Patents

Literature

86results about How to "Excellent high temperature durability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Non-aqueous electrolyte secondary battery

ActiveUS7452631B2Excellent high temperature durabilityIncrease storage capacityNon-aqueous electrolyte accumulatorsActive material electrodesManganeseBattery capacity

Owner:PANASONIC ENERGY CO LTD

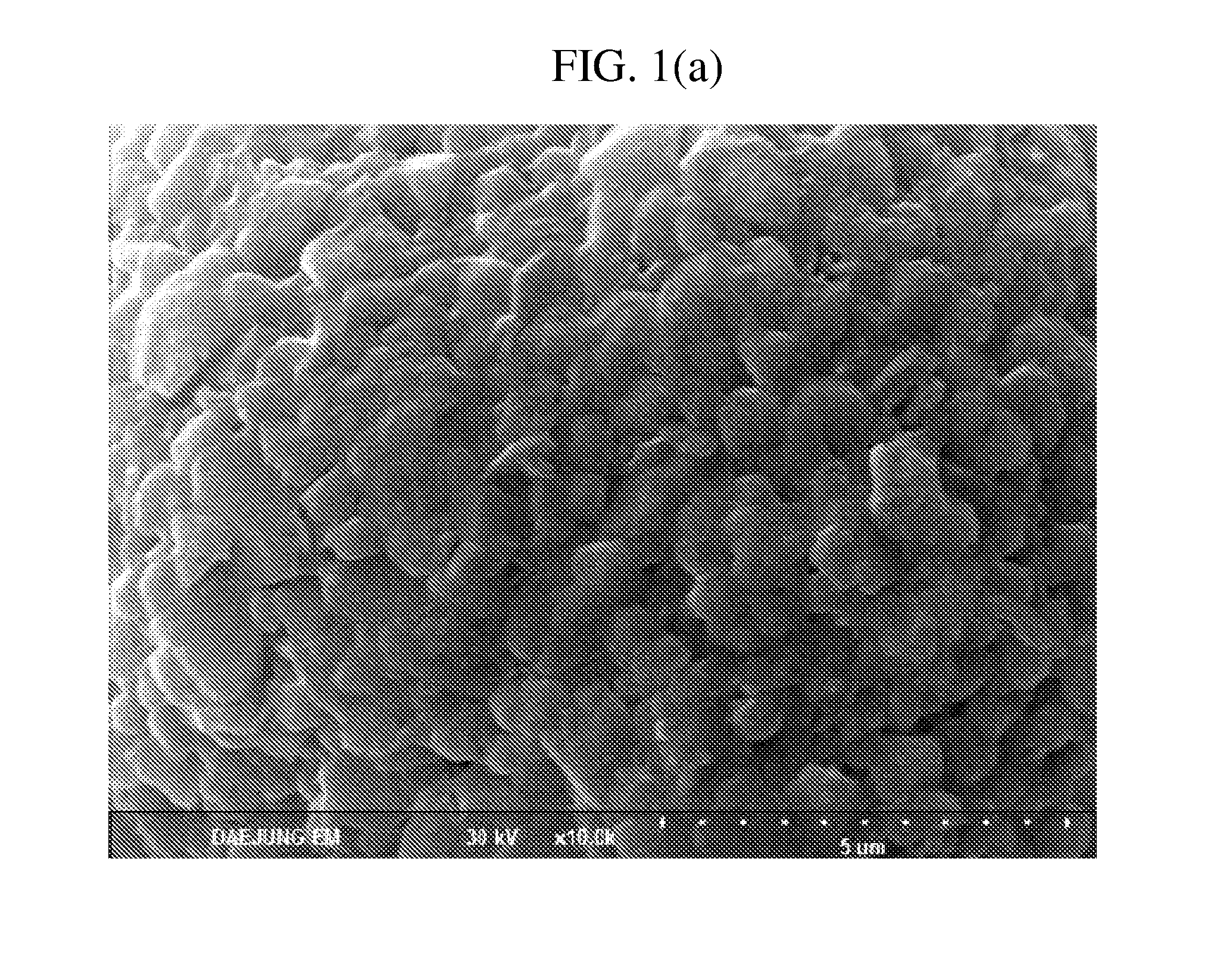

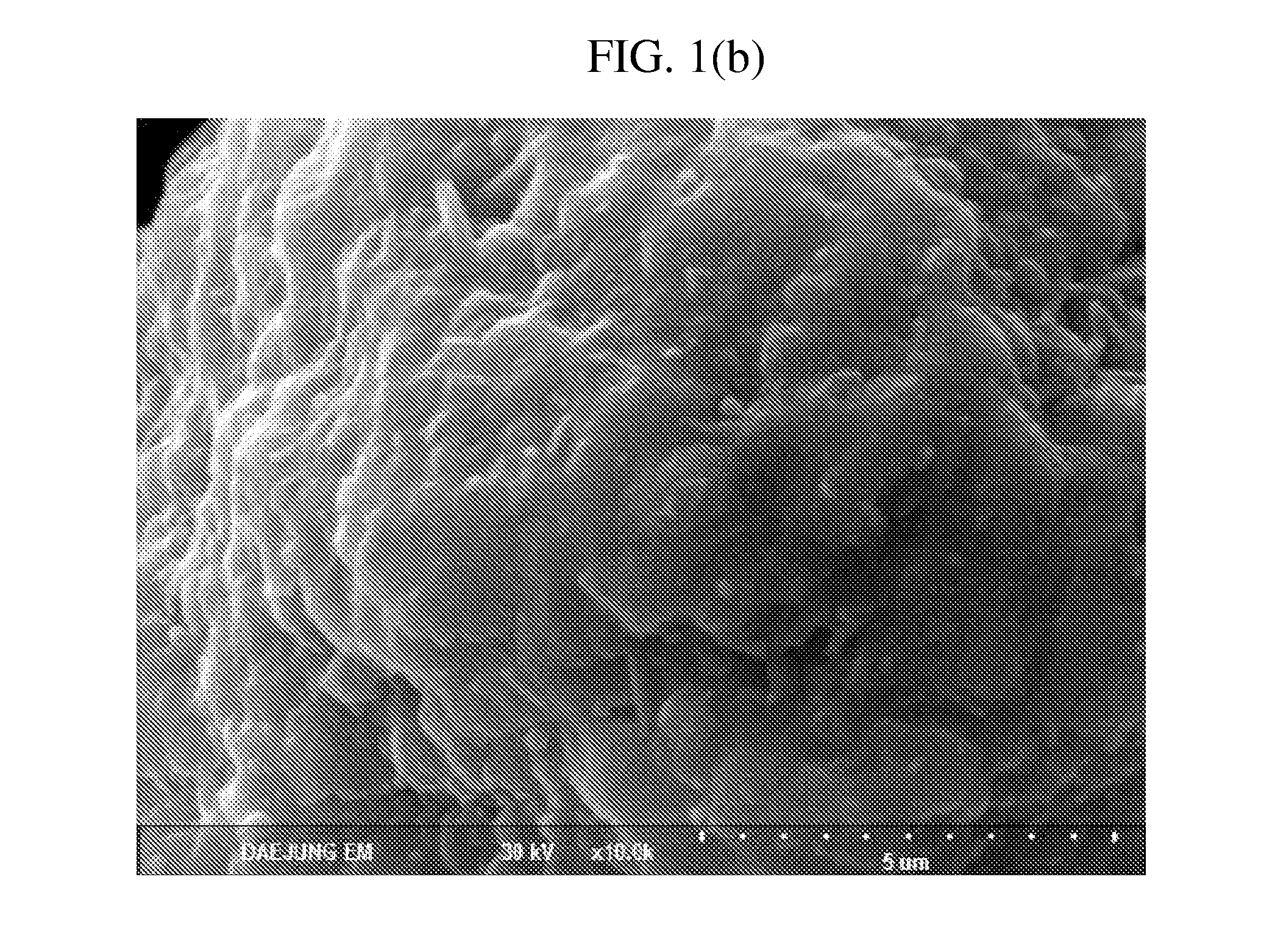

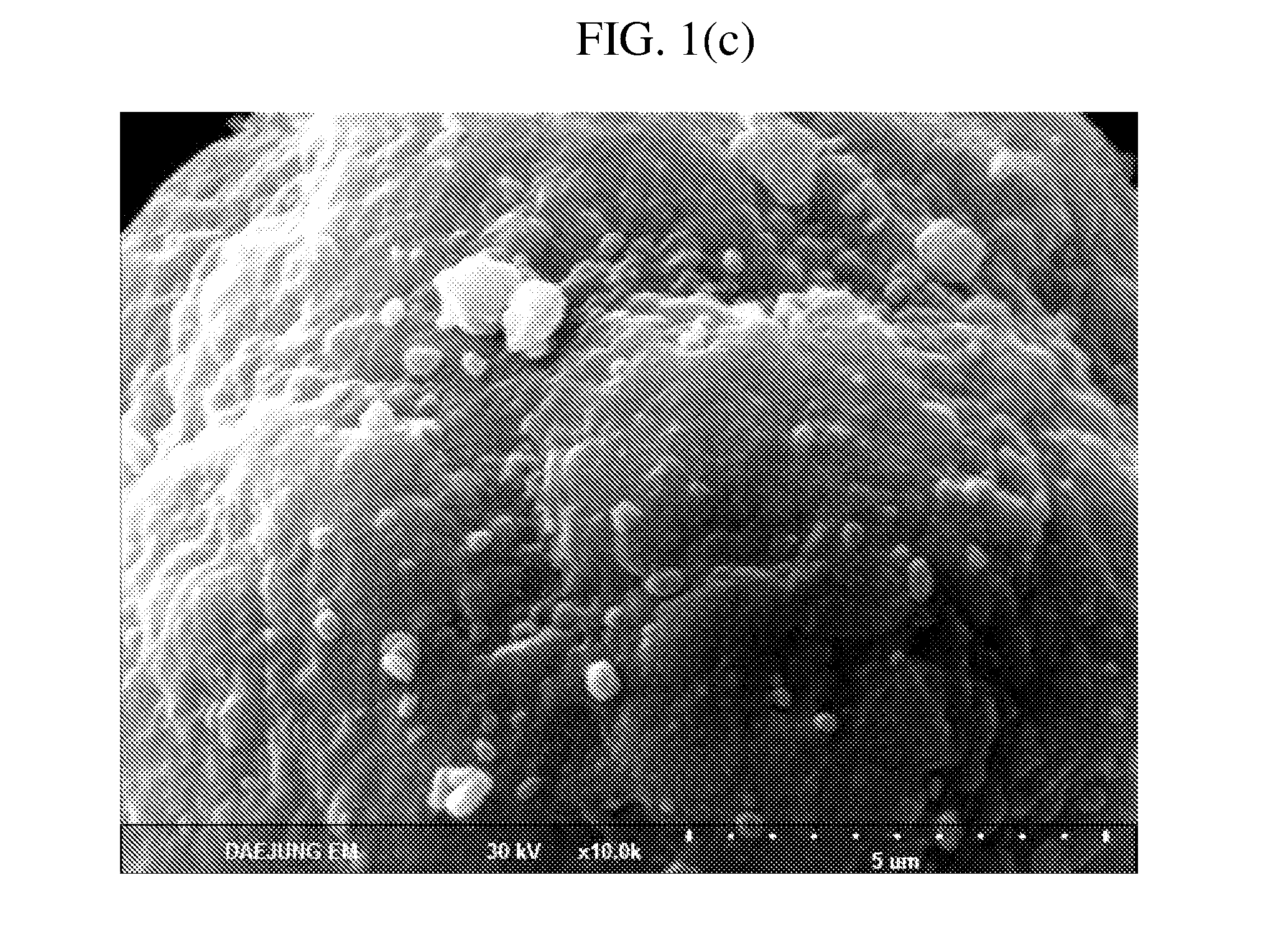

Cathode active material for lithium secondary batteries, method for preparing the same, and lithium secondary batteries comprising the same

ActiveUS20110052991A1Excellent characteristicsExcellent high temperature durabilityAlkaline accumulator electrodesCobalt compoundsOverchargeOxide

Disclosed are a cathode active material for lithium secondary batteries, a method for preparing the same, and lithium secondary batteries comprising the same. The cathode active material for lithium secondary batteries comprises a lithium metal oxide secondary particle core formed by aggregation of a plurality of lithium metal oxide primary particles; a first shell formed by coating the surface of the secondary particle core with a plurality of barium titanate particles and a plurality of metal oxide particles; and a second shell formed by coating the surface of the first shell with a plurality of olivine-type lithium iron phosphate oxide particles and a plurality of conductive material particles. The cathode active material for lithium secondary batteries allows manufacture of lithium secondary batteries having excellent thermal stability, high-temperature durability and overcharge safety.

