Surface-reformed exhaust gas guide assembly of VGS type turbo charger, and method of surface-reforming component member thereof

A technology of turbocharger and surface modification, which is applied in the direction of supporting elements of blades, engine elements, machines/engines, etc., and can solve problems such as difficulty in use and poor sliding properties at high temperatures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

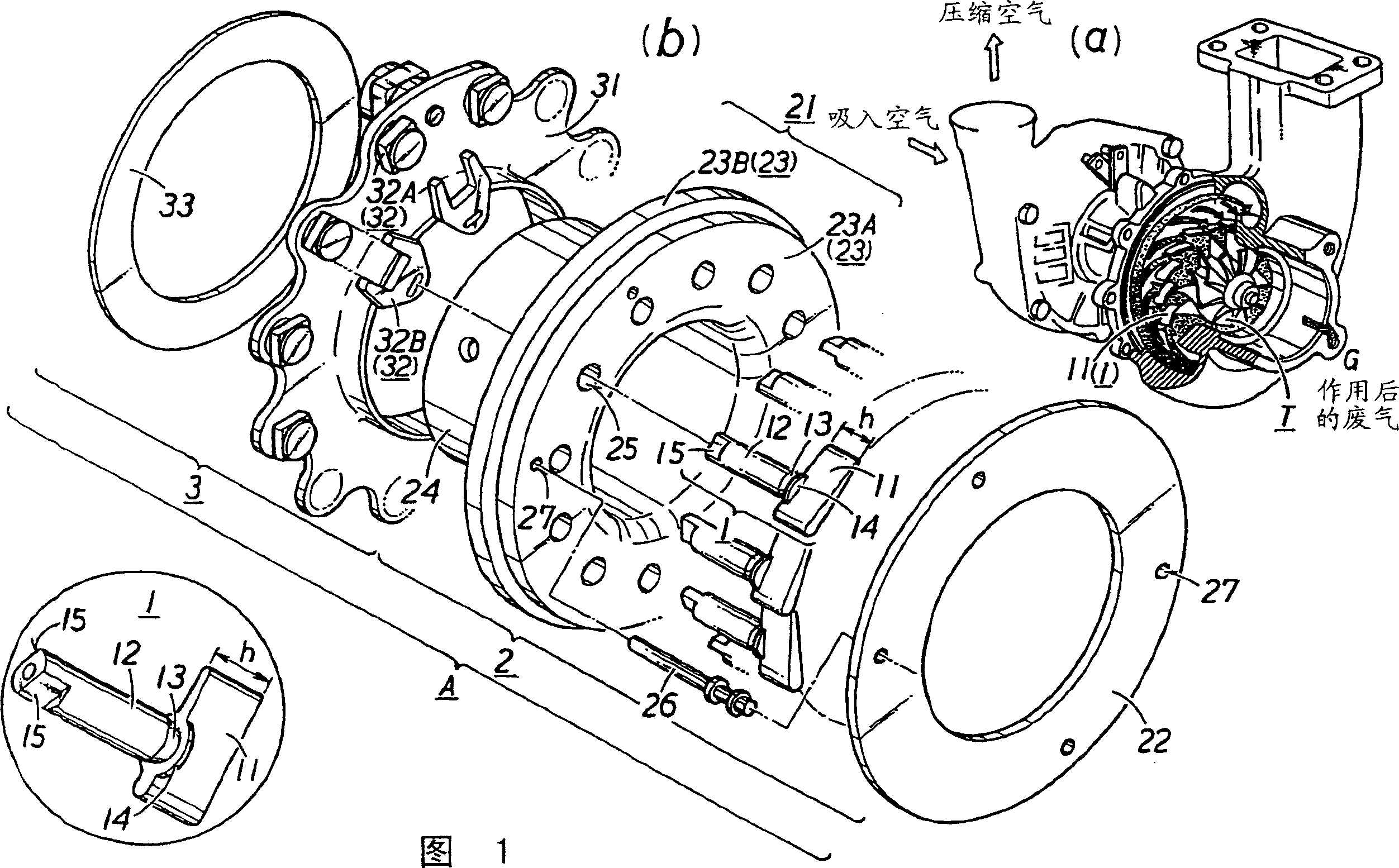

[0089] The present invention will be described in detail below. In the following description, first, the exhaust guide assembly in the VGS type turbocharger according to the present invention will be described, and then the method for modifying the surface of the constituent parts (including sliding parts) of the exhaust guide assembly will be described. illustrate.

[0090] [1] Exhaust guide assembly

[0091] The exhaust guide assembly A is specially used to properly throttle the exhaust gas G to adjust the exhaust flow when the engine rotates at a low speed. An example of it is shown in FIG. 1 . A plurality of variable vanes 1 that substantially set the flow rate of the exhaust gas, a turbine frame 2 that supports the variable vanes 1 so that they can rotate freely, and a system that rotates the variable vanes 1 by a predetermined angle in order to properly adjust the flow rate of the exhaust gas G Variable mechanism3. Next, each component will be described.

[0092] Fir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com