High-quality GH2132 alloy bar for fasteners and production method of high-quality GH2132 alloy bar

A GH2132, alloy bar technology, applied in furnaces, heat treatment equipment, manufacturing tools, etc., can solve the problems of unstable performance, poor organizational uniformity, restricting the development and production requirements of a new generation of aerospace vehicles and aero-engines, etc. Tensile yield strength at room temperature, stable performance, easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

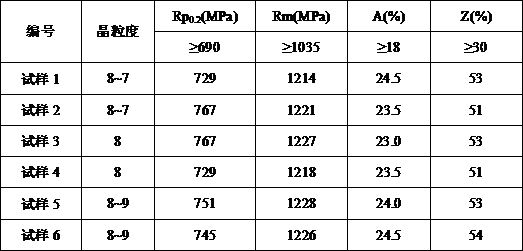

Examples

Embodiment 1

[0045] The high-quality GH2132 alloy bar for fasteners of the present embodiment includes each composition and weight percentage thereof as follows:

[0046] C: 0.04%;

[0047] Si: 0.32%;

[0048] Mn: 0.28%;

[0049] P: 0.010%;

[0050] S: 0.001%;

[0051] Cu: 0.15%;

[0052] Al: 0.15%;

[0053] V: 0.35%;

[0054] Cr: 14.60%;

[0055] Ni: 26.50%;

[0056] Mo: 1.20%;

[0057] Ti: 2.05%;

[0058] B: 0.005%;

[0059] O: 0.001%;

[0060] N: 0.001%;

[0061] Pb: ≤0.0005%;

[0062] Bi: 0.00001%;

[0063] Se: 0.0001%;

[0064] Ca: 0.002%;

[0065] Sn: 0.001%;

[0066] Mg: 0.001%;

[0067] Ag: 0.0002%;

[0068] Te: ≤0.00005%;

[0069] Tl: 0.00005%; the balance is iron;

[0070] The GH2132 alloy rods for the above-mentioned fasteners are prepared by the following method:

[0071] First, batching→vacuum induction melting→casting electrode→electrode surface treatment→vacuum self-consumption melting→steel ingot diffusion annealing→steel ingot surface treatment to obt...

Embodiment 2

[0082] The high-quality GH2132 alloy bar for fasteners of the present embodiment includes each composition and weight percentage thereof as follows:

[0083] C: 0.03%;

[0084] Si: 0.26%;

[0085] Mn: 0.25%;

[0086] P: 0.008%;

[0087] S: 0.001%;

[0088] Cu: 0.14%;

[0089] Al: 0.13%;

[0090] V: 0.33%;

[0091] Cr: 14.86%;

[0092] Ni: 26.62%;

[0093] Mo: 1.21%;

[0094] Ti: 2.07%;

[0095] B: 0.004%;

[0096] O: 0.001%;

[0097] N: 0.001%;

[0098] Pb: ≤0.0005%;

[0099] Bi: 0.00001%;

[0100] Se: 0.0001%;

[0101] Ca: 0.001%;

[0102] Sn: 0.001%;

[0103] Mg: 0.001%;

[0104] Ag: 0.0001%;

[0105] Te: ≤0.00001%;

[0106] Tl: 0.00004%; the balance is iron;

[0107] The GH2132 alloy rods for the above-mentioned fasteners are prepared by the following method:

[0108] First, batching→vacuum induction melting→casting electrode→electrode surface treatment→vacuum self-consumption melting→steel ingot diffusion annealing→steel ingot surface treatment to obt...

Embodiment 3

[0117] The high-quality GH2132 alloy bar for fasteners of the present embodiment includes each composition and weight percentage thereof as follows:

[0118] C: 0.02%;

[0119] Si: 0.24%;

[0120] Mn: 0.24%;

[0121] P: 0.007%;

[0122] S: 0.001%;

[0123] Cu: 0.13%;

[0124] Al: 0.12%;

[0125] V: 0.31%;

[0126] Cr: 14.63%;

[0127] Ni: 26.31%;

[0128] Mo: 1.18%;

[0129] Ti: 2.04%;

[0130] B: 0.01%;

[0131] O: 0.001%;

[0132] N: 0.001%;

[0133] Pb: ≤0.0005%;

[0134] Bi: 0.00001%;

[0135] Se: 0.0001%;

[0136] Ca: 0.002%;

[0137] Sn: 0.002%;

[0138] Mg: 0.002%;

[0139] Ag: 0.0002%;

[0140] Te: ≤0.00001%;

[0141] Tl: 0.00005%; the balance is iron;

[0142] The GH2132 alloy rods for the above-mentioned fasteners are prepared by the following method:

[0143] First, batching→vacuum induction melting→casting electrode→electrode surface treatment→vacuum self-consumption melting→steel ingot diffusion annealing→steel ingot surface treatment to obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com