Owner:SOLAREDGE TECH KOREA LTD CO

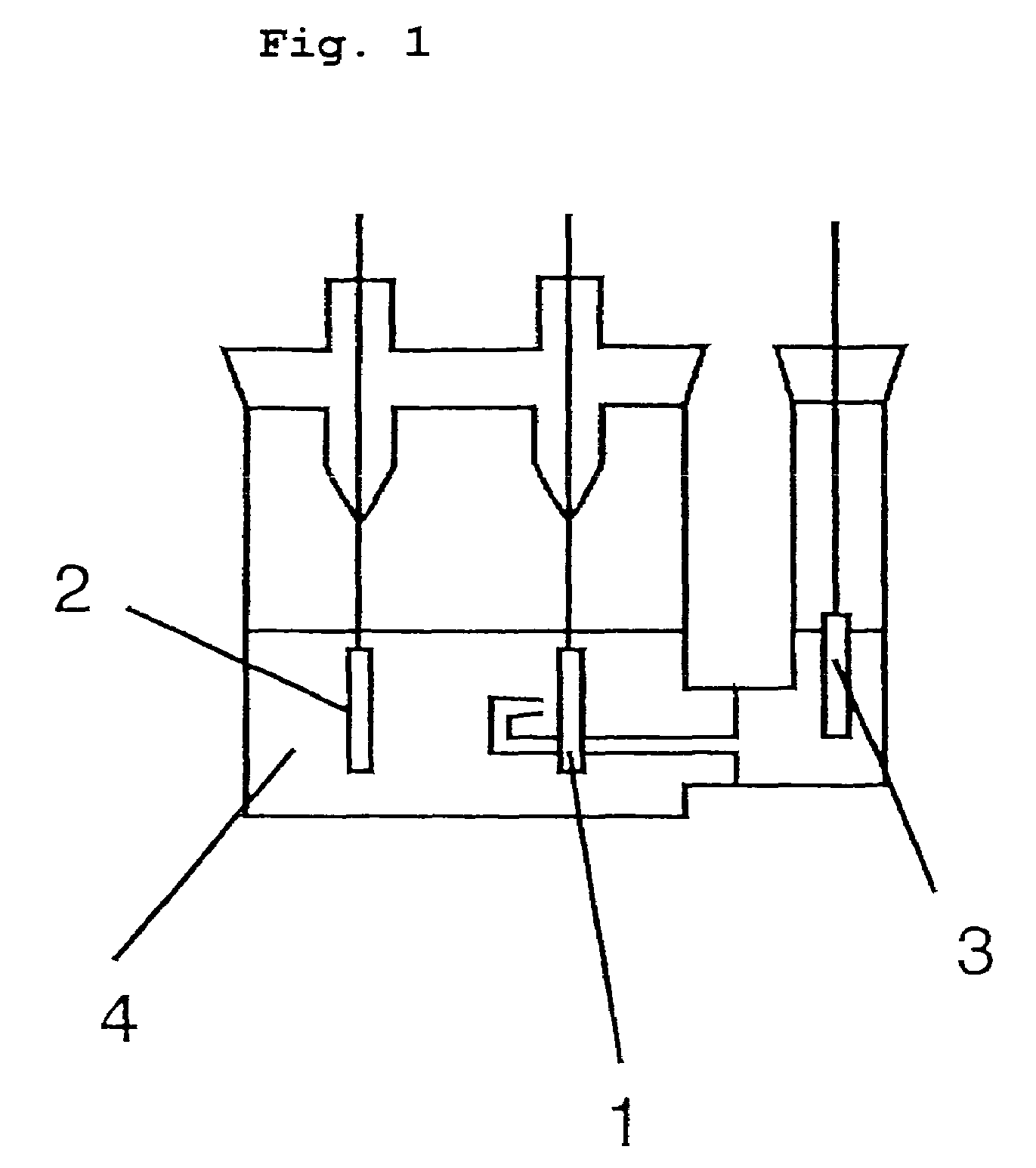

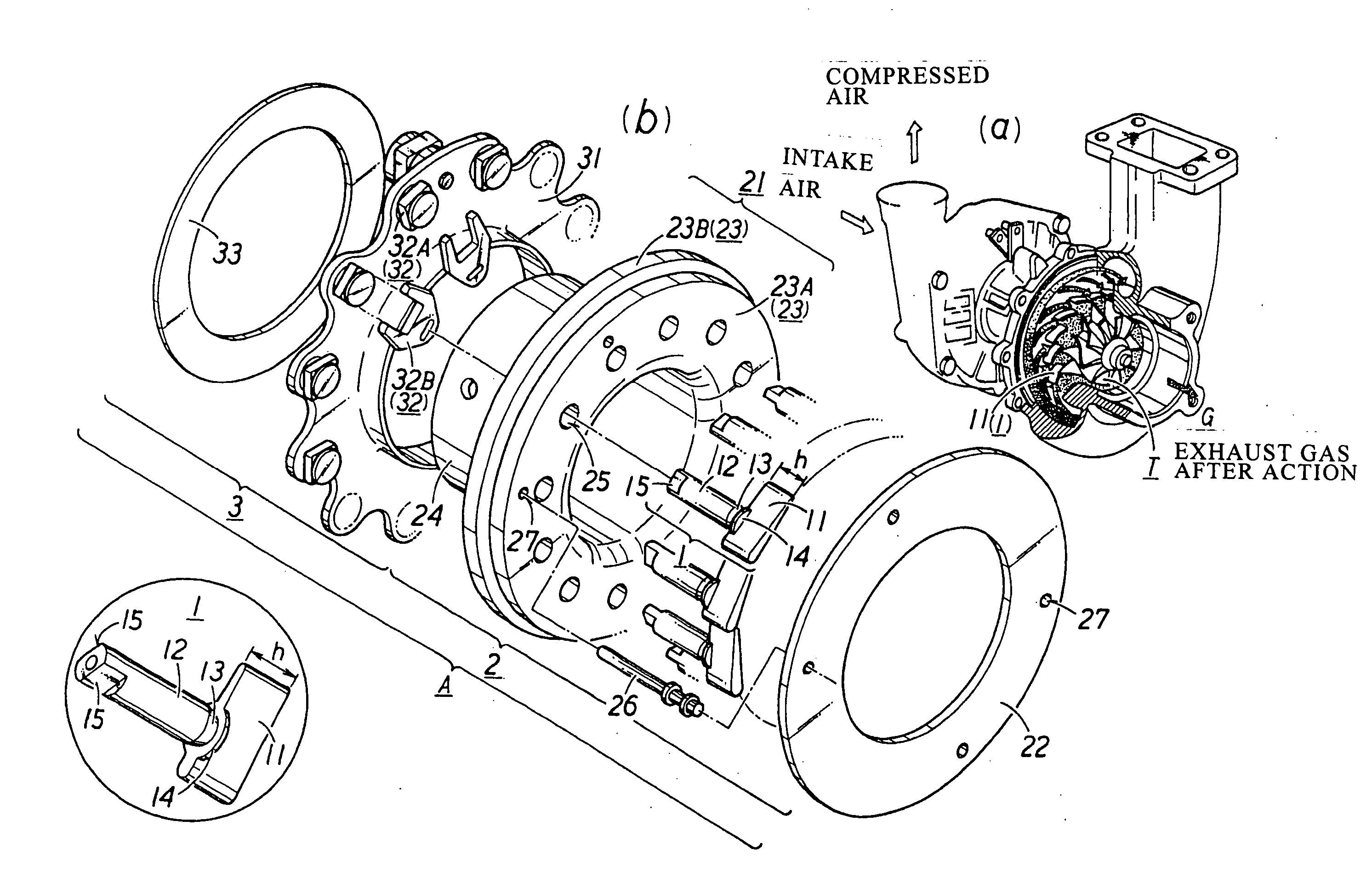

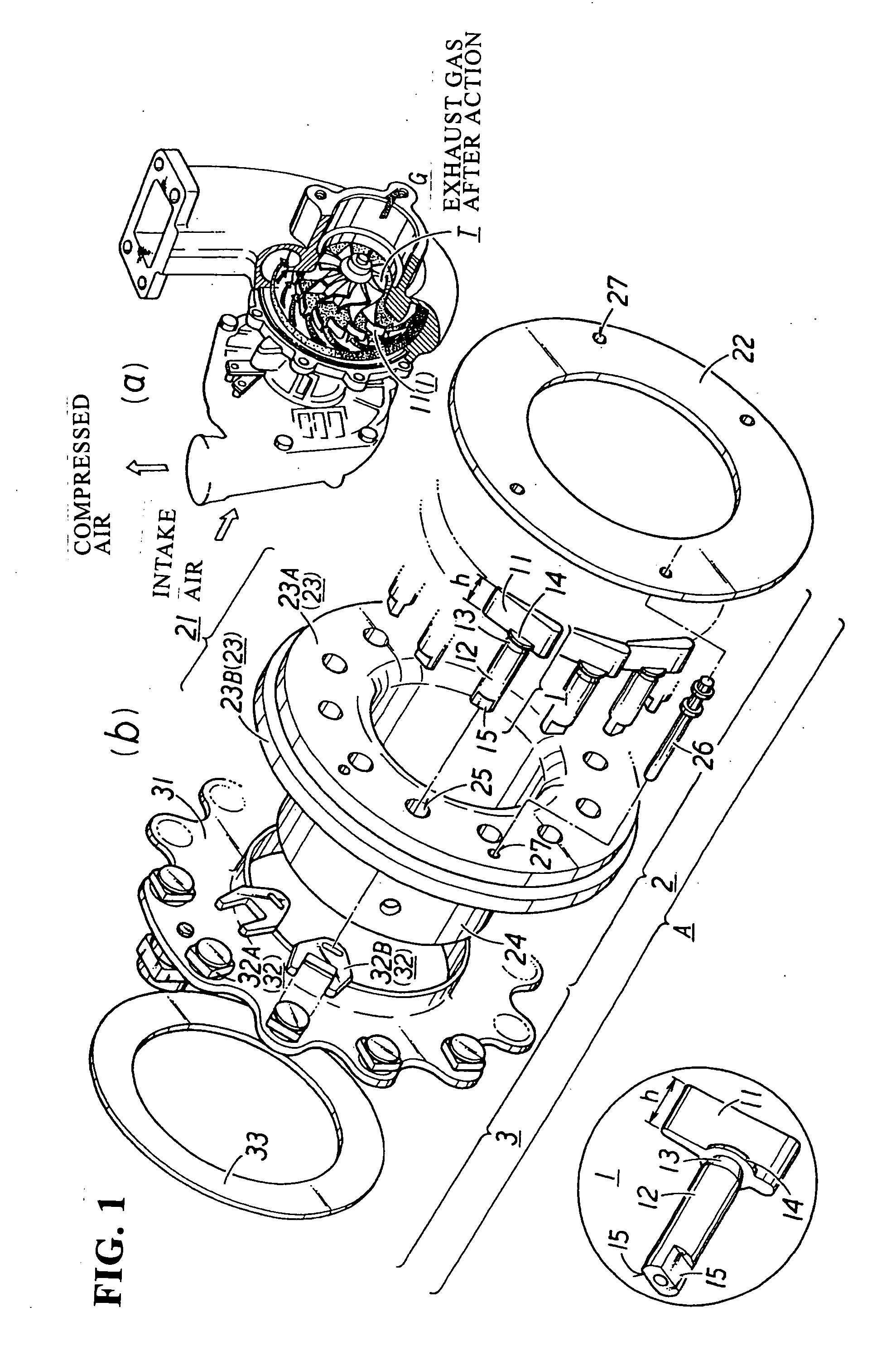

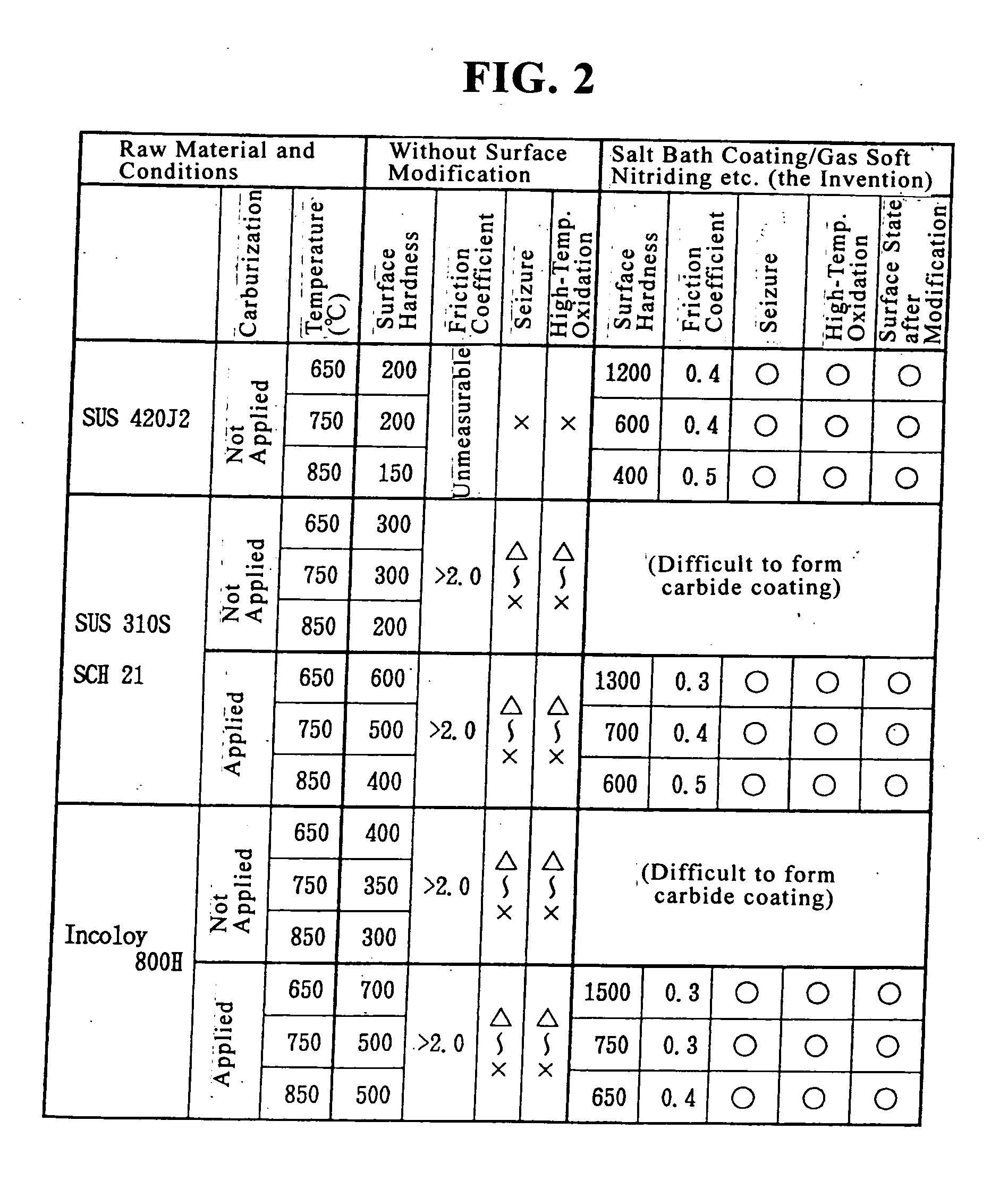

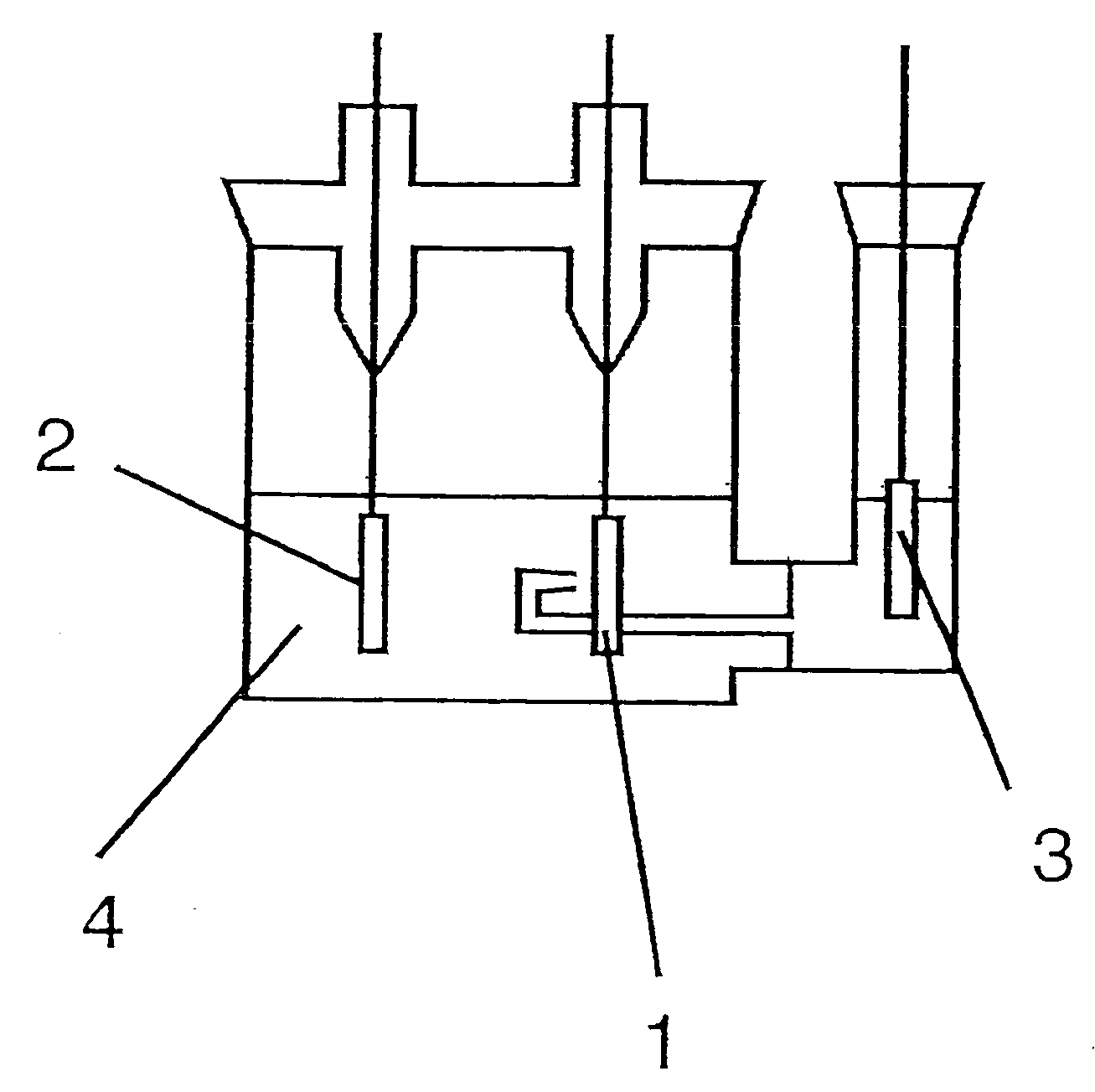

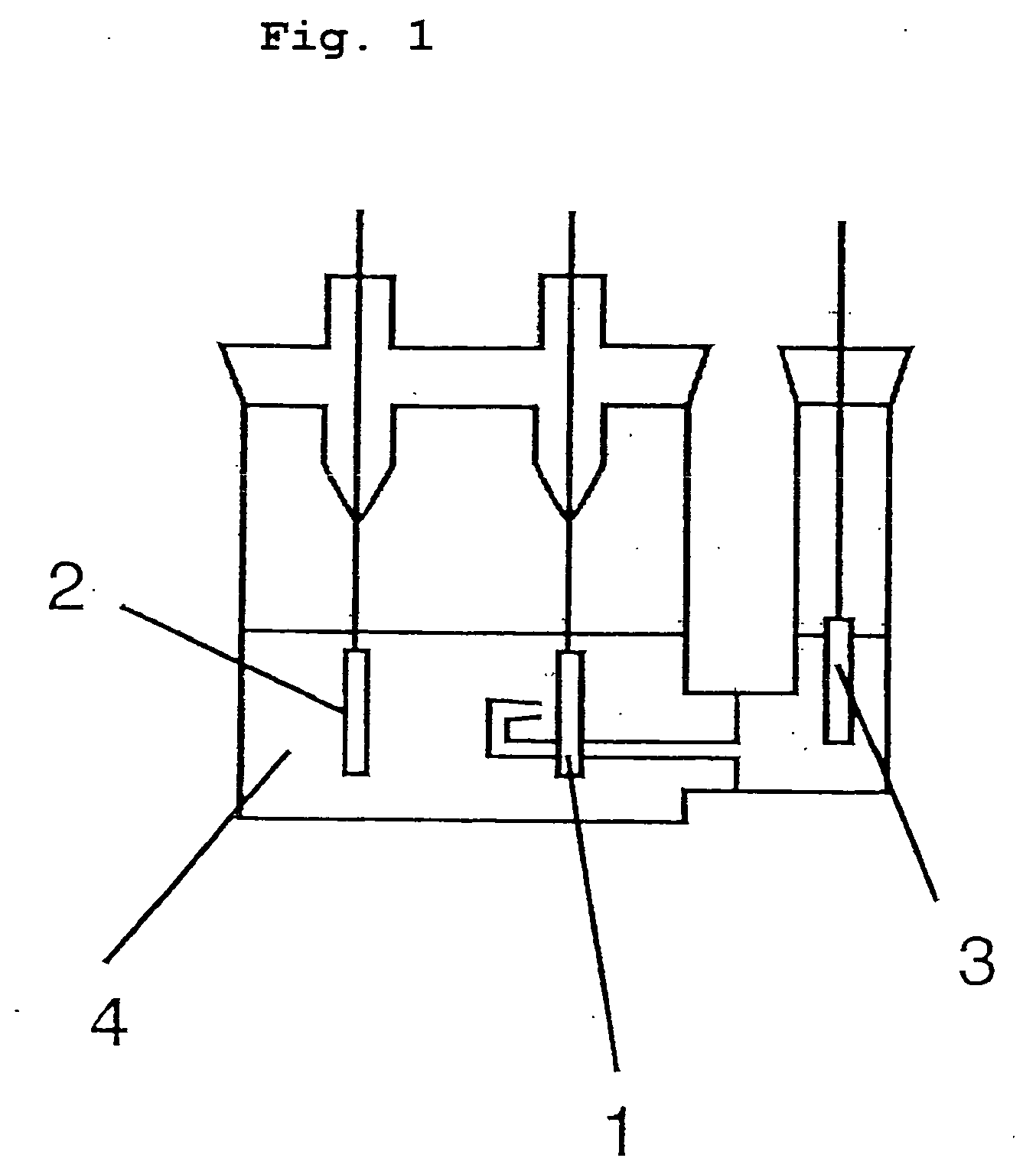

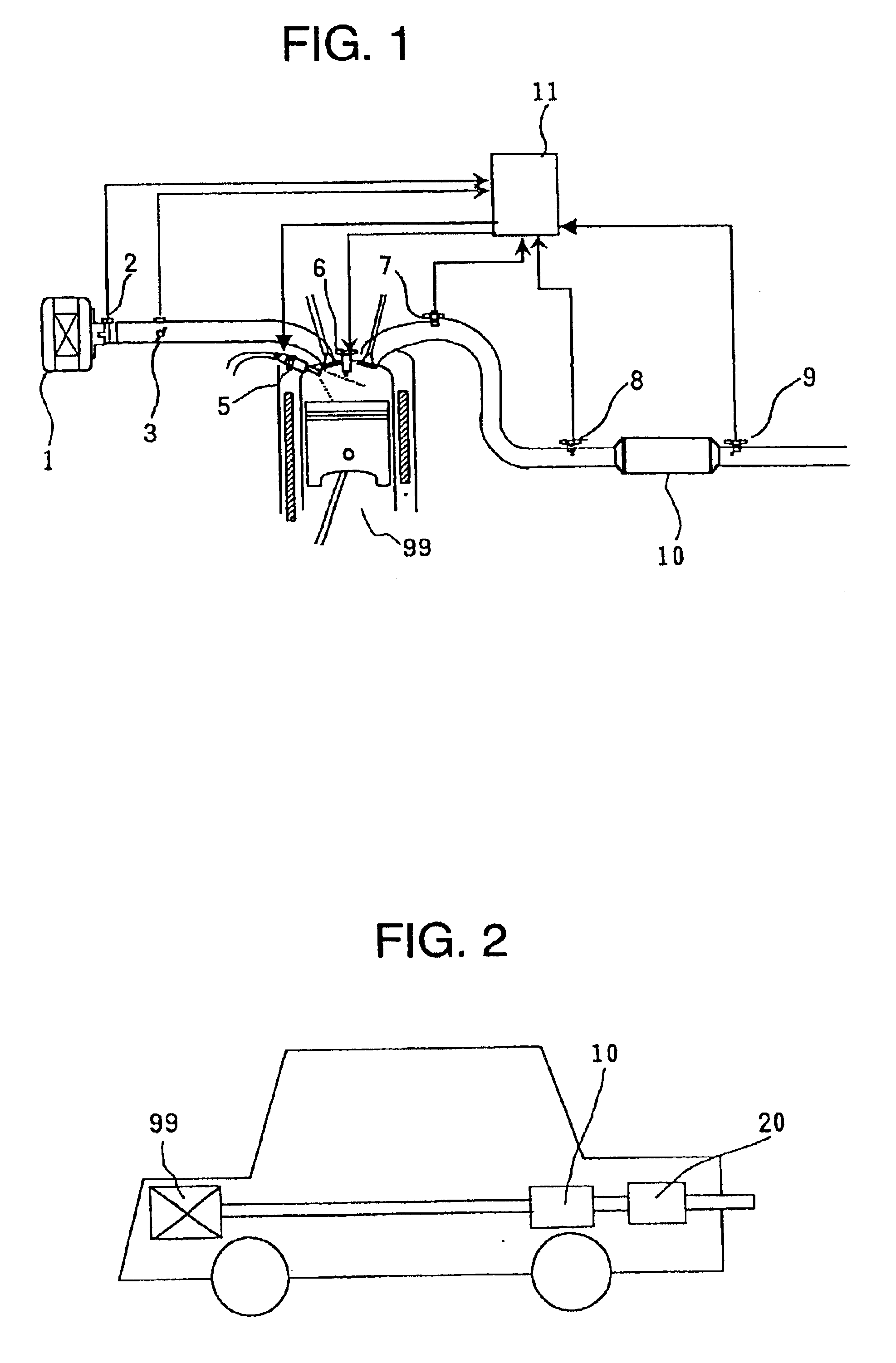

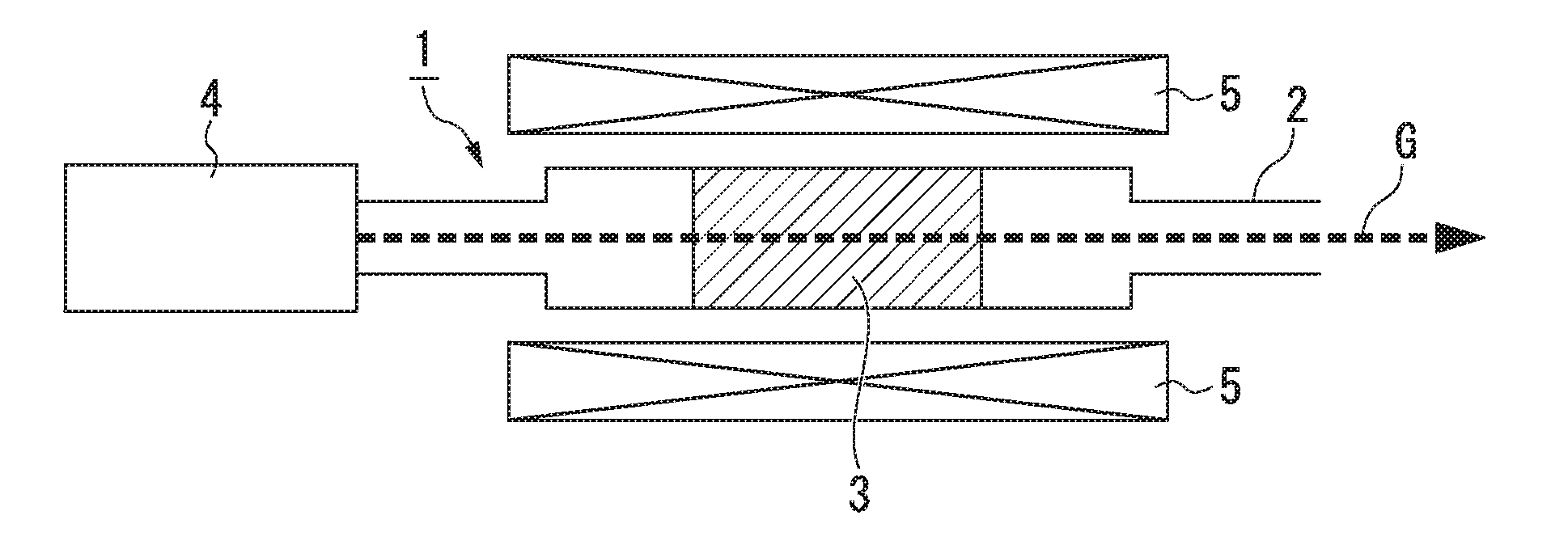

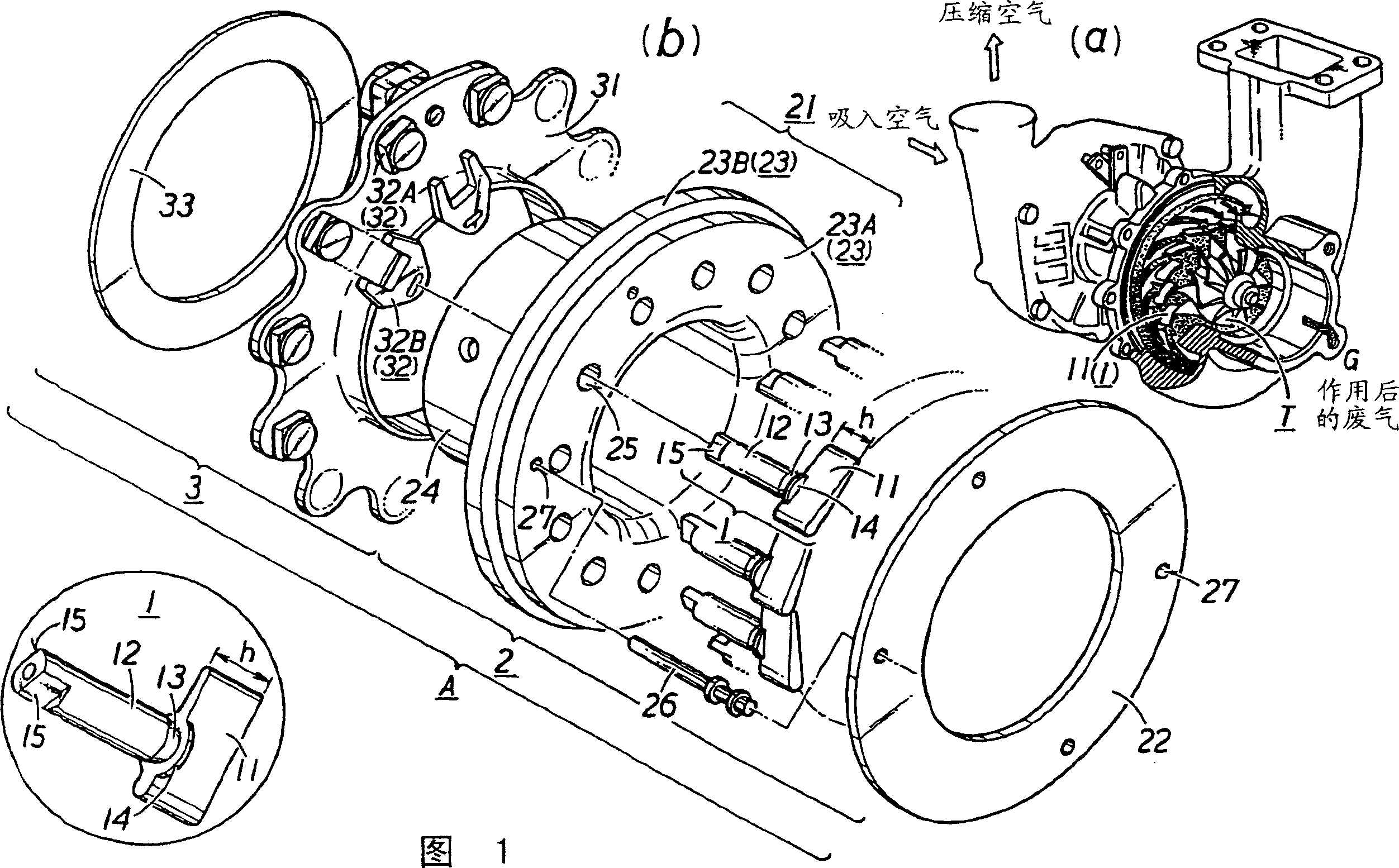

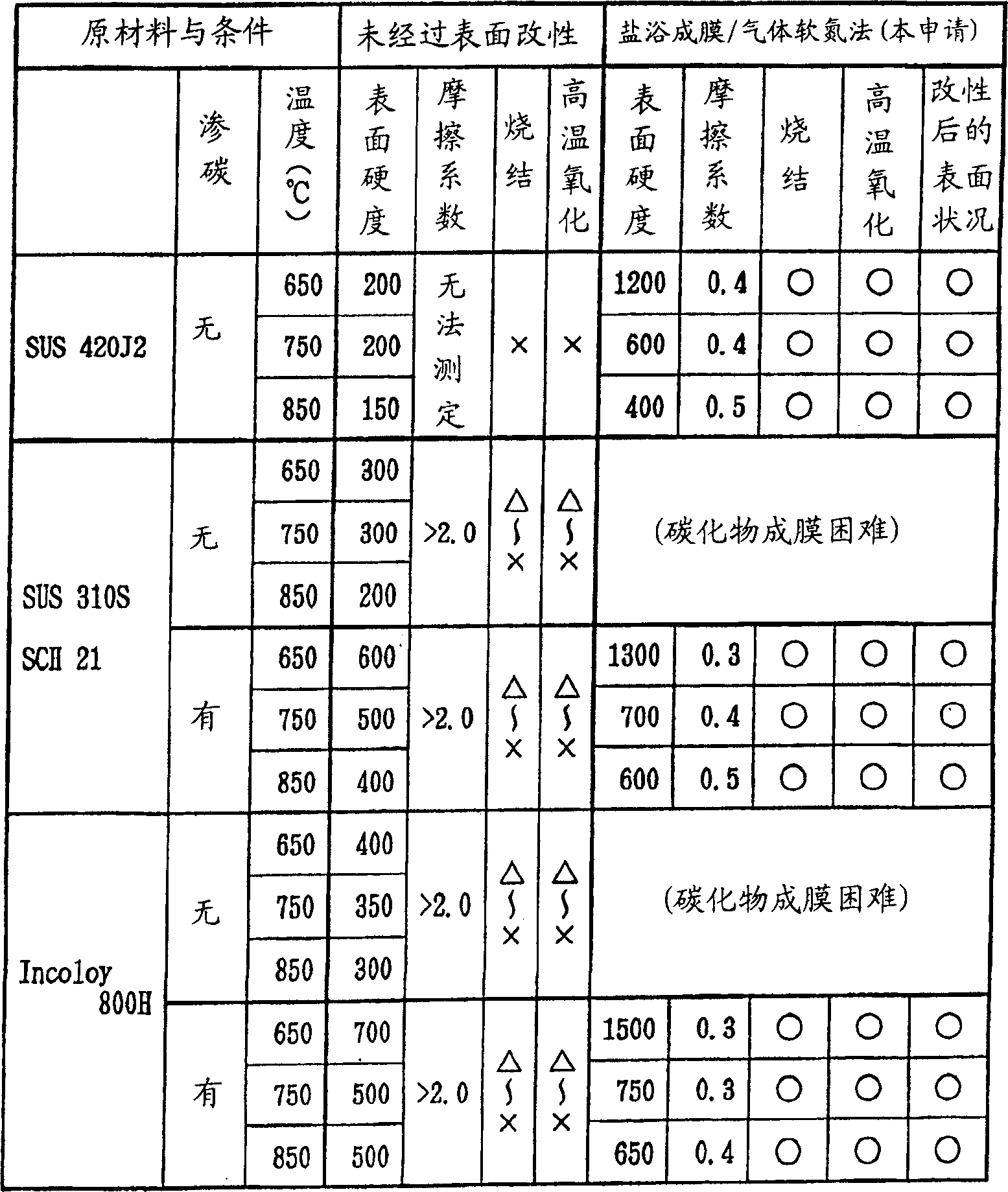

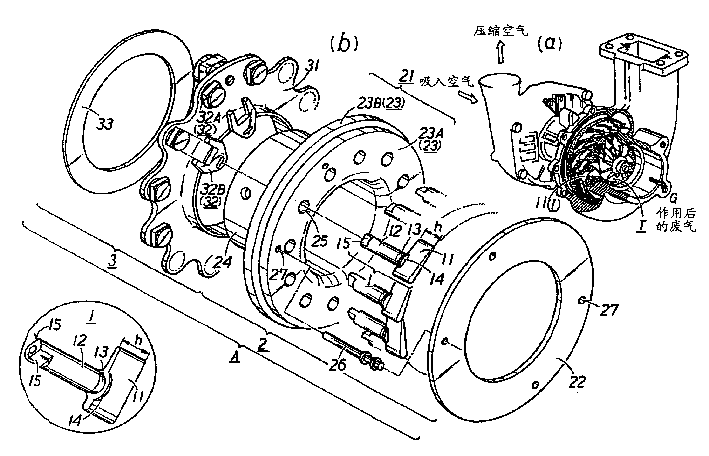

Surface-reformed exhaust gas guide assembly of vgs type turbo charger, and method surface-reforming component member thereof

InactiveUS20050011192A1Increased durabilityExcellent high temperature durabilityHot-dipping/immersion processesInternal combustion piston enginesTurbochargerEngineering

A novel exhaust gas guide assembly with an improved high-temperature sliding wear resistance, oxidation resistance, high-temperature strength or the like for a VGS turbocharger is provided. The invention is characterized in that a surface modification is applied to a component member of the exhaust gas guide assembly (A), such as adjustable blades (1), a turbine frame (2), a blade adjusting mechanism (3), or the like.

