Heat treatment method for improving high-temperature endurance performance of deformed aluminum-copper-magnesium-silver alloy

A heat treatment method and aluminum-copper-magnesium technology, applied in the field of metal material processing, can solve problems such as difficulty meeting performance requirements, failing to reflect high-temperature mechanical properties, failing to produce ideal effects, etc., to improve long-term high-temperature durability and excellent long-term performance High temperature durability, the effect of excellent high temperature durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

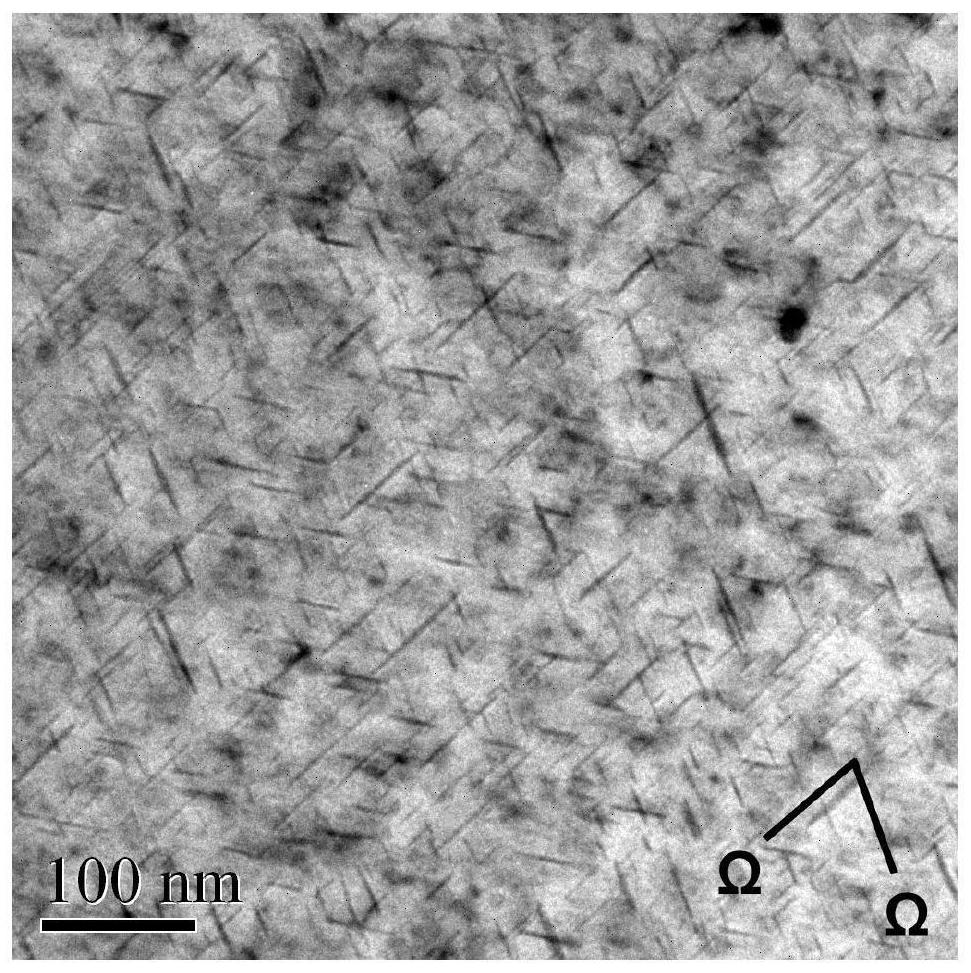

[0027] The composition of alloy 1 is: 5.74% Cu, 0.44% Mg, 0.88% Ag, 0.30% Mn, 0.09% Zr, 0.03% Ti, 0.10% Fe, 0.06% Si, and the balance is aluminum. After the alloy was melted and casted, the ingot was homogenized, and the ingot was hot-rolled, the plate was quenched at 515°C for 6 hours, aged at 180°C for 25 minutes, and then stretched at 1.8%, 3.4% and 5%. Continue aging at 180°C for 4h to obtain corresponding alloy samples. The durable fracture times of the obtained alloy samples under the conditions of 200°C / 180MPa and 200°C / 200MPa are shown in Table 1.

