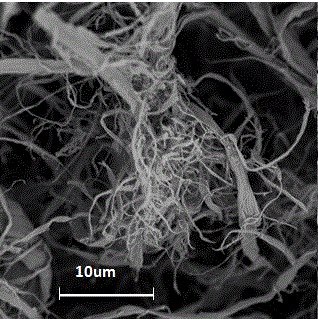

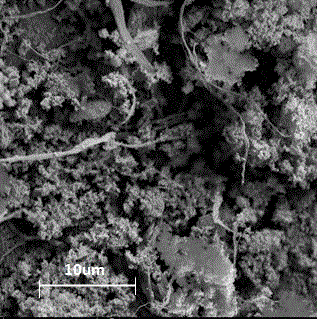

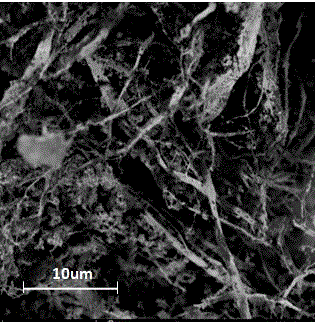

Method for preparing aramid-pulp composite master batches

The invention relates to a method for preparing aramid-pulp composite master batches. The method includes the steps that aramid pulp is fully separated through inorganic filler generated through in-situ polymerization, the aramid pulp after separation is further modified with a coupling agent, the product is dried and bulked at a high speed, then the product and thermoplasticity particles or powder are subjected to extrusion pelletizing, and the corresponding aramid-pulp composite master batches are prepared. By means of the method, microfibril of the aramid pulp can be fully extended, the in-situ-generated particles have the better separating effect on the microfibers, and after modification is carried out through the coupling agent, the combination effect of the pulp and a base body can be further improved; compared with the method that aramid pulp is directly separated with inorganic powder, the method is more obvious in separating effect, and all properties of a base body material are also improved.

Owner:SOUTH CHINA UNIV OF TECH

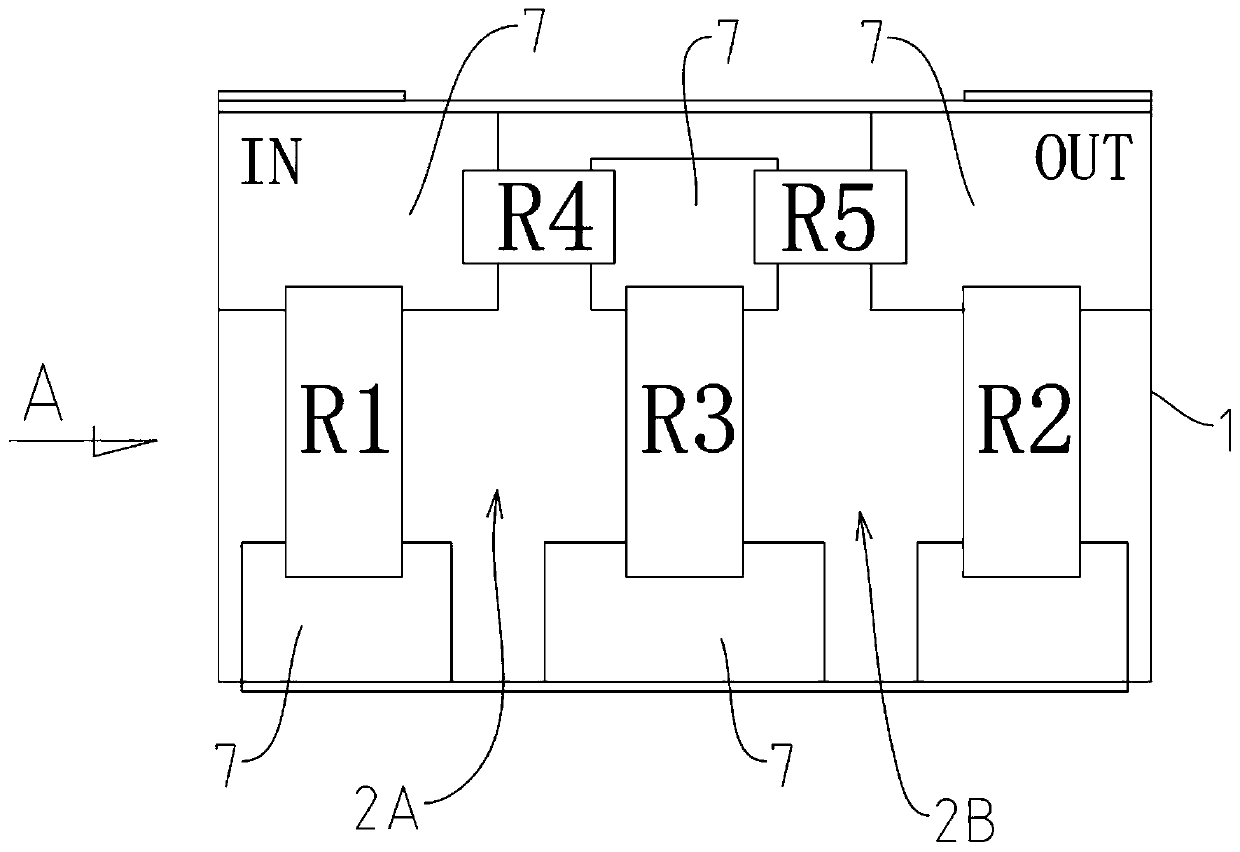

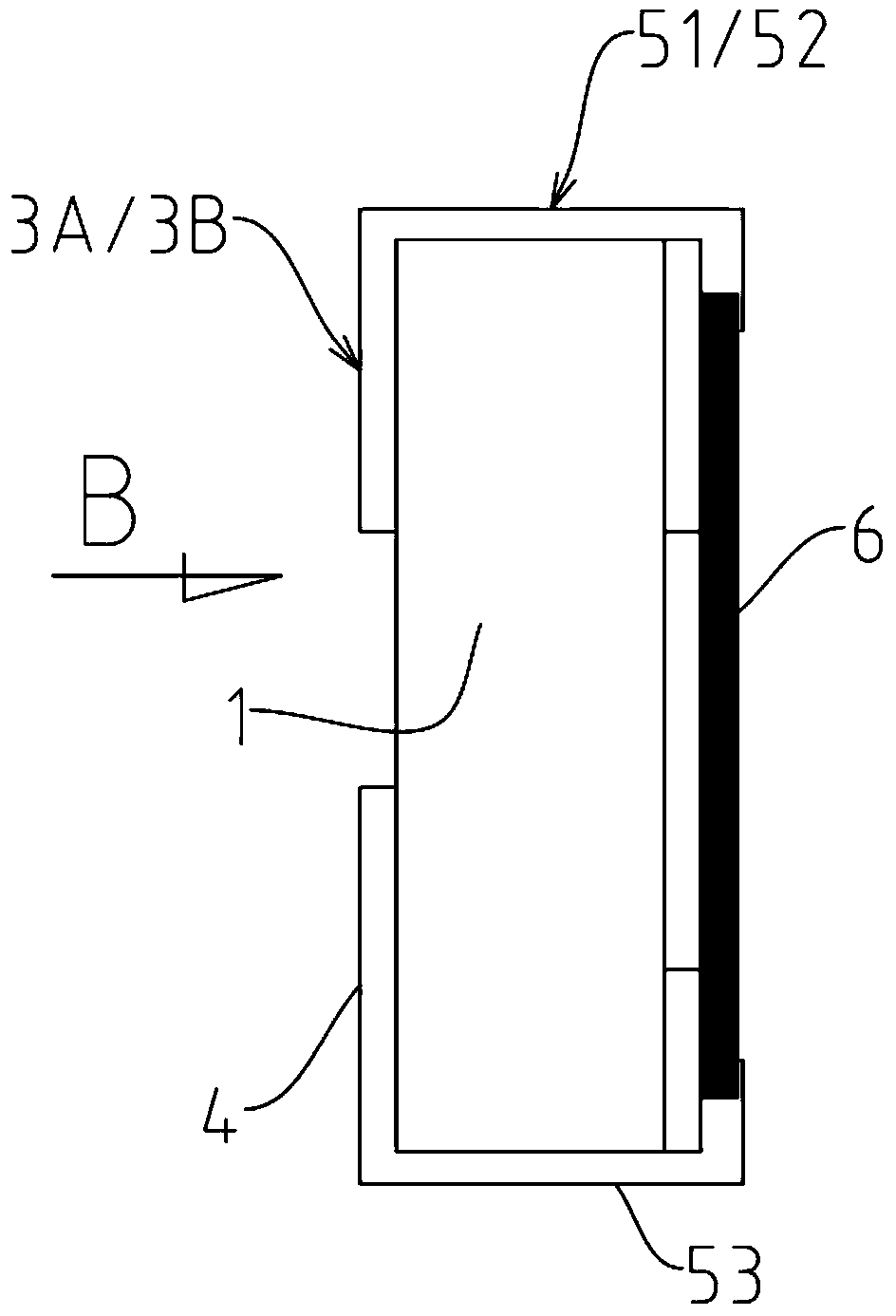

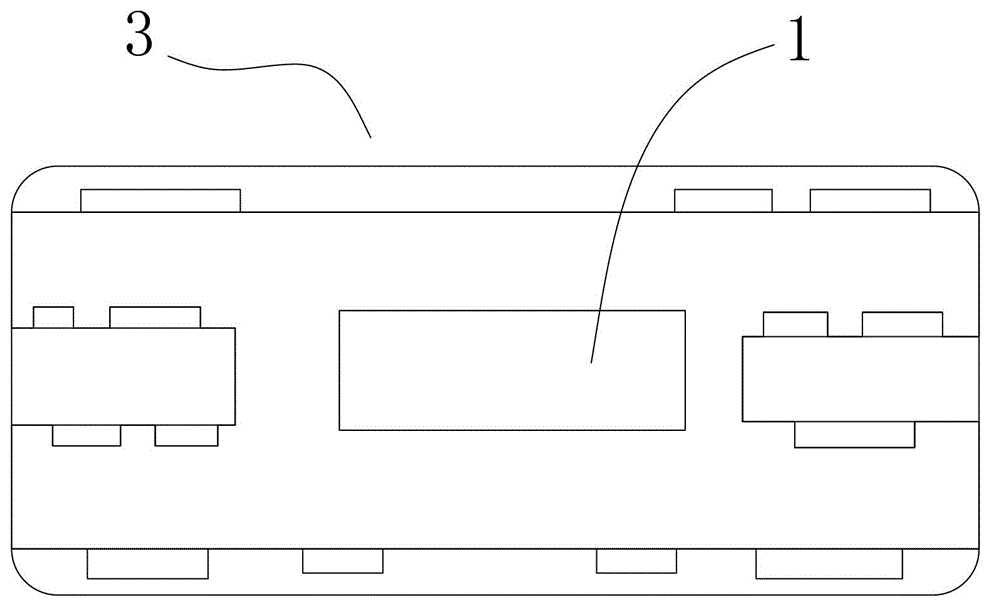

Surface-mounted miniature superimposed circuit attenuation sheet and preparation method thereof

ActiveCN111030640AImprove the attenuation effectReduce volumeFrequency-independant attenuatorsElectrical conductorHemt circuits

The invention discloses a surface-mounted miniature superimposed circuit attenuation sheet and a preparation method thereof. The size of the attenuation sheet is 2.5 mm * 4mm * 0.635 mm, the front surface of the attenuation sheet is provided with a first attenuation circuit and a second attenuation circuit, the first attenuation circuit and the second attenuation circuit are connected in series, and the first attenuation circuit and the second attenuation circuit share one resistor. The two attenuation circuits are connected in series to obtain the attenuation circuit with a higher attenuationvalue, and the relative resistance value is smaller, so that the precision requirement can be better met; and the first attenuation circuit and the second attenuation circuit creatively share one resistor to form respective attenuation circuits, so that the size of the attenuation sheet is effectively reduced, the attenuation sheet is easier to arrange in a high-frequency circuit, and an end conductor of the attenuation sheet is machined at one time, thereby further improving the precision and quality of the attenuation sheet.

Owner:苏州市新诚氏通讯电子股份有限公司

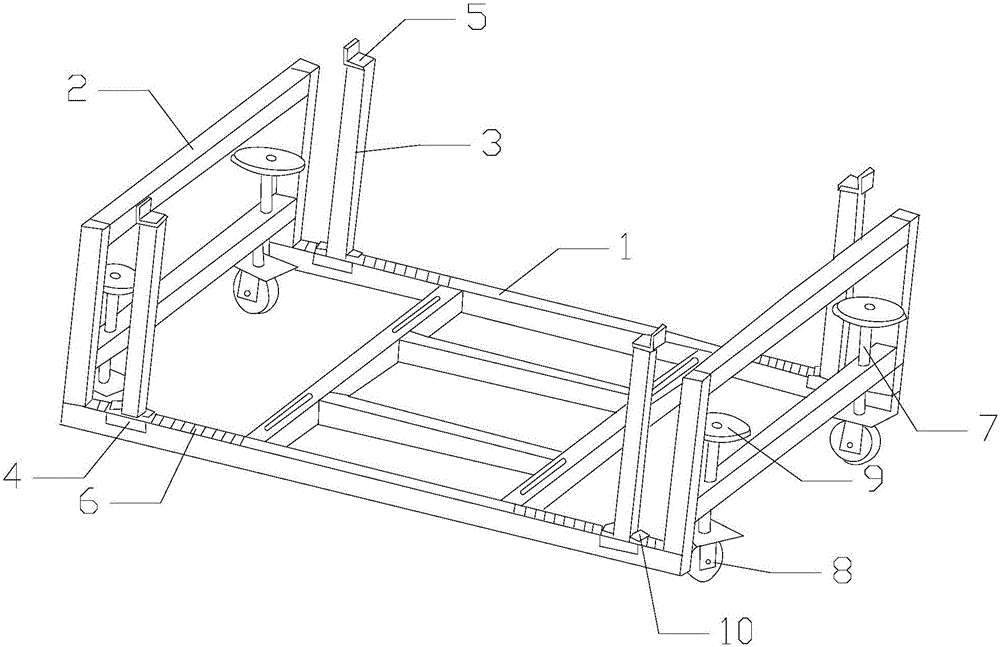

Integrated tool for storage, transfer and installation of braking module

InactiveCN105109948AReduce storageReduce typesPackaging vehiclesContainers for machinesComputer moduleSoftware engineering

Owner:NANJING RUIFA MACHINERY EQUIP

Manufacturing method of explosion-proof mobile phone glass back cover and glass back cover

InactiveCN110202966AReduce processSimplify the process flowOther printing apparatusTelephone set constructionsMobile phoneElectrical and Electronics engineering

The invention discloses a manufacturing method of an explosion-proof mobile phone glass back cover. The method comprises the following steps that 1) a pattern layer is printed, specifically, pattern ink used for printing patterns is printed to the inner side surface of the glass back cover through a gravure movable printing device, the pattern ink is solidified, and the pattern layer is formed; and 2) an explosion-proof layer is printed, specifically, explosion-proof ink is printed to the pattern layer through the gravure movable printing device, and the explosion-proof ink is solidified. According to the manufacturing method of the explosion-proof mobile phone glass back cover, the pattern ink printing precision is high, the thickness is small, the process flow is simplified, productionis more efficient, in addition, the explosion-proof layer is formed through direct ink printing, and the whole back cover is lighter and thinner.