Owner:AKITA FINE BLANKING +1

Nonaqueous Lithium-Type Power Storage Element

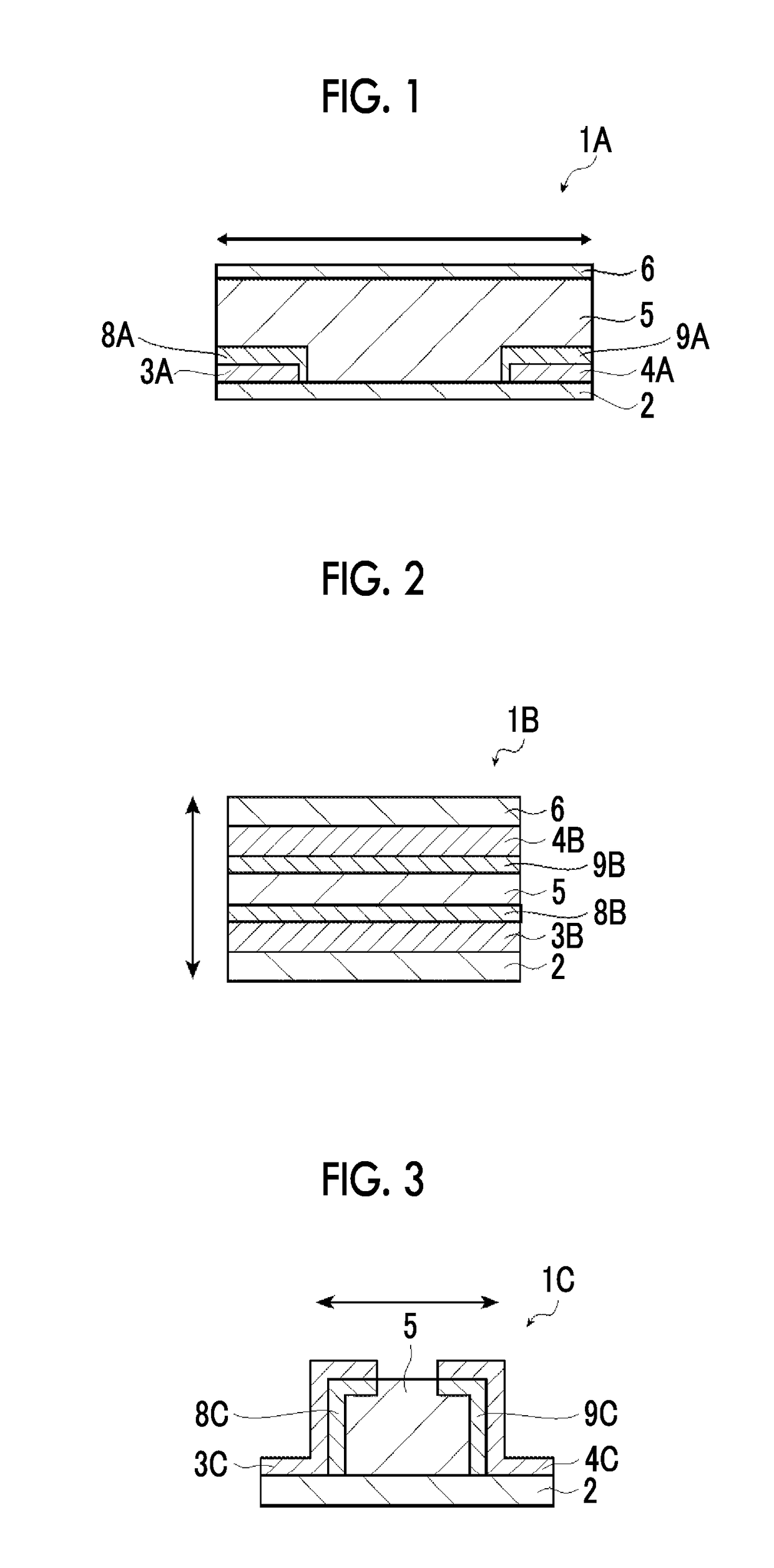

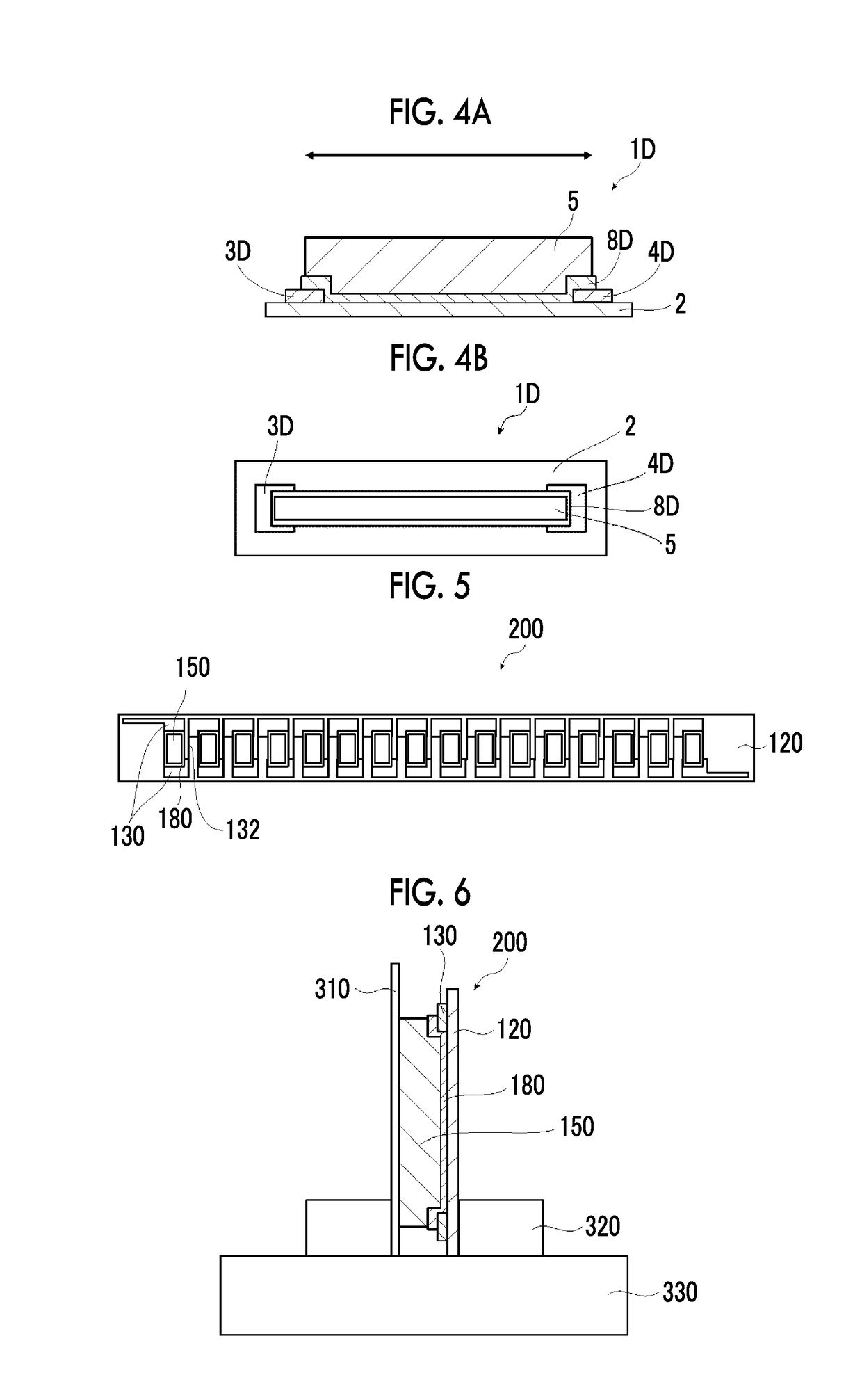

ActiveUS20170207459A1Improve featuresExcellent high temperature durabilityHybrid capacitor separatorsHybrid capacitor electrolytesLithiumEngineering

A non-aqueous lithium-type power storage element obtained by a non-aqueous liquid electrolyte and an electrode laminate having a negative electrode body, a positive electrode body, and a separator being accommodated in an exterior body, wherein: the negative electrode body includes a negative electrode current collector and a negative electrode active material including a carbon material capable of occluding and releasing lithium ions.

Owner:ASAHI KASEI KK

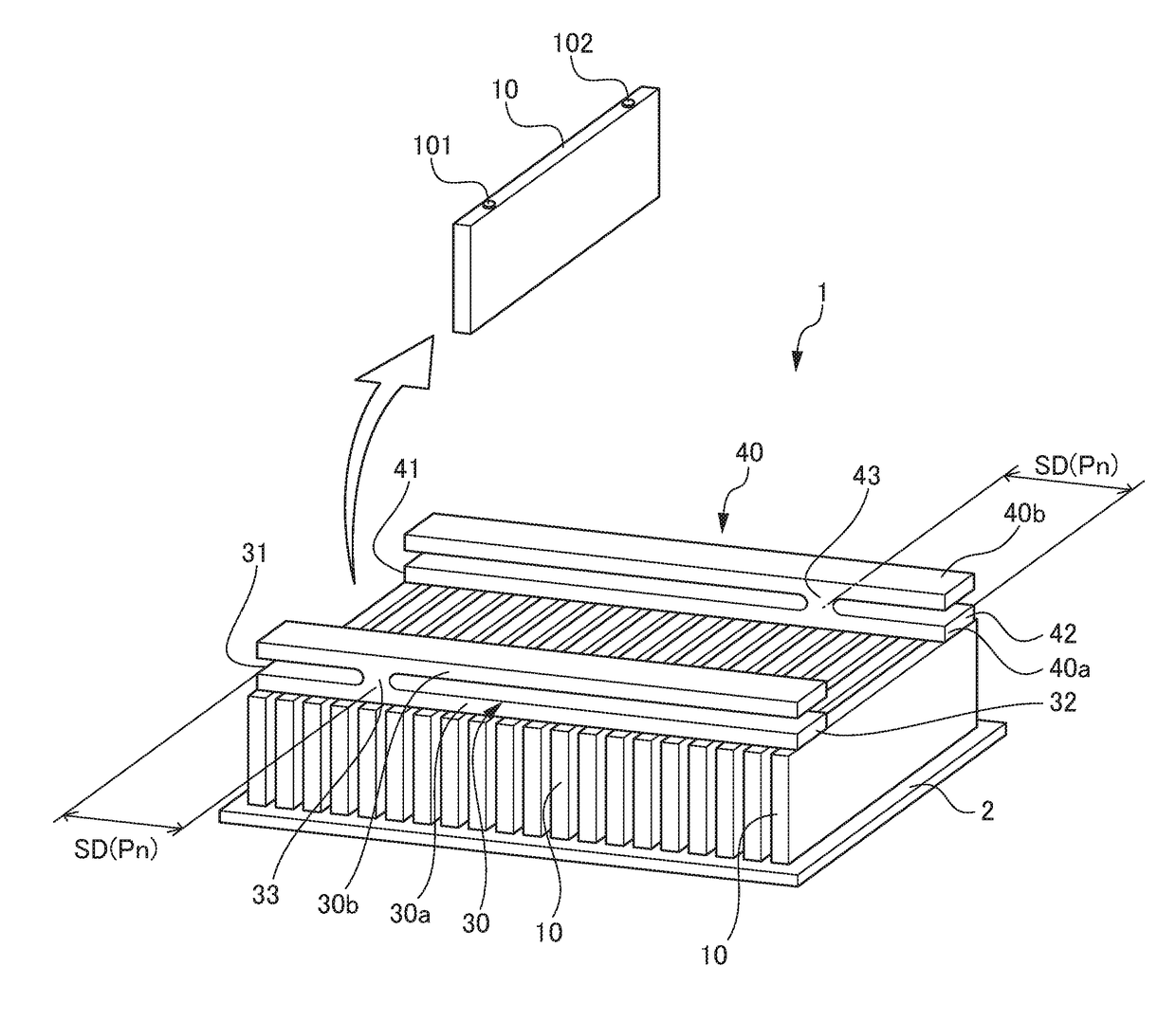

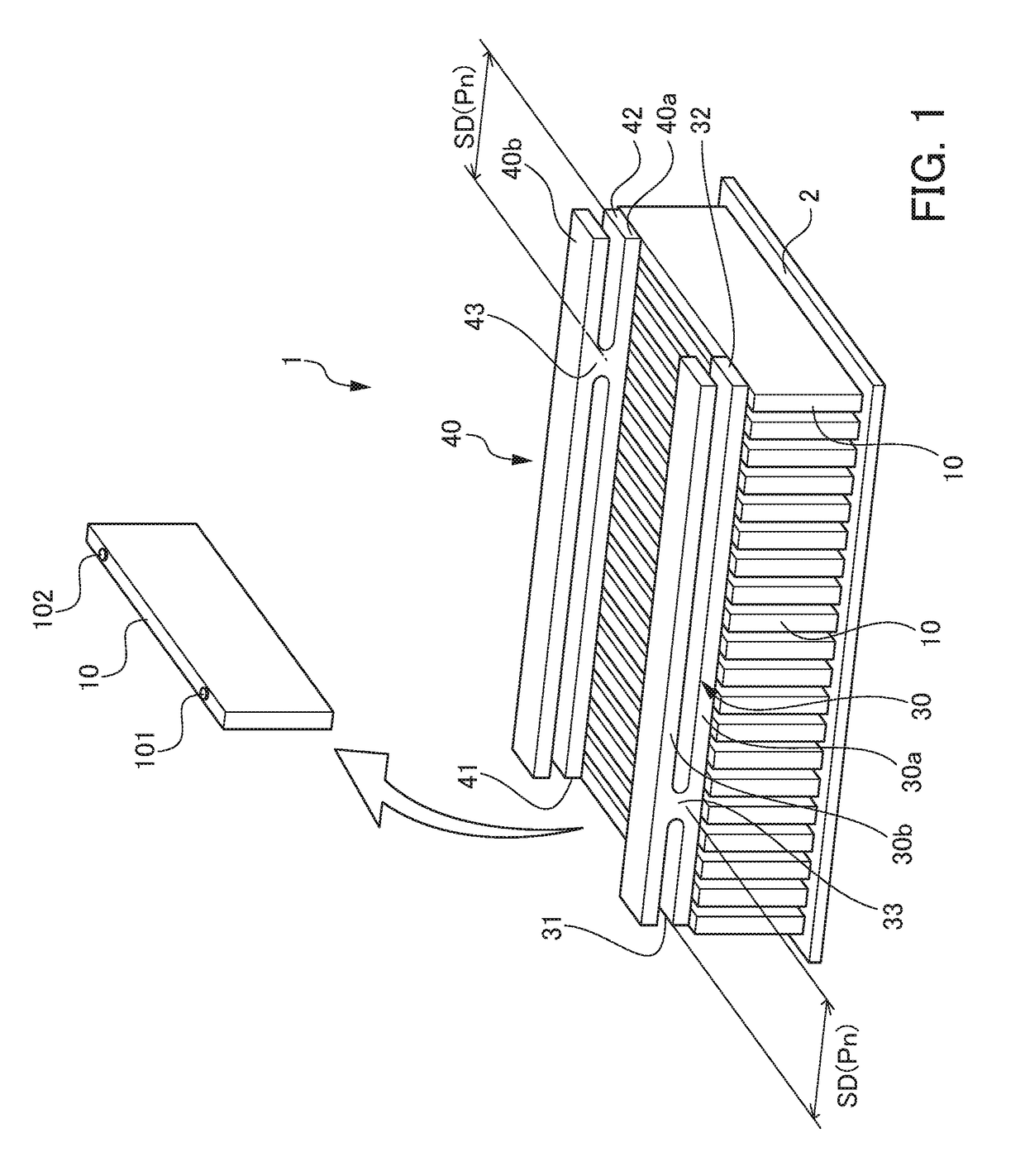

Capacitor-type power supply unit

ActiveUS20180330895A1Extended service lifeExcellent high temperature durabilityMultiple fixed capacitorsHybrid capacitor electrodesTypes of capacitorExternal connection

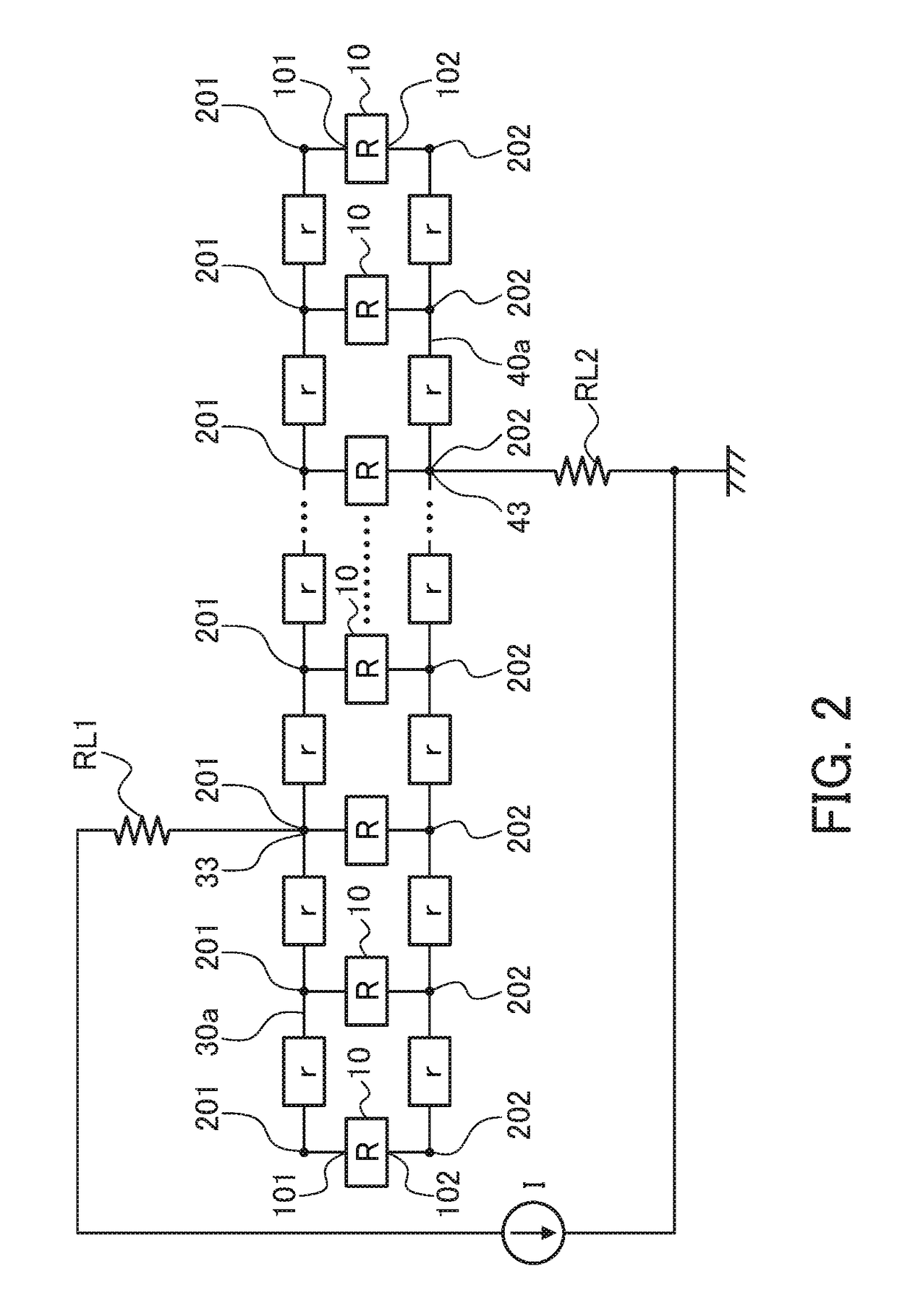

A capacitor-type power supply unit including:a positive bus to which a plurality of capacitor is connected in parallel at each positive-electrode terminal thereof with maintaining equal intervals therebetween, and extends in a parallel direction; and an negative bus to which the plurality of capacitor is connected in parallel, at each negative-electrode terminal thereof with maintaining equal intervals therebetween, and extends in the parallel direction, in which the positive bus has a positive-electrode-side external connection part that is set at a position (SD) separated from the positive-electrode first end by a range of 20% to 30% of the total length in the longitudinal direction thereof, and the negative bus has an negative-electrode-side external connection part that is set at a position (SD) separated from the negative-electrode second end by a range of 20% to 30% of the total length in the longitudinal direction thereof.

Owner:HONDA MOTOR CO LTD

Gel polymer electrolyte and lithium secondary battery including the same

ActiveUS20180342767A1Improve stabilityIncrease freedomSolid electrolytesFinal product manufacturePolymer electrolytesPolymer science

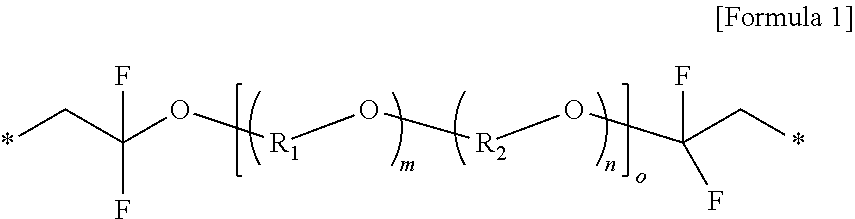

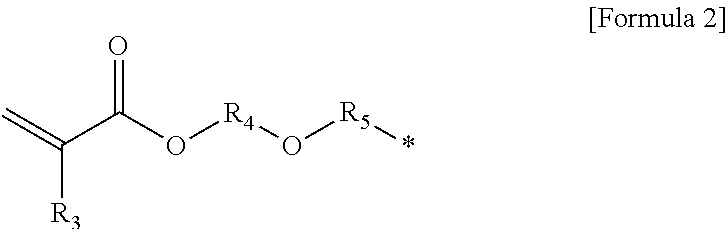

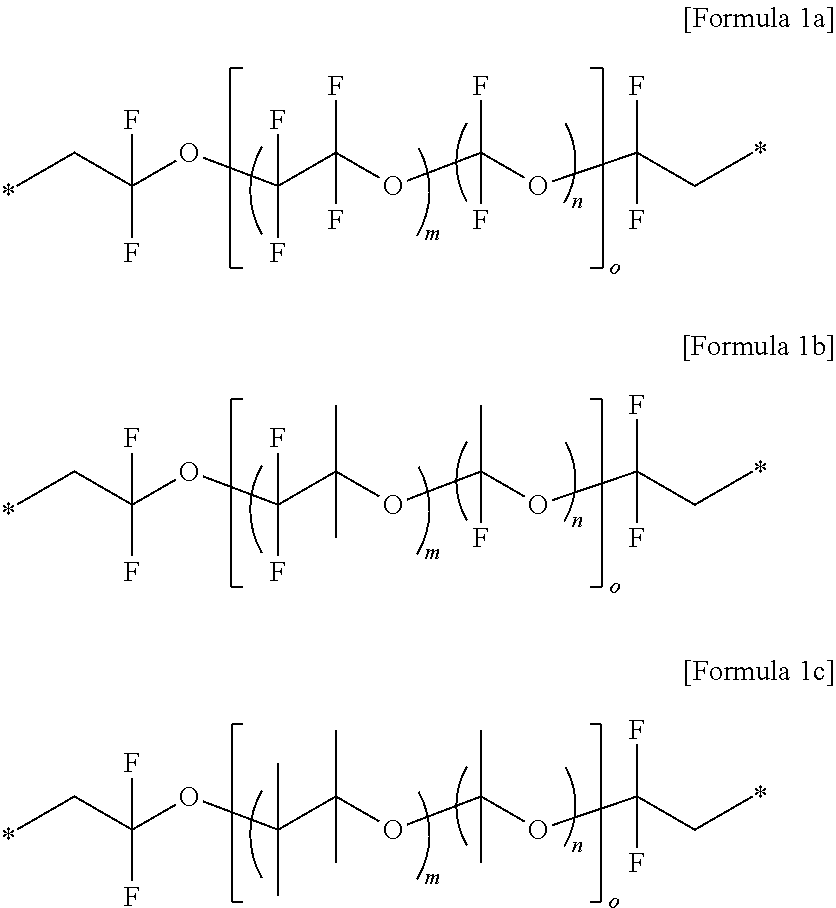

The present invention relates to a gel polymer electrolyte, which includes a matrix polymer and an electrolyte solution impregnated in the matrix polymer, wherein the matrix polymer is formed in a three-dimensional network structure by polymerizing a first oligomer which includes unit A represented by Formula 1 and unit B having a crosslinkable functional group derived from a compound including at least one copolymerizable acrylate group, and a lithium secondary battery including the same.

