Patents

Literature

113results about How to "Improve high temperature durability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-fire resistance A1-Cu-Mg-Ag alloy

InactiveCN101245430AIncreased Ag contentExcellent high-temperature short-term tensile propertiesTemperature stressStructure property

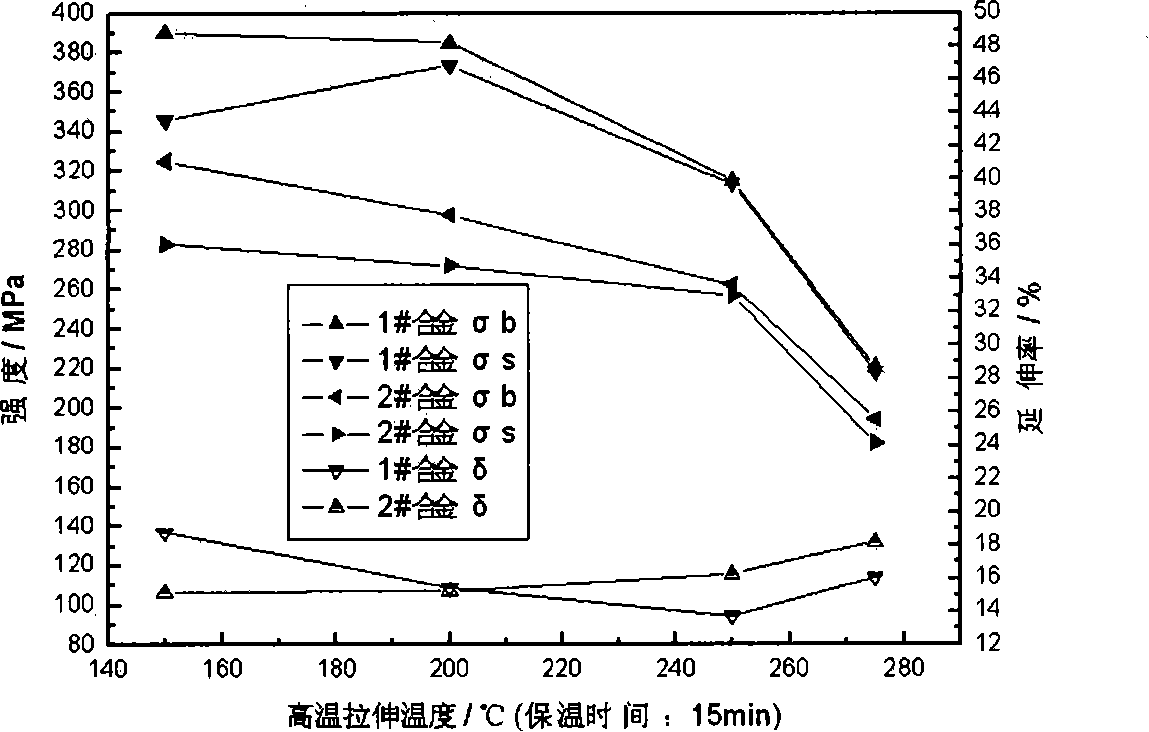

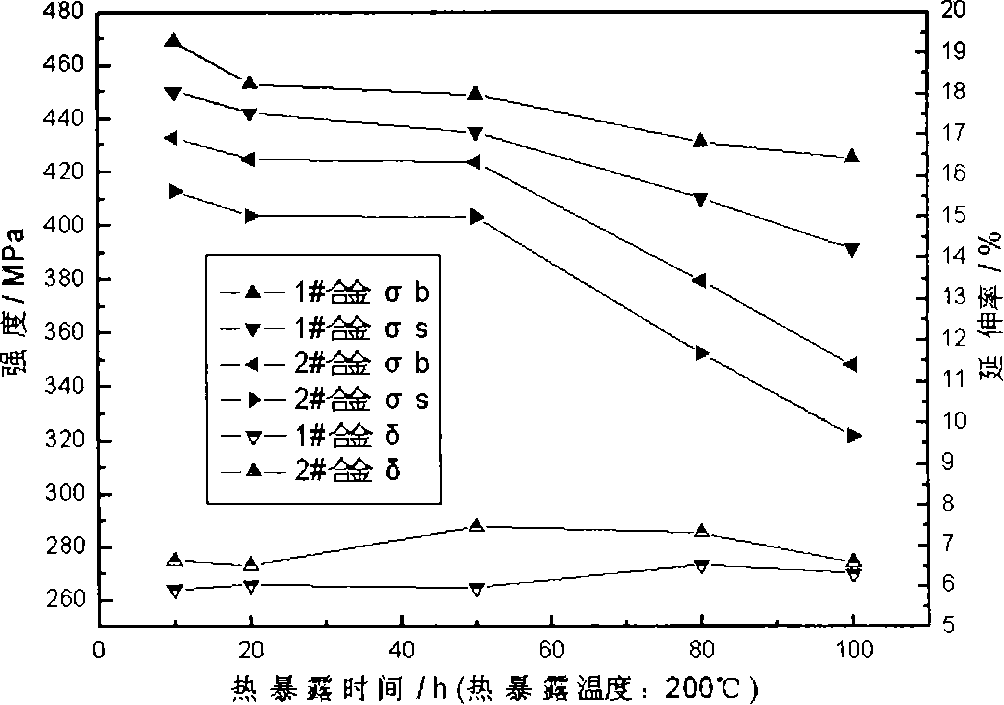

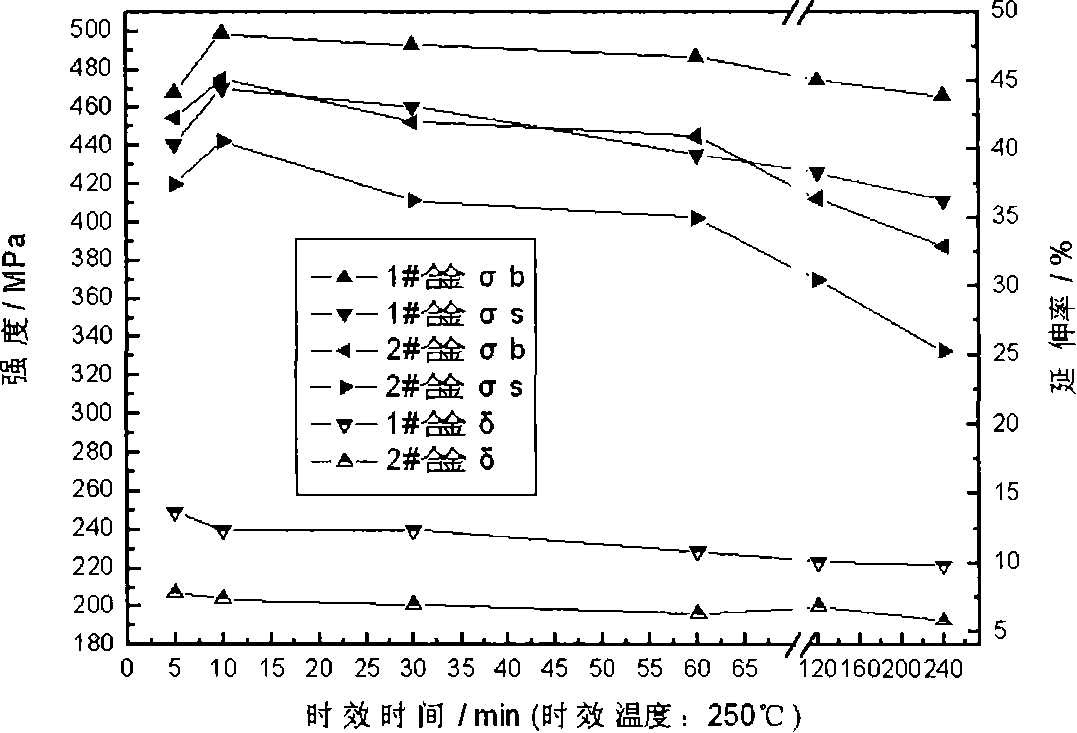

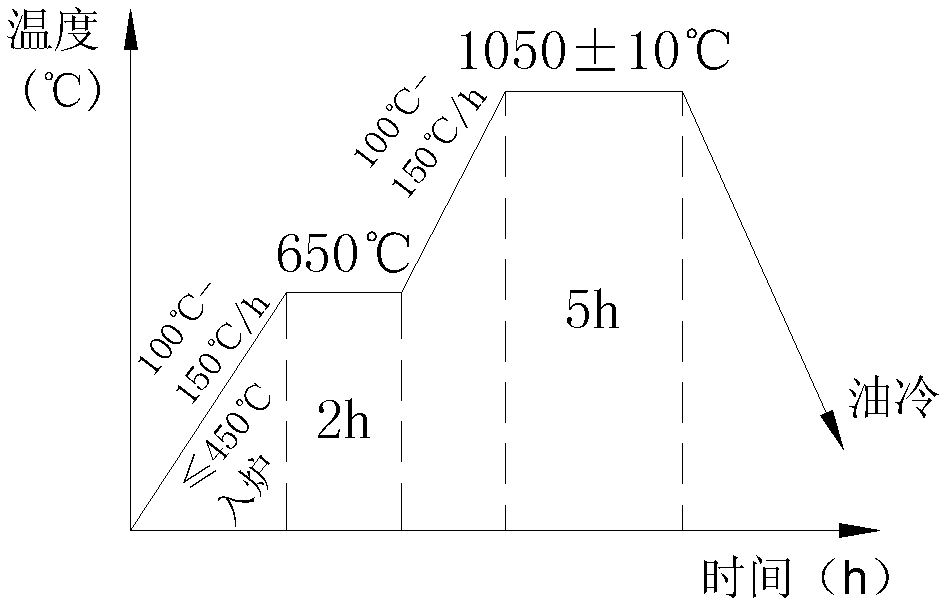

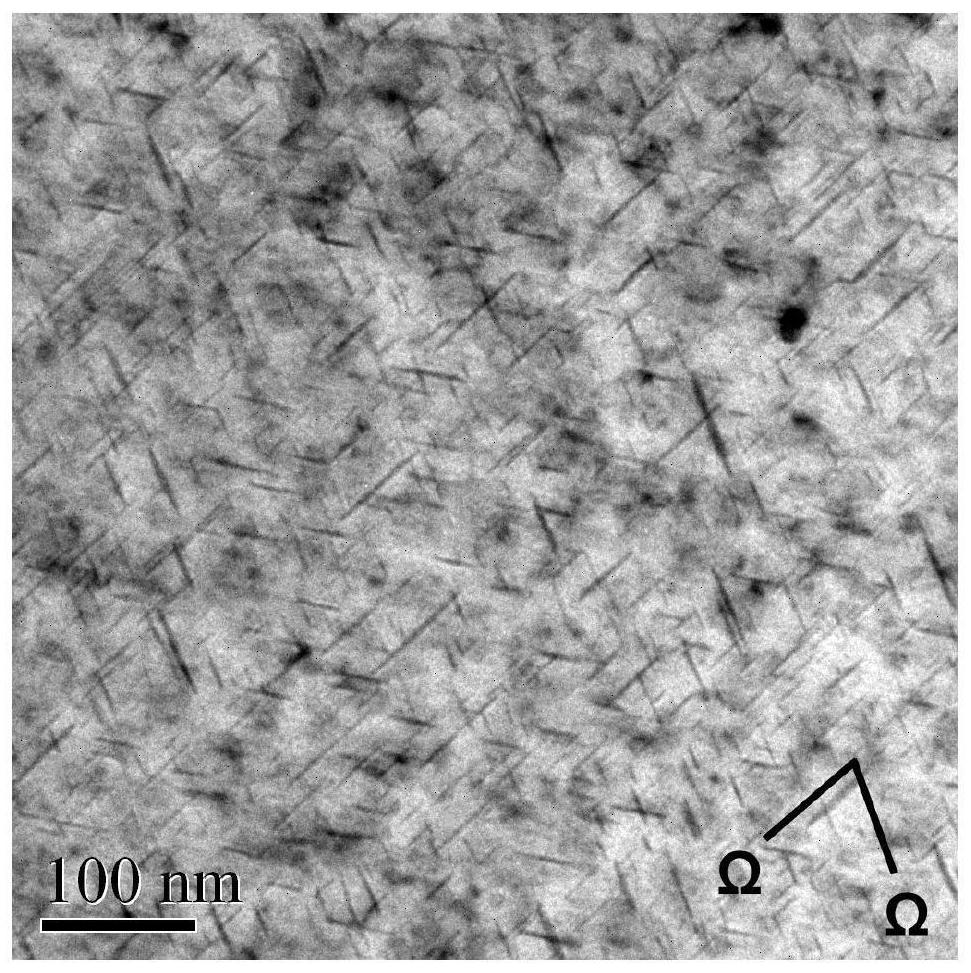

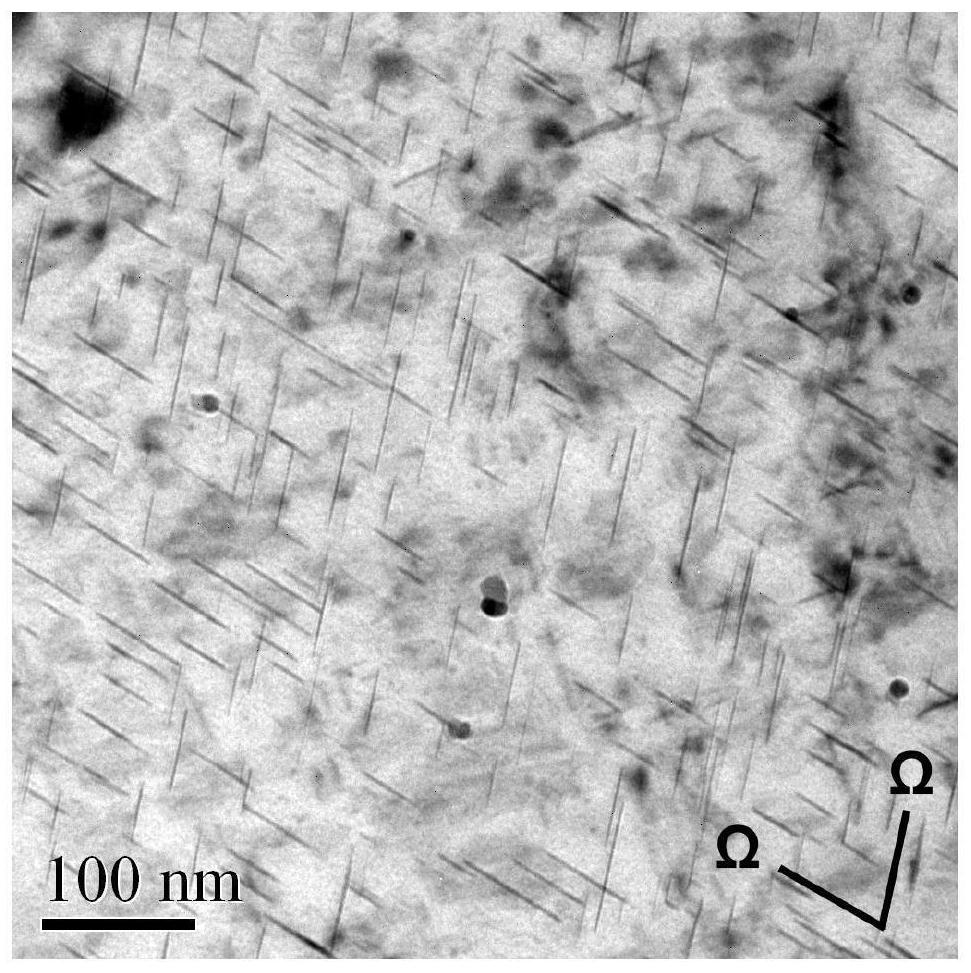

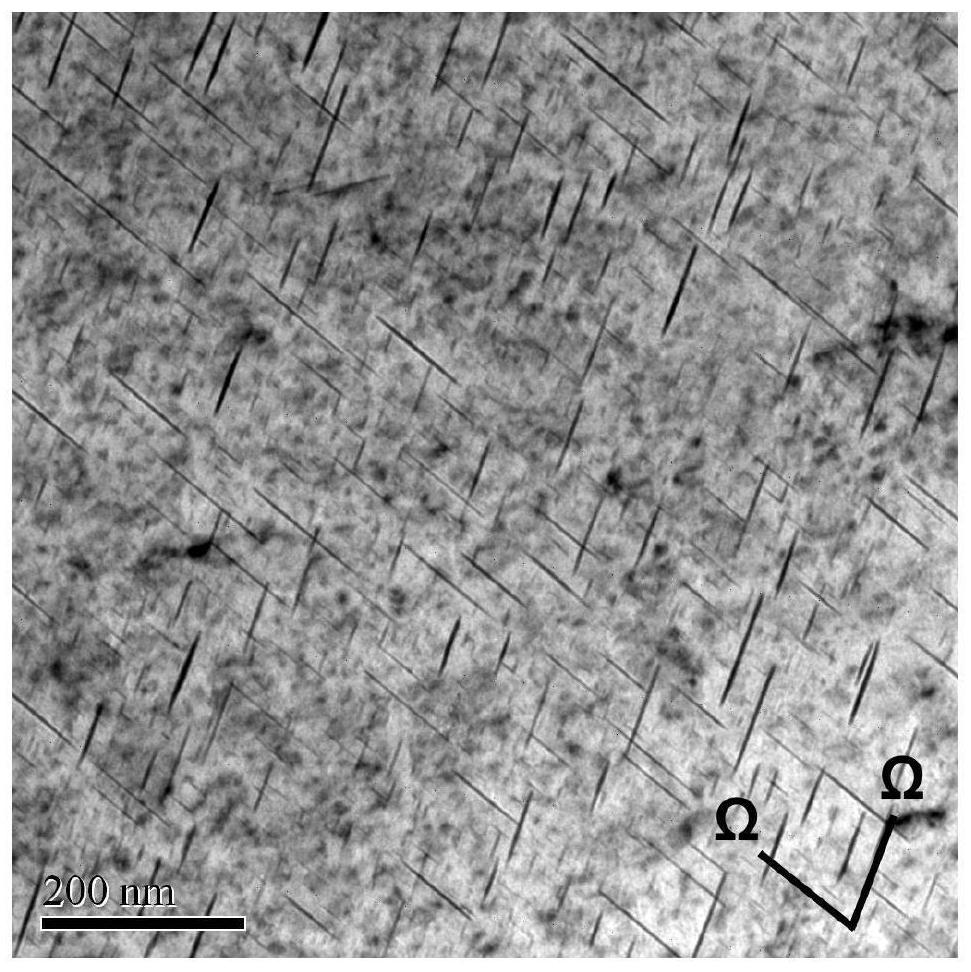

The invention discloses an Al-Cu-Mg-Ag alloy with high heat resistance, the components of which by weight percentage are: 4.6-6.6 percent of Cu, 0.4-0.65 percent of Mg, 1-1.5 percent of Ag, 0-0.06 percent of Fe, 0-0.06 percent of Si, 0.25-0.35 percent of Mn, 0.1-0.2 percent of Zr and the rest is Al. In the invention, the content of Ag in the Al-Cu-Mg-Ag alloy is increased and the atomic ratio of the Ag / Mg is properly increased, which results in that the alloy matrix has more Ohm phase nucleation sites and the Al-Cu-Mg-Ag alloy has more Ohm phases under high temperature, the alloy matrix obtains large amount of dispersed and fine strengthening phases to ensure that the Al-Cu-Mg-Ag alloy has excellent high-temperature short-time tensile property, high temperature stress rupture property, and good structure property and stability after long term thermal exposure; furthermore, the room temperature mechanical properties of the Al-Cu-Mg-Ag alloy of the invention is also superior to that of the existing Al-Cu-Mg-Ag alloy.

Owner:CENT SOUTH UNIV

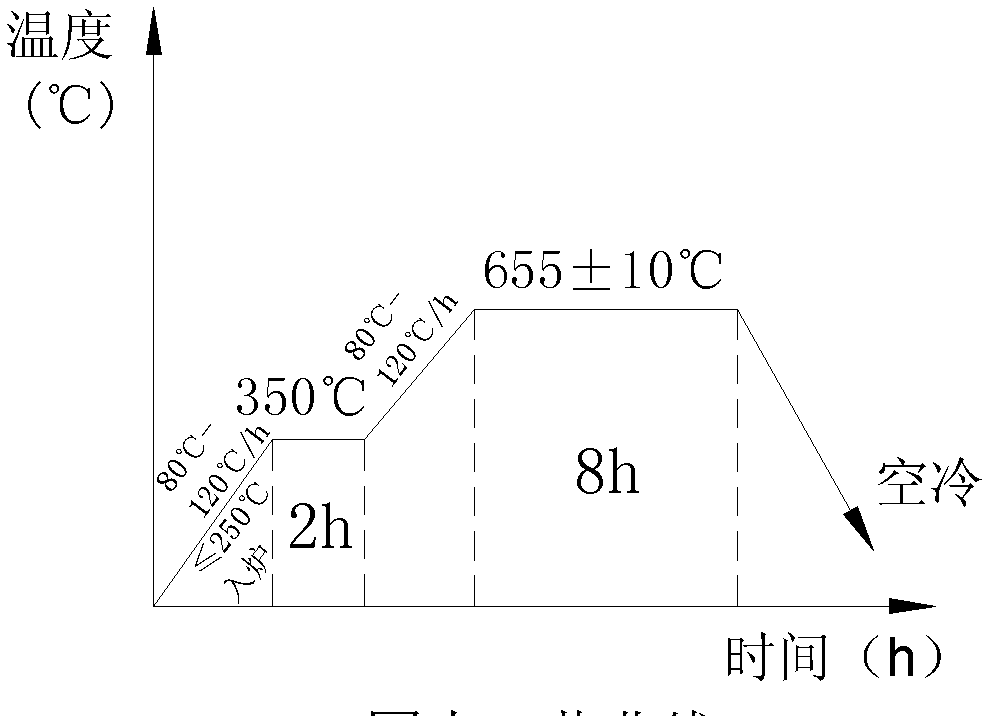

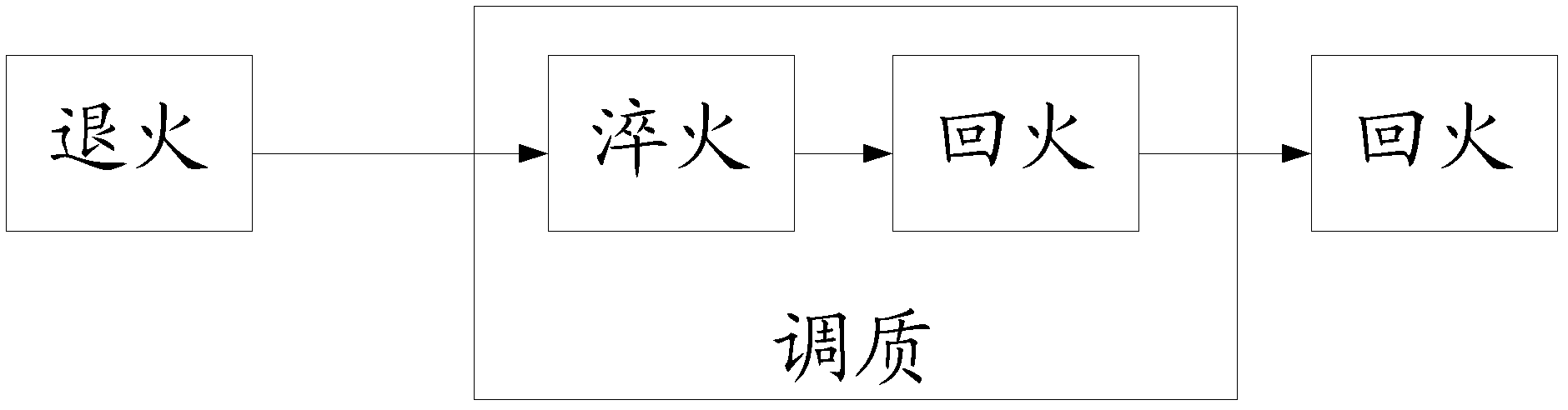

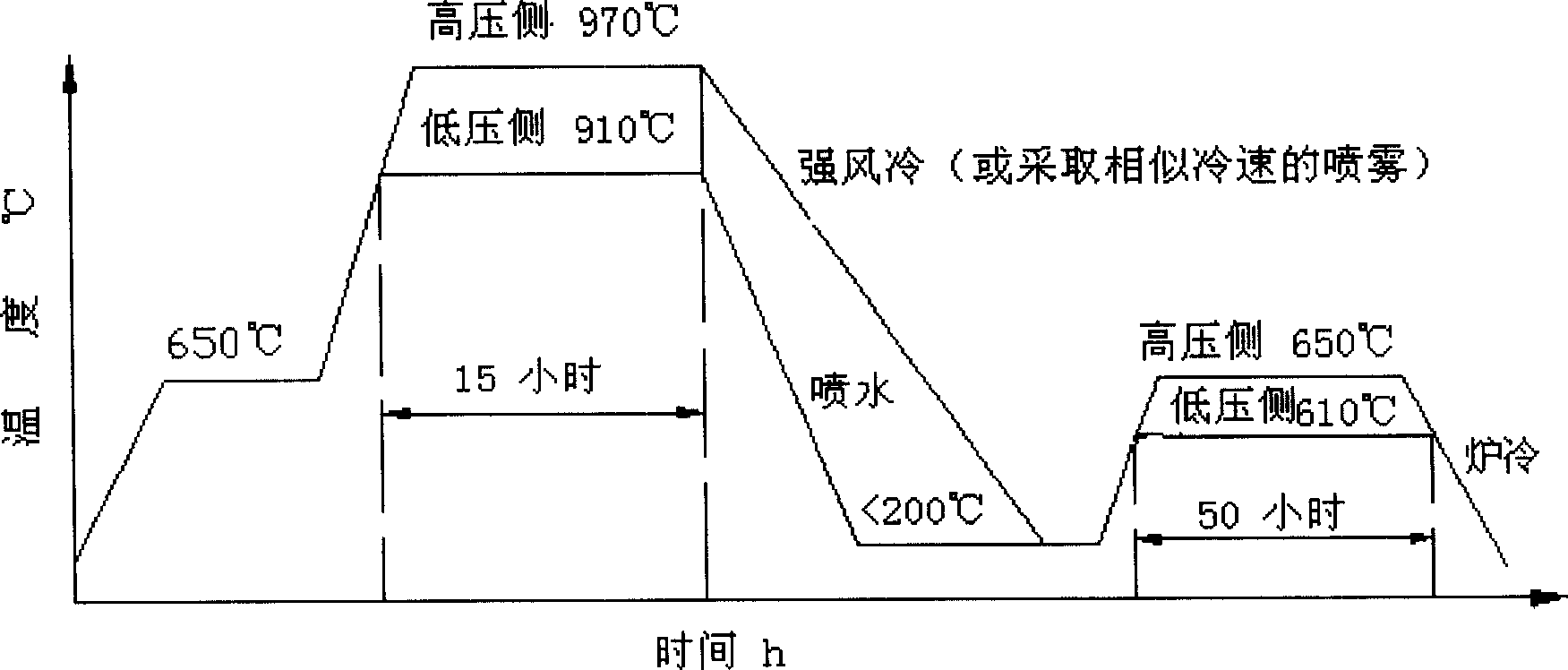

Heat treatment method for stainless steel heat-resistant steel forging