Owner:AENEQ CO LTD

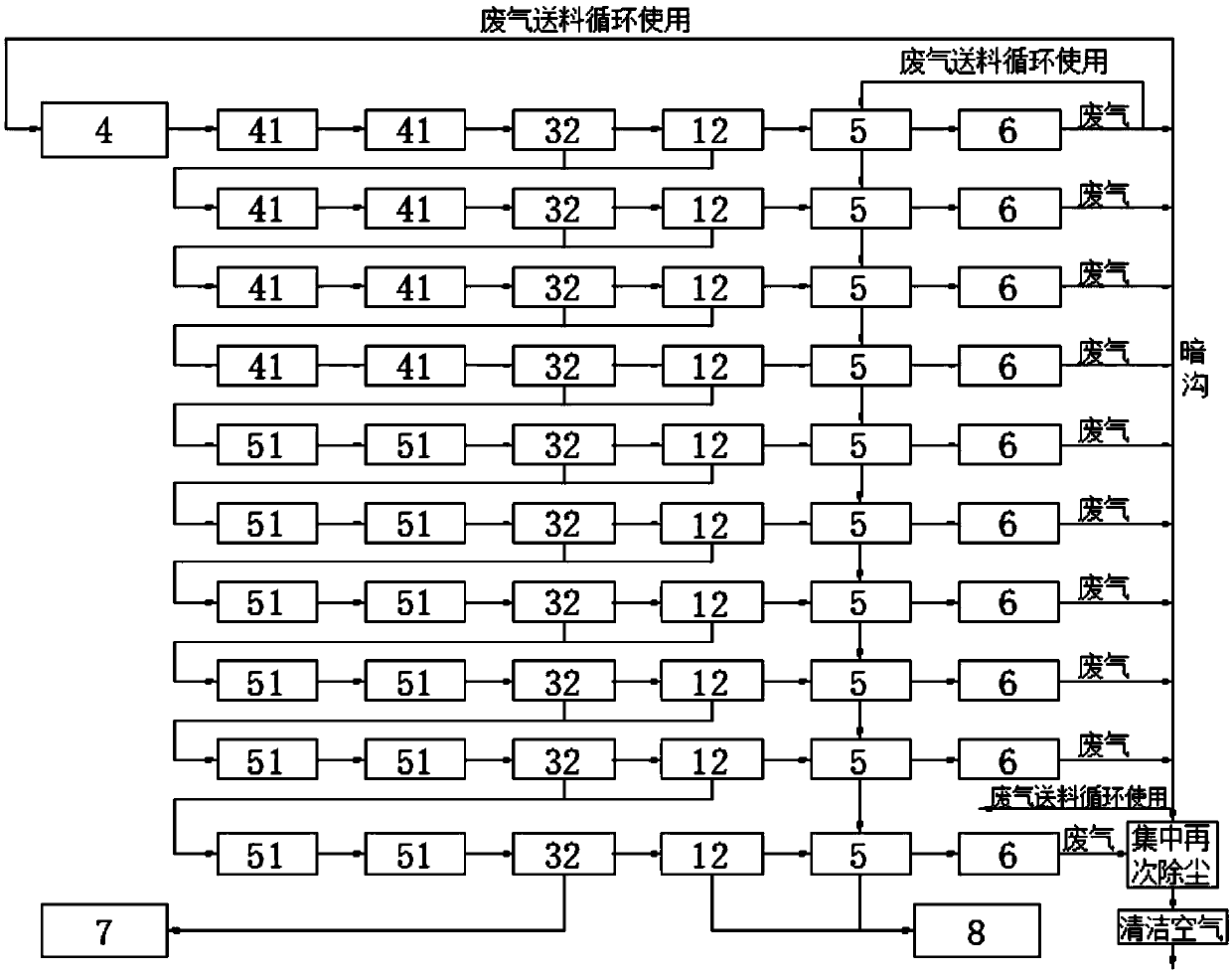

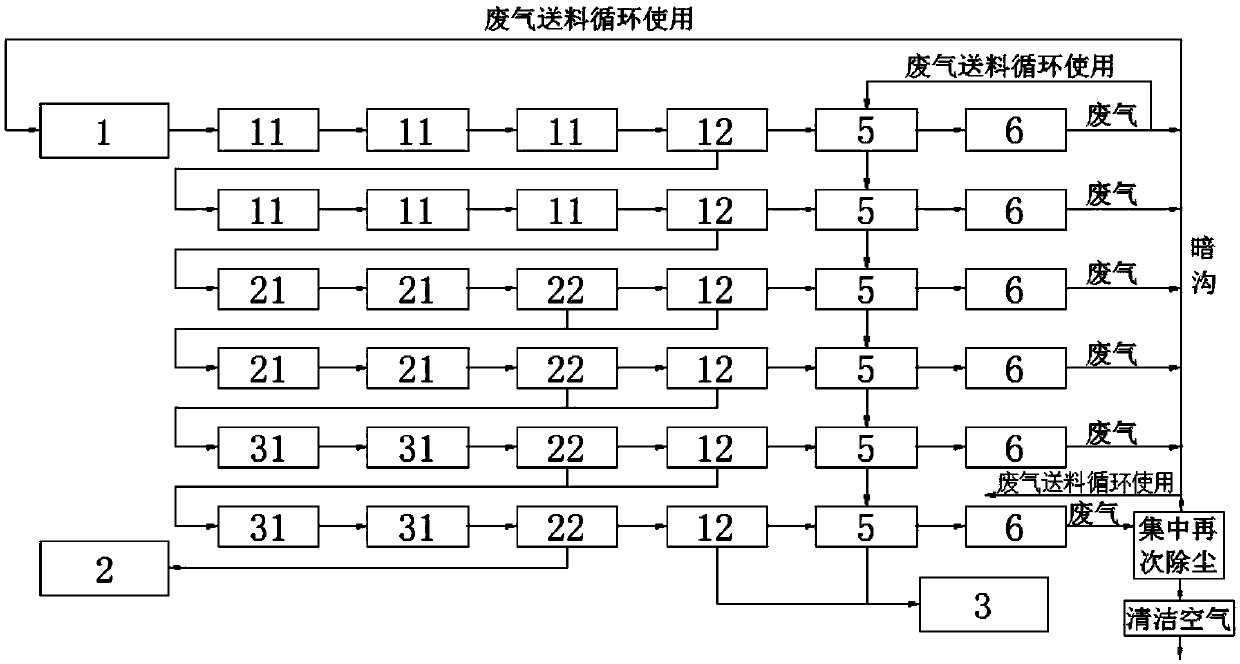

Preparation method and preparation apparatus of spherical graphite for power battery

ActiveCN110872117AAvoid it happening againGood sphericityGraphiteCell electrodesPower batteryDust control

The invention provides a preparation method and a preparation apparatus of spherical graphite for a power battery, wherein a combined process including ultrafine initial pulverization, ultrafine finepulverization and multi-time ultrafine classification is employed, so that the prepared spherical graphite has good degree of sphericity, narrow granularity distribution (D50 = 3-12 [mu]m) and high tap density, which satisfy the use requirement of negative electrode materials for high-grade power batteries. In addition, since a tailing generated from a preparation process of the spherical graphitewith D50 being 13-25 [mu]m can be used as the raw material for producing the small-diameter spherical graphite (D50 = 3-12 [mu]m), the utilization rate on the graphite raw material can be further improved by 25-35%. The method is simple in process and reduces energy resource consumption. The preparation apparatus includes a plurality groups of head-to-tail connected single devices, wherein raw material, after first-stage pulverization, is directly fed into the nest stage for circulating pulverization and classification; the raw materials are conveyed by pipelines. The whole set of apparatus is sealed, so that dust-containing gas is subjected to dust removal and is fed into a blind drain for secondary dust removal treatment after collection, thus achieving zero-pollution emission.

Owner:ZHANJIANG JUXIN NEW ENERGY +1

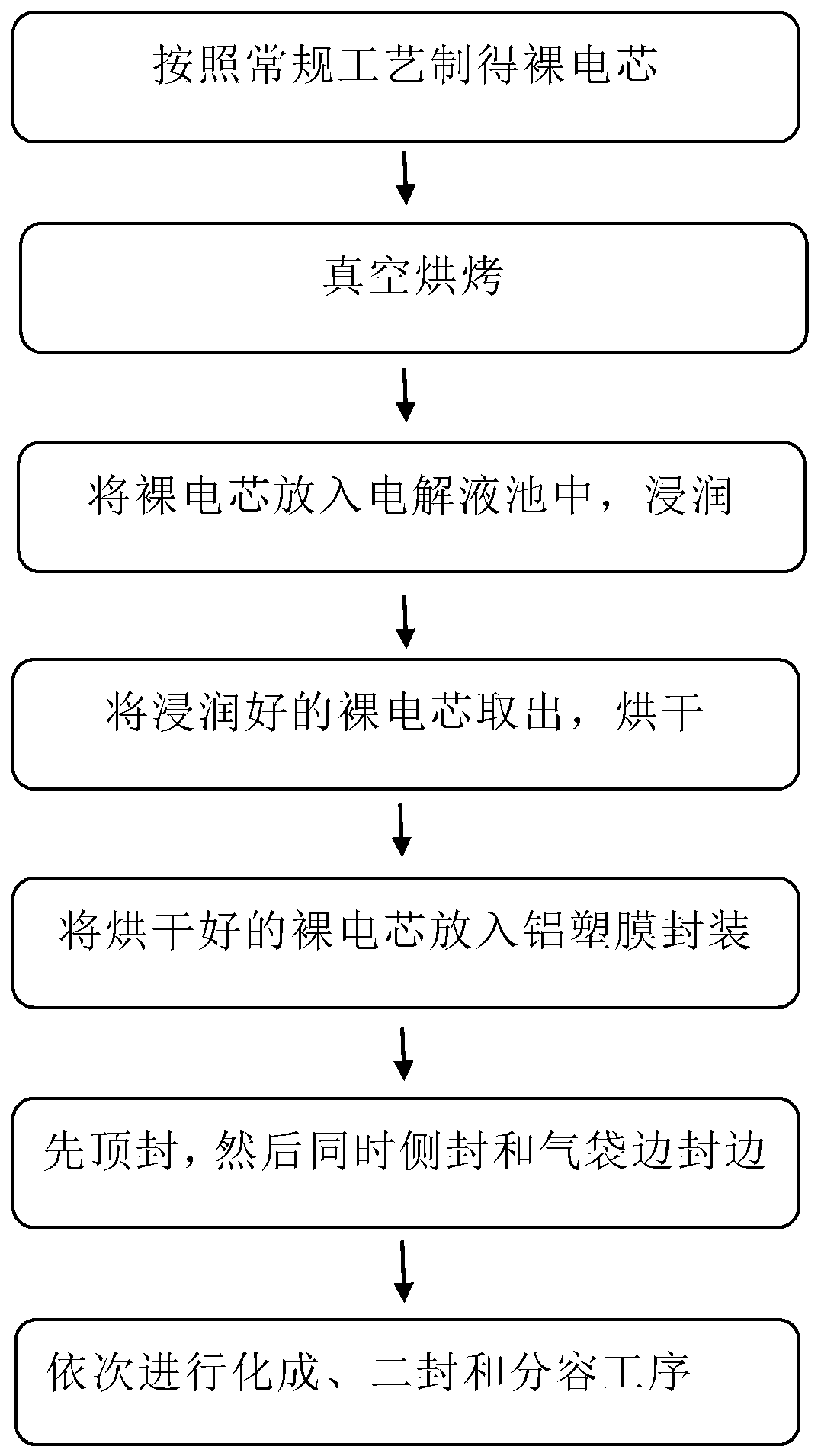

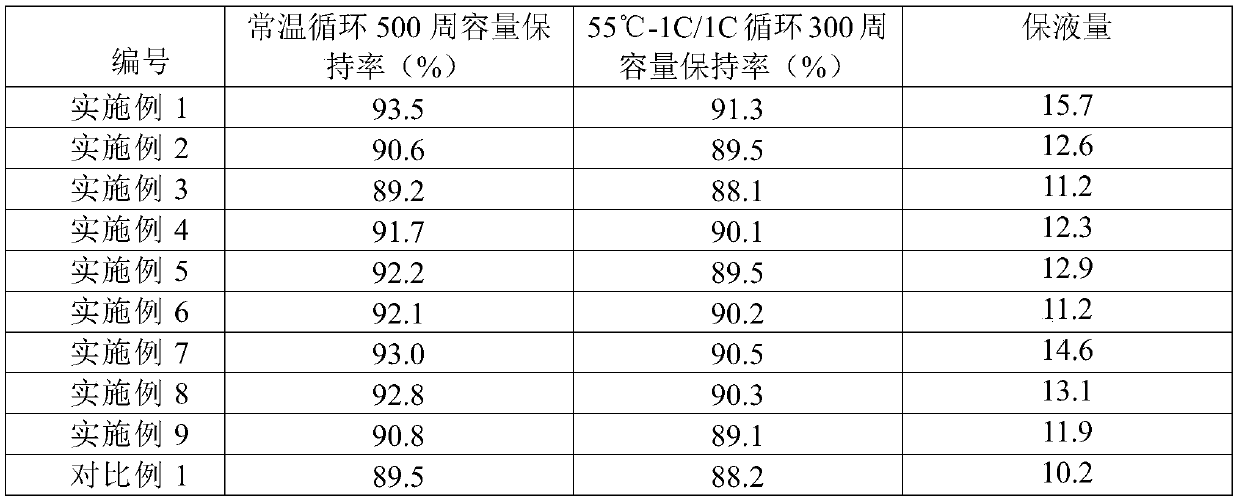

Soft-packed lithium ion battery manufacturing process

InactiveCN110718669APromote reabsorptionShorten production timeFinal product manufactureCell component detailsElectrolytic agentPhysical chemistry

