Precise heat treatment method of nickel-based deforming high-temperature alloy workpiece

A technology of deformed superalloy and heat treatment method, which is applied in the direction of material thermal analysis, material thermal development, sampling device, etc. Different problems such as excellent room temperature mechanical properties and high temperature durability, excellent comprehensive performance, and good batch consistency are achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

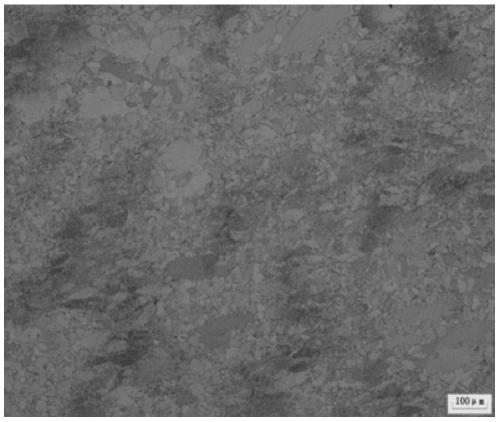

Embodiment 1

[0030] In the precise heat treatment method of this nickel-based deformed superalloy, the chemical composition and weight percentage of the nickel-based deformed superalloy material are: Cr: 13.02%; Co: 15.50%; Mo: 4.12%; W: 3.87%; Al : 3.56%; Ti: 2.61%; Nb: 2.73%; C: 0.045%; the balance is Ni and unavoidable impurities. Melting and forging the above-mentioned nickel-based deformed superalloy to make rods, the melting and billeting process of the above-mentioned nickel-based deformed superalloy are as follows:

[0031] Vacuum induction furnace smelting: Put the prepared raw materials into the vacuum induction furnace for smelting, control the smelting vacuum degree to 0.1Pa, control the refining temperature of the alloy melt to 1560°C during the smelting process; tap the steel at the end of smelting, control the tapping and pouring temperature to 1460°C ; Pouring the alloy melt into a consumable electrode rod;

[0032] Vacuum consumable remelting: put the alloy electrode smel...

Embodiment 2

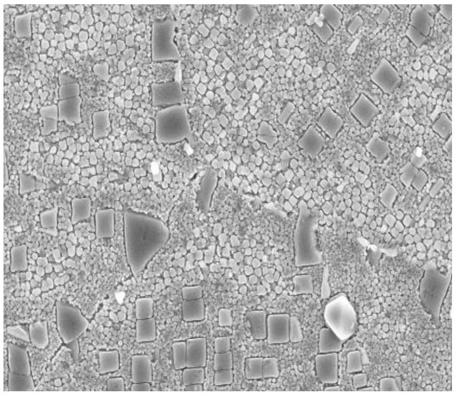

[0044] In the precise heat treatment method of this nickel-based deformed superalloy, the chemical composition and weight percentage of the nickel-based deformed superalloy material are: Cr: 10.52%; Co: 14.81%; Mo: 5.53%; W: 4.06%; Al : 3.15%; Ti: 3.08%; Nb: 3.19%; C: 0.056%; the balance is Ni and unavoidable impurities. Smelting and forging the above-mentioned nickel-based deformed superalloy to make rods, the process of smelting and blanking is the same as in Example 1;

[0045] Adopt the thermal treatment process of the inventive method to be:

[0046] Step 1. Cut a sample block on the nickel-based deformed superalloy, and use the differential thermal analysis method to measure the complete dissolution temperature T of the γ' phase γ′ is 1151°C;

[0047] Step 2. According to the complete dissolution temperature T of the γ' phase γ′ To 1151 ℃, multi-stage composite heat treatment is performed on nickel-based deformed superalloy parts. The steps of this composite heat trea...

Embodiment 3

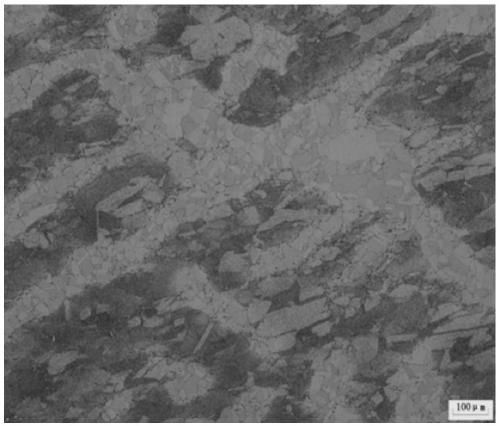

[0055] In the precise heat treatment method of this nickel-based deformed superalloy, the chemical composition and weight percentage of the nickel-based deformed superalloy material are: Cr: 14.16%; Co: 16.80%; Mo: 5.08%; W: 4.87%; Al : 4.11%; Ti: 3.46%; Nb: 3.40%; C: 0.060%; the balance is Ni and unavoidable impurities. Smelting and forging the above-mentioned nickel-based deformed superalloy to make rods, the process of smelting and blanking is the same as in Example 1;

[0056] Adopt the thermal treatment process of the inventive method to be:

[0057] Step 1. Cut a sample block on the nickel-based deformed superalloy, and use the differential thermal analysis method to measure the complete dissolution temperature T of the γ' phase γ′ is 1173°C;

[0058] Step 2. According to the complete dissolution temperature T of the γ' phase γ′ To 1173 ℃, multi-stage composite heat treatment is performed on nickel-based deformed superalloy parts. The steps of this composite heat trea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com