ActiveCN102586550AAdded secondary tempering stepGuaranteed StrengthUltimate tensile strengthQuenching

The invention relates to the metal heat treatment technical field, and especially relates to a heat treatment method for a stainless steel heat resistant steel forging, the heat treatment method can enhance the high temperature endurance performance of the treated workpieces, and is especially suitable for heat treatment of a high temperature part nozzle reinforcing ring of a 600MW steam turbine. The method comprises the following steps: adding an annealing process before quenching and tempering treatment, heating the stainless steel heat resistant steel forging with the speed of 30-80 DEG C / h to the temperature of 900-940 DEG C in the annealing step, insulating for 7-9 hours, then cooling in furnace to the temperature of 450-550 DEG C and air cooling. The method of the invention can improve the original structure of the stainless steel heat resistant steel forging and refine the grain size, and prepare for the subsequent quenching and tempering treatment; in the subsequent quenching and tempering step, by controlling a process curve and guaranteeing the condition of product strength, the grain size can be controlled at 2-4 level, and the high temperature endurance performance can be enhanced.

Owner:重庆新承航锐科技股份有限公司

Nickel base casting high temperature alloy for high temperature mould

ActiveCN1718803AImprove performanceImprove high temperature durabilityChemical compositionOxidation resistant

A high-temp casting Ni-base alloy for high-temp die contains proportionally Co, Al, Cr, Ti, W, Mo, No, Ta, Hf, C, B, Y and Ni. Its advantages are high high-temp strength, plasticity, anti-oxidizing, performance and stability, and better thermal fatigure nature.