The invention provides a soft-packed lithium ion battery manufacturing process which comprises the following steps: S1, after a bare cell is wound, the bare cell is put into an electrolyte tank in a dry and oxygen-free environment until the electrolyte level reaches the tab glue position of the bare cell, the bare cell is soaked for 10 seconds to 2 hours, and the temperature of electrolyte is maintained at 20 to 150 DEG C; S2, the soaked bare cell is taken out, and the bare cell is dried at 20-150 DEG C until the bare cell does not drop electrolyte anymore and the content of the electrolyte meets a preset value; and S3, the bare cell is put into an aluminum-plastic film after being dried, top sealing is carried out first, and then, side sealing and air bag edge sealing are carried out at the same time, and thus, packaging is completed. Compared with the prior art, the bare cell is directly placed and soaked in the electrolyte tank and dried, side sealing and air bag edge sealing are carried out at the same time, and by improving the existing process, the standing time is greatly shortened, the process flow is simplified, and the production efficiency is improved.

Owner:HUIZHOU LIWINON NEW ENERGY TECH CO LTD

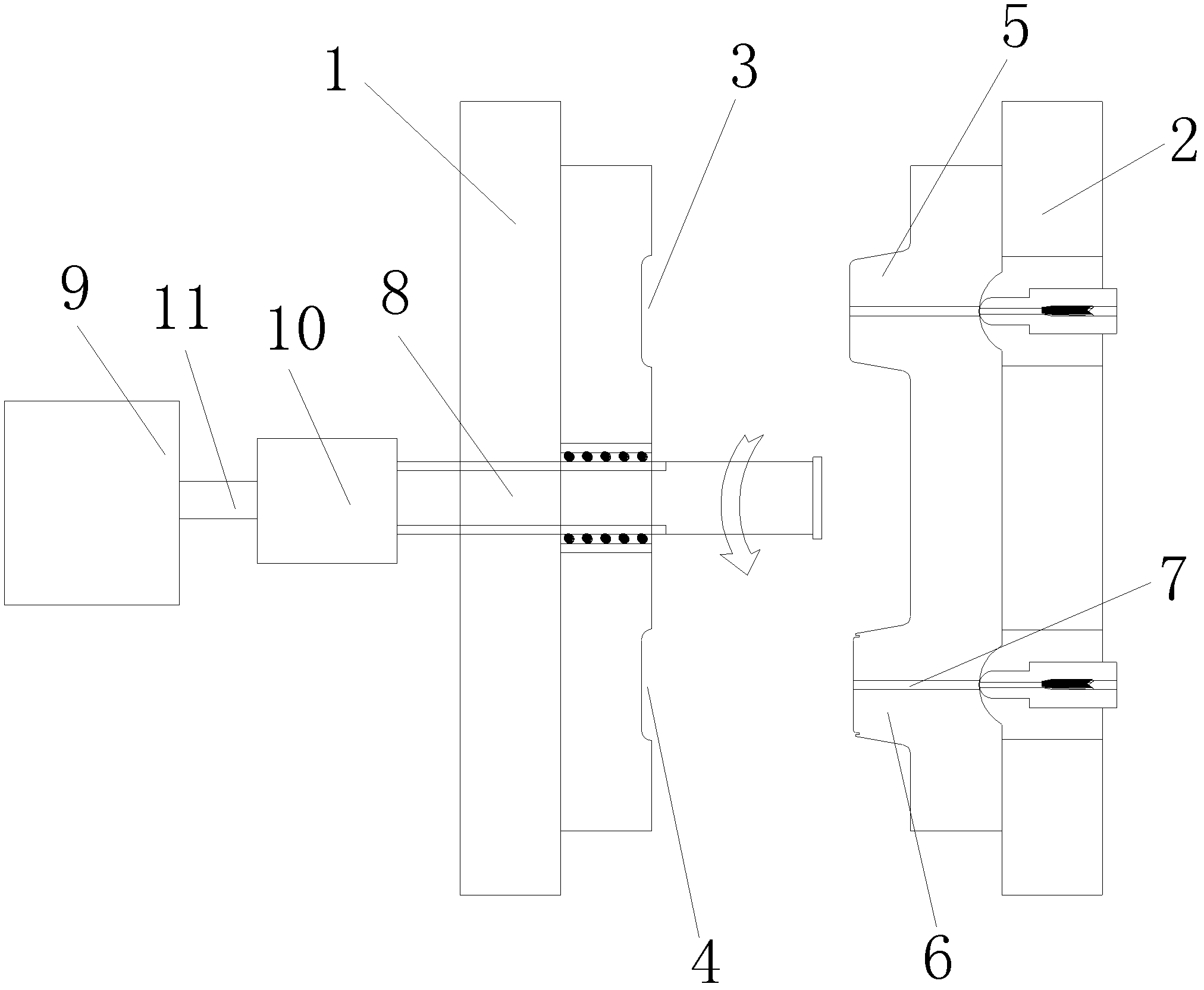

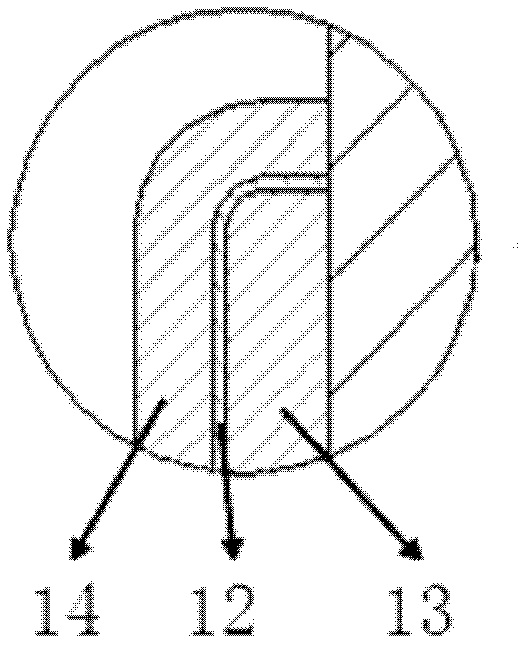

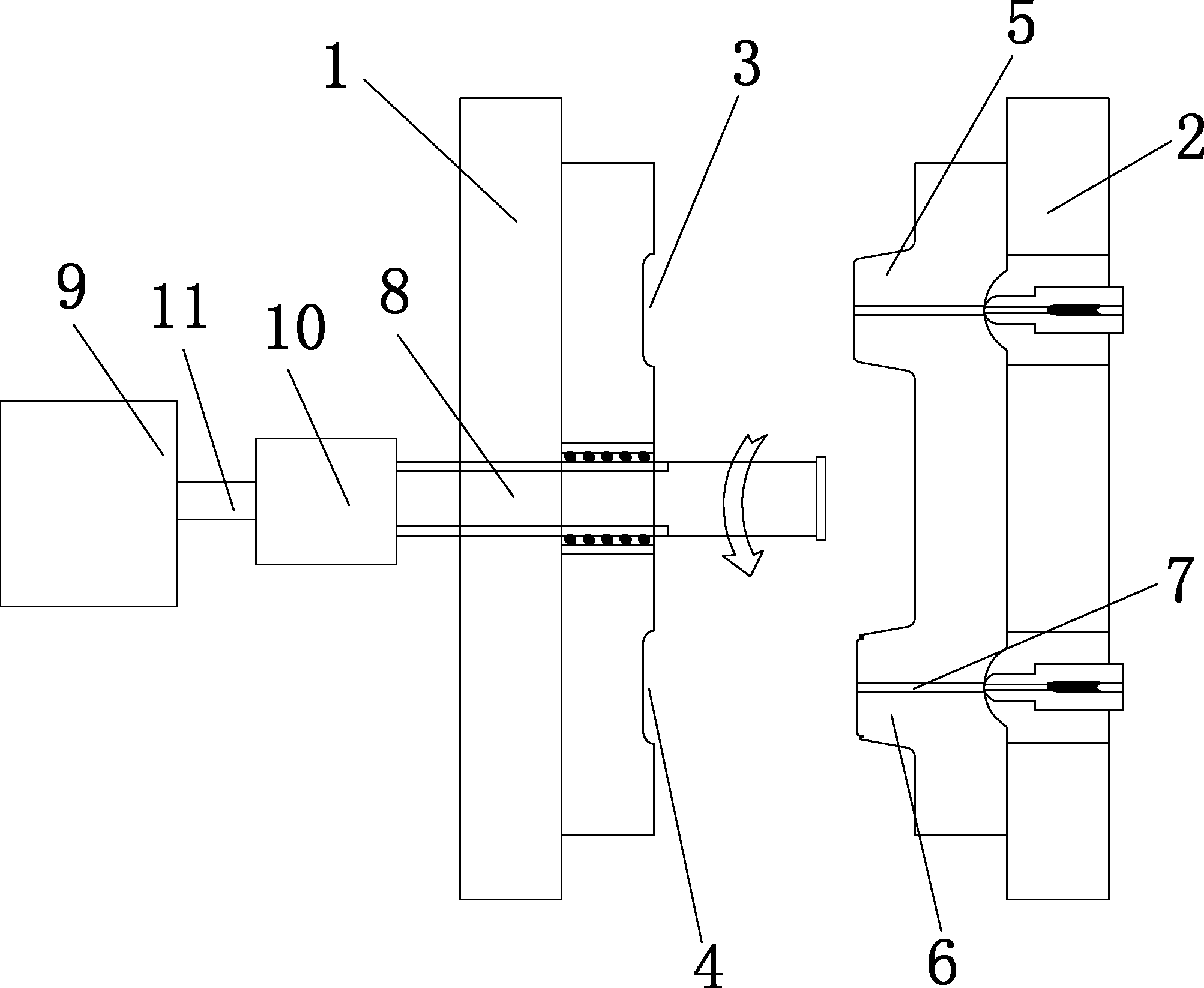

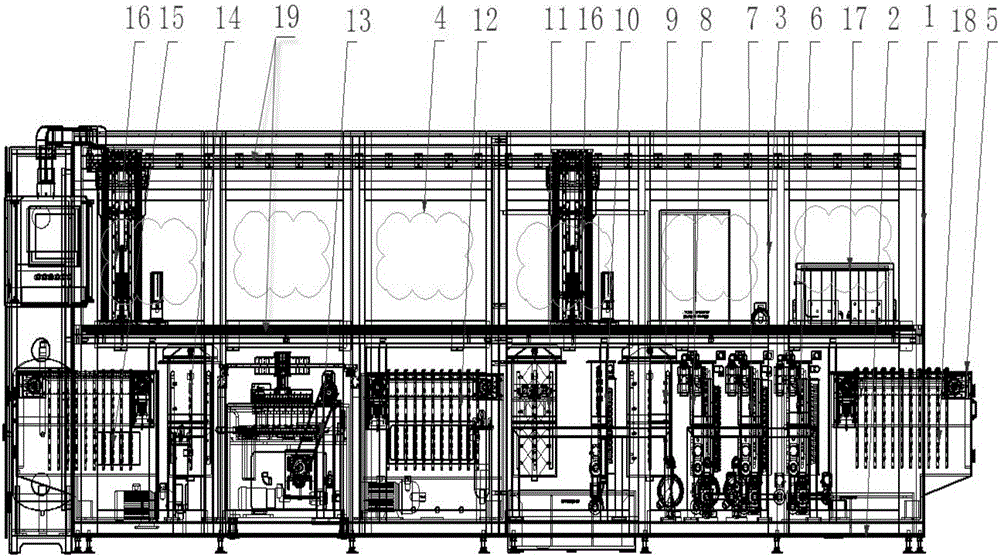

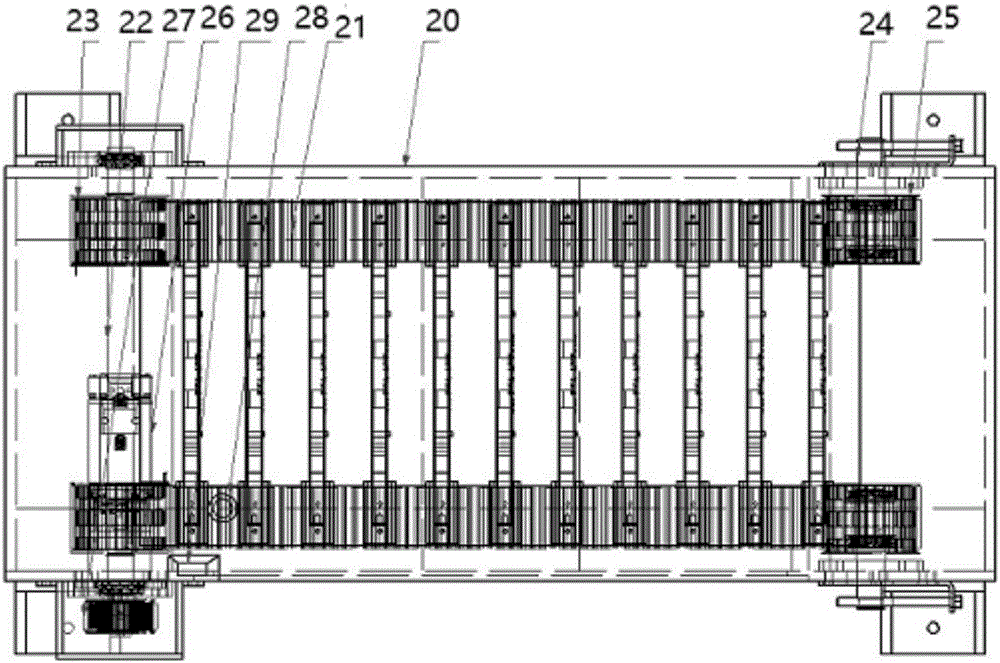

Full-automatic ultrasonic pickling and polishing device for intravascular stent

ActiveCN106119876AImprove work efficiencyImprove automationElectrolysis componentsMedicineInsertion stent