Owner:LG ENERGY SOLUTION LTD

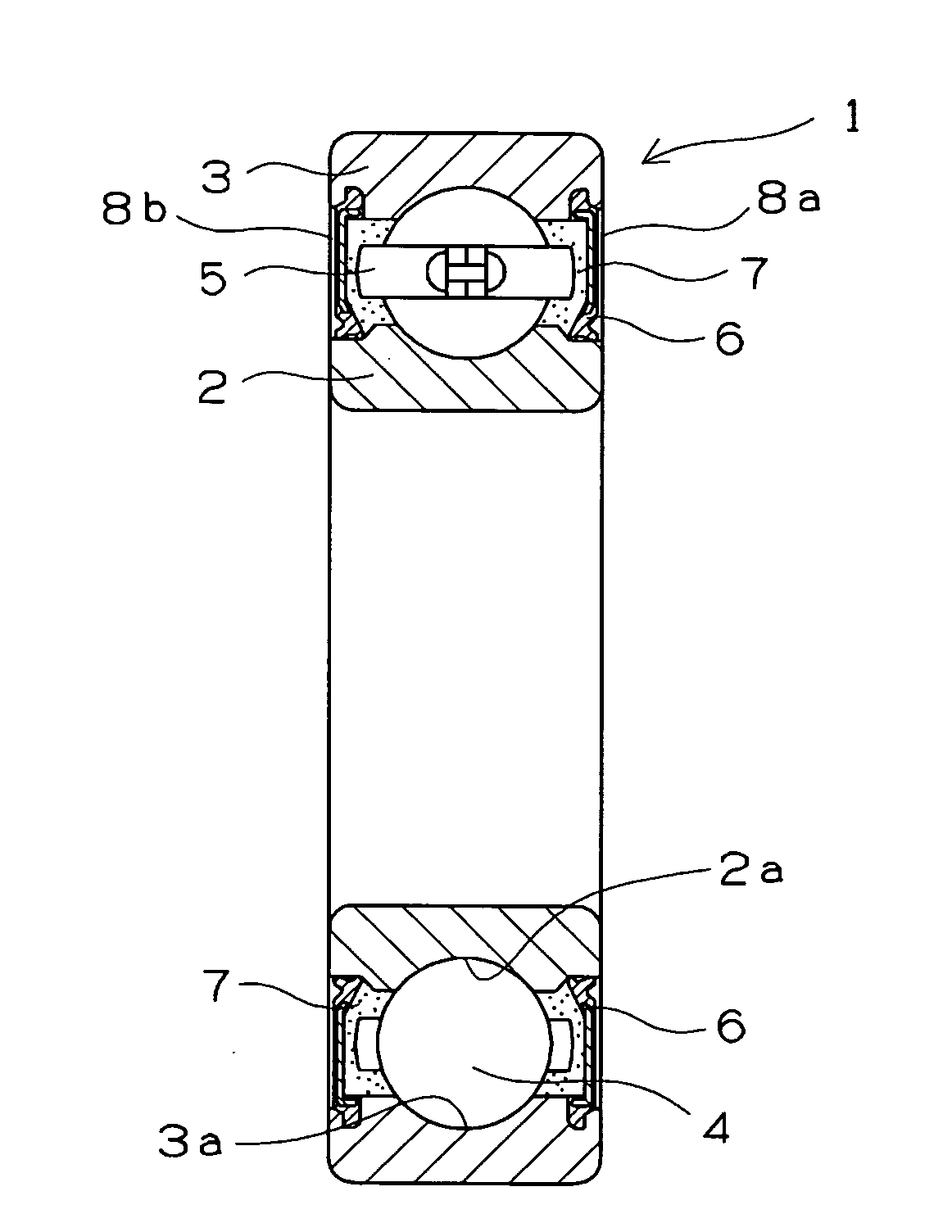

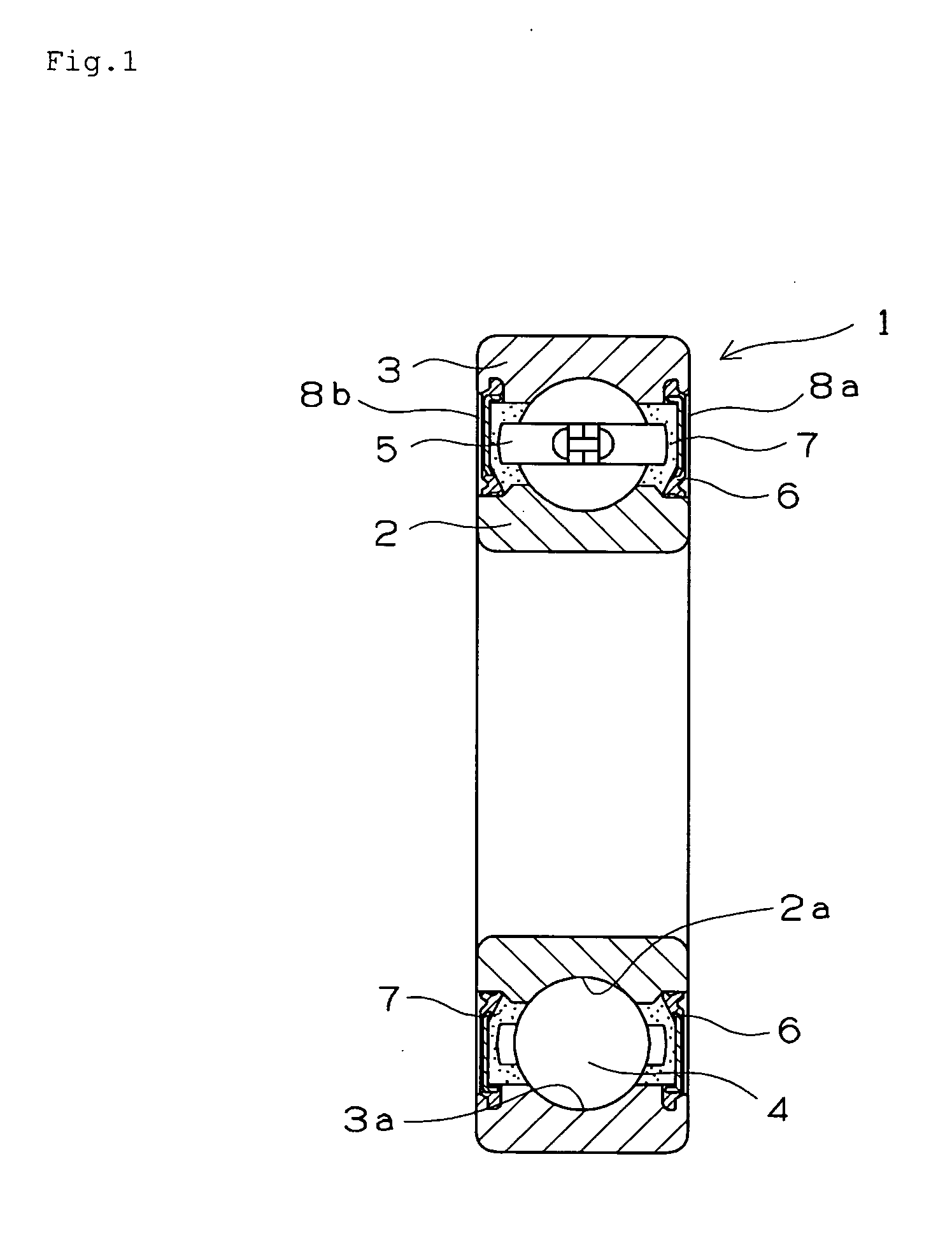

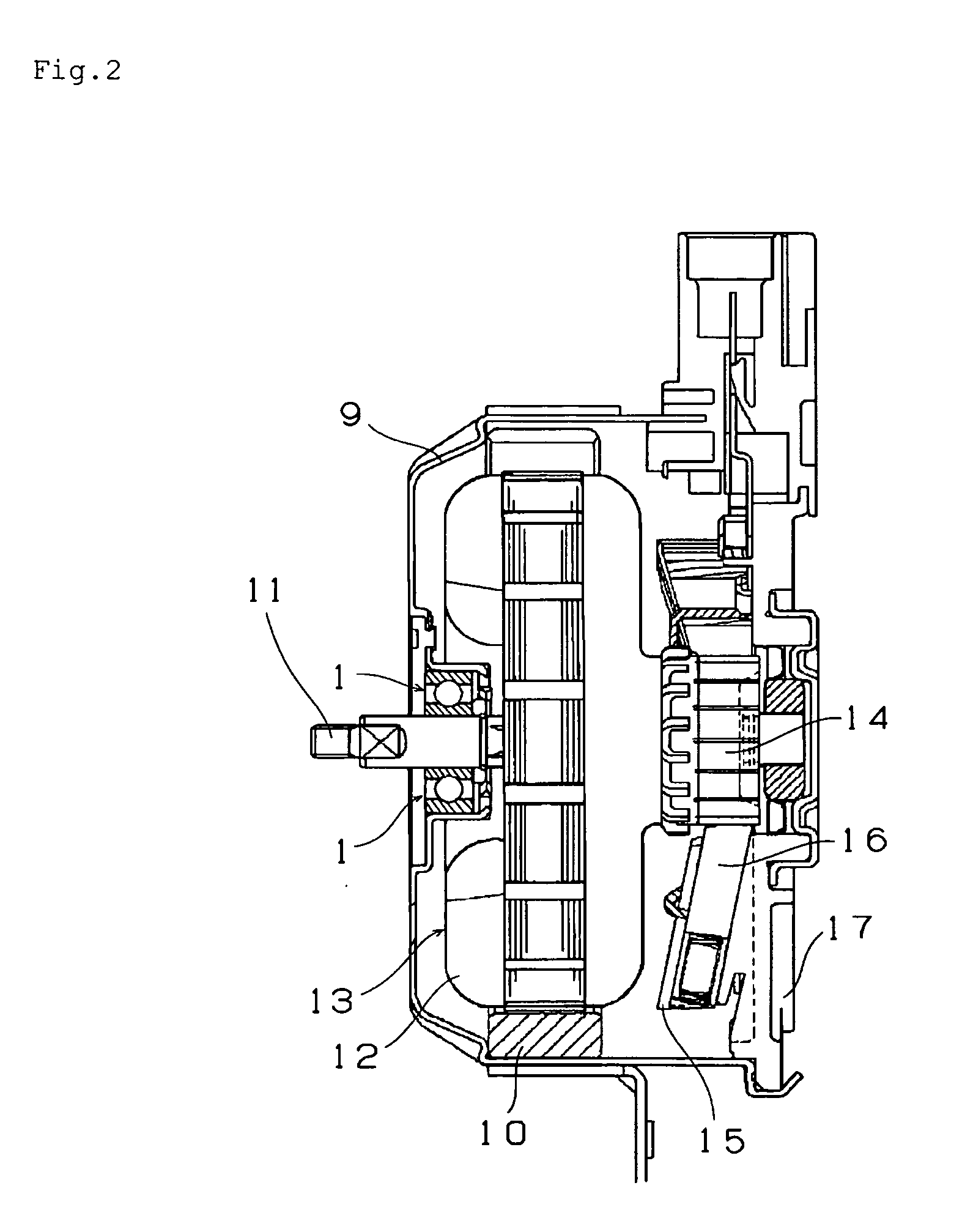

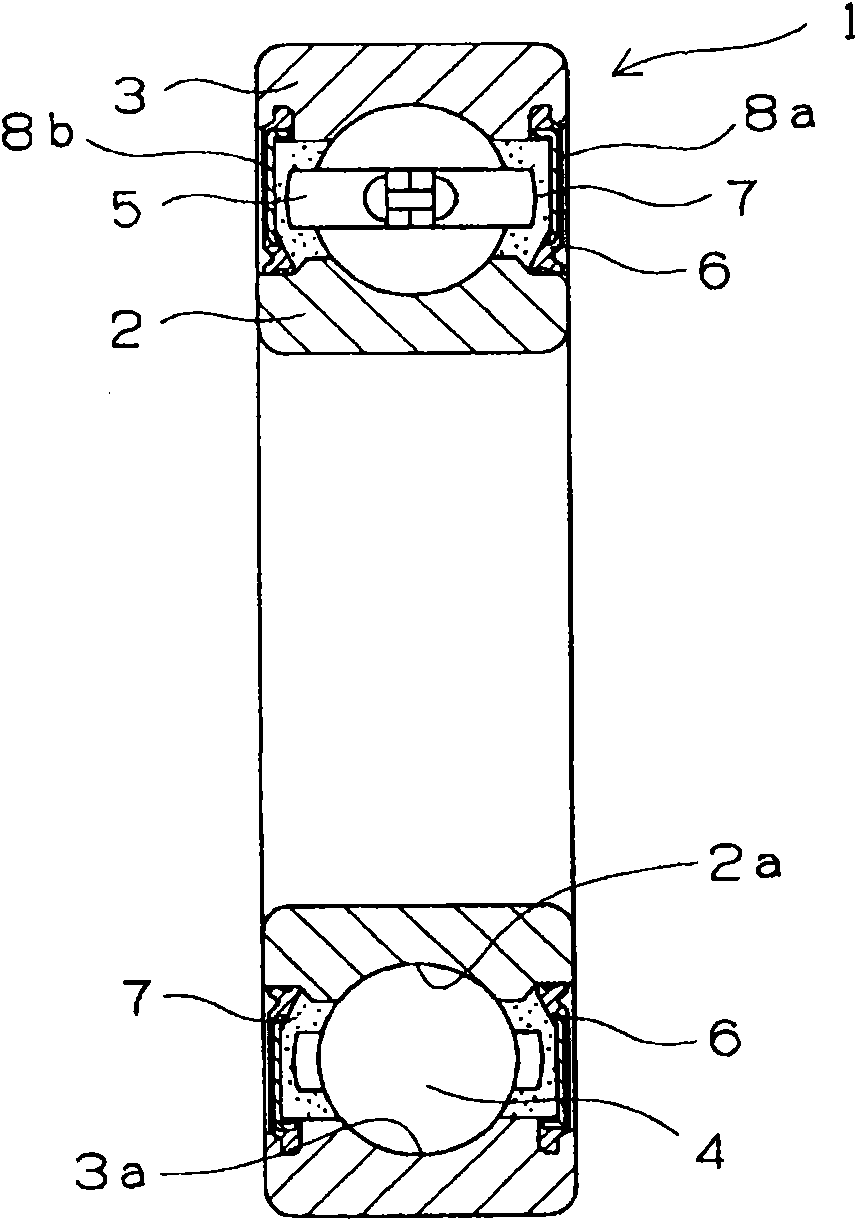

Grease composition, grease-packed bearing, universal joint for propeller shaft, lubricating oil composition, and oil-impregnated sintered bearing

InactiveUS20110306429A1Prevent hydrogen brittleness-caused peculiar peelingImprove resistance to oxidative deteriorationClutchesRoller bearingsGallic acid esterChlorogenic acid

The present invention provides a grease composition or a lubricating oil composition which is capable of effectively preventing hydrogen brittleness-caused peeling from occurring on a rolling surface of a rolling bearing, is excellent in durability in a high temperature and speed operation, and can be used for a long time. A grease-packed bearing (1) has an inner ring (2), an outer ring (3), and a plurality of rolling elements (4). A sealing member (6) for sealing a grease composition (7) is provided at openings (8a) and (8b) disposed at both axial ends of the inner ring (2) and the outer ring (3). The grease composition (7) includes a base grease composed of a base oil and a thickener and an additive added to the base grease. The additive contains at least one compound selected from among plant-derived polyphenolic compounds and compounds formed by decomposition thereof. The above-described compounds include tannin, gallic acid, ellagic acid, chlorogenic acid, caffeic acid, curcumin, quercetin, and quinic acid.

Owner:NTN CORP

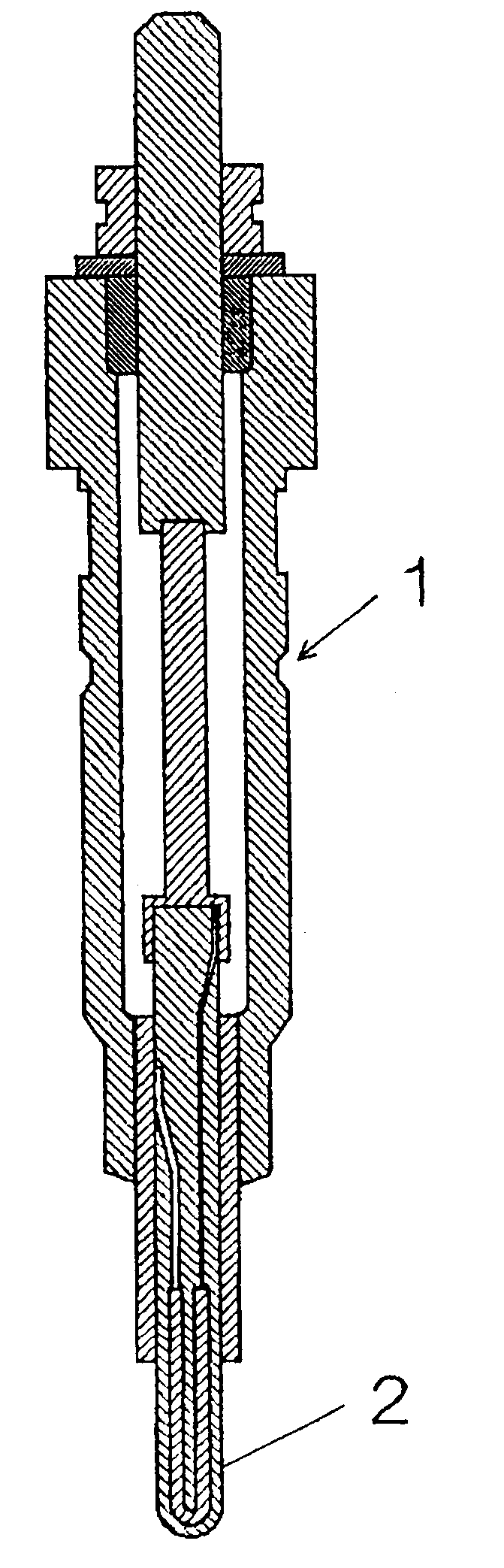

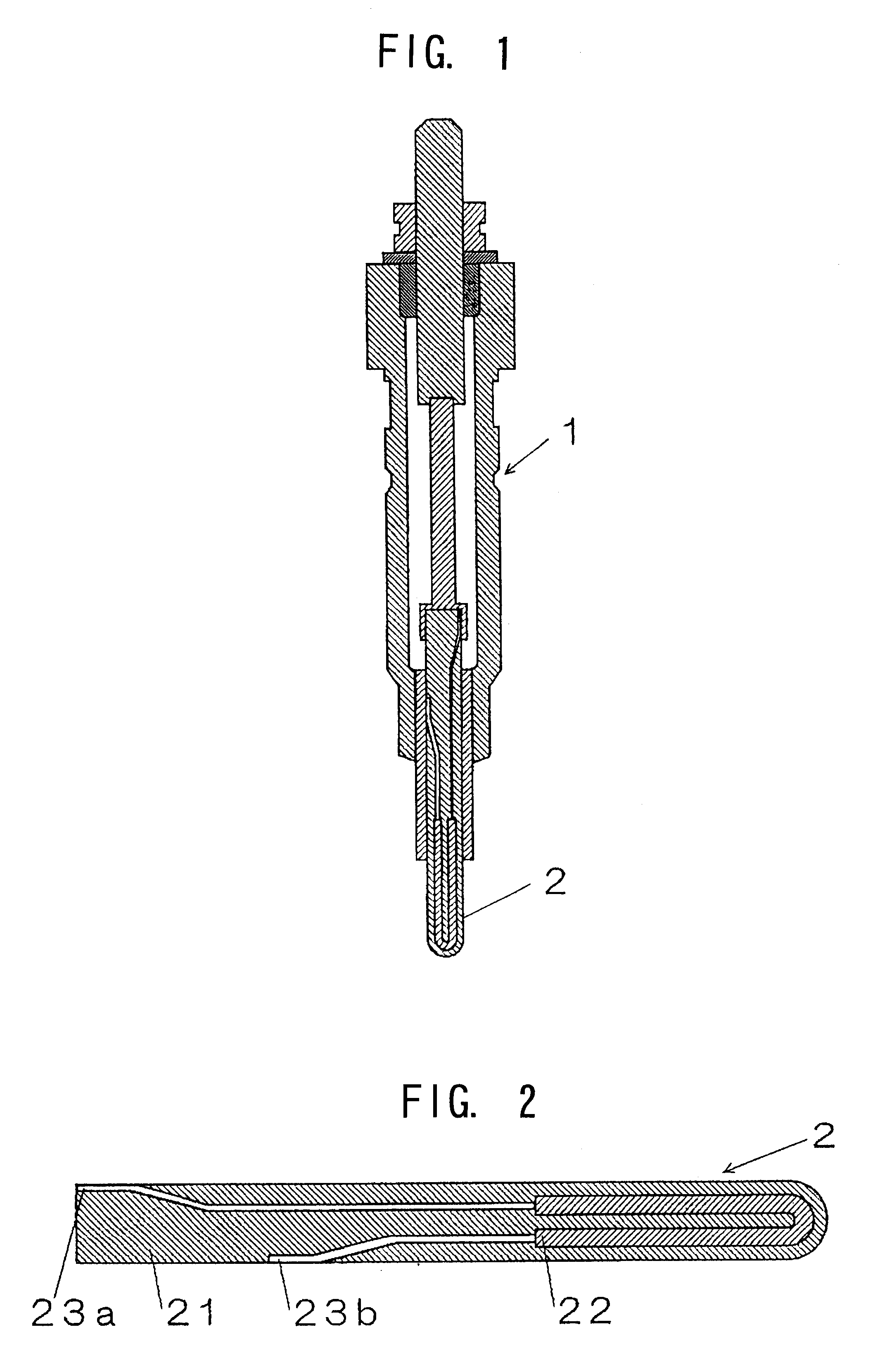

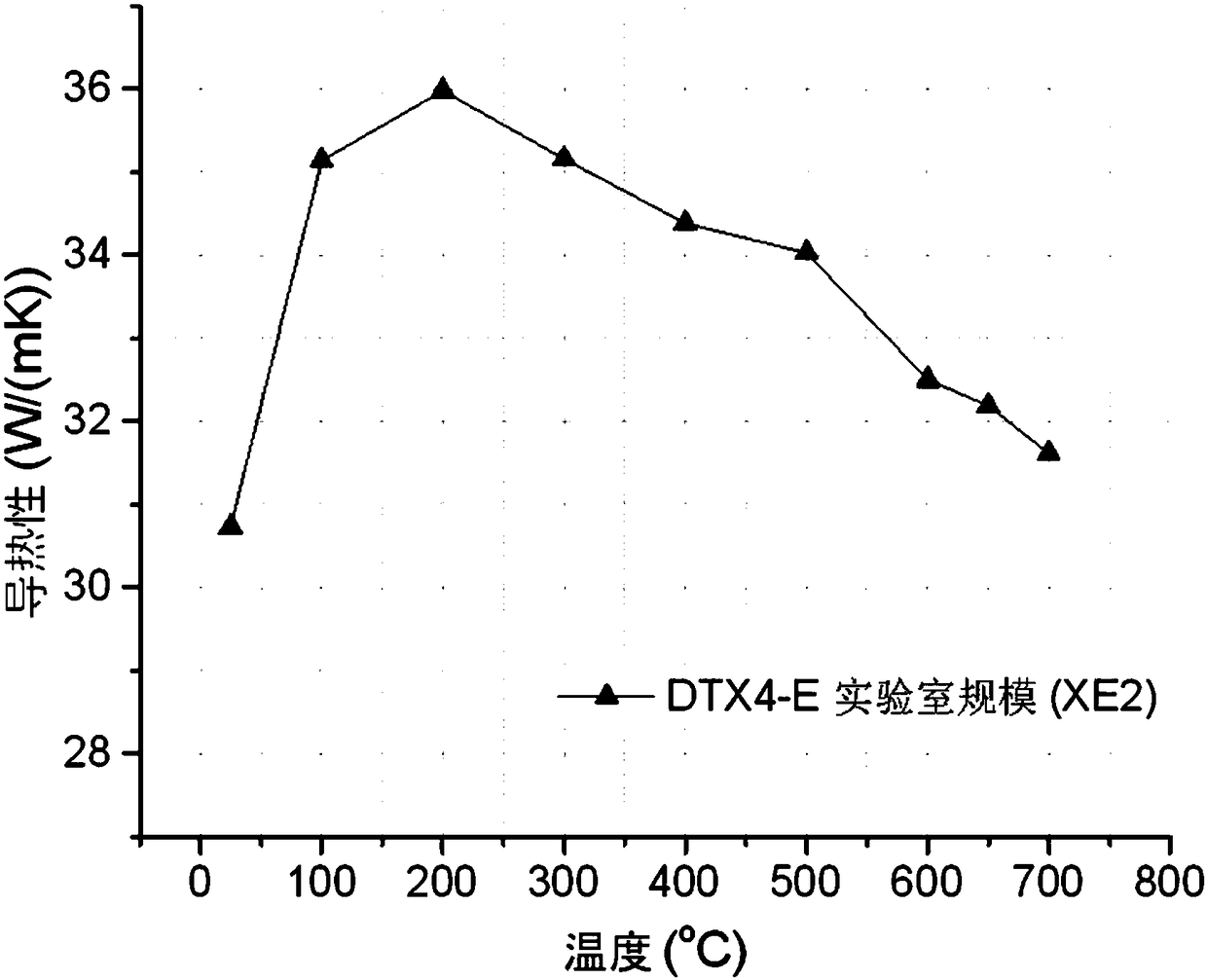

Heating resistor, heating resistor for use in ceramic heater, and ceramic heater using the same

InactiveUS6274853B1High mechanical strengthSolve the lack of durabilityIncandescent ignitionOhmic-resistance heating detailsRare-earth elementGrain boundary

A heating resistor containing RE2O3 (where RE represents a rare earth element) in a predetermined amount. The mole ratio of residual oxygen to RE2O3, the amount of residual oxygen being expressed on an SiO2 basis and being obtained by subtracting the amount of oxygen contained in RE2O3 from the total amount of oxygen, falls within a predetermined range. A crystal phase of disilicate or melilite serves as a predominant phase of grain boundaries. The heating resistor contains a conductive component, such as WC or TiN, which contains one or more elements selected from among Ti, Zr, Hf, V, Nb, Ta, Cr, Mo, and W. The heating resistor is embedded in a substrate, yielding a ceramic heater.

Owner:NGK SPARK PLUG CO LTD

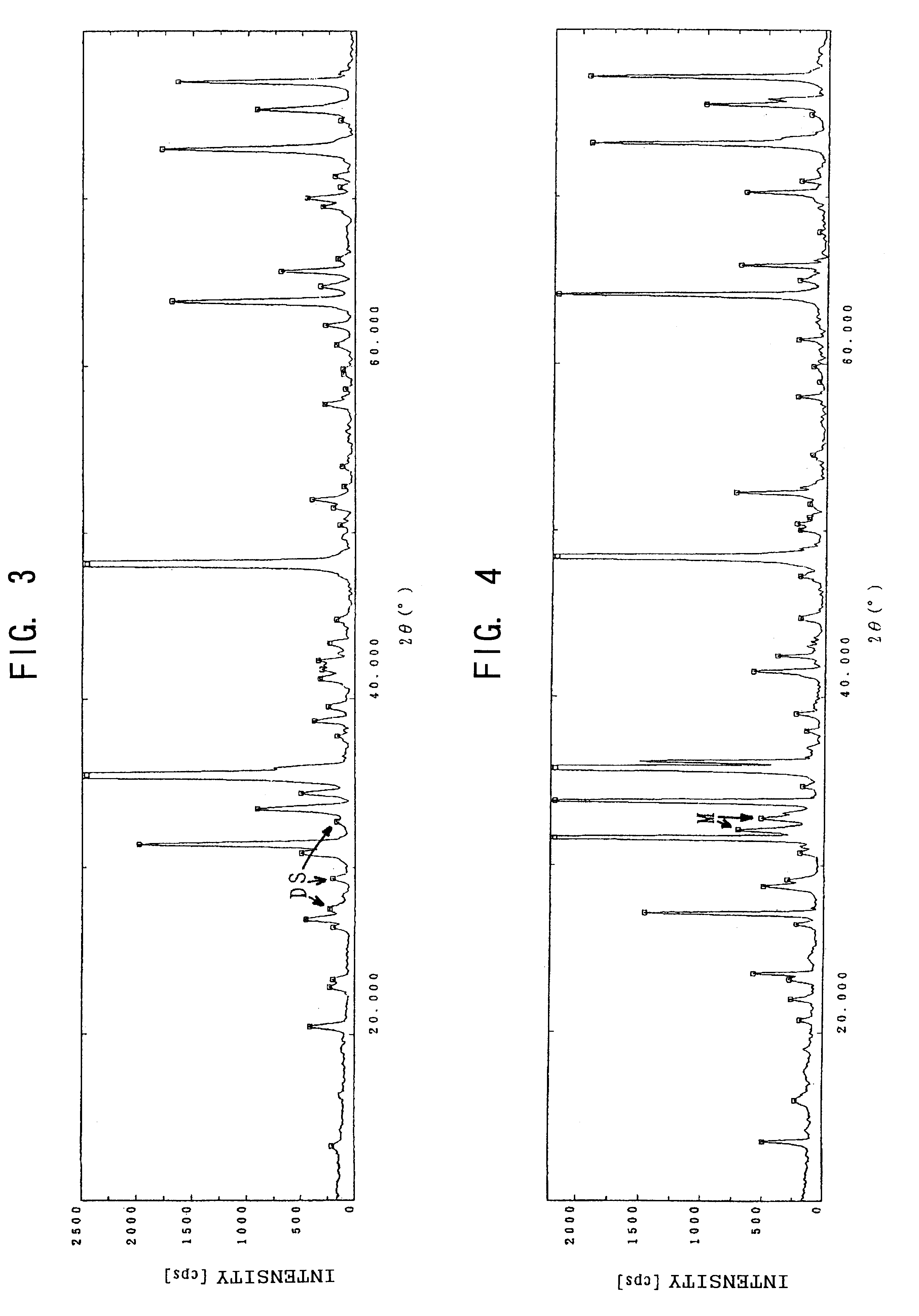

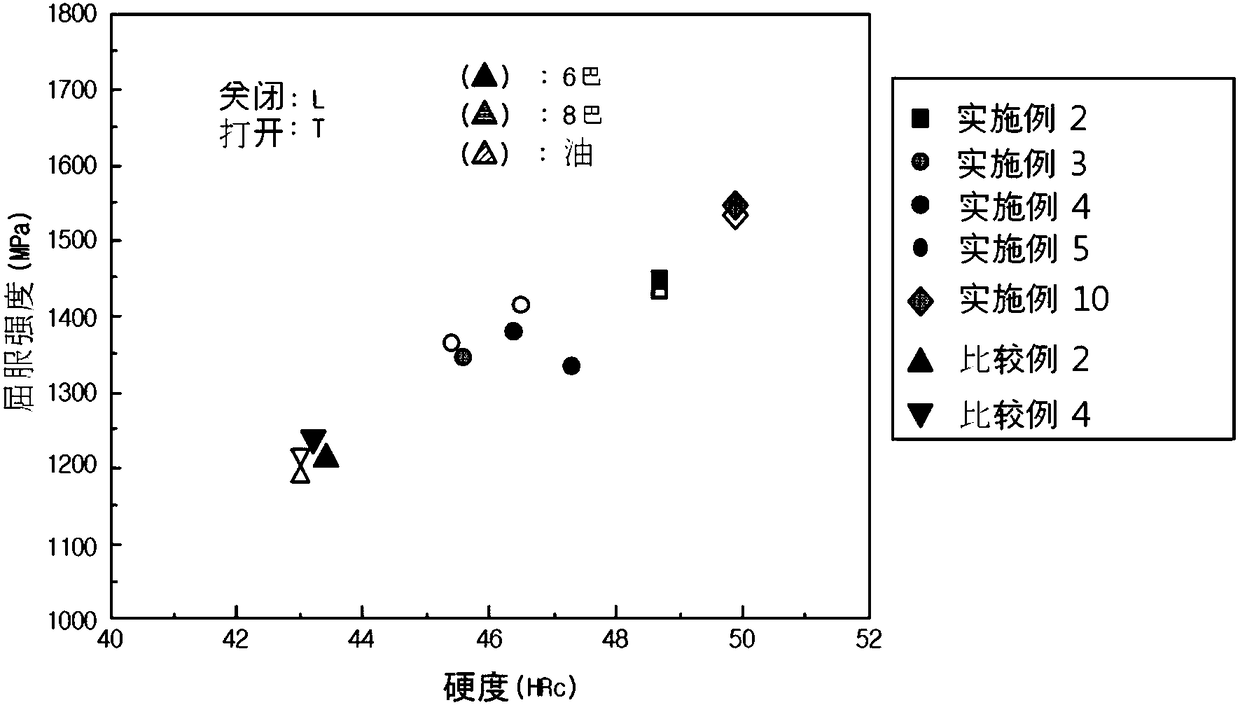

Hot mold steel for long life cycle die casting having high thermal conductivity and method for preparing the same