Owner:BEIJING AVIATION MATERIAL INST NO 1 GRP CORP CHINA AVIATION IND

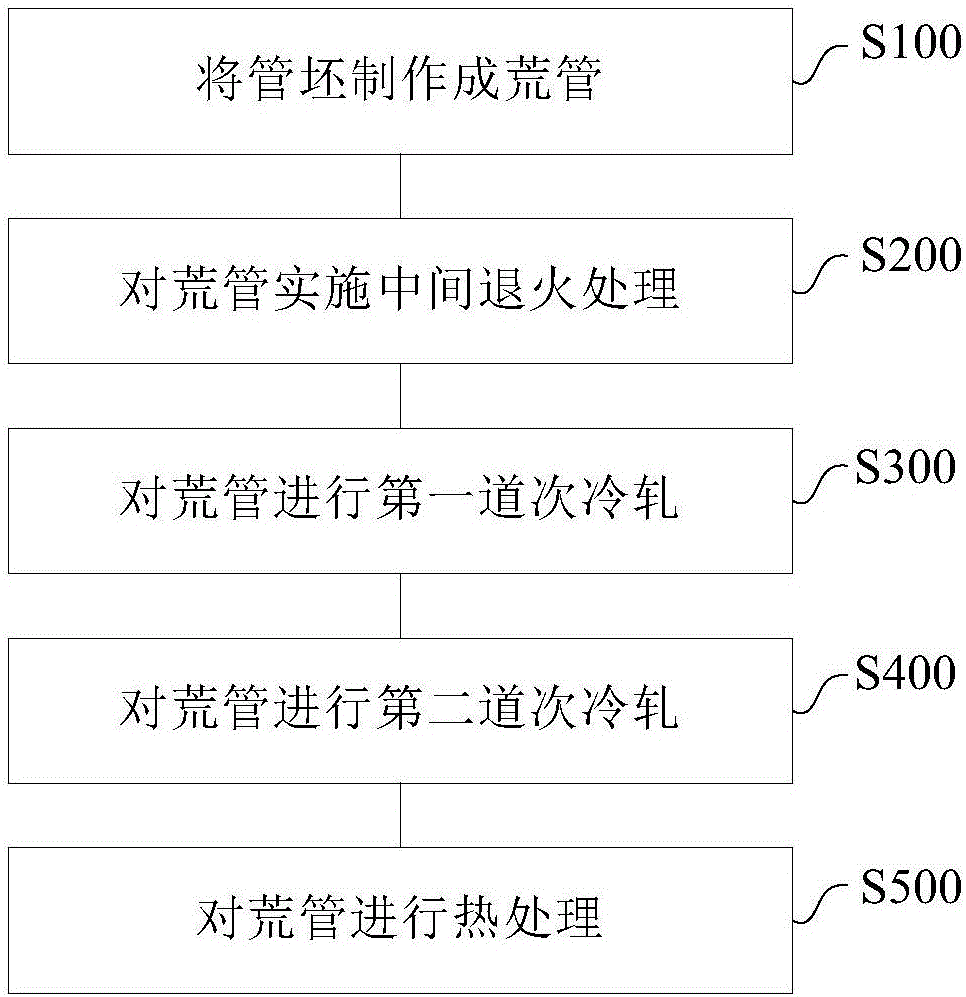

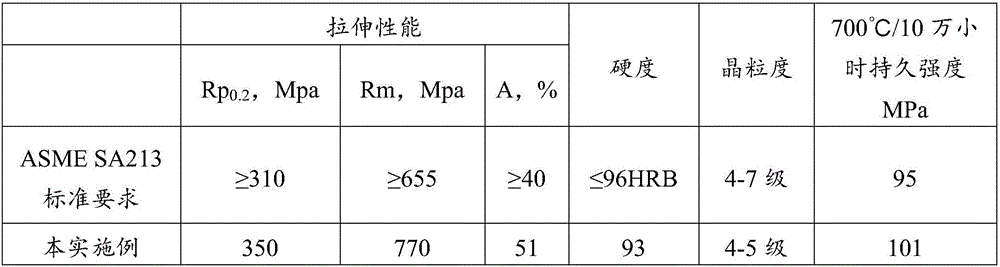

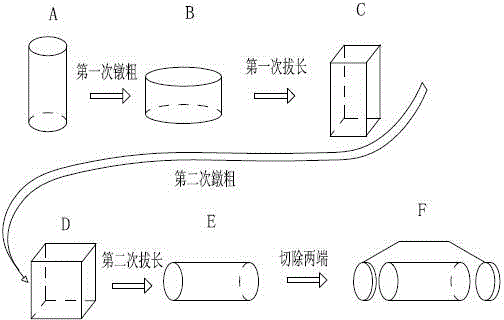

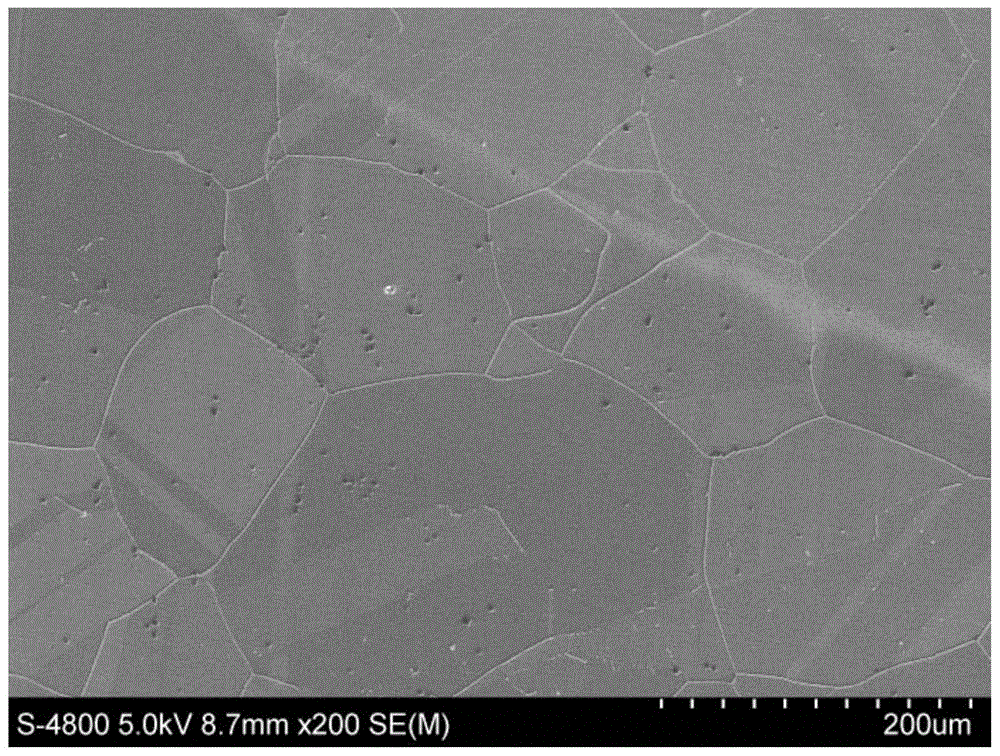

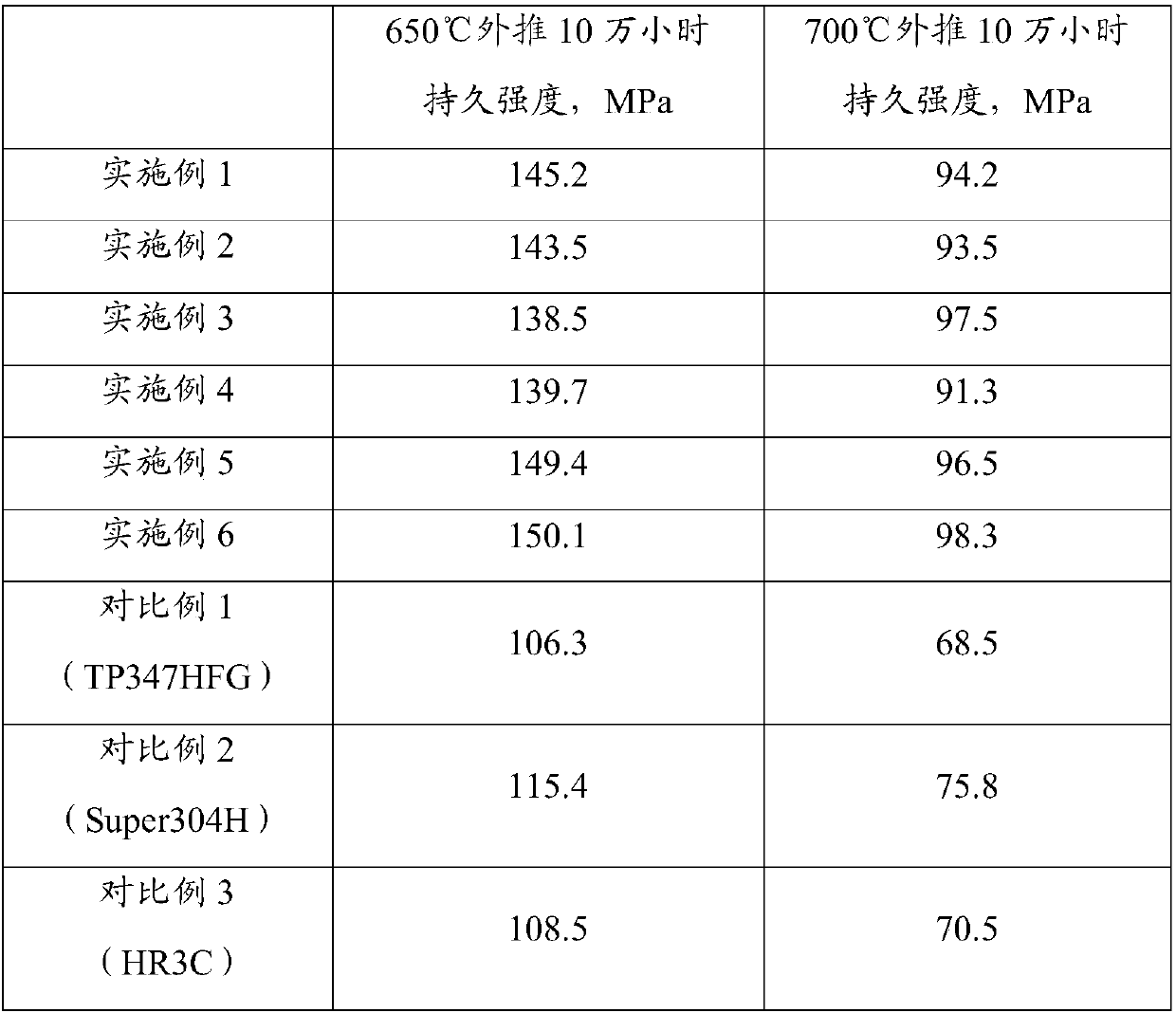

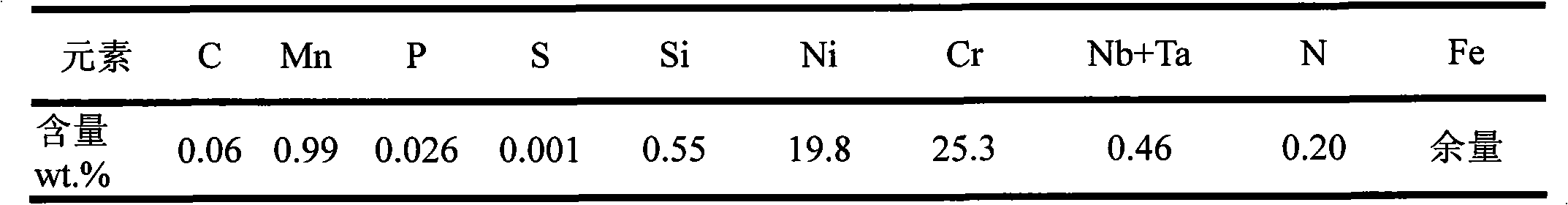

Manufacturing method of wolfram-contained austenite stainless steel seamless tube

InactiveCN106702259AImprove grain uniformityImprove room temperature performanceFurnace typesMetal rolling arrangementsHeat treatedAustenitic stainless steel

The invention discloses a manufacturing method of a wolfram-contained austenite stainless steel seamless tube. The method comprises following steps: 11, a tube blank is manufactured into a pierced billet, in the process of manufacturing the pierced billet, the extrusion ratio of extrusion to the pierced billet ranges from 6 to 12, and the extrusion speed ranges from 130 to 180mm / s; 12, the pierced billet is subject to first-pass cold rolling, and the pass deformation amount of the first-pass cold rolling ranges from 40% to 60%; 13, intermediate annealing treatment is applied to the pierced billet subject to first-pass cold rolling, the annealing temperature ranges from 1120 DEG C to 1200 DEG C, and heat preservation is carried out for 30 min to 60 min; 14, second-pass cold rolling is applied to the pierced billet subject to intermediate annealing treatment, and the pass deformation amount of the second-pass cold rolling is controlled to range from 35% to 50%; 15, the pierced billet subject to second-pass cold rolling is subject to heat treatment, temperature of heat treatment ranges from 1150 DEG C to 1250 DEG C, and heat preservation is carried out for 30 min to 60 min. The manufacturing method solves the problem that the product quality of a wolfram-contained austenite stainless steel seamless tube manufactured at present is poor.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Precise heat treatment method of nickel-based deforming high-temperature alloy workpiece

ActiveCN109576621AIdeal grain structureImprove uniformityMaterial heat developmentWithdrawing sample devicesSolution treatmentAfter treatment

The invention discloses a precise heat treatment method of a nickel-based deforming high-temperature alloy workpiece. According to the technical scheme, the nickel-based deforming high-temperature alloy workpiece of each melt is sampled, testing is carried out, and complete dissolution temperature Tgamma' of a real gamma' phase is obtained. A multistage composite heat treatment system is adopted,before solid solution treatment, according to the tested Tgamm', corresponding pretreatment is adopted, the nickel-based deforming high-temperature alloy workpiece obtains a grain structure with gooduniformity, and the forging grain structure with uneven alloy can be removed. The nickel-based deforming high-temperature alloy workpiece obtained after treatment has the excellent comprehensive property, particularly, the excellent room temperature mechanical property and high-temperature durable property can be achieved, the mechanical property batch consistency is good, due to considering of actual batch gamma' phase complete dissolving temperature, compared with a traditional heat treatment system, the alloy room temperature tensile yield strength is improved by about 8% on average, the tensile strength is improved by about 5% on average, and the high-temperature durable service life is prolonged by above 20h.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

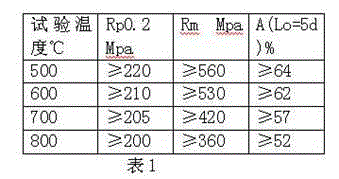

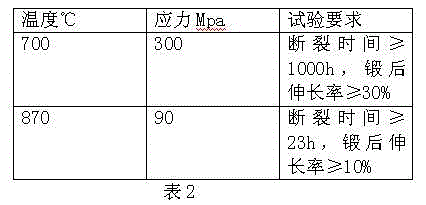

Forging method for high-temperature alloy GH3617M forged pieces

ActiveCN104801645AUniform temperatureMeet the use requirementsMetal-working apparatusThree stageRoom temperature

The invention relates to a forging method for high-temperature alloy GH3617M forged pieces. According to the forging method, by heating and heat-insulating processes of three stages, the internal and external temperature of a cast ingot can be uniform through staged heating, temperature difference is reduced, and crystal grains are prevented from being coarse and bulky; the grain size of the forged pieces obtained by using the method provided by the invention is not coarser than a level 4, and coarse and fine inclusions of the forged pieces do not exceed a level 2; through three forging stages, after solution annealing, the forged pieces have the characteristics that the room-temperature yield property is not lower than 320Mpa, the room-temperature tensile property is 700-980Mpa, the elongation percentage is not lower than 35%, the end face shrinkage ratio is not lower than 35%, the impact property is not lower than 120J, the hardness HBW is 200-250, the high-temperature instantaneous mechanical properties and high-temperature endurance strength are greatly improved, and thus, the use requirements of a gas turbine are effectively met.

Owner:WUXI PAIKE HEAVY CASTING & FORGING

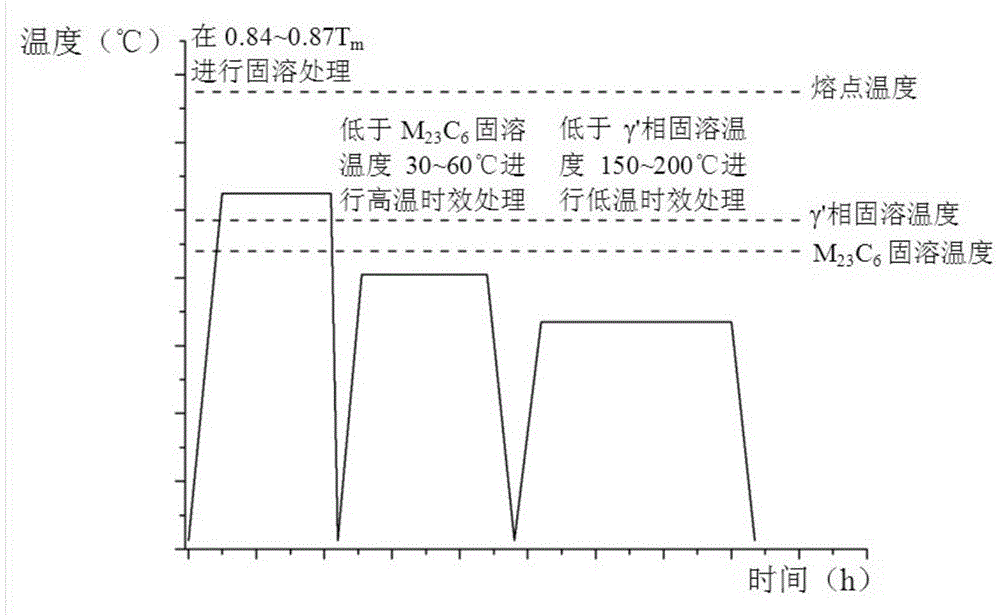

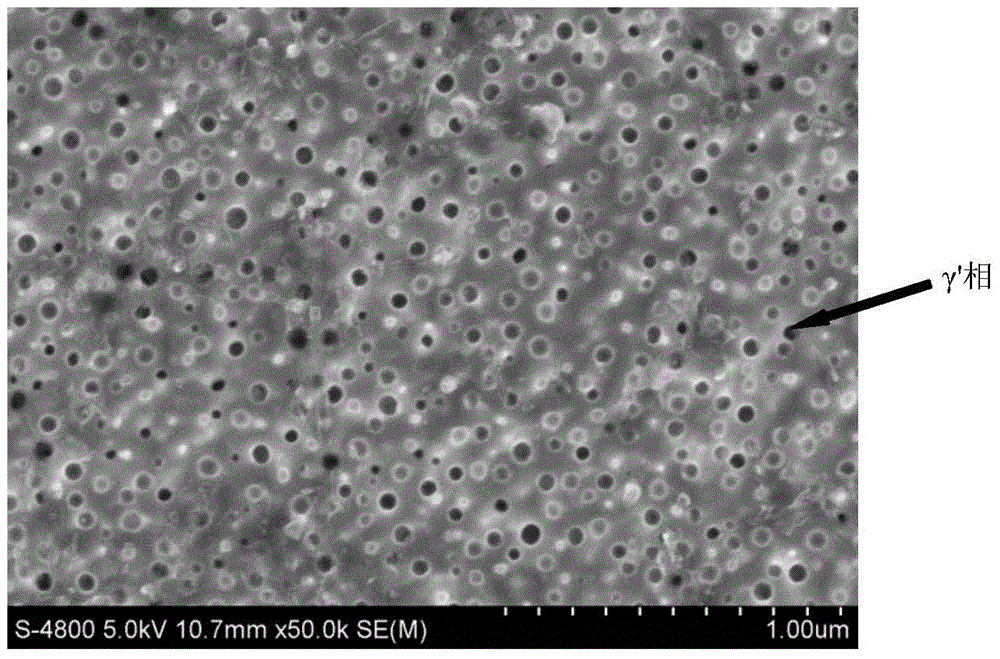

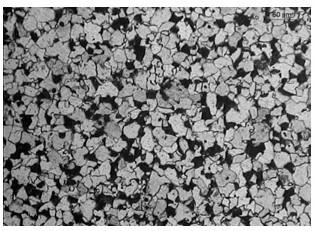

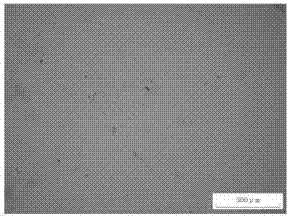

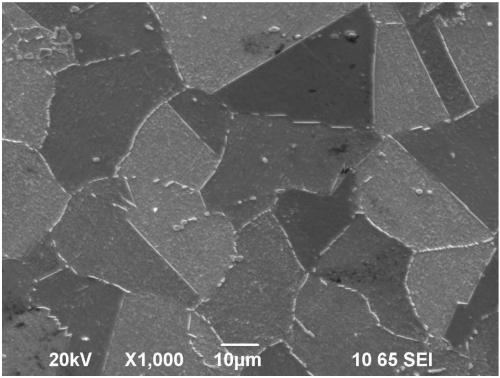

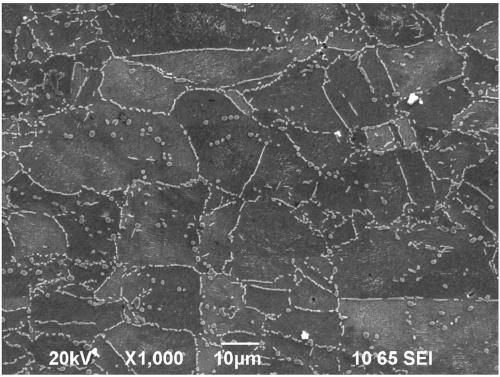

Heat treatment technology for strengthening crystal boundary of cold rolling state ferronickel-based high temperature alloy