The invention discloses a full-automatic ultrasonic pickling and polishing device for an intravascular stent. Firstly, the stent implanted into a blood vessel is placed into a clamp; then the clamp is placed onto an automatic conveying feeding platform, and conveyed to an automatic mechanical arm material-taking position; and an automatic mechanical arm is used for grasping the clamp and conveying the clamp to a primary high-frequency ultrasonic pickling bath, a secondary high-frequency ultrasonic pickling bath, a third high-frequency ultrasonic pickling bath, a low-pressure spraying rinse bath, a high-frequency ultrasonic pure-water clean bath, a mobile water cutting bath, a to-be-polished-and-conveyed material platform, an electrolytic polishing bath, an atomization spraying rinse bath and a conveying and discharging platform sequentially for completing the pickling and polishing process of the intravascular stent. According to the full-automatic ultrasonic pickling and polishing device for the intravascular stent, the integral operation of pickling and polishing is achieved; the problems that the working procedures for pickling and polishing operation on the intravascular stent are complicated, and the working efficiency is low are solved; and the full-automatic ultrasonic pickling and polishing device for the intravascular stent is high in automation and working efficiency and highly-simplified in process flow.

Owner:SHANGHAI ZHANXIE CLEANING EQUIP

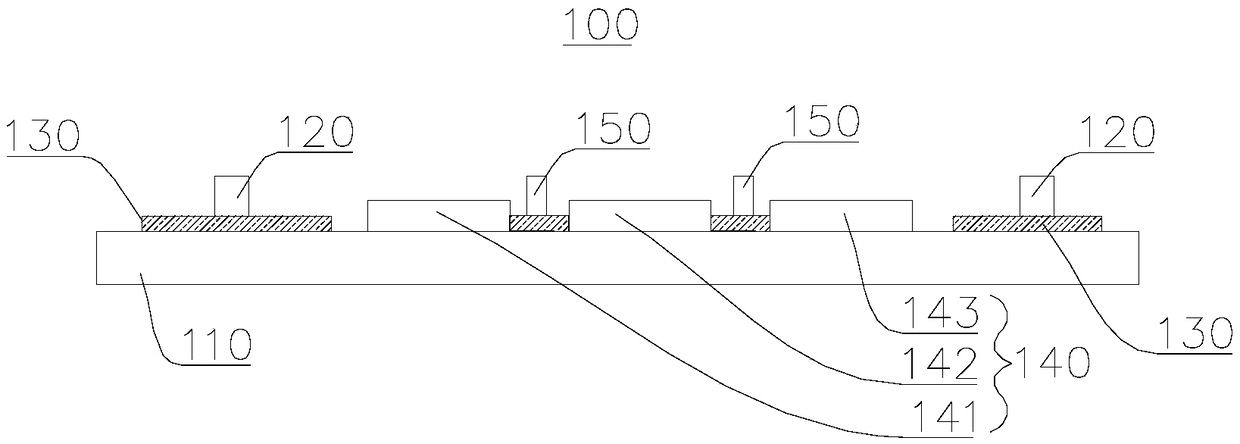

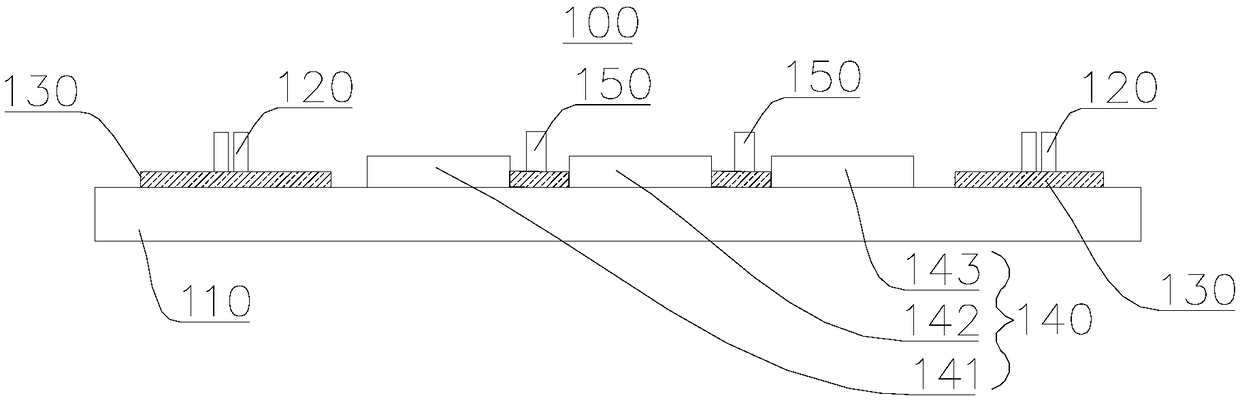

Display panel and production method thereof

The invention relates to a display panel and a production method thereof, and belongs to the technical field of display. The display panel comprises a display substrate, wherein the display substrateis divided into a display area and a non-display area surrounding the display area, and the display substrate is provided with a sealant supporting part arranged in the non-display area. The display panel and the production method thereof have the advantages that the sealant supporting part is arranged in the non-display area of the display substrate, so that when the display substrate and an array substrate are combined to form a box through sealant so as to form a liquid crystal panel, the effect of improving the supporting force of the sealant is achieved without doping supports in the sealant, in addition, the process flow can be simplified, and the use cost of the sealant is reduced.

Owner:HKC CORP LTD +1

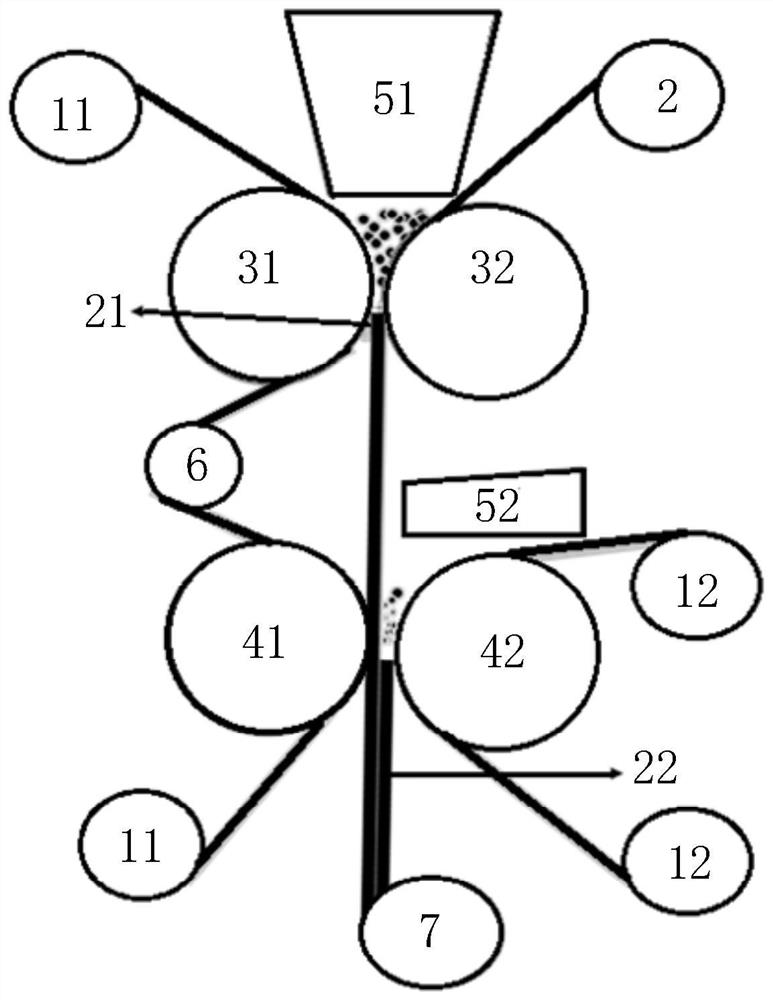

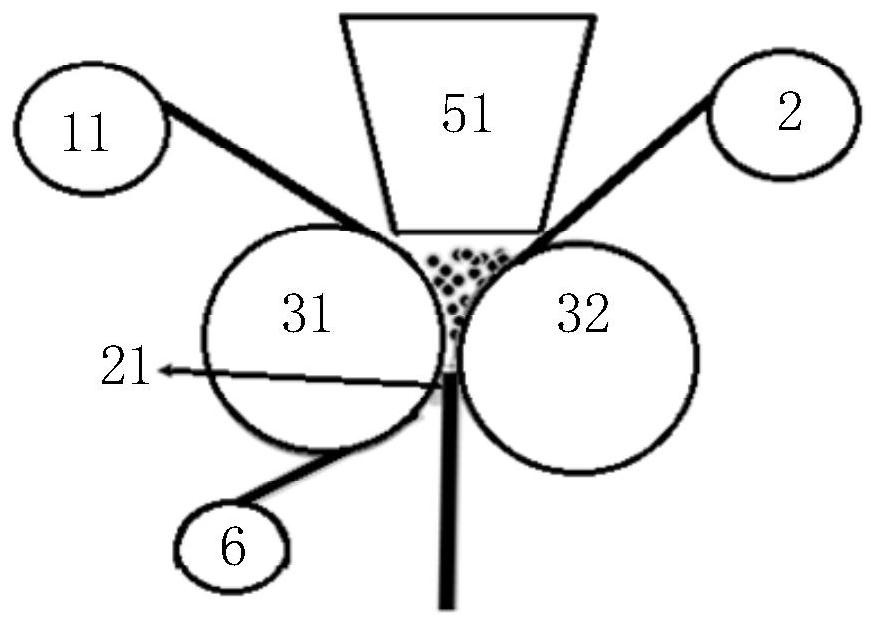

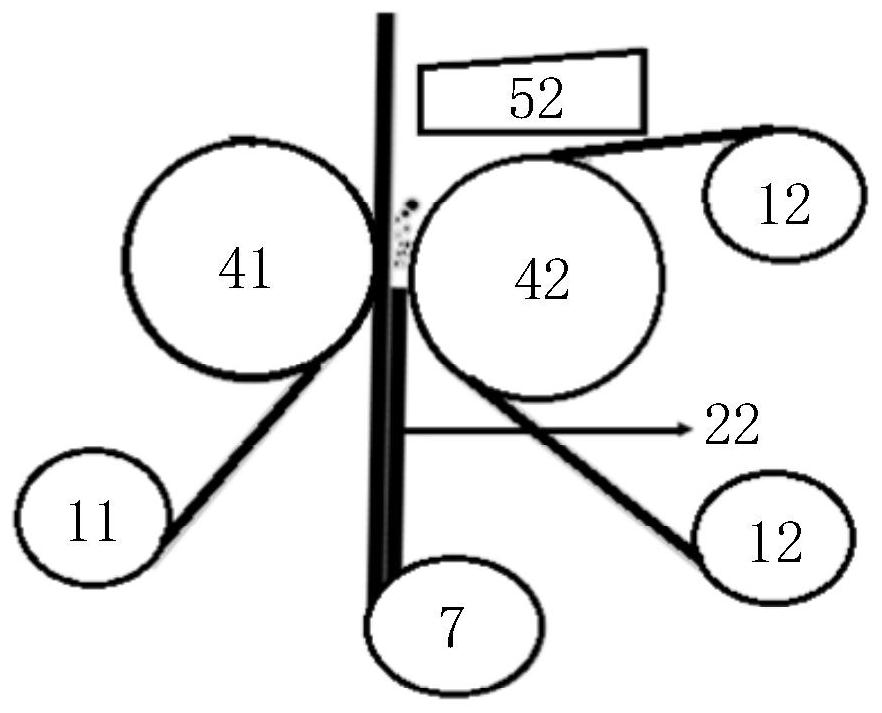

Method for preparing electrode plate by dry rolling

ActiveCN112802987AAvoid uniformityAvoid fragmentsElectrode rolling/calenderingProcess equipmentComposite material

The invention relates to the technical field of lithium ions, and discloses a method for preparing an electrode plate through dry rolling. The method comprises the following steps: (1) enabling a first membrane material and a foil material to simultaneously pass through a space between opposite first rollers, adding first powder into a gap between the first membrane material and the foil material, carrying out first rolling, and forming a first powder material tabletting layer on one side surface of the foil material; (2) enabling the first membrane material, the second membrane material and the foil material with the first powder tabletting layer to simultaneously pass through opposite second rollers, adding second powder into a gap between the second membrane material and the other side surface of the foil material, carrying out second rolling, and forming a second powder tabletting layer on the other side surface of the foil material; and 3) separating the first membrane material and the second membrane material from the side surface of the foil material to obtain the electrode plate. According to the method, double-sided simultaneous rolling and laminating flaking can be realized, the process flow is simplified, the process equipment is reduced, and the electrode plate with uniform thickness can be continuously prepared.

