Manufacturing method of explosion-proof mobile phone glass back cover and glass back cover

A production method and glass technology, which are applied in the direction of telephone structure, printing, printing device, etc., can solve the problems of GDM without explosion-proof effect, the thickness of the back cover of the mobile phone is large, which is not conducive to the production of ultra-thin mobile phones, etc., and achieves high yield and process flow. The effect of simplification and production cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

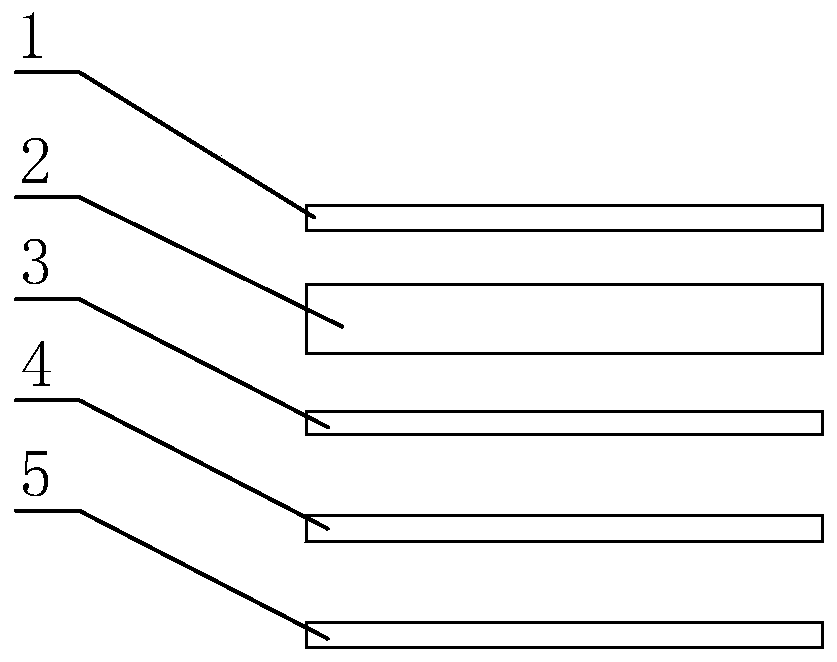

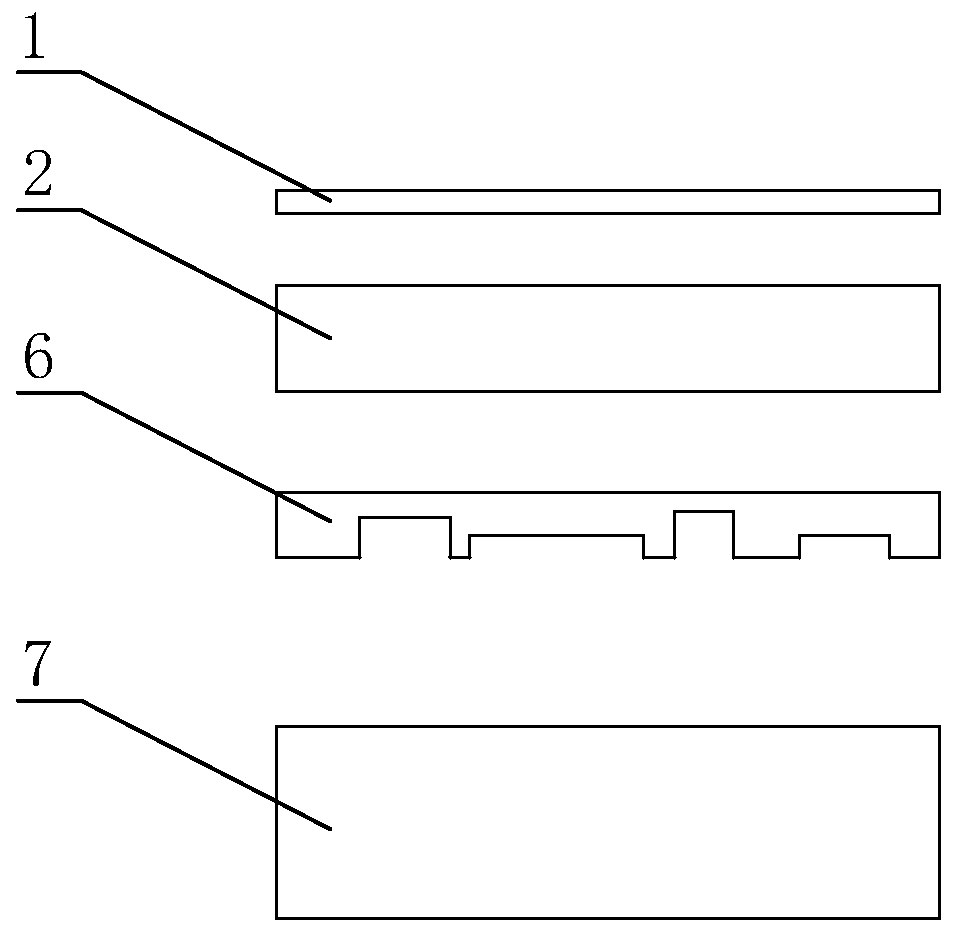

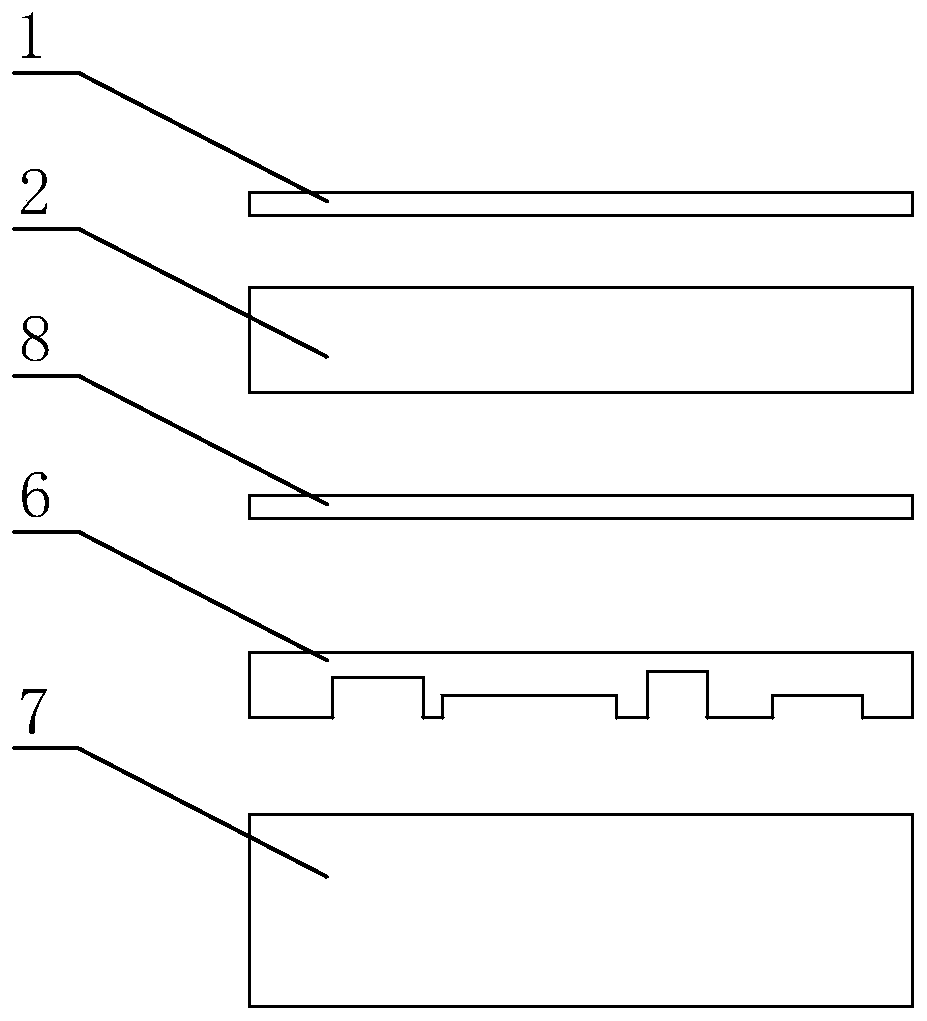

[0035] refer to Figure 2 to Figure 5 The embodiment of the manufacturing method of the explosion-proof mobile phone glass back cover of the present invention will be further described.

[0036] A method for manufacturing an explosion-proof mobile phone glass back cover, comprising the following steps,

[0037] 1) Print pattern layer: Print pattern ink 6 that needs to be printed on the inner surface of glass back cover 2 by gravure pad printing device, and solidify pattern ink 6 to form a pattern layer;

[0038] 2) Printing the explosion-proof layer: the explosion-proof ink 7 is printed on the top of the pattern layer by a gravure pad printing device, and the explosion-proof ink 7 is cured.

[0039] Such as Figure 5 As shown, the gravure pad printing device adopted in this embodiment mainly includes a gravure cylinder 91, a pad printing cylinder 92 and a jig 93, wherein the pad printing cylinder 92 is a rubber roller, and the gravure cylinder is made according to the patter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com