The invention discloses a heat treatment technology for strengthening a crystal boundary of a cold rolling state ferronickel-based high temperature alloy. The heat treatment technology comprises the following three steps: 1) solution heat treatment is performed for 0.75-1.5 hours at 0.84-0.87Tm (Tm is the thermodynamics melting temperature of alloy materials), and then ferronickel-based high temperature alloy samples are taken out of a furnace to be air cooled to a room temperature; 2) the ferronickel-based high temperature alloy samples are preserved at the temperature 30-60 DEG C lower than the solid solution temperature of M23C6 type carbides for 1-2 hours, and then the ferronickel-based high temperature alloy samples are taken out of the furnace to be air cooled to the room temperature; 3) the ferronickel-based high temperature alloy samples are preserved at the temperature 150-200 DEG C lower than a gamma-phase solid solution temperature for 8-20 hours, and then the ferronickel-based high temperature alloy samples are taken out of the furnace to be air cooled to the room temperature. For the ferronickel-based high temperature alloy which is obtained through the heat treatment technology disclosed by the invention, the M23C6 type carbides are continuously and evenly distributed in the crystal boundary, strengthening phases gamma are evenly distributed in crystals, the enduring quality of the alloys at the condition of high temperature is good, the microhardness is higher, and the ferronickel-based high temperature alloys have higher tensile strength.

Owner:HUANENG POWER INT INC +1

Blade ring forged piece and fabrication technology thereof

The invention relates to a blade ring forged piece and a fabrication technology thereof. The fabrication technology comprises the following steps: 1, preparing materials; 2, cogging and forging, including heating, forging, and annealing; 3, baiting, and removing head and tail of a steel ingot; 4, molding and forging, including heating, forming, rolling and annealing; 5, carrying out thermal treatment, including normalizing, tempering for the first time, quenching, tempering for the second time, and tempering for the third time; 6, carrying out ultrasonic flaw detection; 7, carrying out physical and chemical testing; 8, carrying out finish machining; 9, packaging products. Thus, the blade ring forged piece obtains a good fine grain microstructure and high-temperature endurance property, and simultaneously has good tensile strength and yield strength.

Owner:WUXI PAIKE HEAVY CASTING & FORGING

High temperature alloy of nickel based monocrystalline capable of bearing high temperature

InactiveCN101003874ALow Re contentRaise the solution temperatureBlade accessoriesMachines/enginesRoom temperatureSingle crystal

This invention discloses a nickel-based monocrystalline alloy with good heat-bearing ability. The alloy comprises: W 3-4 wt.%, Mo 3-4 wt.%, Ta 7-8 wt.%, Al 5-7 wt.%, Ti 0.5-1.5 wt.%, Cr 3-5 wt.%, Co 8-10 wt.%, Re 2-3 wt.%, Nb 0.5-1 wt.%, and Ni. The alloy comprises less Re than CMSX-4 alloy. The solid solution temperature of the alloy is thus increased by 5-10 deg.C. The alloy also has better room temperature stretching property and better heat-bearing ability than CMSX-4 alloy, thus can be used in aeroengine with high weight bearing.

Owner:BEIHANG UNIV

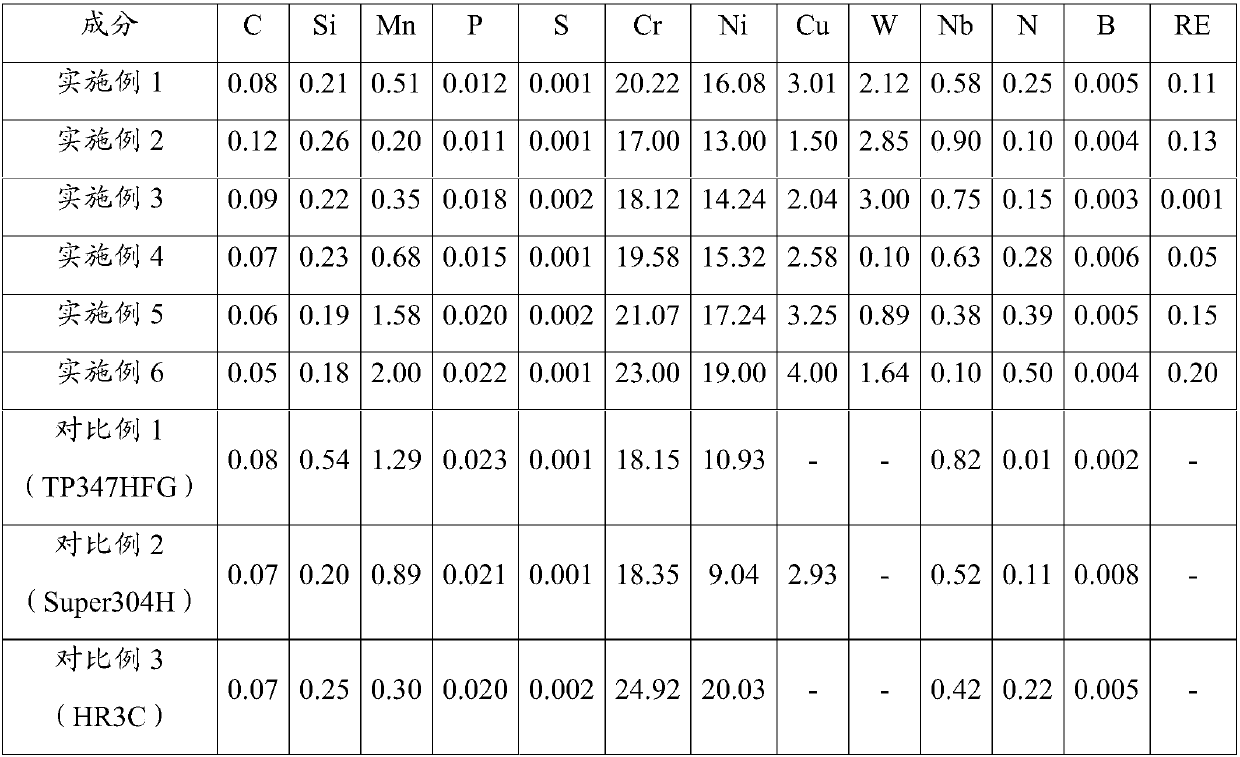

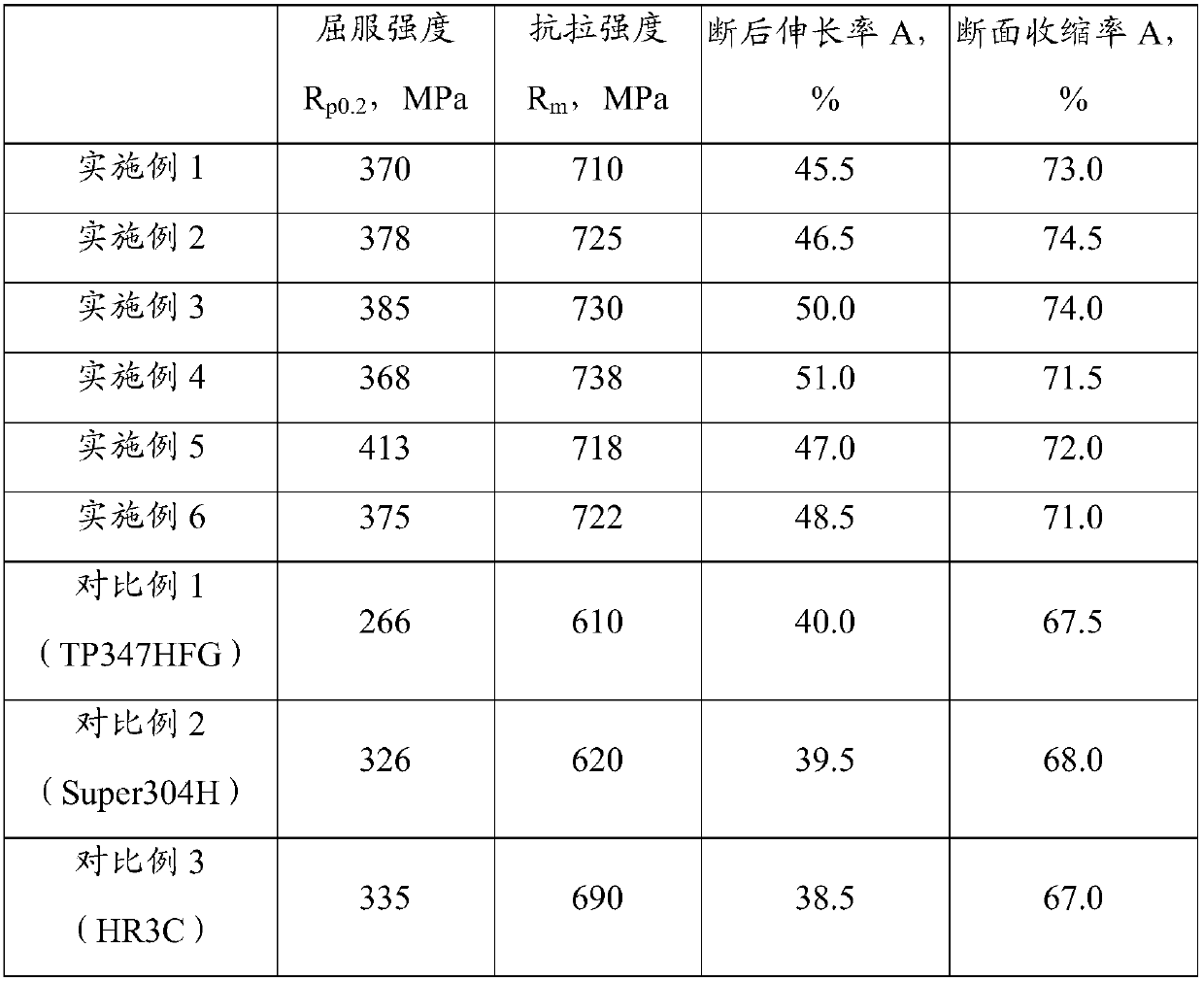

Heatproof stainless steel seamless tube and production method thereof

The invention provides a heatproof stainless steel seamless tube. The heatproof stainless steel seamless tube comprises, by weight, 0.05-0.12% of C, 0.3% or less of Si, 0.2-2% of Mn, 0.03% or less ofP, 0.02% or less of S, 17-23% of Cr, 13-19% of Ni, 1.5-4% of Cu, 0.1-3% of W, 0.1-0.9% of Nb, 0.1-0.5% of N, 0.003-0.006% of B, 0.001-0.2% of RE, and the balance of Fe and inevitable impurities. The invention also provides a production method of the heatproof stainless steel seamless tube. The method comprises the following steps: cogging cast ingots in an open die forging, radial forging or rolling manner to produce a tube blank; carrying out hot working on the tube blank through a hot extrusion technology or a hot piercing technology to produce a tubular billet; finishing the tubular billet,and carrying out cold working in a multi-pass cold rolling or cold drawing manner to obtain a pierced billet; and heating the pierced billet, and performing heat preservation.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

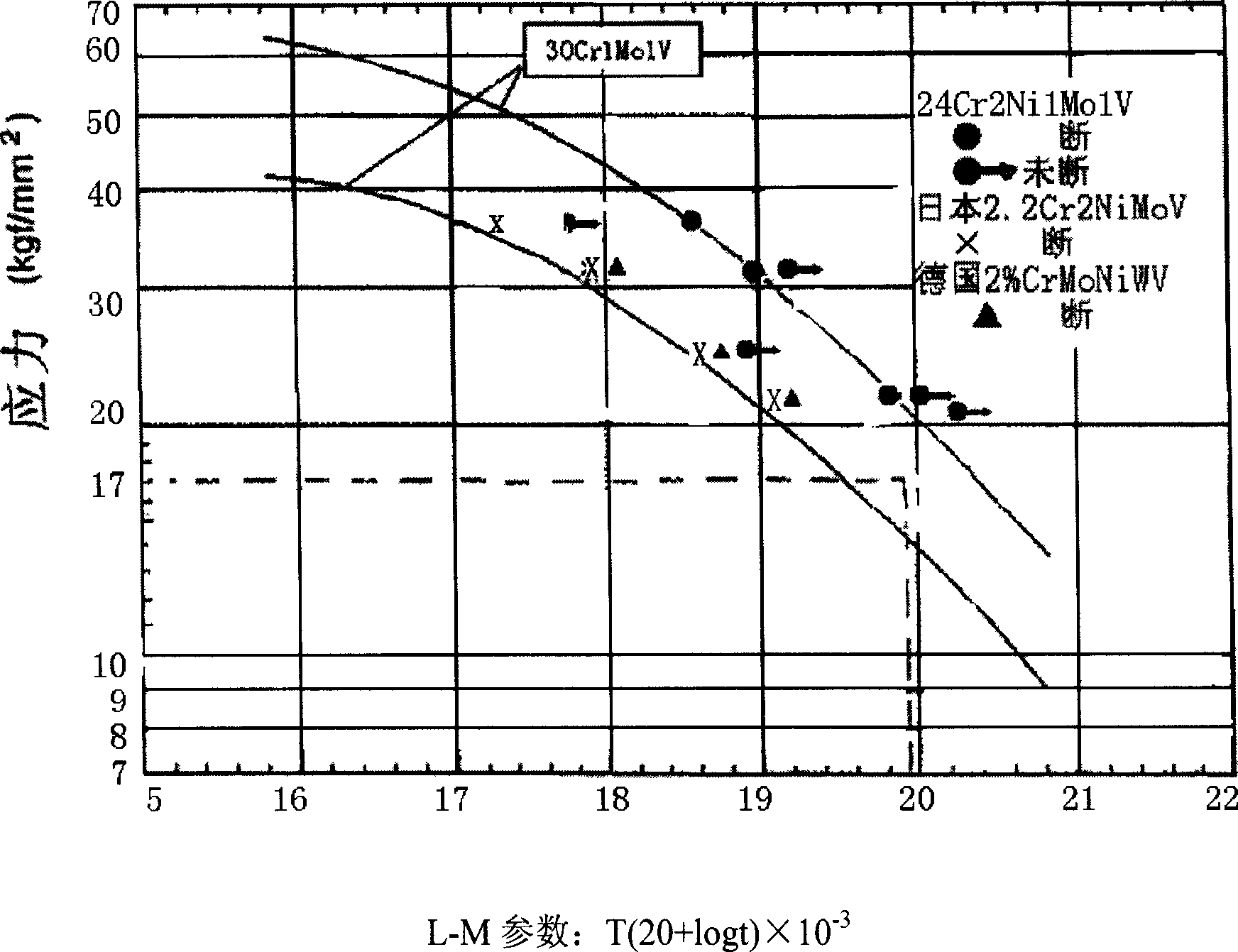

Materials for producing high pressure and low pressure joint rotor of steam turbine

ActiveCN1844437AImprove high temperature durabilitySimple processNon-positive displacement enginesHigh pressureLow stress

The invention relates to a material for manufacturing turbine rotors, which comprises the following constituents (by weight percent): C 0.21-0.26%, Mn 0.1-0.2%, Si <=0.05%, P <=0.005%, S <=0.005%, Cr2.2-2.55%, Ni1.3-1.55%, Mo1.1-1.35%, V0.2-0.31%, Cu <=0.05%, Al <=0.005%, Sn <=0.008%, Sb <=0.002%, As <=0.008%, and balancing Fe.