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

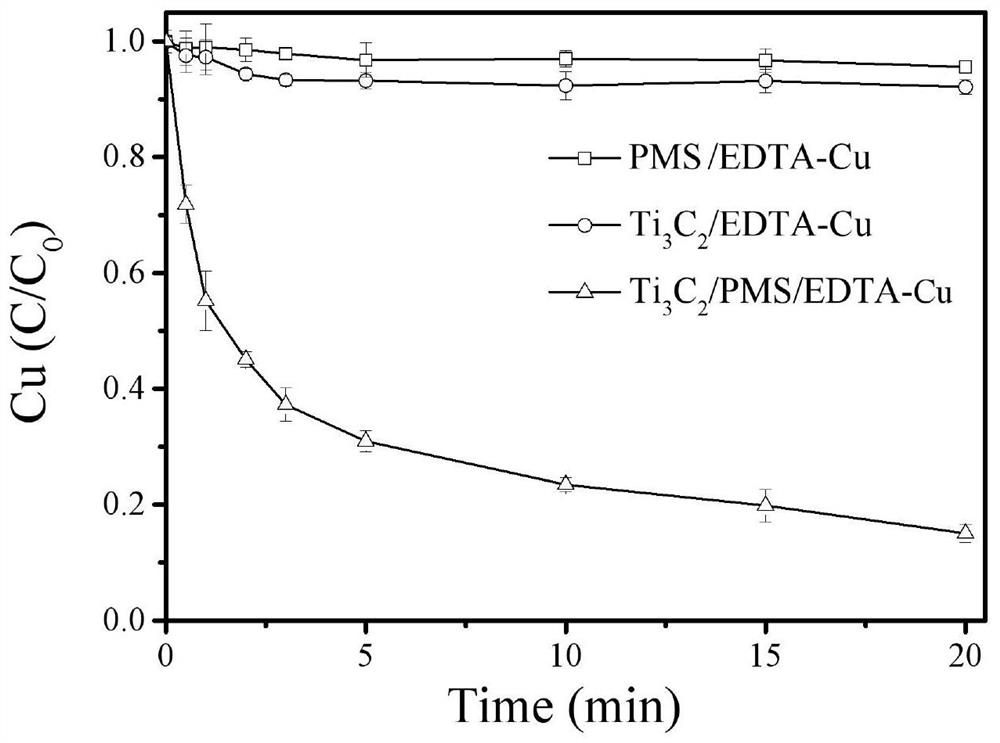

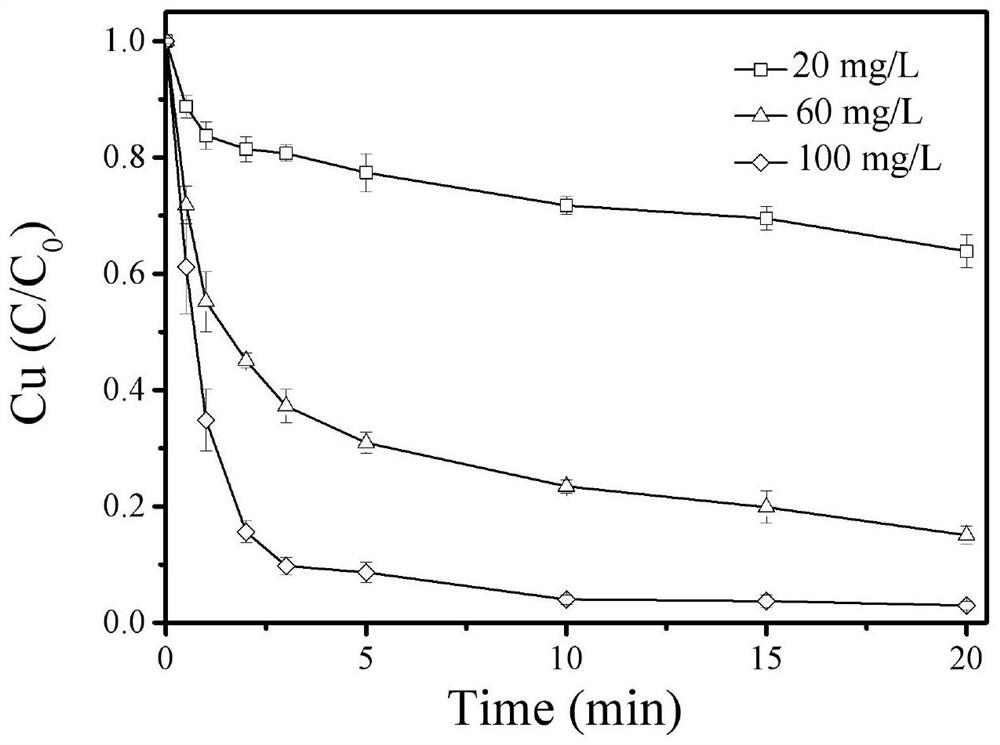

Method for oxidative degradation of heavy metal complex and recovery of heavy metal through MXene reinforced Fenton

ActiveCN113087117AImprove adsorption capacityReductiveWater treatment compoundsWater contaminantsPersulfateSulfate

The invention relates to a method for oxidative degradation of a heavy metal complex and recovery of heavy metal through MXene reinforced Fenton, and belongs to the field of environmental protection. The method comprises the steps of adding MXene with the concentration of 0.1-100 mg / L and persulfate or hydrogen peroxide with the concentration of 0.1-100 mM into the wastewater containing the heavy metal complex, and stirring to react for 10-90 minutes. The method is wide in pH application range, low-valence transition metal ions do not need to be additionally added, the pH value does not need to be repeatedly adjusted, and efficient degradation of the heavy metal complex and synchronous recovery of the heavy metal can be achieved.

Owner:DONGGUAN UNIV OF TECH

Packaging structure of arrayed waveguide grating module and preparation method

InactiveCN105676350AReduce usageLow costFibre mechanical structuresOptical waveguide light guideElectricityGrating

The invention relates to a packaging structure of an arrayed waveguide grating module, which includes a module box of which a side surface is provided with an input end, an output end, and an electrical interface window. A printed circuit board is fixed in the module box and provided with a fixing installation position. An arrayed waveguide grating chip is arranged at the fixing installation position. An electrical interface is welded on the edge of the printed circuit board. After an input optical fiber passes through the input end, the input optical fiber is circled in the module box and is connected to an input end of the array waveguide grating chip. Array optical fibers at an output end of the array waveguide grating chip disperse into multiple single optical fibers. After the single optical fibers are circled in the module box, the single optical fibers pass through the output end and are directly output in a tail fiber manner. The invention also relates to a preparation method of the packaging structure. According to the invention, the batch production is convenient and the optical fiber protection capability of the products can be improved.