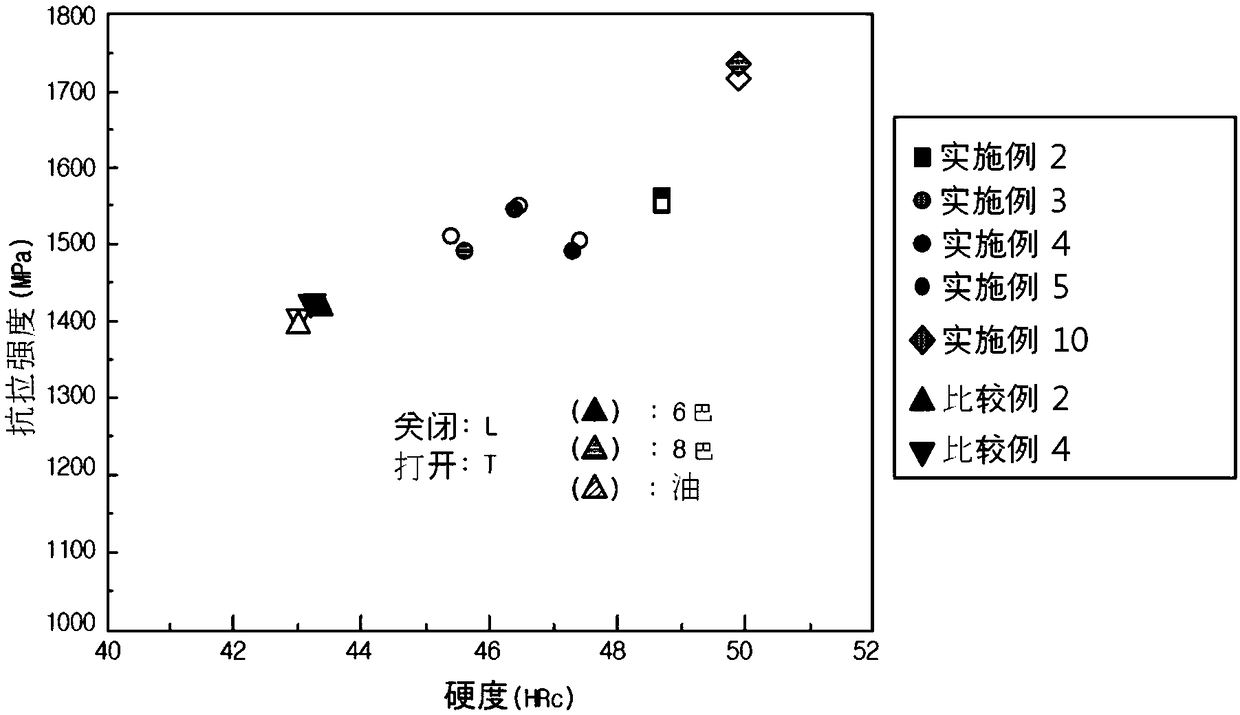

The invention relates to hot mold steel for long life cycle die casting having high thermal conductivity and method for preparing the same. IN particular, the invention relates to the hot mold steel having excellent thermal conductivity and durability and used for production of automobile parts. According to an embodiment, the described hot mold steel may be excellent in high thermal conductivityto decrease the temperature difference in materials at high temperature, thereby making heat-checking properties excellent. When the hot mold steel according to the present disclosure is used for diecasting, the cooling rate of the product produced using the die casting is quick, thereby improving the physical properties of the produced product and shortening the cooling time to improve productivity. Furthermore, the hot mold steel may have excellent high temperature durability, such that the die casting produced using the hot mold steel may have characteristics of a long life cycle.

Owner:DOOSAN HEAVY IND & CONSTR CO LTD

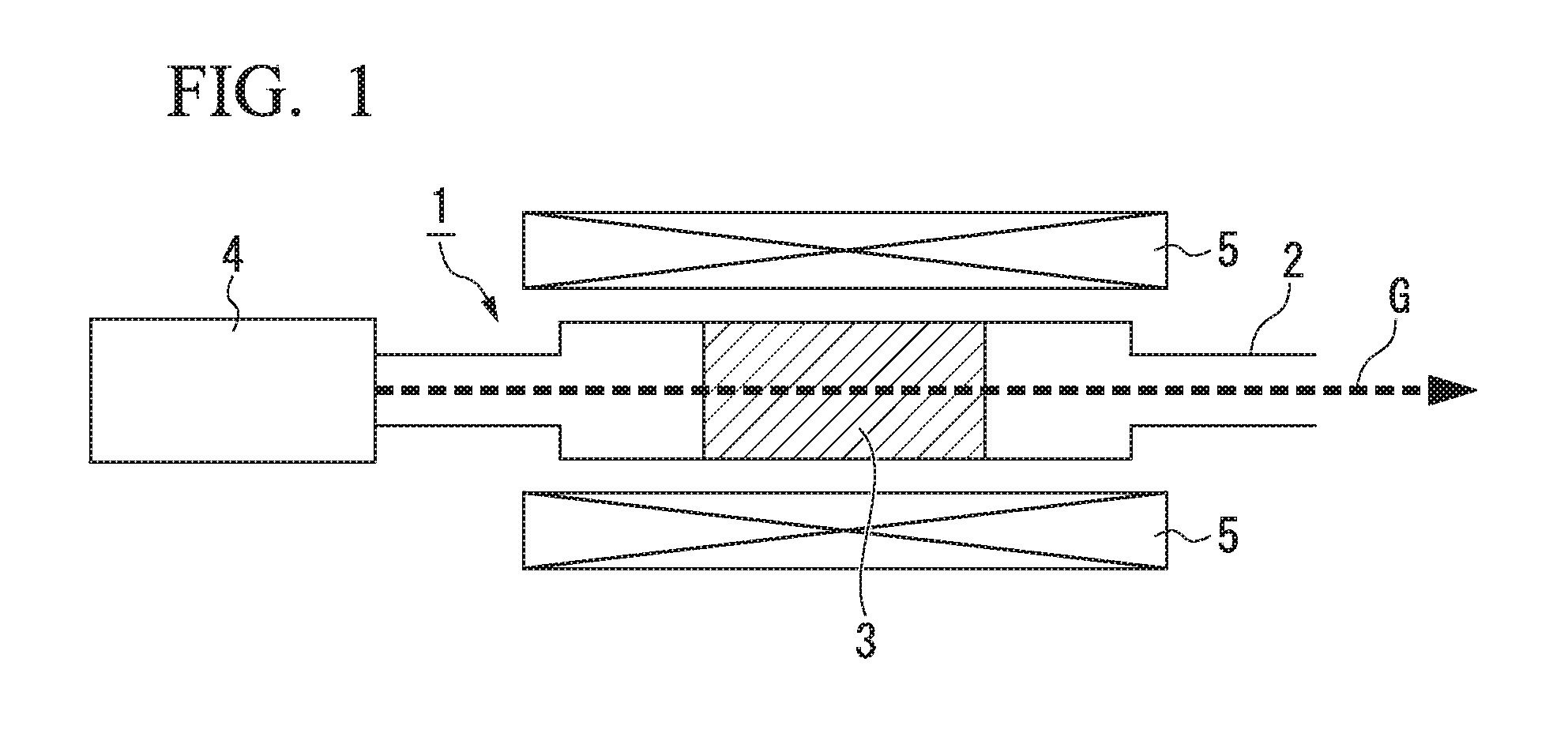

Process for producing polarizing plate, polarizing plate produced by the process, and liquid crystal display device using the polarizing plate

ActiveUS20110308712A1Improve adaptabilityHigh transparencyLamination ancillary operationsLaminationPolymer scienceLiquid-crystal display

Disclosed is a process for producing a polarizing plate which is transparent, has resistance against high temperatures and high humidity, and is significantly improved in brittleness. Specifically disclosed is a process for producing a polarizing plate comprising two polarizing plate protective films and a polarizer intercalated between the polarizing plate protective films, which is characterized in that at least one of the two polarizing plate protective films is an acrylic film comprising an acrylic resin (A) and a cellulose ester resin (B) at a ratio of 85:15 to 55:45 by mass, and the acrylic film is drawn in at least one direction at a draw ratio of 10 to 150% inclusive and is subsequently bonded to the polarizer with an aqueous adhesive agent.

Owner:KONICA MINOLTA OPTO

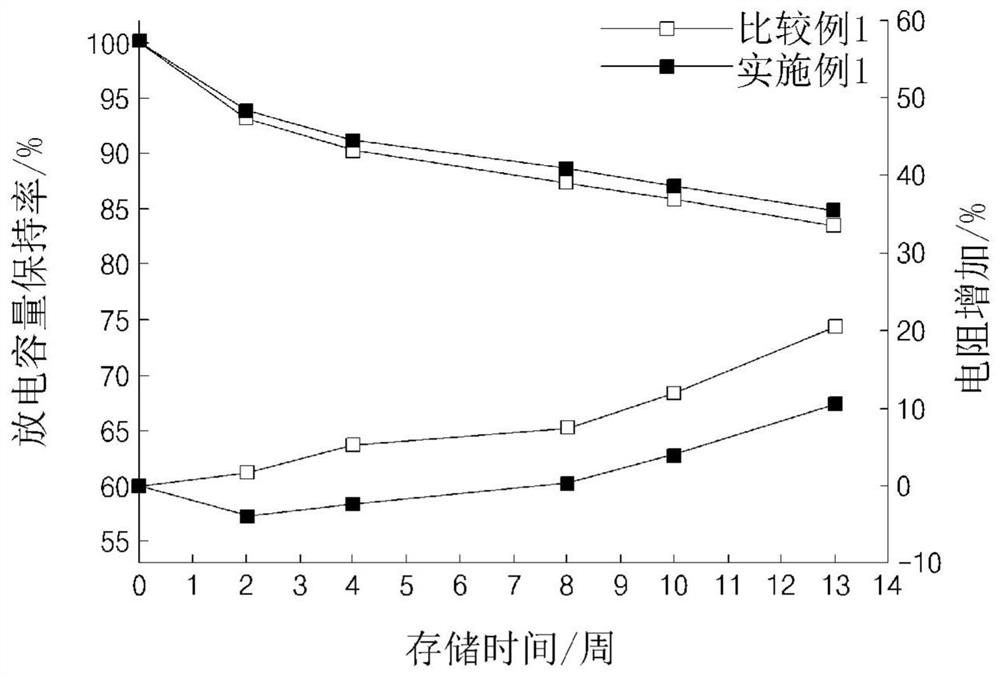

Non-aqueous electrolyte secondary battery

ActiveUS20050266313A1Excellent high temperature durabilityIncrease storage capacityNon-aqueous electrolyte accumulatorsActive material electrodesManganeseBattery capacity

In a non-aqueous electrolyte secondary battery using a layered lithium-transition metal composite oxide as a positive electrode active material, elevated-temperature durability, that is, elevated-temperature storage performance is enhanced without degrading battery capacity. The non-aqueous electrolyte secondary battery includes: a positive electrode including, as a positive electrode active material, layered lithium-transition metal composite oxide containing lithium, nickel, and manganese; a negative electrode active material capable of intercalating and deintercalating lithium; and a non-aqueous electrolyte having lithium ion conductivity, and the lithium-transition metal composite oxide contains a group IVA element and a group IIA element of the periodic table.

Owner:PANASONIC ENERGY CO LTD

Low-rhenium high-strength thermal-corrosion-resistant nickel-based single-crystal high-temperature alloy and manufacturing method thereof

InactiveCN109371288AExcellent high temperature durabilityLow Re elementPolycrystalline material growthAfter-treatment detailsRheniumChemical composition

The invention discloses a low-rhenium high-strength thermal-corrosion-resistant nickel-based single-crystal high-temperature alloy and a manufacturing method thereof. The alloy comprises the followingchemical components of, in percentage by weight, 9.0-12.0% of Cr, 8.0-11.0% of Co, 0.2-1.5% of Mo, 4.5-7.0% of W, 3.5-5.5% of Al, 2.0-4.0% of Ti, 4.5%-6.5% of Ta, 0.1-0.3% of Hf, 1.2-2.0% of Re, andthe balance Ni. The high-temperature endurance performance is superior to that of the PWA1483 alloy, the Re element is low, and good thermal corrosion resistance is achieved; compared with the existing nickel-based single-crystal high-temperature alloy, the content of the Cr element in the alloy component is relatively high, the alloy component has relatively high thermal corrosion resistance; thealloy has good high-temperature endurance performance, the high-temperature performance is superior to that of PWA1483, and the creep time of the 982 DEG C / 100 Mpa is larger than or equal to 5000h.

Owner:DONGFANG TURBINE CO LTD

Grease composition and grease-sealed bearing

InactiveCN101990569AAvoid corrosionReduce frictionTransportation and packagingBall bearingsBase oilPoly tetra fluoro ethylene

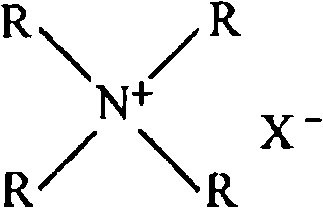

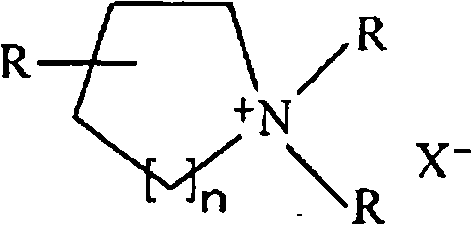

A grease composition which can be improved in high -temperature durability while attaining friction reduction or viscosity reduction and a bearing sealed with this grease composition. The grease composition comprises a base oil, a thickening agent, and an additive. The base oil contains an ionic fluid composed of a cation component and an anion component; the additive contains a corrosion inhibitor such as nitrites, molybdates or dibasic acid salts; and the thickening agent is a fluororesin such as polytetrafluoroethylene resin. The grease-sealed bearing (1) is sealed with the grease composition (7) at least around a rolling element (4).

Owner:NTN CORP

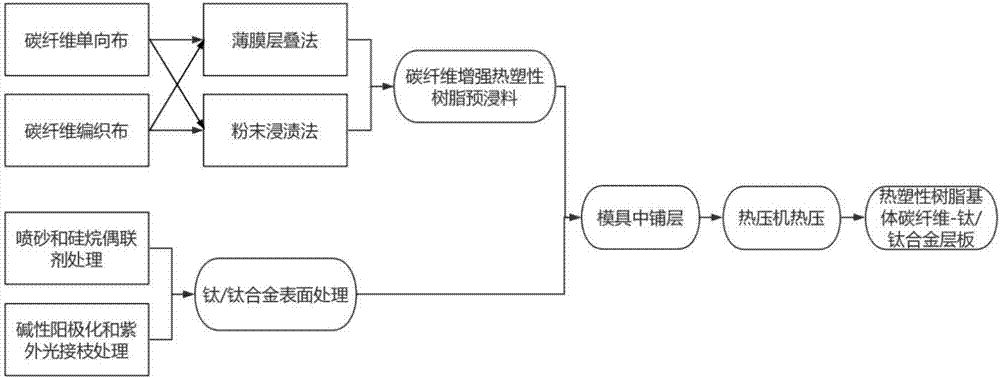

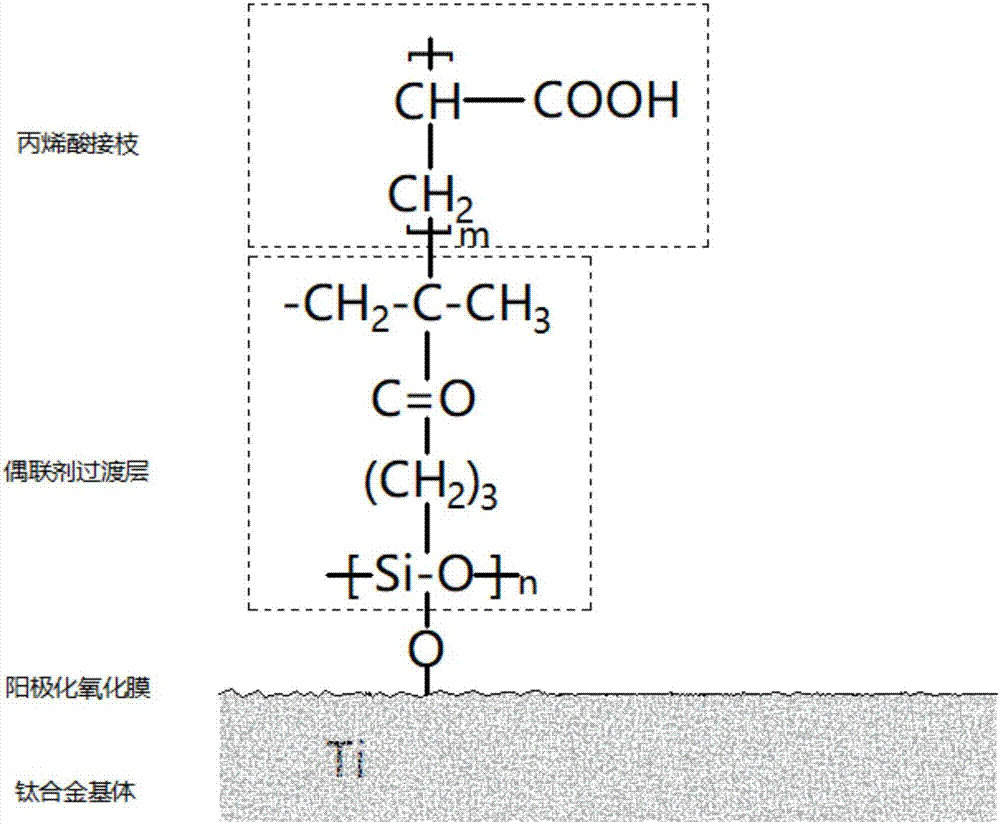

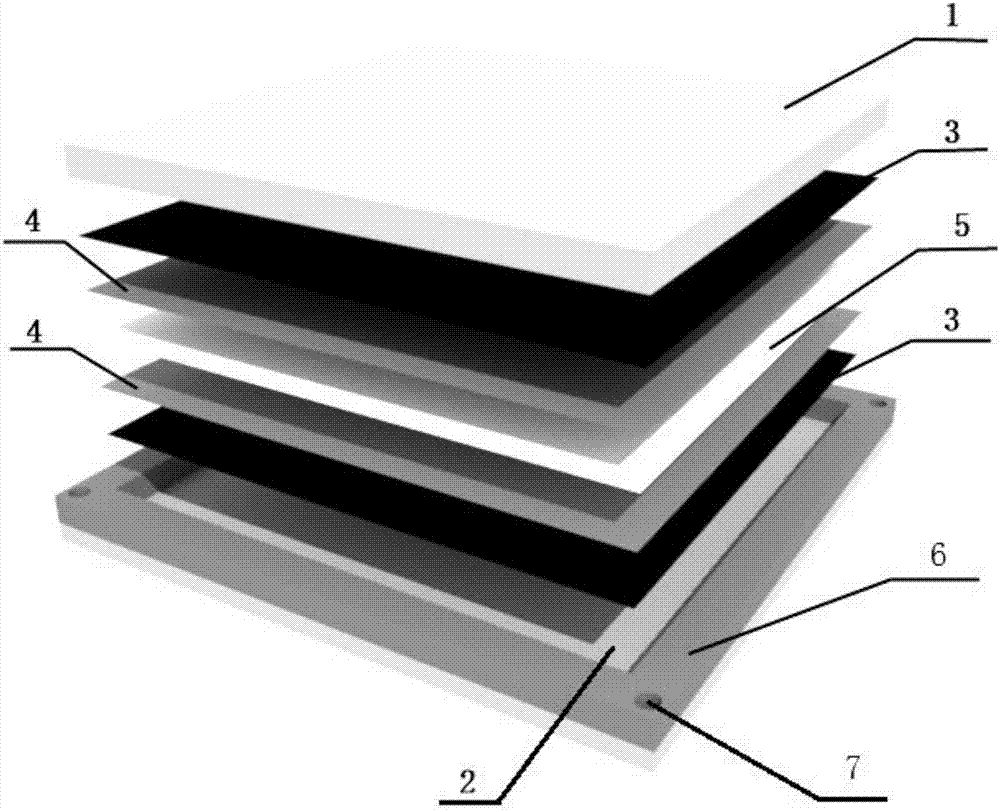

Preparing method of thermoplastic resin matrix carbon fiber-titanium/titanium alloy laminate plate

ActiveCN107283871AImprove impregnation effectHigh mechanical strengthCoatingsThermoplasticCarbon fibers

The invention discloses a preparing method of a thermoplastic resin matrix carbon fiber-titanium / titanium alloy laminate plate, and belongs to the field of light composite materials. The technical purpose is to solve the problem that currently the interface glue joint effect of titanium alloy of carbon fiber reinforcement titanium alloy laminate plate TiGr and a prepreg is poor. The thermoplastic resin comprises three kinds of high-performance thermoplastic resin including polyether-ether-ketone (PEEK), polyphenylene sulfide (PPS) and polyetherimid (PEI), with the coordination of a film laminating method and a powder impregnation method, the problem that the impregnation effect of the thermoplastic resin on carbon fiber is poor is solved.