Owner:HARBIN TURBINE +1

Low-rhenium high-strength thermal-corrosion-resistant nickel-based single-crystal high-temperature alloy and manufacturing method thereof

InactiveCN109371288AExcellent high temperature durabilityLow Re elementPolycrystalline material growthAfter-treatment detailsRheniumChemical composition

The invention discloses a low-rhenium high-strength thermal-corrosion-resistant nickel-based single-crystal high-temperature alloy and a manufacturing method thereof. The alloy comprises the followingchemical components of, in percentage by weight, 9.0-12.0% of Cr, 8.0-11.0% of Co, 0.2-1.5% of Mo, 4.5-7.0% of W, 3.5-5.5% of Al, 2.0-4.0% of Ti, 4.5%-6.5% of Ta, 0.1-0.3% of Hf, 1.2-2.0% of Re, andthe balance Ni. The high-temperature endurance performance is superior to that of the PWA1483 alloy, the Re element is low, and good thermal corrosion resistance is achieved; compared with the existing nickel-based single-crystal high-temperature alloy, the content of the Cr element in the alloy component is relatively high, the alloy component has relatively high thermal corrosion resistance; thealloy has good high-temperature endurance performance, the high-temperature performance is superior to that of PWA1483, and the creep time of the 982 DEG C / 100 Mpa is larger than or equal to 5000h.

Owner:DONGFANG TURBINE CO LTD

Method for producing annealing-free vanadium-containing heat-resistant steel hot-rolled wire rod

The invention provides a method for producing an annealing-free vanadium-containing heat-resistant steel hot-rolled wire rod. According to the method, a converter double-slag low-phosphorus-content control method is adopted to reduce direct cold forming cracking caused by localized enrichment of phosphides; a technology of dynamic soft reduction in continuous casting and long-term high-temperaturediffusion in a cogging process is adopted for effectively reducing segregation of alloying elements in a casting slab; a high-temperature oxidizing coatings is used for effectively avoiding the problem of difficult removal of composite oxide scales; low-temperature laying, low roller speed and other means for controlled rolling and controlled cooling are beneficial to phase transformation of austenite at a high temperature section to pearlite; and an off-line thermal-insulation cover can effectively reduce driving force of transformation of retained austenite to a martensite supercooled structure. The tensile strength of the vanadium-containing heat-resistant steel hot-rolled wire rod is 520-560 MPa, the structure is a combination of ferrite and pearlite, and a heat-resistant steel component directly processed by an annealing-free process by downstream users has good moldability and can maintain good high-temperature long-lasting strength when serving in a high-temperature environment.

Owner:HANDAN IRON & STEEL GROUP +1

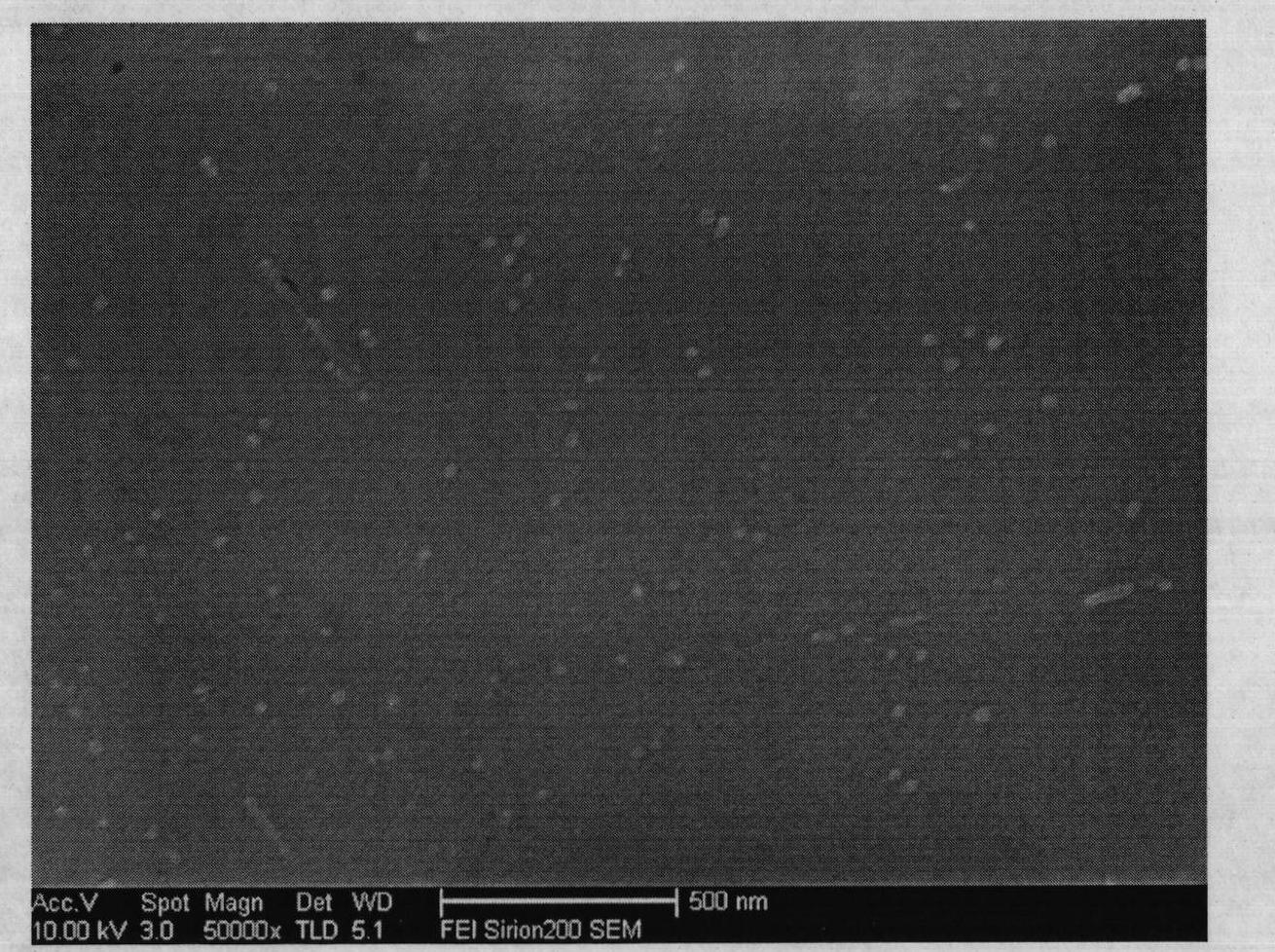

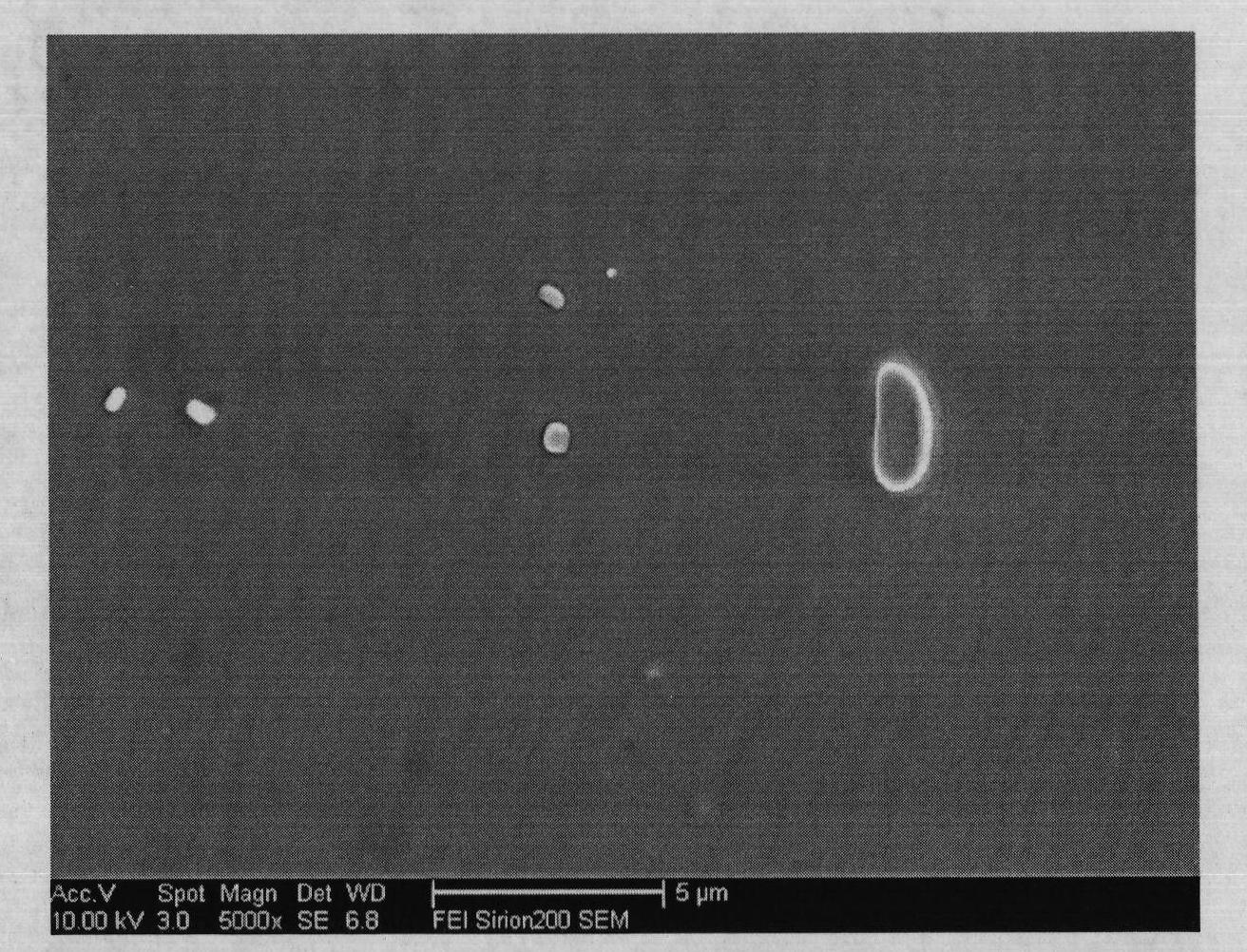

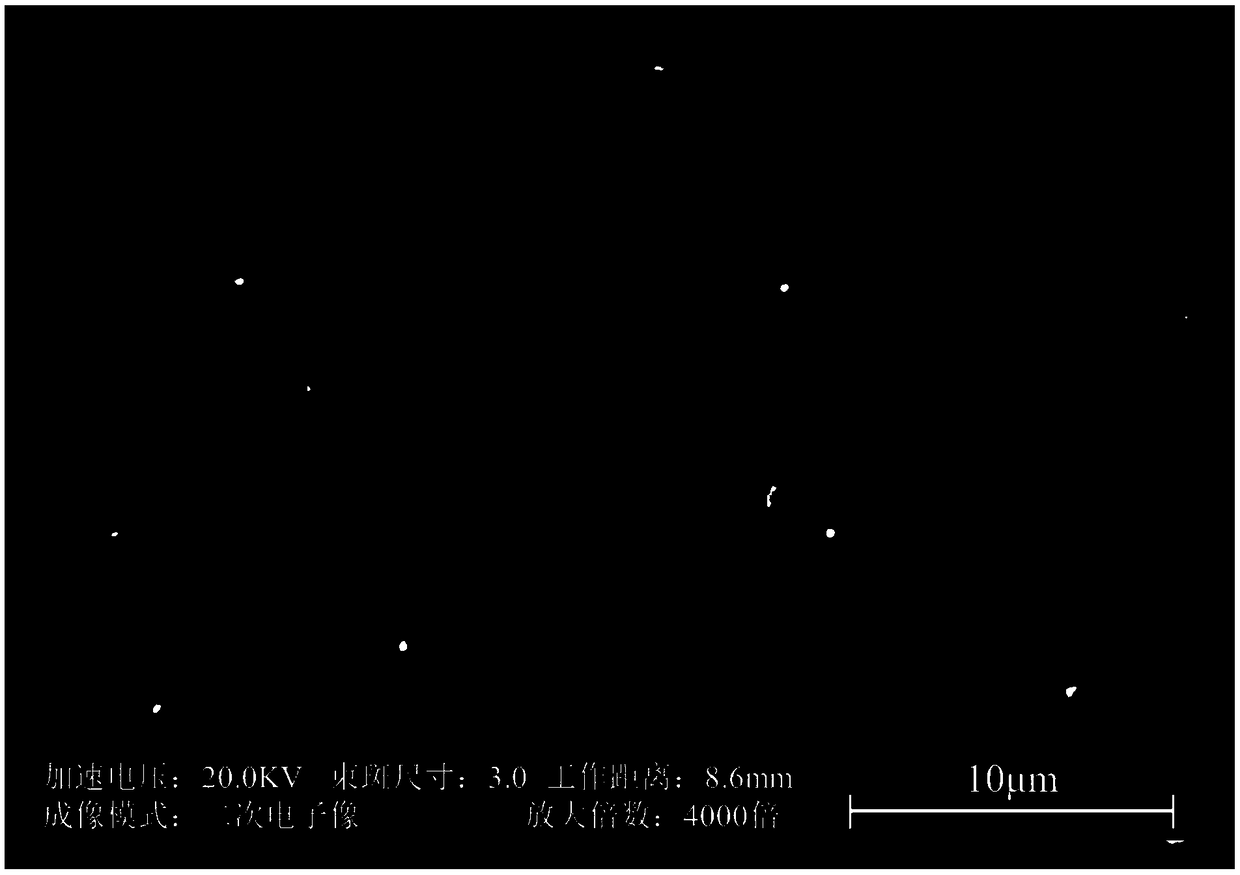

Thermal treatment method for obtaining nanometer strengthening phase by HR3C austenitic heat-resistance steel

InactiveCN101914662AImprove thermal stabilityGood high temperature corrosion resistanceSolution treatmentHigh density

The invention discloses a thermal treatment method for obtaining a nanometer strengthening phase by HR3C austenitic heat-resistance steel. The thermal treatment method comprises two steps as follows: firstly, solution treatment: heating a steel member to 1170-1250 DEG C for 30-60min, and then cooling water to the room temperature; and secondly, annealing treatment: heating the steel member after solution treatment to 800-950 DEG C for 30-240min, and then cooling air to the room temperature. In the HR3C austenitic heat-resistance steel treated by using the thermal treatment method, high-density NbCrN-type nanometer strengthening phases with the size ranging from 20 nm to 60 nm are evenly distributed in the austenite grain, wherein 5-30 strengthening phase grains are distributed in per square micro. The invention obviously improves the high-temperature duration intensity and ensures good high temperature corrosion resistance.