Owner:BROADEX TECH

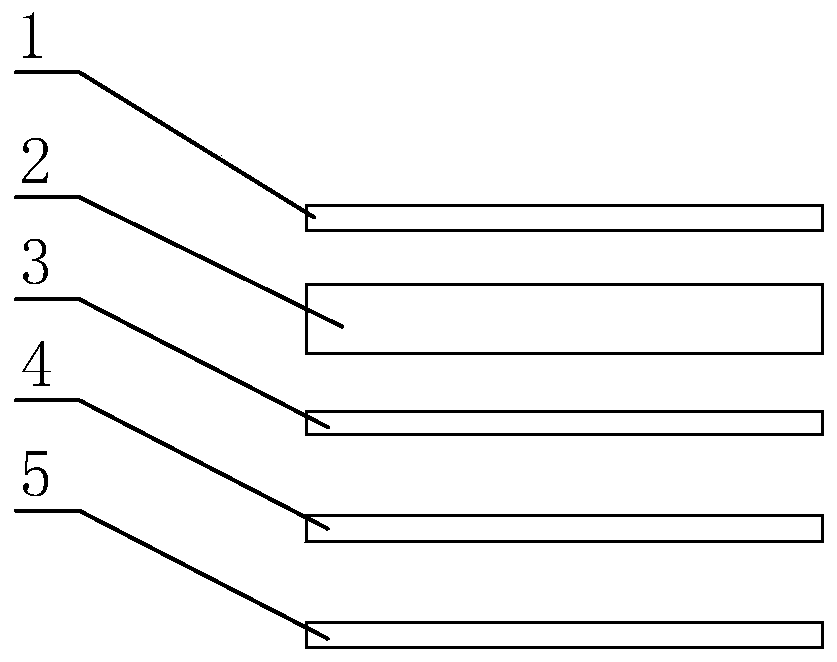

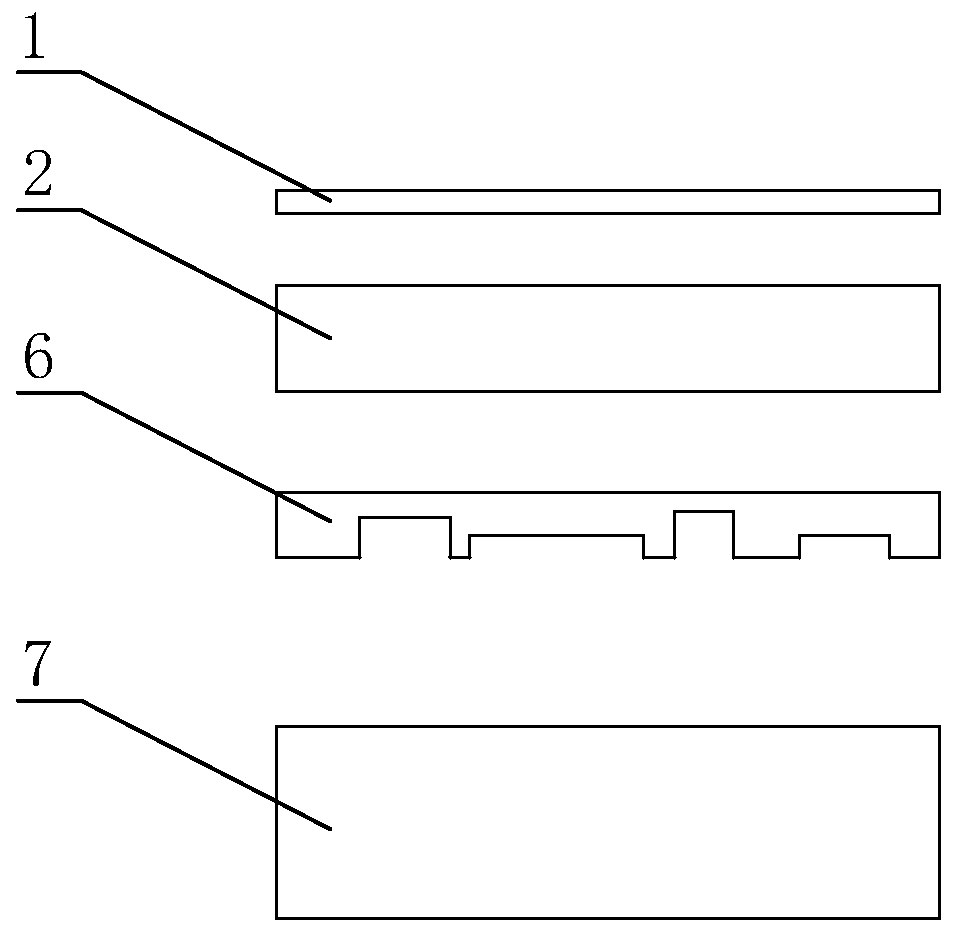

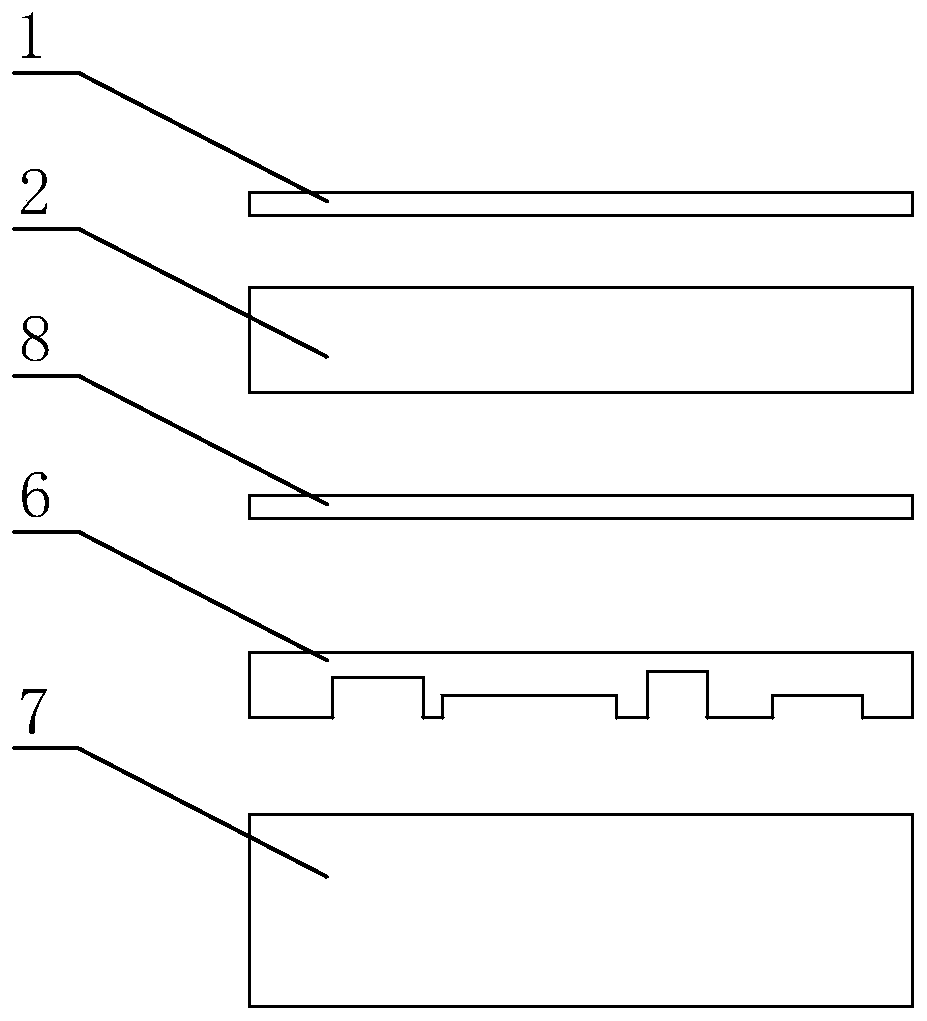

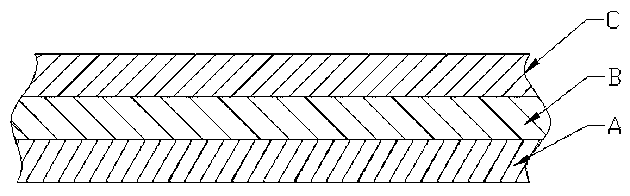

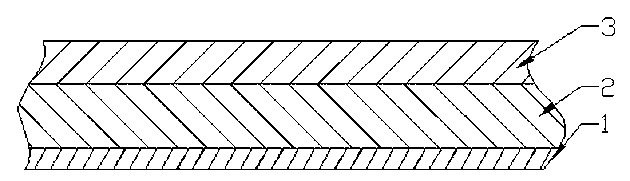

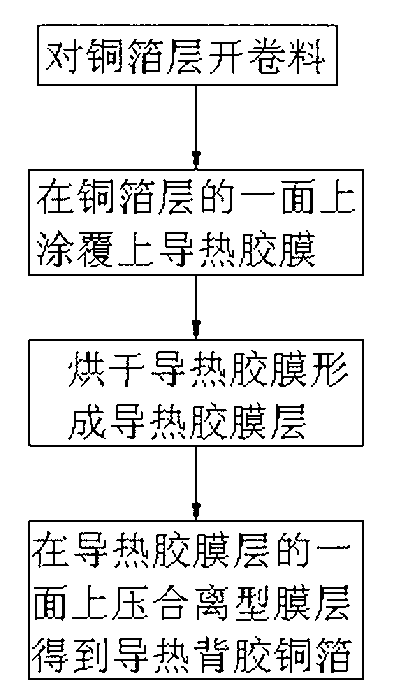

Heat conducting resin coated copper foil, manufacturing method of heat conducting resin coated copper foil and application of heat conducting resin coated copper foil to aluminum substrate manufacturing process

InactiveCN102700188AReduce investmentReduce manufacturing costLaminationLamination apparatusCopper foilHeat conducting

The invention provides heat conducting resin coated copper foil, a manufacturing method of the heat conducting resin coated copper foil and an application of the heat conducting resin coated copper foil to an aluminum substrate manufacturing process. The heat conducting resin coated copper foil comprises a copper foil layer (1), a heat conducting adhesive film layer (2) and a parting film layer (3), wherein the copper foil layer (1), the heat conducting adhesive film layer (2) and the parting film layer (3) are overlapped in sequence; in the process of manufacturing the heat conducting resin coated copper foil, a copper foil roll is unrolled, a heat conducting adhesive film is coated on one surface of the copper foil and then dried, and finally, a parting film is laminated on the heat conducting adhesive film so as to obtain the heat conducting resin coated copper foil; and during manufacturing an aluminum substrate with the heat conducting resin coated copper foil, an aluminum plate is cut and treated, the heat conducting resin coated copper foil is unrolled, the parting film layer on the heat conducting resin coated copper foil is removed, the aluminum plate is pressed on the heat conducting resin coated copper foil, then a protective film is laminated on the external side of the aluminum plate, and the heat conducting resin coated copper foil and the protective film are cut according to the size of the aluminum plate, and finally, an aluminum substrate finished product is obtained. The heat conducting resin coated copper foil provided by the invention can be used in the making field of the aluminum substrates.

Owner:珠海亚泰电子科技有限公司

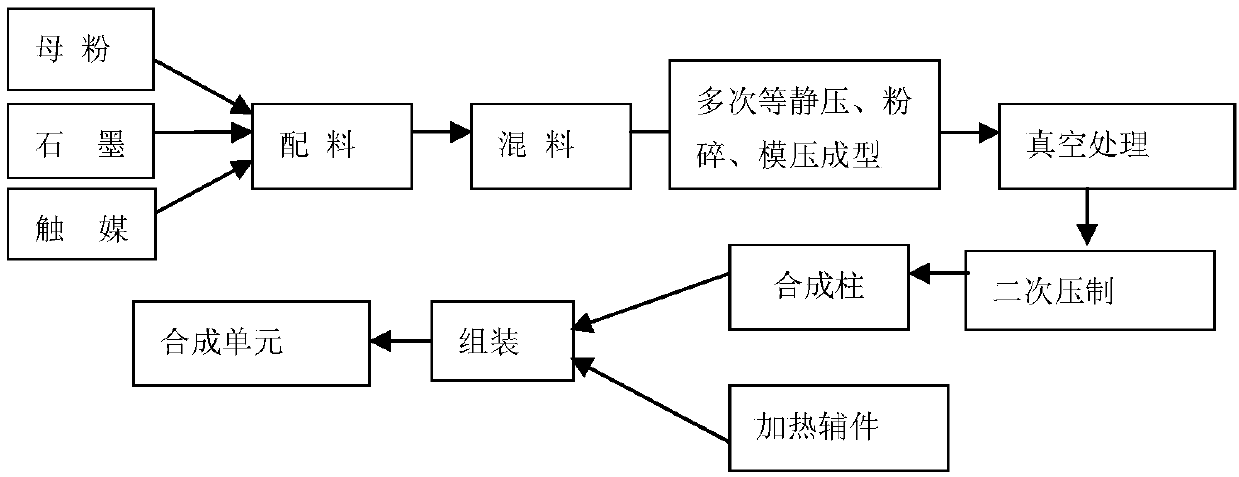

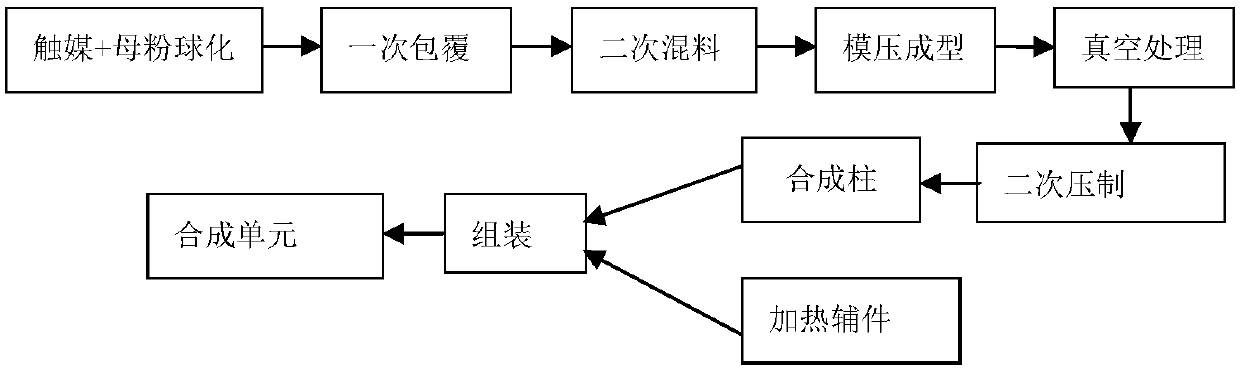

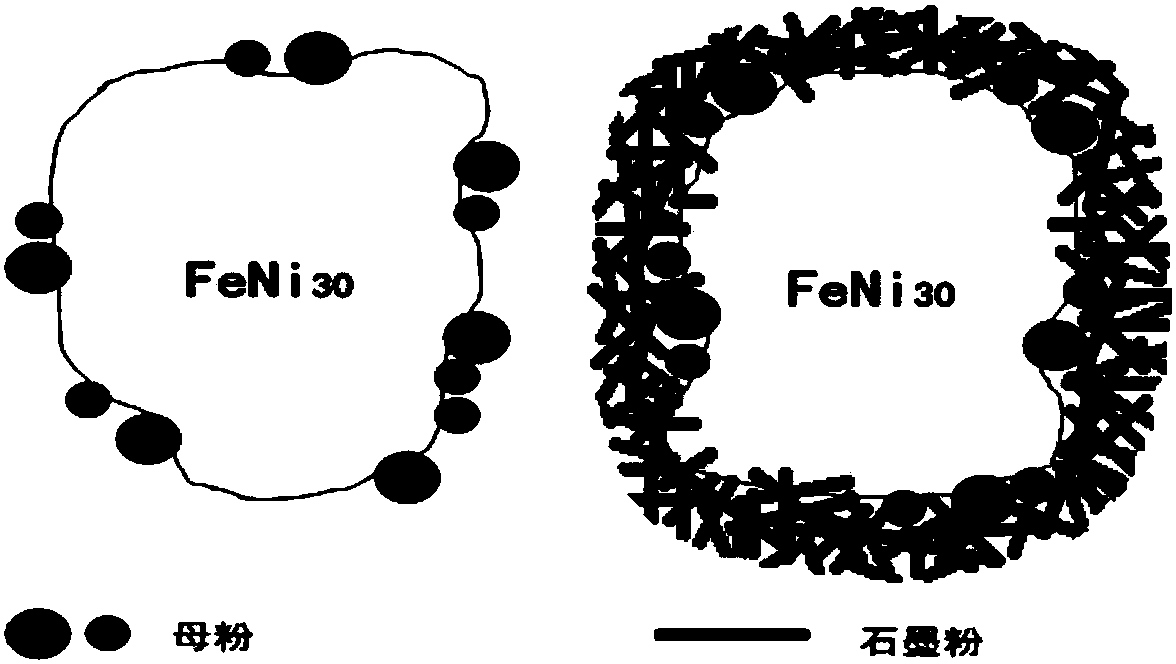

Preparation method of artificial diamond synthetic column

ActiveCN109966992AWell mixedEasy to manufactureUltra-high pressure processesHigh concentrationSuperhard material

Belonging to the field of superhard material synthesis technology and special new material preparation technology, the invention discloses a preparation method of an artificial diamond synthetic column. The method includes: mixing catalyst powder with high concentration dust, then performing spheroidizing by a shaping machine to press or embed high concentration dust particles into the surfaces ofcatalyst particles; mixing the spheroidized catalyst powder with graphite powder to form graphite coated composite catalyst particles; adding graphite powder into the composite catalyst particles again, and mixing the substances evenly by a three-dimensional mixer; selecting a die for pressing into a synthetic column by a four-column press; and subjecting the synthetic column to vacuum heat treatment, then conducting secondary pressing and shaping, and then performing assembly to obtain a synthetic unit. The artificial diamond synthesized from the synthetic column prepared by the method has the advantages of complete crystal form, uniform growth, fewer twin crystal and high grade.

Owner:有研增材技术有限公司

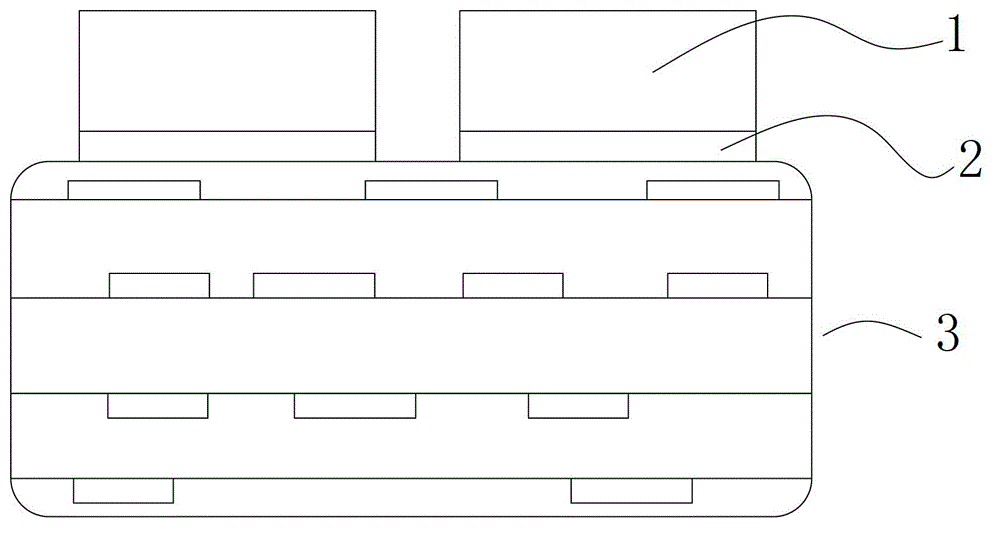

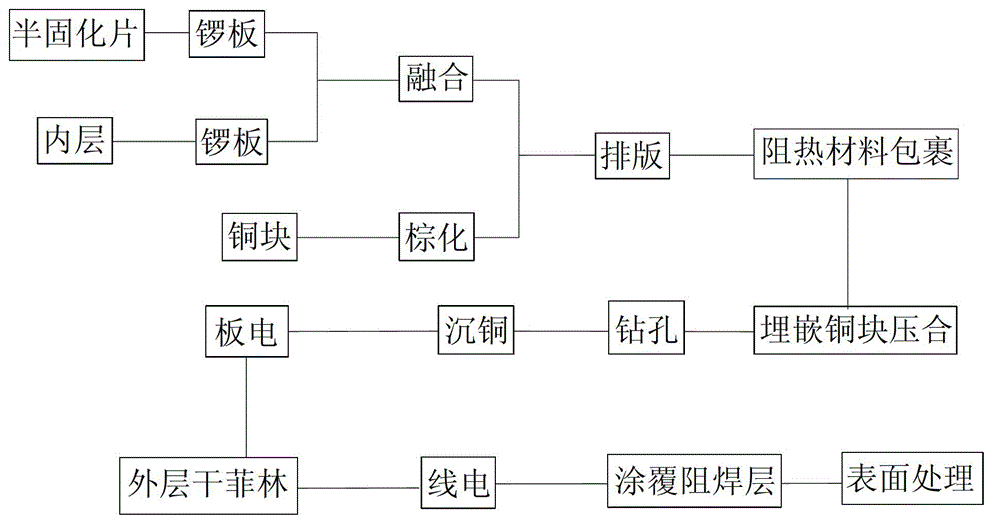

Circuit board with large current module and manufacturing method for circuit board

InactiveCN103338593AAvoid the frontPrevent problems such as broken drill bitsPrinted circuit assemblingPrinted circuit non-printed electric components associationCapacitanceSolder mask

The invention discloses a circuit board with a large current module and a manufacturing method for the circuit board and belongs to the technical field of circuit board manufacturing. The manufacturing method comprises the following steps of (1) routing and fusing an inner layer and a prepreg; (2) imbedding the large current module; (3) drilling; and (4) performing process of plated through hole (PTH), pattern plating, outer layer dry film plating, linear plating, solder mask coating and surface treatment. The circuit board with the large current module manufactured by the manufacturing method has the advantages that the integration cost of a system is reduced, the reliability is improved, the capacitance is increased, the impedance is reduced, wiring errors are reduced, a self-inductance coefficient is reduced, the thermal performance is improved and the space is saved. A powerful support in the aspect of electronic parts and components is provided for marketization acceleration of electric vehicles and hybrid electric vehicles.