Embodiment 2

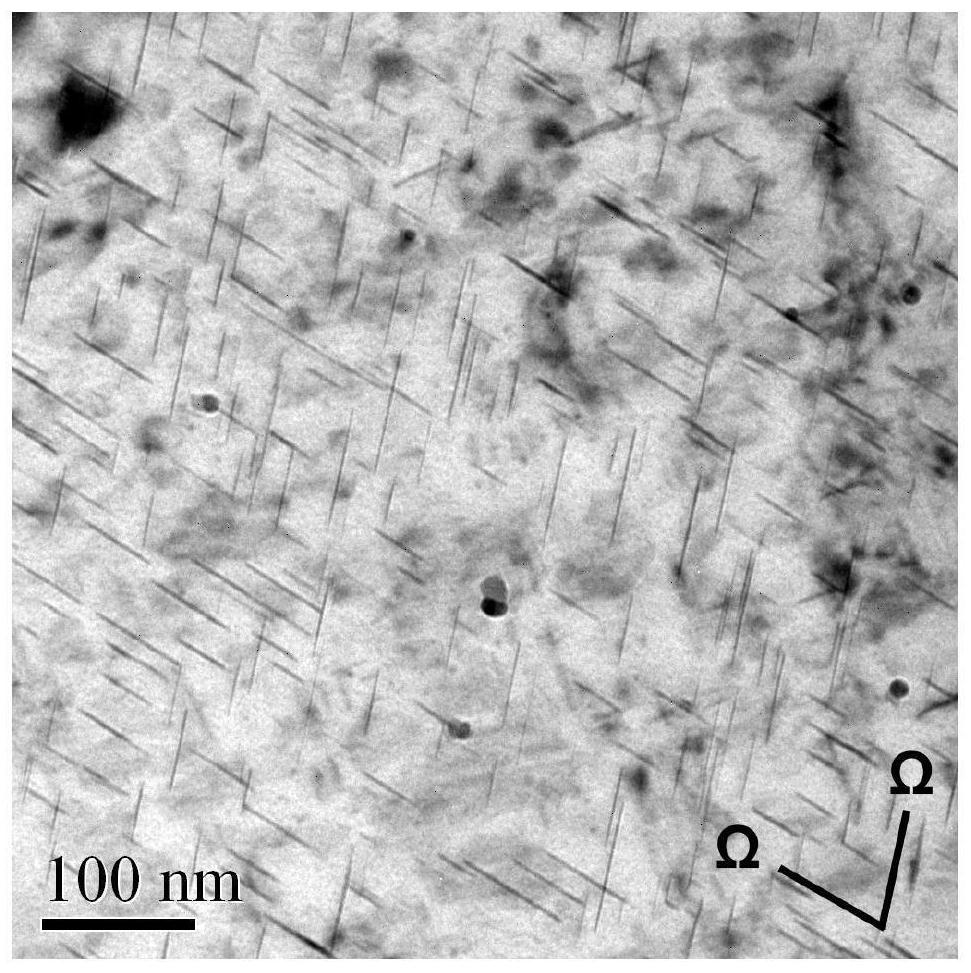

[0033] The composition of alloy 2 is: 6.10% Cu, 0.33% Mg, 1.31% Ag, 0.29% Mn, 0.10% Zr, 0.03% Ti, 0.05% Fe, 0.03% Si, and the balance is aluminum. The alloy is melted and casted, the ingot is homogenized, and the ingot is hot-rolled. The plate is quenched at 525°C for 2h, aged at 190°C for 1h, and then subjected to 2.5% tensile deformation, and then aged at 180°C for 3h to obtain Corresponding alloy samples. Table 2 shows the durable fracture times of the obtained alloy samples under the conditions of 200°C / 160MPa, 200°C / 190MPa and 200°C / 220MPa.