Owner:SHANDONG UNIV OF TECH

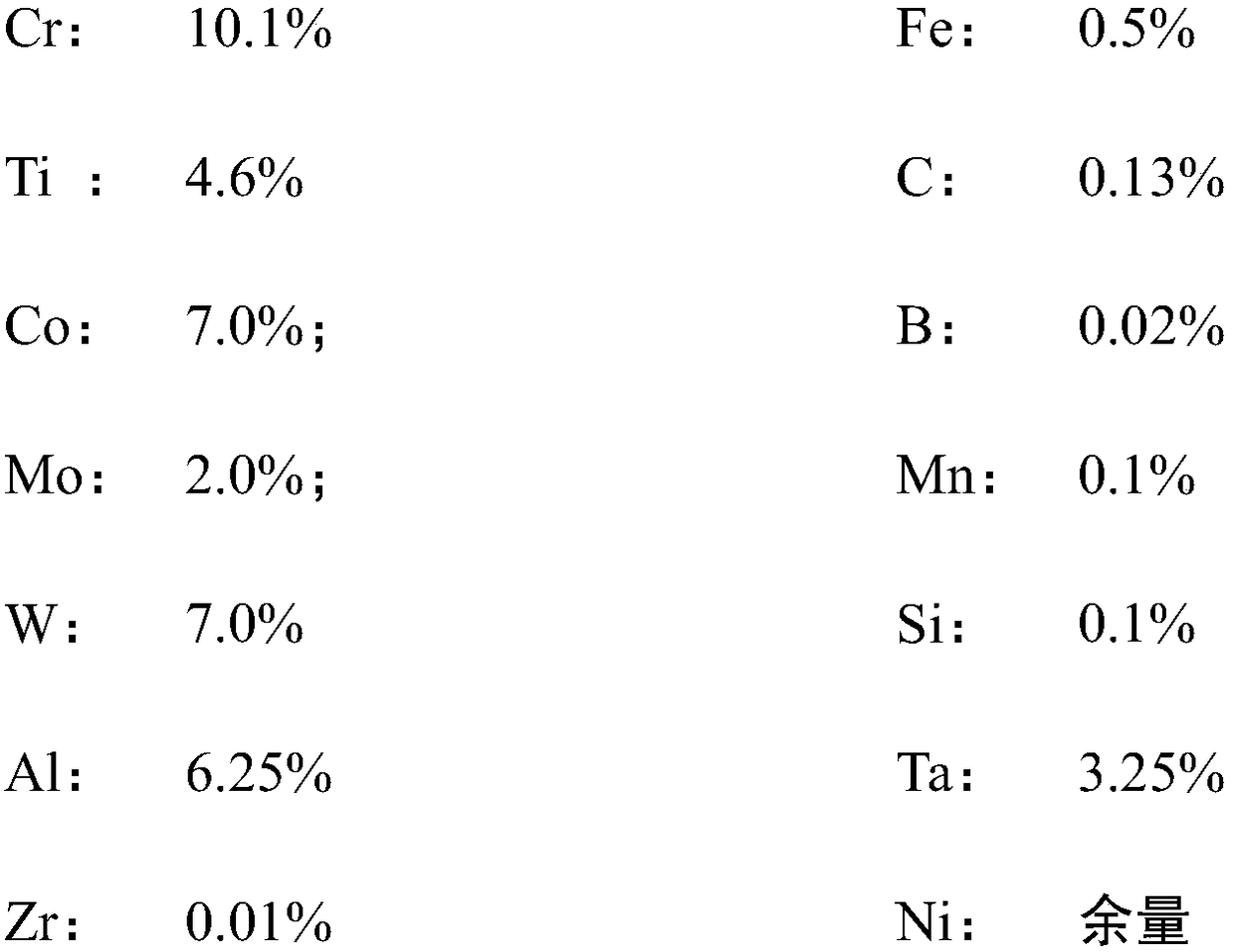

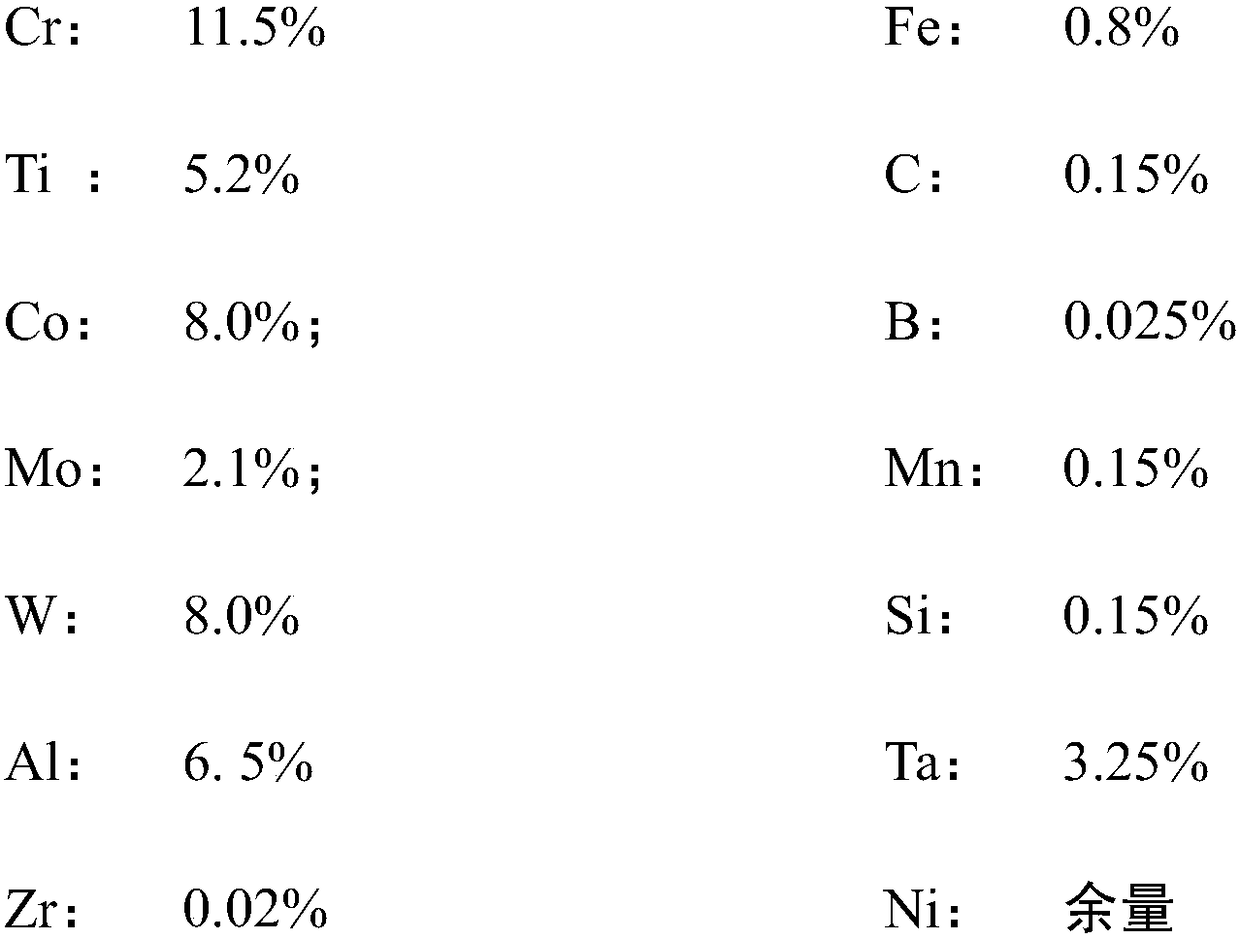

High-temperature alloy and preparation method thereof

The invention discloses a high-temperature alloy. The high-temperature alloy comprises the following raw materials of, by mass percent, 10.1-12.5% of Cr, 4.6-5.8% of Ti, 7.0-9.0% of Co, 2.0-2.25% of Mo, 7.0-9.0% of W, 6.25-6.75% of Al, less than or equal to 0.03% of Zr, less than or equal to 1.0% of Fe, 0.13-0.17% of C, 0.02-0.03% of B, less than or equal to 0.2% of Mn, less than or equal to 0.2%of Si, 3.25-3.75% of Ta, and the balance Ni. The invention further discloses a preparation method of the high-temperature alloy and belongs to the technical field of the high-temperature alloys. Compared with a similar formed material, the high-temperature alloy obtained by the preparation method has higher high-temperature endurance life and has the advantage of excellent resistance to thermal crack, and the thermal crack problem of the high-temperature alloy is solved greatly.

Owner:ANHUI TATSU PRECISION ALLOY

Heat treatment method for improving high-temperature endurance property of GH2132 bolt

InactiveCN105734241ASmall sizeImprove diffusivityFurnace typesHeat treatment furnacesThermodynamicsEngineering

The invention discloses a heat treatment method for improving the high-temperature endurance property of a GH2132 bolt. The bolt is subjected to head forming and heading first and then subjected to solid solution treatment process; and afterwards, the processed bolt is subjected to two aging processes and finally processed to a finished product. The high-temperature endurance property of the bolt is improved sharply, and the fatigue life of the bolt can be guaranteed. According to the heat treatment method, the solid solution process and the two aging processes are adopted, so that the high-temperature endurance property of the GH2132 bolt is improved by a large margin, and the fatigue property and application security are ensured. The technical problem that grain size and high-temperature endurance cannot be guaranteed at the same time in conventional heat treatment production is accordingly solved successfully and therefore the heat treatment method can be popularized in the field of aero-engine GH2132 bolts.

Owner:GUIZHOU AEROSPACE PRECISION PRODS

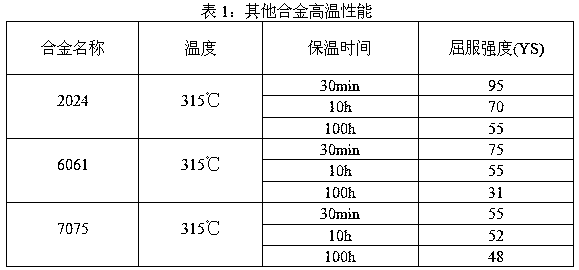

Al-Si-Cu-Mn heat-resistant aluminum alloy with high Fe content and preparation method thereof

ActiveCN109402473AGood casting performanceImprove heat stabilitySolid solutionUltimate tensile strength

The invention discloses an Al-Si-Cu-Mn-Ti heat-resistant aluminum alloy with a high Fe content and a preparation method thereof. The alloy is prepared from, by weight, 6.0-8.0% of Cu, 0.4-1.2% of Mn,0.1-1.0% of Fe, 7.0-12% of Si and 0.1-1.0% of Ti, and the balance is Al and inevitable impurities; the preparation method comprises the steps of 1) smelting; 2) casting; 3) solid solution*aging treatment on a casting blank; the alloy has the advantages of high temperature strength and high temperature durability after heat treatment; heat preservation is conducted at 315 DEG C for 30 minutes, andthe tensile strength is up to 155-225 MPa; the tensile strength is up to 110-135 MPa after the heat preservation at 315 DEG C for 10 hours, and the tensile strength is up to 95-120 MPa after the heatpreservation at 315 DEG C for 100 hours. The preparation method has simple process, and added elements have simple composition and do not contain rare precious metals.

Owner:贵州贵材创新科技股份有限公司

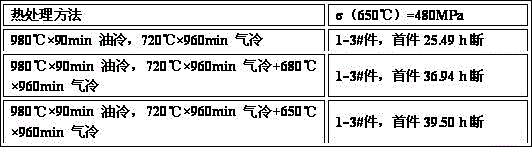

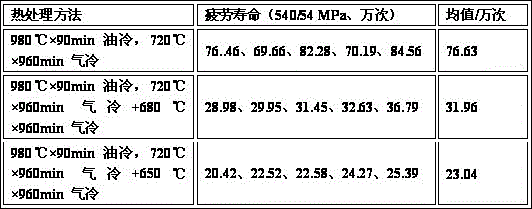

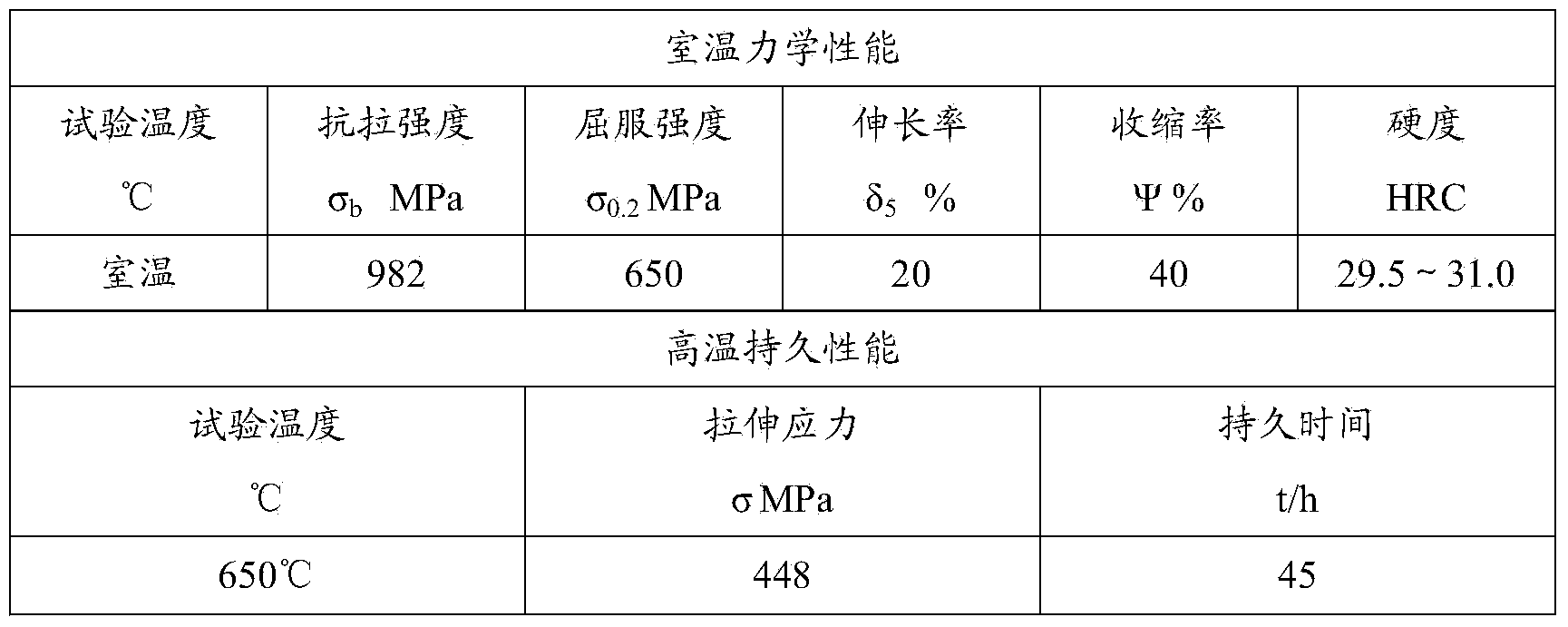

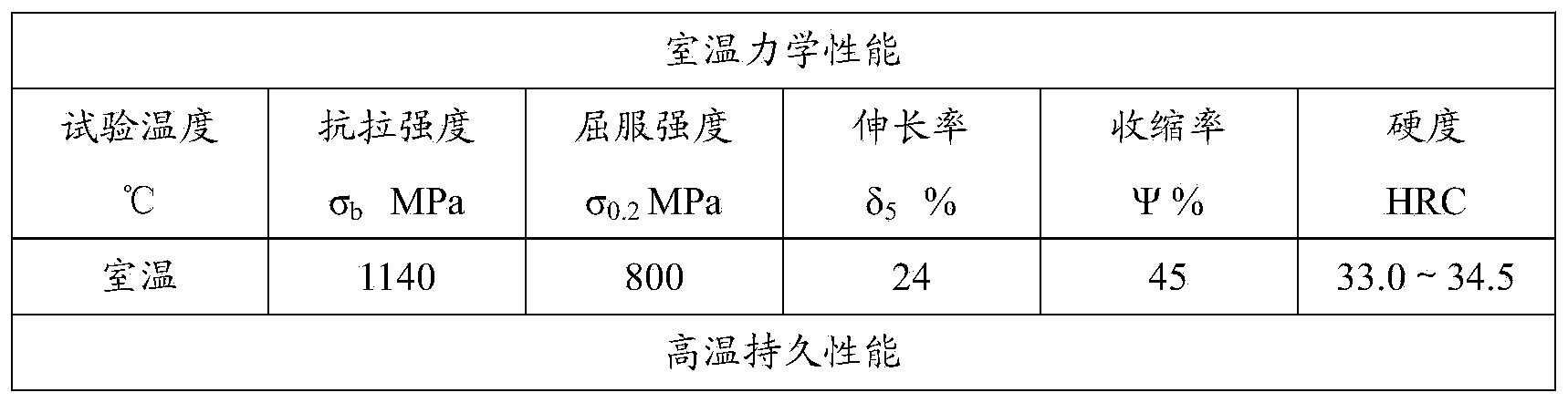

Heat treatment method for super-alloy electromagnetic stirring roller used in high-temperature environment

The invention relates to a heat treatment method for a super-alloy electromagnetic stirring roller used in a high-temperature environment. The heat treatment method comprises steps of placing an electromagnetic stirring roller which is made from a super-alloy UNSS66286 material in a heating electric furnace, and sequentially implementing solution treatment, aging treatment and stabilizing treatment to obtain a super-alloy UNSS66286 electromagnetic stirring roller used in a high-temperature environment, wherein the product processed by heat treatment can be used in a 650 DEG C high-temperature environment. The UNSS66286 electromagnetic stirring roller which is prepared through the heat treatment and is applicable to a high-temperature environment has excellent tensile strength, yield strength, elongation, shrinking percentage, hardness, grain size and high temperature endurance property, the UNSS66286 electromagnetic stirring roller prepared by the heat treatment greatly has high service life; through test, the UNSS66286 electromagnetic stirring roller cannot be worn and fractured after being used for 2 years, thus greatly prolonging the service life.