Owner:KALEX MULTI LAYER CIRCUIT BOARD (ZHONGSHAN) CO LTD

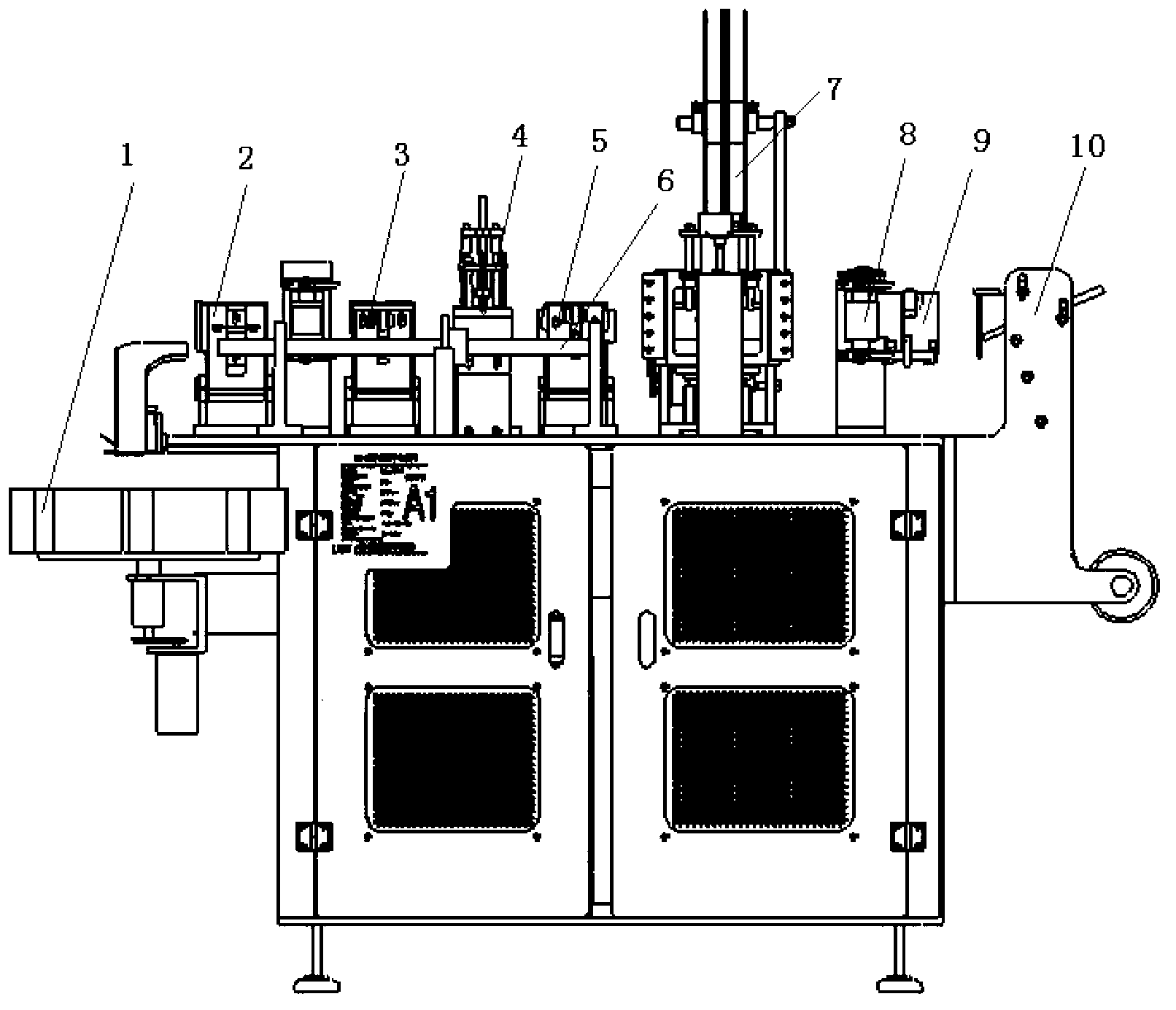

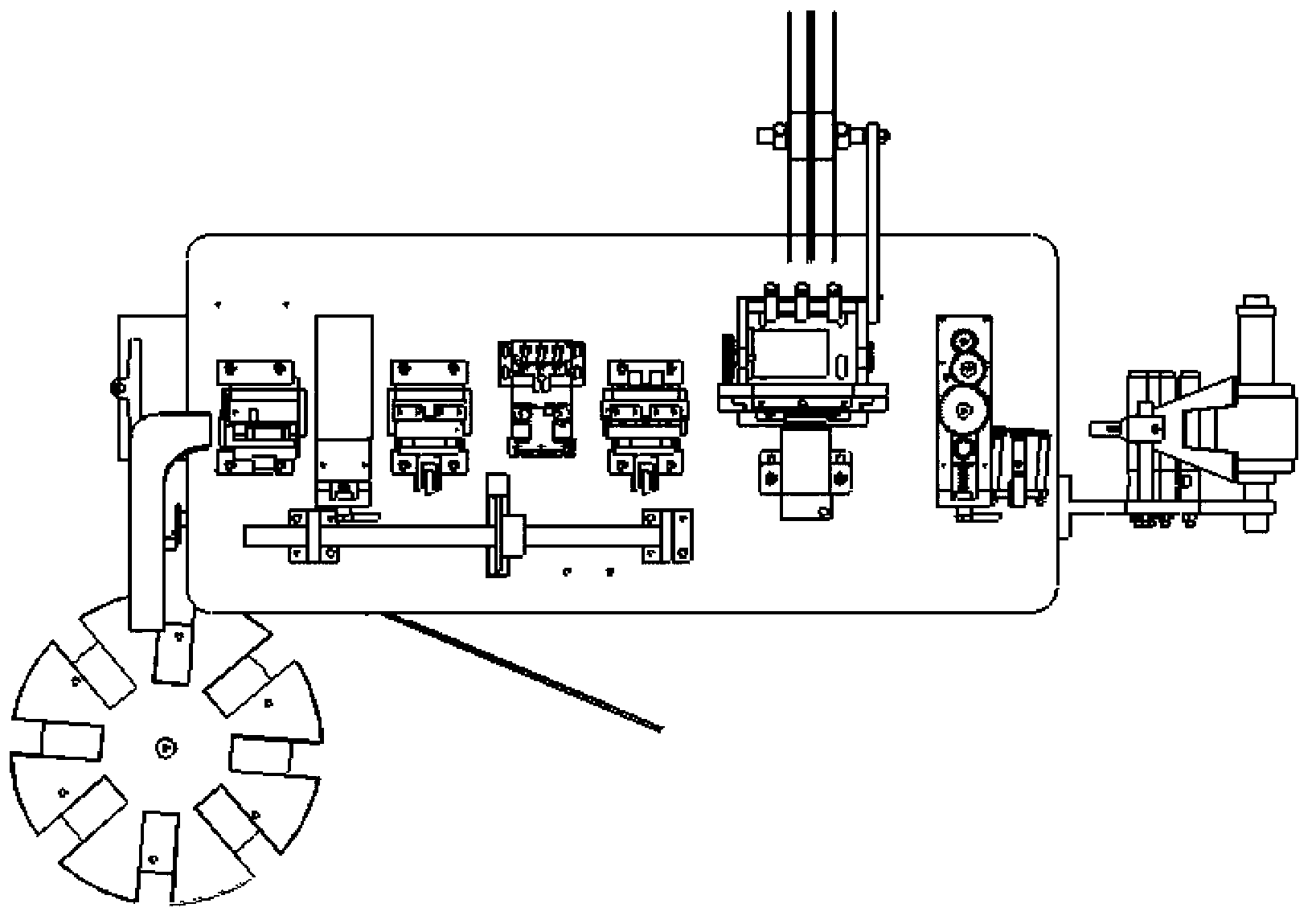

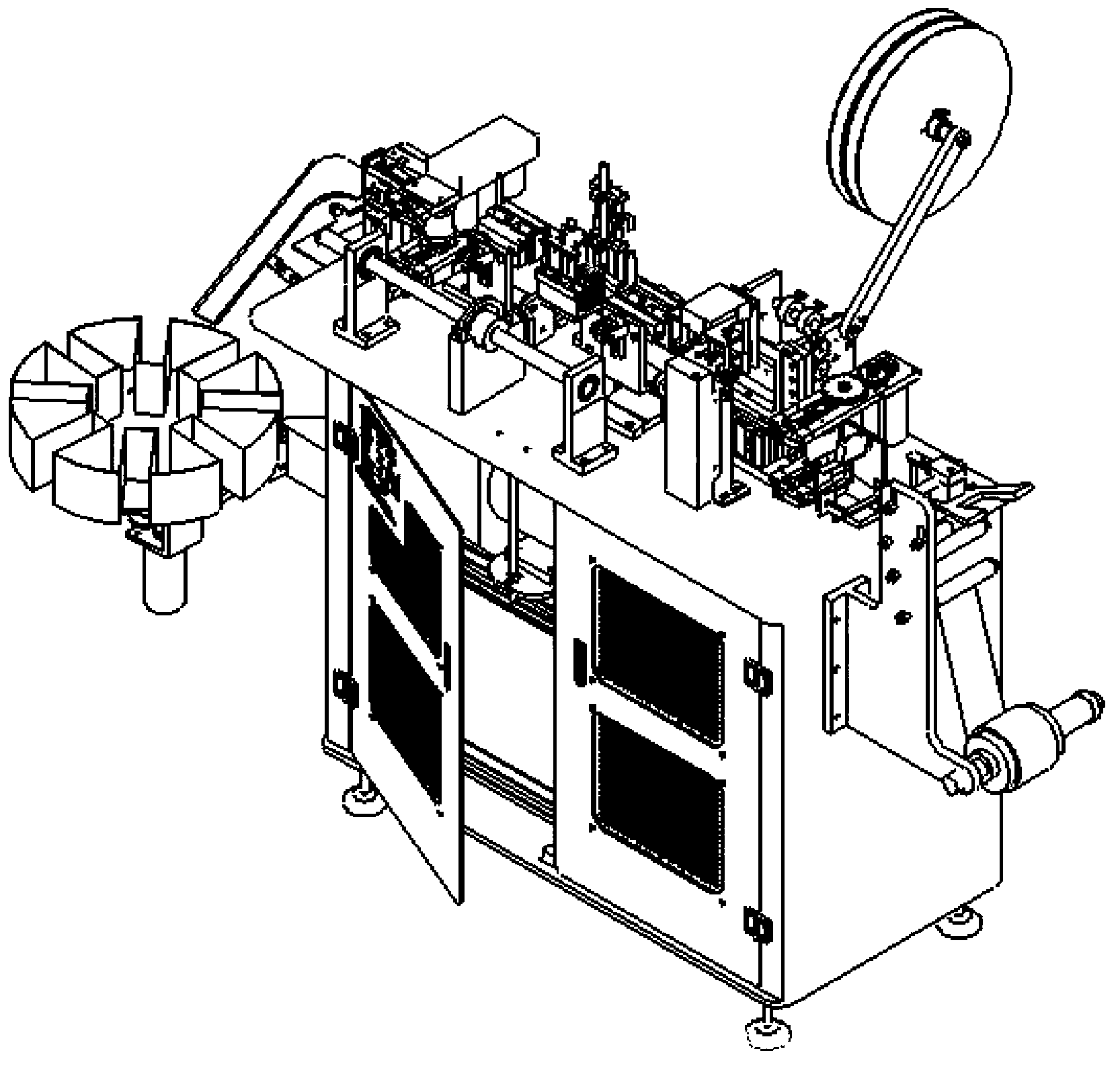

Efficient alcohol pad packer for finger-protective alcohol pad production

ActiveCN103287611AAvoid cross infectionFix technical deficienciesPaper article packagingWrapper twisting/gatheringAlcohol padsAutomation

The invention relates to an efficient alcohol pad packer for finger-protective alcohol pad production. The efficient alcohol pad packer comprises a workbench, a former, a light sensor, a packing paper feed mechanism, a liquid injection mechanism, a sealing mechanism and a finished product cutting mechanism. A core cutting and inserting mechanism and an epsilon-shaped core thermal sealing mechanism. The efficient alcohol pad packer has the advantages that the efficient alcohol pad packer is ingenious in design, simple in structure, high in practicality, and high in automation level, the advantages of original packers are inherited, the defects in the prior art are overcome, high-quality and efficiency production of the finger-protective alcohol pads and like products is achieved, process flow is simplified, equipment automation level is increased, and work efficiency is increased.