Owner:HARBIN INST OF TECH

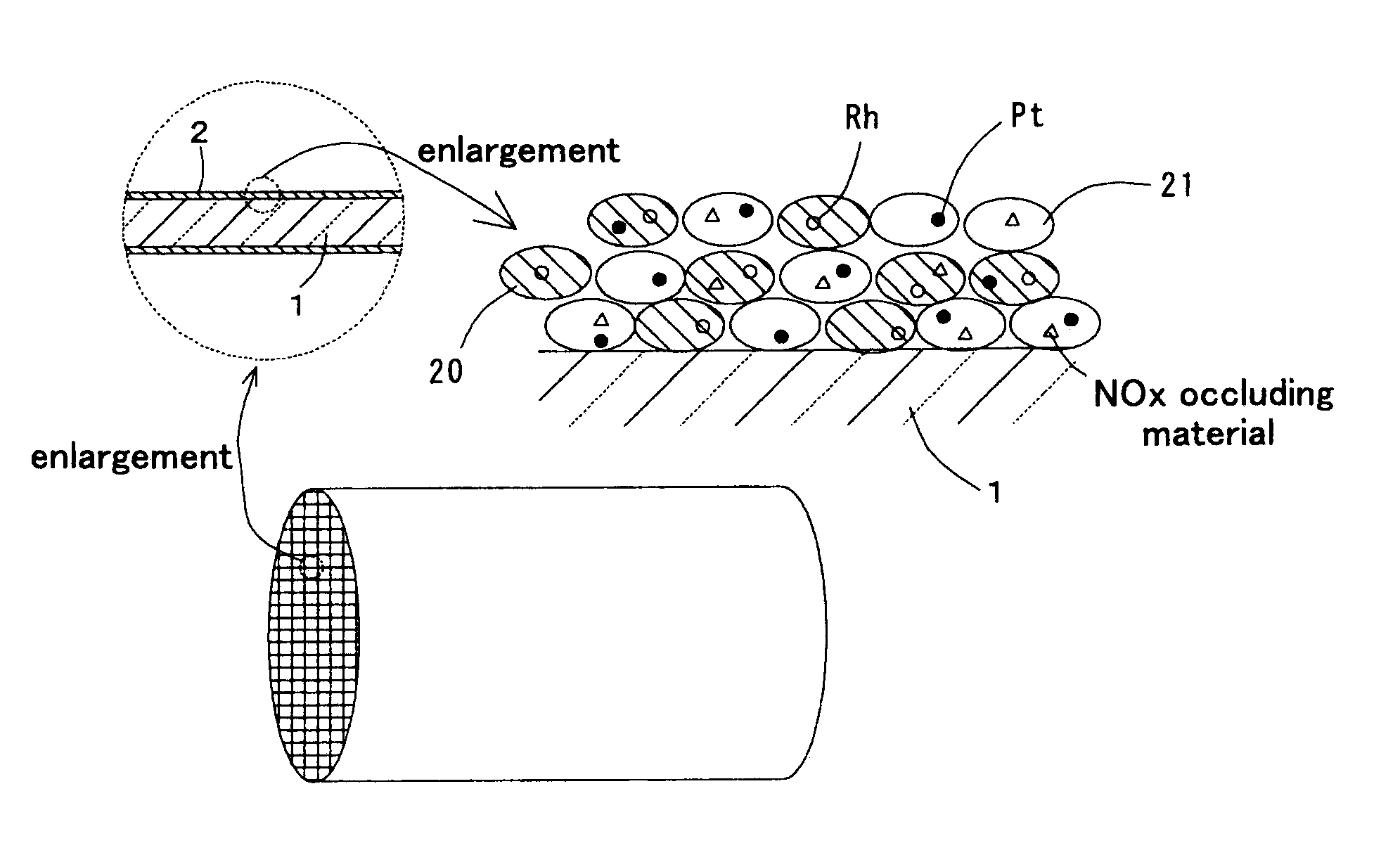

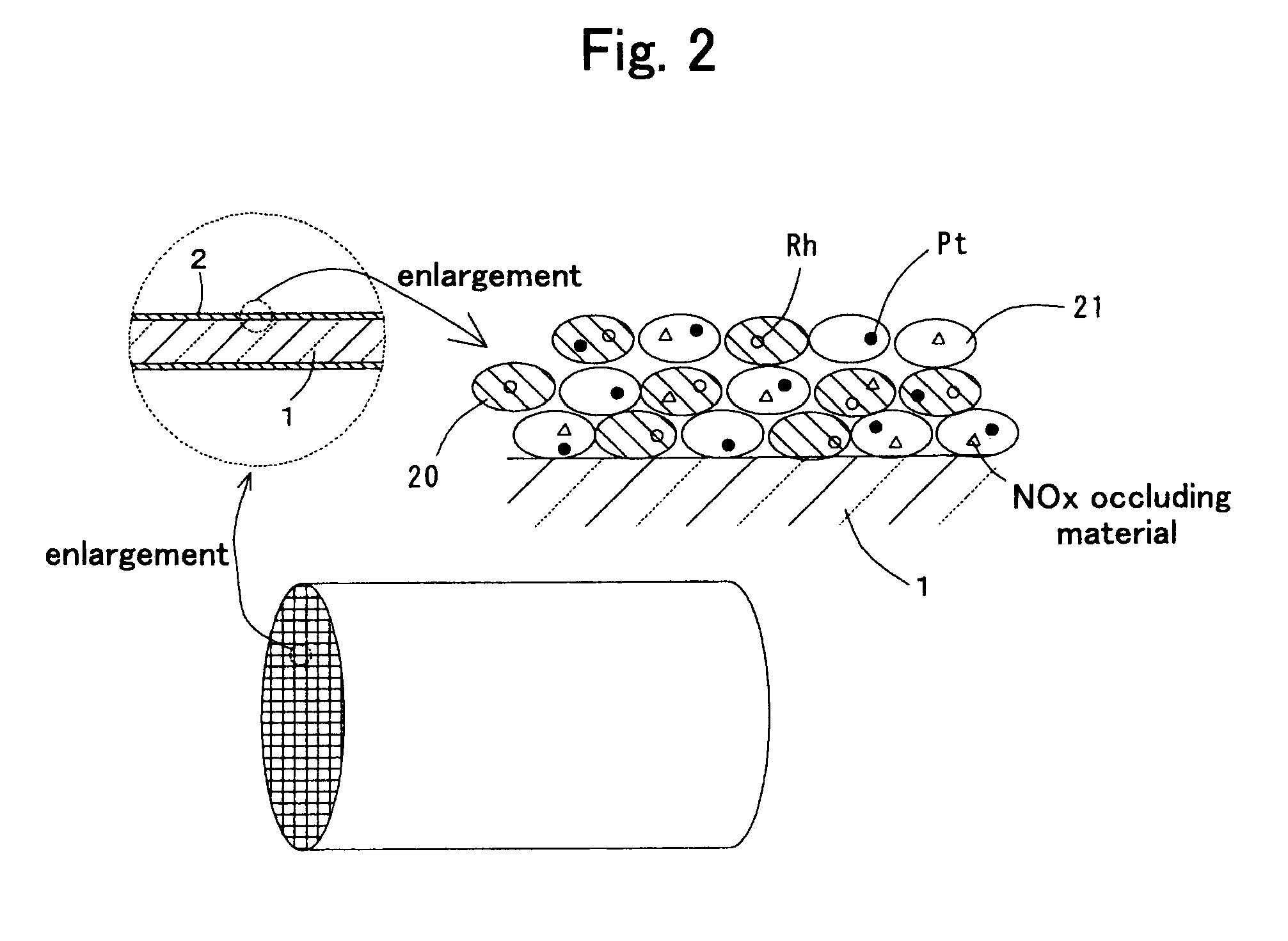

Internal combustion engine exhaust gas purification apparatus, exhaust gas purification process and exhaust gas purification catalyst

InactiveUS6841511B2Improve heat resistanceExcellent high temperature durabilityCombination devicesGas treatmentAlkaline earth metalExternal combustion engine

Nitrogen oxides contained in an exhaust gas emitted from a lean-burn engine-mounted internal combustion engines are eliminated with a high efficiency.In an exhaust gas purification apparatus and process for eliminating nitrogen oxides contained in a combustion exhaust gas emitted from an internal combustion engine with a reducing gas such as carbon monoxide, hydrocarbons, etc. contained in the exhaust gas in the presence of a catalyst, a catalyst comprising all of Rh, Pt and Pd, at least one member selected from alkali metals and alkaline earth metals, and Mn or its compound, supported on a porous carrier is used.

Owner:HITACHI LTD

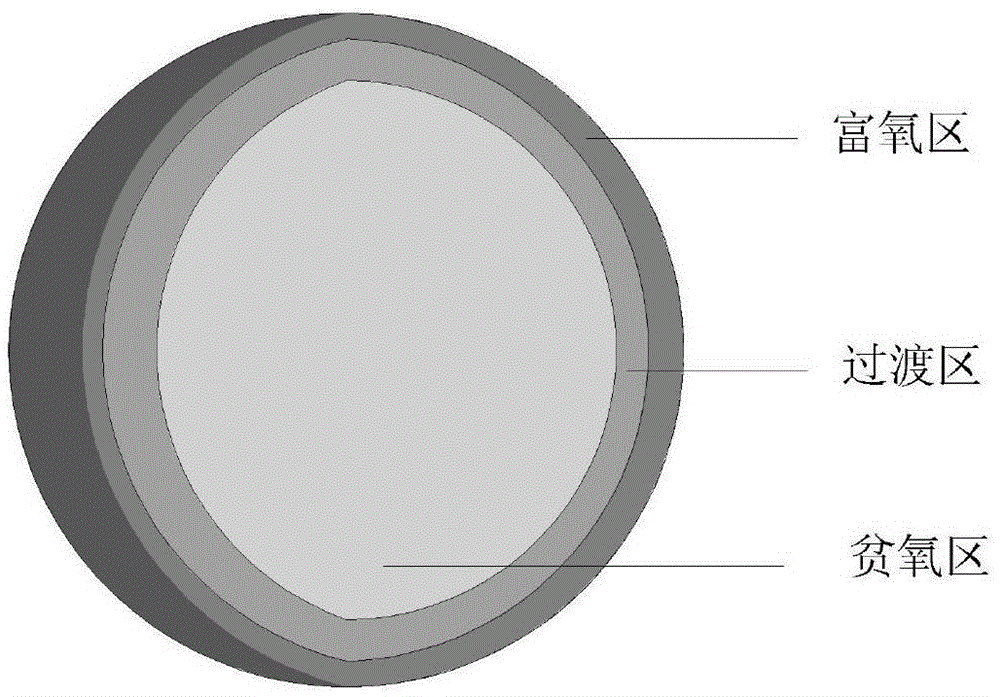

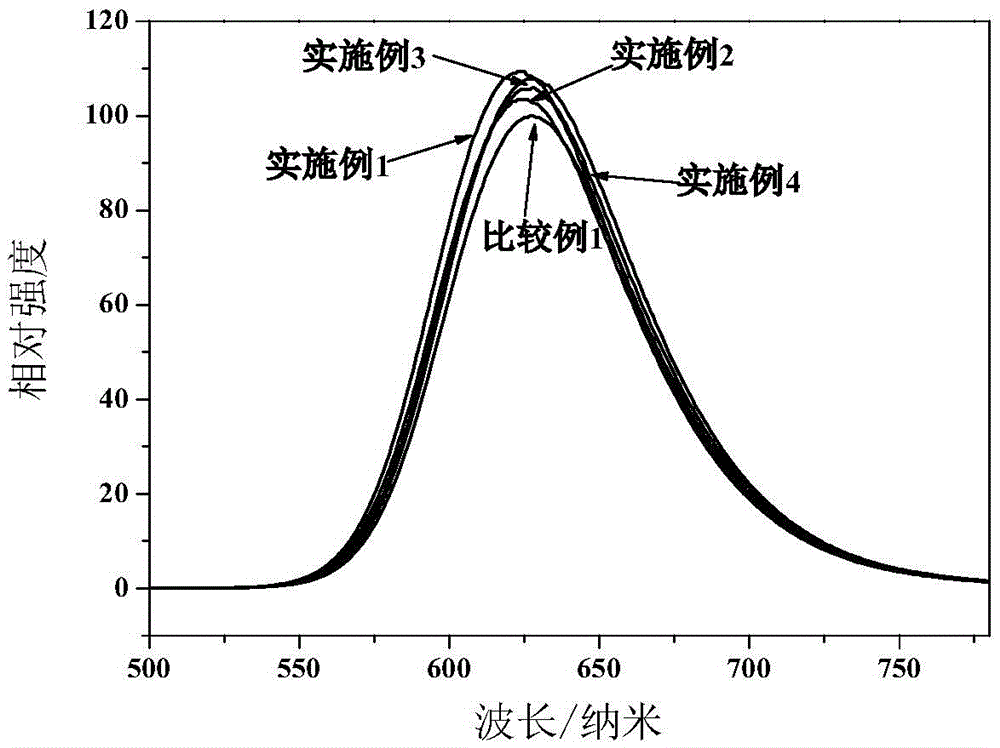

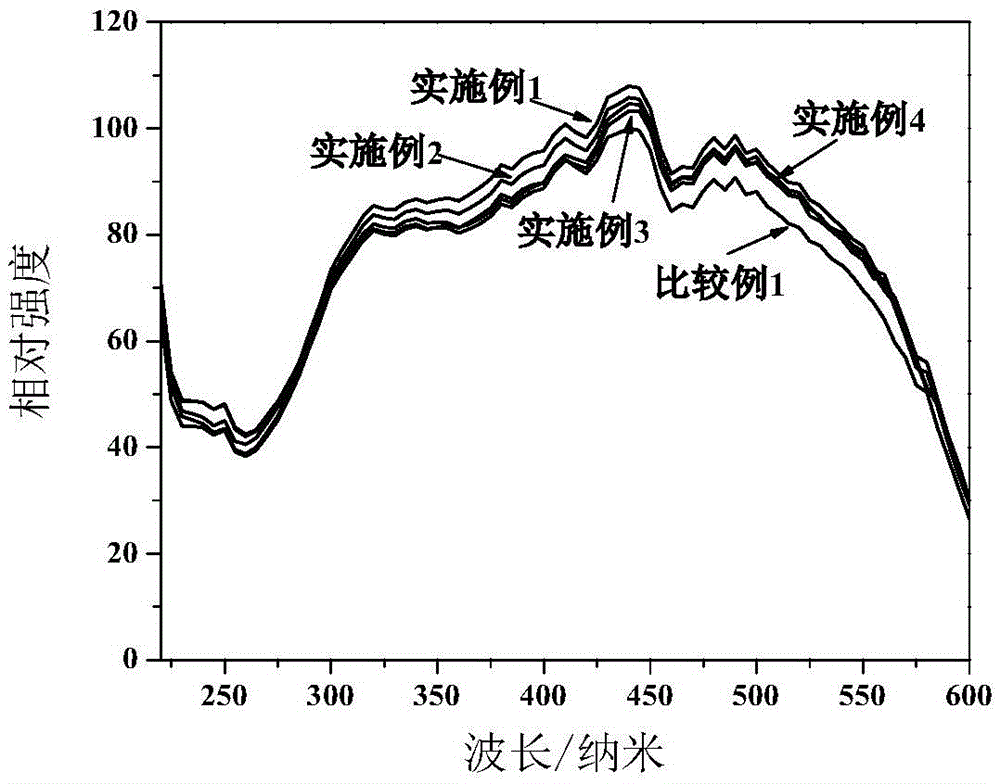

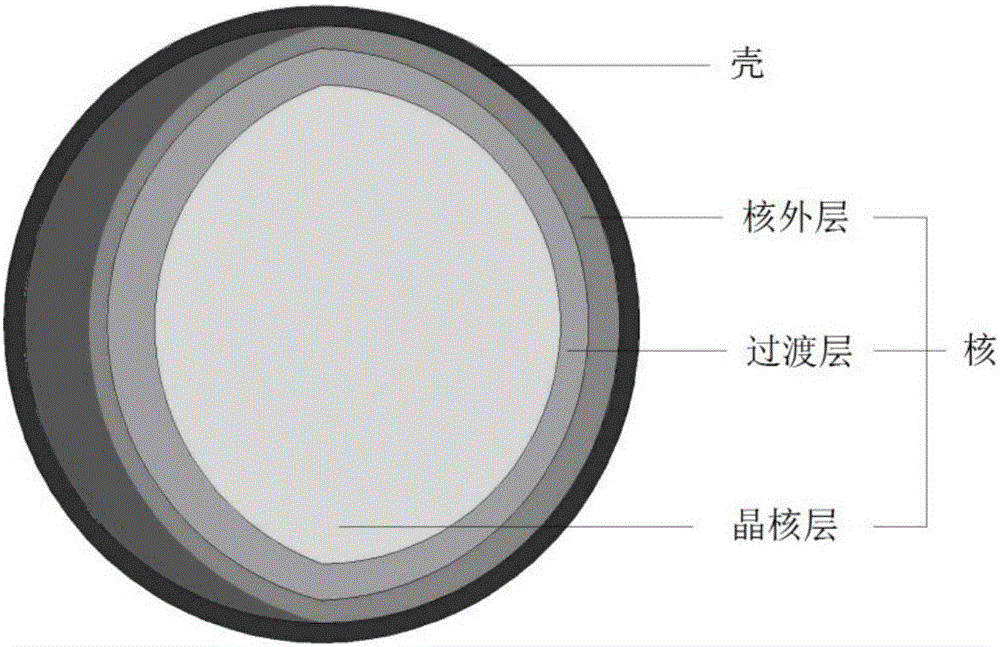

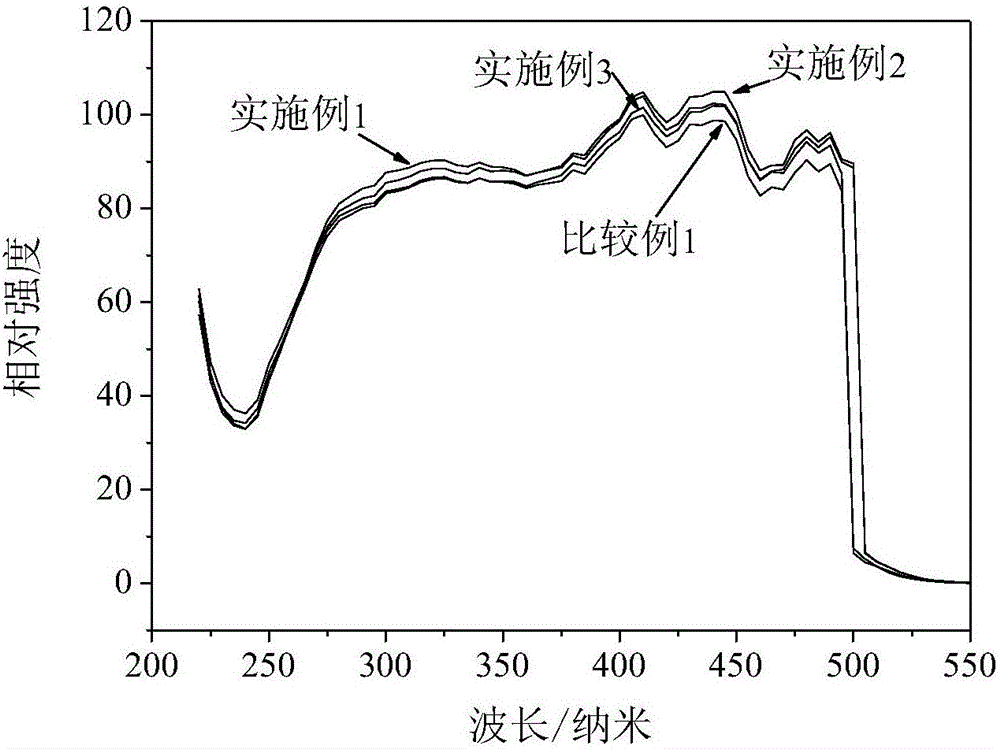

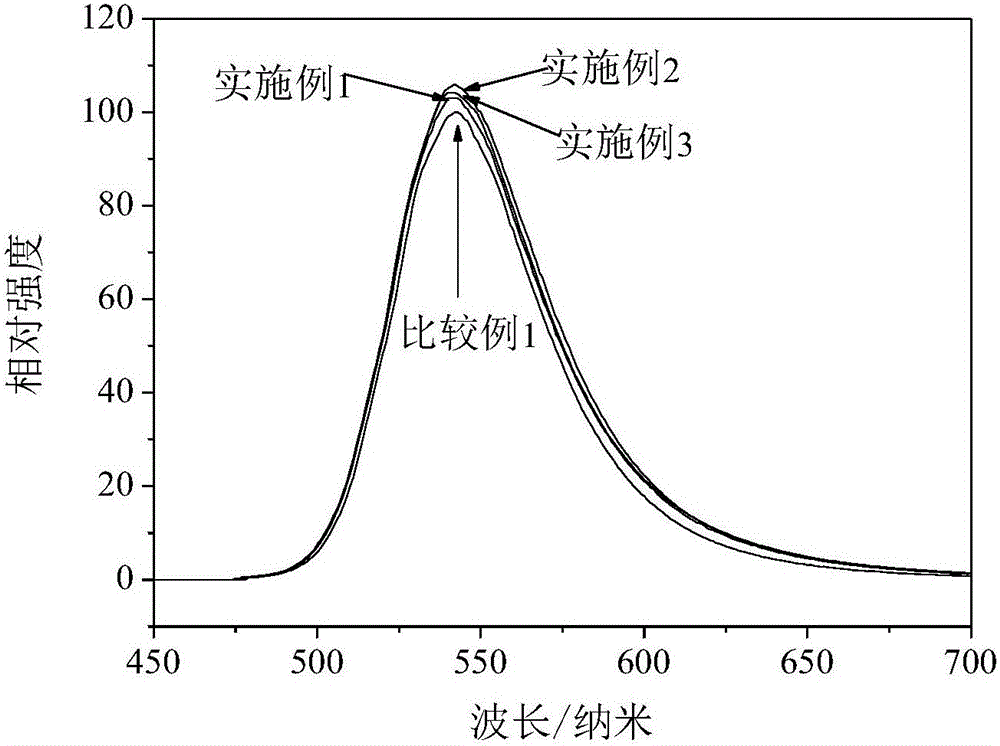

Nitrogenous light-emitting particle, nitrogenous light-emitting particle preparation method, nitrogenous light emitter and light emitting device

ActiveCN105623657AGood weather resistanceMeet growth needsEnergy efficient lightingLuminescent compositionsLight emitting deviceNitride

The invention relates to a nitrogenous light-emitting particle. The nitrogenous light-emitting particle is characterized by structurally comprises an oxygen-deficient region, a transition region and an oxygen-rich region sequentially from the core of the particle to the outer surface along with progressive oxygen content increase. The oxygen-deficient region mainly comprises nitride light-emitting crystal or oxygenous solid solution thereof, the transition region mainly comprises an oxynitride material, and the oxygen-rich region mainly comprises an oxide material or an oxynitride material. The nitride light-emitting crystal or oxygenous solid solution thereof refers to Mm-m1Aa1Bb1Oo1Nn1:Rm1, the oxynitride material refers to Mm-m2Aa2Bb2Oo2Nn2:Rm2, and the oxide material or the oxynitride material refers to Mm-m3Aa3Bb3Oo3Nn3:Rm3. The nitrogenous light-emitting particle and a nitrogenous light emitter are high in chemical stability, excellent in resistance to aging and light attenuation and high in light emitting efficiency and are applicable to various light emitting devices. The preparation method is simple, convenient and reliable and is suitable for industrial batch production.

Owner:JIANGSU BREE OPTRONICS CO LTD

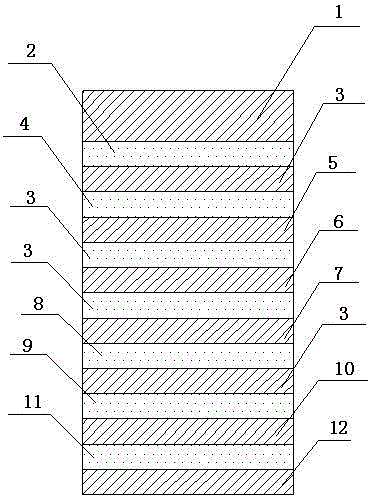

Direct-pasting film

InactiveCN102721991ACompact structureGood chemical mechanical propertiesCoatingsMetal layered productsInfraredPolyethylene glycol

The invention discloses a direct-pasting film which comprises a polyethylene glycol terephthalate (PET) substrate, wherein a composite coating layer is arranged on the PET substrate. The composite coating layer is a three-layer composite structure and sequentially comprises a first reflecting-resisting layer, a transition layer, a first near-infrared reflecting layer, a second near-infrared reflecting layer, a transition layer, a second reflecting-resisting layer, a transition layer, a third near-infrared reflecting layer, a fourth near-reflecting layer, a transition layer, a third reflecting-resisting layer, a protective layer and a neon absorbing adhesive layer from inside to outside, and a release film is arranged on the composite coating layer. The direct-pasting film can effectively block near-infrared and orange light and has good high temperature resisting performance and durability.