Owner:上海康晟航材科技股份有限公司

Heat treatment technique for additive component

InactiveCN107470629AOptimize heat treatment processHigh elongationAdditive manufacturing apparatusPerformance indexQuenching

The invention discloses a heat treatment technique for an additive component. The heat treatment technique for the additive component is used for improving the overall mechanical performance index of the additive component. The heat treatment technique for the additive component comprises the following steps of annealing, specifically, annealing treatment is conducted on the additive component; and quenching, specifically, quenching treatment is conducted on the annealed additive component twice, low-temperature quenching is conducted on the additive component firstly, and then high-temperature quenching is conducted on the additive component. By adoption of the heat treatment technique, the overall mechanical performance index of the additive component can be improved, and the using requirements in the aviation field are met.

Owner:ADVANCED FOR MATERIALS & EQUIP

Martensite heat-resisting steel and preparation method thereof

ActiveCN108866453AImprove high temperature strength and toughnessImproves strength and hardnessAlloy elementNitrogen

The invention discloses martensite heat-resisting steel and a preparation method thereof. The martensite heat-resisting steel is prepared from all elements in mass percent: 0.1 to 0.2% of C, 9 to 14%of Cr, 2.5 to 3.5% of Ni, 1.0 to 2.0% of Mo, 0.5 to 1.0% of W, 0.5 to 1.0% of Mn, 0.10 to 0.5% of Si, 0.10 to 0.5% of V, 0.1 to 0.5% of Nb, 0.02 to 0.05% of N and the balance of Fe, wherein dissolved-out carbon nitride compound is in a dispersively-distributed state, and the carbon nitride compound is prepared from M2X type, M7C3 type, MX type and M6C type carbide. According to the martensite heat-resisting steel disclosed by the invention, an alloying design of the martnesite heat-resisting steel and a tempering technology are accurately controlled and combined; by means of adjusting contentsand kinds of alloy elements and utilizing a lower temperature for tempering, high-temperature toughness performance of the martensite heat-resisting steel can be remarkably improved; high toughness is obtained, higher strength and hardness are kept simultaneously, and tempering brittleness is avoided.

Owner:XIJING UNIV

Method for improving high-temperature endurance performance of large GH4698 turbine disc forged piece

InactiveCN110983107AImprove tissue uniformityImprove high temperature durabilityHot workingSuperalloy

The invention belongs to the technical field of the hot working of high-temperature alloys and relates to a method for improving the high-temperature endurance performance of a large GH4698 turbine disc forged piece. According to the method of the invention, the selection of the components of a GH4698 rod, the deformation heating number of the GH4698 rod and the post-forging-and-hot treatment cooling speed of the GH4698 rod are controlled, and therefore, the structure uniformity of the large GH4698 turbine disc forged piece and the high-temperature endurance performance of the forged piece under a high-stress condition are greatly improved, and the comprehensive performance and market competitiveness of a product are powerfully improved.

Owner:SHAANXI HONGYUAN AVIATION FORGING

Nickel-based interlayer alloy material, preparation method of nickel-based interlayer alloy material, weldment, welding method and application

ActiveCN112853154AReduce contentExtension of timeTransportation and packagingBlade accessoriesChemical compositionInter layer

The invention discloses a nickel-based interlayer alloy material, a preparation method of the nickel-based interlayer alloy material, a weldment, a welding method and application, and relates to the technical field of welding materials. The nickel-based interlayer alloy material comprises the following chemical components in percentage by weight: 11.9-13.2 percent of Cr, 6.5-7.8 percent of Co, 0.5-1.7 percent of Mo, 4.1-5.2 percent of W, 2.4-3.6 percent of Al, 4.1-5.3 percent of Ti, 3.0-4.2 percent of Ta, 0-3.1 percent of Re, 1.5-3.1 percent of Ru, 0.5-1.1 percent of B, 0.3-0.8 percent of Si and the balance of nickel. The preparation method comprises the step of smelting the metal and / or the alloy into the nickel-based intermediate layer alloy materials according to the chemical composition. The welding method comprises the step of welding the weldment by adopting the alloy materials. The weldment is obtained by welding through the welding method. A weldment joint obtained by welding the alloy materials is high in high-temperature strength.

Owner:CHINA-UKRAINE INST OF WELDING GUANGDONG ACAD OF SCI

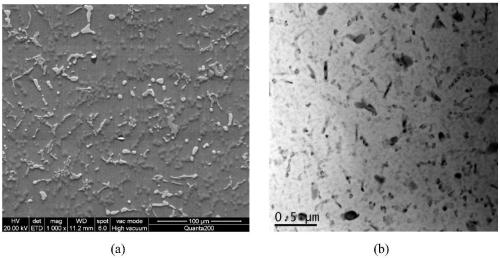

Heat treatment method for improving high-temperature endurance performance of deformed aluminum-copper-magnesium-silver alloy

InactiveCN112662969AExcellent high temperature durabilitySimple heat treatment processAg alloyMagnesium

The invention belongs to the technical field of metal material treatment, and particularly relates to a heat treatment method for improving the high-temperature endurance performance of a deformed aluminum-copper-magnesium-silver alloy. The heat treatment method comprises the steps that S1, the aluminum-copper-magnesium-silver alloy is subjected to solid solution and quenching treatment, and then artificial aging treatment is conducted for 0-1h; and S2, the aluminum-copper-magnesium-silver alloy material treated in the step S1 is subjected to tensile deformation treatment and then subjected to artificial aging treatment for 1-8h, and the deformed aluminum-copper-magnesium-silver alloy with excellent high-temperature endurance performance is obtained. According to the method, the stable formation of the heat-resistant omega phase or the precursor thereof is ensured through short-time artificial aging in advance, so that the heat-resistant omega phase or the precursor thereof can still exist stably after deformation treatment, the mass formation of the heat-resistant omega phase in the subsequent artificial aging process is promoted, and the excellent long-time high-temperature endurance property of the shape-variable alloy is ensured.

Owner:CENT SOUTH UNIV

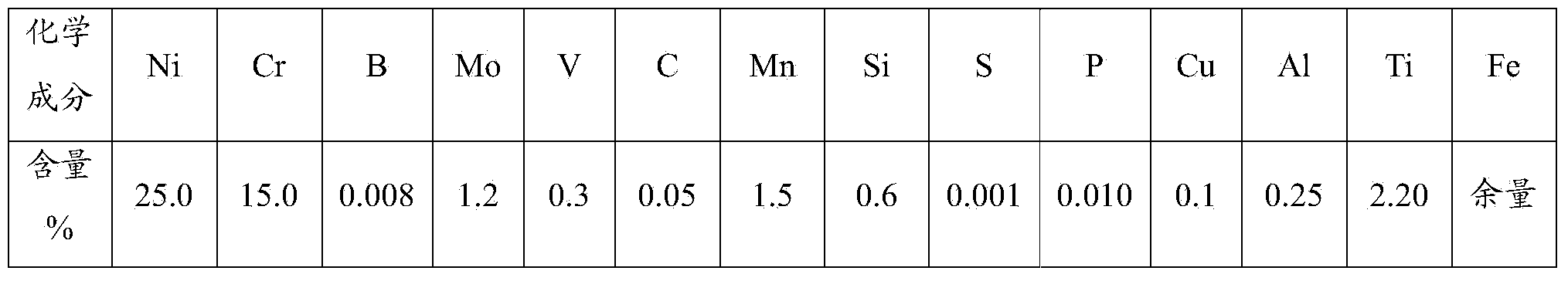

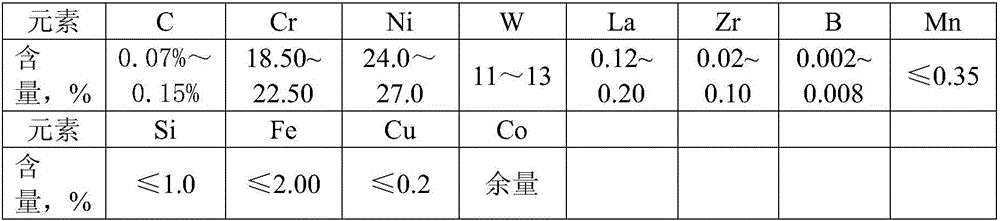

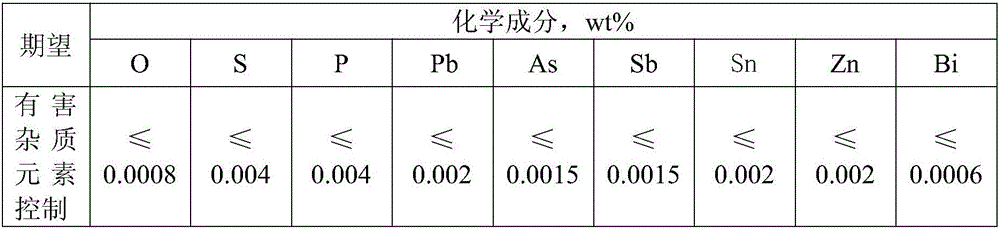

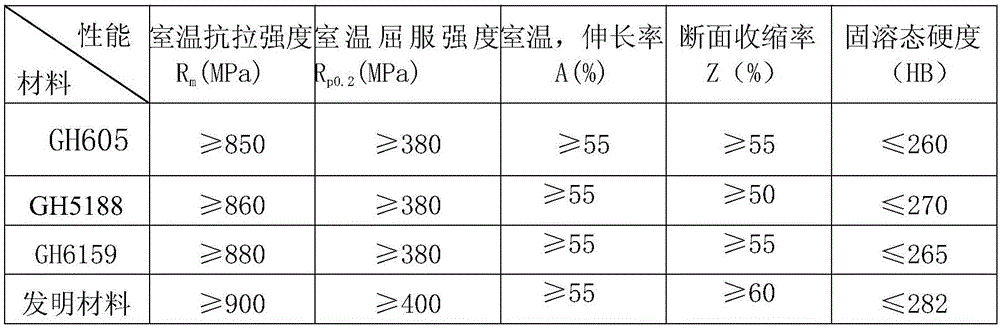

High-strength rare earth doped alloy material with high-temperature oxidation resistance and preparation method

The invention relates to a high-strength rare earth doped alloy material with high-temperature oxidation resistance and a preparation method. The material comprises components in percentage by weight as follows: 0.07%-0.15% of C, 24.0%-27.0% of Ni, 18.50%-22.50% of Cr, 0.02%-0.1% of Zr, 0.002%-0.008% of B, 11%-13% of W, 0.12%-0.20% of La, lower than or equal to 1.0% of Si, lower than or equal to 2.0% of Fe, lower than or equal to 0.20% of Cu, lower than or equal to 0.020% of impurities and harmful elements and the balance of Co. The material has good strength, high-temperature oxidation resistance and high-temperature endurance, fills up the blank of the kind of materials in China and can be applied to the fields of national petrochemical, aerospace, aviation and the like.

Owner:CHONGQING MATERIALS RES INST

Manufacturing method of double-alloy double-structure titanium alloy blisk

ActiveCN112296602AImprove the bonding strength of the interfaceImprove control accuracyTurbinesAdditive manufacturing apparatusTitanium alloyLaser additive manufacturing

The invention discloses a manufacturing method of a double-alloy double-structure titanium alloy blisk. The method comprises the steps that firstly, a Ti60 titanium alloy hub forging blank of a mesh basket fine grain structure is manufactured through a quasi-beta forging method, and a hub rough machining blank is obtained through machining; secondly, a Ti2AlNb titanium alloy blade blank is prepared on the hub rough machining blank through a laser powder feeding additive manufacturing method; and thirdly, local gradient isothermal forging deformation is conducted on a double-alloy blisk prefabricated blank, the defects of air holes, incomplete fusion and the like in the laser additive manufacturing blade blank can be effectively overcome, and a precipitated phase and a microstructure of a sedimentary blade are refined. Meanwhile, uniform diffusion of alloy elements at the interface of the hub rough machining blank and the blade blank is facilitated, and the interface bonding strength between the hub rough machining blank and the blade blank is enhanced. In addition, through local gradient deformation of the blisk prefabricated blank, gradual transition between two remarkably-different structures at the bonding interface of the Ti60 titanium alloy hub rough machining blank of the mesh basket structure and the Ti2AlNb titanium alloy blade blank of an equiaxed structure can be achieved, and the material and structure states of the blade and a disc body better adapt to the actual working condition of the blisk.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Production process for quenching and tempering high-strength stainless steel fastener

InactiveCN110938733AImprove grain size refinementImprove high temperature durabilityQuenching agentsTemperingSS - Stainless steel

The invention discloses a production process for quenching and tempering a high-strength stainless steel fastener. The process comprises process steps that a product is put into an annealing furnace for annealing treatment, cooled to 350-400 DEG C along with the furnace, and taken out for air cooling; quenching is conducted, specifically, the pretreated workpiece is put into a high-temperature furnace, heated to 840-860 DEG C, subjected to heat preservation for 0.5-1 h, then heated to 1080-1100 DEG C and subjected to heat preservation for 2-3 h, after heat preservation is completed, rapid discharging is conducted, the workpiece enters a quenching tank to be cooled in an oil cooling mode to 150-200 DEG C, and then the workpiece is taken out to be subjected to air cooling; tempering is conducted, specifically, the quenched workpiece is put into the high-temperature furnace, heated to 320-380 DEG C and subjected to heat preservation for 0.5 h, then heated to 580-620 DEG C and subjected toheat preservation for 1-2 h, after heat preservation is completed, the workpiece is cooled to 200-240 DEG C along with the furnace, and then the workpiece is taken out and put into air to be cooled for 2 h; the workpiece is put into alkaline solution to be subjected to descaling treatment, the descaling time ranges from 10 min to 20 min, and finally the workpiece is cleaned, dried and packaged. The process is advantaged in that the original structure refining grain size of the stainless steel heat-resistant steel forge piece can be improved, and the quenching and tempering treatment effect isimproved.