Owner:LIGHTS MEDICAL MFR

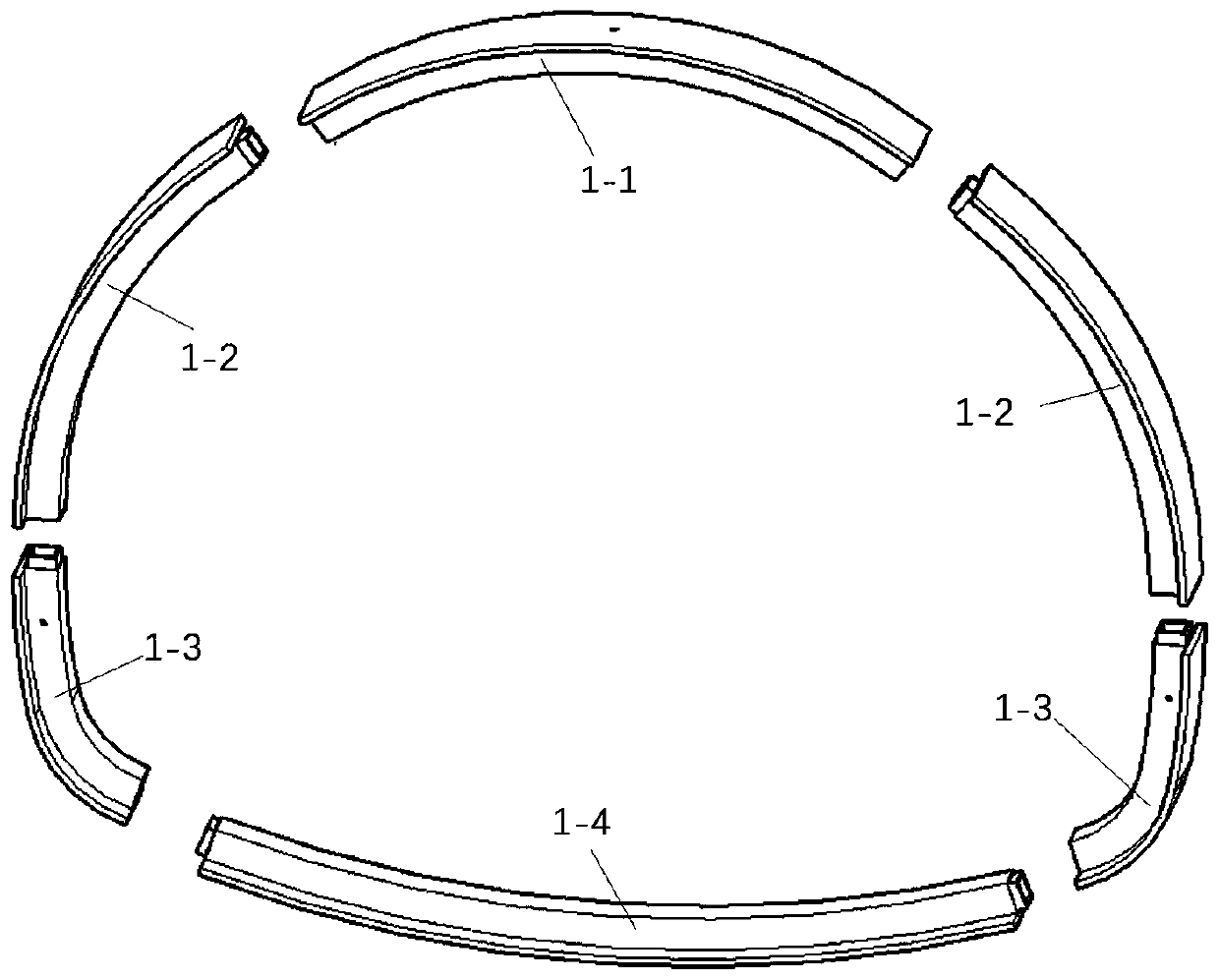

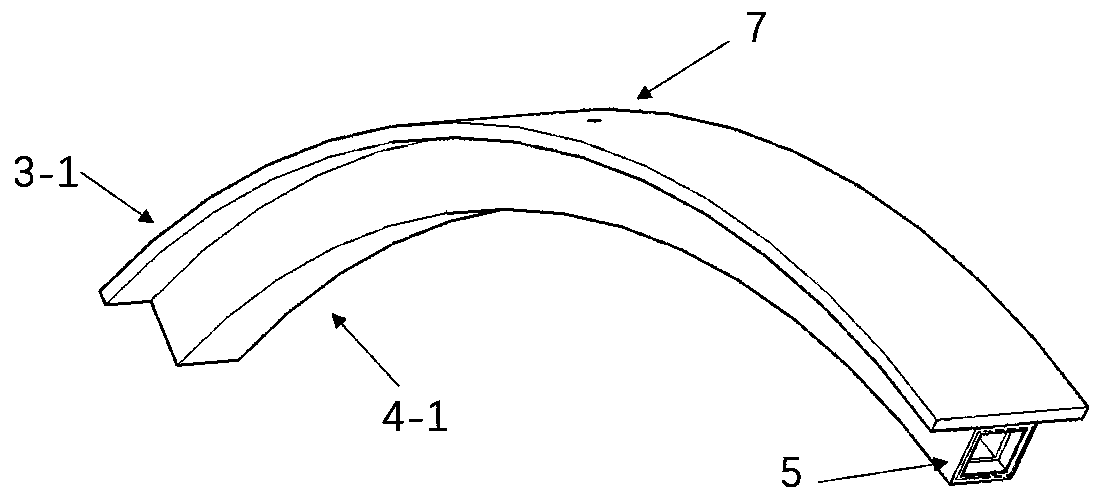

Loess tunnel supporting system and installation method thereof

PendingCN110259485AHigh strengthEasy maintenanceUnderground chambersTunnel liningSupporting systemCarrying capacity

The invention discloses a loess tunnel supporting system and an installation method thereof. The loess tunnel supporting system comprises a plurality of composite structure arches tightly distributed, each composite structure arch comprises a flange and a hollow pipe, the hollow pipe is installed on the inner side of the flange, and in-pipe concrete is poured into the hollow pipe; model-building concrete is poured between every two adjacent composite structure arches; and the composite structure arches are divided into arch top brackets, arch waist brackets, arch foot brackets and arch bottom brackets in the circumferential direction, the brackets are connected in a socket and spigot joint mode, and connection is compact and no gap exists. The composite structure arches, the in-pipe concrete and the model-building concrete act jointly, and the carrying capacity of tunnel preliminary support is improved. The loess tunnel supporting system combines the advantages of steel materials and the concrete and can effectively enable the steel materials and the concrete to be integrated, a composite structure with higher rigidity and high strength is formed, due to the fact that the concrete is wrapped with the steel materials, the concrete is in a triaxial compressive state, and development of the strength is more facilitated.

Owner:CHANGAN UNIV

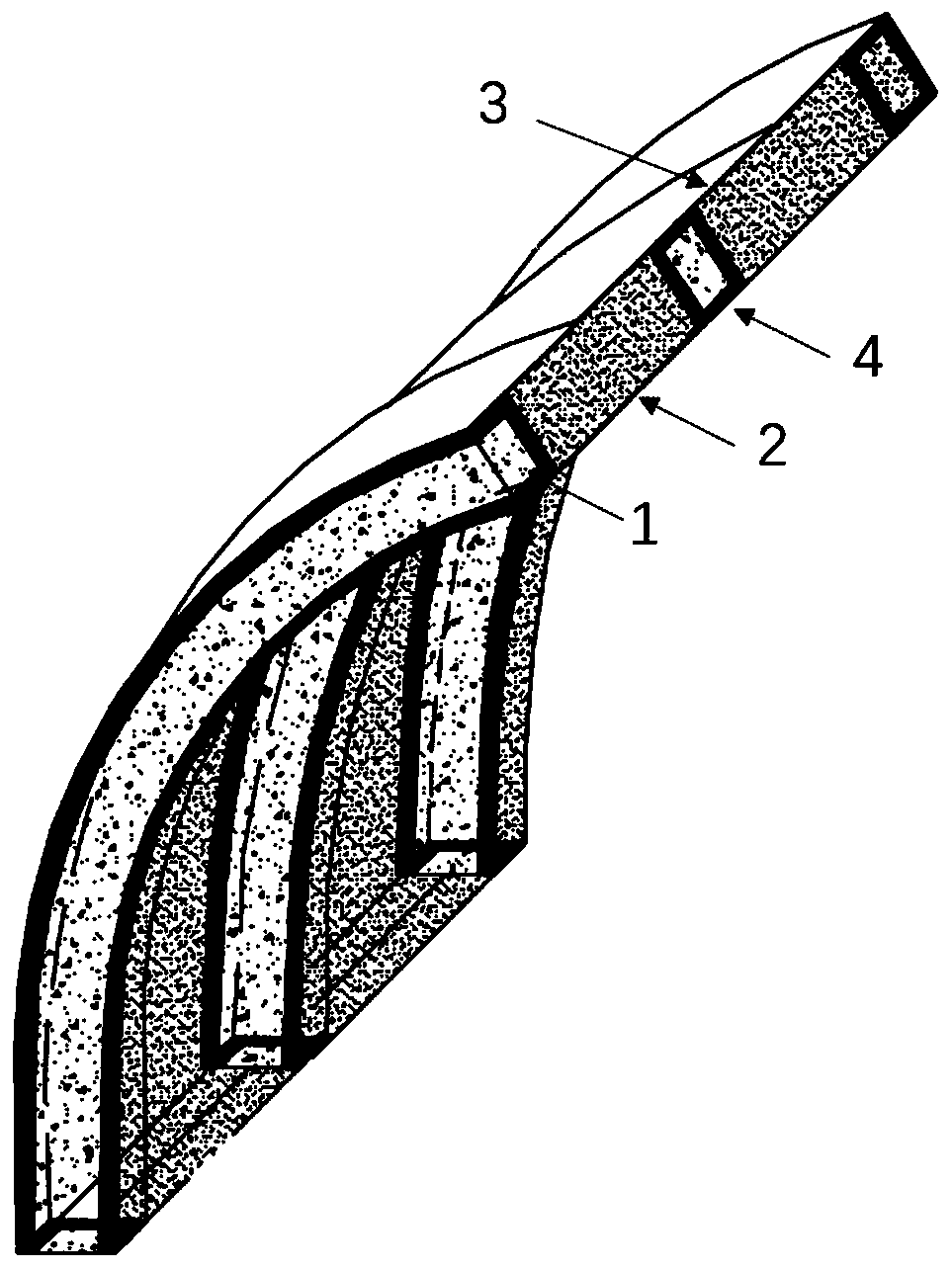

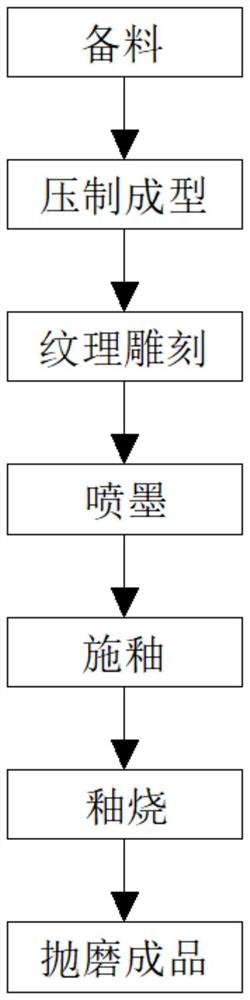

Rock plate with engraved textures and preparation method thereof

The invention discloses a rock plate with engraved textures and a preparation method thereof, the rock plate comprises a green body, auxiliary additives and ink, the green body comprises broad-peak water frosted sand, Jiaohui powder, calcined talc, 102 stone powder, an ultra-white pigment, FC ball clay, Jingle water frosted sand and Tianhe soil; the auxiliary additives comprise carboxymethyl cellulose sodium, a polymer reinforcing agent, a deflocculating agent No.2, sodium tripolyphosphate, a diluent and water glass, the ink comprises powder, a solvent, a dispersing agent, an anti-settling agent and a surfactant, and seven steps of material preparation, compression molding, texture carving, ink jetting, glazing, glaze firing and finished product polishing and grinding are performed, the rock plate can be realized without converting a press mold, the process flow is simplified, the concave-convex mold effect is generated visually and actually, and the colorful pattern has a more three-dimensional effect, and thus the rock plate with the engraved textures is vivid in texture and stronger in three-dimensional sense.

Owner:佛山市高明贝斯特陶瓷有限公司 +3

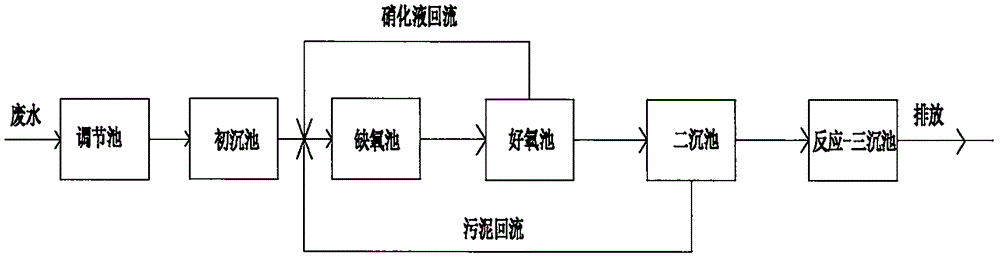

Treatment method of high-concentration refractory ammonia-containing organic wastewater

ActiveCN106673306AIncrease concentrationReduce loadWater contaminantsMultistage water/sewage treatmentHigh concentrationCheck point

The invention discloses a treatment method of high-concentration refractory ammonia-containing organic wastewater. The treatment method is characterized by comprising the following treatment steps of (1) homogenizing of quality and quantity of wastewater; (2) primary settling of wastewater; (3) denitrification of supernatant, and degrading of COD (chemical oxygen demand); (4) removal of COD, BOD (biochemical oxygen demand), ammonia and nitrogen out of primary treated water; (5) separation of mud and water of secondary mixing liquid; (6) removal of chroma of treated water, so as to reduce COD. The treatment method has the advantages that the number of treated buildings and structures is fewer, the number of equipment is fewer, the number of person operation and patrol check points is fewer, the operation and maintenance are simple and convenient, and the treatment efficiency of high-concentration refractory ammonia-containing organic wastewater is higher.

Owner:内蒙古金河环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com