Owner:成都三利亚科技有限公司

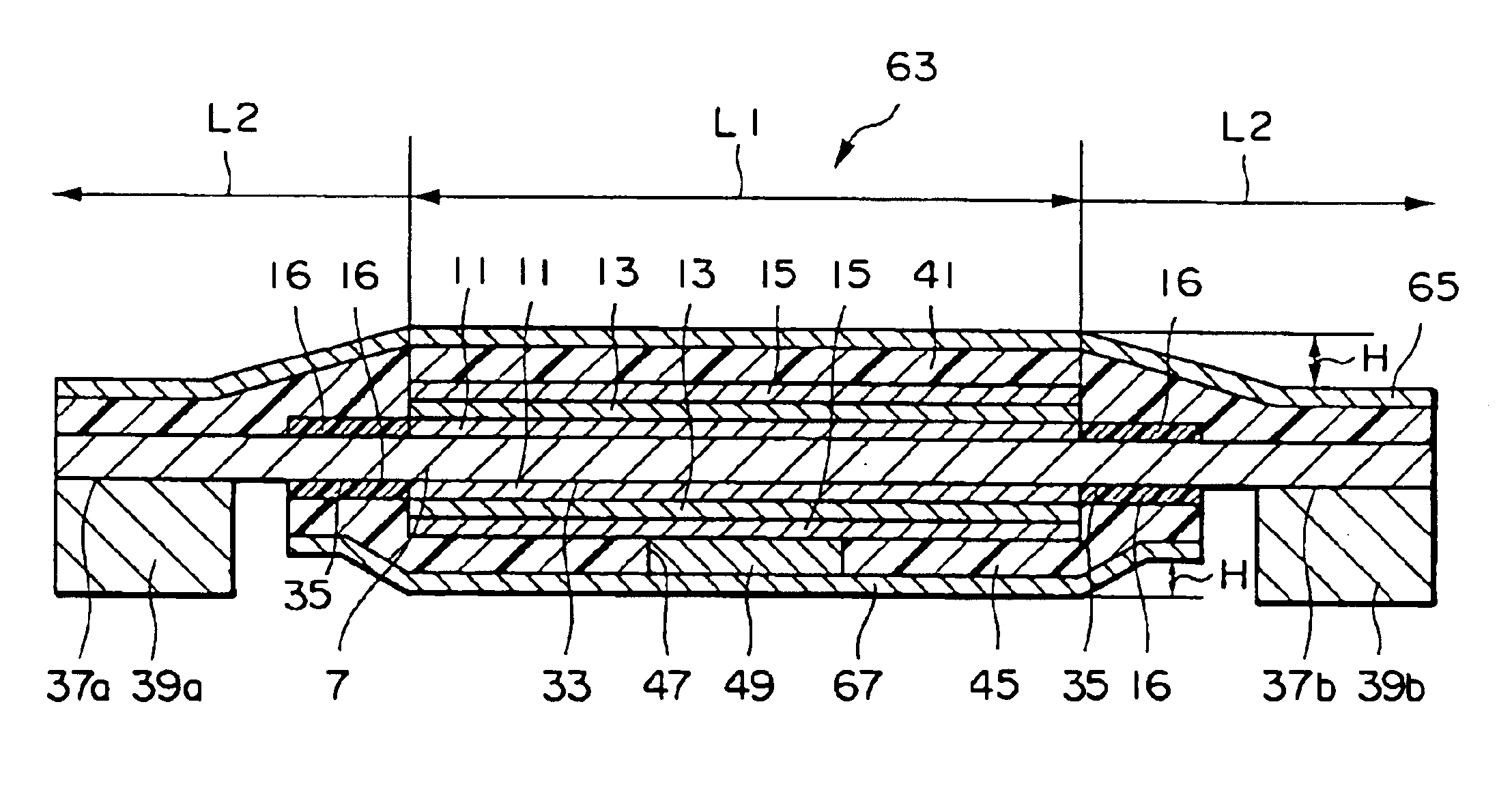

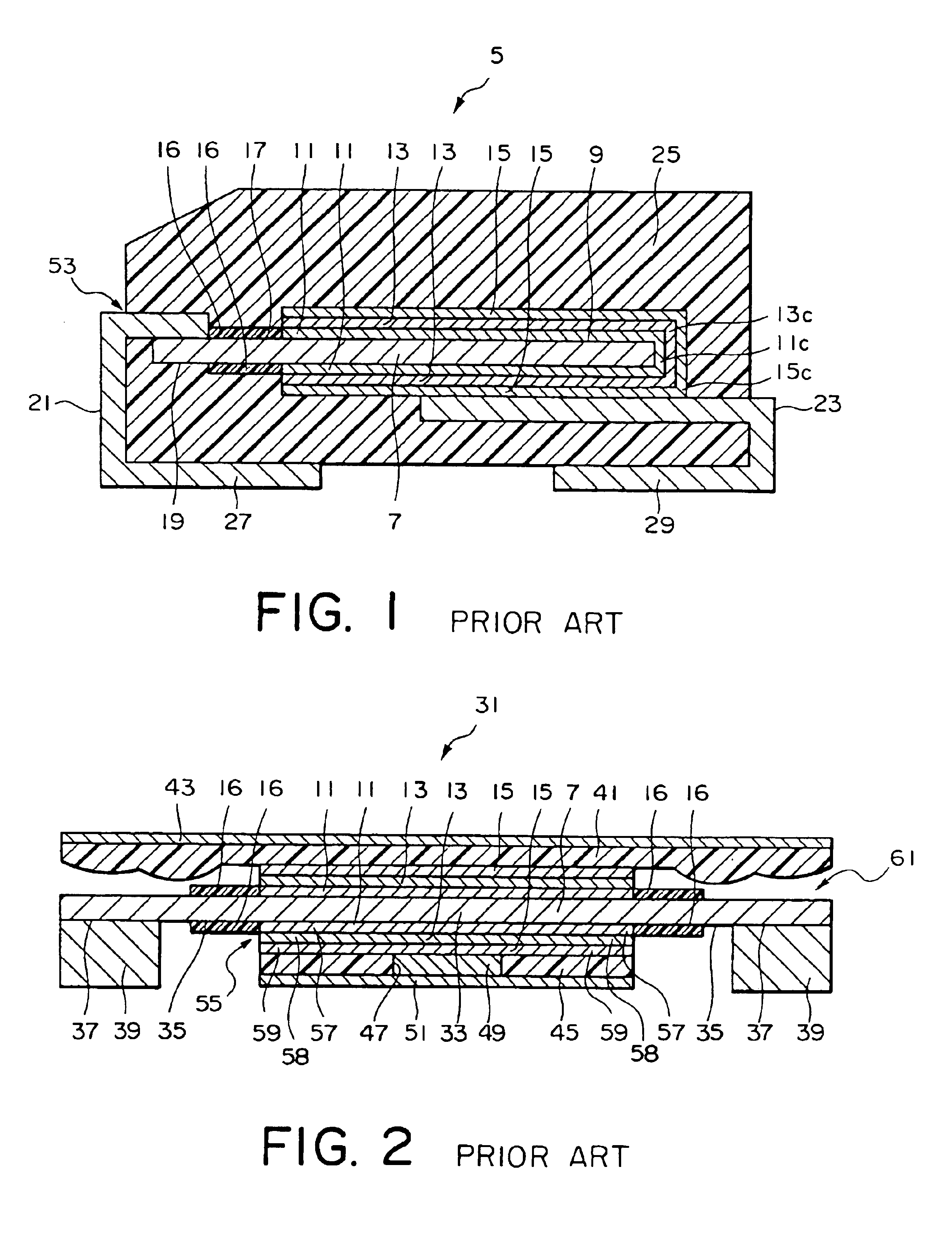

Thin-type surface-mount capacitor

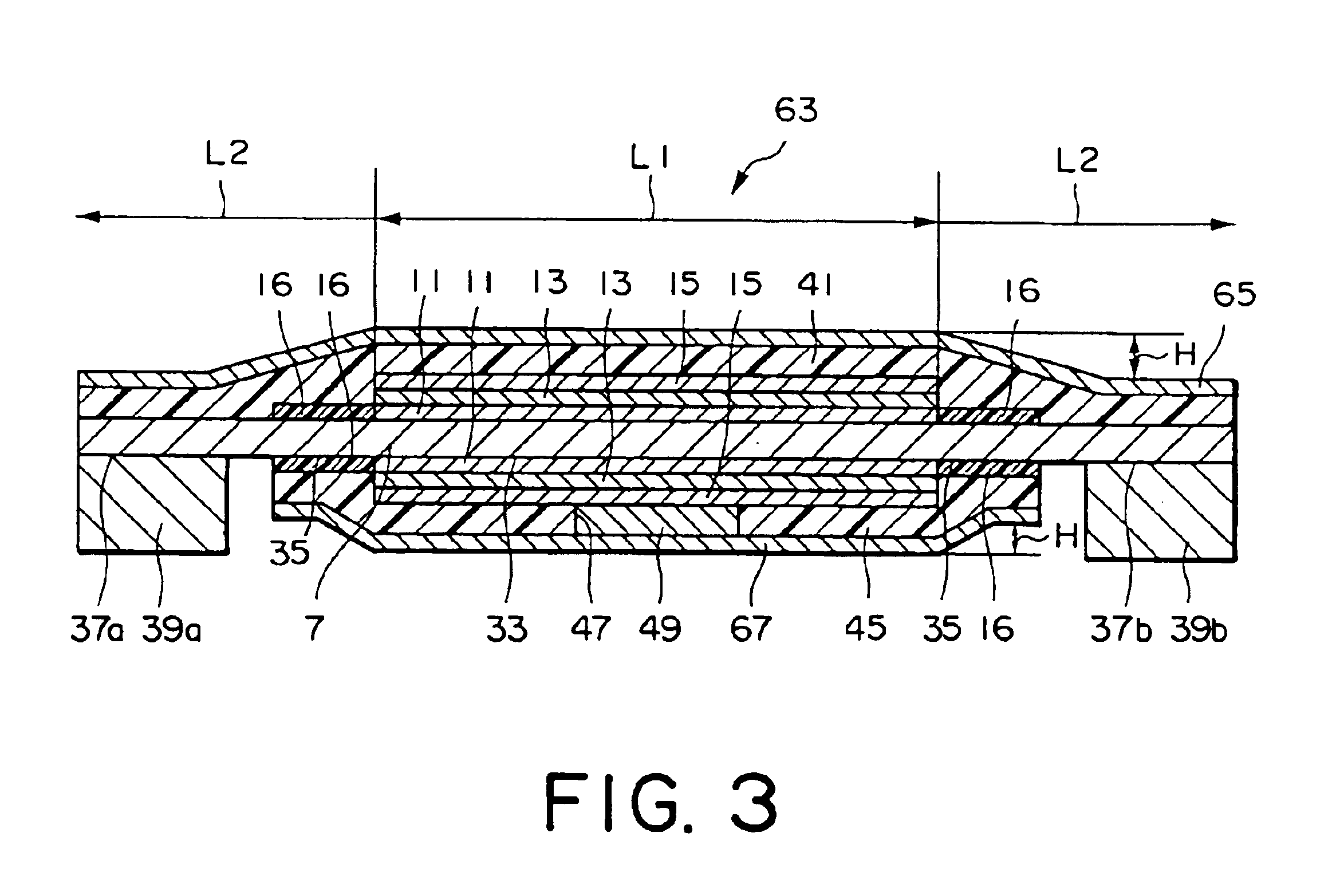

InactiveUS6920035B2Excellent high temperature durabilityPrevent intrusionHybrid capacitor electrolytesSolid electrolytic capacitorsSurface mountingThermal adhesive

A thin-type surface-mount capacitor is a solid electrolytic capacitor. The capacitor includes a capacitor element having an anode body in the form of a plate-like or foil-like valve-action metal that is area-increased, and a conductive functional polymer film used as a solid electrolyte. The capacitor further includes thermal adhesive insulating resin impregnated tapes that are stuck to the capacitor element on upper and lower sides thereof, and an element reinforcing metal plate and a solderable cathode terminal metal plate 67 that are stuck to the tapes, respectively. The capacitor is finally formed by applying a curing treatment under high temperature and pressure. Each of the metal plates is applied with a stepping process that provides a difference in level corresponding to a predetermined thickness.

Owner:TOKIN CORP +1

Thermoelectric conversion element, method for manufacturing thermoelectric conversion element, thermoelectric conversion module, and method for manufacturing thermoelectric conversion module

InactiveUS20190006570A1Excellent high temperature durabilityMaterial nanotechnologyThermoelectric device with peltier/seeback effectDopantElectricity

An object of the present invention is to provide a thermoelectric conversion element having excellent thermoelectric conversion performance and excellent high-temperature durability, a method for manufacturing the thermoelectric conversion element, a thermoelectric conversion module, and a method for manufacturing the thermoelectric conversion module. A thermoelectric conversion element of the present invention has a thermoelectric conversion layer containing an organic thermoelectric conversion material and a dopant, a pair of electrodes disposed at positions separated from each other, and a buffer layer which is disposed between the thermoelectric conversion layer and each of the electrodes and electrically connects the thermoelectric conversion layer and the electrodes to each other, in which the buffer layer contains the same material as the organic thermoelectric conversion material contained in the thermoelectric conversion layer, the buffer layer does not contain a dopant or contains a dopant, and in a case where the buffer layer contains a dopant, a ratio of the dopant contained in the buffer layer to the dopant contained in the thermoelectric conversion layer is equal to or lower than 0.1.

Owner:FUJIFILM CORP

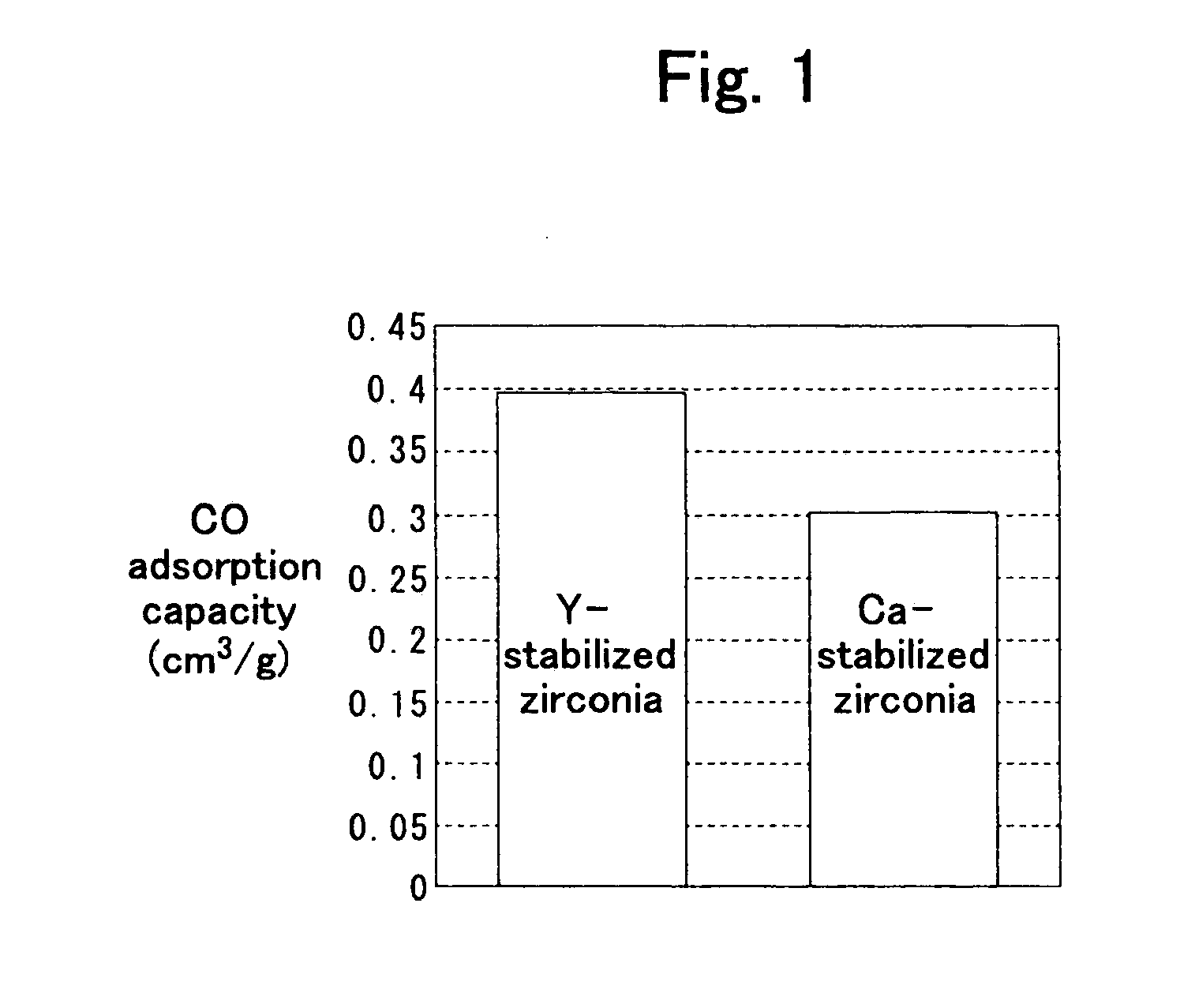

Exhaust gas purifying catalyst

InactiveUS20110118113A1Improve abilitiesExcellent high temperature durabilityInternal combustion piston enginesDispersed particle separationThermal stabilityExhaust gas

Disclosed is an exhaust gas purifying catalyst, including Rh / Y—ZrO2 particles obtained by supporting Rh on zirconia support particles which contain yttria, wherein yttria is contained in an amount of 2˜9 mol % in the support particles. The exhaust gas purifying catalyst exhibits a superior high-temperature durability because the zirconia support can resist heat, thereby particularly increasing the structure retaining power and the thermal stability of Rh.

Owner:TOYOTA JIDOSHA KK +1

Non-aqueous electrolyte secondary battery

InactiveCN1702904AExcellent high temperature durabilityNon-aqueous electrolyte accumulatorsPositive electrodesHigh temperature storageBoron

The nonaqueous electrolyte secondary battery is equipped with a positive electrode containing the lithium transition metal composite oxide having layer structure, a negative electrode containing a negative active material capable of storing or releasing lithium, and a nonaqueous electrolyte having lithium ion conductivity, and boron and at least one kind of group IVa elements are added to the lithium transition metal composite oxide. The objective of the invention is to enhance high-temperature durability (high-temperature storage characteristics) in a nonaqueous electrolyte secondary battery using a lithium transition metal composite oxide having layer structure as a positive active material.

Owner:SANYO ELECTRIC CO LTD

Nonaqueous lithium-type power storage element

ActiveUS10446847B2Improve featuresExcellent high temperature durabilityHybrid capacitor separatorsHybrid capacitor electrolytesLithiumMaterials science

A non-aqueous lithium-type power storage element obtained by a non-aqueous liquid electrolyte and an electrode laminate having a negative electrode body, a positive electrode body, and a separator being accommodated in an exterior body, wherein: the negative electrode body includes a negative electrode current collector and a negative electrode active material including a carbon material capable of occluding and releasing lithium ions.

Owner:ASAHI KASEI KK

Modified sialon fluorescence powder particle and preparation method thereof as well as sialon fluorophor and luminescent devices

ActiveCN106566530AImprove stabilityGood weather resistanceLuminescent compositionsSemiconductor devicesFluorescenceOxygen

The invention relates to a modified sialon fluorescence powder particle and a preparation method thereof as well as a sialon fluorophor and luminescent devices. The structure of the modified sialon fluorescence powder particle is a nucleus-shell structure; a nuclear structure of the modified sialon fluorescence powder particle is successively divided into a crystal nucleus layer, a transition layer and an extranuclear layer from the particle core to the external surface according to the progressive increase of the content of oxygen; a main body of the crystal nucleus layer is a nitrogen oxide material; a main body of the transition layer is a nitrogen oxide material; the main body of the extranuclear layer is an oxide material or an oxynitride material. The modified sialon fluorescence powder particle and the sialon fluorophor have the advantages of high chemical stability, high ageing light attenuation resistance and high luminescent efficiency, and are applicable to various luminescent devices. The preparation method is simple, convenient and reliable, is capable of improving chemical and physical stability of the modified sialon fluorescence powder particle and the sialon fluorophor, and is suitable for industrial mass production.

Owner:JIANGSU BREE OPTRONICS CO LTD

Process for producing conductive coating film, and conductive coating film

InactiveUS20150380123A1Promote lowerPromote sinteringConductive layers on insulating-supportsConductive materialOrganic acidConductive coating

An object of the present invention is to provide a conductive coating film formed of a copper paste on an insulating substrate which has a good conductivity and a good adhesion property to the insulating substrate. The process for producing a conductive coating film according to the present invention comprising the steps of applying a copper paste comprising copper particles, a binder resin and a solvent as main components onto an insulating substrate to form a coating film on the substrate, and then drying the coating film to obtain a copper powder-containing coating film; treating the copper powder-containing coating film with an organic acid or an organic acid salt; and subjecting the thus treated copper powder-containing coating film to heat treatment with superheated steam. According to the present invention, it is possible to obtain a conductive coating film having a good conductivity and a good adhesion property to the insulating substrate.

Owner:TODA IND

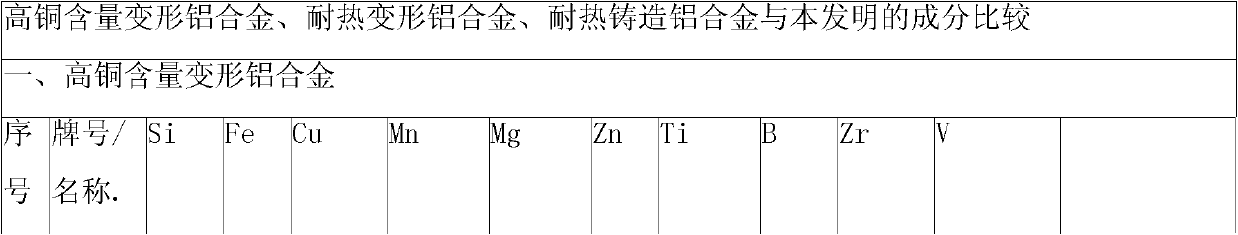

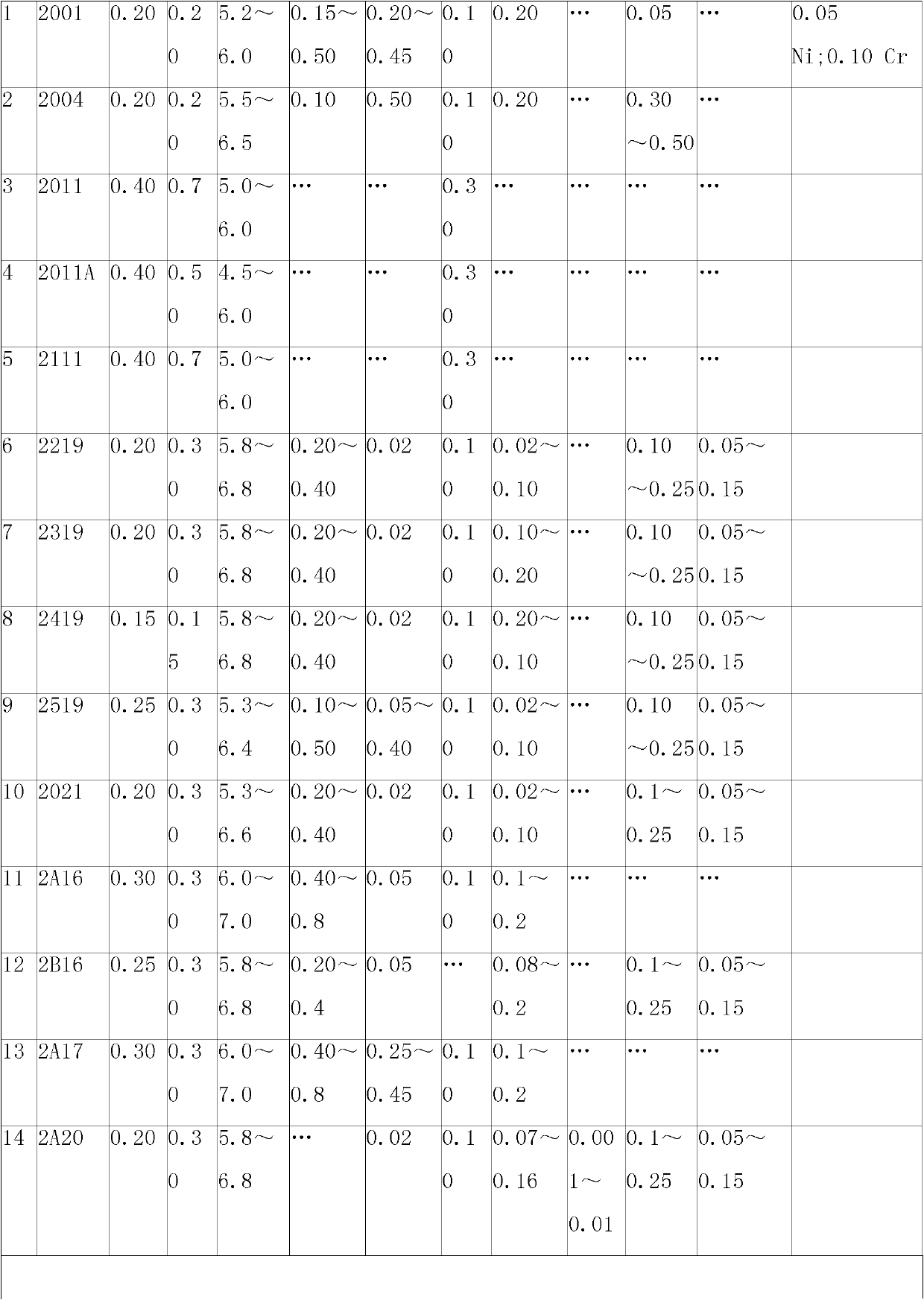

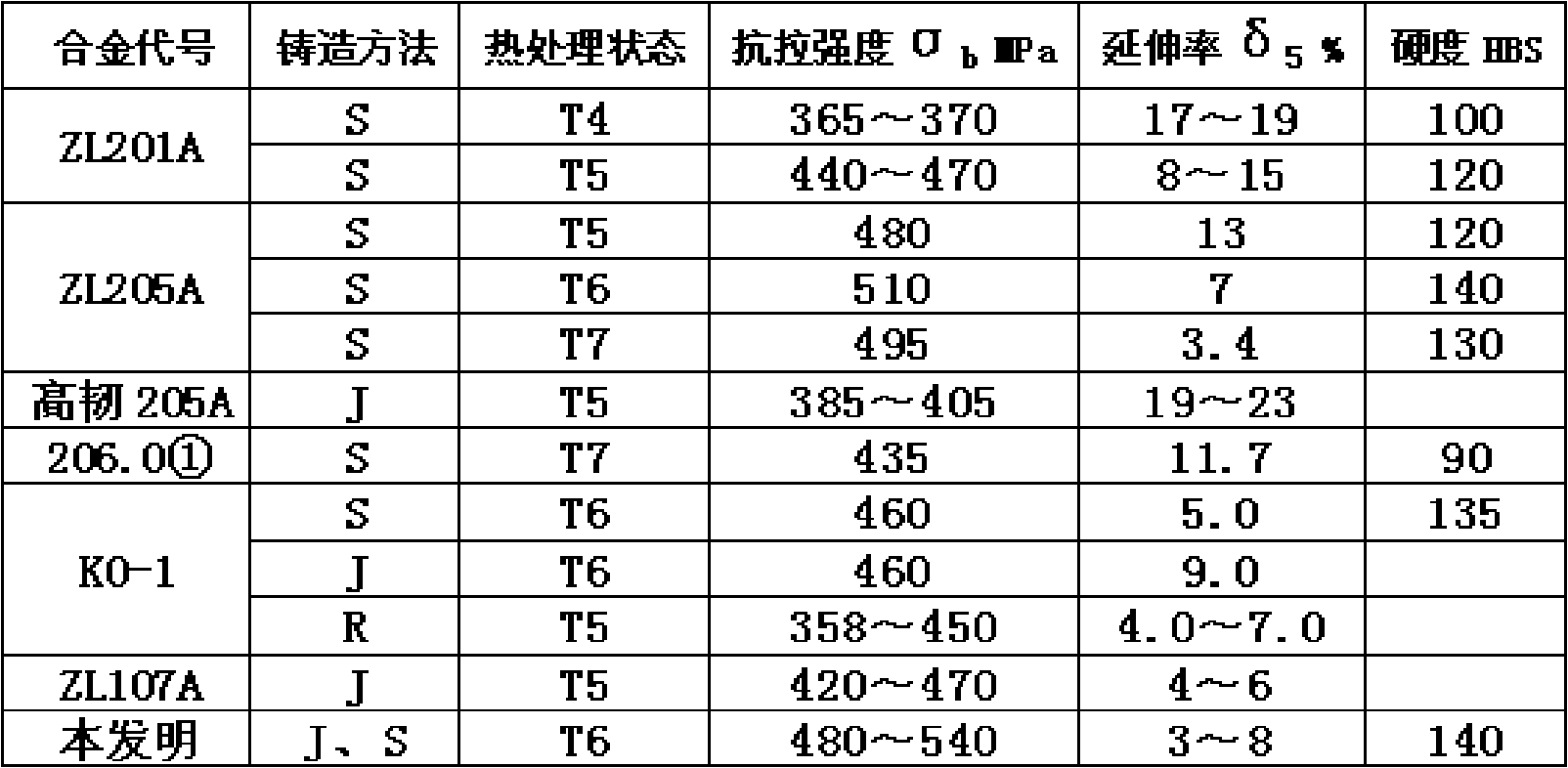

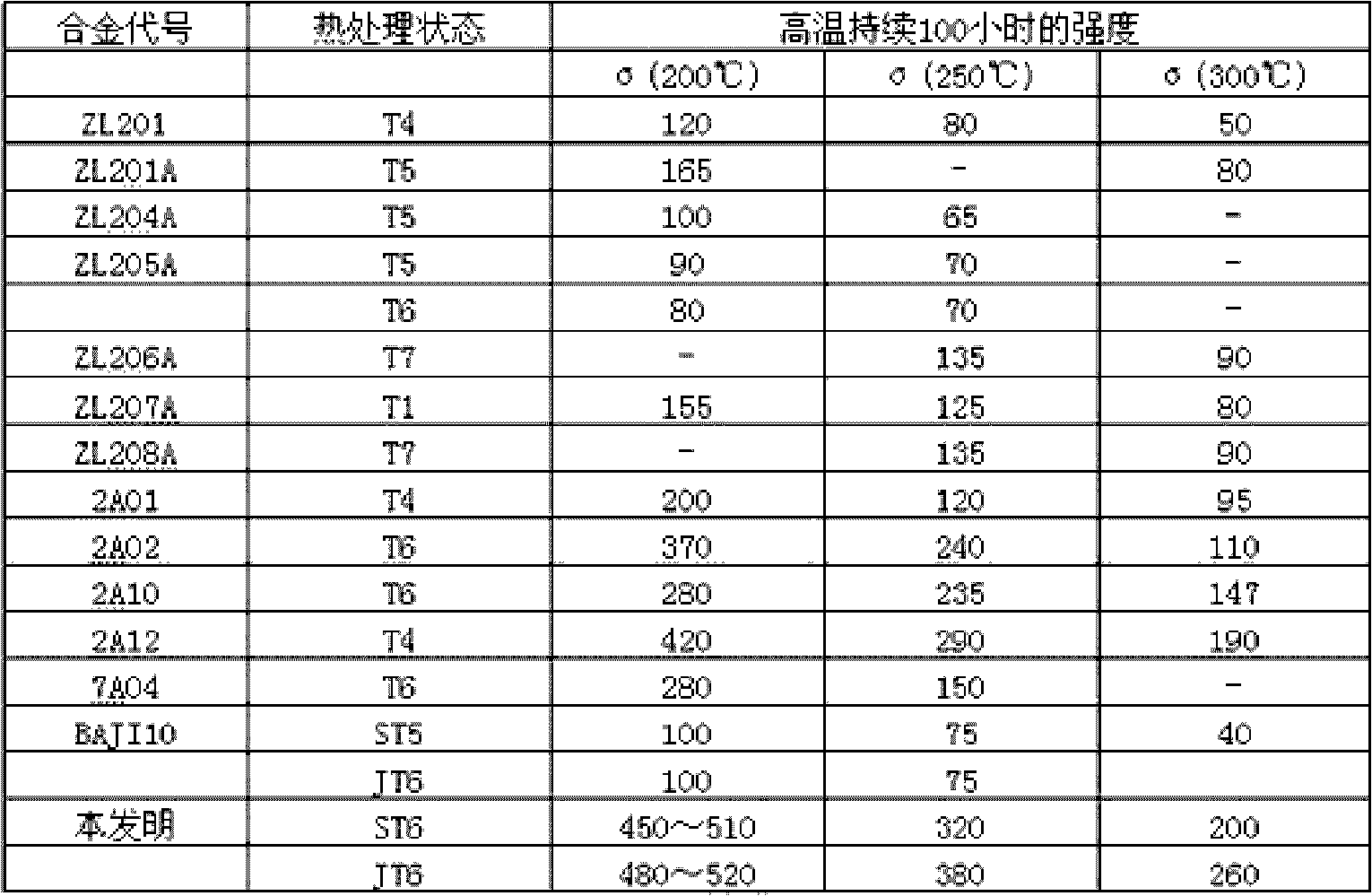

Be-Mo-RE high-strength heat-resistant aluminum alloy material with C as modifier and preparation method thereof

InactiveCN102021390AExcellent high temperature durabilityHigh technology contentRare-earth elementUltimate tensile strength

The invention discloses a Be-Mo-RE high-strength heat-resistant aluminium alloy material with C as a modifier, comprising the following components in weight percent: 1.0-10.0% of Cu, 0.05-1.5% of Mn, 0.01-0.5% of Cd, 0.01-0.5% of Ti, 0.0001-0.15% of C, 0.01-1.0% of Zr, 0.001-0.1% of Be, 0.01-1.0% of Mo, 0.05-5% of rare earth element (RE) and the balance of Al. The invention reduces alloy quasi solid phase temperature range by utilizing high quality melt, solid solution and phase diagram theory as guidance and a C element as a high efficiency modifier and preferably selecting formula of host elements of Cu, Mn and RE and solves the problems that hot rack tendency is high in casting process and product strength of products is low at high temperature; through preferably selecting a low cost multielement microalloyed element formula, a high strength heat resistant aluminium alloy material is finally developed.