Owner:东台市展新不锈钢紧固件制造有限公司

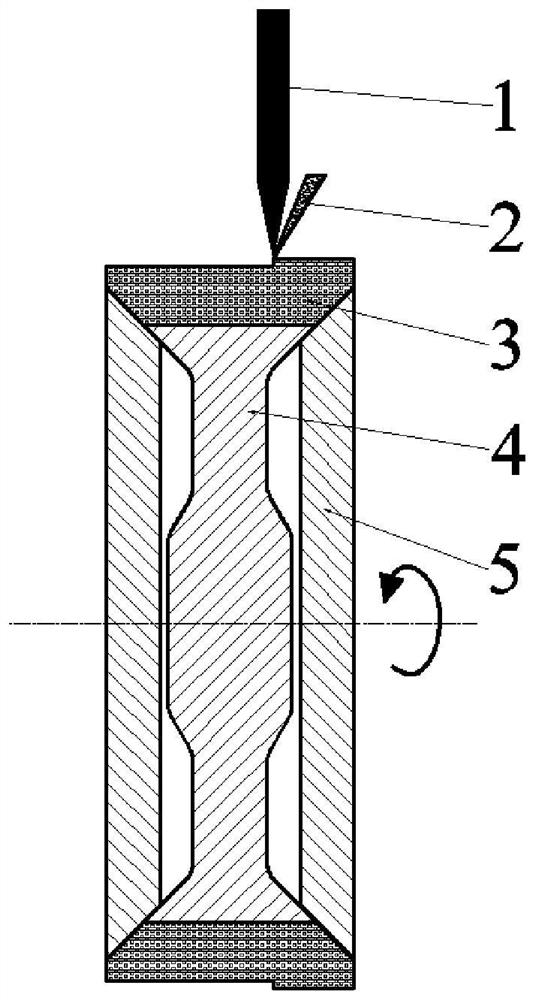

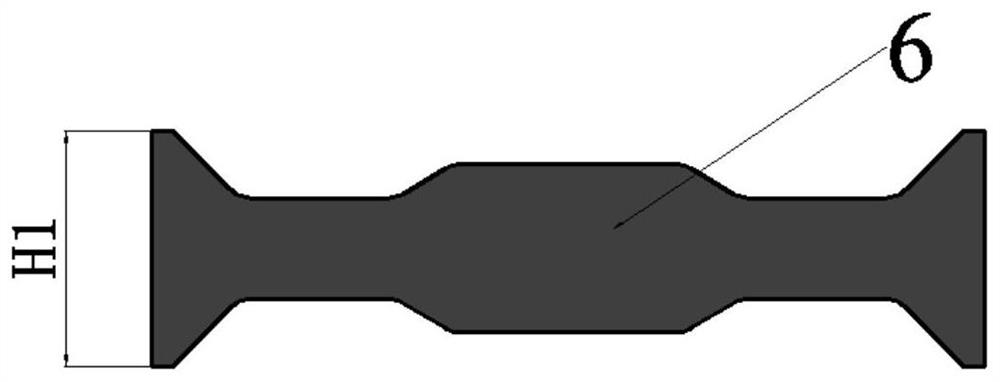

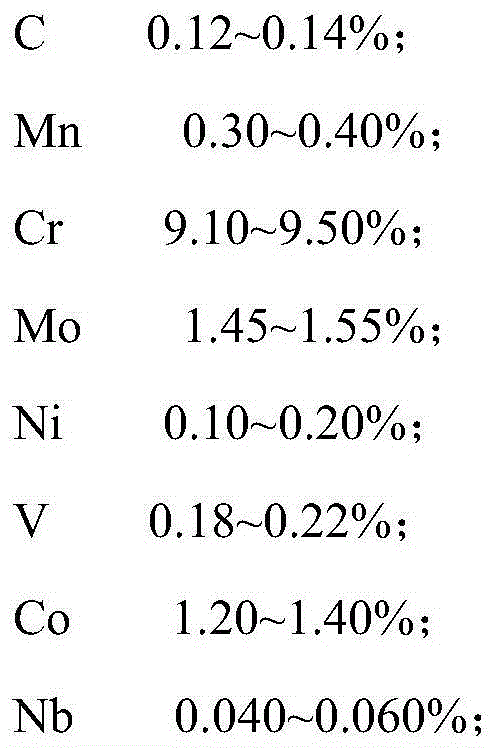

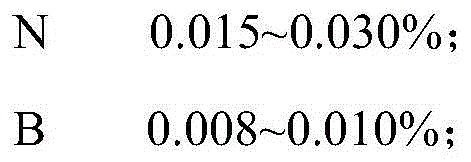

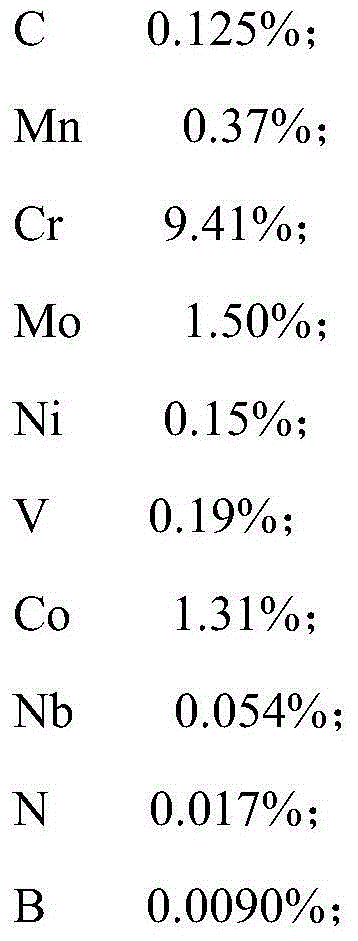

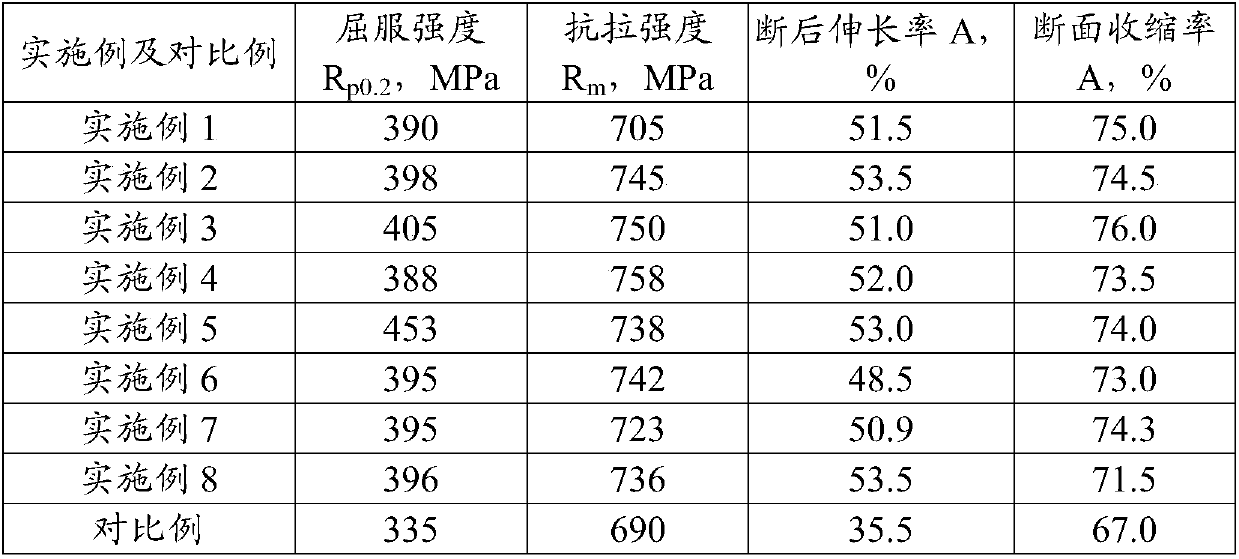

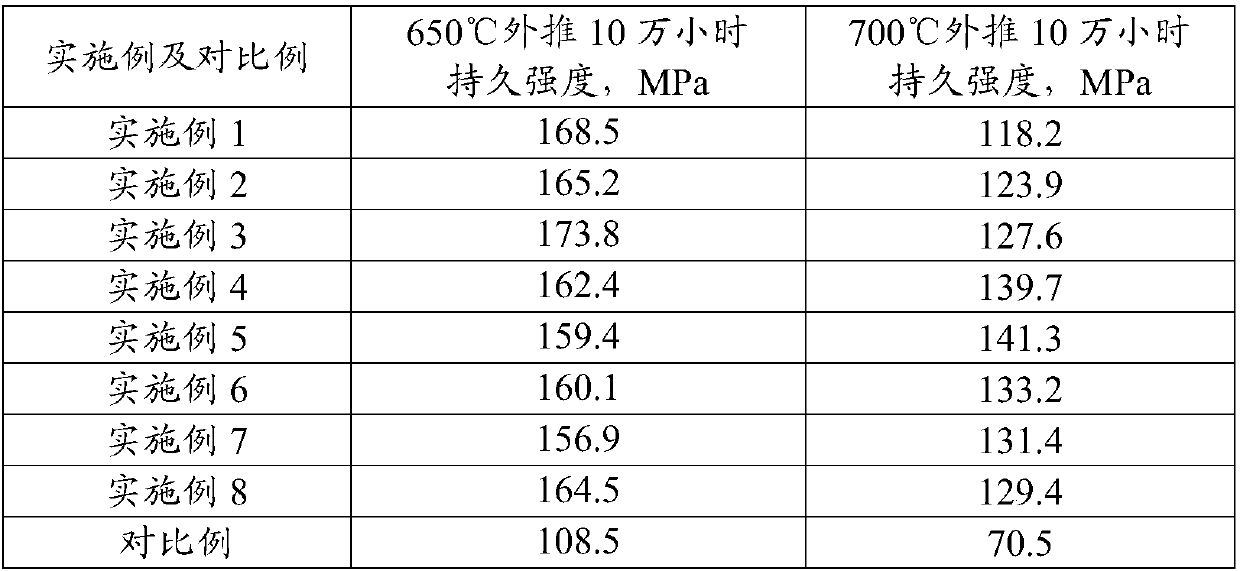

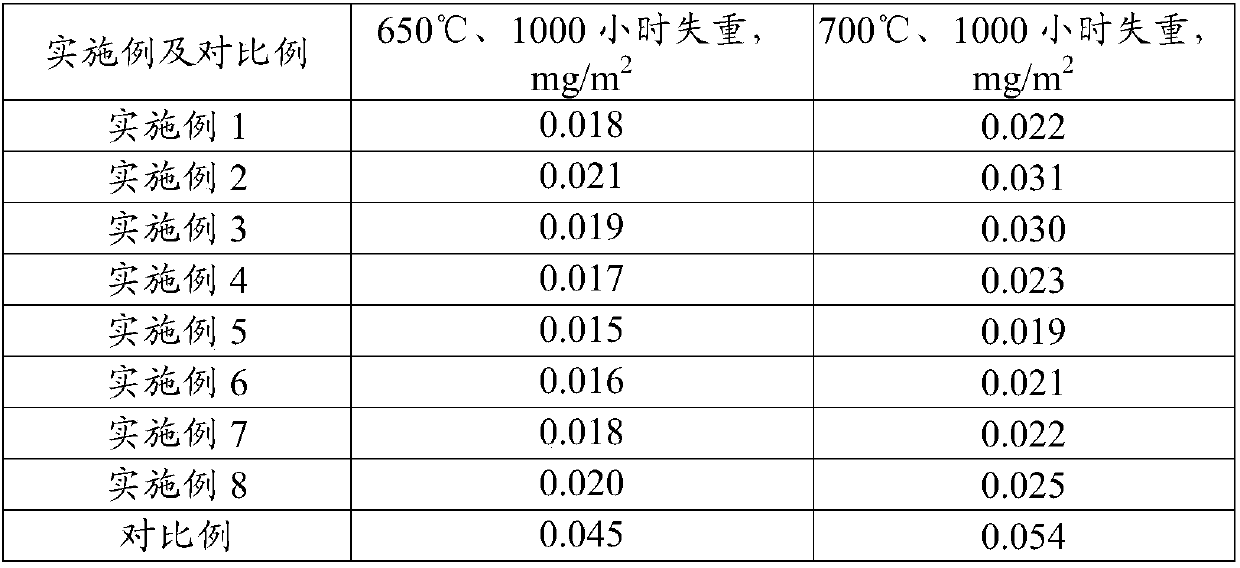

Alloy material for turboset rotor and preparation method thereof

ActiveCN104818432AImprove performanceImprove high temperature durabilityWorking pressureWorking environment

The invention aims at providing an alloy material for a turboset rotor and a preparation method thereof and solves the problems that the steam temperature and the work pressure of an ultra supercritical unit are higher than those of the current unit and the high-temperature endurance property of the current material cannot meet the requirement. The alloy material comprises the following components by weight percentage: 0.12-0.14wt% of C, 0.30-0.40wt% of Mn, 9.10-0.50wt% of Cr, 1.45-1.55 wt% of Mo, 0.10-0.20 wt% of Ni, 0.18-0.22 wt% of V, 1.20-1.40 wt% of Co, 0.040-0.060 wt% of Nb, 0.015-0.030wt% of N, and 0.008-0.010wt% of B. By adopting the alloy material, the requirements of high temperature and high stress work condition can be met, the yield strength RP 0.02 is greater than or equal to 600 MPa, the alloy material can be used as an ultra supercritical turboset high-pressure and medium-pressure rotor alloy material, and the using requirement of a steam turbine rotor under the work environment is met. The alloy material is excellent in room-temperature pull-up performance and high-temperature endurance property, can be used as an supercritical and ultra supercritical turboset high-pressure and medium-pressure rotor alloy material, has important meaning for promoting the application and development of the ultra supercritical turboset and is worthy of large-scale popularization and application.

Owner:SICHUAN JIANGYOU LIUHE STEAM TURBINE MATERIAL

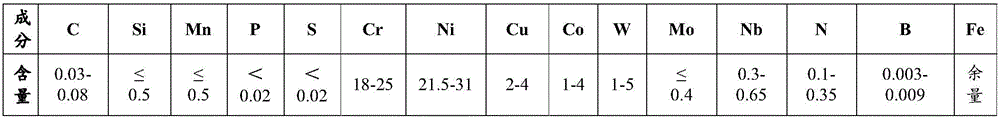

Heat-resistant stainless steel seamless pipe and preparation method thereof

The invention relates to the field of stainless steel, in particular to a heat-resistant stainless steel seamless pipe and a preparation method thereof. The heat-resistant stainless steel seamless pipe of the present invention, by weight percentage, includes: C 0.04-0.1%, Si≤0.4%, Mn≤0.5%, P≤0.03%, S≤0.02%, Cr 20-27%, Ni 23‑28%, Cu 2.0‑3.5%, W 2‑4%, Nb 0.2‑0.6%, N 0.1‑0.3%, Mo 0.05‑0.3%, B 0.002‑0.008%, the balance is Fe and other unavoidable impurity elements. The preparation method of the heat-resistant stainless steel seamless pipe of the present invention comprises the following steps: (1) smelting; (2) thermal processing of a tube blank; (3) thermal processing of a steel pipe; (4) cold processing of a steel pipe. The heat-resistant steel seamless pipe of the present invention has good mechanical properties, high-temperature durable strength, high-temperature oxidation resistance, high-temperature corrosion resistance and high-temperature structure stability, and can meet the use requirements of 630-650°C ultra-supercritical power plant boiler tubes .

Owner:TAIYUAN IRON & STEEL GROUP

Method for preparing high temperature resistant nickel base alloy

InactiveCN102808125AImprove high temperature durabilityHigh temperature strengthRoom temperatureIngot

The invention discloses a method for preparing high temperature resistant nickel base alloy. The nickel base alloy consists of the following components in percentage by weight: 26.0 to 28.0 percent of Cr, 5.3 to 5.7 percent of Co, 8.2 to 8.6 percent of Mo, 2.4 to 2.8 percent of W, 0.4 to 0.6 percent of V, 3.8 to 4.2 percent of Ta, 5.6 to 6.0 percent of Al, 1.3 to 1.7 percent of Ti, 2.1 to 2.5 percent of Nb, 0.004 to 0.006 percent of B, more than or equal to 0.1 percent and less than or equal to 0.4 percent of Cu, more than 0 percent and less than or equal to 0.08 percent of C, more than 0 percent and less than or equal to 0.3 percent of Si, more than 0 percent and less than or equal to 0.5 percent of Mn, and the balance of Ni; the method for preparing the high temperature resistant nickel base alloy comprises the following steps of: mixing the components of the alloy, smelting, controlling vacuum degree to be 0.01 to 0.1Pa, and fully melting all raw materials, and then keeping smelting power constant for 15 to 25 minutes; improving the vacuum degree to be about 0.001 to 0.01Pa, refining at the temperature of between 1,650 and 1,670 DEG C for 6 to 8 minutes, and adjusting the components to ensure that the components meet the requirement; adjusting temperature to be 1,600 to 1,620 DEG C, and pouring to obtain ingots; performing heat treatment, heating the cast ingots to be 1,250 to 1,270 DEG C, preserving heat for 3 to 5hours, performing air cooling to room temperature, heating to 1,140 to 1,160 DGE C, preserving heat for 3 to 5 hours, and performing air cooling to room temperature; and heating to 1,050 to 1,070 DEG C, preserving heat for 30 to 36 hours, and performing air cooling to room temperature.

Owner:瑞安市劲力机械制造有限公司

Heat treatment method of low-expansion high-temperature alloy

The invention discloses a heat treatment method of low-expansion high-temperature alloy, and particularly relates to the heat treatment method of the low-expansion high-temperature alloy in the fieldof heat treatment of metal materials. The heat treatment method of the low-expansion high-temperature alloy, provided by the invention, comprises the following steps: A, heating the alloy to 820-920 DEG C, preserving heat for 20 min to 2 h, and then performing air cooling; B, heating the alloy to 960-980 DEG C, preserving heat for 30 min to 2 h, and then performing air cooling; C, heating the alloy to 720-745 DEG C, and preserving heat for 4-8 h; and D, cooling the alloy to 620 DEG C at a cooling speed of 55 DEG C / h, preserving heat for 4 h, and then performing air cooling. By the heat treatment method of the low-expansion high-temperature alloy, the comprehensive performance of the alloy can be improved and the notch sensitivity of the alloy can be eliminated.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com