Embodiment 3

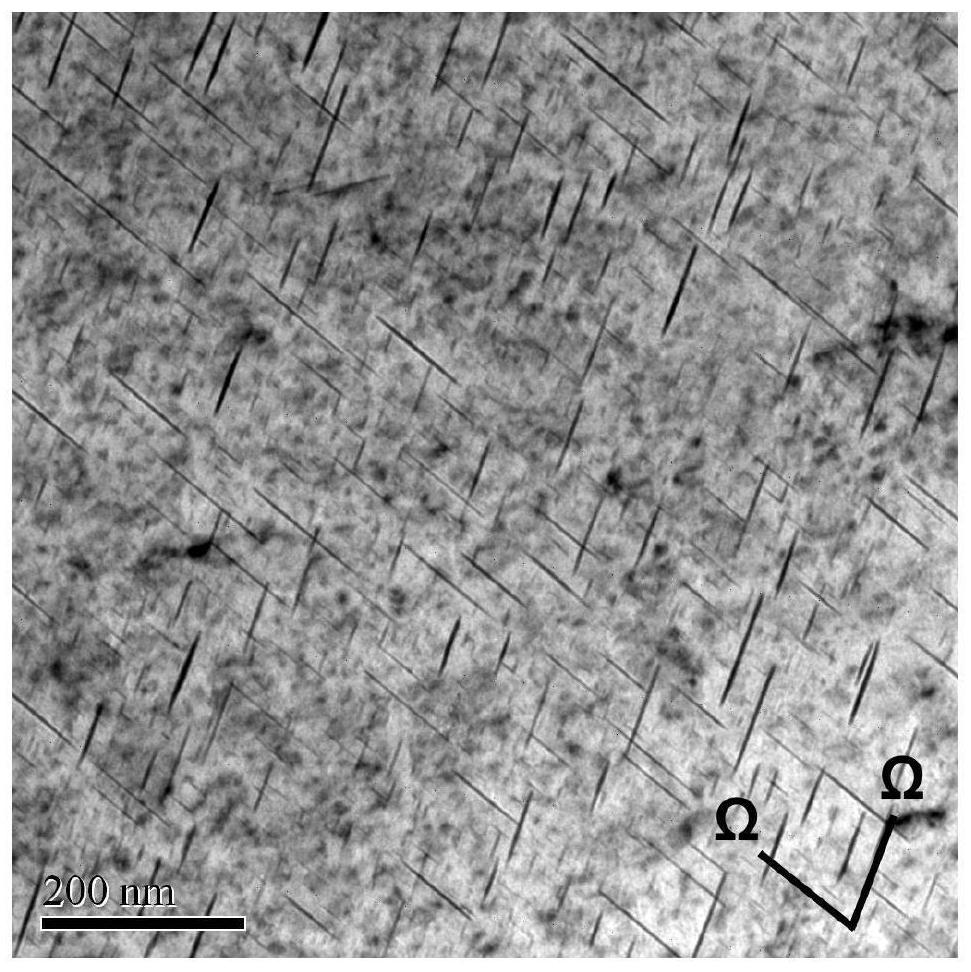

[0041] The composition of alloy 3 is: 6.23% Cu, 0.62% Mg, 1.71% Ag, 0.27% Mn, 0.12% Zr, 0.05% Ti, 0.04% Fe, 0.03% Si, and the balance is aluminum. The alloy was melted and casted, the ingot was homogenized, and the ingot was hot-rolled. The plate was quenched at 515°C for 6 hours, aged at 200°C for 10 minutes, and then subjected to 2% tensile deformation, and then aged at 180°C for 3 hours to obtain Corresponding alloy samples. Table 3 shows the durable fracture times of the obtained alloy samples under the conditions of 200°C / 180MPa and 200°C / 200MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com