Owner:GUIZHOU HUAKE ALUMINUM MATERIAL ENG TECH RES

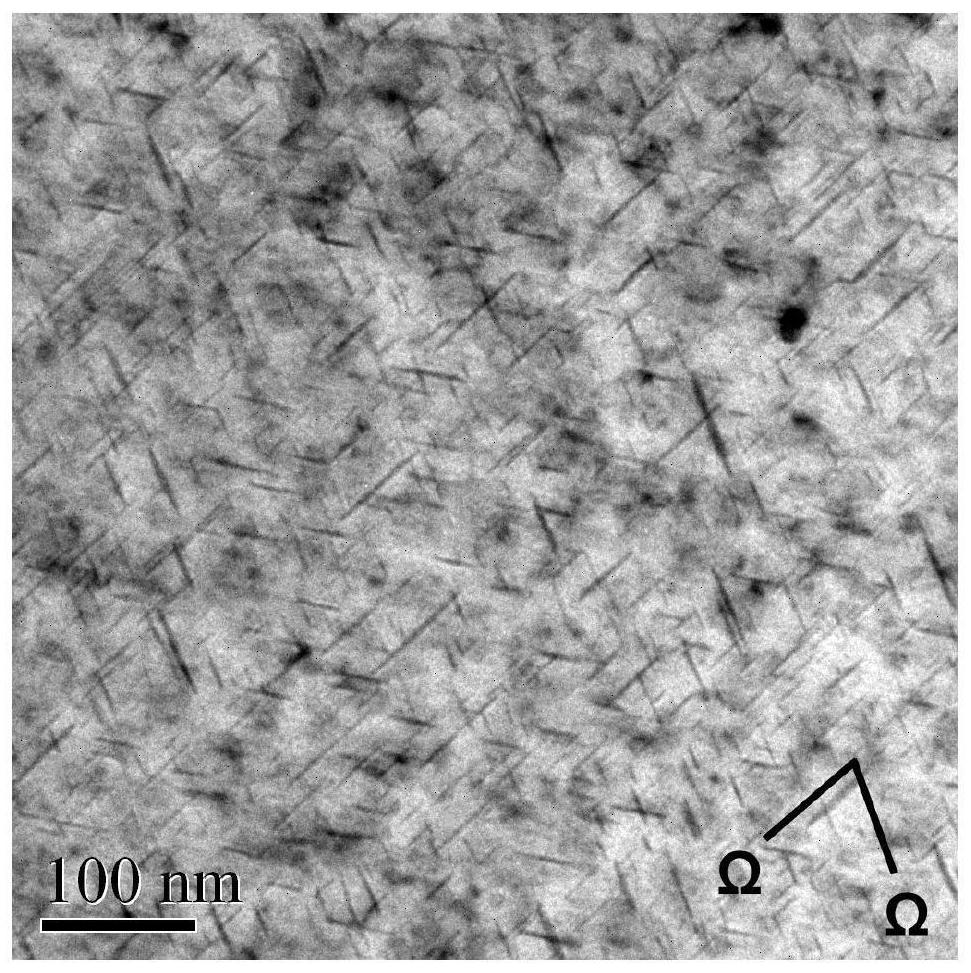

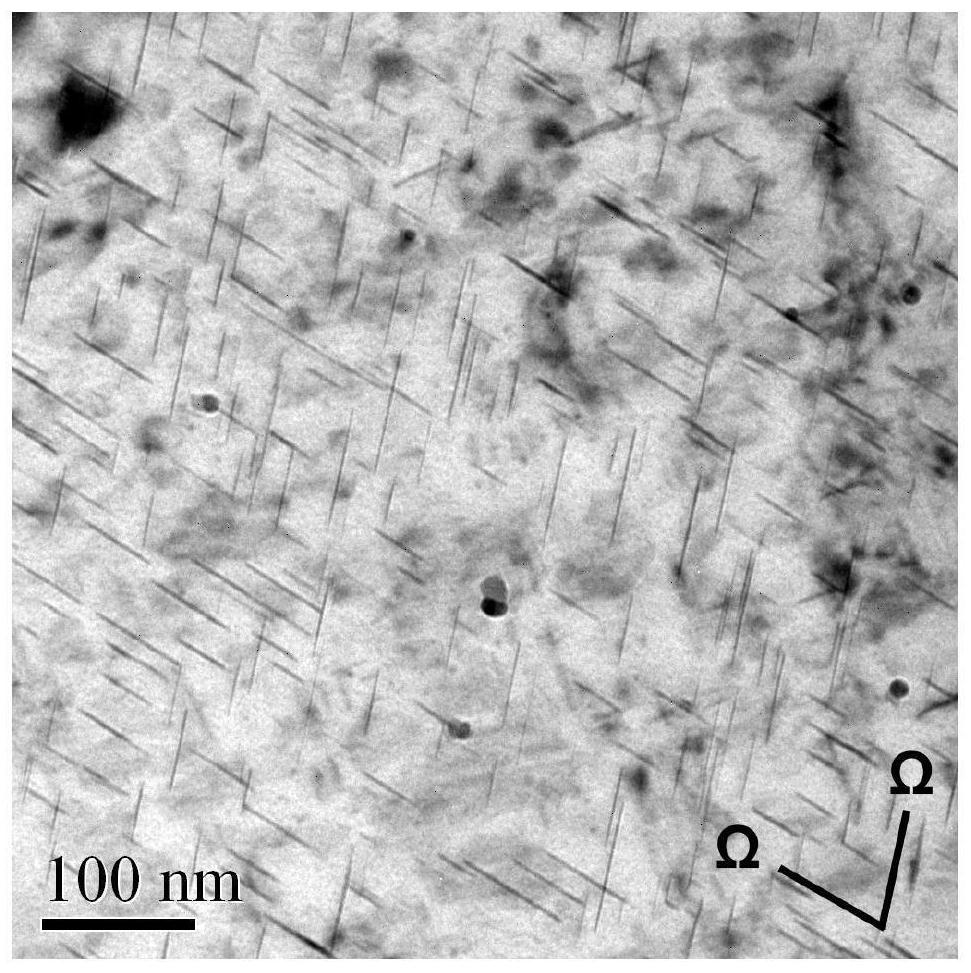

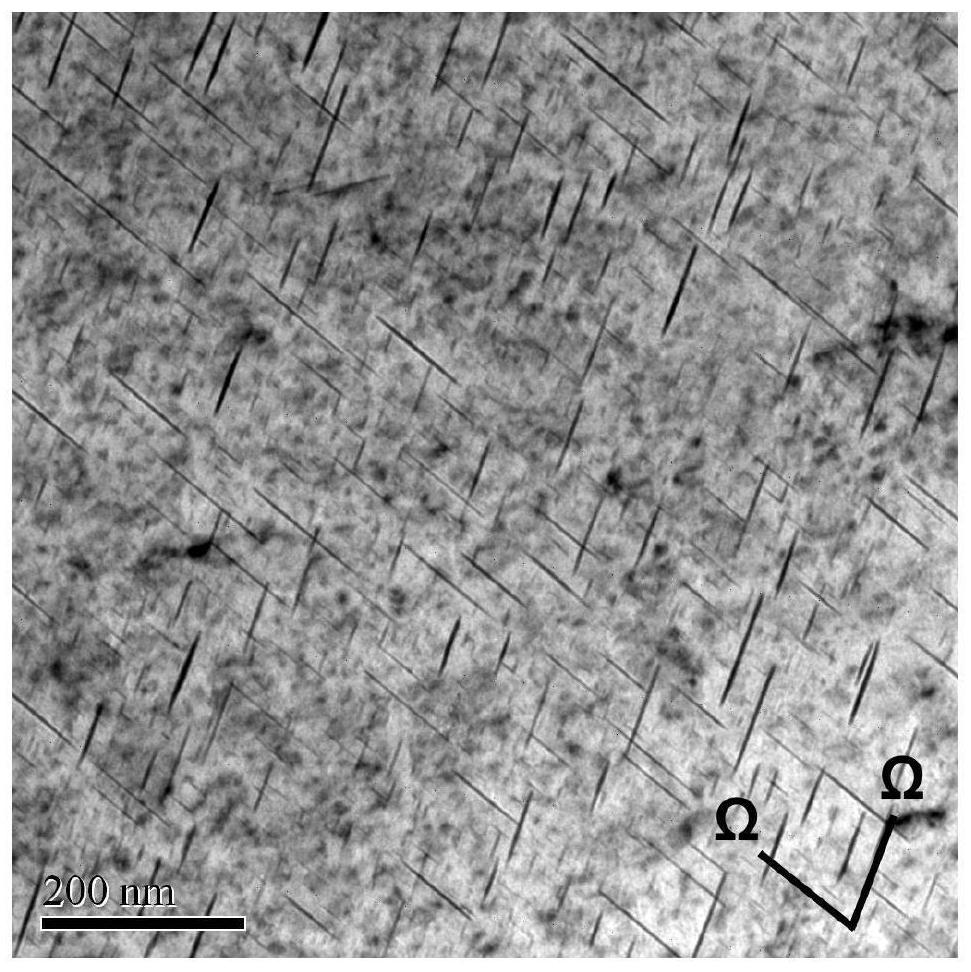

Heat treatment method for improving high-temperature endurance performance of deformed aluminum-copper-magnesium-silver alloy

InactiveCN112662969AExcellent high temperature durabilitySimple heat treatment processAg alloyMagnesium

The invention belongs to the technical field of metal material treatment, and particularly relates to a heat treatment method for improving the high-temperature endurance performance of a deformed aluminum-copper-magnesium-silver alloy. The heat treatment method comprises the steps that S1, the aluminum-copper-magnesium-silver alloy is subjected to solid solution and quenching treatment, and then artificial aging treatment is conducted for 0-1h; and S2, the aluminum-copper-magnesium-silver alloy material treated in the step S1 is subjected to tensile deformation treatment and then subjected to artificial aging treatment for 1-8h, and the deformed aluminum-copper-magnesium-silver alloy with excellent high-temperature endurance performance is obtained. According to the method, the stable formation of the heat-resistant omega phase or the precursor thereof is ensured through short-time artificial aging in advance, so that the heat-resistant omega phase or the precursor thereof can still exist stably after deformation treatment, the mass formation of the heat-resistant omega phase in the subsequent artificial aging process is promoted, and the excellent long-time high-temperature endurance property of the shape-variable alloy is ensured.

Owner:CENT SOUTH UNIV

Exhaust emission control device for internal combustion engine

InactiveUS20120269693A1Reduce temperature riseEvenly supportedMaterial nanotechnologyCombination devicesExternal combustion engineSilicon oxide

An object of the present invention is to provide an exhaust emission control device of an internal combustion engine which is used in purification of exhaust gas and achieves both high catalytic activity at low temperature and high durability at high temperature. In an exhaust emission control device of an internal combustion engine of the present invention, a catalyst is disposed in an exhaust path of the internal combustion engine, at least one kind of the catalyst is noble metal supporting silicon carbide particles, and the noble metal supporting silicon carbide particles include a silicon oxide layer in which noble metal particles are supported on a surface of silicon carbide particles having an average primary particle diameter of 0.005 μm or more and 5 μm or less.

Owner:SUMITOMO OSAKA CEMENT CO LTD +1

Surface-reformed exhaust gas guide assembly of VGS type turbo charger, and method of surface-reforming component member thereof

InactiveCN1526052AExcellent high temperature durabilityHot-dipping/immersion processesEngine manufactureTurbochargerSurface modification

A novel exhaust gas guide assembly with an improved high-temperature sliding wear resistance, oxidation resistance, high-temperature strength or the like for a VGS turbocharger is provided. The invention is characterized in that a surface modification is applied to a component member of the exhaust gas guide assembly (A), such as adjustable blades (1), a turbine frame (2), a blade adjusting mechanism (3), or the like.

Owner:AKITA FINE BLANKING +1

Cr-Lu high-strength heat-resisting aluminum alloy material and preparation method thereof

InactiveCN102031426AExcellent high temperature durabilityHigh technology contentUltimate tensile strengthHeat treated

The invention discloses a Cr-Lu high-strength heat-resisting aluminum alloy material and a preparation method thereof. The Cr-Lu high-strength heat-resisting aluminum alloy material comprises the following alloy components in percentage by weight: 1.0-10.0% of Cu, 0.05-1.5% of Mn, 0.01-0.5% of Cd, 0.01-0.5% of Ti, 0.01-0.2% of B, 0.01-1.0% of Zr, 0.01-1.0% of Cr, 0.05-5% of Lu and balance of Al. Based on high quality fusant and solid solution and the phase diagram theory, the invention optimizes the major alloying element formula (Cu, Mn and Lu) to reduce the quasi solid-phase temperature range of the alloy, thereby solving the problems of high thermal cracking possibility in the casing process, low high-temperature strength of the product and the like; the invention optimizes the low-cost composite microalloying element formula, thereby creating physical and basic conditions for the cultivation and grain refining effect of the high-temperature phase and the strengthening phase in the solid solution; and the invention optimizes smelting and heat treatment technologies to ultimately develop a novel aluminum alloy material.

Owner:贵州铝厂有限责任公司 +2

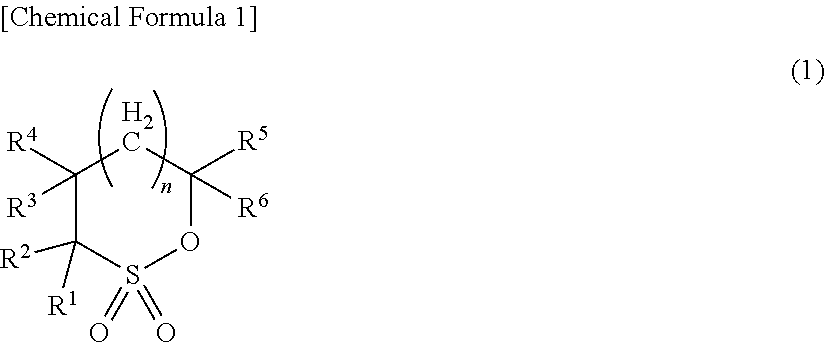

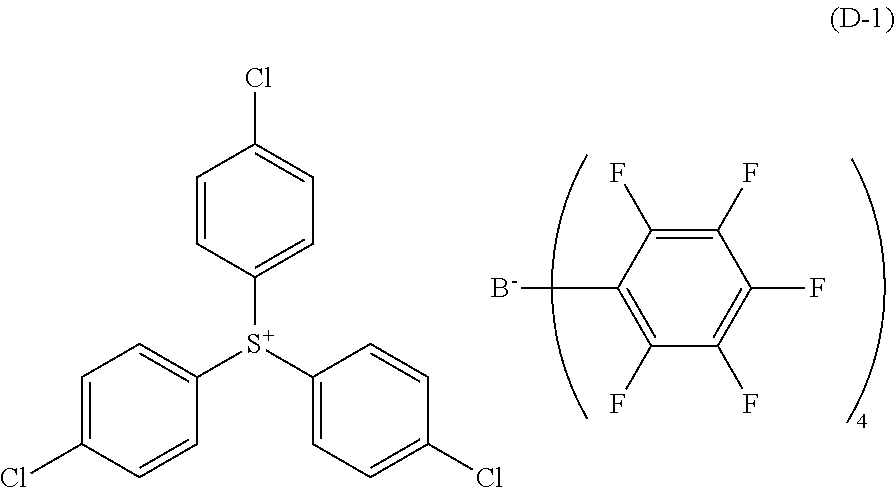

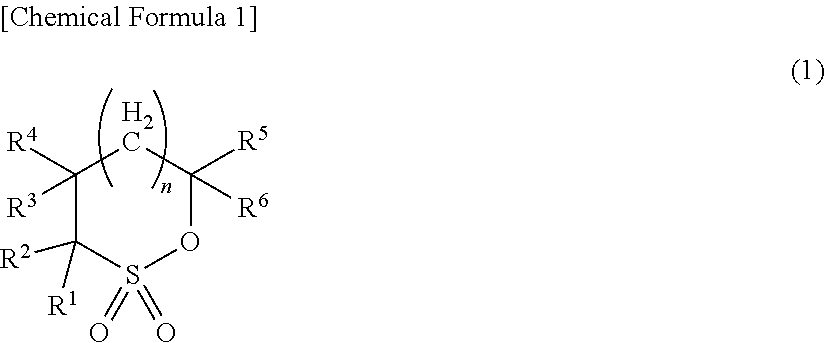

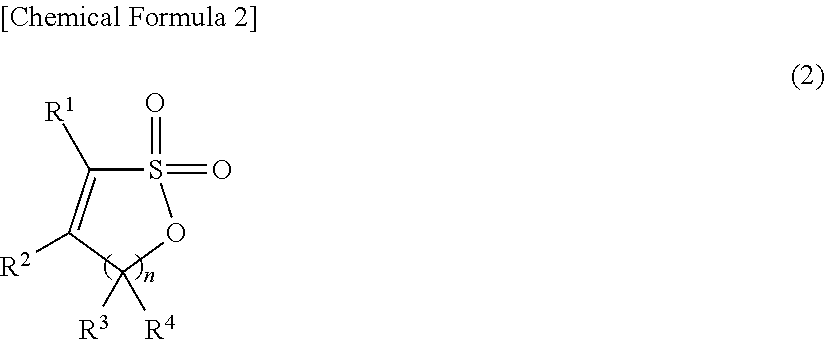

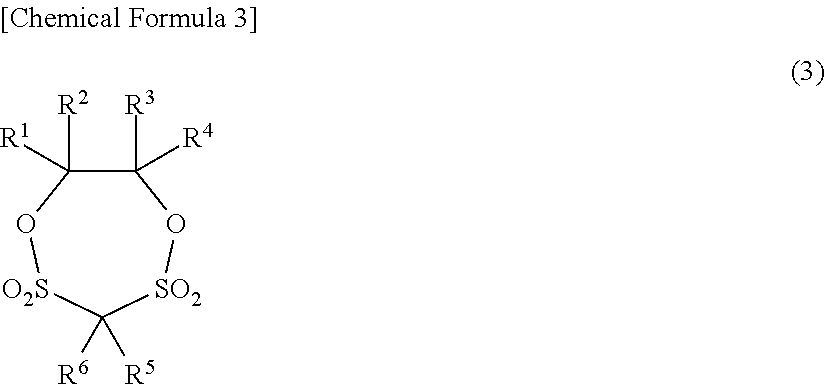

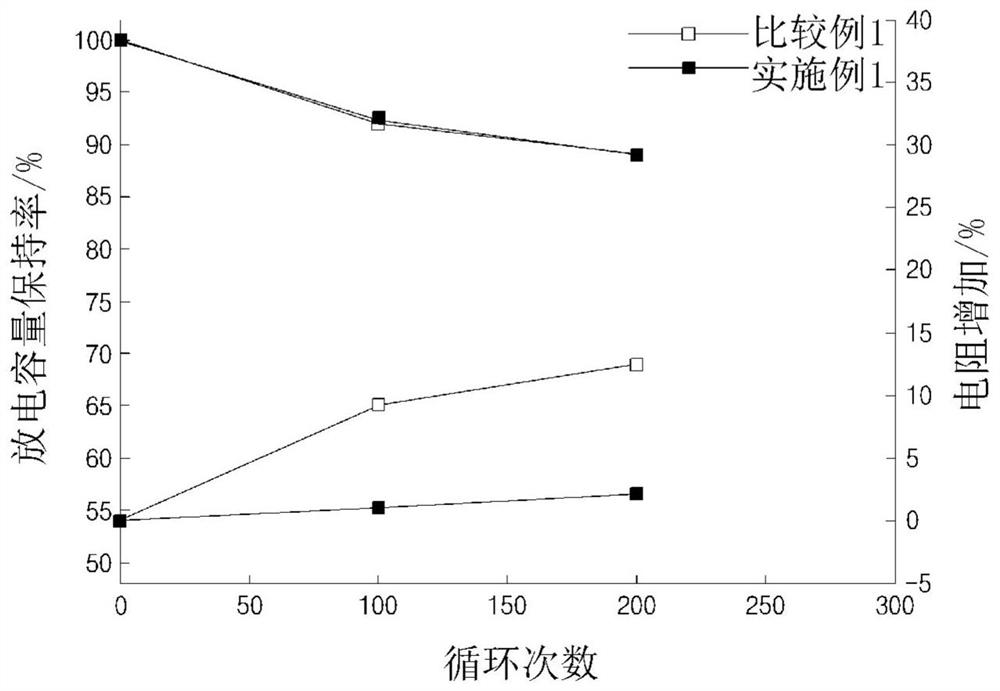

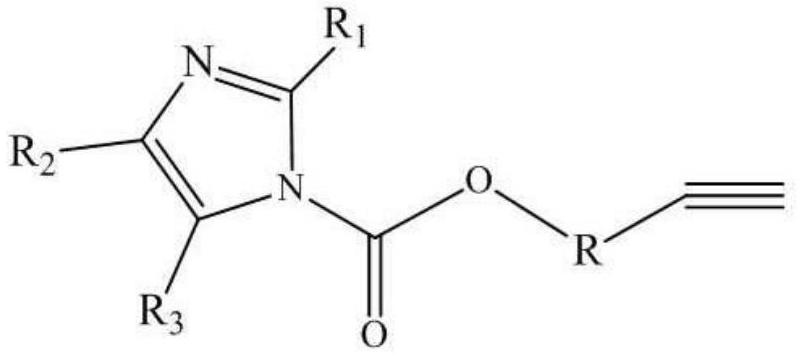

Non-aqueous electrolyte for lithium secondary battery and lithium secondary battery comprising same

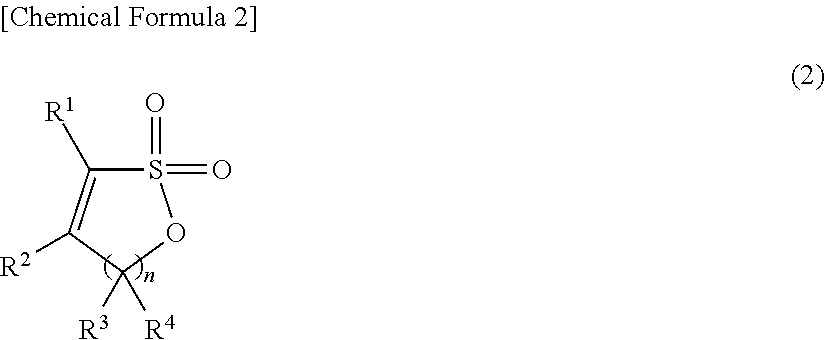

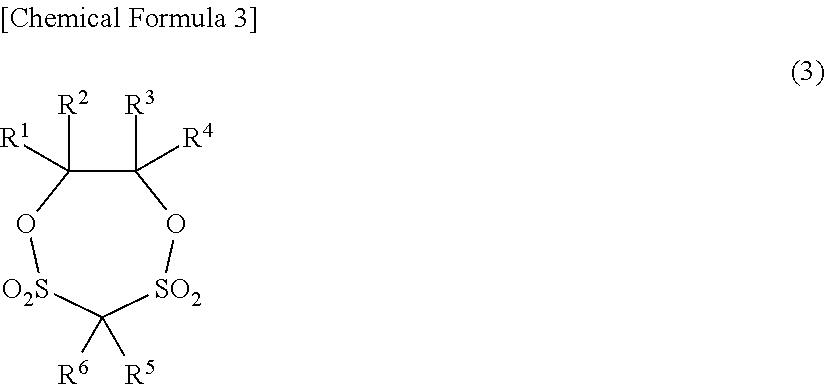

PendingCN113711415AGood film formingExcellent high temperature durabilityOrganic chemistryLi-accumulatorsElectrolytic agentOrganic solvent

The present invention relates to a non-aqueous electrolyte for a lithium secondary battery and a lithium secondary battery comprising the non-aqueous electrolyte, the non-aqueous electrolyte comprising: a lithium salt; an organic solvent; a compound represented by chemical formula 1 as a first additive; and lithium difluorophosphate as a second additive, wherein the weight ratio of the first additive and the second additive is 1:2 to 1:10.

Owner:LG ENERGY SOLUTION LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com